Progressive Die Vs Transfer Die: The Decision Framework That Saves Projects

Making the Right Die Decision for Your Metal Stamping Project

Imagine this: You've invested months in product development, finalized your part design, and secured a promising production contract. Now comes the pivotal moment—selecting the stamping method that will shape thousands (or millions) of metal components. Should you go with a progressive die or a transfer die? This single decision can determine whether your project thrives or struggles from day one.

The stakes are higher than many manufacturers realize. Choosing the wrong die type doesn't just cause minor inconveniences. It leads to wasted tooling investments that can reach tens of thousands of dollars, production inefficiencies that eat into your margins, and quality issues that frustrate your customers. As industry experts note, selecting the wrong stamping method may result in delays, increased material loss, and expensive rework.

Why Die Selection Makes or Breaks Your Production Line

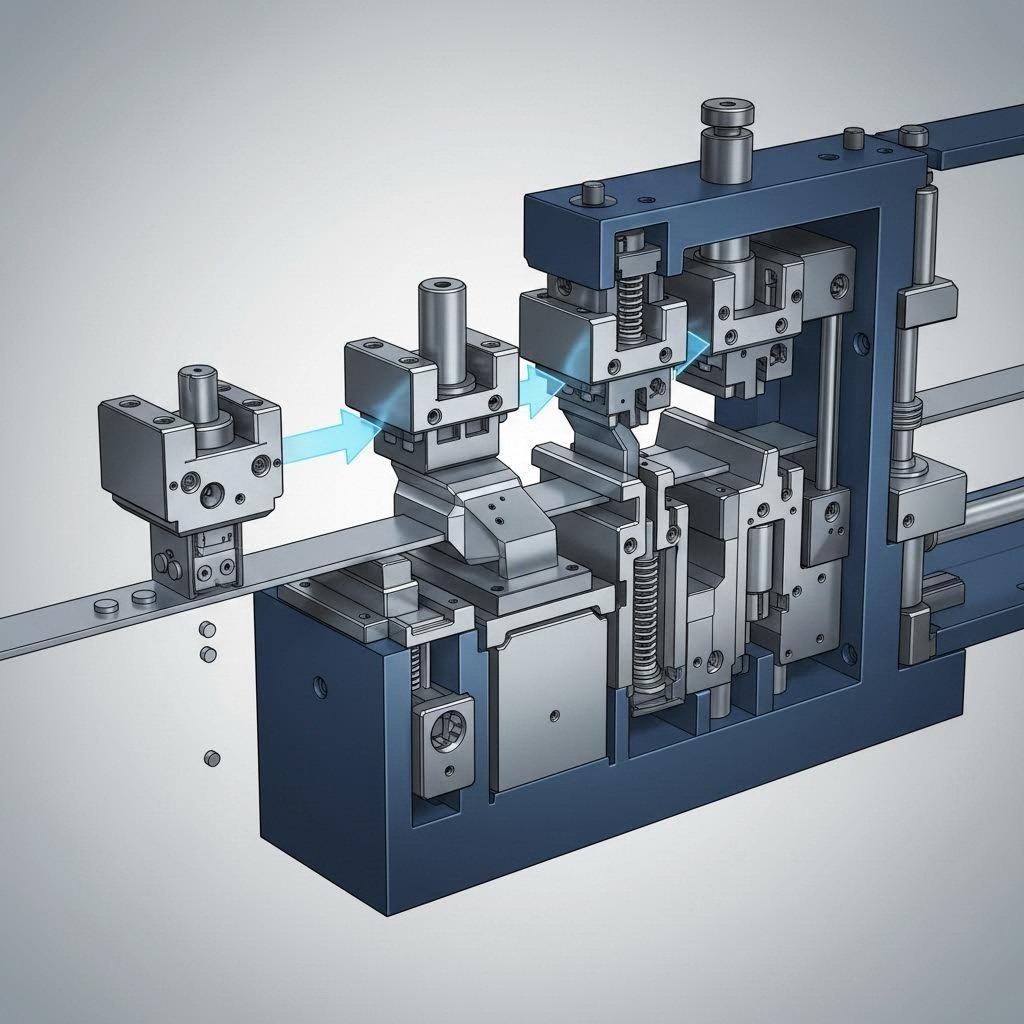

Think of dies and stamping as the foundation of your metal forming operation. A progressive die moves a strip of metal through sequential stations within a single tool, performing multiple operations in one continuous flow. A transfer die, by contrast, uses separate stations where individual blanks are mechanically moved between operations. Each approach has distinct advantages—but only when matched to the right application.

The challenge? Many project managers rely on outdated assumptions or vendor preferences rather than systematic evaluation. This article changes that approach. Instead of drowning you in technical specifications, we'll provide a practical decision-making framework you can apply immediately to your specific project.

The Hidden Costs of Choosing the Wrong Stamping Method

Consider what happens when die selection goes wrong:

- A progressive stamping setup designed for parts too large for the carrier strip creates constant jams and quality defects

- A transfer die chosen for high-volume small parts results in unnecessarily slow cycle times and inflated per-part costs

- Tooling modifications mid-production consume budget and delay delivery schedules

Throughout this guide, you'll learn how to evaluate your project across four critical dimensions: part complexity, production volume, material considerations, and total cost factors. By the end, you'll have a clear roadmap for determining which stamping die approach aligns with your manufacturing goals—saving you from costly trial-and-error decisions.

How to Evaluate Progressive and Transfer Die Stamping Methods

So how do you actually decide between these two stamping approaches? The answer isn't found in a simple chart or a one-size-fits-all recommendation. Instead, it requires a systematic evaluation of your specific project requirements against the strengths of each method. Let's break down the methodology that separates successful die selection from costly guesswork.

Five Critical Factors That Determine Your Ideal Die Type

When comparing progressive die stamping to transfer die stamping, five interconnected factors drive the decision. Understanding how each factor applies to your project will reveal which method delivers optimal results.

Part Geometry Complexity: How intricate is your component? Progressive die stamping excels at producing parts with complex shapes, multiple features, and tight tolerances in a single continuous operation. Transfer die stamping handles complex geometries as well, but shines when parts require forming operations on multiple surfaces or deep three-dimensional features that can't remain attached to a carrier strip.

Production Volume Thresholds: What's your annual output requirement? According to industry analysis, progressive die stamping is ideal for large-scale production runs where efficiency and speed are critical. Transfer die stamping typically suits low to medium volume production, offering greater flexibility with smaller batches.

Material Type Compatibility: Different materials behave differently under stamping pressure. Your die and stamping method must account for material thickness variations, spring-back tendencies, and hardness levels. Both methods work with common metals, but the specific material properties influence which approach minimizes waste and defects.

Secondary Operation Requirements: Will your parts need additional processing after stamping? Progressive dies often eliminate secondary operations by incorporating multiple forming steps into a single tool, producing fully finished parts. Transfer die stamping may require additional machining, welding, or assembly depending on part complexity.

Tooling Investment vs. Per-Part Costs: Progressive die stamping typically demands higher initial tooling investment due to die complexity. However, for high-volume runs, the per-part cost drops dramatically. Transfer tooling usually costs less upfront, making it more economical for prototypes and smaller production quantities.

How We Evaluated Each Stamping Method

To make this comparison actionable, we examined both types of stamping dies against specific, measurable criteria. Here's what you should assess for your own project:

- Dimensional Accuracy Requirements: What tolerances must your finished parts maintain? Precision die stamping demands careful die design regardless of method, but progressive dies often deliver superior consistency for high-volume applications

- Annual Volume Projections: Estimate your production needs realistically—include potential increases or decreases in demand over the tooling lifespan

- Material Thickness Ranges: Account for gauge variations within material batches and how each die type handles those inconsistencies

- Geometric Complexity Levels: Catalog every feature your part requires—bends, holes, embossed details, drawn sections—to determine which method accommodates them efficiently

- Budget Constraints: Calculate total cost of ownership, not just initial tooling expense, including maintenance, material utilization, and production efficiency

Here's the essential truth about this evaluation: there's no universal winner between progressive and transfer die stamping. The "best" choice depends entirely on your project-specific variables. A progressive die that's perfect for producing millions of small electrical connectors would be completely wrong for manufacturing larger structural components in moderate quantities. Similarly, a transfer die setup that excels for deep-drawn automotive housings would create unnecessary costs for simple, high-volume brackets.

With this evaluation framework established, let's examine exactly how each stamping method works—starting with the mechanics of progressive die stamping and the applications where it delivers maximum value.

Progressive Die Stamping Explained with Ideal Applications

Picture a continuous ribbon of metal feeding into a machine, emerging seconds later as a fully formed, precision component. That's progressive die stamping in action—a process that transforms raw coil stock into finished parts through an elegant sequence of operations. Understanding exactly how this process works will help you determine whether it's the right choice for your manufacturing project.

How Progressive Dies Transform Coil Stock Into Finished Parts

The progressive die stamping process begins with a coil of sheet metal mounted on an uncoiler. This metal strip feeds into the press, where it advances through a series of stations—each performing a specific operation on the material. With every stroke of the press, the strip moves forward to the next station while a new finished part exits the die.

What makes progressive metal stamping so efficient? The answer lies in its continuous nature. According to Dayton Rogers, progressive stamping involves feeding a strip of metal through a series of dies to create a finished part with every stroke of the machine. Since each cycle produces a new finished piece, this process is often used to produce high volumes of complex parts quickly and efficiently.

Here's how the material flows through a typical progressive die:

- Feeding: The metal strip enters the die, guided by a feeder mechanism that ensures precise positioning for each operation

- Pilot holes: Initial punches create reference holes that guide the strip through subsequent stations with exacting accuracy

- Sequential operations: Each station performs its designated task—whether cutting, forming, or shaping—as the strip advances

- Part separation: At the final station, the completed part is cut free from the carrier strip and ejected

The strip remains connected throughout the process via a carrier strip, which maintains part alignment and enables the high-speed operation that progressive stamping and fabrication are known for. This carrier strip essentially acts as a conveyor system built into the material itself.

Operations Progressive Dies Can Accomplish

Progressive dies are remarkably versatile tools. Within a single die, manufacturers can incorporate multiple operations that would otherwise require separate machines and handling steps. The main categories of operations include:

Cutting operations:

- Piercing: Creating holes, slots, or openings in the material

- Blanking: Cutting out the part's perimeter shape from the strip

- Notching: Removing material from the edge of the strip

- Trimming: Removing excess material from previously formed features

Forming operations:

- Bending: Creating angular features along a straight line

- Forming: Shaping the material into curved or complex contours

- Coining: Compressing material to create precise thicknesses or detailed surface features

- Embossing: Raising or depressing portions of the material surface

- Drawing: Stretching material into cup-shaped or recessed features

As industry sources explain, stamping dies perform two primary functions: cutting and forming. Cutting dies use sharp-edged tools that exert force to shear or separate the metal along specific contours, while forming operations shape the metal workpiece into desired geometries by exerting pressure to deform it without cutting through.

When Progressive Stamping Delivers Maximum Value

Not every part is suited for progressive die and stamping methods. The process delivers its greatest benefits under specific conditions. Consider progressive stamping when your project meets these criteria:

- High-volume production: Progressive dies typically become cost-effective at 10,000+ parts annually, with efficiency gains increasing dramatically at higher volumes

- Smaller part sizes: Components that can remain attached to the carrier strip throughout processing—generally parts with dimensions that fit within the strip width

- Multiple sequential operations: Parts requiring several forming or cutting steps that can be arranged in a logical progression

- Consistent material thickness: Applications using uniform gauge material that feeds predictably through the die

- Tight tolerance requirements: Parts demanding precision and repeatability across thousands or millions of units

The progressive dies themselves excel with common engineering materials. Steel, aluminum, copper, and brass in consistent thicknesses all run reliably through progressive stamping operations. Reference materials note that steel offers versatility and high strength-to-weight ratio, aluminum provides excellent formability and lightweight properties, and copper alloys deliver superior electrical conductivity for electronic applications.

Industries that rely heavily on progressive stamping include automotive (brackets, clips, electrical connectors), electronics (terminals, contacts, shielding components), and appliance manufacturing (mounting hardware, structural elements). In each case, the combination of high volumes, complex multi-step operations, and demanding quality requirements makes progressive metal stamping the logical choice.

Understanding when progressive stamping shines is only half the equation. Next, we'll examine transfer die stamping—the alternative approach that handles larger parts and complex three-dimensional geometries that progressive methods simply cannot accommodate.

Transfer Die Stamping Process and Best Use Cases

What happens when your part is too large for a carrier strip? Or when you need deep-drawn features that require material to flow freely from all directions? This is where transfer die stamping enters the picture. Unlike progressive stamping where parts remain attached to a moving strip, transfer stamping liberates each workpiece—creating possibilities that simply aren't achievable with connected-strip methods.

Transfer Die Mechanics and Multi-Station Processing

Transfer stamping begins with a fundamental difference: the workpiece becomes independent from the parent material early in the process. According to industry experts, the distinguishing feature that makes transfer die stamping different from progressive die stamping is that the workpiece is cut off the parent material strip at the earliest stage of the process.

Here's how the transfer stamping process unfolds:

- Blanking: A coil of raw metal feeds into the first station where the initial part shape—called a blank—is punched out of the continuous strip. This is the final connection to the parent coil

- Mechanical transfer: As the press ram rises and opens the die, part lifters raise the newly cut blank off the lower die surface. Simultaneously, the transfer system engages

- Precision movement: Two rails running the length of the die move inward, and mechanical fingers or grippers firmly clamp onto the blank's edges

- Station-to-station travel: The entire transfer rail assembly lifts the blank vertically, moves it horizontally to the next station, then deposits it with extreme precision onto locators in the next die

- Release and reset: The fingers release the part and rails retract to their initial position—all before the press ram begins its downward stroke

This entire sequence happens in a fraction of a second. The coordination between press motion and transfer system timing is critical. As AIDA notes, the timing of punch up-stroking, knockout stroking, and transfer motion for automating processing is a critical problem to be solved in transfer stamping applications.

Transfer presses are specifically designed for this process—typically large-bed machines with substantial capacity to accommodate the many die stations needed for complete part production. Think of it as a high-speed, highly automated assembly line compressed into a single machine, where a raw blank enters one end and a complex, finished part emerges from the other.

How the Transfer Mechanism Works

The heart of transfer die stamping is its part-handling system. Two primary mechanisms move discrete blanks between stations:

Mechanical fingers or grippers: These precision-engineered components clamp onto the edges of each blank. Rails carrying the grippers move in a synchronized dance—inward to grip, upward to lift, forward to advance, downward to place, then outward to release. This two-dimensional or three-dimensional motion repeats with every press stroke.

Suction cups: For certain applications, vacuum-based handling replaces mechanical gripping. Suction cups lift blanks from above, making them ideal for parts where edge access is limited or where gripper marks would be unacceptable on the finished component.

The precision of this placement cannot be overstated. Each blank must land exactly on die locators to ensure proper alignment for the next forming operation. Even minor positioning errors compound through subsequent stations, resulting in defective parts.

Complex Geometries That Demand Transfer Die Solutions

Why choose transfer dies over progressive dies? The answer lies in what becomes possible when parts aren't tethered to a carrier strip. Transfer stamping unlocks manufacturing capabilities that progressive methods cannot match.

Consider deep drawing. In transfer stamping, the blank can be lifted, rotated, and manipulated freely. This liberty enables dies to create deep cup-like shapes since material can flow uniformly from all sides into the die cavity. Progressive dies, by contrast, must draw material from only the sides of parts that remain on the carrier strip—a limitation that frequently causes fractures or unacceptable wall thinning in deep-draw applications.

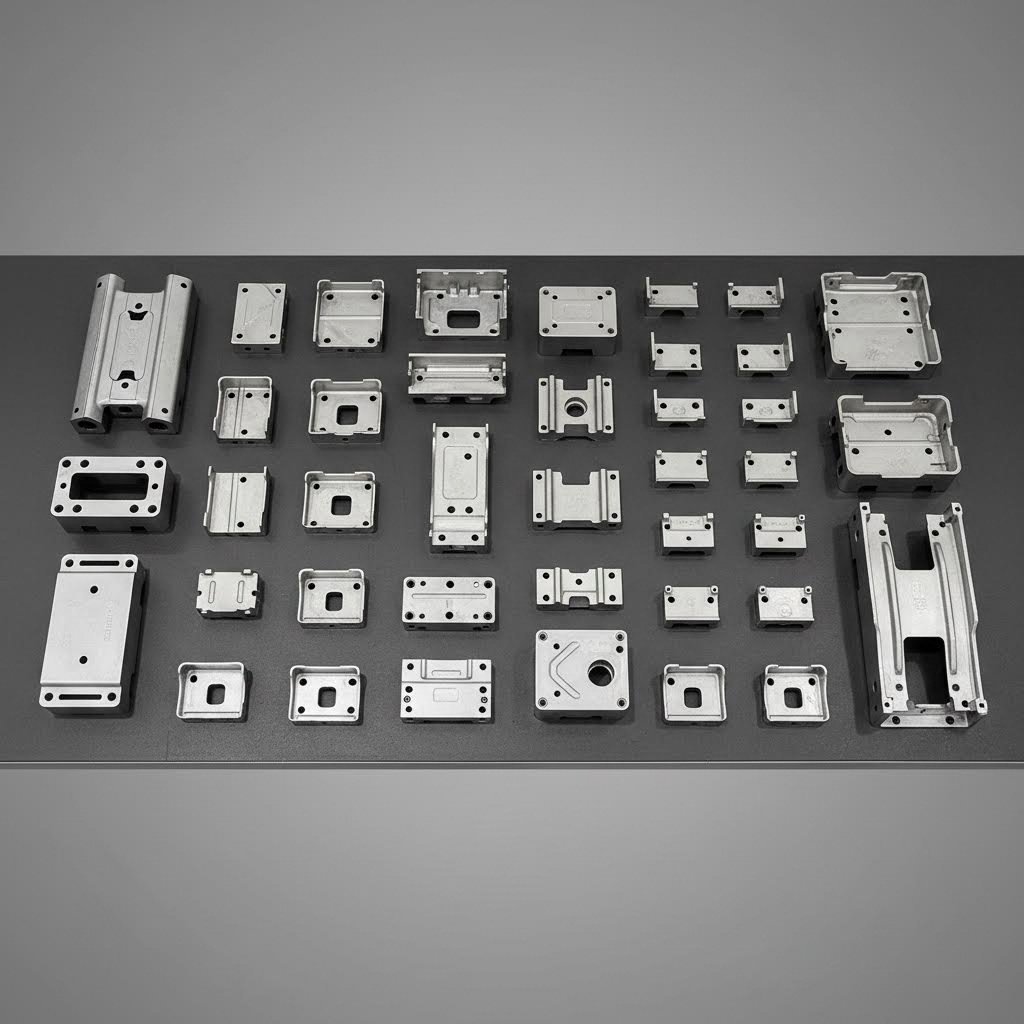

Transfer dies excel in these specific applications:

- Larger parts that cannot remain on carrier strip: Components whose dimensions exceed practical strip widths, or parts requiring forming operations that would distort a connected strip

- Deep-drawn components: Parts where depth exceeds diameter, such as canisters, housings, and cup-shaped features requiring uniform wall thickness

- Parts requiring operations on multiple surfaces: Components needing forming, piercing, or finishing on the top, bottom, and sides—accessible only when the part is free-standing

- Complex 3D geometries: Features including side holes, undercuts, angled flanges, and intricate surface contours that demand 360-degree access at each station

- Integrated secondary operations: Parts benefiting from in-die threading, welding, riveting, or component insertion that would be impossible on a connected strip

The range of operations possible at each transfer station mirrors progressive capabilities but with added flexibility. Typical operations include drawing (creating cup-shaped features), piercing (adding holes and openings), trimming (removing excess material), and forming (shaping complex contours). Additionally, transfer dies may incorporate advanced secondary operations—tapping heads for threaded holes, small welding units for adding nuts or brackets, or automated systems for inserting plastic or rubber components.

Tonnage Requirements and Press Capacity

Transfer stamping press equipment differs significantly from progressive press setups. Transfer presses typically require higher tonnage capacity to accommodate the forming forces needed for larger parts and deep-drawing operations.

To illustrate, AIDA's cold forging transfer presses range from 400 to 1,200 tons (4,000 to 12,000 kN). These machines feature substantial bed areas—bolster dimensions reaching 1,500mm x 1,100mm on larger models—to accommodate multi-station die sets. Stroke rates vary inversely with tonnage: 400-ton presses achieve 30-45 strokes per minute, while 1,200-ton machines operate at 20-30 strokes per minute.

This relationship between tonnage and speed highlights an important consideration. While transfer press stamping operates at slower cycles than high-speed progressive presses, throughput isn't the complete picture. When a progressive-stamped part requires multiple secondary operations after leaving the press, the total production time and cost per part can exceed that of a transfer-stamped part leaving the press fully finished.

The Flexibility Advantage

Transfer tool products offer a significant maintenance and modification advantage over progressive dies. Because transfer dies consist of multiple individual station dies contained within a master die set, manufacturers gain operational flexibility that monolithic progressive tools cannot match.

When a single station in a progressive die breaks, the entire tool may require complex, time-consuming repairs. With transfer dies, modularity simplifies both construction and maintenance. Individual stations can be:

- Removed and repaired without disassembling the entire die set

- Modified independently to accommodate design changes

- Replaced with upgraded tooling without affecting other stations

- Optimized individually for specific operations without compromise

This modularity extends to process optimization. Each station in a transfer die performs focused operations on a free-standing part, allowing engineers to fine-tune individual steps without cascading effects on other stations. The result is exceptional dimensional repeatability, superior surface finishes, and improved part-to-part consistency across production runs of millions of parts.

Now that you understand how both progressive and transfer die stamping work, you're ready for a direct comparison. Let's examine how these methods stack up against each other across the factors that matter most for your production decisions.

Progressive Die vs Transfer Die Performance Comparison

You've seen how each stamping method works individually. But when you're staring at a part drawing and calculating production costs, you need side-by-side answers. Which method runs faster? Which handles your part geometry? Where does each approach save—or cost—money? This chapter delivers the direct comparison you need to make confident decisions for your die stamping project.

Side-by-Side Performance Breakdown

Let's cut through the complexity with a comprehensive comparison. The following table evaluates progressive die metal stamping against transfer die stamping across the performance criteria that directly impact your production outcomes:

| Performance Factor | Progressive Die Stamping | Transfer Die Stamping |

|---|---|---|

| Production Speed | High-speed operation; typically 20-1,500+ strokes per minute depending on part complexity. Ideal for high speed metal stamping of smaller components. | Moderate speed; typically 20-45 strokes per minute. Transfer mechanism timing limits maximum cycle rates. |

| Part Size Capacity | Limited by strip width and carrier strip requirements. Best for smaller to medium-sized parts that remain attached during processing. | Handles larger components freely. No carrier strip constraints allow parts exceeding typical progressive die limits. |

| Geometric Complexity | Excellent for 2D complexity with multiple piercing, forming, and bending operations. Limited 3D capability due to carrier strip attachment. | Superior 3D flexibility. Deep draws, multi-surface operations, and undercuts accessible when parts move freely between stations. |

| Initial Tooling Cost | Generally higher upfront investment due to integrated multi-station die complexity. Compound die stamping within progressive tools adds engineering costs. | Lower initial tooling expense. Modular station construction reduces individual die complexity and build time. |

| Per-Part Cost (High Volume) | Significantly lower at scale. Continuous strip-fed operation minimizes handling and maximizes throughput efficiency. | Higher per-part costs at equivalent volumes due to slower cycle times and more complex part handling. |

| Per-Part Cost (Low Volume) | Higher due to substantial tooling amortization across fewer units. | More economical for smaller runs where tooling investment distributes reasonably across production quantity. |

| Material Utilization | Efficient use of coil stock. Carrier strip creates some inherent waste, but nesting optimization minimizes scrap. According to industry analysis, progressive stamping may result in slightly more efficient material utilization due to its continuous process. | Good utilization with individual blanks. Blank shape can be optimized independently from part geometry. |

| Secondary Operations | Often eliminates secondary operations entirely by incorporating all forming steps within the die. Parts exit finished. | May require additional processing depending on complexity, though in-die threading, welding, and assembly are possible. |

| Maintenance Complexity | More complex repairs. Single integrated die means issues at one station may require extensive teardown. | Modular design simplifies maintenance. Individual stations can be removed, repaired, or replaced without affecting others. |

| Design Change Flexibility | Limited flexibility. Design modifications often require significant die rework or complete retooling. | Greater adaptability. Individual station modifications accommodate design changes without full die reconstruction. |

This comparison reveals an important truth: neither method universally outperforms the other. A prog die delivers unmatched efficiency for high-volume small parts, while transfer tooling provides flexibility that progressive approaches simply cannot match for larger or geometrically complex components.

Matching Die Type to Your Production Requirements

Sounds complex? Here's where volume projections transform this comparison into actionable guidance. Your annual production quantity often serves as the primary decision driver when other factors are roughly equal.

The following table provides volume-based recommendations derived from typical cost-benefit analysis across manufacturing applications:

| Annual Production Volume | Recommended Die Type | Key Considerations |

|---|---|---|

| Under 5,000 parts | Transfer Die Stamping (or alternative methods) | Progressive die tooling costs rarely justify at this volume. Transfer dies offer lower initial investment. Consider compound die stamping for simpler flat parts requiring single-stroke completion. Soft tooling or prototype methods may be more economical. |

| 5,000 - 50,000 parts | Evaluate Both Methods | This volume range requires careful analysis. Part complexity and geometry often determine the winner. Transfer stamping provides flexibility for design iterations. Progressive tooling becomes viable for simpler parts with stable designs. |

| 50,000 - 500,000 parts | Progressive Die Stamping (for appropriate geometries) | Volume justifies progressive tooling investment for most small-to-medium parts. Per-part cost advantages become significant. Use transfer dies only when part size or 3D complexity demands it. |

| 500,000+ parts | Progressive Die Stamping (strongly preferred) | High-volume production demands the speed and efficiency of progressive dies. Reference sources confirm that progressive die stamping stands out for high-speed production, making it ideal for large-volume runs. Only choose transfer for parts that physically cannot be processed progressively. |

Imagine you're evaluating a bracket component for automotive applications. At 20,000 units annually with moderate complexity, the decision requires deeper analysis. But scale that same bracket to 200,000 units? Progressive stamping almost certainly wins on economics, assuming the part geometry allows carrier strip processing.

Critical Decision Points Beyond Volume

While volume thresholds provide useful starting guidance, your die stamping machine selection depends on factors that these tables cannot fully capture:

- Tolerance requirements: Both methods achieve excellent precision, but progressive dies often deliver superior consistency across millions of identical parts due to continuous strip positioning

- Surface finish standards: Transfer stamping's free-handling approach may better preserve surface quality for cosmetic applications

- Production timeline: Progressive die development typically requires longer lead times due to integrated tool complexity

- Future design changes: If your part design may evolve, transfer die modularity offers valuable adaptability

- Press availability: Your existing equipment or accessible contract manufacturing presses may favor one approach

According to industry comparison data, transfer die stamping involves higher operational costs, particularly for intricate designs and short runs, while the initial tooling cost for progressive die stamping can be high but becomes cost-effective in large-volume production due to lower per-part costs.

These performance comparisons set the foundation for informed decision-making. But die selection also depends heavily on your specific industry and material requirements—factors we'll examine next to complete your evaluation framework.

Industry Applications and Material Selection Guide

Now that you understand the performance differences between progressive and transfer die stamping, let's get practical. How do manufacturers in your specific industry approach this decision? And how does your material choice influence which die type makes sense? These real-world considerations often tip the balance when volume and geometry factors seem inconclusive.

Automotive and Aerospace Die Selection Strategies

Walk through any automotive manufacturing facility and you'll find both progressive and transfer dies working side by side—each handling the applications where it excels. The automotive sector's demanding requirements for precision, volume, and cost efficiency make die selection especially critical.

Progressive stamping die applications in automotive:

- Brackets and mounting hardware: High-volume production of seat brackets, engine mounts, and body structure supports rely on progressive dies to maintain tight tolerances across millions of identical parts

- Clips and fasteners: Small retaining clips, spring clips, and fastening components benefit from the speed and repeatability of progressive stamped automotive parts

- Electrical connectors: Terminal connectors, junction box components, and wiring harness brackets demand the precision that progressive stamping delivers consistently

- Sensor housings: Compact electronic sensor enclosures with multiple features are ideal candidates for multi-station progressive processing

Transfer die applications in automotive:

- Structural components: Larger body panels, cross members, and reinforcement plates require the size capacity only transfer dies can provide

- Deep-drawn housings: Oil pans, transmission covers, and fuel system components with substantial draw depths demand transfer processing for uniform wall thickness

- Complex 3D assemblies: Components requiring forming operations on multiple surfaces—impossible while attached to a carrier strip

- Suspension parts: Control arms and mounting brackets with complex geometries that exceed progressive die capabilities

According to Durex Inc., progressive dies are commonly used in the automotive industry for manufacturing components like brackets and clips, while transfer dies are perfect for large-scale manufacturing needs, such as in the aerospace and heavy machinery sectors, where complex assemblies are required.

Aerospace applications follow similar logic but with even tighter tolerance requirements. Structural aircraft components often require transfer processing due to size and geometry, while smaller avionics brackets and electrical components benefit from progressive die precision.

Electronics Industry Preferences

When it comes to the electronics industry, progressive stamping dominates. Why? The combination of small part sizes, extremely high volumes, and demanding precision requirements aligns perfectly with progressive die capabilities.

The electrical stamping process for terminals and contacts illustrates this preference clearly. A single connector housing may contain dozens of precisely formed terminals—each requiring consistent spring properties, exact dimensional tolerances, and reliable electrical conductivity. Progressive dies excel at producing these components at rates exceeding hundreds of strokes per minute.

Common electronics applications for progressive stamping include:

- Connector terminals and pins

- Contact springs and leaf springs

- EMI/RFI shielding components

- Lead frames for semiconductor packaging

- Battery contacts and power distribution components

Transfer dies find limited but important applications in electronics—typically for larger enclosures, heat sinks with deep fins, or components requiring secondary operations that progressive processing cannot accommodate.

Medical Device Requirements

Medical device manufacturing presents unique challenges where precision and consistency aren't just desirable—they're regulatory requirements. For small, high-precision components, progressive stamping delivers the repeatability that medical device manufacturers demand.

A metal stamping die for medical applications must produce parts with exceptional consistency. Surgical instrument components, implant housings, and diagnostic device parts often require tolerances measured in thousandths of an inch across production runs of millions of units. Progressive dies, with their continuous strip feeding and consistent station-to-station positioning, excel in these demanding applications.

According to industry sources, coining dies—often incorporated within progressive die setups—are predominantly used for manufacturing medical devices that require precise and delicate components. Their ability to produce intricate designs with high accuracy makes them invaluable where detail and finish are paramount.

How Material Type Influences Your Die Choice

Your material specification directly impacts die selection. Different metals behave differently under stamping forces, and matching material properties to the right die type prevents quality issues and production headaches.

- Carbon steel progressive stamping: Ideal for high-volume brackets, structural components, and automotive hardware. Carbon steel's consistent forming characteristics and cost-effectiveness make it the workhorse material for progressive operations. Gauges from 0.5mm to 3mm run reliably through most progressive die setups

- Stainless steel considerations: Both methods handle stainless steel effectively, but the material's work-hardening tendency requires careful die design. Progressive dies work well for thinner gauges and simpler forms. Transfer dies become preferable for thicker stainless or deep-draw applications where intermediate annealing steps may be needed

- Aluminum handling differences: Aluminum's softness and tendency to gall (stick to die surfaces) requires specialized coatings and lubrication regardless of die type. Progressive stamping handles aluminum sheet efficiently for lighter-gauge applications. Transfer dies accommodate thicker aluminum plate and deep-drawn aluminum components better

- Copper progressive stamping for electrical applications: Copper and copper alloys (brass, bronze, beryllium copper) are staples in electrical stamping process applications. Their excellent electrical conductivity and formability make them ideal for progressive stamping of terminals, contacts, and connectors. A progressive stamping die running copper alloys can achieve exceptional production rates while maintaining the tight tolerances electrical components demand

Material Thickness and Die Selection

Here's a factor that often gets overlooked: material thickness significantly influences which die type works best for your application.

According to Worthy Hardware, for progressive dies, very thick materials are unsuitable because they are difficult to flatten and feed accurately. The continuous strip-feeding mechanism that makes progressive stamping so efficient becomes problematic as material thickness increases.

Consider these thickness guidelines:

- Thin materials (0.1mm - 1.5mm): Progressive dies excel. Thin stock feeds smoothly, forms predictably, and maintains carrier strip integrity throughout processing

- Medium materials (1.5mm - 3mm): Both methods viable. Part geometry and volume typically determine the better choice

- Thicker materials (3mm+): Transfer dies often preferred. Individual blank handling eliminates strip-feeding challenges. The same reference notes that for parts too thick for progressive dies, manufacturers use single-stage or transfer dies

Thicker materials also require greater forming forces, which aligns with transfer presses' typically higher tonnage capacities. When your part design calls for heavy-gauge steel or aluminum plate, transfer processing usually provides more reliable results.

Understanding these industry and material considerations helps narrow your die selection. But how do you translate this knowledge into actual cost projections and timeline expectations? That's exactly what we'll explore in the next section—the real numbers behind tooling investment and development schedules.

Cost Analysis and Tooling Development Timelines

You've evaluated geometry, volume, and material requirements. Now comes the question that ultimately drives most manufacturing decisions: What will this actually cost? And how long before you're running production parts? Understanding the complete financial picture—not just the initial quote—separates successful projects from budget disasters.

True Cost Comparison Beyond Initial Tooling Investment

When comparing progressive die & stamping costs to transfer die alternatives, manufacturers often make a critical mistake. They focus exclusively on the tooling quote sitting on their desk. That number matters, but it's only one piece of a much larger financial puzzle.

Let's break down the complete cost factors you should evaluate:

Initial tooling investment: Progressive die tooling typically commands higher upfront costs. Why? The integrated multi-station design requires more engineering hours, tighter machining tolerances, and complex assembly. A progressive stamping dies project may run 30-50% higher in initial tooling expense compared to equivalent transfer tooling. However, as industry sources confirm, while the tool itself is quicker to get started with simple dies and costs less initially, making a large quantity of parts takes longer and costs more per piece.

Per-part production costs at various volumes: Here's where progressive die stampings deliver their payback. Once that expensive tooling is running, the continuous strip-fed operation produces parts at remarkable speed with minimal labor intervention. At high volumes, per-part costs drop dramatically. Transfer stamping, with its slower cycle times and more complex part handling, carries higher per-part costs at equivalent volumes—but those costs matter less when your total production quantity is modest.

Maintenance and repair expenses: Progressive die tooling demands more sophisticated maintenance. The integrated design means wear at one station can affect overall die performance. Transfer dies offer modular advantages—individual stations can be pulled, repaired, or replaced without disassembling the entire tool. Over a multi-year production run, these maintenance differences compound significantly.

Material waste percentages: Both pressing and stamping methods generate scrap, but in different ways. Progressive dies create carrier strip waste—the material connecting parts through the process that gets trimmed away at the end. Transfer dies generate scrap from blank nesting efficiency. Depending on part geometry, material utilization rates typically range from 70-85% for either method, with optimization efforts capable of pushing those numbers higher.

The die with the lowest purchase price rarely delivers the lowest total cost of ownership. Evaluate tooling investment, per-part production costs, maintenance expenses, and material utilization together—then calculate your true cost per finished part at your actual production volume.

Lead Time Realities for Die Development

Beyond cost, timeline often determines which stamping approach fits your project. Progressive die tooling development typically requires longer engineering and build time due to its inherent complexity.

Consider what goes into progressive die tooling development:

- Engineering and design: 4-8 weeks for complex multi-station layouts. Every station must integrate precisely with others, and strip progression must be optimized for material flow and die longevity

- Component machining: 6-12 weeks depending on die complexity. Tight tolerances across multiple stations demand precision CNC work and careful grinding

- Assembly and tryout: 2-4 weeks for initial assembly, followed by iterative adjustments during sampling

- Total typical timeline: 12-20 weeks from design approval to production-ready tooling

Transfer die development often moves faster. The modular station approach means individual components can be engineered and manufactured somewhat independently. Typical timelines run 8-14 weeks—a meaningful advantage when time-to-market pressure is intense.

According to The Fabricator, one of the primary challenges in die development is that shops often spend excessive time engineering parts rather than engineering the dies themselves. This misallocated effort extends timelines and increases costs without corresponding value.

How Advanced Design Reduces Development Risk

Modern CAE (Computer-Aided Engineering) simulation has transformed die development economics. Before cutting steel, engineers can virtually test forming operations, predict material behavior, and identify potential failure points.

What does this mean for your project? CAE simulation reduces development risk by:

- Identifying springback issues before tooling is built, allowing compensation in the design phase

- Predicting material thinning and potential fracture locations during deep draws

- Optimizing blank shapes and strip layouts for maximum material utilization

- Validating forming sequences before committing to expensive tool construction

The result? Fewer costly iterations during tryout. According to Chia Chang's case study, optimizing die design precision combined with improved processes led to daily output increases of 175% and yield improvements from 50% to 90%—demonstrating the tangible impact of upfront engineering investment.

Accelerating Validation with Rapid Prototyping

What if you could validate your part design before committing to full production tooling? Rapid prototyping capabilities bridge the gap between design and production, letting you test form, fit, and function with actual stamped samples.

Prototype tooling—sometimes called soft tooling—uses less hardened materials and simplified construction to produce representative parts quickly. While these tools won't survive high-volume production, they serve critical purposes:

- Validating part geometry and tolerances before expensive production die investment

- Providing samples for customer approval and testing

- Identifying design issues early when changes cost hundreds instead of thousands

- Supporting low-volume initial production while hard tooling is developed

Some manufacturers offer rapid prototyping turnaround in as little as 5 days for simpler geometries. This speed-to-first-article capability can dramatically compress your overall project timeline while reducing the risk of expensive production tooling modifications.

With cost and timeline factors clarified, you're nearly ready to make your die selection decision. But first, let's address the misconceptions that trip up even experienced manufacturers—and provide a practical checklist you can apply directly to your own project evaluation.

Common Misconceptions and Decision Checklist

Even experienced manufacturing engineers fall victim to outdated assumptions about progressive and transfer die stamping. These misconceptions lead to suboptimal die selection, wasted budgets, and frustrated production teams. Before you finalize your decision, let's debunk the myths that derail projects—then arm you with a practical checklist for your own evaluation.

Debunking Progressive vs Transfer Die Myths

Myth 1: Progressive dies are always more expensive in the long run.

Reality? Progressive tool and die investments often deliver the lowest total cost of ownership at high volumes. Yes, upfront tooling costs run higher. But consider what happens across a million-part production run. The speed advantage—sometimes 10x faster cycle rates—combined with reduced labor and eliminated secondary operations frequently makes progressive tooling the most economical choice. According to Worthy Hardware, progressive die stamping guarantees consistency and rapid output with minimal labor involvement, keeping per-part prices down at high volumes.

Myth 2: Transfer dies are only for simple parts.

This misconception couldn't be further from the truth. Transfer dies actually handle more complex three-dimensional geometries than progressive dies can accommodate. Deep draws, multi-surface operations, undercuts, and integrated secondary operations like in-die threading or welding—these capabilities exceed what any progressive tool can achieve. The die transfer process liberates parts from carrier strip constraints, enabling forming operations impossible when material remains connected.

Myth 3: You must choose one method or the other.

Hybrid approaches exist for complex manufacturing workflows. Some manufacturers use progressive stamping for initial blanking and basic forming, then transfer those semi-finished parts to secondary operations. Others run compound tool setups within larger transfer systems. A compound die performs multiple cutting operations in a single press stroke—and these can integrate into broader production strategies that leverage both progressive and transfer advantages.

Myth 4: Modern feeders eliminate the need for pitch notches in progressive dies.

Think your advanced coil feeder means you can skip this detail? According to The Fabricator, even feeders accurate to 0.0005 inch don't address edge camber, operator skill variations, or die protection reliability. Bypass notches (also called pitch notches or French notches) in progressive dies serve critical functions beyond simple feeding control:

- Providing solid stops to prevent overfeeding that causes severe die damage

- Removing edge camber from coil stock to ensure smooth material flow

- Establishing first-hit positioning for leading edge material

- Reducing loose scrap and half-hits during production

The same source notes that one severe die crash from overfeeding can cost 100 times more than the additional material consumed by a pitch notch. Understanding these technical details within the die in progressive setups prevents costly assumptions.

Avoiding Costly Die Selection Mistakes

How do you know if you've chosen the wrong stamping method? Your production line will tell you—often loudly. Watch for these warning signs that indicate mismatched die selection:

- Excessive scrap rates: If material waste consistently exceeds 25-30%, your die type may not suit your part geometry. Progressive dies with poorly nested parts or transfer dies with inefficient blank shapes both create unnecessary waste

- Quality inconsistencies: Part-to-part dimensional variation beyond tolerance suggests process instability. Progressive dies running parts too large for reliable strip control, or transfer dies with inadequate part positioning, both cause quality drift

- Production bottlenecks: When stamping becomes your constraint while downstream operations sit idle, cycle time doesn't match your needs. Progressive dies running at their natural speed may still underperform if you've chosen transfer tooling for parts better suited to strip processing

- Maintenance frequency issues: Dies requiring constant attention signal problems. A progressive tool wearing prematurely at one station affects the entire integrated system. Transfer dies with individual station failures may indicate design issues—but at least allow targeted repairs

- Secondary operation accumulation: If parts leaving your die consistently require additional processing you didn't anticipate, the die design may have compromised capability for the wrong reasons

Your Die Selection Decision Checklist

Ready to evaluate your own project? Work through this checklist systematically. Your answers will point toward the right stamping approach for your specific requirements.

| Evaluation Criteria | Your Project Specification | Decision Guidance |

|---|---|---|

| Annual Volume Projection | Document your expected annual quantity and production lifespan | Under 50,000: Lean toward transfer. Over 100,000: Progressive likely wins on economics. Between: Analyze other factors carefully |

| Part Dimensions | Record maximum length, width, and height of finished part | Parts fitting within typical strip widths (up to 300mm) suit progressive. Larger parts or those requiring substantial draw depths favor transfer |

| Geometric Complexity Score | Count: holes, bends, forms, draws, and surfaces requiring operations | High feature count with 2D complexity: Progressive. 3D features requiring multi-surface access: Transfer |

| Material Specifications | List material type, thickness, and any special properties | Thin materials (under 2mm) in steel, aluminum, copper: Progressive-friendly. Thicker gauges or materials requiring controlled forming: Consider transfer |

| Tolerance Requirements | Document critical dimensions and acceptable variation | Both methods achieve tight tolerances. Progressive offers superior repeatability at high volumes. Transfer provides flexibility for complex tolerance stacks |

| Secondary Operation Needs | List any operations required after stamping | Goal: Eliminate secondary operations. Progressive dies often incorporate all steps. Transfer dies can include threading, welding, or assembly in-die |

Score your project honestly. If most factors point toward one method, your path is clear. If you're split down the middle, prioritize volume and part geometry—these factors typically carry the most weight in total cost calculations.

With misconceptions cleared and your evaluation checklist complete, you're ready for the final step: translating your analysis into action. The next section delivers specific recommendations based on your requirements and guidance on selecting the right manufacturing partner to execute your die strategy successfully.

Final Recommendations and Choosing Your Die Partner

You've worked through the analysis. You understand how progressive and transfer die stamping differ, which applications favor each method, and how volume, geometry, and material factors influence your decision. Now it's time to translate that knowledge into action—and identify the right manufacturing partner to bring your project to life.

Your Die Selection Roadmap

Let's distill everything you've learned into clear, actionable guidance. Your die selection ultimately comes down to matching your specific project requirements to the stamping method that delivers optimal results.

Choose progressive die stamping when:

- Your annual production volume exceeds 50,000 parts—and especially when quantities reach into the hundreds of thousands or millions

- Part dimensions fit comfortably within carrier strip width constraints (typically under 300mm)

- Your design requires multiple sequential operations—piercing, forming, bending, coining—that can be arranged in logical progression

- Consistent material thickness allows reliable strip feeding throughout the progressive stamping process

- Tight tolerances and exceptional part-to-part repeatability are non-negotiable requirements

- Eliminating secondary operations matters for your cost structure and production timeline

Choose transfer die stamping when:

- Part size exceeds practical progressive die limits, requiring individual blank handling

- Complex 3D geometries demand forming operations on multiple surfaces—impossible while attached to a carrier strip

- Deep-drawn features require material to flow freely from all directions for uniform wall thickness

- Production flexibility matters—when design changes are likely or multiple part variants will run through the same tooling

- Lower initial tooling investment is essential, even if per-part costs run slightly higher

- Annual volumes fall in the moderate range where progressive tooling amortization doesn't pencil out

The decision becomes straightforward once you honestly evaluate your project against these criteria. High-volume small parts with complex features? Progressive stamping press operations almost certainly deliver the best economics. Larger structural components with deep draws and 3D complexity? Transfer tooling provides capabilities progressive dies simply cannot match.

Partnering with the Right Stamping Die Manufacturer

Here's a truth that experienced manufacturers understand: even the correct die selection fails without the right manufacturing partner executing it. Your stamping die supplier's capabilities, expertise, and quality systems directly determine whether your project succeeds or struggles.

When evaluating potential partners for your progressive tool and manufacturing needs—or transfer die development—prioritize these characteristics:

- Advanced engineering and simulation capabilities: Look for partners using CAE simulation to predict and prevent forming defects before cutting steel. Shaoyi's precision stamping die solutions exemplify this approach, using advanced CAE simulation for defect-free results that eliminate costly trial-and-error iterations. Their engineering team evaluates your specific requirements and recommends the optimal approach—whether progressive or transfer—based on technical merit rather than equipment availability

- Quality certifications that matter: IATF 16949 certification signals automotive-grade quality management systems. This isn't just a certificate on the wall—it represents disciplined processes for design control, production validation, and continuous improvement. Shaoyi's IATF 16949 certification backs their precision stamping die solutions with the quality infrastructure OEM customers demand

- Rapid prototyping capabilities: The ability to produce prototype parts quickly—in as little as 5 days for simpler geometries—lets you validate designs before committing to expensive production tooling. This capability compresses timelines and dramatically reduces development risk. According to Penn United's supplier evaluation guide, a supplier who can design and build precision metal stamping dies will inevitably be much more qualified to succeed than a supplier without these capabilities

- Proven first-pass success rates: Ask potential partners about their first-pass approval rate. A 93% first-pass approval rate—like Shaoyi achieves—indicates mature engineering processes that get tooling right the first time. This metric directly impacts your timeline and budget by minimizing costly rework cycles

- Production volume flexibility: Your needs may evolve. A partner capable of rapid prototyping through high-volume manufacturing provides continuity across your product lifecycle. You shouldn't need to change suppliers as volumes scale

What to Look for in Your Stamping Die Partner

Beyond the prioritized list above, evaluate these additional factors that industry experts recommend when selecting a precision metal stamping supplier:

- Years of experience with your part type: A supplier's expertise in flat parts, formed parts, or both matters. Take time to understand the types of components they've stamped successfully in the past and their ability to hold tight tolerances on parts similar to yours

- Die maintenance program: This often-overlooked factor maximizes die life and optimizes total lifecycle cost. A good maintenance program addresses die inspection, synchronization and adjustment, proper assembly techniques, and component replacement schedules

- Delivery track record: Does the supplier officially track on-time delivery performance? If not, select another supplier. Promises mean nothing without data-backed performance history

- Secondary operation capabilities: A supplier who can perform cleaning, plating, packaging, or product assembly in addition to stamping streamlines your supply chain and reduces logistics complexity

- Attention to detail: A supplier who asks thorough questions about part quality, key features, and tolerances during the quoting process typically delivers superior results. This early engagement signals genuine commitment to your success

According to Arthur Harris, prototyping capabilities help eliminate human error, reduce production time, and optimize die manufacturing during planning stages. Working with partners who offer this capability—combined with the engineering expertise to recommend the right die type—positions your project for success from the start.

Moving Forward with Confidence

The progressive die vs transfer die decision doesn't have to be intimidating. Armed with the evaluation framework from this guide, you can systematically assess your project requirements and identify the stamping method that delivers optimal results.

Remember the core principles:

- Volume drives economics—but geometry determines feasibility

- Initial tooling cost matters less than total cost of ownership

- The right manufacturing partner transforms good die selection into production success

- CAE simulation and rapid prototyping reduce development risk and compress timelines

Whether your project calls for high-speed progressive tooling running millions of precision parts or flexible transfer tooling producing complex 3D components, the decision framework you now possess will guide you toward the right choice. Partner with experienced die manufacturers who bring engineering expertise, quality certifications, and proven performance to your project—and watch your stamping operation deliver the results your business needs.

Frequently Asked Questions About Progressive Die vs Transfer Die Stamping

1. What is the difference between progressive dies and transfer dies?

Progressive dies process metal strips through sequential stations while parts remain attached to a carrier strip, ideal for high-volume small parts. Transfer dies separate blanks early and mechanically move them between stations, enabling larger parts and complex 3D geometries. Progressive stamping achieves higher speeds (20-1,500+ strokes per minute) while transfer stamping offers greater flexibility for deep draws and multi-surface operations. The choice depends on your part size, geometric complexity, and production volume requirements.

2. What are the disadvantages of progressive die stamping?

Progressive die stamping has several limitations: higher initial tooling investment due to integrated multi-station complexity, longer development lead times (12-20 weeks), restricted part size based on carrier strip width constraints, limited 3D forming capability since parts stay connected during processing, and more complex maintenance requirements where issues at one station may require extensive teardown. Additionally, design changes often require significant die rework or complete retooling, reducing flexibility compared to modular transfer die systems.

3. What is a progressive die?

A progressive die is a metal stamping tool that performs multiple operations sequentially as a coil-fed metal strip advances through stations with each press stroke. Each station executes specific tasks—piercing, blanking, bending, forming, coining, or embossing—producing a finished part with every cycle. The strip remains connected via a carrier strip throughout processing, enabling high-speed continuous production ideal for manufacturing large quantities of small, complex parts with exceptional consistency and tight tolerances.

4. When should I choose transfer die stamping over progressive die stamping?

Choose transfer die stamping when your parts are too large for carrier strip processing, require deep-drawn features with uniform wall thickness, need forming operations on multiple surfaces, or demand complex 3D geometries with undercuts. Transfer dies also suit lower-to-medium production volumes where tooling amortization favors lower initial investment, and when design flexibility matters for potential future modifications. The modular station design simplifies maintenance and allows individual station repairs without disassembling the entire tool.

5. How do I determine the right production volume threshold for progressive vs transfer dies?

Volume thresholds vary by application, but general guidelines apply: under 5,000 parts annually favors transfer dies or alternative methods due to progressive tooling costs; 5,000-50,000 parts requires careful analysis of part geometry and complexity; 50,000-500,000 parts typically justifies progressive tooling for appropriate geometries; and 500,000+ parts strongly favors progressive stamping for maximum efficiency. Partners like Shaoyi with IATF 16949 certification can evaluate your specific requirements and recommend the optimal approach based on total cost of ownership rather than just initial tooling expense.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —