Необходимые виды поверхностной обработки автомобильных форм: руководство

Краткое содержание

Обработка поверхности для автомобильных матриц — это специализированные процессы, такие как покрытие методом физического осаждения из паровой фазы (PVD), нитрирование и анодирование, которые изменяют поверхность матрицы для повышения её производительности и срока службы. Эти виды обработки необходимы для увеличения твёрдости, улучшения износостойкости и коррозионной стойкости, а также снижения трения. Применение правильной обработки критически важно для матриц, используемых в условиях высоких нагрузок, например при штамповке высокопрочных сталей (AHSS) или при литье под давлением в больших объёмах, обеспечивая долговечность инструмента и качество деталей.

Ключевая роль обработки поверхности для автомобильных матриц

В условиях сложного производства автомобилей штампы подвергаются значительным нагрузкам, включая высокое давление, экстремальные температуры и постоянное трение. Без надлежащей защиты эти ценные инструменты могут выйти из строя преждевременно, что приведет к дорогостоящему простою, задержкам в производстве и нестабильному качеству деталей. Поверхностные покрытия — это не просто дополнительная опция; они представляют собой основное инженерное решение, предназначенное для повышения устойчивости штампов к таким суровым условиям. Основная цель этих покрытий — улучшение поверхностных свойств, таких как твердость, смазываемость и устойчивость к износу и коррозии, что позволяет продлить срок службы инструмента и оптимизировать его производительность.

Необработанные матрицы зачастую подвержены типичным видам повреждений, таким как заедание, при котором материал заготовки прилипает к поверхности матрицы, вызывая царапины и дефекты. Они также страдают от абразивного износа из-за постоянного контакта с листовым металлом или расплавленными сплавами. Особенно это актуально при работе с передовыми материалами, такими как высокопрочные стали, которые создают экстремальные контактные напряжения на штампах. Со временем такое разрушение влияет на точность размеров и качество поверхности конечных автомобильных компонентов. Нанесение поверхностной обработки позволяет производителям создать функциональный барьер, который снижает эти проблемы, обеспечивая более стабильное производство и уменьшая необходимость в частом техническом обслуживании и замене инструментов.

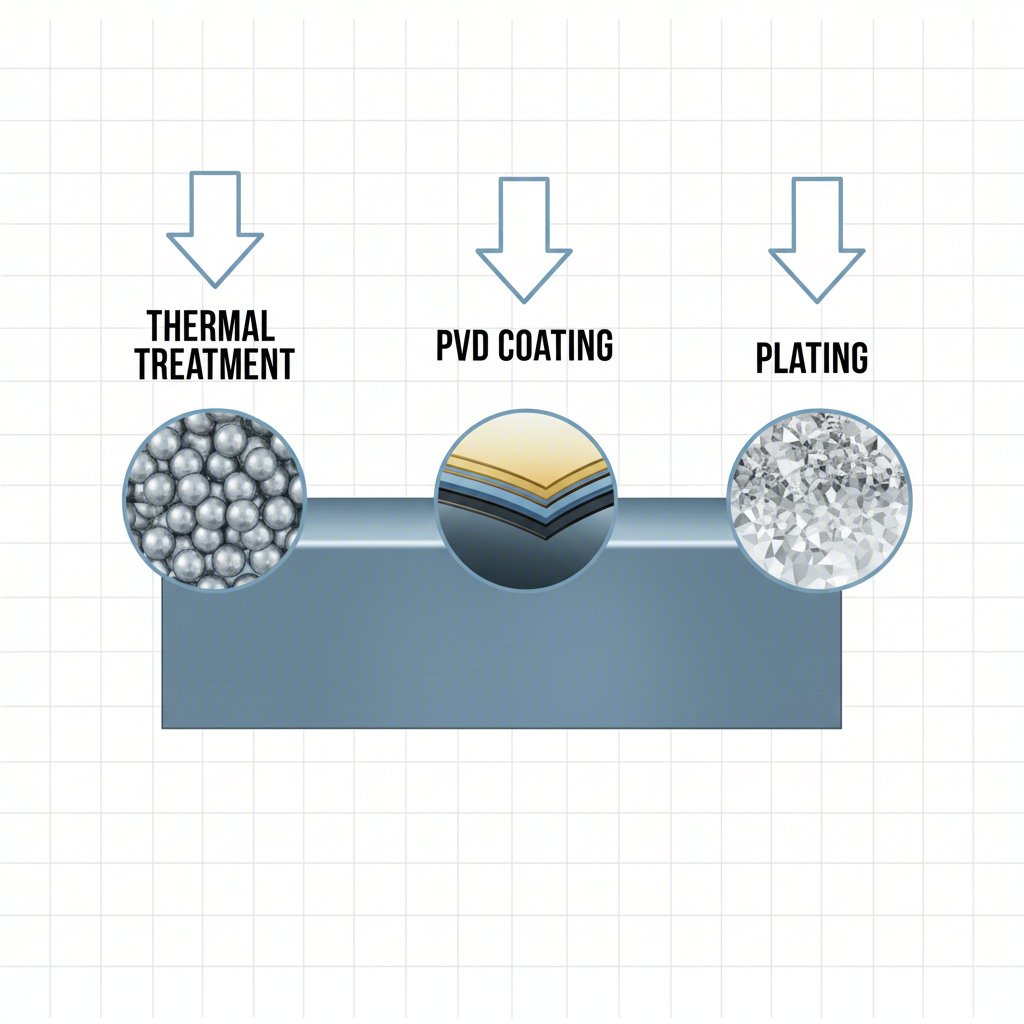

Важно различать поверхностную обработку и поверхностное покрытие, хотя эти термины иногда используются как синонимы. Поверхностная обработка, такая как азотирование или индукционная закалка, изменяет собственные свойства материала поверхности матрицы, зачастую посредством термического или химического процесса. Напротив, поверхностное покрытие предполагает нанесение отдельного слоя материала, например, PVD-пленки или порошкового покрытия, на поверхность матрицы. Как отмечают эксперты отрасли, поверхностная обработка изменяет саму поверхность, в то время как поверхностное покрытие добавляет новый слой . Выбор между ними зависит от конкретного применения, типа матрицы и целей производительности.

Руководство по распространенным процессам поверхностной обработки

Выбор метода поверхностной обработки зависит от множества факторов, включая материал матрицы, материал заготовки и конкретный тип возникающего повреждения. Доступные процессы можно условно разделить на термические/химические обработки и нанесение покрытий. Каждая категория имеет свои уникальные преимущества, адаптированные к различным производственным условиям — от штамповки панелей кузова до литья блоков цилиндров.

Термические и термохимические обработки

Эти процессы изменяют микроструктуру поверхности матрицы, повышая твердость и износостойкость без добавления нового слоя материала. Они известны тем, что создают прочную, интегрированную поверхностную зону, устойчивую к сколам и отслаиванию.

- Нитроцементация: Это термохимический процесс поверхностного упрочнения, при котором азот диффундирует в поверхность стальной матрицы, образуя чрезвычайно твердый внешний слой. Как объясняется в Изготовитель , ионная или плазменная азотирование особенно эффективны для крупных штампов, так как создают глубокий твердый слой, сохраняя более пластичное ядро, что помогает предотвратить растрескивание при высоких ударных нагрузках. Это значительно повышает устойчивость к износу и задирам.

- Укрепление: Процессы, такие как поверхностная закалка пламенем или индукционная закалка, используют локальный нагрев для быстрого разогрева и последующей закалки поверхности матрицы. Это создаёт закалённый слой, устойчивый к износу и деформации. Часто применяется на участках матрицы с повышенным износом, чтобы повысить долговечность без обработки всего инструмента.

Технологии нанесения покрытий и гальванических покрытий

Покрытия предполагают нанесение отдельного слоя материала на поверхность матрицы. Эти слои могут быть разработаны для обеспечения широкого спектра свойств — от смазывающей способности и устойчивости к коррозии до определённых декоративных покрытий на конечной отливке.

- Физическое осаждение из паровой фазы (PVD): PVD — это процесс, при котором в вакууме наносится тонкая, чрезвычайно твердая и малотрениевая пленка. Покрытия PVD, такие как нитрид хрома (CrN) и нитрид титана (TiN), отлично подходят как для штамповки, так и для литья под давлением, обеспечивая превосходную износостойкость и снижая прилипание материала.

- Порошковая окраска: Этот процесс предусматривает электростатическое нанесение сухого порошка, который затем отверждается при нагреве для образования твердого покрытия. Хотя чаще он используется для окончательной обработки отливок в декоративных и защитных целях, его можно применять и к отдельным компонентам пресс-форм для обеспечения коррозионной стойкости.

- Анодирование: Анодирование, применяемое в основном для алюминия, представляет собой электрохимический процесс, при котором поверхность металла превращается в прочное, устойчивое к коррозии анодное оксидное покрытие. Оно, как правило, не используется для стальных пресс-форм, но является распространенным покрытием для алюминиевых деталей, полученных литьем под давлением.

| Тип обработки | Основная польза | Распространённое применение | Ограничение |

|---|---|---|---|

| Ионное/плазменное азотирование | Высокая твердость поверхности, превосходная стойкость к износу/задирам | Крупные стальные штампы для AHSS | Процесс происходит при относительно низких температурах |

| Покрытие пвд | Низкое трение, высокая твердость, тепловой барьер | Пресс-формы для литья под давлением, штампы для вырубки/формовки | Тонкий слой может быть не идеален при экстремальных ударных нагрузках |

| Индукционная закалка | Целевая износостойкость на определенных участках | Режущие кромки, поверхности с высоким износом в штампах | Может создавать концентрации напряжений, если выполнено неправильно |

| Хромовое покрытие | Отличная твердость, коррозионная стойкость, низкое трение | Пресс-формы для литья под давлением, штампы для формовки | Риск сколов или отслаивания при высоких нагрузках |

Различие в штампах: обработки для вырубки и литья под давлением

Хотя оба элемента имеют важное значение для автомобильного производства, штампы и пресс-формы для литья под давлением сталкиваются с совершенно разными эксплуатационными трудностями, требующими различных стратегий поверхностной обработки. Штамповочная матрица формирует твёрдый листовой металл при комнатной температуре, тогда как пресс-форма для литья под давлением формирует расплавленный металл при высокой температуре и давлении. Понимание этого различия имеет ключевое значение для выбора эффективной и экономически выгодной технологии поверхностной обработки.

Штампы, особенно те, которые используются для высокопрочных сталей (AHSS), подвергаются экстремальным механическим нагрузкам, трению и заеданию. Основная цель обработки в данном случае — создание чрезвычайно твёрдой, износостойкой поверхности, способной выдерживать многократные удары и скользящий контакт с листовым металлом. Термохимические процессы, такие как азотирование, часто предпочтительнее, поскольку они формируют глубокий закалённый слой, который является неотъемлемой частью материала штампа, обеспечивая высокую устойчивость к сколам или отслаиванию под давлением. Решение этих сложных задач — специализация производителей, ориентированных на высокопроизводительную оснастку. Например, поставщики, такие как Shaoyi (Ningbo) Metal Technology Co., Ltd. используют передовое инжиниринговое решение для производства индивидуальных штампов для автомобильной промышленности, где выбор подходящей обработки является ключевым этапом обеспечения долговечности и точности для производителей оригинального оборудования (OEM).

Напротив, пресс-формы для литья под давлением подвергаются термическому удару — быстрому циклированию между высокими температурами расплавленного алюминия или цинка и более низкими температурами при охлаждении. Это может привести к образованию термических трещин (поверхностных трещин) и эрозии. В таких случаях покрытия должны обеспечивать тепловую изоляцию, предотвращать прилипание расплавленного сплава к пресс-форме и облегчать извлечение отлитой детали. Покрытия, нанесённые методом физического осаждения из паровой фазы (PVD), крайне эффективны в этом случае, поскольку обеспечивают отличную термостойкость, высокую твёрдость и поверхность с низким коэффициентом трения. Другие виды отделки, например, описанные руководствами лидеров отрасли, таких как Dynacast , часто применяются к готовым отливкам для защиты от коррозии или улучшения внешнего вида, а не к самой пресс-форме.

| Фактор | Штамповые матрицы | Формы для давлением литья |

|---|---|---|

| Основная проблема | Абразивный износ, заедание, высокие механические нагрузки | Термический удар, коррозия, прилипание, эрозия |

| Материал заготовки | Сплошной листовой металл (например, AHSS) | Расплавленный металл (например, алюминий, цинк) |

| Рекомендуемые виды обработки | Нитрирование, PVD-покрытия (TiN, AlCrN), закалка | PVD-покрытия (CrN), нитрирование, специальные покрытия для облегчения извлечения |

Как выбрать правильную поверхностную обработку: ключевые факторы

Выбор оптимальной поверхностной обработки — это сложное решение, которое должно учитывать требования к эксплуатационным характеристикам, совместимость материалов и стоимость. Системный подход гарантирует максимальную отдачу от инвестиций за счёт увеличения срока службы матрицы и повышения качества деталей. Поспешное принятие решения может привести к выбору обработки, недостаточной для конкретного применения или чрезмерно дорогой по отношению к требуемым характеристикам.

Во-первых, обратите внимание на требования к производительности . Основная цель — борьба с абразивным износом, предотвращение задиров, снижение трения или защита от коррозии? Каждая обработка эффективна в различных областях. Например, покрытие методом ионно-плазменного напыления (PVD) может быть выбрано благодаря низкому коэффициенту трения при высокоскоростной формовке, тогда как нитрирование применяется из-за высокой твёрдости глубокого поверхностного слоя для защиты от сильных ударов и износа в штампах. Чёткое определение основного типа отказа, который необходимо предотвратить, является наиболее важным первым шагом.

Далее оцените совместимость со сплавами . Материал матрицы (например, инструментальная сталь D2, горячая сталь H13) и заготовки (например, алюминий, AHSS) определят, какие процессы являются подходящими. Например, как отмечено в комплексном руководстве по отделке алюминиевых отливок под давлением , определённые виды обработки применяются только к готовым литым деталям, например анодирование для алюминия, и не используются для самой стальной пресс-формы. Температура процесса обработки также должна быть совместима с материалом пресс-формы, чтобы не изменить его основные свойства, такие как закалка.

И наконец, стоимость и геометрия детали играют важную роль. Сложные геометрии с внутренними каналами или острыми углами могут быть трудны для равномерной обработки с использованием некоторых методов, требующих прямой видимости, например, PVD. В таких случаях процесс диффузионного насыщения, например нитрирование, может обеспечить лучшее покрытие. Затраты на обработку должны соизмеряться с ожидаемым увеличением срока службы матрицы и общей стоимостью производства. Хотя передовое покрытие может иметь более высокую первоначальную стоимость, оно может многократно окупиться за счёт сокращения простоев и повышения производительности.

Контрольный список решений:

- Каков основной механизм выхода из строя матрицы (например, износ, задиры, коррозия, термическая усталость)?

- Каков материал матрицы и состояние её термической обработки?

- Какой материал заготовки подвергается формованию или литью?

- Каковы рабочие температуры и давления?

- Имеет ли матрица сложную геометрию или сложные детали?

- Каков бюджет на обработку по сравнению с общей стоимостью отказа инструмента?

Часто задаваемые вопросы

1. Какова шероховатость поверхности при литье под давлением?

Отделочные покрытия для литья под давлением, как правило, относятся к обработкам, наносимым на готовую деталь после ее отливки, а не к самой пресс-форме. К распространенным видам отделки относятся порошковое покрытие для прочного декоративного слоя; анодирование для защиты от коррозии алюминиевых деталей; гальваническое покрытие материалами, такими как хром или никель, для улучшения внешнего вида и твердости; а также нанесение химических пленок, например Alodine, для защиты от коррозии и в качестве грунтовки под покраску.

2. В чем разница между поверхностной обработкой и поверхностным покрытием?

Поверхностная обработка изменяет свойства материала на поверхности, например, при нитрировании или индукционной закалке, когда изменяется химический состав или микроструктура поверхности. Поверхностное покрытие, напротив, предполагает нанесение отдельного слоя из другого материала на поверхность, например, PVD-пленки, краски или порошкового покрытия. Обработка становится частью основы, тогда как покрытие представляет собой отдельный слой, нанесенный сверху.

3. Какое покрытие используется при литье под давлением?

Для литейных форм (оснастки) commonly используются PVD-покрытия, такие как нитрид хрома (CrN). Эти покрытия создают тепловой барьер, уменьшают склонность расплавленного алюминия прилипать (свариваться) к форме и повышают износостойкость. Для готовых отливок методом литья под давлением применяются покрытия, такие как порошковое покрытие, катодное покрытие (e-coating) и различные виды гальванических покрытий, в декоративных и защитных целях.

4. Какие бывают два типа поверхностной обработки?

В целом, поверхностную обработку можно разделить на две категории. Первая включает процессы, которые изменяют существующую поверхность без добавления нового материала, например, термическую обработку (нагрев пламенем или индукционный нагрев) и термохимическую обработку (азотирование, цементацию). Вторая категория включает процессы, при которых добавляется новый слой материала, например, нанесение покрытий (PVD, CVD), гальваническое покрытие (электроосаждение) и окрашивание (порошковое покрытие, катодное покрытие).

Малые партии, высокие стандарты. Наша служба быстрого прототипирования делает проверку точнее и проще —

Малые партии, высокие стандарты. Наша служба быстрого прототипирования делает проверку точнее и проще —