Metal Laser Cut Service Secrets: From File Upload To Flawless Parts

Understanding Metal Laser Cutting Technology and How It Works

So, what is laser cutting exactly? Metal laser cutting is a thermal cutting process that uses a focused, high-power-density laser beam to rapidly heat material until it melts, vaporizes, or burns through. As the beam moves across the workpiece, a high-speed jet of gas blows away the molten material, creating a narrow, precise cut called a kerf. This technology has revolutionized sheet metal fabrication by delivering exceptional accuracy, minimal material waste, and the ability to produce complex geometries that traditional cutting methods simply cannot match.

When you're exploring a metal laser cut service, understanding the technology behind it helps you make smarter decisions about your projects. The process begins with a CAD file that gets converted into machine-readable G-code instructions. These instructions guide the cutting head across your material with pinpoint precision—often achieving dimensional accuracy of ±0.05mm. Whether you need intricate decorative panels or precision industrial components, the laser for cutting machine you choose directly impacts your results.

How Fiber Lasers Transform Raw Metal into Precision Parts

Fiber lasers represent the cutting edge of metal laser cutting technology. These systems use a doped fiber optic cable as their lasing medium, pumping photons through a quartz or boron silicate glass core doped with rare earth elements like neodymium or ytterbium. The result? A laser beam with a wavelength around 1 micrometer—significantly shorter than CO2 alternatives.

This shorter wavelength delivers some serious advantages when cutting with a laser. Fiber lasers offer higher absorption rates, which means they excel at cutting reflective metals like aluminum, brass, and copper that would cause problems for other laser types. You'll also notice faster cutting speeds on thin to medium-thickness metals, higher electrical efficiency (around 30% conversion rate compared to just 10% for CO2), and reduced maintenance requirements since there are no mirrors requiring alignment or gases needing replenishment.

The flexibility of fiber optic delivery also opens up possibilities for robotic integration and complex three-dimensional cutting applications that rigid beam paths simply cannot accommodate.

The Science Behind Thermal Cutting Technology

Understanding how lasers actually cut metal comes down to one principle: stimulated emission. When photons interact with excited electrons in a metastable state, those electrons release additional photons with identical properties—same frequency, phase, and polarization. This cascade effect, amplified between reflective surfaces, produces the coherent, high-energy beam that makes laser cutting possible.

CO2 lasers take a different approach, using a gas mixture of carbon dioxide, nitrogen, and helium as the lasing medium. Operating at a wavelength of 10,600 nm (10.6 micrometers), these systems have historically been the workhorses of laser cutting cutting operations. The nitrogen stores energy that transfers to CO2 molecules, while helium helps dissipate residual energy for continuous operation.

The key differentiator between fiber and CO2 laser technologies lies in their wavelengths and what they cut best: fiber lasers (1 μm wavelength) excel at metal cutting with superior speed and efficiency on reflective materials, while CO2 lasers (10.6 μm wavelength) remain the preferred choice for non-metallic materials like wood, acrylic, and plastics.

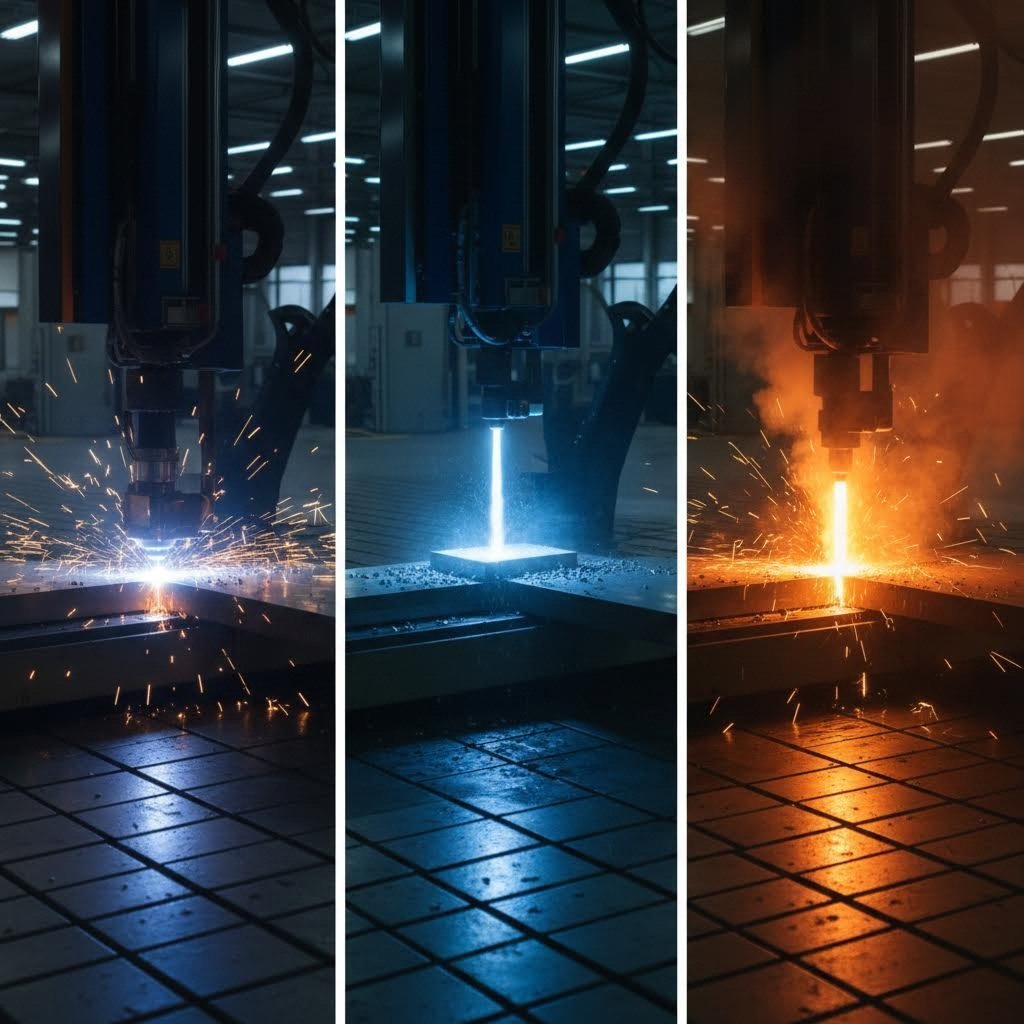

When a laser is used to cut metal, the focused beam creates a localized high-energy point that rapidly heats the material. Depending on the application, cutting happens through one of several mechanisms: vaporization (where material turns directly to gas), fusion cutting (where inert gas blows molten metal away), or oxygen-assisted cutting (where an exothermic reaction accelerates the process on carbon steel). Each method has its place in modern metal fabrication, and understanding these differences helps you communicate more effectively with your service provider about your specific project requirements.

Materials Guide for Metal Laser Cutting Projects

Choosing the right material for your project isn't just about picking a metal—it's about understanding how that metal behaves under intense heat and focused light. Every metal interacts differently with a metal laser cutter, and these differences directly impact your edge quality, achievable tolerances, and overall part performance. Let's break down what you need to know about each material before submitting your next order.

The truth is, not all metals are created equal when it comes to sheet metal laser cutting. Factors like thermal conductivity, reflectivity, and melting point determine how cleanly your parts will cut and how much heat-affected zone you'll see around the edges. Understanding these properties helps you select materials that match your application requirements—and avoid costly surprises.

Steel and Stainless Steel Cutting Capabilities

When it comes to laser cutter for metal applications, steel remains the most straightforward and forgiving material to process. Carbon steel (also called mild steel) cuts beautifully with fiber lasers, producing clean edges with minimal dross. The material's moderate thermal conductivity allows heat to dissipate without causing excessive warping, while its relatively low cost makes it ideal for everything from structural components to decorative panels.

Stainless steel laser cutting requires slightly different considerations. According to Datum Alloys, stainless steel's exceptional corrosion resistance and durability make it a popular choice across automotive, construction, and marine industries. The cutting process produces smooth, clean edges without compromising the material's inherent protective properties—a critical factor for applications exposed to moisture, chemicals, or extreme temperatures.

When you're laser cutting ss for precision applications, edge quality becomes particularly important. Fiber lasers excel at stainless steel because they produce a narrow kerf with minimal heat input, preserving the material's corrosion resistance right up to the cut edge. This matters enormously for food processing equipment, medical devices, and architectural installations where exposed edges remain visible.

| Material Type | Typical Thickness Range | Edge Quality | Heat-Affected Zone | Key Considerations |

|---|---|---|---|---|

| Carbon/Mild Steel | 0.5mm – 25mm | Excellent; clean with minimal dross | Minimal to moderate | Most cost-effective; oxygen-assist cutting accelerates thick sections |

| Stainless Steel | 0.5mm – 20mm | Excellent; smooth, oxide-free with nitrogen assist | Low with proper settings | Higher power needed for thick sections; nitrogen assist preserves corrosion resistance |

| Aluminum | 0.5mm – 15mm | Good; requires careful parameter control | Moderate due to high thermal conductivity | High reflectivity—fiber lasers handle best; prone to burring on thick sections |

| Copper | 0.5mm – 6mm | Good with high-power fiber lasers | Higher due to excellent conductivity | Extremely reflective; requires 3000W+ lasers for reliable cutting |

| Brass | 0.5mm – 8mm | Good; slight discoloration possible | Moderate | Easier than pure copper; zinc content improves absorption |

| Nickel Alloys | 0.5mm – 12mm | Excellent; minimal thermal distortion | Low | Ideal for aerospace; maintains properties after cutting |

Aluminum and Non-Ferrous Metal Considerations

Here's where things get interesting. Aluminum laser cutting presents unique challenges that separate experienced service providers from the rest. According to Universal Tool, aluminum's high thermal conductivity and reflectivity make it "especially tricky to work with"—heat input must be carefully managed to achieve the right balance between cut speed and edge quality.

The good news? Modern fiber lasers have largely solved the reflectivity problem that plagued older CO2 systems. Fiber laser wavelengths absorb more readily into reflective metals, making laser cut aluminum far more practical than it was even a decade ago. Still, the thermal conductivity challenge remains. Heat dissipates quickly through aluminum, which means you need higher power input to maintain cutting speed—but too much power causes warping and poor edge quality.

For aluminium laser cutting on thinner gauges (0.5mm to 3mm), a 1000W to 2000W laser typically delivers excellent results with high precision and minimal distortion. Medium thicknesses from 4mm to 8mm generally require 2000W to 4000W systems, while anything above 9mm demands 4000W or more to achieve clean cuts through the material's higher reflectivity.

Copper and brass round out the non-ferrous options, each with distinct characteristics. Pure copper's extreme reflectivity and thermal conductivity make it the most challenging common metal to laser cut—typically requiring 3000W to 5000W fiber lasers even for relatively thin sections. Brass, with its zinc content, absorbs laser energy somewhat better and cuts more predictably, though you may notice slight discoloration near the edges on some alloys.

Specialty alloys like nickel-based superalloys occupy their own category. As Datum Alloys notes, these materials are prized in aerospace and chemical processing for their strength, corrosion resistance, and heat resistance. The precision of laser cutting minimizes the heat-affected zone, reducing thermal distortion risks that could compromise critical component geometries. For applications where material properties cannot be sacrificed—jet engine components, chemical reactor parts—laser-cut nickel alloys deliver the precision these demanding environments require.

Understanding these material characteristics positions you to have productive conversations with your service provider about what's achievable for your specific application. The next step? Knowing exactly how your project moves from digital file to finished part.

The Complete Metal Laser Cutting Process Explained

Ever wondered what actually happens after you hit "submit" on your design files? The journey from CAD file to finished part involves multiple stages—each designed to catch potential issues and ensure your components meet specifications. Understanding this workflow helps you plan realistic timelines, communicate effectively with your laser cut services provider, and avoid common pitfalls that delay production.

Whether you're searching for a laser cutting service near me or working with a remote provider, the fundamental process remains consistent across the industry. Let's walk through each stage so you know exactly what to expect.

From CAD File to Quote Request

Every laser cutting of metal sheets project begins with your design file. Most service providers accept standard CAD formats including DXF, DWG, STEP, and IGES files. Some platforms also support PDF drawings or even native SolidWorks and Inventor files. The key is providing vector-based geometry that defines exact cut paths rather than raster images that only represent visual approximations.

When you upload your files, the quoting system—whether automated or manual—analyzes several factors: material type and thickness, total cut length, number of parts, complexity of geometries, and any special requirements you've specified. Many modern providers offer a laser cutting instant quote that returns pricing within minutes, while more complex projects may require manual review.

According to Artilux NMF, the CAD file is converted into a format the laser cutting machine for metal can interpret—typically vector files or CAM (Computer-Aided Manufacturing) data. This conversion defines the cutting path with precision, optimizing both speed and material usage from the very beginning.

Don't underestimate the value of a laser cutting quote that includes detailed breakdowns. Transparent quotes show you exactly where costs come from, helping you identify opportunities to optimize your design before committing to production.

Production Stages and Quality Checkpoints

Once your order is confirmed, the real manufacturing process kicks into gear. Here's exactly what happens at each stage:

- Design Review and DFM Analysis – Engineers examine your files for manufacturability issues like features too small to cut reliably, spacing that's too tight between parts, or geometries that could cause thermal distortion. This Design for Manufacturability review catches problems before they become expensive mistakes. According to Artilux NMF, close collaboration during this stage "reduces errors and shortens production time."

- Material Preparation and Nesting – Raw material sheets are selected based on your specifications and inspected for defects. Your parts are then digitally arranged—or "nested"—on the sheet to minimize waste and maximize material utilization. Efficient nesting can reduce material costs by 15% or more on complex jobs.

- Machine Setup and Calibration – As Central Profiles explains, the laser machine is placed on a stable surface and connected to power, ventilation, and cooling systems. The laser beam is focused and aligned to ensure clean cuts. Operators adjust power, speed, and focus settings based on your specific material type and thickness.

- Cutting Operations – The laser head moves along the programmed path, melting or vaporizing material with precision. Assist gases—oxygen for carbon steel, nitrogen for stainless steel and aluminum—blow away molten material and protect the cut edge. The ventilation system continuously removes fumes and debris throughout the process.

- Part Removal and Cleaning – Cut parts are separated from the skeleton (remaining sheet material) and any tabs or micro-joints are removed. Initial cleaning removes smoke deposits, spatter, or residue left from the cutting process.

- Quality Inspection – Dimensional checks verify that cuts match specifications. Visual inspections examine edges for burrs, striations, or discoloration. Critical parts may undergo additional testing—such as fit checks with mating components—before approval.

- Post-Processing (If Required) – Depending on your application, parts may need deburring, edge smoothing, or surface treatments before they're complete. Some parts proceed directly to secondary operations like bending, welding, or finishing.

- Packaging and Shipping – Approved parts are carefully packaged to prevent damage during transit and shipped to your facility or directly to the next stage of your manufacturing process.

The entire laser cutting process timeline varies based on complexity. Simple parts can move from file to finished in hours, while production runs with secondary operations may take days or weeks. Understanding these stages helps you set realistic expectations—and knowing where your project sits in the workflow lets you plan downstream operations with confidence.

Of course, hitting tight tolerances and achieving clean edges depends on more than just process knowledge. The precision standards your provider works to—and the factors that influence them—matter enormously for quality-critical applications.

Precision Tolerances and Quality Standards in Laser Cutting

Here's what most service pages won't tell you: laser cutting precision varies significantly based on material thickness, type, and machine capabilities. When you're specifying tolerances for precision laser cutting projects, understanding achievable accuracy prevents frustration and ensures your parts actually fit together as designed.

So what kind of dimensional accuracy can you realistically expect? According to A-Laser, fiber lasers consistently deliver tight tolerances ranging from ±0.001 to ±0.003 inches (±0.025mm to ±0.076mm), while CO2 lasers typically achieve ±0.002 to ±0.005 inches (±0.05mm to ±0.127mm). UV lasers push this even further—reaching levels as low as ±0.0001 inches for micro-machining applications where sub-micron precision matters.

But those numbers only tell part of the story. When you laser cut metal for real-world applications, several factors influence what's actually achievable on your specific parts.

Dimensional Accuracy and Tolerance Specifications

Most reputable metal laser cut service providers work to established standards rather than arbitrary specifications. As TEPROSA explains, DIN ISO 2768 summarizes generally applicable tolerance dimensions used across technical drawings. This standard defines tolerance classes—fine (f), medium (m), coarse (g), and very coarse (sg)—that establish clear expectations between you and your manufacturer.

For laser cutting metal, the medium tolerance class (m) represents the industry default for most providers. This means your parts will fall within predictable dimensional ranges based on their nominal size—without requiring special callouts on every dimension.

| Material Thickness | Typical Linear Tolerance | Hole Diameter Tolerance | Kerf Width | Minimum Feature Size |

|---|---|---|---|---|

| 0.5mm – 1.5mm | ±0.05mm to ±0.1mm | ±0.05mm | 0.15mm – 0.2mm | 0.5mm (or 1× material thickness) |

| 1.5mm – 3mm | ±0.1mm to ±0.15mm | ±0.1mm | 0.2mm – 0.3mm | 1.0mm (or 1× material thickness) |

| 3mm – 6mm | ±0.15mm to ±0.2mm | ±0.15mm | 0.25mm – 0.4mm | 1.5mm (or 0.5× material thickness) |

| 6mm – 12mm | ±0.2mm to ±0.3mm | ±0.2mm | 0.3mm – 0.5mm | 3mm (or 0.5× material thickness) |

| 12mm – 20mm | ±0.3mm to ±0.5mm | ±0.3mm | 0.4mm – 0.6mm | 6mm minimum |

Notice how tolerances loosen as material thickness increases? As TEPROSA notes, "the thicker a material is, the more challenging it becomes to implement a tight geometric tolerance." This happens because the laser beam diverges as it travels through thicker sections, creating a slightly tapered cut profile rather than a perfectly perpendicular edge.

When laser cutting steel sheet or any thick material, the beam becomes divergent away from the focus point. Depending on focus position, the cut widens toward the top or bottom by a few hundredths of a millimeter. For most applications, this minor taper is acceptable—but for precision fits, you'll want to specify which surface serves as your reference dimension.

Kerf width—the material removed by the laser beam itself—also demands attention. According to Morn Tech, cutting width only significantly affects precision when forming particularly exact internal contours, since the kerf determines the minimum inner radius achievable. Most design software allows you to offset cut paths to compensate for kerf, but you'll need to communicate with your provider about whether they apply kerf compensation automatically or expect it in your files.

Edge Quality and Surface Finish Expectations

Beyond dimensional accuracy, edge quality often determines whether laser cut stainless steel or other materials meet your application requirements. Imagine receiving parts that measure perfectly—but have rough, striated edges that won't work for visible installations or mating surfaces. Understanding what affects edge quality helps you specify appropriately.

According to Morn Tech, cut edge roughness depends on the vertical striations left during cutting. The shallower these lines, the smoother the section. Roughness affects both appearance and friction characteristics—critical considerations for sliding components or aesthetic applications.

Several factors influence the edge quality you'll receive:

- Cutting Speed vs. Power Balance – Too fast creates rough striations; too slow causes excessive heat input and potential burning

- Assist Gas Selection – Nitrogen produces oxide-free edges on stainless steel; oxygen accelerates cutting but leaves an oxide layer on carbon steel

- Focus Position – Optimal focus varies by material and thickness; improper focus creates wider kerfs and rougher edges

- Material Quality – Surface contaminants, internal stresses, and compositional inconsistencies all affect cut quality

The heat-affected zone (HAZ) represents another critical quality consideration. This refers to the depth where the metal's internal structure changes due to thermal input during cutting. For most precision laser cutting applications, fiber lasers minimize HAZ through rapid processing and concentrated energy delivery—but thicker materials and slower speeds inevitably increase thermal effects.

Burr formation rounds out the edge quality picture. Burrs—those small ridges of material left along cut edges—require extra work to remove and directly indicate cutting quality. Well-optimized parameters produce minimal or no burrs, while improper settings leave significant cleanup work that adds cost and time to your project.

With tolerances and quality standards clearly defined, you might wonder how laser cutting stacks up against alternative cutting methods. Understanding when laser cutting outperforms—or underperforms—other technologies helps you select the right process for each specific application.

Laser Cutting Versus Waterjet Plasma and CNC Alternatives

So you've got a cutting project—but should you choose laser, waterjet, plasma, or CNC punching? This decision can make or break your budget, timeline, and part quality. Each method uses fundamentally different energy sources, and understanding when each excels helps you avoid costly mistakes and wasted material.

Here's the reality: there's no single "best" cutting technology. According to Wurth Machinery, choosing the wrong CNC cutter can cost thousands in wasted material and lost time. The right choice depends on what you're cutting, how precise it needs to be, and how quickly you need it done. Let's break down when each method makes sense for your metal cutting laser applications.

| Cutting Method | Material Compatibility | Thickness Limits | Edge Quality | Speed | Cost Factors |

|---|---|---|---|---|---|

| Laser (Fiber/CO2) | Metals, some plastics, wood; fiber excels on reflective metals | Up to 1" (25mm) typical; optimal under 0.5" | Excellent; minimal post-processing needed | Fastest on thin materials | Higher upfront; cost-effective for precision, repeatable jobs |

| Waterjet | Virtually any material—metals, stone, glass, composites | Up to 10"+ (250mm+) | Excellent; no heat-affected zone | Slowest of the three | High operating costs (abrasives); equipment ~$195,000 |

| Plasma | Conductive metals only—steel, aluminum, copper | 0.5" to 2"+ ideal; handles thick plates best | Good for structural work; requires finishing for precision | 3-4× faster than waterjet on thick steel | Lowest operating costs; equipment ~$90,000 |

| CNC Punching | Sheet metals; limited to punchable thicknesses | Typically under 0.25" (6mm) | Good; can leave slight edge marks | ~1,000 hits/min vs laser's 10,000 | Most economical upfront; versatile secondary operations |

When Laser Cutting Outperforms Alternative Methods

Laser cutting dominates when you need precision, clean edges, and complex geometries on thin to medium-thickness metals. According to Rache Corp, lasers excel for "parts that need clean edges, small holes, or intricate shapes." If you're manufacturing electronics enclosures, medical device components, or decorative panels, laser cnc technology delivers results that other methods simply cannot match.

Where does steel laser cutting shine brightest? Consider these applications:

- Thin sheet precision work – Laser cutting produces sharp corners and smooth edges on materials under 0.5" thick, often eliminating secondary finishing entirely

- Fine detail requirements – Minimum hole diameters can reach 1× material thickness; intricate patterns cut cleanly without distortion

- High-volume production – CNC laser cutting offers fastest cycle times on thin materials with exceptional repeatability

- Tight tolerance applications – Achievable accuracy of ±0.001" to ±0.003" surpasses plasma and matches waterjet on most geometries

The laser and cnc integration also matters for automation. According to Rache Corp, if you're planning high-volume, high-precision jobs with minimal operator input, laser cutting will likely be the easiest to automate—making it ideal for production environments where consistency and throughput drive profitability.

However, laser cutting has clear limitations. Materials over 1" thick become problematic—cutting slows dramatically, edge quality suffers, and heat-affected zones expand. That's when alternative methods earn their place.

Choosing Between Laser, Waterjet, and Plasma

Sounds complex? It doesn't have to be. The decision often comes down to three questions: What material are you cutting? How thick is it? And what edge quality do you need?

Choose plasma cutting when:

- You're working with thick conductive metals—especially steel plates over 0.5" thick

- Speed and cost matter more than edge finish precision

- Parts are destined for structural applications, heavy equipment, or fabrication work

- You're searching for plasma cutting near me options for rough cuts or structural components

According to Wurth Machinery, plasma cutting 1" steel runs about 3-4 times faster than waterjet, with operating costs roughly half as much per foot. For metal fabrication shops focused on steel and aluminum structural work, plasma often provides the best return on investment.

Choose waterjet cutting when:

- Heat damage must be avoided—no warping, no hardening, no heat-affected zones

- You're cutting non-metals like stone, glass, composites, or layered materials

- Material thickness exceeds 1" and precision still matters

- Sensitive materials like titanium aerospace components require zero thermal distortion

Waterjet's cold cutting process makes it uniquely suited for heat-sensitive applications. The waterjet market is projected to reach over $2.39 billion by 2034, reflecting growing demand for this versatile technology in aerospace, food processing, and specialty material cutting.

Consider CNC punching when:

- You need secondary operations like tapping, forming, extruding, or deburring in a single setup

- Budget constraints favor lower equipment costs

- Part geometries suit standard punch tooling

According to Caldera MFG, while advanced laser cutters can perform 10,000 hits per minute compared to turret punching's 1,000, "a turret punch's versatile capabilities and reduced lead times can make up for the fewer hits per minute." The ability to perform blanking, forming, and deburring in one operation saves downstream processing time that pure laser cutting cannot match.

Many successful fabrication shops eventually incorporate multiple technologies. Plasma and laser often pair well—plasma handles thick structural cuts while laser delivers precision on thin sheets. Adding waterjet extends capabilities into non-metals and heat-sensitive applications without thermal concerns.

The bottom line? Match your cutting method to your specific project requirements. For precision metal cutting laser work on thin to medium materials, laser cutting typically wins. For thick conductive metals and structural fabrication, plasma offers unbeatable speed and economy. And when heat cannot touch your material—or when you're cutting stone, glass, or composites—waterjet stands alone.

Now that you understand which cutting method suits your application, the next challenge is preparing your design files correctly. Poor file preparation causes more production delays than almost any other factor—so let's cover exactly what you need to submit quote-ready files.

Design Guidelines and File Preparation for Laser Cutting

You've selected your material, you understand tolerances, and you know laser cutting is right for your project. Now comes the step that trips up more people than any other: getting your design files ready. According to Quote Cut Ship, they review hundreds of files each week—and common design missteps lead to frustrating results, production delays, and wasted material.

The good news? Most file preparation problems are entirely preventable. Whether you're using a laser metal cutter for the first time or you've submitted dozens of orders, following these guidelines ensures your parts move from upload to production without unnecessary back-and-forth.

File Format Requirements and CAD Preparation

Here's the fundamental rule: laser cutters need vector files, not images. A metal cutting laser machine interprets precise mathematical paths—lines, arcs, and curves with exact coordinates. Raster images like JPEGs or PNGs only contain pixel information that cannot define cutting paths accurately.

According to Quote Cut Ship, for clean, accurate cuts you need vector-based formats such as .DXF, .AI, or .SVG. These formats define exact paths that the laser can follow, ensuring every cut is crisp and precise.

File Preparation Checklist:

- Use accepted vector formats – DXF and DWG remain industry standards; most providers also accept AI, SVG, STEP, and IGES files

- Convert all text to outlines – If fonts aren't available on the manufacturing system, text may substitute or disappear entirely; converting to outlines eliminates this risk

- Close and join all paths – Open or unjoined paths confuse the laser sheet metal cutter, potentially causing incomplete cuts or erratic behavior

- Remove duplicate lines – Overlapping geometry causes the laser to cut the same path twice, damaging edges and wasting time

- Verify dimensions at 100% scale – As SendCutSend recommends, printing your design at 100% scale helps confirm dimensions are correct

- Delete hidden layers and unused geometry – Extraneous data can import as unintended cut paths

- Set units correctly – Confirm whether your file uses inches or millimeters before uploading

If you've converted your file from a raster format through auto-tracing, double-check every dimension. Auto-trace algorithms introduce approximations that may not match your intended measurements. Many designers find that printing a 1:1 scale copy and physically measuring critical features catches errors before they become expensive mistakes.

Avoiding Common Design Errors That Delay Production

Even experienced designers make mistakes that stall production. Understanding these pitfalls—and building habits to avoid them—saves time, money, and frustration on every project.

Common Mistakes to Avoid:

- Lines too close together – According to Quote Cut Ship, when design lines are placed too tightly or overlap, the laser can overburn or accidentally cut into areas you want to keep intact. Aim for at least 0.010 inches (0.25mm) spacing between critical paths

- Ignoring material thickness – While laser cutting is a 2D process, your material has depth. If you're designing interlocking parts or tight-fit assemblies, failing to account for material thickness results in pieces that don't fit or break easily

- Features too small to cut – Minimum hole diameter should generally equal material thickness; slots and narrow features need similar consideration. Features below these limits may not cut cleanly or may weaken surrounding material

- Forgetting corner radii – Sharp internal corners concentrate stress and can cause cracking. Adding small radii (typically 0.5mm to 1mm minimum) improves part durability and cutting quality

- No bridging for internal cutouts – SendCutSend notes that internal cutouts cannot be retained without bridging. Add small tabs to keep interior pieces attached during cutting, then remove them afterward

- Active text boxes left unconverted – Hover over text elements to verify they're converted to geometry. If text remains editable, it needs conversion to outlines before submission

Geometry optimization also matters for cost and quality. When working with a laser cut cnc machine, consider how your design nests on standard sheet sizes. Odd dimensions or irregular shapes may waste material, increasing your per-part cost. Many providers offer nesting optimization, but designing with standard sheet sizes in mind often produces better results.

For parts requiring tabs or micro-joints—small connections that hold pieces in the sheet during cutting—plan their locations carefully. Place tabs in non-critical areas where the small remaining nub won't affect function or appearance. Typical tab widths range from 0.5mm to 2mm depending on material and part size.

One more consideration: understand what laser cuttable materials your design actually requires. Metals obviously work well with fiber laser systems, while laser cuttable plastics like acrylic and polycarbonate typically need CO2 lasers. If you're uncertain whether your material choice suits laser cutting—or which laser type applies—consult with your provider before finalizing designs. According to Komacut, using standard material thicknesses is one of the easiest ways to optimize the laser cutting process, keeping costs down and lead times short.

Taking these file preparation steps seriously transforms your ordering experience. Clean files mean faster quotes, smoother production, and parts that match your expectations. But even with perfect files, you'll want to understand what drives your final cost—and how design choices affect your bottom line.

Understanding Metal Laser Cutting Costs and Pricing Factors

Ever requested a quote and wondered why your simple-looking part costs more than expected? Or searched for a laser cutter near me hoping to compare prices, only to find wildly different numbers? You're not alone. Laser cutting charges vary significantly based on factors that aren't always obvious—and understanding what drives those costs puts you in a stronger position to optimize your designs and budgets.

Here's the reality: metal laser cutting services don't pull prices from thin air. According to Smart Cut Quote, laser cutting delivers high precision with tolerances as tight as ±0.1mm, but costs can vary significantly based on several interconnected factors. Let's break down exactly what influences your final quote—and how you can control those variables.

Key Factors That Determine Your Laser Cutting Costs

When you're searching for laser cutting near me options or evaluating remote providers, understanding the cost hierarchy helps you interpret quotes intelligently. Not all factors carry equal weight—some dominate your pricing while others make marginal differences.

Cost Drivers in Order of Impact:

- Material type and cost – According to LYAH Machining, different metals have varying costs, with materials like aluminum and stainless steel typically being more expensive than mild steel or iron. Raw material prices fluctuate, but stainless steel commonly costs 2-3× more than mild steel per kilogram

- Material thickness – Thicker materials require more laser power, slower cutting speeds, and increased energy consumption. Smart Cut Quote notes that cutting 12mm steel might cost 3-4 times more than cutting 3mm due to slower feed rates

- Total cut length and complexity – Each pierce point where the laser initiates a cut adds time. Intricate designs with numerous internal cutouts require frequent starts and stops, increasing machine time and gas usage

- Order quantity – Setup costs spread across more parts reduce per-unit pricing. According to Komacut, bulk ordering can significantly reduce per-unit costs by spreading fixed setup costs over larger quantities

- Secondary operations – Post-cutting processes like deburring, bending, powder coating, or hardware insertion add labor, equipment time, and materials to your total

- Lead time requirements – LYAH Machining reports that rush orders requiring overtime or priority scheduling can add 10-25% to standard pricing

Machine time represents a significant cost component that deserves special attention. According to Smart Cut Quote, laser cutting rates in Australia range from $1.50 to $3.00 per minute depending on machine capacity—and those rates vary regionally. A 4kW fiber laser cutting 6mm stainless steel uses around 12-20 m³/hour of nitrogen assist gas alone, which can add several dollars to a single part depending on cut length.

Design complexity affects more than just cutting time. According to LYAH Machining, preparing CAD files for laser cutting typically costs $20-$100 per hour based on designer expertise. Simple shapes may take an hour, while complex geometries can require 2-4 hours of design work before cutting even begins.

How to Optimize Your Design for Better Pricing

Now for the actionable part—how do you actually reduce costs without sacrificing quality? Smart design decisions made early can dramatically impact your final pricing.

Design Optimization Strategies:

- Simplify geometries where possible – According to Komacut, simplifying designs and reducing the number of cutouts lowers machine time and energy consumption

- Design for efficient nesting – Parts that nest tightly together on standard sheet sizes minimize material waste. Komacut explains that efficient nesting maximizes material usage by arranging parts closely together, reducing raw material needs and decreasing cutting time

- Reduce pierce points – Each internal cutout requires a new pierce. Consolidating or eliminating unnecessary internal features cuts time and cost

- Choose cost-effective materials – When specifications allow flexibility, selecting mild steel over stainless steel or choosing standard alloys over specialty grades reduces material costs significantly

- Order in appropriate quantities – Setup costs are relatively fixed regardless of quantity. If you'll eventually need more parts, ordering larger batches often makes economic sense—some shops offer 5-15% discounts for high-volume orders

- Batch similar projects together – Combining multiple part designs using the same material and thickness into a single order spreads setup costs and improves nesting efficiency

The value of instant quote systems cannot be overstated for project planning. Modern platforms analyze your uploaded files and return detailed cost breakdowns within minutes—sometimes seconds. This transparency lets you iterate on designs, comparing how changes affect pricing before committing to production. You can test whether simplifying a feature saves meaningful money or whether switching materials fits your budget.

Fast turnaround options also factor into smart cost management. While rush fees add expense, the ability to receive parts in days rather than weeks enables just-in-time manufacturing strategies that reduce inventory carrying costs. For prototyping and development cycles, speed often outweighs incremental price differences.

Remember that the cheapest quote isn't always the best value. Send cut send prices and similar transparent pricing models help you compare apples to apples, but factor in quality consistency, communication responsiveness, and reliability when evaluating providers. A slightly higher laser cutting rates from a provider who delivers correctly the first time beats a lower quote that requires rework or delays your production schedule.

Understanding these cost factors positions you to have productive conversations with your metal laser cutting services provider—and to make design decisions that balance performance requirements with budget realities. But cutting is just the beginning for many projects. What happens after parts come off the laser table often matters just as much as the cutting itself.

Secondary Operations and Finishing for Laser Cut Parts

Here's something many first-time buyers don't realize: laser cutting is often just the starting point. Your laser cut parts typically need additional processing before they're ready for their final application. According to Minifaber, sheet metal cutting and bending are two consecutive processes—and errors during either phase could result in cancellation of the other, with significant waste of time and material.

Understanding the full range of secondary operations helps you plan projects more effectively, reduce lead times, and find providers who can handle complete part production rather than requiring you to coordinate multiple vendors. Whether you need tube laser cutting services for structural frames or precision laser fabrication for automotive components, the right integrated approach streamlines everything from quote to delivery.

Post-Cutting Operations for Complete Part Production

After parts leave the laser table, several forming and assembly operations transform flat profiles into functional components. Choosing a steel laser cutting service that offers these capabilities in-house eliminates handoff delays and quality control gaps between suppliers.

Forming and Shaping Operations:

- Bending and forming – According to Minifaber, laser cutting and bending should always work synergistically—an accurate laser cut results in smooth bending, reducing warping and enhancing finished product quality. CNC press brakes transform flat laser-cut blanks into brackets, enclosures, and structural shapes with precise angle control

- Welding and joining – MIG, TIG, and robotic welding join multiple laser cut parts into assemblies. Clean laser-cut edges provide excellent weld preparation with minimal grinding required. As MET Manufacturing notes, integrated services like forming, assembly, and finishing help customers streamline production from raw material to finished product

- Hardware insertion – PEM nuts, studs, standoffs, and other fasteners get pressed into laser-cut holes, eliminating separate tapping or welding operations. Proper hole sizing during the cutting phase ensures clean hardware installation

- Tapping and threading – When removable fasteners are required, tapped holes provide threads directly in the material rather than relying on inserted hardware

- Deburring and edge finishing – While fiber laser cutting services produce relatively clean edges, some applications require additional deburring through tumbling, hand finishing, or automated deburring equipment

Automation has transformed how these operations integrate with cutting. According to Minifaber, robotic systems and CNC panels make these processes automated, increasing productivity and decreasing errors. More importantly, automation reduces human intervention, fatigue, and potential errors while boosting overall workplace safety.

For laser tube cutting services and structural applications, the combination of precise cutting with robotic welding proves particularly valuable. Complex tubular assemblies that once required extensive jigging and manual welding now flow through automated cells with consistent quality and reduced cycle times.

When evaluating providers for complete laser fabrication projects, look for manufacturers who demonstrate integration between cutting and forming departments. Shaoyi (Ningbo) Metal Technology exemplifies this approach—combining precision cutting with stamping and assembly services under IATF 16949 certification for automotive applications. Their 5-day rapid prototyping capability demonstrates how integrated operations compress timelines that would stretch to weeks with fragmented supply chains.

Surface Finishing Options for Laser Cut Components

Beyond forming, surface finishing determines how your parts perform in their operating environment. According to Manufacturing Solutions Inc. (MSI), metal finishing is the final—and crucial—step in the manufacturing process. It alters the surface of fabricated metal components to improve their durability, aesthetic appeal, and resistance to corrosion and environmental damage.

Coating and Plating Options:

- Powder coating – According to MSI, powder coated metal products are more resistant to diminished coating quality from chemicals, moisture, ultraviolet light, and extreme weather conditions. Available in virtually unlimited colors and textures, powder coating provides durable protection for everything from outdoor equipment to consumer products

- Electroplating – Deposits metals like zinc, nickel, or chrome onto part surfaces for corrosion protection, wear resistance, or aesthetic enhancement. Commonly used for fasteners, electrical components, and decorative applications

- Electroless plating – Chemical plating without electrical current provides uniform coverage even on complex geometries. MSI notes that electroless plating offers technical advantages including superior coverage on irregular surfaces and consistent thickness across part features

- Phosphate coating – Creates a thin adhering layer that provides strong adhesion and increases corrosion protection. According to MSI, phosphate coating is commonly used as a pretreatment for subsequent coatings such as paint or powder coating

- Passivation – Chemical treatment for stainless steel that enhances corrosion resistance without altering appearance. Critical for medical, food processing, and marine applications where surface contamination must be eliminated

- Hot blackening – Applies a thin black oxide coating that increases abrasion resistance while providing the matte finish required for military, automotive, and firearms applications

Mechanical Surface Treatments:

- Abrasive blasting – According to MSI, abrasive blasting combines surface finishing and cleaning into one process to save money and time. Shot blasting and sandblasting prepare surfaces for coating while creating uniform texture

- Electropolishing – Removes metal ions to create smooth, shiny surfaces on stainless steel and similar alloys. Reduces surface roughness, removes burrs, and enhances cleanability for sanitary applications

- Buff polishing – Machine polishing with cloth wheels provides glossy, decorative finishes. Often used as preparation for electropolishing or as a final cosmetic treatment

Selecting the right finish depends on your specific requirements. According to MSI, consider product function, operating environment, base material, and desired aesthetics when choosing finishing methods. A bracket destined for indoor electronics enclosures needs different protection than structural components exposed to marine environments.

The real advantage comes from working with integrated manufacturing partners who handle multiple operations under one roof. Rather than shipping laser cut parts to a separate bending vendor, then to a welder, then to a powder coater—each handoff adding transit time, potential damage, and communication complexity—vertically integrated providers complete everything in a coordinated workflow.

For automotive and aerospace applications where certification matters, this integration becomes even more critical. Providers like Shaoyi demonstrate comprehensive DFM support with 12-hour quote turnaround, enabling you to optimize designs for manufacturing while maintaining quality standards across cutting, stamping, and assembly operations. Their approach shows how modern metal fabrication consolidates what used to require multiple specialized vendors into streamlined production cells.

With secondary operations and finishing clearly mapped out, the final piece of the puzzle is selecting a provider who can actually deliver on these capabilities. Not all metal laser cut service providers offer the same depth of services—and knowing what to look for separates excellent partnerships from frustrating experiences.

Choosing the Right Metal Laser Cutting Service Provider

You've designed your parts, prepared your files, and understand exactly what finishing operations you need. Now comes the decision that determines whether your project succeeds or stalls: selecting the right provider. When you search for laser cutting services near me or evaluate remote manufacturers, the differences between providers aren't always obvious from their websites—but they dramatically impact your results.

According to Steelway Laser Cutting, most manufacturers lack the funds or resources to purchase and maintain advanced laser cutting machines in-house. For this reason, they partner with a laser cutting company to streamline the manufacturing process. But not all partnerships deliver equal value. The right precision laser cutting services provider becomes an extension of your team—the wrong one creates headaches that consume far more time than they save.

Essential Criteria for Evaluating Laser Cutting Providers

Before you request quotes, establish clear evaluation criteria that match your project requirements. According to All Metals Fabricating, too often businesses treat job shops as interchangeable—sending blanket RFQs, choosing the lowest price or fastest turnaround, then moving on. But countless projects get derailed by partnerships with shops that weren't thoroughly evaluated.

Provider Evaluation Checklist:

- Industry certifications – For quality-critical applications, certifications like ISO 9001 demonstrate documented quality management systems. IATF 16949 certification matters specifically for automotive supply chain work, ensuring processes meet rigorous OEM requirements

- Equipment capabilities – Ask what laser cutting machines they use. According to Steelway Laser Cutting, there are many different types of metal laser cutting machines (fiber lasers, CO2 lasers, etc.), and understanding the variations helps you assess whether they can handle your specific materials and thicknesses

- Material expertise – Most cnc laser cutting services providers detail the material thickness and types of sheet metal they can fabricate. Verify they have experience with your specific materials—especially if you're working with challenging metals like highly reflective aluminum

- Turnaround time commitments – Ask upfront how long projects take from file receipt to shipping. Some providers offer rapid prototyping in days while production runs may require weeks. Shaoyi (Ningbo) Metal Technology, for example, delivers 5-day rapid prototyping alongside automated mass production—demonstrating the benchmark for speed you should seek

- Quote responsiveness – How quickly can you get pricing? A 12-hour quote turnaround like Shaoyi offers indicates operational efficiency and customer focus. Slow quotes often signal slow production

- DFM support quality – Does the provider offer comprehensive Design for Manufacturability review? Catching issues early prevents costly rework. Providers who invest in DFM support demonstrate commitment to your project success, not just order processing

- Secondary operation capabilities – According to Steelway Laser Cutting, ask if they can handle metal bending, powder coating, or other finishing in-house—or whether you'll need separate vendors

- Communication quality – How responsive are they during the quoting process? Do they ask clarifying questions or just process orders? Engaged providers catch problems before they become expensive

According to All Metals Fabricating, don't overlook so-called "soft" factors like management involvement and employee engagement. Engaged leadership always correlates with a manufacturer's performance—understanding a job shop holistically gives you the best insight into its underlying reliability.

Red Flags and Green Lights When Choosing a Service

Sounds straightforward? It should be—but knowing what warning signs to watch for (and what positive indicators to seek) separates smart partnerships from frustrating experiences.

Red Flags to Watch For:

- Vague pricing with hidden extras – According to Steelway Laser Cutting, be wary of providers that offer incentives like low instant prices or free shipping upfront but are hazy on exact costs for your distinct projects. Get all costs—including potential extras like finishing and shipping—documented before committing

- No experience documentation – If they can't provide testimonials, case studies, or examples of similar work, proceed cautiously. According to Steelway Laser Cutting, you'll want assurance that your provider has ample experience in custom laser projects

- Outdated equipment – Older machines may struggle with precision requirements or reflective materials. Ask about equipment age and maintenance schedules

- Poor communication responsiveness – If they're slow to answer questions during the quote phase, expect similar delays during production

- Missing or expired certifications – For industrial laser cutting applications requiring documented quality systems, verify certifications are current and relevant to your industry

Green Lights That Signal Quality Partners:

- Transparent pricing with detailed breakdowns – Clear quotes showing material costs, machine time, and secondary operations indicate organized operations

- Proactive DFM feedback – Providers who identify potential issues in your design files demonstrate expertise and commitment to your success

- Modern equipment with documented capabilities – Optimally, your provider will have decades of experience combined with the most advanced laser cutting technology available

- Relevant industry certifications – IATF 16949 for automotive, AS9100 for aerospace, ISO 13485 for medical devices—certifications matching your industry ensure appropriate quality controls

- Integrated secondary capabilities – Providers handling cutting, forming, and finishing under one roof reduce coordination complexity and transit damage risks

- Rapid prototyping alongside production capacity – The ability to quickly prototype then scale to mass production indicates operational flexibility

When you're evaluating options—whether searching for laser cutter service near me, laser cut near me, or laser metal cutting near me—don't default to geographic convenience alone. Remote providers with strong communication systems and reliable shipping often outperform local shops lacking necessary equipment or certifications.

According to All Metals Fabricating, by evaluating job shops against a clear set of criteria and comparing them on an apples-to-apples basis, you'll improve your chances of finding the best partner to deliver high-quality results on your project.

The investment in proper provider evaluation pays dividends throughout your project—and across future orders. A well-matched cnc laser cutting services partner becomes a manufacturing asset rather than a vendor to manage. Take the time upfront to verify capabilities, certifications, and communication quality, and you'll build relationships that consistently deliver the precision parts your applications demand.

Frequently Asked Questions About Metal Laser Cutting Services

1. What is the cost of metal laser cutting?

Metal laser cutting costs depend on several factors including material type, thickness, cut complexity, and order quantity. Mild steel typically costs less than stainless steel or aluminum per part. Thicker materials require slower cutting speeds, increasing machine time and cost. Most providers charge based on machine time (ranging from $1.50-$3.00 per minute depending on region and equipment), material usage, and setup fees. Rush orders may add 10-25% to standard pricing. For accurate quotes, submit your CAD files to providers offering instant quote systems like those from IATF 16949-certified manufacturers such as Shaoyi, which delivers 12-hour quote turnaround.

2. How much does it cost to get a steel laser cut?

Steel laser cutting costs vary based on material grade, thickness, and design complexity. Carbon steel is the most economical option, cutting cleanly with minimal dross. Setup fees typically range from $15-60 depending on the shop, with machine time billed hourly or by the minute. Thicker steel (over 6mm) costs significantly more due to slower feed rates and increased gas consumption. To optimize costs, simplify geometries, design for efficient nesting on standard sheet sizes, and order in larger quantities to spread fixed setup costs across more parts.

3. How much is laser cutting service?

Laser cutting service pricing includes machine time, material costs, setup fees, and any secondary operations. Machine time rates typically range from $50-100 per hour depending on equipment and location. Simple flat parts with straightforward geometries cost less than intricate designs with numerous internal cutouts. Additional services like bending, welding, powder coating, or hardware insertion add to the total. Many modern providers offer instant online quoting—upload your DXF or STEP files to receive detailed cost breakdowns within minutes, allowing you to compare options and optimize designs before ordering.

4. What materials can be laser cut with metal laser cutting services?

Metal laser cutting services handle a wide range of materials including carbon steel, stainless steel, aluminum, copper, brass, and specialty alloys like nickel-based superalloys. Fiber lasers excel at cutting reflective metals like aluminum and copper that challenge older CO2 systems. Each material has specific thickness limits—steel up to 25mm, stainless steel up to 20mm, aluminum up to 15mm, and copper up to 6mm with high-power lasers. Material selection affects edge quality, heat-affected zone, and achievable tolerances, so consult with your provider about optimal choices for your specific application.

5. What tolerances can I expect from precision laser cutting?

Fiber lasers consistently deliver tolerances ranging from ±0.025mm to ±0.076mm (±0.001 to ±0.003 inches), while CO2 lasers typically achieve ±0.05mm to ±0.127mm. Tolerances loosen as material thickness increases—thin sheets under 1.5mm hold ±0.05mm, while materials over 12mm may only achieve ±0.3mm to ±0.5mm. Factors affecting precision include machine calibration, material flatness, thermal conductivity, and focus position. For quality-critical applications, work with certified providers like those holding IATF 16949 certification, which ensures documented quality management systems and consistent results.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —