Custom Laser Metal Cutting Decoded: From Design File To Finished Part

What Makes Custom Laser Metal Cutting the Precision Standard

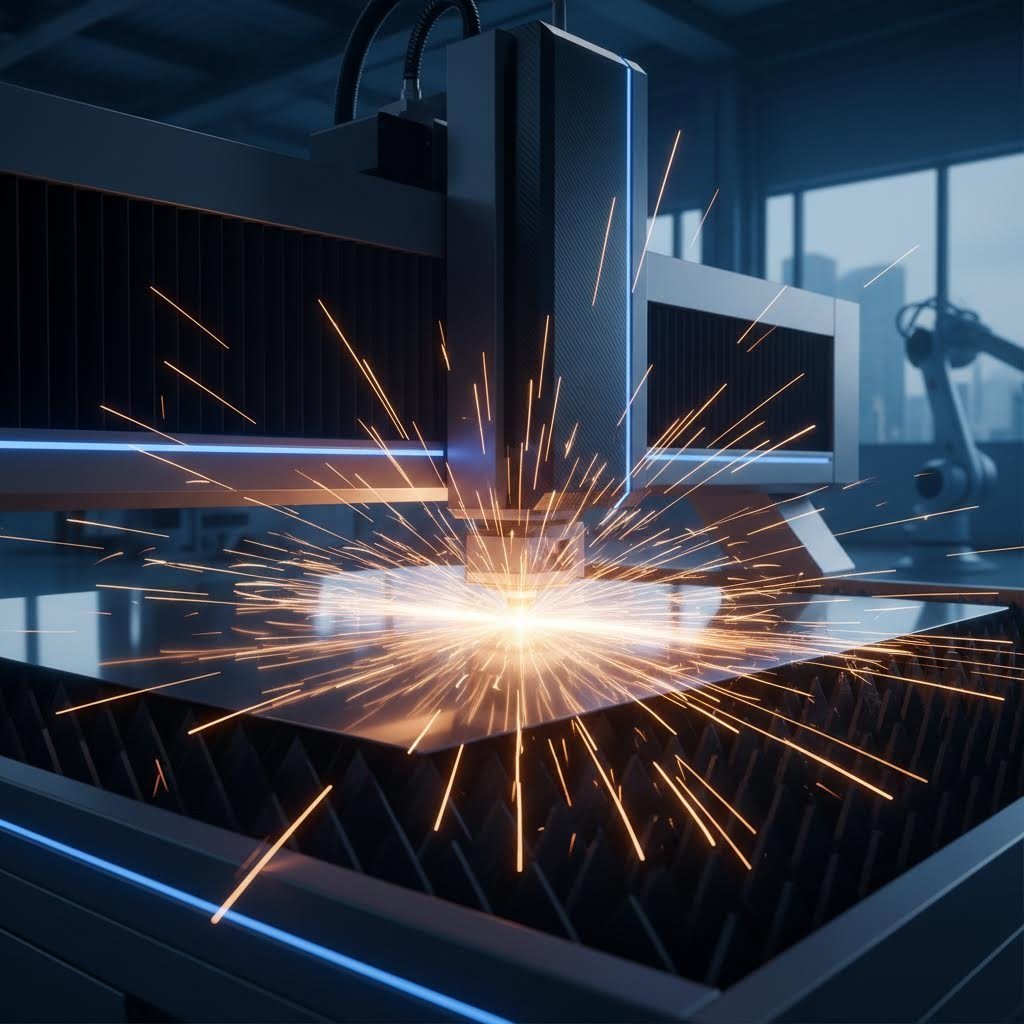

Imagine harnessing a beam of light so intensely focused that it can slice through steel like a hot knife through butter. That's exactly what custom laser metal cutting delivers - a manufacturing process where concentrated light energy transforms raw metal sheets into precisely shaped components with minimal material waste. This technology has revolutionized how industries approach metal fabrication, offering unmatched accuracy that traditional cutting methods simply cannot achieve.

So, what is laser cutting exactly? At its core, it's a thermal separation process where a high-powered laser beam hits the material surface and heats it so intensely that the metal either melts or completely vaporizes at the point of contact. Once the beam penetrates the material at one point, the actual cutting begins as computer-controlled systems guide the laser along your exact design specifications.

How Laser Beams Transform Raw Metal into Precision Parts

The journey from raw metal to finished part begins inside the laser source itself. Commercial laser cutting systems typically use either CO2 lasers or fiber lasers to generate their cutting power. In a CO2 laser, a mixture of gases including carbon dioxide, nitrogen, and helium gets electrically excited to produce the laser beam. Fiber lasers, on the other hand, rely on optical fibers infused with rare-earth elements to generate their cutting energy.

Here's where precision laser cutting truly shines. After generation, the laser beam passes through a series of mirrors and lenses that focus it to an extraordinarily concentrated point. According to manufacturing experts at eMachineShop, this focusing process produces temperatures exceeding 20,000 degrees Celsius (36,000 degrees Fahrenheit) - hot enough to vaporize virtually any metal instantaneously.

The resulting kerf from metal laser cutting is barely larger than the laser beam itself, making it possible to cut extremely fine geometries of virtually any shape with exceptional accuracy.

The Science Behind Thermal Metal Separation

When that intense laser beam makes contact with your metal surface, several scientific principles work together to create clean, precise cuts:

- Absorption: Different metals absorb different wavelengths of light. This interaction between the laser beam's photons and the metal's electrons leads to rapid, localized heating.

- Thermal conductivity: Metals conduct heat quickly away from the cut zone, ensuring surrounding material remains relatively unaffected - resulting in clean, precise edges.

- Assist gas dynamics: Gases like oxygen or nitrogen help remove molten metal and debris from the cut zone, preventing re-solidification and achieving smoother finishes.

Why has this laser metal cutter technology become the preferred method across industries? The answer lies in its unique combination of benefits. Unlike mechanical cutting processes that involve physical contact and tool wear, laser cutting metal is completely contactless. This eliminates tool degradation, reduces setup costs, and delivers consistently accurate results whether you're producing one prototype or thousands of identical parts.

From aerospace and automotive manufacturing to electronics enclosures and architectural detailing, precision metal cutting with lasers handles applications demanding tight tolerances and exceptional repeatability. The technology's versatility, speed, and minimal material wastage make it an ideal choice for modern fabrication needs - setting the foundation for everything we'll explore in the sections ahead.

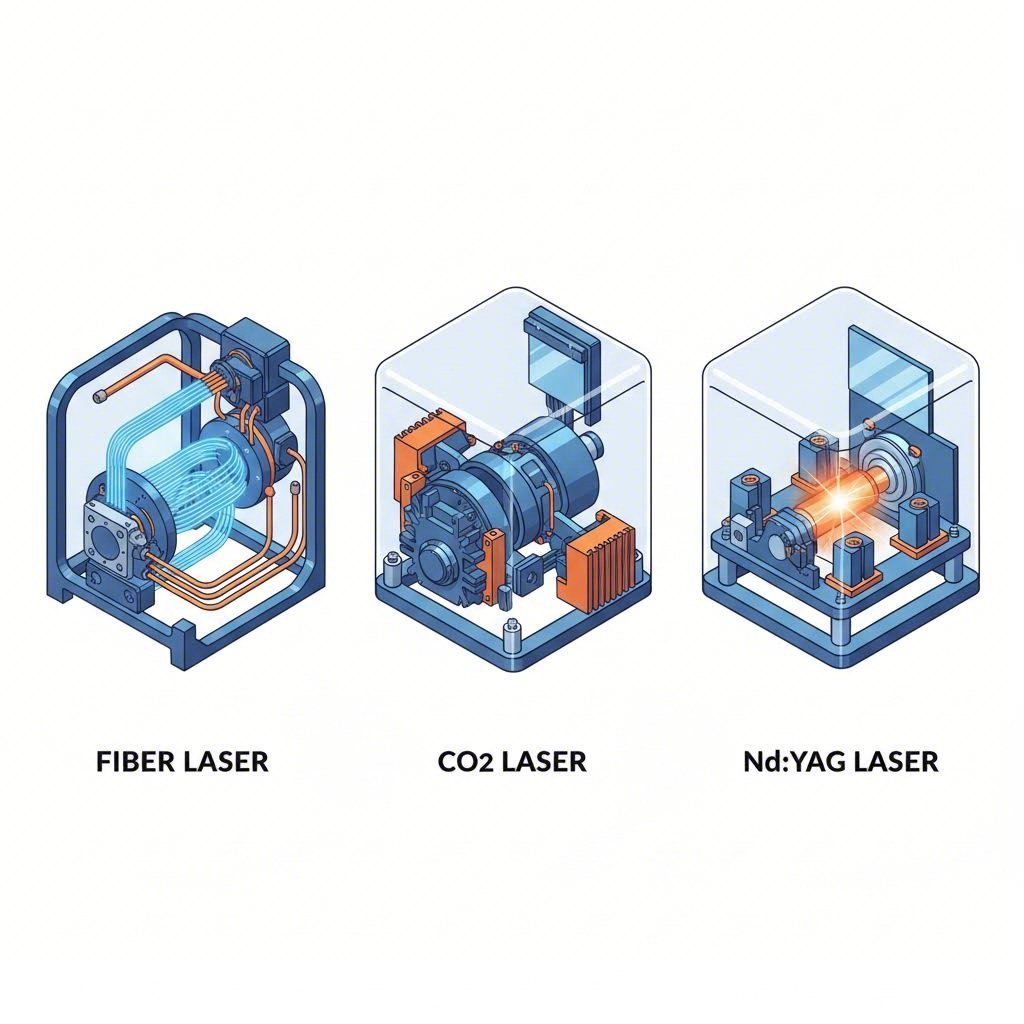

Fiber vs CO2 vs Nd-YAG Laser Technologies Explained

Now that you understand how lasers transform metal into precision parts, here's the next question: which laser technology is right for your project? Not all lasers are created equal, and selecting the wrong type can mean slower cutting speeds, poor edge quality, or unnecessary costs. The three primary laser types used in metal cutting - CO2, fiber, and Nd:YAG - each bring distinct advantages depending on your material and application requirements.

Think of choosing a laser for cutting machine applications like selecting the right tool from a toolbox. A CO2 laser cutting machine for metal works beautifully on thick steel plates but struggles with highly reflective materials. Meanwhile, a fiber laser sheet metal cutter excels at processing thin aluminum and copper with remarkable efficiency. Understanding these differences helps you make informed decisions that directly impact your project outcomes.

Fiber Lasers and Their Dominance in Thin Metal Processing

Fiber lasers have rapidly become the preferred choice for thin metal processing in modern fabrication shops. According to Laser Photonics, these systems use ytterbium-doped optical fibers as their gain medium, producing light at a wavelength of 1064 nanometers. This shorter wavelength is the secret behind their exceptional performance with metals.

Why does wavelength matter so much? Here's the science made simple:

- Superior metal absorption: Metals absorb significantly more energy from fiber lasers than from CO2 systems. Aluminum, for example, absorbs seven times more radiation from a fiber laser than from a CO2 laser with equivalent power output.

- Finer beam focus: The smaller wavelength allows the beam to concentrate into a spot 10 times smaller than a CO2 laser's, delivering higher power density and greater precision.

- Energy efficiency: Fiber lasers convert up to 42% of electrical energy into laser light, compared to just 10-20% for CO2 systems - translating to substantial operational cost savings.

This combination of absorption efficiency and precision makes fiber-based metal cutting laser machines the go-to choice for processing stainless steel, aluminum, brass, and copper sheets under 10mm thick. Their ability to handle reflective metals without back-reflection damage gives them a significant advantage in modern manufacturing environments.

Matching Laser Technology to Your Metal Type

Choosing the right laser cutting machine metal technology requires understanding how each system interacts with different materials. CO2 lasers, despite being older technology, remain valuable for specific applications. As noted by AI Metal Finishing, these gas-based systems use a carbon dioxide gas mixture stimulated by electricity, producing far-infrared light at 10.6 micrometers wavelength.

CO2 lasers excel at cutting thicker mild steel and are still widely used for non-metallic materials like wood, acrylic, and plastics. However, their longer wavelength means higher reflectivity from metals - requiring more power to achieve the same cutting effect as fiber lasers.

Nd:YAG (neodymium yttrium-aluminum-garnet) lasers represent a third option, operating as crystal-based systems. These co2 laser cut metal machine alternatives are particularly effective when high energy and precision are needed for boring, engraving, and cutting ceramics alongside metals. Their main limitation? The expensive components require replacement after 8,000 to 15,000 hours of use, making operational costs considerably higher than fiber alternatives.

| Laser Type | Best Metal Applications | Typical Thickness Range | Cutting Speed | Energy Efficiency |

|---|---|---|---|---|

| Fiber Laser | Stainless steel, aluminum, brass, copper, thin carbon steel | 0.5mm - 25mm | Fastest on thin metals | Up to 42% conversion rate |

| CO2 Laser | Mild steel, thick steel plates, non-metals | 1mm - 30mm+ | Moderate, better on thick materials | 10-20% conversion rate |

| Nd:YAG Laser | Metals, ceramics, precision boring applications | 0.5mm - 15mm | Moderate to slow | Lower than fiber, higher consumable costs |

When evaluating your project requirements, consider both the material you're cutting and your production volume. High-volume thin metal work almost always favors fiber technology due to speed and efficiency advantages. Thicker materials or mixed-material operations might still benefit from CO2 capabilities. For specialized precision work involving ceramics or demanding boring operations, Nd:YAG systems remain relevant despite their higher operational costs.

Understanding these technology differences empowers you to ask the right questions when working with fabrication partners - and ensures your custom laser metal cutting projects achieve optimal results from the start. With laser technology matched to your material, the next consideration becomes which specific metals work best with this technology.

Metal Materials Compatible with Laser Cutting Technology

With laser technology matched to your project, the next critical decision becomes material selection. Not all metals behave the same way under a laser beam - and understanding these differences can mean the difference between flawless parts and costly rework. Whether you're working with stainless steel laser cutting for medical devices or need to laser cut aluminum for aerospace components, each material brings unique characteristics that affect your final results.

The good news? Modern laser systems can process an impressive range of metals when properly configured. The challenge lies in understanding how each material's physical properties - reflectivity, thermal conductivity, and oxide formation tendencies - influence cutting parameters and achievable quality.

Stainless Steel and Aluminum Cutting Considerations

Stainless steel remains one of the most laser-friendly metals in fabrication. Its relatively low reflectivity and predictable thermal behavior make stainless laser cutting straightforward for experienced operators. According to iGoldenLaser, successful stainless steel processing typically uses nitrogen as the assist gas, producing clean, oxide-free edges ideal for applications in medical, food processing, and architectural industries.

Key considerations for stainless steel include:

- Thickness capabilities: Fiber lasers handle stainless steel up to approximately 25mm, with optimal results on sheets under 12mm

- Edge quality: Nitrogen assist produces bright, oxidation-free edges requiring minimal post-processing

- Heat-affected zone: Relatively narrow due to stainless steel's moderate thermal conductivity

- Surface finish: Maintains excellent aesthetics when proper parameters are used

Aluminium laser cutting presents more complexity. This lightweight metal's high thermal conductivity means heat dissipates rapidly from the cutting zone, requiring higher power levels to maintain consistent penetration. As noted by IVY CNC, aluminum's reflective nature demands specialized handling - fiber lasers are strongly recommended over CO2 systems for this material.

When you laser cut aluminum, expect these material-specific factors:

- Reflectivity challenges: High surface reflectivity can bounce laser energy back toward the cutting head without proper machine protection

- Thermal management: Rapid heat dissipation requires optimized speed and power balance

- Oxide formation: Aluminum oxide has a higher melting point than the base metal, potentially affecting cut quality

- Assist gas selection: Nitrogen produces clean cuts; high-pressure air offers economical alternatives for certain thicknesses

Working with Reflective Metals Like Copper and Brass

Copper laser cutting and brass laser cutting represent the most challenging applications in metal fabrication. These highly reflective materials can bounce a significant portion of laser energy back toward the optical system, creating both efficiency and safety concerns. According to BCAM CNC, without proper protection measures, reflected beams can cause protective lens burns, output instability, and premature damage to internal optical components.

The solution? Modern fiber laser systems equipped with pulsed cutting mode. Unlike continuous-wave cutting, pulsed mode delivers energy in short, controlled bursts:

- Each pulse instantly melts a small section of material

- Brief cooling periods between pulses reduce sustained reflective energy

- Risk of dangerous back-reflection drops significantly

- More stable penetration and cleaner edges result

When you need to laser cut copper or laser cut brass, surface preparation becomes critical. Contaminants including oil, oxidation, film coatings, and moisture increase reflection and reduce laser absorption. A clean surface dramatically improves cutting efficiency and reduces risk to machine components.

Carbon steel rounds out the commonly processed metals, offering excellent laser compatibility. Its lower reflectivity compared to non-ferrous metals means straightforward processing with either fiber or CO2 systems. Oxygen assist gas is typically used, creating an exothermic reaction that aids the cutting process - though this produces an oxide layer on cut edges that may require removal for certain applications.

Selecting the right material for your project involves balancing application requirements against processing considerations. Medical and food-service applications often demand stainless steel's corrosion resistance. Aerospace and automotive weight reduction calls for aluminum despite its processing complexity. Electrical and decorative applications may require copper or brass despite their challenging reflective properties. Understanding these trade-offs helps you communicate effectively with fabrication partners and set realistic expectations for your custom laser metal cutting projects.

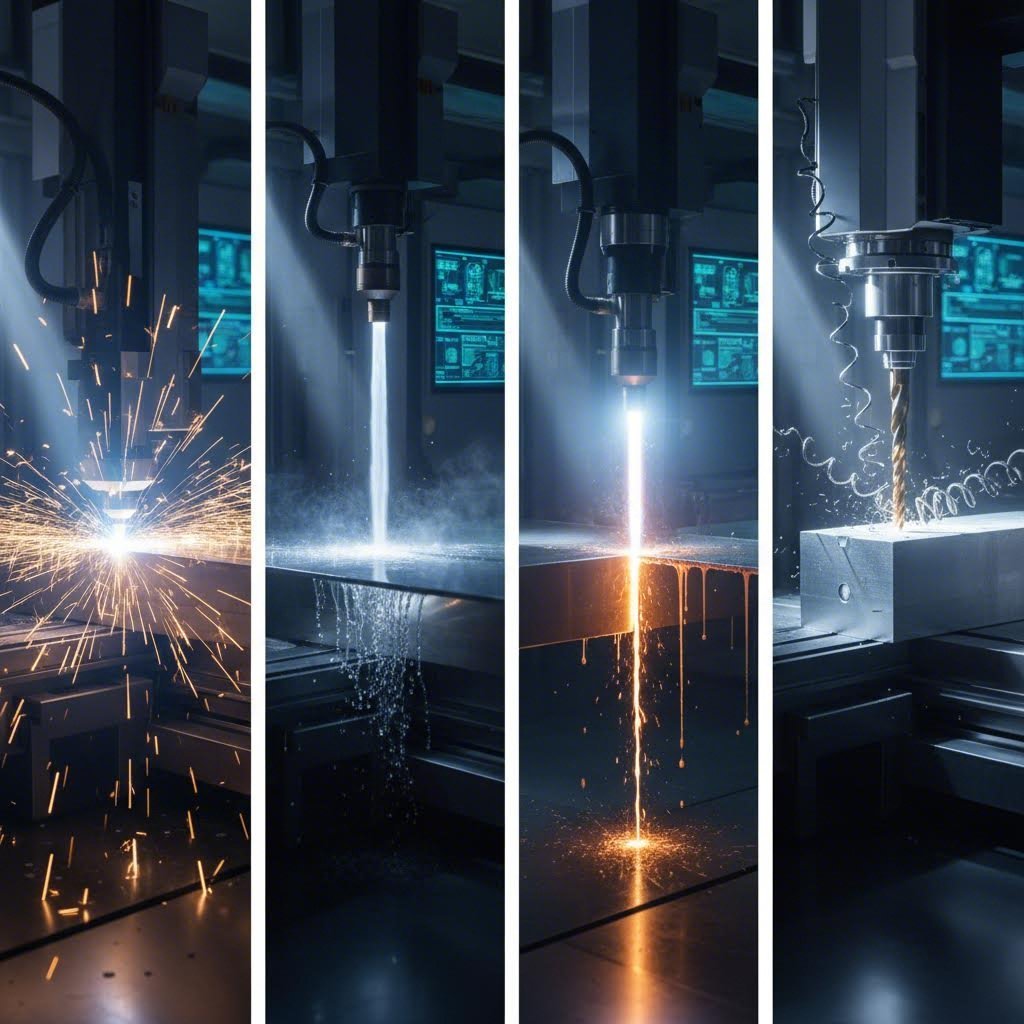

Laser Cutting vs Waterjet Plasma and CNC Alternatives

You've selected your material and understand which laser technology works best - but here's a question worth asking: is laser cutting actually the right method for your project? While custom laser metal cutting delivers exceptional precision for many applications, alternative technologies like plasma, waterjet, and EDM each offer distinct advantages in specific scenarios. Understanding when to choose each method can save you thousands in production costs and prevent frustrating quality issues.

Think about it this way: if you're searching for "plasma cutting service near me" or "metal cutting near me," you might actually need laser cutting - or vice versa. The key lies in matching the cutting technology to your specific requirements rather than defaulting to whatever's most familiar. Let's break down how these technologies compare so you can make confident decisions.

When Laser Cutting Outperforms Plasma and Waterjet

CNC laser cutting dominates when precision and edge quality are paramount. According to testing by Wurth Machinery, laser cutting creates exceptionally clean edges with minimal post-processing needed - especially valuable when fabricating parts that require tight tolerances or intricate geometries.

Here's where laser and CNC technologies truly shine:

- Thin material processing: Fiber lasers achieve exceptional speeds on sheets under 1/4" thick, outpacing both plasma and waterjet significantly

- Precision features: Small holes, sharp corners, and fine details are laser cutting's specialty - plasma simply cannot match this capability

- Minimal heat-affected zone: The focused beam creates narrow kerf widths with less thermal distortion than plasma cutting

- Clean edge quality: Parts often need no secondary finishing, reducing total production time and cost

However, plasma cutting takes the lead in different scenarios. When processing thick conductive metals - particularly steel plates over 1/2" - plasma offers the best speed and cost efficiency. As noted by StarLab CNC, a high-powered plasma system can cut 1/2" mild steel at speeds exceeding 100 inches per minute, making it 3-4 times faster than waterjet with roughly half the operating cost per foot.

Waterjet cutting becomes the clear winner when heat damage must be avoided entirely. Operating at pressures up to 90,000 PSI, waterjet systems cut without generating heat - preserving material structural integrity and eliminating heat-affected zones completely. This makes waterjet ideal for heat-sensitive materials, hardened metals, and applications where metallurgical properties cannot be altered.

Choosing the Right Cutting Method for Your Project

Selecting between laser CNC, plasma, waterjet, or EDM requires evaluating several interconnected factors. Your material type, thickness range, precision requirements, and production volume all influence the optimal choice. According to ESAB, there's no one-size-fits-all solution - instead, a combination of factors guides you toward the most suitable approach.

| Cutting Method | Precision Level | Material Thickness Range | Heat-Affected Zone | Edge Quality | Ideal Applications |

|---|---|---|---|---|---|

| Laser Cutting | ±0.001" to ±0.005" | Up to 1.25" (mild steel) | Minimal, narrow kerf | Excellent - smooth, clean edges | Electronics, medical devices, precision parts, intricate designs |

| Plasma Cutting | ±0.015" to ±0.030" | 0.018" to 2"+ (optimal 1/4" to 1.5") | Moderate, wider than laser | Good - may need finishing on thin/thick extremes | Structural steel, heavy equipment, shipbuilding, HVAC |

| Waterjet Cutting | ±0.003" to ±0.005" | Virtually unlimited (practical limits apply) | None - cold cutting process | Very good - smooth, no thermal effects | Aerospace components, stone/glass, heat-sensitive materials |

| EDM (Wire) | ±0.0001" to ±0.0005" | Up to 12"+ (conductive materials only) | Very minimal | Exceptional - mirror-like finish possible | Tool and die, molds, ultra-precision components |

When making your decision, consider these practical guidelines:

- Choose laser cutting when you need intricate designs, precision holes, or clean edges on thin to medium-thickness metals without extensive post-processing

- Choose plasma cutting when processing thick steel plates quickly and cost-effectively matters more than achieving the finest edge quality

- Choose waterjet cutting when heat cannot affect your material, you're cutting non-metals, or working with very thick materials requiring no thermal distortion

- Choose EDM when ultra-tight tolerances on hardened materials or complex internal geometries are required

Many successful fabrication shops combine multiple technologies to cover diverse project requirements. Laser and plasma often pair well - laser handles precision thin work while plasma tackles heavy plate processing. Adding waterjet capabilities expands versatility further, enabling cutting of materials and thicknesses that thermal processes cannot address effectively.

The right cutting method ultimately depends on your specific project requirements. By understanding each technology's strengths and limitations, you're equipped to select the optimal approach - or to have informed conversations with fabrication partners about which method best serves your needs. With the cutting method selected, your next step involves preparing design files that maximize the capabilities of your chosen technology.

Design Best Practices for Laser Cut Metal Parts

You've selected your cutting method and material - now comes the step that separates successful projects from costly mistakes: design preparation. Even the most advanced laser cut CNC machine cannot compensate for poorly optimized design files. The reality? Many project delays and budget overruns trace back to preventable design issues that could have been caught before the first cut was made.

Design for Manufacturability (DFM) principles transform your creative vision into parts that a sheet metal laser cutting machine can produce efficiently and accurately. Whether you're creating custom cut metal brackets for automotive applications or intricate custom cut sheet metal enclosures for electronics, understanding these guidelines puts you in control of your project outcomes.

Optimizing Your CAD Files for Clean Laser Cuts

Preparing files for laser fabrication requires attention to details that might seem minor but significantly impact results. According to SendCutSend's design guidelines, the better your file quality, the better your finished parts will be. Here's a step-by-step process to ensure your designs translate perfectly to laser cut parts:

- Convert to proper vector format: Submit 2D vector files in DXF or DWG format at 1:1 scale. Unlike pixel-based raster files (JPG, BMP), vector formats provide the exact geometry that laser cutting software needs.

- Convert all text to outlines: Active text boxes cause processing errors. In Illustrator, use "convert to outlines"; in CAD software, look for "explode" or "expand" functions. Hover over any text - if it's editable, it needs conversion.

- Verify dimensions after conversion: If you've converted from a raster file, double-check all measurements. Printing your design at 100% scale helps confirm accuracy before submission.

- Eliminate floating cut-outs: Internal pieces that aren't connected to the main part will fall away during cutting. Either submit these as separate designs or add bridging tabs to retain them.

- Apply kerf compensation correctly: According to DW Laser's kerf guide, kerf is the width of material vaporized by the beam. Most fabricators' software automatically compensates for this - simply provide accurate 1:1 scale files with your intended final dimensions.

Understanding kerf compensation deserves extra attention. When the laser cuts, it removes a small amount of material - typically 0.1mm to 0.4mm depending on material and thickness. Professional fabricators use CAM software that automatically offsets the cutting path outward for external contours and inward for internal features, ensuring your parts match design intent precisely.

Design Mistakes That Increase Costs and Delay Projects

Sounds complex? It doesn't have to be - if you avoid these common pitfalls that trip up even experienced designers. According to Prime FabWorks' DFM guide, understanding a few key rules prevents costly problems from the first run.

The most critical rule involves minimum hole size. Here's the physics made simple:

- The 1:1 rule: Hole diameter should equal or exceed material thickness. For a 3mm steel sheet, design holes no smaller than 3mm diameter.

- Why it matters: Smaller holes trap intense heat with nowhere to dissipate, causing taper, blowout, and quality defects that fail inspection.

- Exception handling: If your design requires smaller features, discuss alternatives with your fabricator - sometimes material changes or secondary operations provide solutions.

Beyond hole sizing, these design considerations directly impact your costs:

- Sharp internal corners: Add small fillets (radii) to internal corners. Sharp 90-degree internal corners are impossible for laser cutting - the beam has a minimum radius. Fillets also reduce stress concentrations in your finished parts.

- Feature spacing: Maintain adequate distance between holes and edges. A general guideline: spacing should be at least 1.5 times material thickness to prevent distortion and ensure structural integrity.

- Minimize pierce points: Every time the laser starts a new cut, it must pierce the material - this takes time and costs money. Designs with long, continuous cutting paths are more efficient than those with hundreds of small, separate features.

- Use shared cut lines: When nesting multiple parts, designs that share cutting edges between adjacent parts reduce machine time and material waste significantly.

For most materials up to 6mm thick, expect dimensional tolerances of ±0.1mm from quality fabricators - precision governed by standards like ISO 2768-m. Setting realistic expectations based on these capabilities helps you design parts that succeed on the first production run.

Taking time to optimize your design files pays dividends throughout your project. Fewer revisions, faster production, and lower costs all flow from proper preparation. With your design ready for manufacturing, the next consideration becomes understanding exactly what precision and tolerances you can expect from your finished parts.

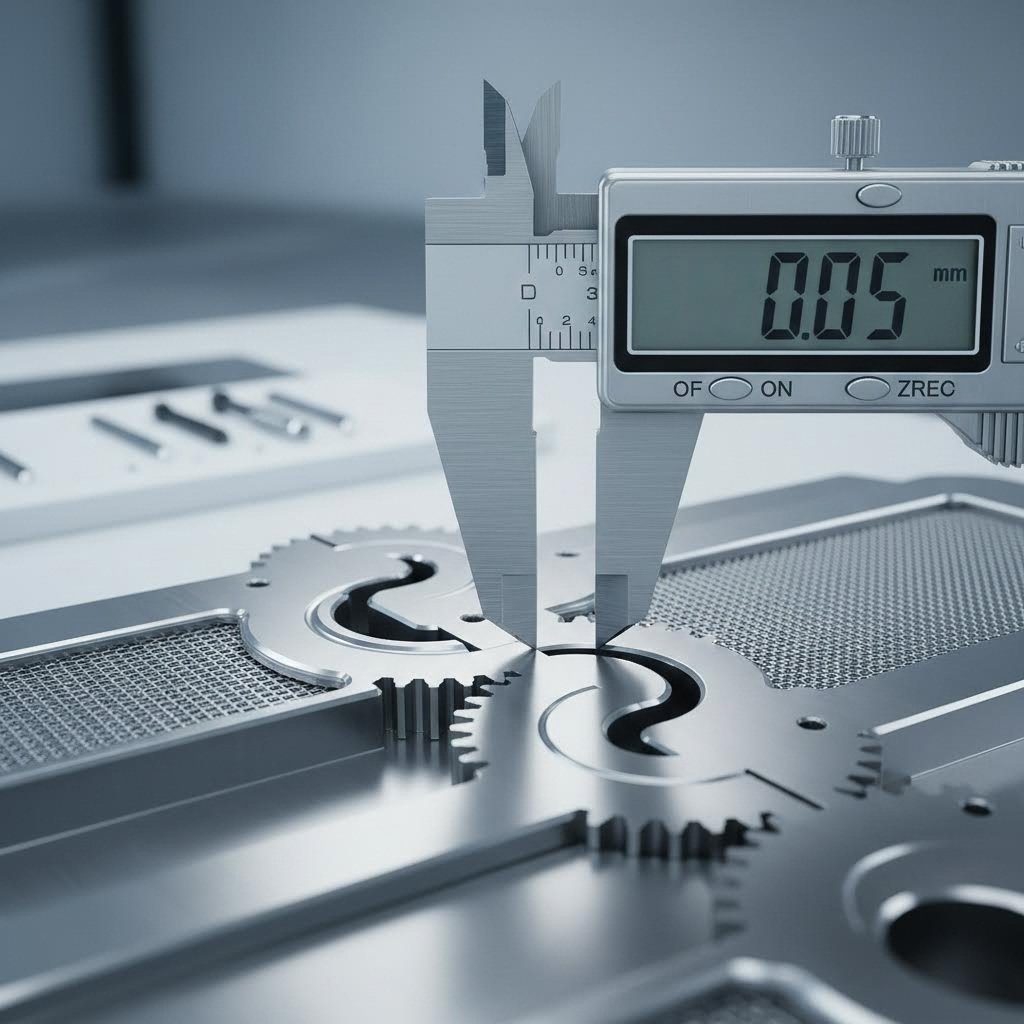

Precision Tolerances and Accuracy in Laser Cut Parts

Your design files are optimized and ready - but what precision can you actually expect from your finished parts? This question matters enormously, yet many fabrication providers gloss over the specifics. Understanding tolerance specifications empowers you to design appropriately, set realistic expectations, and communicate effectively with manufacturing partners about your project requirements.

Here's the good news: precision metal cutting with lasers achieves remarkable accuracy compared to traditional methods. According to Accurl's precision analysis, cutting tolerances are typically within ±0.005 inches (±0.127mm), with dimensional accuracy reaching approximately ±0.0005 inches in optimal conditions. These specifications make laser cutting the preferred choice for industries like aerospace, electronics, and automotive where exacting standards are non-negotiable.

Understanding Tolerance Specifications in Metal Cutting

What do tolerance numbers actually mean for your project? Think of tolerance as the acceptable range of variation from your intended dimension. When a fabricator quotes ±0.005 inches, they're guaranteeing your parts will measure within five-thousandths of an inch from your specified dimensions - either slightly larger or slightly smaller.

According to JTV Manufacturing's technical documentation, precision laser cutting services can achieve even tighter specifications under ideal conditions:

- Focus capability: Laser cutting can focus down to 25 microns - approximately one-quarter the width of a human hair

- Cut width (kerf): Can be as narrow as 0.001 inches, enabling extremely fine features

- Dimensional accuracy: Typically ±0.0005 inches when all variables are optimized

- Repeatability: Computer-controlled systems deliver identical cuts across production runs

Laser cutting precision surpasses traditional methods by a significant margin - plasma cutting typically offers only ±0.020 inches tolerance, making lasers up to four times more accurate for demanding applications.

For aluminum laser cutting and laser cutting ss (stainless steel) applications, these tolerance capabilities translate into practical advantages. Medical device manufacturers can produce intricate instrument components with confidence. Electronics enclosure designers can specify tight-fitting assemblies. Automotive engineers can create brackets and mounts that interface perfectly with existing systems.

Factors That Impact Your Final Part Accuracy

Achieving advertised tolerances isn't automatic - several interconnected factors determine whether your parts meet specification. Understanding these variables helps you work more effectively with fabrication partners and troubleshoot quality issues if they arise.

According to Elephant CNC's technical analysis, laser cutting precision depends on careful control of multiple process parameters:

- Beam focus quality: The relative position of the focal point to the workpiece surface is critical. When focus is properly positioned - typically just on or slightly below the material surface - you achieve the narrowest slit, highest efficiency, and best cutting quality. Poor cooling can cause focal length changes during operation, requiring adjustment.

- Material flatness: Warped or bowed sheets create inconsistent focus distance across the cutting area. This variation affects penetration depth and edge quality, potentially pushing parts outside tolerance specifications.

- Thermal expansion: Metal heats during cutting and expands. While the heat-affected zone in laser cutting is narrow, accumulated heat in large parts or long cutting sequences can cause dimensional changes that affect final measurements.

- Machine calibration: Regular calibration ensures the cutting head moves precisely where programmed. Motion system accuracy, mirror alignment, and servo tuning all contribute to positional accuracy.

- Material thickness consistency: Sheet metal thickness varies within manufacturer tolerances. A nominally 3mm sheet might measure 2.9mm in one area and 3.1mm in another - affecting both cutting parameters and final part dimensions.

Additional factors influence your results beyond the core five:

- Laser power stability: According to Elephant CNC's research, setting power too low leaves insufficient heat for clean cuts, while excessive power causes overburning and wider kerf. The optimal power density often appears at levels below maximum output.

- Cutting speed optimization: Speed affects both precision and edge quality. Too fast creates incomplete penetration; too slow causes excessive melting and rough edges.

- Assist gas purity: When using oxygen for carbon steel cutting, a 2% reduction in purity can decrease cutting speed by 50% while degrading edge quality. Nitrogen purity similarly affects stainless steel and aluminum results.

- Workpiece stability: Vibration from an unstable workbench transfers directly to cut paths, causing deviation from programmed geometry.

What does this mean practically? For most laser cutting charges and quotes, standard tolerances of ±0.005 inches apply to typical materials and thicknesses. Tighter tolerances may require additional processing time, more careful material selection, or secondary machining operations - factors that affect project pricing.

Setting realistic expectations from the start prevents disappointment and costly revisions. Discuss your critical dimensions with fabrication partners early in the project. Identify which features truly require tight tolerances versus those where standard precision suffices. This conversation often reveals opportunities to reduce costs while maintaining the accuracy that matters most for your application.

With precision specifications understood, you're ready to consider what happens after cutting - the finishing operations and secondary processes that transform raw laser-cut parts into complete, functional components.

Finishing Options and Secondary Operations After Cutting

Your parts emerge from the laser with precise geometries and clean edges - but for most projects, that's just the beginning. The journey from raw laser cut sheet metal to finished component typically involves several additional operations that add functionality, durability, and visual appeal. Understanding this complete fabrication workflow helps you plan projects more effectively and communicate requirements clearly with manufacturing partners.

Think of sheet metal laser cutting as the foundation of your part. What you build on that foundation - through deburring, bending, welding, and surface finishing - determines whether your component succeeds in its intended application. A modern laser cutting service sheet metal fabrication provider integrates these operations into seamless workflows, transforming flat laser cut metal sheets into three-dimensional, production-ready assemblies.

Secondary Operations That Complete Your Metal Parts

After cutting, your parts typically require some combination of finishing processes depending on their end use. According to SendCutSend's finishing guide, metal finishes improve material properties over the unfinished metal - enhancing corrosion resistance, abrasion resistance, surface hardness, or aesthetic appearance. Here's what each major operation accomplishes:

- Deburring: Removes sharp edges, burrs, and minor imperfections left from the cutting process. Linear deburring brushes one side of larger parts to smooth scratches and remove dross, preparing surfaces for later painting or assembly. This operation is often included at no additional charge by quality fabricators.

- Tumbling: A vibratory-abrasive process ideal for smaller parts. Ceramic tumbling media removes rough edges consistently across all surfaces, producing a more uniform finish than manual methods can achieve.

- Bending and forming: CNC press brakes transform flat laser cut sheets into three-dimensional components - from simple brackets to complex housings. According to Full Spectrum Laser's fabrication guide, modern press brakes deliver precision automation with servo-driven accuracy, integrating seamlessly with laser cutting workflow.

- Welding: Joins multiple cut pieces into unified assemblies. Laser welding systems offer speed and precision, while traditional MIG and TIG welding handle heavier structural requirements. Some systems combine welding, cleaning, and cutting functions in integrated equipment.

- Hardware insertion: PEM nuts, standoffs, and threaded inserts are pressed or welded into cut features, adding fastening capability without secondary machining operations.

From Raw Cut to Finished Component

Surface finishing represents the final transformation stage, protecting your parts and defining their appearance. The coating or treatment you select depends on your application requirements, environmental exposure, and aesthetic preferences.

- Powder coating: Applied electrostatically and cured in an oven, powder coating creates a durable finish that lasts up to 10 times longer than paint. It contains no VOCs, and overspray can be recycled. Common colors include black (matte, gloss, and wrinkle finishes), red, white, and yellow.

- Anodizing: Ideal for aluminum parts, this electrochemical process thickens the natural oxide layer, creating scratch-resistant, corrosion-resistant finishes. Available in clear or dyed options, anodizing provides exceptional aesthetics while adding heat and electrical resistance.

- Plating: Deposits a metal coating onto your parts through electrochemical processes. Zinc plating protects steel from corrosion, while nickel plating enhances conductivity and appearance on copper or steel substrates.

- Passivation: A chemical treatment that improves corrosion resistance without changing part dimensions - particularly valuable for stainless steel components in demanding environments.

How do cutting parameters affect these downstream processes? Surface finish quality from the laser directly influences coating adhesion and appearance. Clean, oxide-free edges produced with nitrogen assist gas accept powder coating and anodizing more uniformly. Parts cut with oxygen assist may require additional surface preparation to remove oxide layers before finishing.

Sheet metal laser cutting and bending workflows benefit from design consideration at the earliest stages. Bend relief cuts, proper hole placement relative to bend lines, and appropriate material selection all affect how smoothly your parts transition from flat stock to finished assemblies. When laser cutting and engraving operations combine on single parts - adding logos, part numbers, or decorative elements - the engraving typically occurs before bending or finishing operations.

A truly integrated approach to fabrication considers the entire workflow from initial design through final finishing. By understanding how each operation connects to the next, you can make informed decisions about material selection, design features, and finishing specifications that optimize both quality and cost. With your complete fabrication workflow mapped out, the next consideration becomes understanding the cost factors that drive project pricing.

Cost Factors That Drive Custom Laser Cutting Pricing

You've mapped out your fabrication workflow and finishing requirements - now comes the question everyone wants answered: what will this actually cost? Here's what most fabricators won't tell you upfront: the single most important factor driving your custom metal laser cutting price isn't the area of material you're cutting. It's the machine time required to complete your design.

According to Fortune Laser's pricing analysis, the fundamental formula that nearly every laser cutting provider uses is: Final Price = (Material Costs + Variable Costs + Fixed Costs) x (1 + Profit Margin). Understanding each component of this formula empowers you to make design decisions that directly reduce your project costs - without compromising the quality your application demands.

Material and Complexity Factors in Project Pricing

When requesting a laser cutting quote, you'll notice that material selection affects your price in two distinct ways: the raw cost of the metal itself, and how challenging it is to cut. A sheet of mild steel costs less than stainless steel or aluminum - but beyond purchase price, each material's cutting behavior influences machine time and operational complexity.

Here are the primary cost drivers you should understand when budgeting for custom metal cutting projects:

- Material type: Different metals have unique purchase costs, reflectivity characteristics, and cutting requirements. According to Komacut's pricing guide, cutting stainless steel generally requires more energy and time compared to carbon steel, making it more expensive. Soft or thin materials are typically faster and cheaper to process.

- Material thickness: This is a critical cost multiplier. Doubling material thickness can more than double cutting time and cost because the laser must move much slower to penetrate cleanly. Always verify whether a thinner gauge can meet your structural requirements.

- Part complexity and cutting time: Intricate designs with tight curves and sharp corners force the machine to slow down. More pierce points - where the laser starts each new cut - accumulate significant time. A design with 100 small holes costs more than one large cutout because of cumulative piercing time.

- Cut distance: The total linear distance the laser travels directly correlates with machine time. Longer cutting paths mean higher costs, making design optimization essential for budget-conscious projects.

- Finishing requirements: Secondary processes like deburring, bending, powder coating, and hardware insertion add labor, equipment time, and material expenses. According to Komacut's analysis, these additional steps are necessary for achieving specific mechanical features or quality finishes, but they increase overall project costs.

- Turnaround time: Rush orders typically command premium pricing. Standard lead times allow fabricators to optimize scheduling and material usage, reducing your per-part costs.

Tight tolerances deserve special attention in your cost considerations. Specifying tighter precision than functionally necessary forces machines to run at slower, more controlled speeds - directly increasing your laser cutting charges. Design to the tolerance your application actually requires, not the tightest tolerance available.

How Quantity Affects Your Per-Part Costs

Perhaps no factor influences per-unit pricing more dramatically than order quantity. Every metal cutting services provider incurs fixed costs for each job - setup fees, file preparation, machine calibration, and material loading. These costs exist whether you're cutting one part or one thousand.

Here's how quantity economics work:

- Setup fee amortization: Fixed costs spread across all parts in your order. A $50 setup fee adds $50 to a single prototype but only $0.05 per part on a 1,000-piece run.

- Material efficiency: Larger orders enable better nesting - efficiently arranging parts on material sheets to minimize waste. According to Fortune Laser's research, discounts for high-volume orders can reach 70% compared to prototype pricing.

- Production optimization: Batch processing allows fabricators to optimize cutting sequences, reduce material handling, and maximize machine utilization - savings passed along to customers.

This brings us to the prototyping versus production cost question. When you need a laser cutting online quote for rapid prototyping, expect higher per-part costs that reflect the inherent inefficiencies of small-batch work. Manufacturers like Shaoyi address this reality by offering 5-day rapid prototyping alongside automated mass production capabilities - demonstrating the cost efficiency spectrum from development through volume manufacturing.

For tube laser cutting services and other specialized operations, the same economic principles apply. Complex setups and specialized tooling add fixed costs that benefit from volume distribution.

What about getting accurate quotes quickly? The quoting process itself varies significantly between providers. Some online platforms deliver instant pricing from CAD file uploads - convenient but sometimes missing opportunities for cost-saving design feedback. Traditional fabricators offer manual quotes with DFM (Design for Manufacturability) guidance that can significantly reduce your costs, though response times are longer. Modern manufacturers increasingly bridge this gap - Shaoyi, for example, provides 12-hour quote turnaround with comprehensive DFM support, helping customers understand costs quickly while identifying optimization opportunities.

The relationship between design optimization and cost reduction cannot be overstated. According to Strouse's cost analysis, material cost often makes up 70-80% of total project costs. Simplifying geometries, reducing pierce counts, and using the thinnest appropriate material creates compounding savings that significantly impact your bottom line. These optimizations don't require sacrificing functionality - they require understanding how your design translates to machine time and material usage.

Armed with this understanding of cost factors, you're prepared to evaluate quotes intelligently, ask informed questions, and make design decisions that balance performance requirements against budget realities. The next step? Understanding how these cost considerations apply across different industry applications and use cases.

Industry Applications for Custom Laser Cut Metal Parts

Now that you understand the cost factors shaping your projects, here's the practical question: what are manufacturers actually producing with this technology? From the chassis beneath your car to the surgical instruments in hospitals, industrial laser cutting powers an astonishing range of applications across virtually every manufacturing sector. Understanding where laser cutting metal sheet applications thrive helps you determine whether your project aligns with this technology's strengths.

According to Great Lakes Engineering, precision laser cutting has become indispensable across multiple sectors due to its ability to handle complex contours, thin foils, and a variety of metals without damaging the material. The technology's capacity to produce clean cuts with minimal heat-affected zones ensures parts maintain their integrity under demanding conditions - whether that's the extreme temperatures of jet engines or the corrosive environments of marine applications.

Automotive and Aerospace Precision Component Applications

The automotive industry relies heavily on laser cutting steel and aluminum for high-volume component production. According to Accurl's industry analysis, manufacturers use this technique to create chassis parts, body panels, engine components, and intricate fittings with the precision that modern vehicle safety demands.

Why does steel laser cutting dominate automotive fabrication? Consider these advantages:

- Chassis and structural components: Frame brackets, cross members, and reinforcement plates require tight tolerances and consistent repeatability across thousands of identical parts. Laser cutting delivers both.

- Suspension components: Control arms, mounting brackets, and suspension links demand precision interfaces that mate perfectly with existing assemblies - exactly what laser technology provides.

- Body panels and trim: Complex curves and precise edge quality eliminate extensive secondary finishing, streamlining production workflows.

- Engine components: Heat shields, gaskets, and mounting brackets benefit from the minimal heat-affected zone that preserves material properties.

For automotive manufacturers requiring IATF 16949-certified quality, specialized partners like Shaoyi (Ningbo) Metal Technology combine precision cutting with comprehensive DFM support for chassis, suspension, and structural components - demonstrating how industry-specific expertise translates to reliable production outcomes.

Aerospace applications push precision requirements even further. According to McKiney Manufacturing, fiber lasers can cut materials with accuracy up to a few micrometers - essential when manufacturing critical parts like turbine blades, structural components, and avionics enclosures where even the slightest deviation can compromise safety.

- Turbine blades: Precision-cut blades are essential for maintaining engine efficiency and safety. Each blade must meet exacting standards to reduce failure risk in extreme operating conditions.

- Airframe components: Wing sections, fuselage panels, and structural elements require lightweight yet strong parts that laser cutting of metal sheets produces with maintained structural integrity.

- Electronic enclosures: As avionics become increasingly sophisticated, laser cut stainless steel enclosures protect sensitive electronics with the fine details and precise dimensions these applications demand.

- Defense components: Vehicles, weapons systems, and communication equipment require the precision and reliability that only laser cutting delivers.

Architectural and Industrial Equipment Uses

Beyond transportation, laser cutting transforms how architects and industrial designers bring their visions to reality. The technology's ability to produce complex patterns and high-quality finishes with minimal distortion makes it ideal for both aesthetic and functional applications.

Architectural metalwork applications include:

- Decorative facades: Intricate metal panels, screens, and sunshades featuring complex geometric patterns that would be impossible or prohibitively expensive with traditional methods

- Interior elements: Stair railings, room dividers, ceiling panels, and custom furniture components with consistent quality across large installations

- Signage: Precision-cut letters, logos, and dimensional displays that maintain design integrity at any scale

- Structural connections: Steel brackets, gussets, and connection plates where precision ensures proper load transfer and structural safety

Electronics manufacturers depend on laser cutting for enclosures, chassis, and heat sinks that protect and support sensitive components. According to Great Lakes Engineering, the technology's ability to cut circuit boards, semiconductor materials, and connectors from metals like copper and brass - leveraging fine details and high accuracy - supports the industry's relentless push toward miniaturization.

Industrial equipment applications demonstrate the technology's versatility:

- Heavy machinery: Durable components for agricultural equipment, construction machinery, and manufacturing systems that withstand harsh operating conditions

- Energy sector: Parts for turbines, heat exchangers, and containers in power generation - including renewable energy components for wind turbines and solar panel mounting systems

- Medical devices: Surgical instruments, diagnostic tools, and device housings produced with the clean, burr-free edges that medical safety standards require

- Food processing: Stainless steel components for equipment where hygiene, corrosion resistance, and precision cleaning capability are essential

The common thread across these diverse applications? Each leverages laser cutting's unique combination of precision, repeatability, and material versatility. Whether you're fabricating structural components that must withstand enormous loads or decorative elements where appearance is paramount, this technology adapts to your specific requirements.

Identifying your project within these application categories helps you communicate effectively with fabrication partners and set appropriate expectations for precision, material selection, and finishing requirements. With your application context established, the final consideration becomes selecting the right manufacturing partner to bring your project to successful completion.

Selecting the Right Custom Laser Cutting Partner

You've navigated the technology options, material considerations, design principles, and cost factors - now comes the decision that brings everything together: choosing the right metal laser cutting service provider. Whether you're searching for "laser cutting service near me" or evaluating online fabrication platforms, the partner you select directly determines whether your project succeeds or stumbles.

Here's the reality: not all laser cutting services near me or anywhere else deliver equivalent results. According to Steelway Laser Cutting's comprehensive guide, before forming a beneficial outsourcing partnership, there are a range of factors to consider that go far beyond simple pricing comparisons. The lowest quote often costs more in the long run when quality issues, delays, or communication breakdowns derail your project.

Evaluating Service Providers for Your Metal Cutting Needs

When evaluating potential CNC laser cutting services partners, use this systematic checklist to ensure you're comparing providers on the factors that actually matter for successful outcomes:

- Verify relevant certifications: For automotive applications, look for IATF 16949 certification - this automotive-specific standard includes requirements for continuous improvement, defect prevention, and supply chain management that ISO 9001 alone doesn't address. For other industries, confirm ISO certifications appropriate to your sector.

- Confirm material capabilities: Most metal laser cutting services can handle common materials like stainless steel, but verify they can process your specific requirements. Ask about thickness ranges, reflective metal handling (copper, brass, aluminum), and whether their equipment matches your material needs.

- Assess turnaround times: Understand standard lead times versus rush options. Ask how quickly they can turn around projects from file receipt to shipping - and what premium applies for expedited service.

- Evaluate DFM support: According to Hubs' DFM guide, successful Design for Manufacturability analysis minimizes cost while retaining or increasing part performance. Providers offering comprehensive DFM feedback help you optimize designs before production begins - preventing costly revisions later.

- Examine quality assurance processes: Ask about inspection protocols, measurement equipment, and how they handle parts that don't meet specification. Quality-focused providers document their processes and stand behind their work.

- Review secondary operation capabilities: Can they handle bending, welding, powder coating, and hardware insertion in-house? Integrated services streamline your supply chain and reduce coordination headaches.

- Request references and examples: Ask for testimonials from clients with similar projects. Experienced providers readily share examples demonstrating their capabilities and expertise.

Preparing Your Project for Manufacturing Success

Finding a capable provider is only half the equation - how you prepare your project determines the outcome you'll receive. Apply the knowledge you've gained throughout this guide to set your project up for success from the start.

The most critical factor in successful custom laser metal cutting isn't finding the cheapest provider - it's clear communication of your requirements combined with design optimization that matches manufacturing capabilities.

Before submitting your first file, ensure you've addressed these fundamentals:

- Optimize your design files: Follow DFM principles - appropriate hole sizes, adequate feature spacing, proper tolerances for your application

- Specify critical dimensions: Identify which features truly require tight tolerances versus those where standard precision suffices

- Define finishing requirements: Communicate surface finish, coating, and secondary operation needs upfront

- Establish quantity expectations: Share both immediate needs and projected volumes to help providers optimize pricing

When searching for "laser metal cutting near me" or evaluating remote providers, remember that geographic proximity matters less than capability alignment. Modern shipping makes location secondary to finding a partner whose equipment, expertise, and quality systems match your specific requirements.

The knowledge you've gained - from laser technology selection through material compatibility, design optimization, tolerance specifications, finishing operations, cost factors, and industry applications - positions you to engage confidently with any fabrication partner. Proper preparation transforms custom laser metal cutting from a black-box mystery into a predictable, successful manufacturing process that delivers exactly the parts your application demands.

Frequently Asked Questions About Custom Laser Metal Cutting

1. What is the difference between fiber laser and CO2 laser cutting?

Fiber lasers use ytterbium-doped optical fibers producing 1064nm wavelength light, offering superior metal absorption, finer beam focus, and up to 42% energy efficiency. They excel at cutting thin metals like stainless steel, aluminum, brass, and copper. CO2 lasers use carbon dioxide gas mixtures producing 10.6 micrometer wavelength light, making them better suited for thicker mild steel and non-metallic materials like wood and acrylic. Fiber lasers are typically faster on metals under 10mm, while CO2 systems remain valuable for thick plate processing and mixed-material applications.

2. How much does custom laser metal cutting cost?

Custom laser metal cutting pricing follows the formula: Final Price = (Material Costs + Variable Costs + Fixed Costs) x (1 + Profit Margin). Key cost drivers include material type and thickness, part complexity and cutting time, quantity and setup fee amortization, finishing requirements, and turnaround time. Material often represents 70-80% of total costs. Prototype orders carry higher per-part costs due to setup fee distribution, while volume orders of 1,000+ parts can see discounts up to 70%. IATF 16949-certified manufacturers like Shaoyi offer 12-hour quote turnaround with DFM support to help optimize costs quickly.

3. What metals can be laser cut?

Laser cutting handles a wide range of metals including stainless steel, carbon steel, aluminum, copper, brass, and various alloys. Stainless steel is the most laser-friendly due to low reflectivity and predictable thermal behavior. Aluminum requires higher power due to rapid heat dissipation and high reflectivity. Copper and brass present the greatest challenges due to extreme reflectivity, requiring fiber lasers with pulsed cutting mode and clean surface preparation. Material thickness capabilities vary by laser type - fiber lasers typically handle up to 25mm stainless steel, while CO2 systems can process mild steel over 30mm.

4. How precise is laser cutting compared to other methods?

Laser cutting achieves tolerances of ±0.005 inches (±0.127mm) with dimensional accuracy reaching ±0.0005 inches under optimal conditions. This is approximately four times more accurate than plasma cutting (±0.020 inches) and comparable to waterjet cutting (±0.003 to ±0.005 inches). Only wire EDM offers tighter tolerances at ±0.0001 inches. Precision depends on beam focus quality, material flatness, thermal expansion management, machine calibration, and material thickness consistency. The laser's ability to focus down to 25 microns with kerf widths as narrow as 0.001 inches enables extremely fine features impossible with other thermal cutting methods.

5. What file format do I need for laser cutting?

Submit 2D vector files in DXF or DWG format at 1:1 scale for optimal results. Unlike raster files (JPG, BMP), vector formats provide exact geometry for laser cutting software. Before submission, convert all text to outlines, verify dimensions after any file conversion, eliminate floating cut-outs by adding bridging tabs, and ensure your design follows the 1:1 rule for holes (diameter should equal or exceed material thickness). Most professional fabricators automatically compensate for kerf width, so provide files with your intended final dimensions rather than pre-adjusted measurements.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —