Uzură neuniformă a anvelopelor? Brațul de direcție din oțel stampat este principalul suspect

REZUMAT

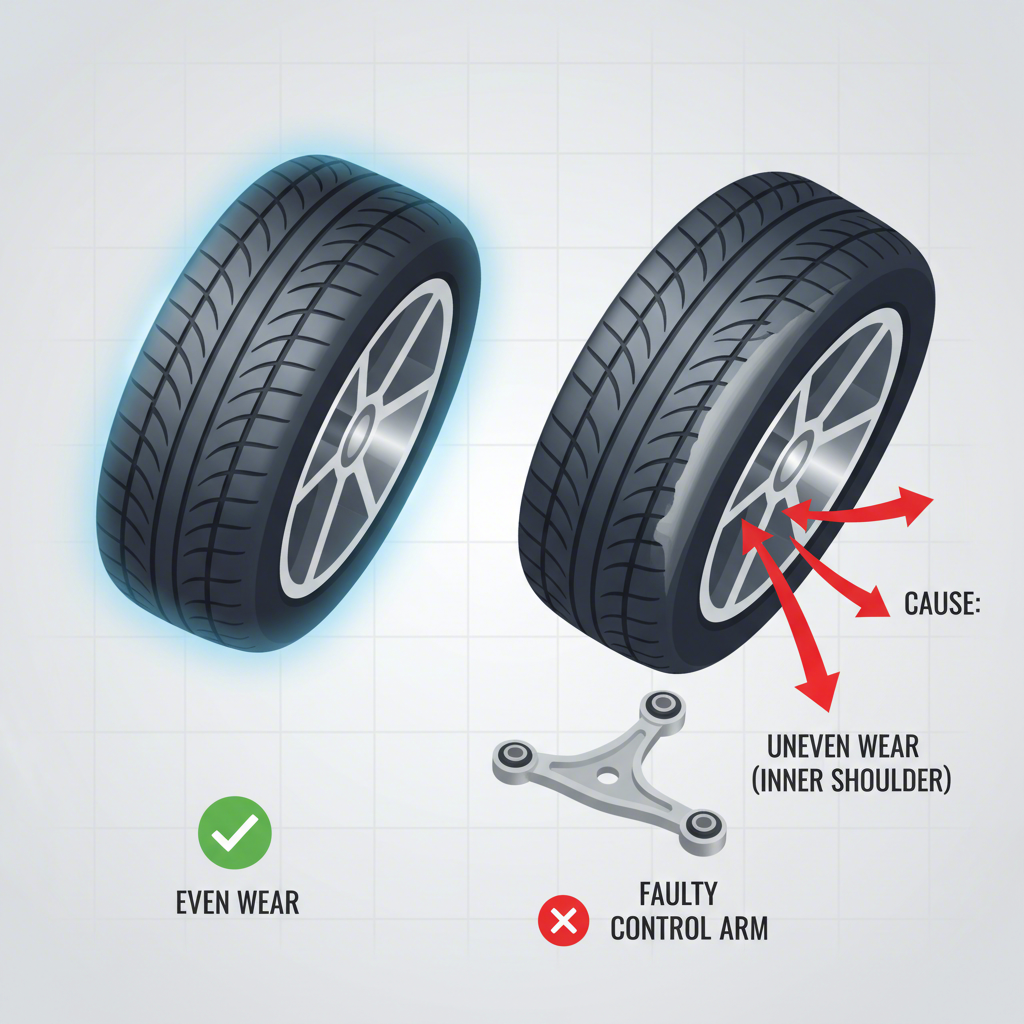

Un braț de comandă din oțel stampat defect, îndoit sau uzat este o cauză directă a uzurare neuniformă a pneurilor . Acest component esențial al suspensiei menține alinierea roților, iar atunci când eșuează, perturbă unghiul anvelopei, ducând la deteriorarea rapidă și neregulată a benzii de rulare. Alte simptome importante de observat includ zgomote distincte de bătăi pe denivelări și o direcție imprecisă, cu senzația de abateri ale volanului în timpul conducerii.

Legătura esențială: Cum un braț de comandă defect provoacă uzura neuniformă a anvelopelor

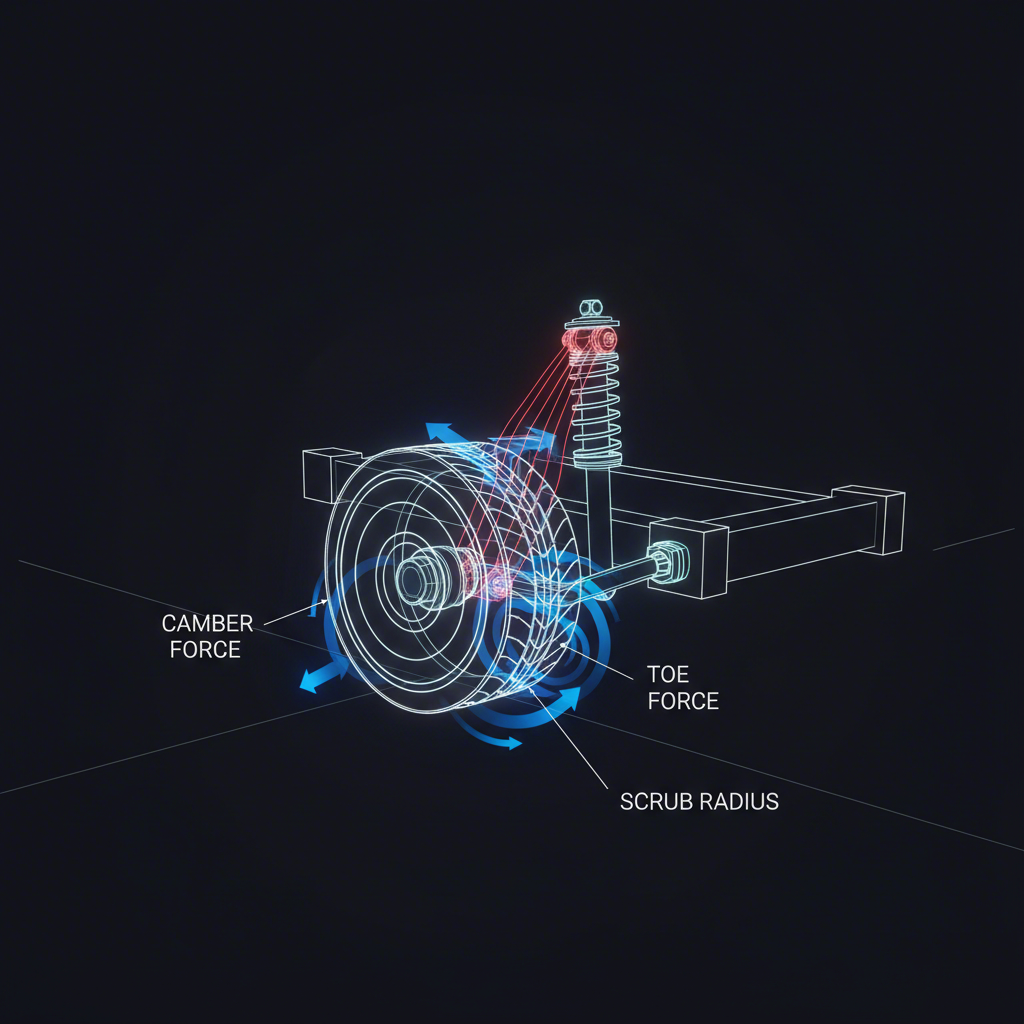

Brațul de comandă este o legătură pivotală care unește cadru vehiculului cu butucul roții sau fuzeta. Rolul său principal este de a permite roților să se miște în sus și în jos conform suprafeței drumului, menținându-le totodată în alinierea corectă. Conform experților auto de la AutoZone , atunci când un braț de comandă este îndoit din cauza unui impact sau lagărele sale se uzează, acesta nu mai poate menține unghiurile precise — cădere (camber), înclinare (caster) și convergență (toe) — care determină modul în care anvelopele vin în contact cu drumul.

Această pierdere a aliniamentului este cauza directă a deteriorării premature a anvelopelor. De exemplu, dacă o bară de direcție este îndoită, poate modifica unghiul de călare, făcând ca partea superioară a anvelopei să se încline spre interior sau spre exterior. Acest lucru forțează unul dintre marginile anvelopei să preia o parte mai mare din greutatea vehiculului, ceea ce duce la o uzură accelerată a umărului interior sau exterior. În mod similar, tampoanele uzate ale barii de direcție pot permite mișcări nedorite, determinând aliniamentul să se deplaseze dinamic în timp ce conduceți, frânați și accelerați. Această instabilitate poate elimina cauciucul de pe anvelope în modele neregulate.

Inspecia vizuală a anvelopelor este unul dintre primii pași în diagnosticarea unei probleme posibile la bara de direcție. Fiți atenți la anumite modele de uzură care indică o problemă la suspensie, nu doar o suprapresiune insuficientă. Aceste semne sunt adesea cele mai vizibile dovezi că există ceva în neregulă cu geometria vehiculului dumneavoastră.

- Uzură unilaterală: Uzura semnificativă pe marginea interioară sau exterioară a benzii de rulare a anvelopei este un semn clasic al unei probleme de înclinare negativă sau pozitivă (camber), adesea legată de o bară de direcție deteriorată.

- FeatherinG: Acest lucru apare atunci când crestele benzii de rulare sunt mai uzate pe o parte și mai puțin pe cealaltă, creând un model asimetric asemănător penelor sau dințișilor de ferăstrău. Puteți simți acest lucru trecând mâna peste bandă. Aceasta indică adesea o problemă de unghi de convergență (toe alignment).

- Cavitate sau Undulații: Aceasta apare sub forma unor pete aleatorii de uzură de-a lungul circumferinței anvelopei, creând un efect de cavități sau undulații. Sugerează faptul că anvelopa sare în timp ce se rotește, o problemă adesea legată de componente de suspensie uzate, cum ar fi barele de direcție sau amortizoarele.

Diagnosticarea Problemei: Simptome Cheie ale unei Bare de Direcție Defecte

În afară de deteriorarea anvelopelor, un braț de suspensie defectuos se anunță prin diverse avertismente auditive și tactice. Atenția acordată acestor semne vă poate ajuta să identificați problema înainte ca aceasta să ducă la riscuri majore de siguranță. Unul dintre cele mai frecvente indicii este un sunet distinct zgomot de pocnitură sau bătăi , mai ales atunci când conduceți peste denivelări, gropi sau faceți viraje strânse. Acest sunet este adesea cauzat de tampoane uzate care permit un contact excesiv metal-pe-metal între brațul de suspensie și cadrul vehiculului, așa cum este detaliat de GSW Auto Parts în ghidul lor despre simptome ale brațului inferior de suspensie .

Un alt simptom principal este o schimbare în senzația de direcție. S-ar putea să observați că vehiculul tinde să tragă într-o parte sau că direcția pare slabă, imprecisă sau neproductivă. Această senzație este adesea descrisă ca abateri ale volanului , unde trebuie să faci corecții mici constante pentru a menține mașina pe traiectorie rectilinie. Acest lucru se întâmplă deoarece un braț de direcție uzat sau un pivot sferic defect permit prea mult joc, împiedicând roata să fie menținută ferm în poziție. De asemenea, s-ar putea simți vibrații excesive prin volan, mai ales la viteze mari, deoarece componenta deteriorată nu mai poate amortiza eficient neregularitățile drumului.

Deși atât tampoanele brațului de direcție, cât și pivoții sferici pot eșua, uneori produc simptome ușor diferite. Înțelegerea diferenței poate ajuta la identificarea exactă a punctului de defect.

| CompoNent | Simptome Comune |

|---|---|

| Tampoane defecte | Zgomote puternice de pocnitură sau lovituri la trecerea peste denivelări; senzație de joc la frânare sau accelerare. |

| Articulație sferică defectă | Direcție imprecisă sau instabilă; zgomote de pocnitură sau clic-clic la întoarcerea volanului. |

Dacă bănuiți o problemă, puteți efectua o inspecție fizică de bază. Cu vehiculul susținut în siguranță pe cricuri, verificați următoarele:

- Deteriorare vizuală: Examinați brațul de direcție în sine. Este vizibil îndoit, crapat sau puternic ruginit?

- Starea tampoanelor: Inspectați tampoanele de cauciuc acolo unde brațul se conectează la cadru. Căutați crăpături, rupturi sau semne că materialul de cauciuc s-a degradat sau își lipsește porțiuni.

- Jocul roții: Apucăți ferm anvelopa la pozițiile 9 și 3 și încercați să o mișcați lateral. Apoi repetați procedura la pozițiile 12 și 6. Orice joc semnificativ sau zgomote ciocănite pot indica un cap de bară uzat sau tampoane defecte.

Oțel tipărit vs. Alternative: Alegerea materialului potrivit pentru brațul de direcție

Brațele de direcție din oțel tipărit sunt cel mai frecvent tip întâlnit pe autovehiculele de serie. Sunt fabricate prin ștanțare și sudare a foilor de oțel, un proces eficient din punct de vedere al costurilor și care oferă o rezistență structurală și durabilitate bună pentru utilizarea zilnică. După cum se menționează într-o prezentare tehnică realizată de Carico Auto , rigiditatea lor este potrivită pentru gestionarea forțelor tipice ale suspensiei. Pentru producătorii auto, fabricarea acestor componente necesită o precizie extremă pentru a asigura siguranța și performanța. Aici devin esențiali furnizorii specializați. De exemplu, companiile care se concentrează pe ambutisarea precisă a metalelor, cum ar fi Shaoyi (Ningbo) Metal Technology Co., Ltd. , oferă expertiza inginerească și procesele certificate necesare pentru a produce piese fiabile OEM și de schimb, cum ar fi brațele de suspensie.

Cu toate acestea, oțelul ambutisat nu este singura opțiune disponibilă, mai ales atunci când se iau în considerare înlocuiri sau upgrade-uri de performanță. Materialul ales poate influența greutatea, manevrabilitatea și durabilitatea vehiculului dumneavoastră. Aliajul turnat din aluminiu, de exemplu, oferă reduceri semnificative ale greutății și o excelentă rezistență la coroziune, fiind o alegere populară pentru vehiculele de lux și de performanță, unde reducerea greutății nesuspendate este o prioritate. Brațele din țevi de oțel, utilizate frecvent în kiturile de ridicare aftermarket și aplicații de performanță, cum ar fi cele pentru Camioane Silverado , oferă rezistență mare și poate fi proiectat pentru o geometrie îmbunătățită a suspensiei.

Luarea unei decizii informate depinde de vehiculul dumneavoastră, stilul de condus și buget. Pentru majoritatea șoferilor care doar înlocuiesc o piesă uzată, un braț din oțel stampilat de înaltă calitate este cea mai practică și economică opțiune. Pentru cei care doresc performanțe sporite sau care conduc în condiții dificile, o actualizare ar putea merita investiția.

| Material | Avantaje | Dezavantaje | Cel Mai Bine Pentru |

|---|---|---|---|

| Oțel stampat | Rentabil, rezistență bună, larg disponibil. | Mai greu decât aluminiul, flexibilitate limitată în proiectare. | Înlocuire OEM, utilizare zilnică. |

| Fier de fier | Rezistență și rigiditate excelente, amortizare bună a vibrațiilor. | Foarte greu, predispus la coroziune dacă nu este acoperit. | Camioane heavy-duty și vehicule clasice. |

| Aluminiu fundit | Ușor, rezistent la coroziune, design flexibil. | Mai scump, poate să nu fie la fel de puternic ca oțelul. | Vehicule de performanță și lux. |

| Oțel tubular | Raport mare de rezistență la greutate, geometrie personalizabilă. | De obicei cel mai scump, în principal pentru piețele aftermarket. | Aplicații off-road, de curse și personalizate. |

Întrebări frecvente

1. Care este cel mai bun material pentru brațele de suspensie?

Nu există un singur material "cel mai bun" pentru toate aplicațiile; alegerea ideală depinde de nevoile dumneavoastră. Pentru înlocuirea standard OEM pe un vehicul uzual, oțelul tanat oferă un echilibru excelent între rezistență, durabilitate și cost. Pentru vehicule de performanță sau lux, unde reducerea greutății este esențială pentru îmbunătățirea manevrabilității și calității mersului, aliajul turnat din aluminiu este adesea opțiunea preferată datorită proprietăților sale de ușurință și rezistență la coroziune. Pentru utilizare intensivă sau off-road, brațele din fontă sau din țevi tubulare personalizate oferă rezistență și durabilitate maximă.

Serii mici, standarde ridicate. Serviciul nostru de prototipare rapidă face validarea mai rapidă și mai ușoară —

Serii mici, standarde ridicate. Serviciul nostru de prototipare rapidă face validarea mai rapidă și mai ușoară —