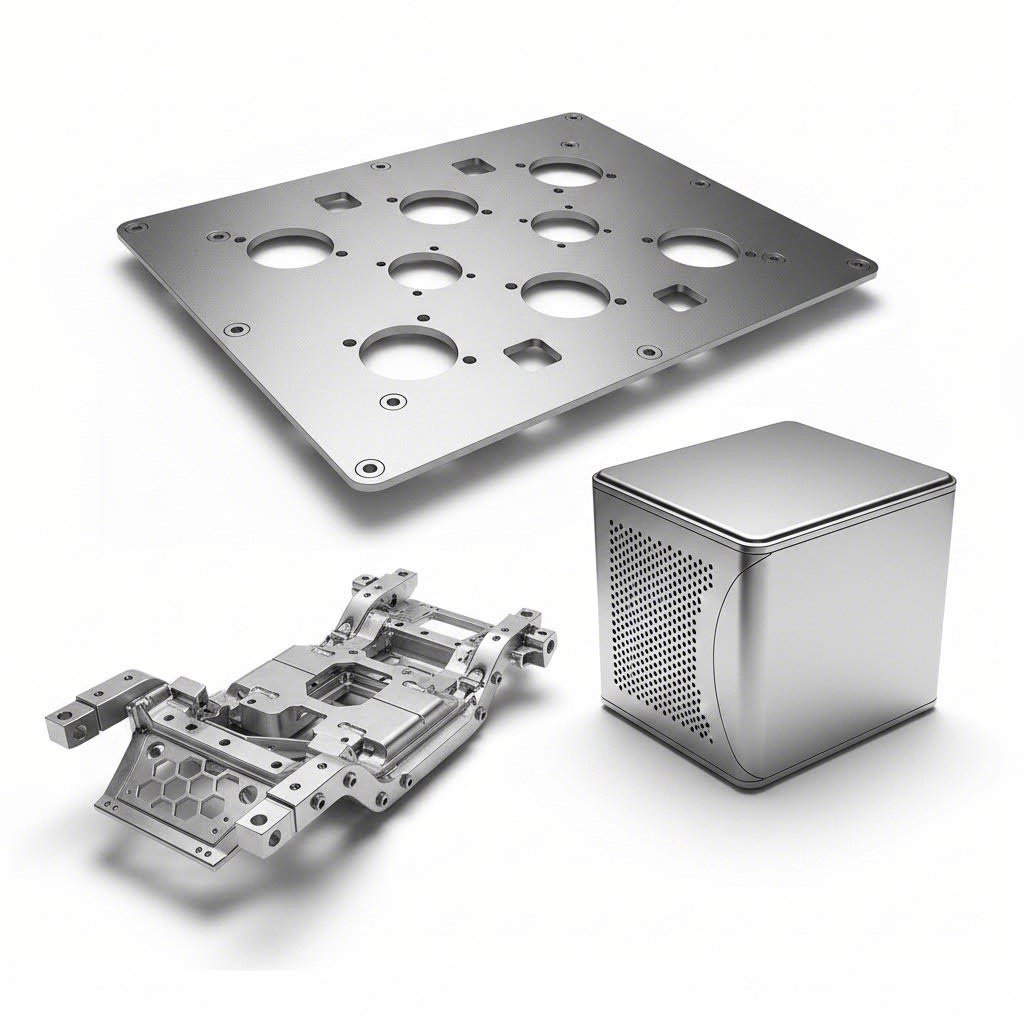

Usługi precyzyjnego kształtowania blach – wyjaśnienie: od wyboru materiału po gotowy element

Zrozumienie usług precyzyjnej obróbki blach i ich znaczenie

Kiedy słyszysz termin " usługi z zakresu precyzyjnej obróbki blach ", co przychodzi Ci na myśl? Jeśli wyobrażasz sobie podstawowe cięcie i gięcie metalu, to dopiero zaglądasz pod powierzchnię. Ta specjalistyczna dziedzina produkcji to połączenie zaawansowanych technologii, starannego kontroli jakości oraz wiedzy inżynieryjnej, która przekształca płaskie półfabrykaty metalowe w elementy spełniające wyjątkowo ścisłe specyfikacje.

Precyzyjna obróbka blach osiąga dokładność wymiarów w zakresie od ±0,005" do ±0,010" (±0,13 mm do ±0,25 mm), w porównaniu do standardowej dokładności obróbki wynoszącej od ±1/16" do ±1/8" (±1,6 mm do ±3,2 mm). Różnica ta może decydować o tym, czy komponenty pasują idealnie do siebie, czy też wymagają kosztownej poprawki.

Zrozumienie tej różnicy ma znaczenie, ponieważ luka między pracą standardową a precyzyjną bezpośrednio wpływa na sukces projektu, jego opłacalność oraz harmonogram.

Co sprawia, że produkcja blach stalowych osiąga poziom precyzyjny

Różnica między standardową obróbką blach a precyzyjną produkcją metalu nie sprowadza się jedynie do posiadania lepszego sprzętu. Jest to kompleksowe podejście obejmujące zaawansowaną maszynérie, wyrafinowane systemy jakości, głęboką wiedzę o materiałach oraz szczegółowe możliwości dokumentowania procesów.

Rozważ tolerancje jako podstawę. Zgodnie z Baillie Fabricating and Welding, standardowe tolerancje dla części wykonanych z blach stalowych wahają się od ±0,02" do ±0,03", podczas gdy precyzyjne części obrobione maszynowo utrzymują wartość ±0,005". Precyzyjna produkcja blach stalowych likwiduje tę lukę, stosując dokładność na poziomie obróbki maszynowej w procesach blacharskich.

Co podnosi produkcję do kategorii precyzyjnej? Trzy kluczowe czynniki działają razem:

- Systemy pomiarowe: Dokładni wykształcicieli wykorzystują maszyny pomiarowe współrzędnościowe (CMM), komparatory optyczne oraz systemy pomiarowe laserowe zamiast podstawowych suwmiarek i wizualnej kontroli

- Kontrola procesów: Statystyczna kontrola procesu (SPC) ciągle monitoruje wymiary krytyczne, uruchamiając automatyczne alerty, gdy trendy odchylają się od specyfikacji

- Ekspertyza materiałowa: Zrozumienie, jak różne stopy zachowują się podczas przetwarzania, w tym obliczenia odbicia sprężystego i uwzględnienie kierunku ziarna

Brzmi skomplikowanie? Tak jest. Jednak właśnie ta złożoność pozwala na tworzenie komponentów, w których odchyłka o 0,020 cala, która może być akceptowalna w budownictwie, uczyniłaby część lotniczą całkowicie nieprzydatną do użycia

Kluczowe kompetencje definiujące jakość wyrobu

Co odróżnia takie działania jak precyzyjni wykształciciele metali inc od zwykłych warsztatów metalowych? Odpowiedź tkwi w zintegrowanych kompetencjach gwarantujących spójność od pierwszego egzemplarza do końcowej dostawy

Wysokiej jakości konstrukcje z blach wymagają zaawansowanych technologii cięcia, w tym systemów laserowych światłowodowych z cięciem mikro-łącznym, które utrzymują wąskie tolerancje na skomplikowanych geometriach. Operacje gięcia wykorzystują robotyczne giętarki CNC z systemami pomiaru kąta i automatyczną korektą na podstawie właściwości odbicia materiału.

Ponad same urządzenia, wszelkie precyzyjne prace blacharskie zależą od solidnych systemów zarządzania jakością. Certyfikaty takie jak ISO 9001 i AS9100 to nie tylko dyplomy na ścianie. Reprezentują one udokumentowane procesy gwarantujące, że każdy komponent podlega inspekcji pierwszego artykułu (FAI), pełnej śledzalności materiałów oraz posiada certyfikaty zgodności wspierające wymagania regulacyjne.

Inwestycja w możliwości precyzyjnej obróbki zazwyczaj kosztuje od 3 do 5 razy więcej niż standardowe narzędzia. Jednak ta inwestycja eliminuje potrzebę poprawek, zmniejsza odpady i zapewnia spójną jakość w całym cyklu produkcji. Dla branż wymagających udokumentowanych systemów jakości oraz pełnej śledzenia, precyzyjna obróbka blach stalowych oferuje wartość wykraczającą daleko poza sam proces produkcji.

Przewodnik wyboru materiału dla projektów z blachy

Wyobraź sobie dobór materiału na następny precyzyjny element bez rozumienia, jak ta decyzja wpływa na wszystkie kolejne etapy procesu. Koszty produkcji, terminy realizacji, opcje wykończenia, a nawet wydajność gotowego elementu zależą od tej jednej decyzji. Dobór materiału w precyzyjnym formowaniu blach stalowych to nie tylko wybór tego, co jest dostępne. To dopasowanie właściwości materiału do konkretnych wymagań aplikacji.

Przemysł produkcji blach stalowych pracuje z dziesiątkami gatunków materiałów, ale zrozumienie podstawowych opcji i ich cech daje podstawę do świadomych decyzji. Przeanalizujmy najpopularniejsze materiały i to, co czyni każdy z nich odpowiednim dla różnych zastosowań precyzyjnych.

Najczęstsze materiały w precyzyjnej obróbce blach

Pięć rodzin materiałów dominuje w precyzyjnej obróbce blach: aluminium, stal nierdzewna, stal węglowa, miedź i mosiądz. Każda z nich oferuje charakterystyczne zalety i ograniczenia, które bezpośrednio wpływają na wyniki projektu.

Stopy aluminium wyróżniają się wyjątkowym stosunkiem wytrzymałości do masy oraz naturalną odpornością na korozję. Zgodnie z Prototek , stopa 6061 oferuje doskonałą spawalność i wytrzymałość konstrukcyjną, podczas gdy 5052 zapewnia lepszą odporność na korozję w środowiskach morskich oraz zastosowaniach wymagających długotrwałej trwałości. Aluminium łatwo nadaje się do formowania skomplikowanych kształtów, co czyni je niezwykle cennym w elementach lotniczych, częściach samochodowych i zastosowaniach architektonicznych, gdzie liczy się redukcja masy.

Stal nierdzewna prowadzi do doskonałej odporności na korozję dzięki zawartości chromu wynoszącej co najmniej 10,5%. Nierdzewna stal marki 304 zapewnia doskonałą ogólną odporność na korozję przy jednoczesnej dobrej obrabialności, podczas gdy stal 316 zawiera molibden, który zwiększa odporność na kwasy chlorowe i nieutleniające. Te właściwości czynią stal nierdzewną głównym wyborem w sprzęcie medycznym, przetwórstwie żywności oraz zastosowaniach chemicznych.

Stal węglowa oferta najlepszy kompromis wytrzymałości, kształtowalności i opłacalności. Odmiany o niskim zawartości węgla (0,05% do 0,25% węgla) łatwo się spawają i kształtują, podczas gdy wyższa zawartość węgla zwiększa twardość i odporność na zużycie. Usługi obróbki metali poprzez walcowanie często wykorzystują stal węglową w zastosowaniach konstrukcyjnych, elementach ciężkiego sprzętu oraz urządzeniach przemysłowych, gdzie priorytetem jest wytrzymałość, a nie odporność na korozję.

Miedź doskonale sprawdza się w zastosowaniach wymagających dobrej przewodności elektrycznej i cieplnej. Niska rezystancja elektryczna czyni ją niezastąpioną w przypadku okablowania, płytek drukowanych i łączników elektrycznych. Antymikrobowe właściwości miedzi czynią ją również wartościową w środowiskach medycznych i gastronomicznych, gdzie kluczowe znaczenie ma czystość.

Mosiądz , stop miedzi i cynku, łączy doskonałą łatwość obróbki skrawaniem z odpornością na korozję oraz atrakcyjnym złotym wykończeniem. Firmy zajmujące się precyzyjną obróbką wykorzystują mosiądz do produkcji dekoracyjnej armatury, elementów instalacji sanitarnych oraz instrumentów muzycznych, gdzie liczą się zarówno funkcjonalność, jak i estetyka.

| Materiał | Typowy zakres grubości | Podstawowe właściwości | Najlepsze zastosowania |

|---|---|---|---|

| Aluminium (5052, 6061) | 0,020" - 0,250" | Lekki, odporny na korozję, doskonała formowalność | Lotnictwo i kosmonautyka, motoryzacja, obudowy elektroniczne |

| Stal nierdzewna (304, 316) | 0,018" - 0,190" | Odporny na korozję, trwały, higieniczny | Urządzenia medyczne, sprzęt do przetwórstwa żywności, przetwórstwo chemiczne |

| Stal węglowa | 0,024" - 0,500" | Wysoka wytrzymałość, opłacalność, nadaje się do spawania | Konstrukcje nośne, maszyny, wyposażenie przemysłowe |

| Miedź | 0,016" - 0,125" | Doskonała przewodność, właściwości przeciwdrobnoustrojowe, kowalny | Komponenty elektryczne, wymienniki ciepła, instalacje rurowe |

| Mosiądz | 0,020" - 0,125" | Obrabialny, odporny na korozję, dekoracyjna powierzchnia | Wyposażenie, elementy złączne, instrumenty muzyczne |

W jaki sposób właściwości materiałów wpływają na wyniki projektu

Wybór materiału wywołuje efekt domina w każdym etapie produkcji. Zrozumienie tych powiązań pozwala zoptymalizować koszty, jakość i wydajność jednocześnie.

Kształtowanie i zachowanie sprężystego odkształcenia różni się znacząco w zależności od materiału. Aluminium łatwo poddaje się formowaniu, ale wykazuje duże odkucie sprężyste, wymagające dokładnej kompensacji kąta gięcia. Stal nierdzewna szybko hartuje się plastycznie podczas kształtowania, co oznacza, że skomplikowane geometrie mogą wymagać operacji wyżarzania pośredniego. Stal węglowa charakteryzuje się przewidywalnymi cechami kształtowania, przez co jest preferowana w produkcji blach z wieloma gięciami.

Uwagi dotyczące cięcia i przetwarzania różni się również. Aluminium cięte jest szybciej przy użyciu lasera i przebijania CNC, ale wymaga starannego usuwania wiórów, aby zapobiec zaciskaniu. Stal nierdzewna wymaga mniejszych prędkości cięcia i specjalistycznego narzędzia, by zapobiec nagrzewaniu się i zmianie koloru krawędzi. Stal węglowa przetwarza się efektywnie, ale wymaga natychmiastowej ochrony powierzchni, aby zapobiec powstawaniu rdzy.

Wpływ kosztów wykraczają poza cenę surowca. Chociaż stal węglowa jest tańsza za kilogram niż stal nierdzewna, ta druga może okazać się bardziej opłacalna, gdy weźmie się pod uwagę brak potrzeby wykańczania oraz dłuższą trwałość. Wyższy koszt materiału aluminiowego często równoważy mniejsza waga przesyłek i krótsze czasy obróbki.

W przypadku precyzyjnych elementów metalowych spójność materiału jest równie ważna co jego rodzaj. Różnice w składzie stopu, utwardzeniu i grubości w ramach jednej partii mogą wpływać na dokładność gięcia i końcowe wymiary. Dlatego dostawcy precyzyjnej obróbki określają certyfikaty materiałów i często testują materiały przychodzące przed rozpoczęciem produkcji.

Gdy zrozumiesz, jak wybór materiału wpływa na procesy dalsze, dokonasz wyborów optymalizujących zarówno koszty natychmiastowej produkcji, jak i długoterminową wydajność komponentów. Kolejnym krokiem jest zrozumienie, w jaki sposób technologie precyzyjnego cięcia i kształtowania przekształcają wybrane materiały w gotowe elementy.

Krok po kroku: analiza procesów precyzyjnej obróbki

Wybrałeś już materiał. Co dzieje się dalej z płaską płytą aluminiową, ze stali nierdzewnej lub ze stali węglowej, zanim stanie się ona gotowym komponentem? Przekształcenie to odbywa się w dokładnie skoordynowanej sekwencji operacji, z których każda przyczynia się do dokładności wymiarowej i jakości definiującej precyzyjną obróbkę metali.

Zrozumienie tej sekwencji pozwala efektywnie komunikować się z wykonawcami, przewidywać potencjalne problemy oraz projektować części, które będą sprawnie przechodzić przez proces produkcyjny. Przejdźmy krok po kroku przez każdy etap — od momentu przybycia surowego materiału aż po wysyłkę gotowego elementu.

- Przygotowanie i weryfikacja materiału: Materiał przychodzący jest sprawdzany pod kątem grubości, wytrzymałości i stanu powierzchni przed rozpoczęciem przetwarzania

- Operacje cięcia: Cięcie laserowe, tłoczenie CNC lub inne metody tworzą płaski kształt części z arkusza

- Kształtowanie i gięcie: Operacje na giętarce prasowej przekształcają płaskie zagotki w trójwymiarowe kształty

- Spajanie i montaż: Spawanie, montaż elementów złącznych lub łączenie mechaniczne łączy wiele komponentów

- Wykończenie: Zadzierzganie, obróbka powierzchniowa i nanoszenie powłok kończą produkcję części

- Inspekcja i pakowanie: Ostateczna weryfikacja jakości zapewnia zgodność przed wysyłką

Każdy etap opiera się na poprzednim. Błąd cięcia przenosi się przez proces formowania. Niedokładne gięcie wpływa na pasowanie podczas montażu. Ta wzajemna zależność wyjaśnia, dlaczego precyzyjna obróbka blach wymaga starannego kontroli procesu na każdym etapie.

Technologie cięcia umożliwiające niewielkie допусki

Cięcie to pierwszy etap wytwarzania elementów z blachy, a wybrana metoda ma bezpośredni wpływ na jakość krawędzi, dokładność wymiarową oraz wymagania związane z dalszymi procesami obróbkowymi. Trzy główne technologie dominują w precyzyjnej obróbce: cięcie laserem, tłoczenie CNC oraz cięcie wodą pod wysokim ciśnieniem.

Cięcie laserowe stało się podstawą precyzyjnej obróbki blach. Zgodnie z informacjami firmy JLC CNC , cięcie laserowe włóknem osiąga tolerancje na poziomie ±0,1 mm dla stali miękkiej o grubości do 3 mm, gdy maszyny są prawidłowo skalibrowane, a operatorzy kompensują dryft cięcia. Skoncentrowana wiązka światła generuje minimalne strefy wpływu cieplnego, czyste krawędzie oraz wyjątkową rozdzielczość detali na złożonych geometriach.

Kiedy należy wybrać cięcie laserowe? Weź pod uwagę następujące zastosowania:

- Złożone wzory i małe elementy wymagające gładkich, bezfazowych krawędzi

- Aluminium, stal nierdzewna oraz materiały odbijające, gdzie jakość krawędzi ma znaczenie

- Produkcja małych i średnich serii, gdzie koszt narzędzi do tłoczenia nie jest uzasadniony

- Elementy wymagające minimalnej obróbki końcowej przed operacjami kształtowania

Wiertarka CNC doskonale sprawdza się, gdy wymagana jest szybkość i opłacalność przy powtarzalnych wzorach otworów i standardowych kształtach. Zmaszyna sterowana komputerowo napędza specjalistyczne wykrojniki przez blachę, tworząc otwory, wycięcia i nacięcia z zadziwiającą spójnością. W przypadku produkcji dużych serii części ze stali konstrukcyjnej o standardowych cechach, toczenie CNC często przewyższa cięcie laserowe pod względem zarówno szybkości, jak i kosztów.

Jednak toczenie CNC wiąże się z pewnymi kompromisami. Spodziewaj się tolerancji około ±0,2 mm, chyba że używasz precyzyjnie szlifowanego narzędzia. Proces mechaniczny może powodować lekkie wgłębienia wokół otworów, a grubość materiału wpływa na minimalny średnicę otworu, jaką można osiągnąć. Jako zasadę należy przyjąć, że średnica otworu nie powinna być mniejsza niż 1,2-krotność grubości materiału, aby zapobiec odkształceniom wykrojnika.

Wycinanie wodne wykorzystuje wodę pod wysokim ciśnieniem mieszанą z cząsteczkami ściernymi do cięcia metalu bez generowania ciepła. Ten proces cięcia na zimno całkowicie eliminuje strefy wpływu cieplnego, co czyni go idealnym dla materiały wrażliwe na ciepło lub zastosowania wymagające niezmienionych właściwości materiału w całym elemencie. Cięcie strumieniem wody radzi sobie z grubymi materiałami, które stanowiłyby wyzwanie dla systemów laserowych, i nie powoduje odkształceń termicznych.

Wady? Cięcie wodą jest wolniejsze niż obróbka laserowa i droższe za każdy cal cięcia. Zastrzegaj tę technologię do sytuacji, w których efekty cieplne są niedopuszczalne lub podczas cięcia materiałów, które słabo reagują na metody cięcia termicznego.

Metody kształtowania i łączenia dla skomplikowanych geometrii

Gdy profil płaski zostanie wycięty, usługi kształtowania blach przekształcają dwuwymiarowe заготовki w trójwymiarowe komponenty. Giętarka mechaniczna pozostaje głównym narzędziem precyzyjnego gięcia, ale wybór techniki i narzędzi decyduje o tym, czy osiągniesz spójne wyniki.

Gięcie powietrzne jest najczęstszą techniką stosowaną przy precyzyjnej pracy. Blacha metalowa gięta jest nad matrycą w kształcie litery V, podczas gdy tłok wywiera siłę z góry. Ta metoda oferuje dużą elastyczność, ponieważ różne kąty można uzyskać za pomocą tego samego narzędzia poprzez po prostu dostosowanie głębokości przebiegu. Nowoczesne numeryczne giętarki wyposażone są w systemy pomiaru kąta, które automatycznie kompensują odbicie materiału, zapewniając stałe kąty gięcia w całym cyklu produkcji.

Jakie czynniki wpływają na dokładność gięcia? Wahań grubości materiału, kierunek ziarna oraz wcześniejsze umocnienie odkształceniem wpływają na zachowanie się materiału pod względem odbicia. Precyzyjni wykonawcy neutralizują te zmienne poprzez inspekcję pierwszego egzemplarza i walidację procesu przed przystąpieniem do pełnej produkcji.

Dociskanie (czasem nazywane koinowanie) zapewnia mniejsze tolerancje niż gięcie powietrzne, w pełni kompresując materiał w gnieździe matrycy. Ta technika minimalizuje zmienność odbicia sprężystego, ale wymaga zestawów tłoków i matryc dopasowanych do każdego kąta gięcia. Dodatkowe narzędzia czynią gięcie dno najbardziej praktycznym rozwiązaniem w zastosowaniach wielkoseryjnych wymagających wyjątkowej spójności.

Po procesie kształtowania większość zespołów wymaga operacji łączenia. Spawanie pozostaje podstawową metodą tworzenia trwałych połączeń w precyzyjnej blacharce:

- Złóżka TIG tworzy najwyższej jakości spoiny z doskonałą kontrolą, co czyni ją preferowaną dla cienkich materiałów i widocznych połączeń, gdzie liczy się wygląd

- Włókno MIG ofaruje szybsze tempo napawania i działa w szerszym zakresie grubości, nadaje się do połączeń konstrukcyjnych, gdzie ważniejsza jest szybkość niż wygląd estetyczny

- Spawanie punktowe tworzy lokalne połączenia poprzez zastosowanie ciśnienia i prądu elektrycznego, powszechnie stosowane w przemyśle motoryzacyjnym i AGD do łączenia nakładających się blach

Każda metoda spawania wprowadza ciepło, które może powodować odkształcenia. Doświadczeni spawacze oraz odpowiednie przyrządy montażowe minimalizują te skutki, jednak projektanci powinni zakładać, że złożone elementy spawane mogą wymagać operacji wyprostowania w celu spełnienia wymagań dotyczących płaskości.

Operacje wykańczające dokończenie ciągu procesów produkcyjnych. Usunięcie zadziorów polega na usunięciu ostrych krawędzi pozostawionych po cięciu i przebijaniu. Przygotowanie powierzchni, takie jak szczotkowanie lub polerowanie w celu uzyskania nadgładkich wykańczeń, przygotowuje części do powlekania. Powlekanie proszkowe, malowanie, chromowanie lub anodowanie zapewniają ochronę przed korozją oraz poprawiają wygląd estetyczny, dostosowany do wymagań danej aplikacji.

Inspekcja jakości obejmuje cały ten ciąg procesów, a nie tylko etap końcowy. Krytyczne wymiary są weryfikowane w trakcie procesu, a kontrola statystyczna procesu monitoruje trendy, które mogą wskazywać na pojawiające się problemy. Takie podejście pozwala wykryć usterki zanim rozprzestrzenią się na kolejne operacje, co zmniejsza koszty odpadów i przeróbek.

Po zrozumieniu procesów wytwarzania kolejnym kluczowym pytaniem jest: jak projektować elementy, które będą skutecznie przechodzić przez te operacje, zachowując jednocześnie precyzję wymaganą przez Twoje zastosowanie?

Wytyczne projektowania pod kątem możliwości produkcji, które oszczędzają czas i pieniądze

Zaprojektowałeś na ekranie wydawałoby się idealny komponent. Geometria jest elegancka, cechy znajdują się dokładnie tam, gdzie powinny, a Twój model 3D wygląda doskonale. Następnie nadchodzi rzeczywistość: Twój precyzyjny dostawca blacharski dzwoni z pytaniami dotyczącymi luzów gięcia, ryzyka odkształcenia otworów oraz cech, których nie można wykonać standardowym narzędziem.

Ten scenariusz rozgrywa się codziennie w całym świecie produkcji. Niezgodność między intencją projektową a rzeczywistością produkcyjną kosztuje firmy tysiące godzin pracy ponownej, opóźnień i uszkodzonych części. Zasady projektowania pod kątem technologii (DFM) likwidują tę lukę, integrując ograniczenia związane z produkcją bezpośrednio w procesie projektowania.

Korzystając z usług precyzyjnego producenta blach, wcześniejsze zrozumienie tych wytycznych przekształca relację z reaktywnego rozwiązywania problemów w proaktywną współpracę. Przyjrzyjmy się kluczowym zasadom, które odróżniają projekty gotowe na płynną produkcję od tych skazanych na kosztowne komplikacje.

Niezbędne zasady DFM dla konstrukcji z blach

Wyobraź sobie blachę jako kawałek tektury. Zginaj ją zbyt ostro, a zewnętrzny brzeg pęknie. Umieść otwór zbyt blisko linii gięcia, a wydłuży się w owal. Te fizyczne ograniczenia wyznaczają podstawowe zasady, których musi przestrzegać każdy projekt indywidualnej produkcji blach.

Podstawy promienia gięcia: Zgodnie z wytycznymi DFM firmy Norck, wewnętrzny promień wygięcia powinien wynosić co najmniej grubość metalu. Zapobiega to pękaniu na zewnętrznej powierzchni, gdzie skupia się naprężenie rozciągające podczas kształtowania. Gdy wszystkie gięcia zaprojektujesz z jednakowym promieniem, producenci mogą używać jednego narzędzia do każdego zagięcia, oszczędzając czas montażu i obniżając koszt pojedynczej części.

Zasady rozmieszczenia otworów: Otwory usytuowane zbyt blisko linii gięcia ulegają rozciąganiu i odkształceniom podczas procesu kształtowania. Prosta zasada? Zachowaj minimalną odległość dwóch grubości materiału między otworem a miejscem gięcia. Dla blachy o grubości 0,060", oznacza to, że otwory powinny znajdować się w odległości co najmniej 0,120" od osi gięcia. To gwarantuje, że Twój komponent idealnie się ześle po raz pierwszy podczas montażu.

Wymagania dotyczące wycięć kompensacyjnych: Gdy zgięcie biegnie wzdłuż płaskiego brzegu, metal ma tendencję do pękania w narożniku. Wycięcia kompensacyjne, małe prostokątne lub okrągłe wycięcia na końcach linii gięcia, zapobiegają temu pękaniu. Jak wspomniano w przewodniku Xometry Pro dotyczącym gięcia, te elementy gwarantują czyste, profesjonalne wykończenie i zapobiegają uszkodzeniom spowodowanym naprężeniami podczas eksploatacji.

Minimalna długość płata Oprzyrządowanie do gięcia na prasie potrzebuje wystarczająco dużo materiału, aby dobrze się przychwycić podczas gięcia. Jeśli płatek jest zbyt krótki, to tak, jakby próbować złożyć malutki skrawek papieru ogromnymi palcami. Upewnij się, że długość płatka wynosi co najmniej czterokrotność grubości materiału. Zbyt krótkie, tzw. "nielegalne" płatki wymagają specjalnego, drogiego oprzyrządowania, co może podwoić koszty produkcji.

Znaczenie kierunku ziarna: Blachy metalowe rozwijają tzw. "włókno" w trakcie procesu walcowania w hucie. Gięcie wzdłuż tego włókna znacznie zwiększa ryzyko pęknięć. Projektuj części tak, aby zginanie odbywało się możliwie poprzecznie do kierunku włókna. Ta ukryta zasada zapobiega uszkodzeniom, które mogą nie ujawnić się przez miesiące po dostawie.

W przypadku niestandardowych projektów z blachy precyzyjnej te zasady stają się jeszcze bardziej kluczowe. Wysokie dokładności nie pozostawiają żadnego marginesu na zmiany wymiarowe spowodowane słabym rozmieszczeniem elementów lub niewystarczającymi wycięciami przy gięciu.

Typowe błędy projektowe zwiększające koszty

Nawet doświadczeni inżynierowie wpadają w pułapki prowadzące do wzrostu kosztów produkcji. Rozpoznanie tych schematów pozwala uniknąć najdroższych błędów przed przesłaniem ofert na produkty z precyzyjnej blachy.

Przeczernianie tolerancji: Określanie ±0,005 cala dla każdego wymiaru, gdy tylko kilka cech rzeczywiście wymaga takiej dokładności, drastycznie zwiększa czas inspekcji i wskaźnik odrzuceń. Zgodnie z Przewodnikiem produkcyjnym ACE , stosowanie tolerancji funkcjonalnych zamiast domyślnego przyjmowania możliwie najściślejszych ograniczeń poprawia wykonywalność i obniża koszty bez kompromitowania wydajności części.

Ignorowanie kompensacji odpружynienia: Metal jest lekko sprężysty. Gdy zostanie wygięty do kąta 90 stopni i zwolniony, naturalnie powraca o 1-3 stopnie, w zależności od materiału i promienia gięcia. Zbyt rygorystyczne trzymanie się tolerancji kątów tam, gdzie nie jest to konieczne, zwiększa czas i koszt kontroli. Dopuszczaj pewien luz w miejscach niemających znaczenia, zachowując ścisłe dopasowanie tam, gdzie faktycznie ma to znaczenie.

Niestandardowe średnice otworów: Określenie otworu o średnicy 5,123 mm oznacza, że producent może być zmuszony do zakupu specjalnego wiertła lub stempla. Stosowanie standardowych średnic otworów (5 mm, 6 mm, 1/4 cala) pozwala na szybkie przebijanie istniejącym narzędziem, co skraca czas realizacji i obniża koszty.

Wąskie wycięcia powodujące odkształcenia: Laserowe cięcie generuje intensywne ciepło. Długie, cienkie językiki lub wąskie szczeliny mogą ulec wygięciu lub skręceniu podczas cięcia. Zachowaj szerokość wąskich wycięć co najmniej 1,5-krotnie większą niż grubość materiału, aby zapewnić płaskość i dokładność.

Nieprawidłowe rozmieszczenie pogłębień stożkowych: Wytłoczenia umieszczone zbyt blisko gięć lub krawędzi powodują odkształcenia, nieprawidłowe dopasowanie lub pęknięcia, szczególnie w cienkich lub twardych materiałach. Zachowaj wystarczający luz od wszystkich uformowanych cech.

Przed przesłaniem plików na precyzyjne cięcie i produkcję blach grubych, przejdź przez tę listę kontrolną DFM:

- Sprawdź, czy wszystkie promienie gięcia spełniają lub przekraczają wymagania dotyczące grubości materiału

- Upewnij się, że osie otworów zachowują minimalną odległość 2x grubość materiału od linii gięcia

- Sprawdź, czy przy wszystkich przecięciach gięcia z krawędzią określono wycięcia kompensacyjne

- Zweryfikuj minimalne długości płetw wynoszące 4x grubość materiału

- Przejrzyj orientację wzdłuż ziarna dla krytycznych gięć

- Zapewnij, że wąskie elementy zachowują minimalną szerokość 1,5x grubość materiału

- Zastosuj funkcjonalne tolerancje: dokładne tam, gdzie są wymagane, standardowe w pozostałych miejscach

- Określ standardowe rozmiary otworów tam, gdzie niestandardowe rozmiary nie są funkcjonalnie konieczne

- Sprawdź luzowania i tolerancje rozmieszczenia luzowań względem uformowanych cech

- Potwierdź, czy wysokości stopni zgięcia Z spełniają minimalne wymagania narzędziowe

Poświęcenie czasu na sprawdzenie tych punktów kontrolnych przed przesłaniem zapobiega korespondencji w tę i z powrotem, która opóźnia projekty i frustruje zarówno projektantów, jak i wytwórców. Twoje elementy płyną gładko przez proces produkcji, koszty pozostają przewidywalne, a Twoje precyzyjne wyroby blacharskie docierają gotowe do montażu, bez niespodzianek.

Zrozumienie zasad DFM jest niezbędne, ale skąd wiedzieć, kiedy obróbka blachy jest właściwą metodą wytwarzania? W następnym rozdziale omówione zostało, kiedy precyzyjna obróbka blachy przewyższa alternatywy, takie jak tłoczenie, odlewanie czy druk 3D.

Wybór między precyzyjną obróbką blachy a alternatywnymi metodami wytwarzania

Musisz wyprodukować element metalowy. Projekt jest gotowy, specyfikacje ustalone, a teraz nadszedł kluczowy moment decyzji: która metoda produkcji zapewni najlepszy kompromis między kosztem, jakością i terminem realizacji w Twojej konkretnej sytuacji? Firmy specjalizujące się w precyzyjnej obróbce blach rywalizują o Twój projekt z tłoczeniem, odlewaniem, kuciem, a nawet drukowaniem metali w technologii 3D. Każda z tych metod ma swoje atuty w różnych warunkach.

Popełnienie błędu w tej decyzji może oznaczać przepłacenie o 50% lub więcej, oczekiwanie tygodniami dłużej niż to konieczne, albo otrzymanie części nie spełniających wymagań jakościowych. Zrozumienie zalet i ograniczeń każdej metody zamienia tę decyzję z strzelania z palca w strategiczne planowanie.

Kiedy obróbka blach jest lepsza niż tłoczenie lub odlewanie

Zacznijmy od najczęstszej porównywalnej metody: precyzyjna obróbka blach versus tłoczenie metalu. Obie procesy kształtują materiał w postaci blachy, ale służą fundamentalnie różnym scenariuszom produkcyjnym.

Wyciąganie Metalu używa dedykowanych matryc pod wysokim ciśnieniem do szybkiego formowania części. Zgodnie z Aero Metals , tłoczenie pozwala na szybkie wytwarzanie części, gdy narzędzia są już gotowe, ale oferuje ograniczoną elastyczność pod względem kształtu i grubości. Im większa złożoność, tym więcej dodatkowych komponentów trzeba dodać, co znacząco podnosi koszty.

Kiedy przemysłowe gięcie blachy sprawdza się lepiej niż tłoczenie? Rozważ następujące scenariusze:

- Niskie do średnich serie: Koszt matryc do tłoczenia wynosi od 10 000 do ponad 500 000 USD, w zależności od złożoności. Te koszty opłacalne są jedynie przy produkcji tysięcy lub milionów sztuk. Dla partii poniżej 1000 sztuk precyzyjne gięcie całkowicie eliminuje konieczność inwestycji w narzędzia

- Elastyczność projektowania: Potrzeba zmodyfikować wymiar lub dodać element? W przypadku gięcia aktualizujesz plik CAD. W przypadku tłoczenia musisz zmodyfikować lub wymienić drogie narzędzia

- Złożone geometrie: Głębokie tłoczenie, wiele kierunków gięcia oraz zintegrowane funkcje często wymagają wielu operacji tłoczenia lub oddzielnych zespołów. Gięcie obsługuje tę złożoność w jednej sekwencji ustawienia

- Skrócone terminy realizacji: Wykonanie narzędzi tłoczarskich trwa od 8 do 16 tygodni. Usługi obróbki metali mogą dostarczyć pierwsze sztuki w ciągu kilku dni

Tłoczenie wygrywa zdecydowanie w produkcji wielkoseryjnej. Gdy koszty narzędzia zostaną rozłożone na ponad 50 000 sztuk, cena pojedynczej jednostki znacząco spada poniżej cen obróbki. Jednak ten punkt przełomowy zależy od stopnia skomplikowania i wielkości elementu.

FORMOWANIE przedstawia inną porównywalność. Zgodnie z Tuckey Metal Fabricators, odlewanie polega na wlewaniu stopionego metalu do form w celu tworzenia skomplikowanych kształtów dla produkcji masowej. Jest to jedna z bardziej elastycznych metod, zdolna do kształtowania stali, żelaza, miedzi, aluminium oraz innych metali.

Wybierz dużą obróbkę metali zamiast odlewania, gdy:

- Grubość ścianek ma znaczenie: Blachy łatwo osiągają grubość ścianek 0,030", która byłaby problematyczna w odlewnictwie

- Wykańczanie powierzchni jest kluczowe: Elementy wytworzone przez obróbkę charakteryzują się czystymi powierzchniami gotowymi do wykończenia, podczas gdy odlewy zazwyczaj wymagają intensywnej obróbki skrawaniem, aby osiągnąć porównywalną gładkość

- Właściwości materiału są najważniejsze: Blachy kute oferują lepsze właściwości mechaniczne w porównaniu z odlewanymi odpowiednikami z tego samego stopu

- Redukcja masy jest kluczowa: Konstrukcje blachowe mogą być projektowane z strategicznym rozmieszczeniem materiału, unikając pełnych przekrojów, które często wymagają odlewy

Odlewanie doskonale nadaje się do skomplikowanych trójwymiarowych kształtów, których nie dałoby się wytworzyć z płaskiego materiału, szczególnie bloki silników, obudowy pomp oraz dekoracyjne elementy architektoniczne.

Druk 3D metalowy reprezentuje nowego, najnowszego konkurenta. Zgodnie z porównaniem produkcji firmy Norck, wytwarzanie przyrostowe umożliwia projektowanie geometrii, takich jak struktury mikropodporowe i kanały przepływu wewnętrzne, które nie są możliwe przy użyciu tradycyjnych technik.

Jednak inżynieria spawania i gięcia metali zazwyczaj przewyższa druk 3D w zakresie:

- Opłacalność: metalowe części drukowane metodą 3D pozostają 5–20 razy droższe niż odpowiedniki wykonane metodą konwencjonalną dla większości geometrii

- Asortyment materiałów: Chociaż druk 3D działa z określonymi stopami proszkowymi, dostawcy ogólnych usług obróbki blach pracują praktycznie z każdym gatunkiem blachy metalowej

- Jakość powierzchni: Części drukowane wymagają intensywnego wykańczania, aby osiągnąć jakość powierzchni, jaką zapewniają części wytworzone metodą blacharską już w trakcie produkcji

- Możliwości rozmiarowe: Wymiary części drukowanych są ograniczone przez objętość budowy, podczas gdy blacha nie ma praktycznych ograniczeń wielkości

Zastrzegaj druk metalu w 3D dla rzeczywiście złożonych geometrii wewnętrznych, scalonych zespołów wieloelementowych lub specjalistycznych stopów niedostępnych w formie blachy

Uwagi dotyczące ilości sztuk przy doborze metody

Ilość produkcji decyduje o wyborze metody wytwarzania bardziej niż jakikolwiek inny czynnik. Każda metoda ma swój ekonomiczny punkt optymalny, w którym zapewnia najlepszą wartość

Prototypowanie (1–10 sztuk): Precyzyjna obróbka blach dominuje w tym zakresie. Brak potrzeby inwestycji w formy, szybki czas realizacji oraz elastyczność w iteracjach projektowych czynią ją najbardziej oczywistym wyborem. Druk metalu w 3D może konkurować w przypadku geometrii, których nie da się wykonać z blachy, ale przy znacznie wyższych kosztach jednostkowych

Niska seria (10–500 sztuk): Wytwarzanie pozostaje optymalne. Brak kosztów form sprawia, że cena za sztukę pozostaje konkurencyjna, a programowanie CNC szybko się amortyzuje nawet przy małych partiach. Ten zakres stanowi rdzeń rynku usług blacharskich skoncentrowanych na precyzyjnej pracy.

Średnia seria (500–5 000 sztuk): To strefa decyzyjna. Proste elementy z powtarzalnymi cechami mogą uzasadniać inwestycję w formy tłocznikowe. Złożone detale wymagające wielu operacji są zazwyczaj opłacalniejsze przy produkcji blacharskiej. Szczegółowe wyceny od dostawców zarówno blacharstwa, jak i tłoczenia pokazują rzeczywisty punkt przejścia dla Twojego konkretnego projektu.

Duża seria (5 000+ sztuk): Koszty tłoczenia i odlewnictwa stają się atrakcyjne. Koszty narzędziowe rozłożone na duże ilości znacząco obniżają cenę jednostkową. Jednak produkcja blacharska nadal obsługuje ten segment rynku w przypadku złożonych zespołów, materiałów specjalnych oraz produktów wymagających ciągłej elastyczności projektowej.

| Metoda produkcji | Optymalny zakres wielkości produkcji | Możliwości złożoności | Typowy czas realizacji | Struktura kosztów |

|---|---|---|---|---|

| Precyzyjna obróbka blachy | 1 – 5 000 sztuk | Wysoki: wiele gięć, spawane zespoły, ciasne tolerancje | 1–4 tygodnie (nie wymagane formy) | Niskie koszty uruchomienia, umiarkowane koszty sztuka |

| Wyciąganie Metalu | 5 000 - 1 000 000+ sztuk | Umiarkowana: ograniczona przez złożoność formy i grubość materiału | 10-20 tygodni (w tym przygotowanie narzędzi) | Duża inwestycja w narzędzia, niskie koszty sztuka przy dużych nakładach |

| Odlewanie (precyzyjne/formowe) | 500 - 100 000+ sztuk | Bardzo wysoka: złożone kształty 3D, wnęki wewnętrzne | 8-16 tygodni (w tym przygotowanie narzędzi) | Umiarkowane-wysokie koszty narzędzi, niskie koszty sztuka przy dużych nakładach |

| Druk 3D metalowy | 1 - 500 sztuk | Skrajne: kratownice, kanały wewnętrzne, zestawy skonsolidowane | 1-3 tygodnie (bez potrzeby wykonywania narzędzi) | Brak narzędzi, wysoka cena za sztukę |

| Wyroby szlachetne | 1 000 - 100 000+ sztuk | Niska-umiarkowana: bryły stałe, wymaga drugiego etapu obróbki | 12-24 tygodnie (w tym czas na wykonanie narzędzi) | Bardzo wysokie koszty narzędzi, niskie koszty jednostkowe przy dużych seriach |

Zrozumienie tych aspektów ekonomicznych pozwala od początku wybrać odpowiedniego partnera produkcyjnego. Ogólny dostawca usług blacharskich może prowadzić projekt od prototypowania przez produkcję średnich serii, podczas gdy programy o dużej wielkości mogą z czasem przejść na tłoczenie lub odlewanie, gdy projekt się ustabilizuje, a liczba sztuk wzrośnie.

Porównanie metod wyjaśnia, kiedy precyzyjna obróbka blachy ma sens. Jednak w ramach poszczególnych branż specyficzne wymagania dodają kolejny poziom złożoności. Jakie tolerancje są wymagane w aplikacjach lotniczych? Jakie certyfikaty są konieczne w produkcji urządzeń medycznych? W następnym rozdziale omówione zostaną sposoby, w jakie branżowe potrzeby kształtują wymagania dotyczące precyzyjnej obróbki.

Zastosowania przemysłowe i specjalistyczne wymagania

Każdy komponent opowiada historię o tym, dokąd zmierza i jakie obciążenia musi wytrzymać. Uchwyt przeznaczony do samolotu staje przed zupełnie innymi wymaganiami niż ten, który trafi do aparatu MRI w szpitalu lub do obudowy akumulatora pojazdu elektrycznego. Zrozumienie, jak usługi precyzyjnej obróbki blachy dostosowują się do branżowych wymagań, pomaga skutecznie przekazywać swoje potrzeby i wybierać dostawców wyposażonych odpowiednio dla danej branży.

Co odróżnia typową warsztat od zakładu obsługującego branże regulowane? Certyfikaty, śledzenie materiałów, protokoły inspekcji oraz możliwości dokumentacyjne różnią się w zależności od wymagań końcowego zastosowania. Przyjrzyjmy się, jak główne branże wykorzystują precyzyjną obróbkę blachy i jakie specjalistyczne kompetencje każda z nich wymaga.

Zastosowania w motoryzacji i transporcie

Sektor motoryzacyjny zużywa ogromne ilości precyzyjnych komponentów z blachy. Od konstrukcyjnych elementów podwozia po ozdobne listwy, pojazdy zawierają setki wyprodukowanych części wymagających spójnej jakości w całych seriach produkcyjnych.

Według Przewodnik Geomiq dotyczący produkcji , precyzyjnie wyprodukowane blachy karoserii, elementy szkieletu i ram zapewniają integralność konstrukcyjną, zmniejszają wagę pojazdu oraz zwiększają bezpieczeństwo. Samochody zawierają liczne części ze stali cienkolistnej, w tym blachy karoserii, błotniki boczne, podłogi, szyny ramy, osłony kół, uchwyty i płyty montażowe. Elementy te muszą być wystarczająco dokładne, aby umożliwić bezproblemową montaż.

Zastosowania motoryzacyjne zazwyczaj wymagają:

- Certyfikat IATF 16949: Ten specyficzny dla branży motoryzacyjnej standard zarządzania jakością opiera się na ISO 9001 i obejmuje dodatkowe wymagania dotyczące zapobiegania wadom oraz ciągłej poprawy

- Dokumentacja PPAP: Dokumentacja Procesu Zatwierdzania Części Produkcji (PPAP) potwierdza, że procesy produkcji konsekwentnie wytwarzają części spełniające specyfikacje

- Stabilność produkcji dużych serii: Części muszą zachować dokładność wymiarową w tysiącach lub milionach sztuk

- Śledzenie materiałów: Kompletna dokumentacja łącząca gotowe części z konkretnymi partiami materiału wspiera zarządzanie reklamacjami

Niestandardowe zespoły metalowe do pojazdów elektrycznych stwarzają nowe wyzwania. Obudowy baterii wymagają wyjątkowego kontroli wymiarów, aby chronić wrażliwe ogniwa oraz zarządzać wymaganiami termicznymi. Lekka konstrukcja z aluminium zmniejsza wagę pojazdu, wydłużając zasięg bez utraty ochrony przed zderzeniami.

Wymagania dokładności w sektorze lotniczym i obronnym

Gdy awaria nie wchodzi w grę, produkcja elementów lotniczych wymaga najbardziej rygorystycznych kontroli jakości w procesie wytwarzania. Komponenty lecące na wysokości 35 000 stóp lub podróżujące w przestrzeń kosmiczną są narażone na ekstremalne wahania temperatury, drgania i cykle naprężeń, które ujawniają każdy defekt produkcji.

Geomiq zauważa, że precyzyjna produkcja blach stalowych ma kluczowe znaczenie dla zapewnienia, że blacha kadłuba rakiety jest projektowana i formowana zgodnie z bardzo konkretnymi wymiarami, co poprawia aerodynamikę, wagę, integralność strukturalną i efektywność. Odchylenia i błędy mogą mieć poważne skutki, w tym problemy z aerodynamiką, przegrzewanie, wysokie zużycie paliwa oraz uszkodzenia mechaniczne pod wpływem obciążeń.

Zastosowania w przemyśle lotniczym wymagają:

- Certyfikat AS9100: Według Geater Machining , AS9100 jest standardem certyfikacyjnym dla organizacji zajmujących się projektowaniem, produkcją i instalacją produktów lotniczych. Opiera się na wymaganiach ISO 9001, ale obejmuje dodatkowe specyfikacje charakterystyczne dla przemysłu lotniczego

- Inspekcja pierwszego wyrobu (FAI): Kompleksowa weryfikacja wymiarów próbek z początkowej produkcji zgodnie z specyfikacjami technicznymi

- Zgodność z ITAR: Elementy związane z obronnością wymagają rejestracji zgodnie z przepisami International Traffic in Arms Regulations regulującymi eksport i przekazanie technologii wojskowej

- Przetwarzanie materiałów specjalistycznych: Tytan, Inconel oraz stopy aluminium o klasie lotniczej wymagają specyficznych narzędzi i parametrów przetwarzania

Usługi metalowych wyrobów gotowych dla przemysłu lotniczego zapewniają kompleksową dokumentację na każdym etapie produkcji. Każdy numer partii materiału, parametr procesu i wynik kontroli staje się częścią trwałego rekordu, zapewniającego śledzenie komponentów przez cały okres ich eksploatacji.

Wymagania dokładności w medycynie i elektronice

Branża urządzeń medycznych działa w oparciu o jedne z najbardziej rygorystycznych standardów bezpieczeństwa w przemyśle. Zdaniem Pinnacle Precision, gdy nawet najmniejszy błąd może mieć poważne konsekwencje dla zdrowia i bezpieczeństwa pacjenta, precyzyjna obróbka blach odgrywa kluczową rolę w produkcji wysoce niezawodnych i bezpiecznych urządzeń medycznych.

Zastosowania medyczne stawiają wyjątkowe wymagania:

- Biokompatybilność: Komponenty mające kontakt z pacjentami muszą być wykonane z materiałów kompatybilnych z tkanką ludzką, zazwyczaj ze stali nierdzewnej lub tytanu

- Odporność na korozję: Częste procedury sterylizacji narażają urządzenia na surowe warunki, wymagające powłok, które zachowują swoje właściwości przez tysiące cykli

- Certyfikat ISO 13485: Ten międzynarodowy standard określa wymagania dotyczące systemów zarządzania jakością w zakresie projektowania, produkcji, magazynowania, instalacji i serwisowania urządzeń medycznych

- Zero-defektowa tolerancja: Każda niedoskonałość w procesie produkcyjnym może mieć poważne konsekwencje dla bezpieczeństwa pacjenta

Przykłady precyzyjnych komponentów ze blachy stosowanych w medycynie to obudowy instrumentów chirurgicznych, osłony urządzeń diagnostycznych, ramy łóżek szpitalnych, stoły lecznicze oraz ochronne obudowy dla wrażliwego elektronicznego sprzętu monitorującego.

Zastosowania w elektronice wymagają podobnej precyzji, ale kładą nacisk na inne cechy. Geomiq podkreśla, że precyzyjna obróbka blach pozwala tworzyć lekkie, estetycznie wykończone obudowy i osłony do laptopów, komputerów stacjonarnych, telefonów komórkowych oraz innych urządzeń elektronicznych użytkownika.

Wytwarzanie elementów elektronicznych koncentruje się na:

- Ochrona przed EMI/RFI: Obudowy muszą blokować zakłócenia elektromagnetyczne, zapewniając jednocześnie odpowiednie uziemienie

- Zarządzanie cieplne: Funkcjach odprowadzania ciepła, w tym żebrowaniach, otworach wentylacyjnych oraz powierzchniach montażowych do komponentów chłodzących

- Ścisłe tolerancje estetyczne: Powierzchnie widoczne dla użytkownika końcowego wymagają spójnego wyglądu w całym cyklu produkcji

- Złożone zespoły: Integracja wielu komponentów, elementów hardware’owych oraz cech mechanicznych

Sprzęt i maszyny przemysłowe

Zastosowania przemysłowe obejmują szeroki zakres, od małych obudów paneli sterowania po ogromne ramy konstrukcyjne. To, co je łączy, to wymóg trwałości, dokładności wymiarowej niezbędnego do montażu oraz opłacalności przy różnej wielkości produkcji.

Według Geomiq precyzyjna obróbka blach jest niezbędna w urządzeniach i maszynach przemysłowych, aby tworzyć dokładne części umożliwiające bezproblemowy montaż oraz funkcjonalne, niezawodne i trwałe systemy. Komponenty ze stali w systemach automatycznych wymagają precyzyjnej obróbki, by zagwarantować funkcjonalność i bezpieczne współdziałanie z innymi elementami.

Typowe zastosowania przemysłowe to:

- Wykonanie ram metalowych: Podpory konstrukcyjne dla maszyn, systemów przenośników i sprzętu do transportu materiałów

- Obudowy elektryczne: Obudowy ocenione zgodnie z normą NEMA chroniące elementy sterujące przed wpływami środowiska zewnętrznego

- Osłony i pokrywy: Bezpieczne obudowy spełniające wymagania OSHA dotyczące ruchomych maszyn

- Zawiasy i płyty montażowe: Komponenty interfejsowe łączące podsystemy w ramach większych zespołów

Wytwarzanie przemysłowe często podkreśla aspekty praktyczne, a nie ekstremalną precyzję wymaganą w pracach lotniczych lub medycznych. Jednak spójność pozostaje kluczowa, gdy elementy muszą być montowane w sposób przewidywalny w różnych lokalizacjach klientów.

Zrozumienie wymagań branżowych pomaga ocenić, czy potencjalni partnerzy produkcyjni posiadają certyfikaty, sprzęt i doświadczenie potrzebne do realizacji projektu. Ale jak przetłumaczyć wymagania projektowe na realistyczne harmonogramy? W następnej sekcji omówione zostaną typowe czasy realizacji oraz czynniki wpływające na harmonogram projektu.

Harmonogramy projektów i oczekiwane czasy realizacji

Kiedy dotrą Twoje części? To pozornie proste pytanie rzadko ma jednoznaczną odpowiedź. Projekty precyzyjnej obróbki blach obejmują wiele etapów, z których każdy charakteryzuje się własnymi zmiennymi czasowymi. Zrozumienie tych etapów pozwala ustalić realistyczne oczekiwania i skutecznie zaplanować harmonogram produkcji.

Nie ważne, czy rozwijasz prototyp do weryfikacji, czy przygotowujesz się do pełnej produkcji, proces od pierwszego kontaktu po dostarczone elementy przebiega zgodnie z przewidywalną kolejnością. Przeanalizujmy, co dzieje się na każdym etapie i ile czasu powinien on zająć.

Typowe harmonogramy od oferty do dostawy

Harmonogram Twojego projektu rozpoczyna się w momencie wysłania wniosku o ofertę (RFQ). Zgodnie z H&S Manufacturing , sam proces wyceny obejmuje kilka kroków: weryfikację zgłoszenia, rejestrowanie, przegląd zakresu prac, szacowanie materiałów, przegląd specyfikacji oraz dyskusję dotyczącą marży, zanim końcowa propozycja dotrze do Ciebie.

Większość precyzyjnych wytwórców zwraca oferty w ciągu 24–72 godzin dla standardowych projektów. Złożone zespoły lub specjalistyczne materiały mogą wymagać dodatkowej analizy technicznej, co wydłuża ten okres do 5–7 dni roboczych.

Po zatwierdzeniu oferty rzeczywiste terminy produkcji znacząco różnią się w zależności od typu projektu. Zgodnie z danymi Fathom Manufacturing, typowe czasy dostawy wahają się od 2 dni dla prostych płaskich elementów do 4-6 tygodni dla złożonych komponentów wymagających oprzyrządowania:

| Faza projektu | Prototyp (1-25 sztuk) | Mała seria (25-500 sztuk) | Duża seria (500+ sztuk) |

|---|---|---|---|

| Ofertowanie i przegląd | 1-3 Dni | 2-5 dni | 5-10 dni |

| Przegląd inżynieryjny/analiza DFM | 1-2 dni | 2-5 dni | 5-10 dni |

| Zakup Materiałów | 1-5 dni (jeśli nie ma na stanie) | 3-10 Dni | 5-15 Dni |

| Produkcja | 2-8 dni | 5-15 Dni | 10-25 dni |

| Wykończenie/operacje wtórne | 1-5 dni | 3-7 dni | 5-10 dni |

| Inspekcja i pakowanie | 1 dzień | 1-3 Dni | 2-5 dni |

| Szacowany całkowity czas realizacji | 1-3 tygodnie | 2-5 tygodni | 4-10 tygodni |

Te zakresy zakładają użycie standardowych materiałów i procesów. Dostawca usług kontraktowych z zakresu blacharstwa może skrócić czas realizacji dla powtarzanych zamówień, w przypadku których programowanie i oprzyrządowanie już istnieją.

Czynniki wpływające na harmonogram projektu

Dlaczego terminy realizacji tak bardzo się różnią? Kilka czynników może przyspieszyć lub wydłużyć harmonogram Twojego projektu, a ich zrozumienie pozwala lepiej zaplanować pracę.

Kompletność dokumentacji: Przekazanie rysunków gotowych do produkcji z kompletnymi specyfikacjami eliminuje potrzebę wielokrotnych doprecyzowań. Zgodnie z informacjami H&S Manufacturing, dostarczenie od początku modeli 3D CAD, specyfikacji technicznych oraz jasnych wymagań dotyczących dostawy znacząco skraca czas oczekiwania.

Dostępność materiałów: Typowe materiały, takie jak stal nierdzewna 304 lub aluminium 5052, są zwykle dostępne w ciągu kilku dni. Specjalistyczne stopy lub nietypowe grubości mogą wymagać 2-4 tygodni na zamówienia hutnicze. Twój precyzyjny wykonawca może doradzić w zakresie czasu dostawy materiałów podczas przygotowywania oferty.

Złożoność projektu: Elementy wymagające wielu operacji kształtowania, złożenia spawanego lub ciasnych tolerancji potrzebują dodatkowego czasu na przygotowanie i kontrolę. Proste płaskie elementy ze standardowymi otworami mogą zostać wysłane w ciągu kilku dni, podczas gdy skomplikowane obudowy z wyposażeniem i wykończeniem zajmują tygodnie.

Wymagania dotyczące wykończenia: Procesy po obróbce dodają czasu. Lakierowanie proszkowe zwykle dodaje 3–5 dni. Powlekanie może wymagać 5–10 dni w zależności od dostawcy. Planowanie tych operacji wtórnych zapobiega niespodziankom w harmonogramie.

Pojemność kontraktowej obróbki: Obciążenie warsztatu wpływa na dostępność. W okresach szczytowych nawet doświadczeni wykonawcy mogą podać dłuższe czasy realizacji. Budowanie relacji z wiarygodnymi dostawcami pomaga zapewnić priorytetowe terminy, gdy są potrzebne.

W przypadku dużych projektów blacharskich rozważ strategie dostawy etapowej. Otrzymanie najpilniejszych komponentów jako pierwszych pozwala rozpocząć montaż, podczas gdy pozostałe części kończą proces obróbki. Takie podejście skraca całkowity harmonogram projektu bez konieczności ponoszenia opłat za przyspieszoną realizację.

Zrozumienie realistycznych harmonogramów pozwala na ustalenie odpowiednich oczekiwań. Jak jednak znaleźć partnerów produkcyjnych, którzy będą systematycznie dotrzymywać tych terminów, utrzymując jednocześnie wysoką jakość? W następnej sekcji przedstawiono ramy oceny i wyboru dostawców precyzyjnej blachowni.

Jak ocenić i wybrać dostawcę precyzyjnej blachowni

Zdefiniowałeś wymagania projektowe, wybrałeś materiały oraz rozumiesz procesy produkcyjne. Nadchodzi decyzja, która zadecyduje o powodzeniu lub niepowodzeniu Twojego projektu z zakresu precyzyjnej blachowni: wybór odpowiedniego partnera produkcyjnego. Skoro setki dostawców usług obróbki metalu twierdzą, że posiadają kompetencje w zakresie precyzji, jak odróżnić rzeczywistą wiedzę specjalistyczną od czystej reklamy?

Odpowiedź tkwi w systematycznej ocenie. Zamiast wybierać wyłącznie według ceny, doświadczeni specjaliści ds. zakupów oceniają dostawców pod wieloma kryteriami: możliwości techniczne, systemy jakości, wsparcie inżynieryjne oraz szybkość reakcji w komunikacji. Takie podejście pozwala wyłonić partnerów oferujących stabilną jakość i uniknąć tych, których ograniczenia ujawniają się dopiero po zaistnieniu problemów.

Przeanalizujmy konkretne kryteria, które odróżniają najlepsze firmy zajmujące się obróbką metali w USA od tych, które jedynie spełniają minimalne wymagania.

Kluczowe certyfikaty i normy jakości do sprawdzenia

Certyfikaty stanowią niezależne potwierdzenie, że producent utrzymuje udokumentowane systemy jakości. Zgodnie z Hartford Technologies, certyfikaty jakości świadczą o zaangażowaniu producenta wobec klienta i swojej profesji, umożliwiają produkcję wysokiej klasy komponentów oraz dodatkowe gwarancje dla nabywców, że wyprodukowane elementy spełniają wszystkie wymagania.

Które certyfikaty mają znaczenie dla Twojego zastosowania? Odpowiedź zależy od branży:

ISO 9001 reprezentuje powszechną podstawę. Ten certyfikat potwierdza, że produkty lub usługi organizacji spełniają oczekiwania klientów oraz wymagania regulacyjne. Prawie wszyscy poważni wydajni producenci precyzyjnych elementów metalowych utrzymują certyfikat ISO 9001 jako minimalną kwalifikację.

IATF 16949 jest niezbędny w zastosowaniach motoryzacyjnych. Zgodnie z Hartford Technologies, ten globalny standard zarządzania jakością rozwija wymagania ISO 9001 i obejmuje dodatkowe aspekty związane z projektowaniem produktów, procesami produkcyjnymi, doskonaleniem oraz specyficznymi wymaganiami klientów. Gwarantuje zgodność z rygorystycznymi przepisami branżowymi, poprawia jakość produktu i stawia na pierwszym miejscu satysfakcję klienta. Dostawcy tacy jak Shaoyi (Ningbo) Metal Technology wykazują te kompetencje poprzez certyfikat IATF 16949 połączony z kompleksowym wsparciem DFM oraz bardzo krótkimi terminami prototypowania, wynoszącymi nawet 5 dni.

AS9100 służy aplikacjom lotniczym z dodatkowymi wymaganiami wykraczającymi poza ISO 9001, specyficznymi dla bezpieczeństwa i niezawodności lotniczej. Jeśli Twoje komponenty latają, Twój producent musi posiadać to certyfikat.

ISO 13485 dotyczy produkcji urządzeń medycznych i zapewnia, że wszystkie urządzenia medyczne są projektowane i wytwarzane z myślą o bezpieczeństwie poprzez rygorystyczne kontrole i dokumentację.

Poza certyfikatami należy sprawdzić, czy producenci utrzymują solidne wewnętrzne procesy jakościowe. Zgodnie z przewodnikiem produkcyjnym TMCO, solidna ramy jakości obejmują inspekcję pierwszego egzemplarza, kontrolę wymiarów w trakcie produkcji, sprawdzanie jakości spoin i testowanie konstrukcji, końcową inspekcję oraz weryfikację wydajności, a także wykorzystywanie maszyn pomiarowych z pomiarem współrzędnościowym (CMM).

Ocenianie wsparcia inżynierskiego i możliwości DFM

Listy wyposażenia ukazują tylko część rzeczywistości. To, co odróżnia ekspertów odlewni metali od podstawowych warsztatów, to wsparcie inżynierskie oferowane przed rozpoczęciem produkcji.

Według Przewodnik zakupowy Southern Metalcraft , dobrzy dostawcy nie tylko dostarczają części; współpracują, aby Twoje produkty były lepsze i bardziej opłacalne. Szukaj partnerów gotowych do angażowania się w inżynierię zwiększającą wartość – pracujących razem z Tobą, by znaleźć sposoby na poprawę możliwości produkcji i obniżenie kosztów.

TMCO podkreśla ten aspekt: udana produkcja nie zaczyna się od maszyny, lecz od etapu projektowania. Niezawodny wytwórca będzie współpracował z Tobą już na wczesnym etapie procesu, przeglądając rysunki, pliki CAD, tolerancje oraz wymagania funkcjonalne. Wiele projektów korzysta z wskazówek dotyczących projektowania pod kątem technologii (DFM), które pomagają dopracować konstrukcje w celu osiągnięcia opłacalnej produkcji bez kompromitowania wydajności.

Oceniając usługi precyzyjnej obróbki, zadaj potencjalnym partnerom następujące pytania:

- Czy oferujecie wsparcie CAD/CAM? Możliwość pracy z Twoimi rodzimymi formatami plików oraz proponowanie modyfikacji przyspiesza realizację projektów

- Jaki jest czas realizacji oferty? Szybcy wytwórcy, tacy jak Shaoyi, przygotowują wyceny w ciągu 12 godzin, umożliwiając szybsze podejmowanie decyzji

- Czy oferujesz usługi prototypowania? Możliwość produkcji próbek weryfikacyjnych przed przystąpieniem do produkcji seryjnej zmniejsza ryzyko

- Jakie informacje zwrotne DFM udzielacie? Proaktywne sugestie ułatwiające produkcję przy zachowaniu funkcjonalności wskazują na wysoki poziom inżynieryjny

- Jak radzicie sobie ze zmianami projektu? Elastyczność w wprowadzaniu modyfikacji bez nadmiernych opóźnień czy kosztów świadczy o dojrzałości procesu

W zastosowaniach motoryzacyjnych wymagających precyzyjnej obróbki metalu i szybkiej iteracji należy ocenić, czy dostawcy potrafią szybko dostarczyć części prototypowe. Na przykład pięciodniowa zdolność do szybkiego prototypowania firmy Shaoyi umożliwia cykle weryfikacji projektu, które u wolniejszych dostawców trwałyby tygodniami.

Ocena sprzętu i możliwości własnych

Według TMCO, nie wszystkie warsztaty wykrojno-spawalnicze oferują ten sam poziom możliwości. Niektóre jedynie tną metal, podczas gdy inne zlecają na zewnątrz obróbkę, wykańczanie lub montaż – co może prowadzić do opóźnień, luki w komunikacji oraz niestabilnej jakości. Oferujące pełen zakres usług, zintegrowane zakłady upraszczają cały proces w jednym miejscu, zapewniając lepszą kontrolę nad produkcją, szybsze czasy realizacji i stabilne standardy jakości.

Kluczowe możliwości, które należy zweryfikować, to:

- Systemy cięcia laserowego, plazmowego lub strumieniowo-wodnego

- Możliwości toczenia i frezowania CNC

- Precyzyjne kształtowanie i gięcie na prasach hamulcowych z pomiarem kąta

- Spawanie TIG/MIG oraz spawanie robotyczne dla zapewnienia spójności

- Malowanie proszkowe, anodowanie lub inne opcje wykończenia

- Wsparcie montażu i testowania

Przewodnik zakupowy firmy Southern Metalcraft podkreśla, że choć starsze urządzenia mogą wciąż być skuteczne, nowoczesna maszynaria i oprogramowanie oferują znaczące zalety. Proces stosowany przez dostawcę jest ważniejszy niż lista jego urządzeń — należy zawsze odwiedzić zakłady, aby ocenić, jak są one utrzymywane i wykorzystywane.

Komunikacja i podejście partnerskie

Możliwości techniczne są ważne, ale dynamika relacji decyduje o długoterminowym sukcesie. Zdaniem Southern Metalcraft podstawą każdej silnej relacji z dostawcą jest jasna, spójna komunikacja oraz zaangażowanie w realizację zobowiązań.

Oceń szybkość reakcji w zakresie komunikacji podczas procesu ofertowego. Jak szybko odpowiadają na zapytania? Czy zadają pytania doprecyzowujące, które pokazują zrozumienie Twoich wymagań? Poziom zaangażowania podczas ofertowania przeważnie przewiduje jakość wykonywania prac w trakcie produkcji.

TMCO zauważa, że idealnym partnerem jest ten, który potrafi wspierać zarówno obecne potrzeby, jak i przyszły rozwój. Firma zajmująca się obróbką blach musi być w stanie skalować produkcję od prototypów do pełnych serii, nie rezygnując przy tym z jakości. Przejrzysta komunikacja zapewnia jasne harmonogramy, aktualizacje projektu oraz realistyczne oczekiwania.

Lista kontrolna oceny dostawcy

Zanim wybierzesz partnera w zakresie precyzyjnej obróbki metalu, sprawdź te kluczowe elementy:

- Certyfikaty: Potwierdź aktualne certyfikaty ISO 9001 oraz branżowe certyfikaty specyficzne (IATF 16949, AS9100, ISO 13485) istotne dla Twojego zastosowania

- Możliwości urządzeń: Zweryfikuj możliwość wykonania cięcia laserowego, gięcia CNC, spawania i wykańczania we własnym zakresie, aby uniknąć opóźnień związanych z outsourcingiem

- Wsparcie inżynieryjne: Potwierdź możliwości CAD/CAM, procesy przeglądu DFM oraz usługi prototypowe

- Systemy jakości: Zapytaj o inspekcję pierwszego sztucznika, kontrolę bieżącą, dostępność maszyn pomiarowych CMM oraz praktyki dokumentacyjne

- Szybkość reakcji na zapytania ofertowe: Oceń czas realizacji oraz kompletność ofert kalkulacyjnych

- Źródło Materiałów: Zrozum strategię odporności łańcucha dostaw i zdolność do pozyskiwania materiałów specjalistycznych

- Skalowalność: Potwierdź możliwość skalowania produkcji od prototypów do wielkich serii

- Zasady komunikacji: Oceń szybkość reakcji, przejrzystość i chęć udzielania informacji o postępach projektu

- Odwołania: Poproś o studia przypadków lub kontakty z podobnych aplikacji w Twojej branży

- Wycieczka po obiekcie: Jeśli to możliwe, odwiedź obiekt, aby zaobserwować organizację, stan sprzętu oraz zaangażowanie pracowników

Doświadczony zakupowy z Southern Metalcraft podsumowuje filozofię doboru: wybór odpowiedniego partnera w dziedzinie gięcia blach to coś więcej niż tylko cena czy lista wyposażenia. Chodzi o budowanie relacji opartej na zaufaniu, komunikacji i wspólnych celach. Gdy znajdziesz dostawcę, który inwestuje w swoich ludzi, procesy i technologię – i który traktuje Twój sukces jako własny – wtedy znalazłeś partnera wartego zachowania.

Po ustaleniu kryteriów oceny i wybraniu odpowiedniego partnera, jak przejść od oceny do działania? Ostatnia sekcja zawiera konkretne następne kroki umożliwiające realizację projektu precyzyjnego gięcia blach w produkcji.

Dalsze kroki w realizacji projektu precyzyjnego gięcia blach

Poznałeś podstawy usług precyzyjnej obróbki blach, od doboru materiałów przez procesy produkcyjne po ocenę dostawców. Nadchodzi teraz pytanie praktyczne: co dalej? Odpowiedź zależy całkowicie od etapu, na którym znajduje się Twój projekt.

Nie ważne, czy nadal badasz dostępne opcje, aktywnie opracowujesz specyfikacje, czy jesteś gotowy, by dziś zażądać ofert — konkretne działania skutecznie przesuną Twój projekt naprzód. Przekształćmy wszystko, czego się nauczyłeś, w konkretne kroki dostosowane do obecnego etapu Twojego projektu.

Przygotowanie projektu do powodzenia

Zanim skontaktujesz się z jakimkolwiek producentem, to przygotowanie decyduje o płynnym przebiegu realizacji projektu. Zgodnie z Baillie Fabricating , starannie opracowane wnioski ofertowe (RFQ) pozwalają zespołom produkcyjnym szybciej wykonać zlecenia, uzyskać lepsze ceny i zapewnić optymalną jakość.

Co należy przygotować przed złożeniem wniosków ofertowych?

- rysunki 2D i modele CAD 3D: Te pliki umożliwiają efektywne generowanie i programowanie ścieżek narzędzi. Zgodnie z Approved Sheet Metal, pliki STEP są standardem branżowym w dziedzinie wymiany 3D CAD, zachowując precyzyjne wymiary niezbędne do programowania produkcji

- Kompletne specyfikacje materiałów: Nie proszę po prostu o „stal”. Określ dokładny gatunek, stan materiału i grubość. Wybór materiału ma znaczący wpływ na wyceny i harmonogramy

- Wymagania dotyczące tolerancji: Zastosuj tolerancje funkcjonalne tam, gdzie liczy się precyzja, unikając jednocześnie nadmiernego wyznaczania wymagań, które powodują niepotrzebne koszty

- Wymagania dotyczące wykończenia: Dołącz proszę o nawarstwienie proszkowe, powłoki galwaniczne lub inne obróbki powierzchni już we wstępnym zapytaniu, aby uniknąć niespodzianek związanych z terminami

- Ilość i oczekiwania dotyczące dostawy: Wykonawcy potrzebują informacji o wielkości zamówienia, aby zapewnić dokładne wyceny i realistyczne czasy realizacji

Jako ReNEW Manufacturing podkreśla, że wcześniejsze zaangażowanie partnera produkcyjnego w procesie zapewnia możliwość realizacji Twojej wizji przy mniejszej liczbie przeszkód. Nie czekaj, aż projekty zostaną zamknięte, by prosić o opinię.

Najważniejszym czynnikiem decydującym o sukcesie projektu precyzyjnej blacharstwa nie jest złożoność projektu, wybór materiału ani nawet budżet. Kluczowe znaczenie ma jakość współpracy między Twoim zespołem a partnerem wykonawczym. Wczesne zaangażowanie, jasna komunikacja oraz kompletna dokumentacja zamieniają trudne projekty w płynny proces produkcji.

Kolejny krok w kierunku produkcji

Twoja dalsza droga zależy od obecnego etapu projektu:

Jeśli nadal prowadzisz badania: Skoncentruj się na zrozumieniu wymagań swojej aplikacji przed wybraniem metod obróbki blachy. Udokumentuj tolerancje, materiały i certyfikaty wymagane przez Twoją branżę. Skorzystaj z wytycznych DFM zawartych w tym artykule, aby udoskonalić projekty przed uzyskaniem ofert. Wyszukiwanie fraz „precyzyjne blacharstwo niedaleko mnie” lub „usługi blacharskie niedaleko mnie” może pomóc zidentyfikować lokalnych dostawców do pierwszych rozmów, choć nie ograniczaj się geograficznie, jeśli specjalistyczne możliwości są ważniejsze niż bliskość.

Jeśli opracowujesz specyfikacje: Zweryfikuj założenia projektowe z potencjalnymi wytwórcami przed finalizacją plików CAD. Poproś o opinie DFM, aby zidentyfikować potencjalne problemy, gdy zmiany nadal są tanie. Rozważ zamówienie prototypowych ilości, aby zweryfikować kształt, dopasowanie i funkcjonalność przed rozpoczęciem produkcji narzędziowej lub dużych partii.

Jeśli jesteś gotowy, aby poprosić o wyceny: Przygotuj kompletne zestawy dokumentacji, w tym pliki CAD, rysunki, specyfikacje materiałów i wymagane ilości. Wyślij do wielu wykwalifikowanych wytwórców w celu porównania konkurencyjnego. Oceniaj odpowiedzi nie tylko pod kątem ceny, ale również jakości opinii inżynierskich i szybkości reakcji w komunikacji.

Dla zastosowań motoryzacyjnych wymagających szybkiej iteracji, dostawcy tacy jak Shaoyi (Ningbo) Metal Technology ofrują możliwość przygotowania wyceny w ciągu 12 godzin oraz szybkiego prototypowania w ciągu 5 dni, co umożliwia cykle weryfikacji projektu znacznie skracające harmonogramy projektów. Ich certyfikat IATF 16949 oraz kompleksowe wsparcie DFM odpowiadają na wymagania jakościowe i inżynierskie, jakie stawiają zastosowania motoryzacyjne.

Jeśli szukasz „precyzyjnej obróbki metalu blacharskiego w pobliżu” lub „producentów blach w pobliżu”, pamiętaj, że geograficzna bliskość jest mniej ważna niż dopasowanie możliwości. Dostawca z odpowiednimi certyfikatami, sprzętem i wsparciem inżynieryjnym położony w innej części kraju często radzi sobie lepiej niż lokalny zakład nie spełniający specjalistycznych wymagań Twojej branży.

Twój projekt precyzyjnej obróbki blach reprezentuje inwestycję w jakość produktu, efektywność produkcji oraz przewagę konkurencyjną. Wiedza, którą zdobyłeś dzięki tej poradnikowi, pozwala Ci podejmować świadome decyzje, skutecznie komunikować się z partnerami wykonawczymi i osiągać rezultaty przekraczające oczekiwania. Następny krok należy do Ciebie.

Często zadawane pytania dotyczące usług precyzyjnej obróbki blach

1. Jaka jest różnica między precyzyjną obróbką blach a standardową obróbką?

Precyzyjna obróbka blach osiąga tolerancje w zakresie ±0,005" do ±0,010" (±0,13 mm do ±0,25 mm), podczas gdy standardowa obróbka zazwyczaj utrzymuje tolerancje na poziomie ±1/16" do ±1/8" (±1,6 mm do ±3,2 mm). Różnica wynika z zastosowania zaawansowanego sprzętu CNC, maszyn pomiarowych współrzędnościowych (CMM), statystycznej kontroli procesu oraz kompleksowych systemów zarządzania jakością, takich jak certyfikat ISO 9001 lub IATF 16949. Te możliwości zapewniają idealne dopasowanie komponentów bez konieczności kosztownej poprawki.

2. Ile kosztuje obróbka blach?

Koszty wykonywania blach stalowych wahają się od 4 do 48 USD za stopę kwadratową, w zależności od rodzaju materiału, grubości, złożoności i wymagań dostosowania. Prace precyzyjne są cenowane wyżej ze względu na mniejsze dopuszczenia i ulepszoną kontrolę jakości. Czynniki wpływające na koszt to wybór materiału (aluminium vs stal nierdzewna), wymagania dotyczące wykończenia (powłoka proszkowa, powlekanie), ilość zamówienia oraz złożoność projektu. Dostawcy tacy jak Shaoyi oferują przygotowanie wyceny w ciągu 12 godzin, aby szybko poznać cenę konkretnego projektu.

3. Jakie certyfikaty należy poszukiwać u precyzyjnego producenta wyrobów z blach?

Niezbędne certyfikaty zależą od branży. ISO 9001 stanowi uniwersalną podstawę zarządzania jakością. IATF 16949 jest obowiązkowe w zastosowaniach motoryzacyjnych, AS9100 dla komponentów lotniczych, a ISO 13485 dla urządzeń medycznych. Dodatkowo upewnij się, że dostawcy stosują protokoły inspekcji pierwszego sztucznika, możliwości CMM, pełną śledzenie materiałów oraz udokumentowane procesy jakościowe zapewniające stałą jakość produkcji.

4. Jaki jest typowy czas realizacji dla precyzyjnych części z blachy?

Czasy realizacji różnią się w zależności od zakresu projektu. Prototypy (1-25 sztuk) są zazwyczaj wysyłane w ciągu 1-3 tygodni. Produkcja małoseryjna (25-500 sztuk) wymaga 2-5 tygodni, natomiast serie duże (500+ sztuk) mogą trwać 4-10 tygodni. Czynniki wpływające na harmonogram to dostępność materiałów, złożoność konstrukcji, wymagania dotyczące wykończenia oraz pojemność zakładu. Niektórzy dostawcy oferują szybkie prototypowanie już w ciągu 5 dni dla pilnych projektów motoryzacyjnych i przemysłowych.

5. Kiedy należy wybrać gięcie blachy zamiast tłoczenia lub odlewania?

Wybierz precyzyjne gięcie blachy dla niskich i średnich partii (poniżej 5000 sztuk), gdzie koszty form tłoczących (10 000–500 000+ USD) nie uzasadniają inwestycji. Gięcie sprawdza się również w przypadku projektów wymagających elastyczności, złożonych geometrii z wieloma gięciami oraz krótkich terminów realizacji, ponieważ nie wymaga ono narzędzi. Tłoczenie staje się opłacalne przy nakładach powyżej 50 000 sztuk, gdy koszty form ulegają rozłożeniu. Odlewanie jest odpowiednie dla złożonych kształtów 3D, których nie da się wykonać z płaskiego materiału, podczas gdy druk 3D z metalu służy do tworzenia skrajnie skomplikowanych struktur wewnętrznych w mniejszych ilościach.

Małe partie, wysokie standardy. Nasza usługa szybkiego prototypowania sprawia, że weryfikacja jest szybsza i łatwiejsza —

Małe partie, wysokie standardy. Nasza usługa szybkiego prototypowania sprawia, że weryfikacja jest szybsza i łatwiejsza —