Sekrety precyzyjnej obróbki blachy: od tolerancji po wybór partnera

Co naprawdę oznacza precyzyjna obróbka blach

Kiedy słyszysz termin „precyzyjna blacha”, co przychodzi Ci na myśl? Jeśli wyobrażasz sobie nieco niedokładne metalowe elementy, to przegapiasz kluczową różnicę oddzielającą standardową obróbkę od produkcji inżynieryjnej. Przebijmy się przez tę niejasność i zdefiniujmy dokładnie, co oznacza precyzja w mierzalnych jednostkach.

Precyzyjna obróbka blach to produkcja komponentów metalowych z niewielkimi tolerancjami wymiarowymi, zwykle w zakresie od ±0,005 cala do ±0,010 cala, osiąganymi dzięki zaawansowanym urządzeniom, wyrafinowanym systemom jakości oraz specjalistycznej wiedzy na temat materiałów.

Brzmi technicznie? Tak jest. Ale zrozumienie tej różnicy może zaoszczędzić Ci sporo czasu, pieniędzy i problemów podczas pozyskiwania komponentów metalowych do krytycznych zastosowań.

Definiowanie precyzji w obróbce metali

Branża obróbki metali działa w skali różnych poziomów dokładności. Z jednej strony znajdują się ogólne usługi obróbki metali, obsługujące tolerancje na poziomie ±1/16 cala do ±1/8 cala (±1,6 mm do ±3,2 mm) . Te luźniejsze specyfikacje doskonale sprawdzają się w konstrukcjach budowlanych, podstawowych obudowach oraz elementach strukturalnych, gdzie dokładne wymiary nie są krytyczne.

Standardowa produkcja blacharska zajmuje miejsce pośrodku, oferując lepsze dopuszczalne odchyłki w zakresie ±1/32 cala do ±1/16 cala. Ten poziom jest odpowiedni dla instalacji wentylacyjnych i klimatyzacyjnych, obudów elektrycznych oraz komponentów urządzeń gospodarstwa domowego, gdzie większa dokładność ma znaczenie, ale perfekcja nie jest niezbędna.

Precyzyjna produkcja blacharska obejmuje wysoką dokładność w tym zakresie. Tutaj dopuszczalne odchyłki zmniejszają się znacząco do ±0,005 cala do ±0,010 cala (±0,13 mm do ±0,25 mm). Dla porównania, odpowiada to grubości ludzkiego włosa. Wszystkie precyzyjne operacje blacharskie na tym poziomie wymagają zaawansowanych systemów laserowych światłowodowych, automatycznych giętarek wyposażonych w systemy pomiaru kątów oraz maszyn pomiarowych z pomiarem współrzędnościowym do weryfikacji.

Dlaczego dopuszczalne odchyłki są ważne w pracach blacharskich

Wyobraź sobie zamówienie kluczowego komponentu dla urządzenia medycznego. Projekt zakłada wymiar 2 cali. Czy „2 cale” oznaczają dokładnie 2,000 cala? Może to być 1,995 cala? A może 2,030 cala?

Dokładnie dlatego istnieją tolerancje. Zgodnie z eksperci branżowi , tolerowanie określa dopuszczalne odchylenia wymiarów części, aby zapewnić poprawne pasowanie elementów, ich prawidłowe działanie oraz spełnienie standardów jakości. Bez jasno określonych tolerancji producenci i nabywcy posługują się różnymi kryteriami.

Oto, co oznaczają różne poziomy tolerancji w praktyce:

- Ogólna obróbka (±0,063 do ±0,125 cala): Akceptowalne w zastosowaniach niemających charakteru krytycznego, gdzie możliwe są korekty pasowania

- Standardowa obróbka blachy (±0,031 do ±0,063 cala): Odpowiednie dla ogólnych obudów i komponentów wymagających umiarkowanej dokładności

- Precyzyjna obróbka (±0,005 do ±0,010 cala) :Wymagana w przemyśle lotniczym, urządzeniach medycznych, elektronice oraz wszędzie tam, gdzie dokładność wymiarowa bezpośrednio wpływa na wydajność lub bezpieczeństwo

Kluczowe spostrzeżenie? Mniejsze dopuszczalne odchyłki nie są automatycznie lepsze. Są droższe, ponieważ wymagają specjalistycznego sprzętu, dłuższego czasu przygotowania, dodatkowych kontroli jakości oraz często dodatkowych części zamiennych na te, które nie spełniają rygorystycznych norm. Określanie mniejszych odchyłek niż naprawdę wymaga aplikacja po prostu marnuje pieniądze, nie dodając wartości.

Zrozumienie tej hierarchii odchyłek pomaga w jasnej komunikacji z partnerami produkcyjnymi oraz w podejmowaniu świadomych decyzji dotyczących rzeczywistego poziomu precyzji potrzebnego dla projektu. W kolejnych sekcjach omówimy konkretne zakresy tolerancji według procesu, uwarunkowań materiałowych oraz sposób doboru odpowiedniego poziomu dokładności dla poszczególnych zastosowań.

Specyfikacje tolerancji i wyjaśnienie standardów branżowych

Teraz, gdy już wiesz, co odróżnia precyzyjną obróbkę blach od standardowej, pojawia się następne logiczne pytanie: jakie tolerancje można rzeczywiście oczekiwać od różnych procesów produkcyjnych? Właśnie na tym etapie wielu zakupowych odczuwa frustrację. Dostawcy często mówią o „precyzji”, nie podając konkretnych wartości, na podstawie których można by projektować.

Naprawmy to. Poniżej znajdziesz kompleksowy przegląd specyfikacji tolerancji, które firmy zajmujące się precyzyjną obróbką blach rzadko publikują otwarcie. Podane wartości reprezentują standardy branżowe osiągalne przy użyciu dobrze utrzymanego sprzętu i odpowiedniej kontroli procesu.

Zakresy tolerancji według procesu obróbki

Każdy proces obróbki ma swoiste ograniczenia dokładności wynikające z zaangażowanych zasad fizyki. Laser włóknowy działa inaczej niż giętarka, a spawanie wprowadza zmienne, których nie ma cięcie. Zrozumienie tych zależnych od procesu tolerancji pomaga dobrać metodę produkcji do wymagań dotyczących precyzji.

| Proces produkcji | Tolerancja standardowa | Wysoka precyzja tolerancji | Główne zmienne |

|---|---|---|---|

| Cięcie laserowe (położenie cech) | ±0,005 cala (±0,127 mm) | ±0,003 cala (±0,076 mm) | Grubość materiału, typ gazu pomocniczego |

| Cięcie laserowe (średnica otworu) | ±0,005 cala (±0,127 mm) | ±0,003 cala (±0,076 mm) | Skupienie wiązki, prędkość cięcia |

| Wycinanie wodne | ±0,005 cala (±0,127 mm) | ±0,003 cala (±0,076 mm) | Przepływ ścierniwa, odległość dystansowa |

| Wiertarka CNC | ±0,010 cala (±0,254 mm) | ±0,005 cala (±0,127 mm) | Wynoszenie narzędzia, pozycjonowanie blachy |

| Gięcie precyzyjne (kąt) | ±1° | ±0.5° | Wybicie materiału, szerokość matrycy V |

| Gięcie precyzyjne (gięcie do gięcia) | ±0,015" (±0,381 mm) | ±0,010 cala (±0,254 mm) | Grubość materiału do 1/8" |

| Gięcie precyzyjne (gięcie do elementu) | ±0,010 cala (±0,254 mm) | ±0,007" (±0,178 mm) | Dokładność ogranicznika tylnego |

| Spawanie (wymiar na 2 miejsca) | ±0,060" (±1,524 mm) | ±0,030" (±0,762 mm) | Deformacja termiczna, sztywność oprzyrządowania |

| Spawanie (pomiar w 3 miejscach) | ±0,030" (±0,762 mm) | ±0,015" (±0,381 mm) | Kolejność spawania, kontrola wprowadzania ciepła |

Zauważ coś ważnego? Te tolerancje obowiązują wyłącznie wtedy, gdy części pozostają w stanie płaskim. Gdy wprowadzisz operacje kształtowania, tolerancje się kumulują. Część, która została wycięta laserem, a następnie wygięta, będzie miała skumulowane odchyłki od obu procesów.

Zrozumienie osiągalnych poziomów dokładności

Oto rzeczywistość, którą dobrze znają producenci precyzyjnych komponentów z blachy: grubość materiału podstawowo wpływa na to, jakie tolerancje można osiągnąć. Cieńsze materiały zazwyczaj pozwalają na mniejsze tolerancje podczas operacji cięcia, jednak stwarzają znaczne wyzwania związane z ich manipulacją podczas gięcia.

Rozważ zależność między grubością materiału a tolerancjami gięcia:

| Zakres grubości materiału | Tolerancja gięcie do gięcia | Tolerancja gięcie do cechy | Dopuszczalne odchylenie kąta |

|---|---|---|---|

| Do 1/8" (3,2 mm) | ±0,015" (±0,381 mm) | ±0,010 cala (±0,254 mm) | ±1° |

| 1/8" do 1/2" (3,2 mm do 12,7 mm) | ±0,030" (±0,762 mm) | ±0,015" (±0,381 mm) | ±1° |

Dlaczego grubsze materiały wymagają luźniejszych tolerancji gięcia? Odpowiedź tkwi w odbiciu sprężystym – irytującej tendencji metalu do częściowego powrotu do pierwotnego kształtu po usunięciu siły giącej. Grubsze i twardsze materiały wykazują bardziej widoczne odbicie sprężyste, co utrudnia dokładną kontrolę kąta.

W zastosowaniach produkcyjnych blach, gdzie wymagana jest wysoka precyzja pozycjonowania, zrozumienie tych ograniczeń pomaga projektować części rzeczywiście możliwe do wykonania. Możesz osiągnąć ±0,005", na detalu ciętym laserem, ale oczekiwanie tej samej tolerancji na wymiarze obejmującym gięcie w stali o grubości 1/4" po prostu nie jest realistyczne.

Odczytywanie oznaczeń tolerancji na rysunkach technicznych

Przy przeglądaniu ofert lub pracy z Precision Sheet Metal Products Inc. oraz innymi producentami napotkasz specyfikacje tolerancji wyrażone na kilka sposobów. Zrozumienie tych konwencji zapobiega nieporozumieniom:

- Tolerancje obustronne (±0,005"): Wymiary mogą się różnić równomiernie w obu kierunkach od wartości nominalnej

- Tolerancje jednostronne (+0,005"/-0,000"): Dopuszczalne odchylenie tylko w jednym kierunku

- Wymiary graniczne (1,995" - 2,005"): Jawne określenie górnego i dolnego ograniczenia

- Tolerancja położenia w warunku RFS: Często wyrażana jako średnica (Ø0,014"), definiująca okrągłą strefę tolerancji dla lokalizacji elementu

Normy branżowe stanowią podstawę dla tych oznaczeń. ISO 2768 ustala ogólne tolerancje dla wymiarów liniowych i kątowych w precyzyjnej produkcji, dzieląc specyfikacje na klasy tolerancji. Tymczasem ASME Y14.5 zawiera szczegółowe wytyczne dotyczące geometrycznych zasad wymiarowania i tolerowania (GD&T), obejmujące kontrolę kształtu, orientacji i położenia, które są niezbędne dla złożonych precyzyjnych komponentów blacharskich.

Wniosek praktyczny? Gdy na Twoim rysunku nie określono tolerancji, większość wytwórców stosuje swoje standardowe tolerancje blokowe — które mogą, ale nie muszą odpowiadać Twoim oczekiwaniom. Zawsze jasno komunikuj krytyczne wymiary i poproś potencjalnych partnerów produkcyjnych o dokumentację ich standardowych tolerancji przed złożeniem zamówienia.

Po ustaleniu tych specyfikacji dotyczących tolerancji pojawia się kolejne pytanie: w jaki sposób konkretne procesy produkcyjne osiągają ten poziom dokładności i kiedy należy wybrać jedną metodę zamiast innej?

Podstawowe precyzyjne procesy i techniki produkcji

Zobaczyłeś już wartości tolerancji. Ale jak właściwie wydawcy osiągają dokładność ±0,005 cala na arkuszu stali? Odpowiedź tkwi w zrozumieniu każdego procesu produkcyjnego — jego fizyki, możliwości i ograniczeń. Przeanalizujmy podstawowe precyzyjne techniki obróbki blachy, które przekształcają płaski materiał w dokładne, funkcjonalne elementy.

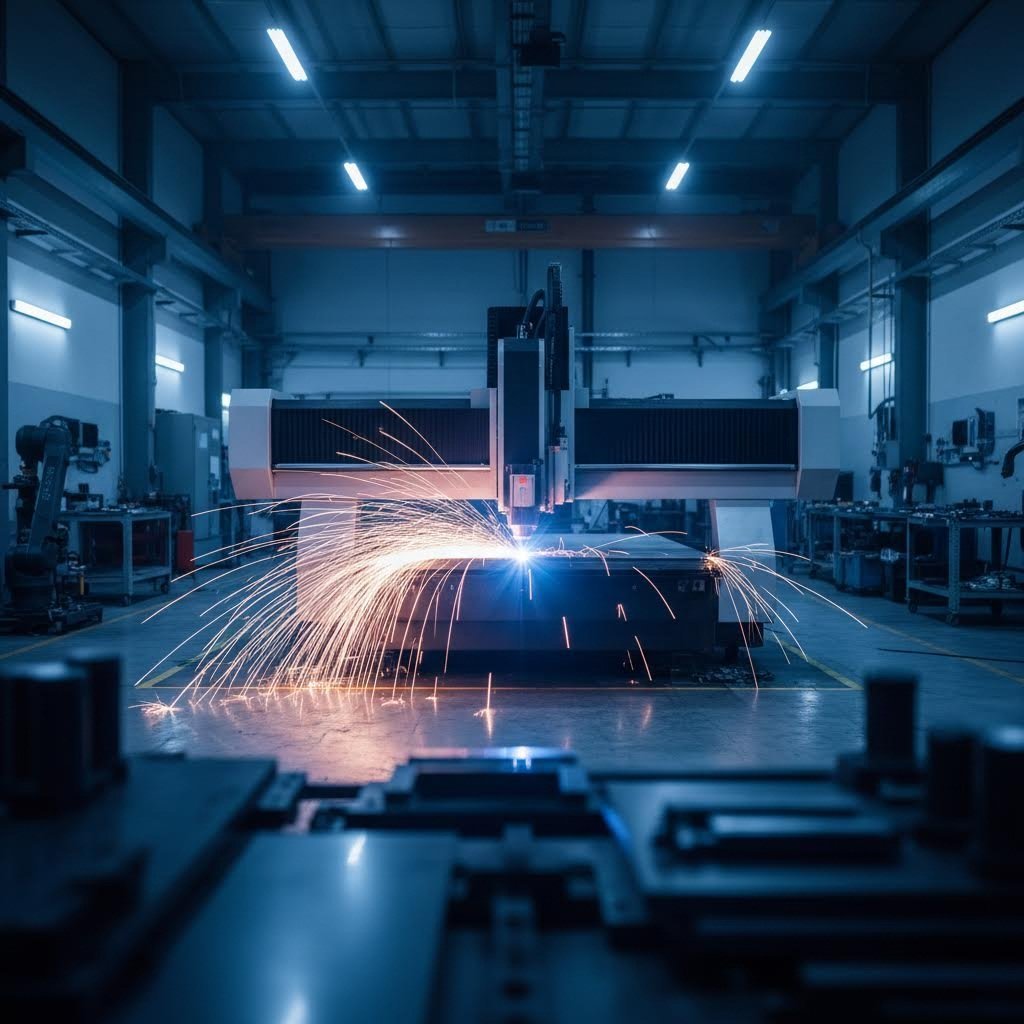

Cięcie laserowe dla maksymalnej dokładności

Wycinanie laserowe blach o wysokiej precyzji pozycjonowania reprezentuje standard złoty pod względem dokładności wymiarowej w cięciu płaskich kształtów. Nowoczesne lasery światłowodowe generują wiązki o długościach fal zwykle w zakresie od 800 nm do 2200 nm, umożliwiając skupienie energii w plamkach o rozmiarze aż do 0,1 mm. Ta skoncentrowana moc topi materiał w dokładnie kontrolowanej ścieżce, podczas gdy gaz pomocniczy usuwa stopiony metal.

Co czyni cięcie laserowe tak precyzyjnym? Kilka parametrów działa razem:

- Moc lasera (mierzona w kW): Określa zdolność tnącą. Laser światłowodowy o mocy 1 kW skutecznie tnie stal nierdzewną do grubości 5 mm, podczas gdy urządzenie o mocy 3 kW radzi sobie z grubością 12 mm tego samego materiału

- Prędkość cięcia (metry na minutę): Zrównoważenie prędkości i mocy zapewnia czyste cięcie bez przypalenia lub niepełnego przebicia

- Pozycja fokusu: Dokładny punkt, w którym wiązka się koncentruje, musi być zgodny ze środkiem grubości materiału, aby osiągnąć optymalny rozkład energii

- Typ i ciśnienie gazu pomocniczego: Azot produkuje krawędzie pozbawione tlenków na stali nierdzewnej; tlen przyspiesza cięcie stali węglowej, ale wpływa na skład chemiczny krawędzi

Według eksperci od cięcia laserowego , dokładność cięcia w nowoczesnych systemach laserowych światłowodowych osiąga zazwyczaj wartość ±0,25 mm (około ±0,010"), a maszyny o wysokiej precyzji osiągają jeszcze wyższe specyfikacje. Szerokość cięcia – materiał usunięty podczas cięcia – wynosi zazwyczaj od 0,1 mm do 0,3 mm, w zależności od grubości materiału i parametrów wiązki.

Jakość krawędzi jest równie ważna jak dokładność wymiarowa. Odpowiednio zoptymalizowane precyzyjne cięcie blach daje krawędzie wymagające minimalnej dodatkowej obróbki. Zbyt duża prędkość cięcia powoduje szorstkie, paskowane krawędzie. Zbyt mała powoduje nadmierne nagrzanie, tworząc większą strefę wpływu ciepła i potencjalne wyginanie. Znalezienie optymalnego punktu wymaga zrozumienia konkretnej kombinacji materiału i jego grubości.

Techniki gięcia i formowania CNC

Precyzyjne gięcie blach przekształca płaskie, wycięte laserowo zagotki w trójwymiarowe elementy. Nowoczesne numeryczne prasy giętarek wykorzystują serwonapędzane prowadnice tylnie do pozycjonowania materiału z powtarzalnością mierzoną w tysięcznych cala. Jednak osiągnięcie spójnych gięć wymaga więcej niż dokładnego pozycjonowania.

Tutaj precyzyjne gięcie i składanie blach staje się skomplikowane: sprężystość materiału (springback). Każdy metal częściowo powraca do swojego pierwotnego płaskiego stanu po usunięciu siły gięcia. To odkształcenie sprężyste zmienia się w zależności od typu materiału, grubości, kierunku ziarna i promienia gięcia. Doświadczeni wykonawcy kompensują to przez nadgięcie – celowe wygięcie poza docelowy kąt, aby po sprężystym powrocie element miał właściwy kąt.

Główne czynniki wpływające na dokładność gięcia to:

- Dobór szerokości matrycy V: Szersze matryce zmniejszają wymagane obciążenie, ale zwiększają sprężystość; węższe matryce poprawiają dokładność kąta, ale ryzyko uszkodzenia powierzchni materiału

- Obliczenia zapasu gięcia: Oś obojętna materiału przesuwa się podczas gięcia, co wpływa na obliczenia końcowych wymiarów

- Pozycjonowanie ogranicznika tylnego: Określa położenie linii gięcia względem cech elementu

- Systemy pomiaru kąta: Zaawansowane maszyny wyposażone w systemy sprzężenia zwrotnego w czasie rzeczywistym automatycznie kompensują odbicie sprężyste

Precyzyjne formowanie blach wykracza poza proste gięcie. Procesy takie jak tłoczenie głębokie, formowanie rozciągane i walcowanie kształtują materiał w złożone geometrie. Każda z tych technik nadaje się do konkretnych zastosowań — tłoczenie głębokie do misek i obudów, walcowanie do długich, jednolitych profili, a formowanie rozciągane do wygiętych powłok lotniczych.

Dopasowanie procesu do wymagań elementu

Wybór odpowiedniego procesu produkcyjnego nie jest przypadkowy. Geometria detalu, wymagania dotyczące tolerancji, właściwości materiału oraz wielkość produkcji wpływają na optymalne podejście. Weź pod uwagę następujące wytyczne doboru procesu:

- Wysokodokładne pozycjonowanie cięcia laserowego blach: Najlepszy dla złożonych płaskich wzorów, ciasnych tolerancji wymiarowych i czystych krawędzi. Idealny od prototypów po średnie serie produkcyjne

- Z wyłączeniem: Opłacalny dla dużych serii części ze standardowymi wzorami otworów i prostą geometrią. Szybszy niż laser dla grubszych materiałów z powtarzalnymi cechami

- Precyzyjne gięcie i składanie :Niezbędny do tworzenia kołnierzy, kanałów i obudów. Osiąga tolerancję kąta ±1° przy odpowiednim wyposażeniu

- Precyzyjne kształtowanie: Wymagane dla powierzchni zakrzywionych, wyciąganych elementów oraz złożonych trójwymiarowych kształtów wykraczających poza proste gięcia

Dla operacji wymagających wysokiej precyzji pozycjonowania cięcia blachy — tworzenia wąskich pasków z szerszych taśm — parametry procesu są analogiczne do cięcia laserowego. Spójny luz noża, odpowiednia kontrola napięcia oraz dokładne pozycjonowanie zapewniają dokładność wymiarową na całej szerokości paska

Związek między wyborem procesu a jakością końcowego elementu nie może być przeceniony. Projekt wymagający tolerancji ±0,005 cala na otworze wykrojonym laserowo rzeczywiście może osiągnąć taką specyfikację. Jednak oczekiwanie identycznej tolerancji na wymiarze obejmującym dwa gięcia w materiale o grubości 1/4 cala ignoruje skumulowane efekty operacji kształtowania.

Zrozumienie możliwości tych procesów pozwala od początku projektować części nadające się do produkcji. Wybór materiału stanowi jednak kolejny krytyczny czynnik, który znacząco wpływa zarówno na osiągalną precyzję, jak i ogólną wydajność elementu.

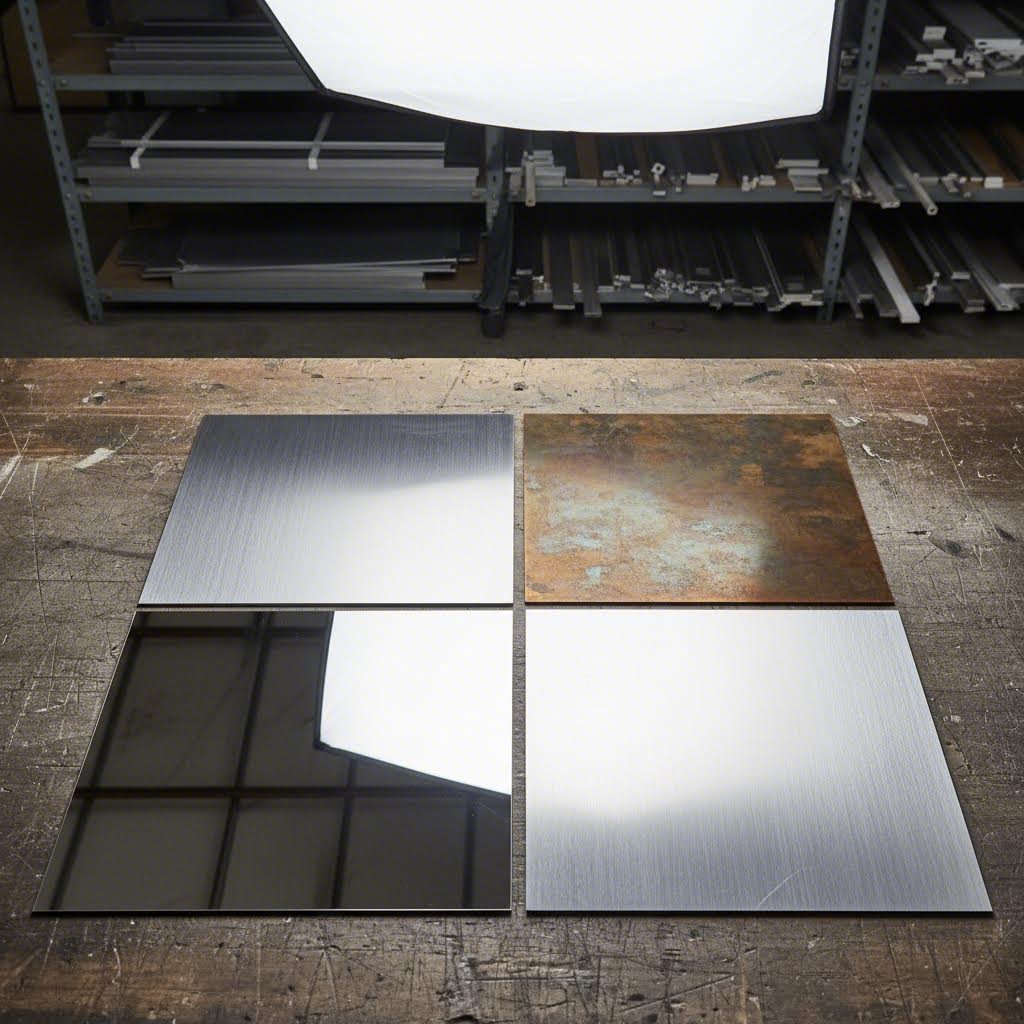

Wybór materiału dla optymalnych wyników precyzji

Opanowałeś tolerancje. Rozumiesz procesy. Ale oto pytanie, które wprowadza w zakłopotanie nawet doświadczonych inżynierów: dlaczego ta sama operacja gięcia daje różne wyniki na aluminium i stali nierdzewnej? Odpowiedź tkwi we właściwościach materiału — a wybór odpowiedniego metalu pod kątem wymaganych tolerancji może decydować o tym, czy elementy idealnie pasują do siebie, czy też staną się kosztownym odpadem.

Zamawiając niestandardowe precyzyjne komponenty ze blachy, wybór materiału to nie tylko kwestia wytrzymałości czy odporności na korozję. Bezpośrednio wpływa on na formowalność, zachowanie sprężyste (springback) oraz ostatecznie na to, czy Twój dostawca będzie w stanie osiągnąć te wąskie tolerancje, które określiłeś.

W jaki sposób właściwości materiałów wpływają na precyzję

Każdy metal inaczej zachowuje się pod wpływem naprężeń. Niektóre łatwo się gną i utrzymują kształt. Inne opierają się, powracając do pierwotnej formy zaraz po zwolnieniu nacisku. Zrozumienie tych zachowań pozwala projektować części rzeczywiście możliwe do wykonania zgodnie z założonymi specyfikacjami.

Według Eksperci od gięcia blach CNC , czynniki materiałowe znacząco wpływają na dokładność gięcia. Równość powierzchni odniesienia, równomierne rozłożenie naprężeń oraz spójność grubości wpływają na końcową precyzję. Różne metale charakteryzują się różnymi właściwościami gięcia — niektóre stopy są bardziej podatne na odkształcenia plastyczne lub koncentrację naprężeń, co bezpośrednio wpływa na dokładność wymiarową.

Oto, co dzieje się podczas gięcia: zewnętrzna powierzchnia ulega wydłużeniu, podczas gdy wewnętrzna jest ściskana. Między nimi znajduje się oś obojętna — linia wyobrażona, która nie doświadcza ani rozciągania, ani ściskania. Położenie tej osi obojętnej zmienia się w zależności od właściwości materiału, wpływając na obliczenia zapasu gięcia oraz końcowe wymiary.

Odrost sprężysty stanowi największe wyzwanie przy precyzyjnych wyrobach blacharskich. Twardsze i wytrzymalsze materiały wykazują bardziej widoczną odwracalną deformację. Element ze stali nierdzewnej może odbić się o 2–4 stopnie po gięciu, podczas gdy miękki aluminium odbudowuje jedynie 0,5–1 stopień. Blacharze kompensują to nadgięciem, jednak dokładna kompensacja wymaga znajomości zachowania konkretnego materiału.

Wybór odpowiedniego metalu dla wymaganych tolerancji

Różne zastosowania wymagają różnych właściwości materiałowych. Poniższa tabela porównuje popularne materiały do precyzyjnej obróbki blacharskiej pod kątem cech bezpośrednio wpływających na osiągalne tolerancje:

| Materiał | Wytrzymałość na rozciąganie | Wykształcalność | Efekt zwrotu | Typowe zastosowania |

|---|---|---|---|---|

| Aluminium 5052 | ~195 MPa | Doskonały | Niski (0,5–1°) | Obudowy morskie, elementy systemów klimatyzacji i wentylacji |

| Aluminium 6061 | ~310 MPa | Dobre | Umiarkowany (1–2°) | Konsolki konstrukcyjne, obudowy elektroniczne |

| nierdzewna stal 304 | ~515 MPa | Umiarkowany | Wysoki (2–4°) | Sprzęt spożywczy, urządzenia medyczne |

| 316 ze stali nierdzewnej | ~580 MPa | Umiarkowany | Wysoki (2–4°) | Przemysł chemiczny, osprzęt morski |

| Stal węglowa (1008/1010) | ~340 MPa | Dobre | Umiarkowany (1–2°) | Elementy karoserii samochodów, części konstrukcyjne |

| Stopy miedzi (C110) | ~220 MPa | Doskonały | Niski (0,5–1°) | Komponenty elektryczne, wymienniki ciepła |

Zauważasz wzór? Zmniejszona wytrzymałość na rozciąganie aluminium w porównaniu ze stalą nierdzewną staje się właściwie zaletą podczas operacji kształtowania. Niższa wytrzymałość sprawia, że aluminium jest znacznie łatwiejsze do cięcia, tłoczenia, gięcia i formowania. Jednak ta sama miękkość powoduje trudności w obsłudze podczas precyzyjnej niestandardowej produkcji blach — cienkie aluminium łatwo ulega zarysowaniom i może odkształcać się pod własnym ciężarem.

Stal nierdzewna oferuje doskonałą wytrzymałość i odporność na korozję, ale stawia wyższe wymagania wobec partnera wykonującego obróbkę. Osiągnięcie wysokiej dokładności pozycjonowania przy produkcji wyrobów blachowych ze stali nierdzewnej wymaga solidnego sprzętu, starannego kompensowania odkucia oraz często wielu operacji kształtowania, aby osiągnąć docelowe wymiary bez pęknięć.

Grubość materiału i kompromisy dotyczące dokładności

Cieńsze materiały stwarzają paradoks w precyzyjnej obróbce. Z jednej strony, cienkie blachy pozwalają zwykle na mniejsze допусki cięcia — mniej materiału oznacza mniejsze odchylenia ścieżki cięcia. Z drugiej strony, cienkie materiały łatwiej ulegają odkształceniom podczas manipulacji, mocowania i kształtowania.

Weź pod uwagę te czynniki związane z grubością:

- Materiały poniżej 0,060" (1,5 mm): Doskonała dokładność cięcia, ale skłonne do wyginania się pod wpływem ciepła. Wymagają starannego uchwytu i mocowania podczas gięcia

- Materiały od 0,060" do 0,125" (1,5 mm do 3,2 mm): Optymalny zakres dla wielu precyzyjnych zastosowań. Dostateczna sztywność umożliwiająca łatwe manipulowanie przy jednoczesnej dobrej kutejności

- Materiały powyżej 0,125" (3,2 mm): Wymagane jest większe kompensowanie odbicia sprężystego. Utrzymanie ciasnych dopuszczalnych tolerancji staje się coraz trudniejsze wraz ze wzrostem grubości

Temperatura wpływa również na dokładność wyników. Jak wskazują źródła branżowe, zmiany temperatury powodują rozszerzanie lub kurczenie się materiałów metalowych, szczególnie podczas dużych operacji gięcia. Różnice w temperaturze maszyny, matrycy i blachy mogą powodować niewielkie odchylenia wymiarowe – coś, co należy brać pod uwagę przy precyzyjnych wyrobach z blachy wymagających najwyższej dokładności.

Twardość materiału jest bezpośrednio związana z trudnościami podczas gięcia. Twardsze materiały, takie jak wysokowytrzymałe stopy stalowe, wymagają większego siłownika do formowania i wykazują większe odbijanie sprężyste. Wykonawcy muszą stosować węższe otwory matryc V-kształtnych i większe kąty przebicia, aby to skompensować. To zwiększa naprężenia narzędzi i ogranicza osiągalne promienie wewnętrznego gięcia.

Wniosek praktyczny? Realistycznie doboraj wybór materiału do wymaganych tolerancji. Określenie tolerancji kąta ±0,5° dla uchwytu ze stali nierdzewnej 316 wymaga znacznie większej kontroli procesu niż ta sama tolerancja dla aluminium. Oba rozwiązania są możliwe do osiągnięcia — ale jedno kosztuje znacznie więcej niż drugie.

Po ustaleniu kwestii materiałów, w jaki sposób można zapewnić, że projekt części skutecznie przejdzie od modelu CAD do gotowego elementu? Właśnie tutaj zasady projektowania uwzględniającego możliwości produkcji stają się niezwykle ważne.

Zasady projektowania gwarantujące sukces w produkcji

Oto frustrująca sytuacja, którą każdy inżynier już przeżył: projektujesz idealną część w programie CAD, wysyłasz ją w celu uzyskania ofert, a następnie otrzymujesz informację zwrotną, że projekt „nie może zostać wyprodukowany zgodnie z podanymi specyfikacjami”. Co poszło nie tak? Odpowiedź zwykle tkwi w pominięciu zasad projektowania uwzględniającego możliwości produkcji (DFM) — praktycznych wytycznych łączących świat cyfrowych projektów z fizyczną rzeczywistością.

Wykwalifikowany specjalista od precyzyjnej obróbki blach może tworzyć cuda przy użyciu odpowiedniego sprzętu. Jednak nawet najbardziej zaawansowane maszyny nie potrafią przezwyciężyć projektów łamiących podstawowe prawa fizyki kształtowania metalu. Poznajmy zasady DFM, które oddzielają wykonalne projekty od kosztownych cykli ponownego projektowania.

Zasady DFM dla elementów precyzyjnych

Projektowanie pod kątem produkowalności (DFM) nie ogranicza kreatywności — chodzi o zrozumienie, jak blacha zachowuje się w trakcie cięcia, gięcia i formowania. Gdy projektujesz z uwzględnieniem tych zasad, Twoje części wychodzą poprawnie już za pierwszym razem, co oszczędza czas i pieniądze.

Według eksperci ds. projektowania blach , DFM opiera się całkowicie na zrozumieniu przez inżyniera projektanta, w jaki sposób pożądane cechy i ich tolerancje są wpływowane przez zakres przewidywanych operacji formowania. Oto kluczowe aspekty, które należy wziąć pod uwagę w każdym projekcie precyzyjnej produkcji blach:

- Minimalne promienie gięcia względem grubości materiału: Jako ostrożne założenie wyjściowe, promień wewnętrznego gięcia powinien być co najmniej równy grubości materiału w przypadku materiałów plastycznych. Twardsze stopy, takie jak aluminium 6061-T6, wymagają minimalnego promienia gięcia równego 4-krotności grubości lub większego, aby zapobiec pękaniu

- Odległości otworów od krawędzi: Dla materiałów o grubości 0,036" (0,914 mm) lub mniejszej, zachowaj co najmniej 0,062" (1,574 mm) od krawędzi otworu do krawędzi materiału. Dla grubszych materiałów zwiększ tę wartość do minimum 0,125" (3,175 mm), aby uniknąć odkształceń

- Odstęp między otworem a gięciem: Umieszczaj otwory w odległości co najmniej 2,5× grubości materiału plus jeden promień gięcia od linii gięcia. Umieszczenie bliżej może spowodować owalne otwory i niepoprawne dopasowanie elementów łączących po formowaniu

- Odstęp między detalami: Zachowaj odstęp 2× grubości materiału między sąsiednimi otworami lub wybitymi detalami, aby zapobiec odkształceniom materiału i zagwarantować czyste cięcie

- Uwzględnianie kierunku ziarna: Orientuj linie gięcia prostopadle do kierunku walcowania materiału, o ile to możliwe. Gięcie równoległe do kierunku ziarna zwiększa ryzyko pęknięć, szczególnie przy małych promieniach i materiałach poddanych hartowaniu lub mniej plastycznych metalach

- Minimalna długość płata Krawędzie zakładki muszą mieć co najmniej 4-krotną grubość materiału, aby zapewnić odpowiednie przytrzymanie podczas gięcia. Krótsze krawędzie mogą się przesuwać, powodując niestabilne kąty gięcia

Te wytyczne mają zastosowanie uniwersalnie we wszystkich precyzyjnych warsztatach blacharskich. Jednak możliwości konkretnego sprzętu różnią się — zawsze potwierdź kluczowe wymagania ze swoim partnerem produkcyjnym przed ostatecznym sfinalizowaniem projektu

Unikanie typowych błędów w projektowaniu

Nawet doświadczeni inżynierowie wpadają w typowe pułapki podczas określania wymagań dla projektów precyzyjnej obróbki blach. Zrozumienie tych najczęstszych błędów pozwala uniknąć kosztownych przebudów i opóźnień w produkcji

Błąd nr 1: Pomijanie zapasu gięcia i odbicia sprężystego Twój model CAD pokazuje gotowy kształt 3D, ale technologowie pracują na bazie rozwinięć płaskich. Jak zauważają specjaliści od obróbki blach , płaskie schematy ignorujące odkształcenie przy gięciu i efekt sprężystego powrotu prowadzą do błędnych końcowych wymiarów i złego dopasowania. Używaj współczynników K i tabel gięcia odpowiednich dla danego materiału w systemie CAD lub omów kompensację gięcia z producentem na etapie projektowania.

Błąd #2: Brak ulgi przy gięciu. Gdy gięcia przecinają się lub kończą przy krawędziach, materiał może ulec rozerwaniu lub wygięciu bez odpowiednich cięć ulgowych. Dodanie prostokątnych, owalnych lub okrągłych ulg przy gięciu — o szerokości równej co najmniej połowie grubości materiału — umożliwia kontrolowane odkształcenie i zapobiega koncentracji naprężeń w strefach gięcia.

Błąd #3: Określanie zbyt ciasnych tolerancji niż to konieczne. Traktowanie blach jak części tokarskich znacząco zwiększa koszty. Operacje gięcia charakteryzują się naturalnymi odchyleniami, których nawet najlepsze urządzenia nie potrafią wyeliminować. Zgodnie z danymi Protolabs, standardowa tolerancja kąta gięcia wynosi ±1°, a tolerancja wysokości przesunięcia to ±0,012" (0,304 mm). Ogranicz ciasne tolerancje tylko do naprawdę kluczowych cech, a w innych miejscach stosuj realistyczne, oparte na procesie tolerancje.

Błąd nr 4: niestandardowe średnice otworów i narzędzia. Określanie nietypowych średnic otworów wymusza użycie specjalnych wykrojników lub cięcie laserowe, co wydłuża czas cyklu i zwiększa koszty. Dąż do standaryzacji średnic otworów, aby pasowały do powszechnie stosowanych narzędzi, o ile to możliwe.

Błąd nr 5: ignorowanie procesów wtórnych. Ciepło spawalnicze wygina cienkie elementy. Powłoka proszkowa dodaje grubość 0,002"–0,004", która może naruszyć pasowania. Weź pod uwagę powlekanie, malowanie i sekwencje spawania już na etapie projektowania — a nie jako dodatkowe myślenie po fakcie.

Rzeczywistość dotycząca tolerancji prototypu a produkcji seryjnej

Oto powszechny błąd, który zaskakuje wielu nabywców: dopuszczalne odchyłki w prototypach często różnią się od odchyłek produkcyjnych. Zrozumienie dlaczego to ważne ma kluczowe znaczenie dla skutecznego skalowania.

Podczas prototypowania wytwórcy zazwyczaj korzystają wyłącznie z cięcia laserowego, ręcznie dostosowując programy i sprawdzając każdą część. To pozwala osiągnąć mniejsze odchyłki dzięki indywidualnemu podejściu. Jednak produkcja wiąże się z innymi uwarunkowaniami ekonomicznymi. Precyzyjna produkcja blach na dużą skalę często przechodzi na tłoczenie ze względu na wydajność, stosuje standardowe zamiast wysokiej jakości narzędziowanie oraz polega na statystycznym sterowaniu procesem zamiast kontroli 100% części.

W przypadku precyzyjnego pozycjonowania gięcia blach na skalę produkcyjną, zautomatyzowane urządzenia wyposażone w systemy pomiarowe kąta pomagają zachować spójność. Jednak nawet najlepsza automatyzacja podlega zużyciu narzędzi, zmienności materiału oraz czynnikom środowiskowym, które powodują różnice między poszczególnymi elementami.

Praktyczna rada? Projektuj tolerancje zgodnie z rzeczywistością produkcji, a nie możliwościami prototypowania. Jeśli Twoje zastosowanie rzeczywiście wymaga precyzji na poziomie prototypu w produkcji seryjnej, odpowiednio zaplanuj budżet — i jasno przekaż te wymagania podczas przygotowywania oferty.

Inspekcja pierwszego sztucznika staje się kluczowa dla potwierdzenia, że procesy produkcyjne osiągają zamierzony cel projektowy. Jak zauważają eksperci branżowi, inspekcje pierwszych sztukników oraz solidny plan kontroli jakości są szczególnie ważne w przypadku blachowych elementów ze względu na zmienne związane z operacjami kształtowania.

Projektowanie części, które precyzyjni wykonawcy blach mogą faktycznie wyprodukować, stanowi połowę wyzwania. Druga połowa? Zweryfikowanie, że gotowe części spełniają Twoje specyfikacje — co wymaga zrozumienia metod kontroli jakości i inspekcji.

Kontrola jakości i inspekcja w precyzyjnej obróbce blach

Zaprojektowałeś element z małymi tolerancjami. Twój wytwórca twierdzi, że dysponuje możliwościami precyzyjnej produkcji. Ale skąd wiesz, czy gotowe komponenty rzeczywiście spełniają specyfikacje? Właśnie tutaj kontrola jakości oddziela profesjonalne operacje precyzyjnej obróbki blach od warsztatów, które po prostu deklarują dokładność bez jej weryfikacji.

Rzeczywistość jest prosta: precyzja nie oznacza nic bez pomiaru. Wytwórca może posiadać najnowocześniejszy dostępny system cięcia laserowego, ale bez odpowiedniego sprzętu kontrolnego i udokumentowanych procesów jakości, te deklaracje dotyczące tolerancji pozostają niepotwierdzonymi obietnicami.

Technologie inspekcji do weryfikacji precyzji

Nowoczesne firmy zajmujące się precyzyjną obróbką blach stosują wiele technologii inspekcji, z których każda nadaje się do konkretnych zadań pomiarowych. Zrozumienie tych metod pozwala ocenić, czy potencjalni partnerzy dysponują możliwościami weryfikacji niezbędnymi do realizacji Twojego projektu.

- Maszyny pomiarowe współrzędnościowe (CMM): Te precyzyjne instrumenty wykorzystują sondy dotykowe do zbierania trójwymiarowych danych współrzędnych z elementów. Zgodnie z opinią specjalistów ds. kontroli jakości , maszyny CMM są w stanie mierzyć skomplikowane geometrie z dokładnością na poziomie mikronów. Doskonale sprawdzają się przy weryfikacji położeń otworów, lokalizacji szczegółów konstrukcyjnych oraz zależności wymiarowych w wielu płaszczyznach — co jest kluczowe dla weryfikacji usług blacharskich wymagających wysokiej precyzji.

- Komparatory optyczne: Te urządzenia rzutują powiększone profile części na ekran z szablonami nakładkowymi umożliwiając szybką wizualną kontrolę. Są szczególnie skuteczne przy sprawdzaniu konturów 2D, układów otworów i stanu krawędzi bez konieczności fizycznego kontaktu, który mógłby uszkodzić delikatne cechy.

- Mierniki chropowatości powierzchni: Specjalistyczne instrumenty służące do określania faktury powierzchni za pomocą igły ze spiczastym diamentem lub metod optycznych. Zapewniają numeryczne wartości chropowatości, takie jak Ra (średnia chropowatość) i Rz (maksymalna wysokość), przeznaczone do dokumentacji kontroli jakości.

- Skanery laserowe: Urządzenia bezdotykowe, które pozyskują pełne dane powierzchniowe poprzez rzutowanie wiązek laserowych na elementy. Idealne do powierzchni swobodnych, materiałów giętkich oraz pełnego porównania elementów z modelami CAD.

- Zautomatyzowane systemy wizyjne: Systemy inspekcyjne oparte na kamerach, które w wysokiej prędkości porównują elementy z szablonami cyfrowymi. Doskonałe do kontroli jakości na liniach produkcyjnych, gdzie wymagana jest 100% inspekcja.

Wiele zakładów produkcyjnych zajmujących się precyzyjną obróbką blach implementuje obecnie hybrydowe strategie inspekcji. Jak zauważają eksperci branżowi, połączenie wielu metod umożliwia kompleksową ocenę jakości przy jednoczesnej optymalizacji czasów cyklu inspekcji. Typowe podejście może obejmować systemy wizyjne do kontroli inline, weryfikację CMM dla pierwszych sztuk i okresowych audytów oraz testery powierzchni do zastosowań krytycznych pod względem wykończenia.

Inspekcja pierwszej sztuki: Weryfikacja możliwości produkcyjnych

Zanim przejdziesz do pełnej produkcji, jak upewnić się, że twój dostawca rzeczywiście spełni Twoje specyfikacje? Inspekcja pierwszej sztuki (FAI) daje odpowiedź.

Według ekspertów ds. jakości produkcji, FAI to formalny proces weryfikacji, w którym pierwszy egzemplarz wyprodukowany w nowej serii produkcyjnej jest starannie sprawdzany i mierzony pod kątem wszystkich specyfikacji konstrukcyjnych i technicznych. W przeciwieństwie do losowych kontroli jakości podczas produkcji, FAI to zapobiegawcza kontrola jakości przeprowadzana przed rozpoczęciem produkcji seryjnej.

Kompleksowy proces FAI dla precyzyjnej blachy obejmuje zazwyczaj:

- Przegląd dokumentacji inżynieryjnej, tolerancji i specyfikacji

- Kontrolę wymiarów za pomocą maszyn pomiarowych CMM, mikrometrów oraz odpowiednich wzorców

- Weryfikację wykończenia powierzchni, w tym grubości powłoki i jakości krawędzi

- Weryfikację materiału na podstawie protokołów badań hutniczych i certyfikatów

- Kompletną dokumentację zawierającą rysunki z naniesionymi pomiarami, porównującymi wartości zmierzone z wartościami nominalnymi

Raport FAI staje się odniesieniem dla przyszłych serii produkcyjnych, umożliwiając spójną jakość w całej partii. Dla firm zajmujących się precyzyjną obróbką blach, działających na rzecz branż regulowanych, dokumentacja FAI potwierdza zgodność ze standardami klientów i organów regulacyjnych już od pierwszej wyprodukowanej sztuki.

Certyfikaty jakości, które mają znaczenie

Certyfikaty zapewniają niezależne potwierdzenie, że producent utrzymuje systematyczne procesy jakościowe. Jednak nie wszystkie certyfikaty mają taką samą wagę w każdej aplikacji.

ISO 9001 reprezentuje podstawowy standard systemu zarządzania jakością. Zdaniem ekspertów ds. certyfikacji , certyfikat ISO 9001 ma zastosowanie do każdej organizacji niezależnie od jej wielkości, branży czy oferowanych produktów i usług. Ustala on podstawowe wymagania dotyczące udokumentowanych procedur, odpowiedzialności zarządu oraz ciągłej poprawy.

IATF 16949 ma szczególne znaczenie dla zastosowań motoryzacyjnych. Certyfikat ten opiera się na ISO 9001, wprowadzając dodatkowe wymagania specyficzne dla branży motoryzacyjnej, w tym:

- Udocumentowane procesy zarządzania bezpieczeństwem produktu w całym cyklu życia produktu

- Programy rozwoju dostawców i audyty drugiej strony

- Zastosowanie narzędzi podstawowych AIAG, w tym PPAP, FMEA, MSA i SPC

- Integracja Wymagań Specyficznych dla Klienta (CSRs) w systemie jakości

- Audyty procesów produkcyjnych i audyty produktu poza standardowym zgodnym z systemem zarządzania jakością

Dla producentów precyzyjnej obróbki blach cienkich działających na rzecz OEM-ów motoryzacyjnych certyfikat IATF 16949 nie jest opcjonalny — zazwyczaj stanowi wymóg kwalifikacyjny dla dostawcy. Ten standard zapewnia, że wytwórcy utrzymują rygorystyczne procesy planowania jakości i kontroli, jakie wymaga produkcja motoryzacyjna.

Jak dokumentacja jakości wspiera Twoje wymagania

Ponad certyfikaty, dokumentacja jakości zapewnia możliwość śledzenia, której wymagają branże regulowane. Profesjonalne zakłady obróbki blach precyzyjnych prowadzą rejestr powiązań między certyfikatami surowców a gotowymi elementami, łączą wyniki inspekcji z konkretnymi partiami produkcyjnymi oraz dokumentują wszelkie odchylenia lub działania korygujące.

Dokumentacja ta spełnia wiele celów. Umożliwia analizę przyczyn podstawowych w przypadku wystąpienia problemów. Spełnia wymagania audytowe ze strony klientów. A także dowodzi, że deklaracje dotyczące precyzji są weryfikowane poprzez systematyczne pomiary – a nie są jedynie językiem marketingowym.

Oceniając potencjalnych partnerów wykonawczych, pytaj o ich możliwości kontrolne, status certyfikacji oraz praktyki dokumentacyjne. Dostawca pewny swoich systemów jakości chętnie odpowie na takie pytania. Ci, którzy się wykręcają lub udzielają niejasnych odpowiedzi, mogą nie posiadać niezbędnego zaplecza weryfikacyjnego, które wymaga prawdziwa precyzyjna obróbka blach.

Systemy jakości gwarantują, że części spełniają specyfikacje, ale co z konsekwencjami kosztowymi różnych poziomów dokładności? Zrozumienie zależności między tolerancjami a kosztami produkcji pomaga w podjęciu świadomych decyzji dotyczących rzeczywistej potrzeby dokładności.

Zrównoważenie wymagań dotyczących precyzji z kosztami produkcji

Oto pytanie, którego nikt nie chce zadać na głos: czy tolerancja ±0,005 cala jest naprawdę konieczna, czy może płacisz nadmierną cenę za dokładność, której w rzeczywistości nie potrzebujesz? To właśnie rozmowa, której większość profesjonalnych warsztatów blacharskich unika — przecież ścisłe tolerancje oznaczają wyższe faktury. Jednak szczera ocena zależności między dokładnością a kosztem pozwala zaoszczędzić znaczne kwoty bez utraty funkcjonalności elementów.

Nieprzyjemna prawda? eksperci od tolerancji technicznych , zbyt ścisłe tolerancje zwiększają czas obróbki i koszty, podczas gdy zbyt luźne mogą prowadzić do awarii. Znalezienie odpowiedniego balansu wymaga dokładnego zrozumienia, w jaki sposób specyfikacje dotyczące tolerancji wpływają na ekonomikę produkcji.

Zrozumienie kosztów ścisłych tolerancji

Dlaczego precyzja jest droższa? Odpowiedź wiąże się z każdym etapem procesu produkcyjnego. Ścisłe tolerancje wymagają:

- Bardziej zaawansowanego sprzętu: Osiągnięcie wartości ±0,003 cala wymaga maszyn CNC wyposażonych w systemy sprzężenia zwrotnego w czasie rzeczywistym, precyzyjnych narzędzi oraz kontrolowanych warunków środowiskowych, jakich typowe zakłady produkcyjne po prostu nie posiadają

- Dłuższego czasu przygotowania: Dostrojenie ścisłych tolerancji wymaga dodatkowych próbek testowych, cykli pomiarowych oraz regulacji maszyny przed rozpoczęciem produkcji

- Wolniejszych prędkości przetwarzania: Cięcie laserowe zapewniające maksymalną jakość krawędzi odbywa się wolniej niż standardowe parametry cięcia

- Dodatkowej kontroli: Mniejsze tolerancje wymagają większej liczby punktów pomiarowych, często konieczne jest weryfikowanie przy użyciu maszyny CMM zamiast prostego sprawdzania granicznego

- Wyższe wskaźniki sortowania: W miarę jak tolerancje stają się mniejsze, większa liczba elementów wychodzi poza dopuszczalne granice, co zwiększa odpady materiałowe i konieczność przeróbki

Jako Herold Precision Metals wyjaśnia , „Tolerancje obróbkowe na elementach blacharskich mogą spowolnić proces i zwiększyć koszty, ponieważ wymagają bardziej złożonych i czasochłonnych metod oraz zmniejszają wydajność produkcji.”

Zależność nie jest również liniowa. Przejście od ±0,030" do ±0,015" może zwiększyć koszt elementu o 10–15%. Jednak zawężenie tolerancji od ±0,010" do ±0,005" może podwoić cenę – lub nawet więcej. Osiągnięcie tej końcowej dawki precyzji wymaga wykładniczo większego nakładu pracy.

| Klasa tolerancji | Zakres typowy | Względny wpływ na koszt | Wymagania dotyczące inspekcji |

|---|---|---|---|

| Klasa Komercyjna | ±0,030" do ±0,060" | Poziom podstawowy (1×) | Standardowe kontrole wymiarowe |

| Standardowa precyzja | ±0,015" do ±0,030" | 1,2× do 1,5× | Rozszerzone próbkowanie inspekcyjne |

| Wysoka Precyzja | ±0,005" do ±0,015" | 1,5× do 2,5× | Weryfikacja CMM, kontrole statystyczne |

| Ultra-wysoka precyzja | Poniżej ±0,005 cala | 3× do 5×+ | 100% kontrola CMM, kontrolowane środowisko |

Te mnożniki różnią się w zależności od złożoności części, materiału i wielkości produkcji. Jednak schemat pozostaje ten sam: każdy kolejny poziom dokładności wiąże się z coraz wyższymi kosztami.

Kiedy wystarczająca jest standardowa precyzja

Oto praktyczne pytanie: jak określić, jaki poziom dokładności rzeczywiście wymaga Twoje zastosowanie? Zacznij od zastanowienia się, co się stanie, jeśli wymiary znajdą się na skrajnych granicach pasma tolerancji.

Weź pod uwagę te oparte na zastosowaniu wytyczne dotyczące precyzyjnych elementów blacharskich:

- Panele dekoracyjne i osłony: Stopień komercyjny (±0,030" do ±0,060") zazwyczaj wystarcza. Wygląd wizualny jest ważniejszy niż dokładne wymiary

- Ogólne obudowy i uchwyty: Standardowa precyzja (±0,015" do ±0,030") zapewnia spełnienie większości wymagań montażowych przy rozsądnych luzach

- Powierzchnie stykające się i interfejsy funkcjonalne: Wysoka precyzja (±0,005" do ±0,015") gwarantuje odpowiednie pasowanie elementów ruchomych, powierzchni uszczelniających oraz krytycznych punktów mocowania

- Branża lotnicza, urządzenia medyczne i instrumenty precyzyjne: Ekstremalnie wysoka precyzja (poniżej ±0,005") w przypadku, gdy dokładność wymiarowa bezpośrednio wpływa na bezpieczeństwo lub wydajność

Główne spostrzeżenie specjalistów od tolerancji produkcyjnych: „Ściślejsze tolerancje dają bardziej precyzyjne części, ale zwiększają koszty produkcji, podczas gdy luźniejsze tolerancje są tańsze, ale mogą powodować problemy z dopasowaniem.” Celem nie jest maksymalna precyzja — lecz odpowiednia precyzja dostosowana do konkretnego zastosowania.

Podejmowanie celnych decyzji dotyczących tolerancji

Producenci precyzyjnej obróbki blach doceniają klientów, którzy rozumieją kompromisy związane z tolerancjami. Oto jak mądrze podejść do specyfikacji:

- Zidentyfikuj rzeczywiście kluczowe cechy: Które wymiary wpływają na dopasowanie, funkcjonalność lub bezpieczeństwo? Stosuj ścisłe tolerancje tylko tam, gdzie to ma znaczenie

- Strategicznie wykorzystuj klasy tolerancji: Stosuj różne poziomy dokładności do różnych cech tego samego elementu. Otwór montażowy może wymagać ±0,005", podczas gdy ogólny kontur części dopuszcza ±0,030"

- Weź pod uwagę metody montażu: Czy łączniki, kleje czy spawanie będą tolerować niewielkie odchylenia wymiarowe? Jeśli tak, odpowiednio złagodź tolerancje

- Oceń możliwe tryby uszkodzeń: Jeśli wymiar na granicy tolerancji nadal zapewnia akceptowalną funkcjonalność, najprawdopodobniej został właściwie określony

- Porozmawiaj ze swoim wykonawcą: Doświadczone zakłady zajmujące się precyzyjną obróbką blach mogą doradzić, jakie tolerancje naturalnie osiągają ich procesy, oraz gdzie zaostrzenie specyfikacji znacząco wpłynie na koszt

Jak stwierdził jeden z kierowników ds. inżynierii: „Realistyczne podejście do wymagań dotyczących tolerancji redukuje koszty i pozwala firmom oferować konkurencyjniejsze ceny oraz szybsze terminy realizacji.”

Podsumowując? Precyzja kosztuje pieniądze. Niepotrzebna precyzja marnuje pieniądze. Zrozumienie, gdzie aplikacja rzeczywiście wymaga ścisłych tolerancji, a gdzie nie, zmienia Cię z klienta wydającego nadmiar w kupującego, który otrzymuje dokładnie potrzebną jakość za odpowiednią cenę.

Po wyjaśnieniu kwestii kosztów, jak te zasady dotyczące tolerancji stosują się w różnych branżach? Odpowiedź różni się znacząco w zależności od tego, czy produkujesz komponenty samochodowe, zespoły lotnicze, czy obudowy elektroniczne.

Zastosowania precyzyjnej obróbki blach w różnych branżach

Różne branże nie tylko mają inne części — mają zasadniczo różne relacje z precyzją. Komponenty podwozia samochodowego działają w warunkach drgań i obciążeń, jakich obudowy urządzeń medycznych nigdy nie doświadczają. Zespoły lotnicze napotykają skrajne temperatury, które byłyby bez znaczenia dla obudów elektroniki użytkowej. Zrozumienie tych specyficznych dla branży wymagań pomaga określić odpowiednie tolerancje i znaleźć partnerów produkcyjnych wyposażonych w środki niezbędne do spełnienia unikalnych potrzeb Twojej branży.

Niezależnie od tego, czy szukasz precyzyjnej obróbki blach w pobliżu mnie, czy oceniasz globalnych dostawców, znajomość wymagań Twojej branży oraz certyfikatów potwierdzających te możliwości pozwala odróżnić skuteczne pozyskiwanie od kosztownych błędów.

Wymagania dotyczące precyzji w motoryzacji

Przemysł motoryzacyjny wymaga unikalnej kombinacji precyzji, trwałości i efektywności kosztowej przy dużych wolumenach produkcji. Zdaniem ekspertów od tłoczenia metali, możliwości tłoczenia zapewniają doskonałą jakość dla zastosowań motoryzacyjnych, a metoda przetwarzania przez tłoczenie gwarantuje spójność produktu końcowego.

Typowe zastosowania precyzyjnej blachy w przemyśle motoryzacyjnym obejmują:

- Elementy szkieletu i konstrukcji nośnej: Szyny ramy, poprzeczki, wsporniki i wzmocnienia zapewniające integralność konstrukcyjną oraz ochronę przed wypadkami

- Części zawieszenia: Dźwignie zawieszenia, podwozia, drążki i wsporniki montażowe wymagające ścisłych tolerancji dla prawidłowych właściwości jezdnych

- Płaszczyzny karoserii i elementy zamykające: Drzwi, maski, nadkola i klapki bagażnika, które muszą być lekkie, a jednocześnie dokładnie ukształtowane, aby zapewnić spójne pasowanie i wykończenie

- Elementy silnika i skrzyni biegów: Pokrywy głowic cylindrów, miski olejowe, obudowy skrzyń biegów i pokrywy łożysk zaprojektowane tak, aby wytrzymać wysokie temperatury i obciążenia mechaniczne

- Wykończenia wnętrza i exterioru: Ramy paneli instrumentów, konsoli środkowych, uchwyty drzwi i kratki łączące wymagania estetyczne z precyzją funkcjonalną

Co czyni zastosowania motoryzacyjne szczególnie wymagającymi? Części tłoczone ze blachy od OEM muszą zachować spójność wymiarową w całych partiach produkcyjnych liczących tysiące lub miliony sztuk. Wspornik zawieszenia różniący się o ±0,030 cala w prototypie może być akceptowalny — ale ta sama różnica w 100 000 sztukach produkcyjnych wywoła chaos na linii montażowej.

Certyfikat IATF 16949 staje się niezbędnym elementem dla dostawców obsługujących producentów OEM z branży motoryzacyjnej. Ta norma wymaga udokumentowanego zarządzania bezpieczeństwem produktów, stosowania narzędzi podstawowych AIAG (PPAP, FMEA, MSA, SPC) oraz audytów procesów produkcyjnych wykraczających poza standardowe wymagania systemu jakości. Szukając precyzyjnego tłoczenia blach w pobliżu mnie na potrzeby motoryzacyjne, certyfikat IATF powinien znaleźć się na samej górze listy kwalifikacyjnej.

Dla producentów specjalizujących się w tej dziedzinie, Shaoyi (Ningbo) Metal Technology stanowi przykład możliwości, których wymagają programy motoryzacyjne. Jako producent specjalizujący się w precyzyjnym tłoczeniu z certyfikatem IATF 16949, oferuje komponenty zawieszenia, podwozia i konstrukcyjne z szybkim prototypowaniem w ciągu 5 dni oraz kompleksowym wsparciem DFM — dokładnie taką kombinację wymagają harmonogramy rozwoju pojazdów.

Branżowe standardy dopuszczalnych odchyleń

Poza sektorem motoryzacyjnym każda branża stawia wyraźne wymagania dotyczące dokładności, ukształtowane przez warunki eksploatacji, środowisko regulacyjne oraz oczekiwania dotyczące wydajności.

Zastosowania w lotnictwie

Według specjaliści przemysłowi od obróbki blachy , w lotnictwie każdy gram ma znaczenie, a kompromisy dotyczące bezpieczeństwa są niedopuszczalne. Typowe precyzyjne elementy blacharskie w lotnictwie obejmują:

- Elementy konstrukcyjne kadłuba wymagające tytanu i specjalnych stopów aluminium

- Obudowy silników i gondole o złożonych krzywiznach

- Płyty wnęk wnętrza spełniające normy dotyczące palności i masy

- Obudowy systemów awioniki z wymaganiami dotyczącymi osłony przed zakłóceniami elektromagnetycznymi (EMI)

Tolerancje lotnicze często wykraczają poza zakres ultra wysokiej precyzji (poniżej ±0,005 cala) dla krytycznych styków konstrukcyjnych. Wymagają one maksymalnej dokładności w procesach takich jak cięcie laserowe 5-osiowe lub cięcie strumieniem wody, aby zminimalizować wpływ temperatury. Złożone procesy gięcia i certyfikowane procedury spawania to standardowe oczekiwania.

Zastosowania elektroniczne i elektryczne

Tam, gdzie komponenty elektryczne wymagają ochrony, organizacji i chłodzenia, precyzyjne obróbki blach stają się niezastąpione. Typowe zastosowania obejmują:

- Obudowy szaf serwerowych z precyzyjnymi wzorami montażowymi dla standardowego sprzętu

- Obudowy szaf sterowniczych wymagające wycięć wentylacyjnych oraz rozwiązań do zarządzania przewodami

- Radiatorów i komponentów do zarządzania temperaturą, wymagających stałego kontaktu powierzchniowego

- Obudowy ekranujące EMI/RFI z ciasnymi tolerancjami szczelin zapewniającymi integralność sygnału

Zastosowania elektroniczne zazwyczaj wymagają standardowych do wysokich dokładności (±0,010" do ±0,020") ze szczególnym naciskiem na powtarzalne wzory otworów do mocowania elementów. Wybór materiałów preferuje stopy aluminium ze względu na lekkość i przewodność termiczną lub stal ocynkowaną w zastosowaniach ekranujących o korzystnej relacji kosztu do efektywności.

Zastosowania w urządzeniach medycznych

Technologia medyczna koncentruje się na zdrowiu człowieka i niezawodności diagnostyki, wymagając najwyższych standardów higieny, możliwości czyszczenia oraz biokompatybilności. Zgodnie z danymi branżowymi, typowe zastosowania precyzyjnej blachy w technice medycznej obejmują:

- Obudowy instrumentów chirurgicznych wymagające kompatybilności z procesem sterylizacji

- Obudowy sprzętu diagnostycznego z precyzyjnym dopasowaniem paneli

- Ramy sprzętu laboratoryjnego spełniające specyfikacje pomieszczeń czystych

- Komponenty związane z implantami, wymagające biokompatybilnych materiałów

Wybór materiału znacząco się ogranicza w zastosowaniach medycznych — dominują wysokiej jakości stalenie nierdzewne (gatunki 304 i 316) lub tytan. Procesy produkcyjne podkreślają cięcie bez zadziorów za pomocą precyzyjnego cięcia laserowego oraz szczelne połączenia metodą spawania TIG. Często po wyrobowieniu stosuje się obróbkę powierzchni, taką jak elektropolerowanie, aby zapewnić maksymalną czystość.

Budowla i architektura

Nowoczesna konstrukcja łączy funkcjonalność z designem, tworząc widoczne elementy metalowe, które muszą być zarówno estetyczne, jak i niezwykle trwałe:

- Płyty elewacyjne i systemy okładzin o spójnym wyglądzie wizualnym

- Elementy łącznikowe konstrukcyjne z certyfikowanymi nośnościami

- Niestandardowe komponenty poręczy i balustrad odpowiadające specyfikacjom architektonicznym

- Kanały wentylacyjne i systemy dystrybucji powietrza

Zastosowania budowlane zazwyczaj akceptują tolerancje dokładności od komercyjnych do standardowych, przy czym nacisk kładziony jest na odporność na warunki atmosferyczne i jakość wykończenia, a nie na dokładność wymiarową.

Dopasowanie partnerów wykonawczych do wymagań branżowych

Znalezienie odpowiedniego dostawcy precyzyjnych tłoczonych elementów z blachy odlewniczej oznacza dopasowanie możliwości do specyficznych wymagań Twojej branży. Regionalni producenci, tacy jak Cortec Precision Sheet Metal, US Precision Sheet Metal i Nevada Precision Sheet Metal, obsługują różne rynki krajowe — jednak globalne łańcuchy dostaw coraz częściej łączą kupujących ze specjalistycznymi międzynarodowymi producentami oferującymi konkurencyjne możliwości.

Kluczowe pytania pozostają takie same we wszystkich branżach:

- Czy wytwórca posiada certyfikaty istotne dla Twojej branży (IATF 16949 dla motoryzacji, AS9100 dla przemysłu lotniczego, ISO 13485 dla medycyny)?

- Czy może wykazać się doświadczeniem w zakresie konkretnych typów komponentów i materiałów, których potrzebujesz?

- Czy jego możliwości kontroli jakości odpowiadają Twoim wymaganiom dotyczących tolerancji?

- Czy może wspierać Twoje objętości produkcji — od prototypów po seryjną produkcję?

W przypadku zastosowań motoryzacyjnych producenci tacy jak Shaoyi łączą certyfikat IATF 16949 z możliwościami szybkiego prototypowania (czas realizacji 5 dni), infrastrukturą zautomatyzowanej produkcji seryjnej oraz czasem odpowiedzi na ofertę w ciągu 12 godzin. Ten zestaw rozwiązań odpowiada podwójnym wymaganiom przemysłu motoryzacyjnego: szybkości rozwoju w fazie inżynieryjnej oraz opłacalnej produkcji masowej dla wytwarzania seryjnego.

Zrozumienie wymagań dotyczących precyzji w Państwa branży oraz znalezienie partnerów wyposażonych w środki do ich spełnienia stanowi fundament skutecznego pozyskiwania precyzyjnych blach giętych. Jednak certyfikaty i możliwości to tylko dwa czynniki w wyborze partnera. W następnej sekcji omówiono kompletny model oceny przy doborze odpowiedniego partnera produkcyjnego.

Wybór odpowiedniego partnera ds. precyzyjnej obróbki blach

Zdefiniowałeś swoje tolerancje, wybrałeś materiały, zaprojektowałeś pod kątem możliwości produkcji i rozumiesz wymagania swojej branży. Nadchodzi decyzja, która decyduje o tym, czy cała ta przygotowanie przyniosą efekty: wybór partnera odnoszącego się do produkcji Twoich elementów. Ten wybór wpływa na wszystko – od harmonogramów rozwoju po koszty produkcji oraz długoterminową niezawodność łańcucha dostaw.

Zdaniem ekspertów ds. zakupów z dziesięcioleciowym doświadczeniem, wybór odpowiedniego partnera wykonującego gięcie blach to coś więcej niż tylko cena czy lista wyposażenia. Chodzi o budowanie relacji opartej na zaufaniu, komunikacji i wspólnych celach. Przeanalizujmy ramy oceny, które oddzielają wyjątkowych partnerów od tych, którzy jedynie twierdzą, że posiadają możliwości precyzyjnej obróbki.

Ocena możliwości producenta

Zanim poprosisz o wyceny, potrzebujesz systematycznych kryteriów oceny, czy potencjalni partnerzy rzeczywiście mogą dostarczyć to, czego wymaga Twój projekt. Jak zauważają specjaliści ds. wyboru partnerów odgięciowych , wyraźne zrozumienie Twoich konkretnych potrzeb pozwala lepiej ocenić, czy dana firma produkcyjna może spełnić Twoje oczekiwania i dostarczyć wymagane wyniki.

Oto lista kontrolna stosowana przez nabywców precyzyjnych blach, którzy oceniają potencjalnych dostawców:

- Możliwości sprzętu i inwestycje technologiczne: Nowoczesne maszyny i oprogramowanie zapewniają znaczące korzyści pod względem dokładności, efektywności i spójności. Poszukuj systemów laserowych światłowodowych, giętarek CNC z pomiarem kąta gięcia oraz automatycznego transportu materiałów. Jednak, jak zauważają doświadczeni zakupowcy, proces realizacji u dostawcy jest ważniejszy niż lista posiadanego sprzętu — dobrze utrzymany starszy sprzęt obsługiwany przez wykwalifikowanych techników może osiągać lepsze wyniki niż zaniedbywana nowoczesna maszyna.

- Certyfikaty jakości odpowiednie dla Twojej branży: ISO 9001 określa podstawowe wymagania systemu jakości. Certyfikat IATF 16949 jest niezbędny w zastosowaniach motoryzacyjnych i wymaga udokumentowanego zarządzania bezpieczeństwem produktu oraz wykorzystania narzędzi podstawowych AIAG. W przypadku przemysłu lotniczego poszukaj certyfikatu AS9100; dla urządzeń medycznych – ISO 13485. Certyfikaty świadczą o systematycznym podejściu do jakości — a nie tylko o marketingowych zapowiedziach.

- Doświadczenie od prototypu do produkcji: Według ekspertów od prototypowania niektórzy partnerzy potrafią dostarczyć wyłącznie prototypy, podczas gdy inni są w stanie przejść do produkcji niskoseryjnej lub pełnoskalowej. Wybór partnera, który może skalować się razem z Tobą, oznacza mniej straconego czasu na wprowadzanie nowego dostawcy wtedy, gdy będziesz gotowy, by ruszyć dalej. Oceń, czy potencjalny partner obsługuje zarówno rozwój, jak i produkcję seryjną.

- Dostępność wsparcia DFM: Wspaniali dostawcy nie tylko dostarczają części — współpracują, aby Twoje produkty były lepsze i bardziej opłacalne. Szukaj partnerów gotowych do angażowania się w inżynierię zwiększającą wartość, którzy przeanalizują Twoje projekty pod kątem możliwości produkcji i zaproponują ulepszenia przed rozpoczęciem produkcji. Ta wiedza zapobiega kosztownym błędom i optymalizuje projekty pod kątem konkretnych procesów.

- Czas otrzymania wyceny: Harmonogramy rozwoju rzadko pozwalają na powolne reakcje dostawców. Szybkie przygotowanie oferty świadczy o responsywności w komunikacji i efektywności działań. Niektórzy dostawcy precyzyjnej obróbki blach dostarczają oferty w ciągu 24–48 godzin, podczas gdy inni potrzebują tygodni. Twoje wymagania dotyczące terminów powinny określać dopuszczalne czasy reakcji.

- Możliwości inspekcji i dokumentacji jakości: Upewnij się, że potencjalni partnerzy posiadają sprzęt CMM, udokumentowane procedury kontroli oraz możliwość dostarczania dokumentacji jakościowej wymaganej w Twojej branży. Procesy inspekcji pierwszego sztucznego elementu, certyfikaty materiałów oraz raporty pomiarowe powinny być standardową ofertą, a nie dodatkowym żądaniem.

- Odporność łańcucha dostaw: W ostatnich latach podkreśla się znaczenie niezawodnego zaopatrzenia materiałowego. Zapytaj o relacje związane z pozyskiwaniem materiałów, praktyki dotyczące zapasów oraz plany awaryjne na wypadek zakłóceń dostaw.

Dla wszystkich precyzyjnych prac z blachy kryteria te mają zastosowanie powszechne. Jednakże ich wagę należy dostosować do konkretnego zastosowania. Programy motoryzacyjne mogą stawiać na certyfikat IATF i skalowalność produkcji. Prace rozwojowe skupiające się na prototypach podkreślają szybkość realizacji i współpracę w zakresie DFM. Zastosowania medyczne wymagają możliwości dokumentacyjnych i śledzenia materiałów.

Pytania zadawane potencjalnym partnerom

Listy kontrolne oceny określają, co należy ocenić — ale potrzebne są również konkretne pytania, które ujawnią rzeczywiste możliwości, a nie tylko marketingowe sformułowania. Podczas wyboru dostawców precyzyjnej obróbki blach cienkich, te pytania pozwalają odróżnić kwalifikowanych partnerów od pozorów:

- "Czy możecie pokazać przykłady elementów o podobnej dokładności i złożoności?" Wykonane wcześniej prace lepiej niż deklaracje pokazują rzeczywiste możliwości. Poproś o studia przypadków lub próbne elementy z porównywalnych projektów.

- "Jaka jest Wasza standardowa tolerancja cięcia laserowego, gięcia i spawania?" Dostawcy pewni swojej precyzji natychmiast podadzą konkretne wartości. Niejasne odpowiedzi sugerują brak jasnej kontroli procesu.

- "Jak Państwo realizujecie procedurę DFM podczas przygotowywania ofert?" Szukaj partnerów, którzy aktywnie wskazują problemy projektowe, zamiast po prostu wyceniać to, co przesyłasz. Według źródeł branżowych, dobry partner nie tylko wykona Twoje części — poprawi je, przeglądając pliki CAD i sugerując modyfikacje projektu w celu obniżenia kosztów lub poprawy funkcjonalności.

- jaki jest Wasz typowy czas przygotowania oferty? Szybkość w tym zakresie często odzwierciedla ogólną efektywność operacyjną. Partnerzy tacy jak Shaoyi (Ningbo) Metal Technology ofertę przygotowują w ciągu 12 godzin dla aplikacji tłoczenia karoserii samochodowych — standard, który wskazuje na zoptymalizowane procesy i skupienie się na klientach.

- "Jak weryfikujesz pierwsze sztuki przed rozpoczęciem produkcji?" Odpowiedź ujawnia rygorystyczność kontroli oraz praktyki dotyczące dokumentacji jakości. Kompleksowe procesy FAI chronią zarówno Ciebie, jak i wytwórnię przed problemami produkcyjnymi.

- "Czy możesz wspierać szybkie prototypowanie, a następnie przejść na produkcję seryjną?" To pytanie pozwala zidentyfikować partnerów, którzy są w stanie wspierać cały cykl życia Twojego produktu. Niektórzy wytwórcy wyróżniają się przy prototypach, ale nie posiadają infrastruktury produkcyjnej. Inni koncentrują się wyłącznie na produkcji wielkoseryjnej. Idealny partner—szczególnie w zastosowaniach motoryzacyjnych—sprawnie obsługuje oba etapy.

- "Jakie certyfikaty posiadasz i kiedy odbył się ostatni audyt?" Aktualne certyfikaty są ważniejsze niż historyczne. Poproś o kopie certyfikatów oraz daty audytów, aby potwierdzić bieżące zgodność.

Zwróć uwagę, jak wytwórcy odpowiadają podczas pierwszych rozmów. Jak zauważają doświadczeni specjaliści ds. zakupów, sposób komunikacji w fazie ofertowej przewiduje to, czego można się spodziewać w trakcie całego projektu. Szybkie, szczegółowe odpowiedzi wskazują na działanie skoncentrowane na kliencie. Powolne reakcje lub unikanie odpowiedzi sygnalizują potencjalne problemy w przyszłości.

Szybkie prototypowanie: kluczowy etap weryfikacji

Przed przystąpieniem do produkcji narzędzi lub zamównienia partii produkcyjnej, szybkie prototypowanie potwierdza, że projekt działa w formie fizycznej. Ten etap wykrywa problemy pomijane przez symulacje CAD — takie jak kolizje podczas montażu, trudności obsługi oraz rzeczywiste odchyłki wymiarów, które ujawniają się dopiero przy użyciu rzeczywistych części.

Według specjaliści od prototypowania , szybkość jest często kluczowa w rozwoju produktu. Sprawdź, czy Twój partner oferuje usługi o krótkim czasie realizacji i poproś o realistyczne terminy dostawy oparte na Twoim konkretnym projekcie — a nie tylko o ogólne zapewnienia.

W zastosowaniach motoryzacyjnych, gdzie cykle rozwojowe stale się skracają, szybkość prototypowania bezpośrednio wpływa na czas wprowadzenia produktu na rynek. Możliwość Shaoyi tworzenia prototypów w ciągu 5 dni dla części tłoczonych stosowanych w motoryzacji stanowi przykład reaktywności wymaganej w obecnych programach rozwojowych. Połączenie tej cechy z infrastrukturą zautomatyzowanej produkcji seryjnej pozwala na płynny przejście od walidacji projektu do produkcji seryjnej.

Podczas oceny możliwości prototypowania należy rozważyć, czy partner oferuje konkretne technologie wymagane dla Twoich elementów. Różne prototypy wymagają różnych metod produkcji — cięcie laserowe dla płaskich kształtów, obróbkę CNC dla giętych części, a czasem wiele procesów dla złożonych zestawów. Partner o różnorodnych możliwościach pozwala uniknąć zarządzania wieloma dostawcami podczas rozwoju projektu.

Podjęcie ostatecznej decyzji

Po ocenie możliwości, zadaniu szczegółowych pytań oraz ocenie wsparcia w zakresie prototypów, jak podjąć ostateczną decyzję? Weź pod uwagę następujące czynniki:

- Zgodność z wymaganiami branżowymi: Producent certyfikowany zgodnie z IATF 16949, taki jak Shaoyi, jest odpowiedni do potrzeb łańcucha dostaw motoryzacyjnych. Natomiast lokalne warsztaty mogą lepiej sprostać jednorazowym projektom architektonicznym. Dostosuj specjalizację partnera do swojego zastosowania.

- Całkowita wartość w porównaniu do ceny jednostkowej: Najniższa podana cena często staje się najdroższym wyborem, gdy problemy z jakością, opóźnienia lub awarie w komunikacji generują ukryte koszty. Oceń pełny obraz: spójność jakości, niezawodność dostaw, wsparcie inżynieryjne oraz potencjał długoterminowego partnerstwa.

- Wizyty w zakładach, o ile to możliwe: Według eksperci zakupowi , regularne osobiste spotkania utrzymują silne relacje i ujawniają nowe możliwości. Przeglądanie zakładów pokazuje dyscyplinę procesową, stan sprzętu oraz profesjonalizm personelu, czego nie da się oddać w ofertach ani certyfikatach.

- Dopasowanie kulturowe i styl komunikacji: Będziesz współpracować ze swoim partnerem produkcyjnym przez miesiące lub lata. Kompatybilny styl komunikacji oraz wspólne oczekiwania dotyczące reaktywności zapobiegają frustracjom i umożliwiają współprace w rozwiązywaniu problemów.

Niezależnie od tego, czy oceniasz US Precision Sheet Metal Inc, Precision Sheet Metal LLC, czy producentów międzynarodowych, te kryteria mają zastosowanie powszechne. Celem nie jest znalezienie najtańszego dostawcy – chodzi o wybranie partnera, którego możliwości, systemy jakości oraz podejście do obsługi są zgodne z wymaganiami Twoich konkretnych projektów.

Dla kupujących z branży motoryzacyjnej idealny profil partnera definiuje kombinacja certyfikatu IATF 16949, szybkiego prototypowania, produkcji zautomatyzowanej, kompleksowego wsparcia DFM oraz szybkiej odpowiedzi ofertowej. Shaoyi (Ningbo) Metal Technology reprezentuje tę kombinację możliwości w zastosowaniach dotyczących podwozia, zawieszenia i komponentów konstrukcyjnych — jednak ramy oceny mają zastosowanie niezależnie od tego, których dostawców bierzesz pod uwagę.

Wybrany partner w zakresie precyzyjnej obróbki blach staje się rozszerzeniem Twoich możliwości inżynieryjnych i produkcyjnych. Dokonaj wyboru na podstawie zweryfikowanych kompetencji, udokumentowanych systemów jakości oraz rzeczywistej zgodności z Twoimi wymaganiami. Gdy znajdziesz dostawcę, który inwestuje w swoich ludzi, procesy i technologię – i traktuje Twój sukces jako własny – znaczy, że znalazłeś partnera wartego zachowania.

Często zadawane pytania dotyczące precyzyjnej obróbki blach

1. Czym jest precyzyjna obróbka blach?

Precyzyjna obróbka blach to proces wytwarzania komponentów metalowych z niewielkimi tolerancjami wymiarowymi, zazwyczaj w zakresie od ±0,005 cala do ±0,010 cala. W przeciwieństwie do standardowej obróbki, gdzie dopuszczalne odchyłki wynoszą ±1/16 cala lub większe, praca w klasie precyzyjnej wymaga zaawansowanych systemów laserowych światłowodowych, urządzeń gięcia CNC z pomiarem kąta i maszyn pomiarowych współrzędnościowych do weryfikacji. Taki poziom dokładności jest niezbędny w przemyśle lotniczym, medycznym, elektronicznym oraz motoryzacyjnym, gdzie precyzja wymiarowa bezpośrednio wpływa na wydajność lub bezpieczeństwo.

2. Czym są precyzyjne komponenty z blach?

Precyzyjne elementy z blachy to części wykonywane z cienkich arkuszy metalu poprzez cięcie, gięcie, przebijanie i procesy montażowe zaprojektowane tak, aby spełniać dokładne specyfikacje. Obejmują one podwozia i elementy zawieszenia samochodów, elementy konstrukcyjne w przemyśle lotniczym, obudowy urządzeń elektronicznych oraz korpusy urządzeń medycznych. To, co odróżnia je od standardowych komponentów, to wymagane niewielkie dopuszczalne odchyłki—często w zakresie ±0,005 do ±0,015 cala—i procesy weryfikacji jakości gwarantujące spójność w całych seriach produkcyjnych.

3. Jakie tolerancje można osiągnąć przy użyciu różnych procesów obróbki blach?

Różne procesy wytwórcze osiągają różne poziomy dokładności. Cięcie laserowe zazwyczaj osiąga tolerancję ±0,005 cala dla położenia elementów i średnicy otworów, a systemy o wysokiej precyzji osiągają nawet ±0,003 cala. Gięcie numeryczne oferuje standardowo ±0,010 cala, co poprawia się do ±0,005 cala przy użyciu precyzyjnego sprzętu. Tolerancje gięcia wahają się od ±1° dla kątów oraz ±0,015 cala dla wymiarów między gięciami na materiałach o grubości do 1/8 cala. Spawanie wprowadza większe odchylenia, przy czym wymiary dwumiejscowe mają standardowo tolerancję ±0,060 cala, a trzymiejscowe ±0,030 cala.

4. W jaki sposób dobór materiału wpływa na precyzję w obróbce blach?

Właściwości materiału znacząco wpływają na osiągalną dokładność. Miększe materiały, takie jak aluminium (gatunek 5052), charakteryzują się niewielkim odbiciem sprężystym w zakresie 0,5–1° po gięciu, co ułatwia uzyskanie ścisłych tolerancji kątów. Stal nierdzewna (gatunki 304 i 316) wykazuje duże odbicie sprężyste na poziomie 2–4°, wymagając większej kompensacji i dokładniejszej kontroli procesu. Grubość materiału również ma znaczenie — cieńsze materiały pozwalają na mniejsze tolerancje cięcia, ale są bardziej podatne na odkształcenia podczas manipulacji i kształtowania. Twardsze materiały wymagają większej siły tłoczenia i węższych otworów matrycy V, co ogranicza osiągalne promienie wewnętrznego gięcia.

5. Jakie certyfikaty powinienem szukać u partnera wykonującego precyzyjną obróbkę blach?

Wymagane certyfikaty zależą od branży. ISO 9001 zapewnia podstawowe zarządzanie jakością w ogólnym przemyśle produkcyjnym. IATF 16949 jest niezbędnym standardem dla zastosowań motoryzacyjnych i wymaga udokumentowanego zarządzania bezpieczeństwem produktu oraz narzędzi AIAG Core Tools (PPAP, FMEA, MSA, SPC). AS9100 dotyczy komponentów lotniczych, a ISO 13485 obejmuje urządzenia medyczne. Poza certyfikatami warto ocenić możliwości inspekcyjne, w tym wyposażenie CMM, procesy kontroli pierwszej sztuki oraz praktyki dokumentacyjne zapewniające śledzenie od surowców po gotowe części.

Małe partie, wysokie standardy. Nasza usługa szybkiego prototypowania sprawia, że weryfikacja jest szybsza i łatwiejsza —

Małe partie, wysokie standardy. Nasza usługa szybkiego prototypowania sprawia, że weryfikacja jest szybsza i łatwiejsza —