Czy aluminium rdzewieje? Prawdziwa odpowiedź, profilaktyka i sposoby naprawy

Czy aluminium rdzewieje?

Krótka odpowiedź na pytanie, czy aluminium rdzewieje

Czy kiedykolwiek zastanawiałeś się, „Czy aluminium rdzewieje jak żelazo lub stal?” Krótka odpowiedź: aluminium nie rdzewieje. Może jednak może ulegać korozji. Zrozumienie tej różnicy jest kluczowe przy podejmowaniu świadomych decyzji dotyczących wyboru materiałów na Twój następny projekt lub naprawę.

Rdza a korozja w ujęciu codziennym

Wytłumaczmy to w prosty sposób. Rdza rdza to konkretna forma korozji, która występuje wyłącznie w przypadku żelaza i metali na bazie żelaza, takich jak stal. To właśnie ta czerwonawo-brunatna, łuszcząca się warstwa, którą widzimy na starych ogrodzeniach lub narzędziach pozostawionych na zewnątrz. W ujęciu naukowym rdza powstaje, gdy żelazo reaguje z tlenem i wodą, tworząc tlenki żelaza.

Korozja korozja z kolei to szerszy proces. Obejmuje każdą reakcję chemiczną, która stopniowo pogarsza stan metalu, niekoniecznie żelaza. Tak więc, mimo że każda rdza to korozja, nie każda korozja to rdza. To właśnie ta różnica leży u podstaw często spotykanej w dyskusjach technicznych konfrontacji korozji z rdzą.

Dlaczego glin tworzy ochronny tlenek

W tym właśnie miejscu glin wyróżnia się. Gdy jest wystawiony na działanie powietrza lub wilgoci, glin szybko reaguje, tworząc cienką, twardą warstwę tlenku glinu na swojej powierzchni. Wyobraź sobie to jako przezroczysty, niewidzialny pancerz – jest dobrze przywarty, nie łuskuje się i faktycznie chroni metal znajdujący się pod nim przed dalszym uszkodzeniem. Dlatego rzadko widzimy rdzę na glinie, nawet jeśli jest używany na zewnątrz lub w wilgotnych warunkach.

Czy jednak glin może rdzewieć lub wykazywać podobne uszkodzenia? W większości codziennych warunków odpowiedź brzmi nie. Jednak jeśli ochronna warstwa tlenku glinu zostanie zaburzona – przez agresywne chemikalia, wodę morską lub kontakt z innymi metalami – może dojść do korozji glinu. Zamiast czerwonawej rdzy, jaką widzimy na stali, zauważysz na powierzchni matową, białawą lub szarawą, pudrowatą resztkę.

- Kolor: Rdza na żelazie/stali jest rudej lub brązowej; korozja glinu jest biała lub szara.

- Mechanizm: Rdza wymaga obecności żelaza; glin tworzy ochronny tlenek.

- Postęp: Z rdzy łuszczą się płatki i rozprzestrzenia się; tlenek aluminium zazwyczaj pozostaje na miejscu i chroni metal.

- Naprawialność: Rdza często nadal się rozprzestrzenia; warstwa tlenkowa aluminium może się samonaprawiać, chyba że warunki są ekstremalne.

Aluminium nie rdzewieje, ulega korozji – jednak zazwyczaj znacznie wolniej dzięki swojej samonaprawiającej się warstwie tlenkowej.

Zatem porównując aluminium i rdzę, pamiętaj: prawdziwym problemem jest korozja aluminium, a nie rdza. W kolejnych sekcjach dowiemy się, jak rozpoznać objawy, zapobiec uszkodzeniom, oczyścić dotknięte powierzchnie oraz dobrać odpowiedni stop aluminium do własnych potrzeb. Gotowy, by głębiej zająć się ochroną aluminium przed korozją? Zacznijmy od nauki o pasywacji i praktycznych strategiach zapobiegania.

W jaki sposób utlenianie aluminium chroni metal i gdzie zawodzi

Jak działa pasywacja aluminium

Czy kiedykolwiek zastanawiałeś się, dlaczego aluminium nie rdzewieje, ale czasem widać na nim matowy, sypki nalot zamiast jasnego połysku? Odpowiedź tkwi w procesie zwanym pasywacja . Gdy aluminium wystawione jest na działanie powietrza lub wody, niemal natychmiast reaguje z tlenem. Reakcja ta tworzy cienką, twardą i prawie niewidzialną warstwę tlenku glinu (Al 2O 3) na powierzchni. To właśnie istota utleniania aluminium —naturalnego zabezpieczenia, które chroni podstawowy metal przed dalszym zniszczeniem.

Właśnie ta warstwa tlenkowa sprawia, że aluminium jest tak trwałe w codziennym użyciu. Zauważysz, że świeżo przycięte lub wypolerowane aluminium szybko traci swój połysk i staje się jednolitym, matowym szarym. To właśnie powstaje ochronny tlenek. W przeciwieństwie do rdzy na żelazie, która odpada i odsłania kolejne warstwy metalu, warstwa tlenku glinowego trzyma się mocno, tworząc barierę, która zatrzymuje dalsze utlenianie aluminium. W skrócie, gdy zadasz pytanie „czy aluminium się utlenia?”, odpowiedź brzmi: tak – ale to utlenianie jest korzystne, a nie problemem.

- Ekspozycja: Aluminium wchodzi w kontakt z tlenem w powietrzu lub wodzie.

- Reakcja: Atomy na powierzchni reagują, tworząc tlenek glinu (Al 2O 3).

- Ochrona: Ta warstwa tlenkowa przylega ciasno, zamykając dostęp do metalu znajdującego się poniżej.

- Samonaprawiające się: Jeśli warstwa zostanie zarysowana, nowy tlenek tworzy się niemal natychmiast, naprawiając ochronę.

Gdy warstwa tlenkowa ulega rozbiciu

Brzmi to jak niezawodne? W większości środowisk niemal tak jest. Ale pewne warunki mogą pokonać ten pancerz. Warstwa ochronna może zostać naruszona przez:

- Kwasy lub zasady (które atakują tlenek bezpośrednio)

- Opadający sól lub środowiska morskie (chlorek przenika i niszczy warstwę)

- Stojącą wodę lub uwięziony brud (które mogą tworzyć szczeliny i lokalne uszkodzenia)

- Ścieranie mechaniczne (zarysowania zbyt częste lub zbyt głębokie, by tlenek zdążył się zregenerować)

- Kontakt z innymi metalami (zwłaszcza w obecności wilgoci, co prowadzi do korozji galwanicznej)

Na przykład, jeśli pozostawi się aluminiową część w solnym, wilgotnym środowisku – takim jak pomost łodziowy lub powietrze przybrzeżne – chlorki mogą przedostać się przez warstwę tlenkową, powodując ubytki i widoczne uszkodzenia. Wówczas mogą pojawić się białe, mączyste plamy lub nawet drobne otwory, co jest oznaką utlenienia aluminium wykraczającego poza proste ścielenie powierzchni [Wiley Metal] .

Zachowanie samonaprawcze i jego granice

Jedną z najbardziej niezwykłych cech utlenionego aluminium jest jego zdolność do samonaprawy. Zarysuj powierzchnię, a odsłonięty metal chwyta tlen z powietrza, tworząc nową warstwę tlenkową w ciągu kilku sekund. Dlatego aluminium jest tak popularne w budownictwie, transporcie i zastosowaniach na zewnątrz. Jednak ta samonaprawa nie nadąża, jeśli środowisko jest zbyt agresywne lub jeśli powierzchnia jest powtarzalnie uszkadzana szybciej, niż warstwa tlenkowa zdąży się odbudować. W takich przypadkach korozja może postępować, a trwałość metalu jest zagrożona.

Pasywacja to ochronna warstwa, a nie pancerz – wspieraj ją dobrym projektem i konserwacją.

Zatem choć utlenianie aluminium jest w większości przypadków korzystne, zrozumienie jego ograniczeń jest kluczowe. Jeśli chcesz, by Twoje aluminium służyło długo, utrzymuj je w czystości, unikaj agresywnych chemikaliów i projektuj części tak, aby odprowadzały wodę i zanieczyszczenia. W kolejnym kroku przyjrzymy się, jak rozpoznać różne typy korozji i co te sygnały ostrzegawcze oznaczają dla trwałości Twojego projektu.

Rozpoznawanie korozji aluminium

Najczęstsze typy korozji aluminium

Gdy zauważysz biały, pudrowaty nalot lub niepokojące zmiany na powierzchni części aluminiowych, naturalne jest pytanie: jak wygląda korozja aluminium i jakie są jej przyczyny? W przeciwieństwie do żelaza, aluminium nie rdzewieje, może jednak ulegać różnym typom korozji – każdy z nich ma swoiste objawy i czynniki wywołujące. Przeanalizujmy najczęstsze typy korozji aluminium i sposób ich rozpoznawania w praktyce.

| Typ korozji | Wygląd | Czynniki wywołujące | Metody Diagnozy |

|---|---|---|---|

| Wykrywanie | Małe, punktowe wgłębienia; często otoczone białym proszkiem (wodorotlenkiem glinu) | Chlorki (sól), wady powierzchni, zanieczyszczony powietrzny | Kontrola wzrokowa, lupa do wgłębień, test przetarcia powierzchni |

| Szczelina | Lokalne zniszczenie w szczelinach, szwach lub pod uszczelkami; biały/szary osad | Zatrzymana wilgoć, zanieczyszczenia, zła odprowadzalność wody | Sprawdź połączenia, miejsca styku elementów mocujących, zbiorniki wody |

| Galwaniczne | Korozja w pobliżu punktów kontaktu metal-metal; może występować szybkie żłobkowanie lub matowienie | Kontakt z bardziej szlachetnymi metalami (np. miedź, stal) i elektrolitem (woda) | Sprawdź połączenia metalów o różnych właściwościach, szukaj korozji w strefach styku |

| Filiformny | Paski przypominające robaki, nitkowate ślady pod powłokami lub farbą | Uszkodzenie powłoki, wysoka wilgotność, obecność chlorków | Zdejmij farbę w celu inspekcji, szukaj nitek |

| Mundur | Równomierne, matowe przyciemnienie lub cienienie powierzchni; utrata połysku | Stałe narażenie na silne kwasy/zasady, niestabilne pH | Porównanie powierzchni, sprawdź występowanie powszechnego cienienia |

Diagnostyka terenowa, na którą możesz polegać

Zastanawiasz się, jak rozpoznać korozję aluminium od zwykłego brudu na powierzchni? Wypróbuj te proste metody kontroli:

- Sprawdź krawędzie powłok, główki elementów łączących oraz miejsca gromadzenia się wody – to typowe miejsca występowania ukrytej korozji.

- Użyj lupki: Osadziny korozyjne pojawiają się jako ostre, drobne otworki, podczas gdy brud łatwo się usuwa.

- Sprawdź obecność wilgoci: Uwięziona woda lub zanieczyszczenia w złączach często wskazuje na korozję szczelinową.

- Zwróć uwagę na biały lub szary proszkowaty nalot – jest to klasyczny objaw korozji aluminium, a nie tylko brud.

Nadal nie jesteś pewien? Zrób kilka zdjęć do dokumentacji. Oto szybka lista zdjęć, które warto wykonać dla kompleksowej oceny:

- Ogólny (makroskopowy) widok obszaru objętego uszkodzeniem

- Częściowy widok wgłębnień, śladów lub osadów

- Zdjęcie kontekstowe pokazujące pobliskie połączenia, elementy mocujące lub powłoki

Zrozumienie, co powoduje korozję aluminium, jest kluczowe dla jej zapobiegania. Chlorki pochodzące z soli, zła odprowadzalność wody oraz bezpośredni kontakt z innymi metalami są częstymi przyczynami. Dlatego, jeśli zastanawiasz się, co powoduje korozję aluminium lub dlaczego aluminium ulega korozji, należy przede wszystkim przyjrzeć się środowisku i szczegółom konstrukcyjnym.

Kiedy stosować standaryzowane badania

W przypadku części krytycznych lub gdy inspekcja wizualna nie wystarcza, najlepszym rozwiązaniem są standaryzowane badania laboratoryjne. Testy oparte na soli neutralnej – takie jak ASTM B117 lub ISO 9227 – pozwalają porównać skuteczność powłok lub symulować agresywne środowiska. W przypadku analizy wnikliwej, badania metalograficzne mogą ujawnić głębokość wgłębnień lub korozję międzykrystaliczną. Metody nieniszczące, takie jak prąd wirowy czy ultradźwięki, są również skuteczne w wykrywaniu ukrytej lub podpowierzchniowej korozji w konstrukcjach aluminiowych [Voliro] .

Dokładna diagnoza zaczyna się od uważnej obserwacji — jeśli masz wątpliwości, udokumentuj i skonsultuj się z ekspertami lub wykorzystaj standaryzowane testy.

Wczesne rozpoznanie typów korozji aluminium umożliwia podjęcie skutecznych działań. W dalszej części dowiemy się, jak zapobiec korozji elektrolitycznej i projektować mądrzejsze połączenia, aby wydłużyć żywotność aluminium.

Zatrzymanie korozji elektrolitycznej

Dlaczego różne metale atakują aluminium

Czy kiedykolwiek zastanawiałeś się, dlaczego mieszanie metali — na przykład stosowanie stalowych śrub na aluminiowej ramie — może czasem przynieść kłopoty? Cała sprawa sprowadza się do procesu zwanego korozja galwaniczna . Gdy dwa różne metale się stykają i występuje obecność elektrolitu (np. woda, wilgoć lub nawet słoneczne powietrze), rozpoczyna się reakcja elektrochemiczna. W takim układzie aluminium jest bardziej „anodowe” (chętniej oddaje elektrony) niż stal nierdzewna lub węglowa. Dlatego, gdy te metale się spotykają, aluminium zaczyna się pierwsze korodować, zwłaszcza w wilgotnych lub morskich środowiskach. Dlatego często pojawiają się pytania takie jak: „czy stal nierdzewna reaguje z aluminium?”. Odpowiedź brzmi: tak – korozja stali nierdzewnej z aluminium to realny problem, jeśli nie zostaną podjęte odpowiednie środki zapobiegawcze.

Odpowiednie praktyki izolacji i łączników

Brzmi to skomplikowanie? Nie musi tak być. Wyobraź sobie, że montujesz balustradę lub wspornik: chcesz mieć wytrzymałość stali nierdzewnej i lekkość aluminium, ale nie chcesz ponosić kosztownych napraw w przyszłości. Oto praktyczne kroki, które pomogą zapobiec korozji stali nierdzewnej i aluminium w miejscach połączeń:

- Do używaj niemetalicznych podkładek, tulei lub uszczelnień (plastikowych, gumowych) między częściami metalowymi, aby zablokować bezpośredni kontakt.

- Do nanesz kompatybilne powłoki (epoksydowe, antykorozyjne podkłady lub farby) na oba metale przed montażem.

- Do używaj past lub smarów hamujących korozję pod głowicami śrub i nakrętek.

- Do zapewnij dobre odprowadzenie wody — uszczelniaj szczeliny i projektuj złącza tak, aby odprowadzały wodę, a nie ją zatrzymywały.

- Nie używaj dużych elementów z aluminium z małymi częściami ze stali nierdzewnej; utrzymuj małą powierzchnię katody (stali) w stosunku do anody (aluminium).

- Nie zaniedbuj regularne inspekcje i konserwację, zwłaszcza w środowiskach słonych lub wilgotnych.

Projekt i konserwacja mające na celu przerwanie obwodu

Przerwanie obwodu galwanicznego to kwestia inteligentnego projektowania i utrzymania. Oto prosta tabela porównawcza najczęściej stosowanych kombinacji metali i ich względnego ryzyka korozji galwanicznej:

| Kombinacja metali | Względne ryzyko (w wilgotnych środowiskach) | Uwagi |

|---|---|---|

| Aluminium do aluminium | Niski | Brak pary galwanicznej, tylko standardowe ryzyko korozji aluminium |

| Aluminium do stali nierdzewnej | Umiarkowany do wysokiego | Ryzyko korozji aluminium i stali nierdzewnej wzrasta w wodzie morskiej |

| Aluminium do stali węglowej | Wysoki | Korozja aluminium i stali jest szybka bez izolacji |

| Aluminium do stali ocynkowanej | Zmienna | Zależy od stanu powłoki cynkowej; cynk działa jako anoda ofiarna |

Podsumowując, czy aluminium reaguje ze stalą nierdzewną? Tak, ale można zminimalizować problemy, izolując metale i utrzymując wodę poza połączeniem. Pamiętaj, że reakcja między stalą nierdzewną a aluminium jest najbardziej agresywna, gdy obecna jest wilgoć i sole. Regularna konserwacja, taka jak sprawdzanie uszczelnień i ponowne pokrywanie narażonych powierzchni, jest kluczem do długotrwałej trwałości.

Izoluj, uszczelniaj i odprowadzaj – przerwij każdy element obwodu galwanicznego, aby zmniejszyć ryzyko.

Dzięki przestrzeganiu tych najlepszych praktyk skutecznie zapobiegniesz korozji ze stali nierdzewnej i aluminium oraz wydłużysz żywotność swoich zespołów. W kolejnym kroku porównamy aluminium z innymi metalami, abyś mógł podjąć najbardziej świadomą decyzję dotyczącą materiałów w zależności od środowiska i zastosowania.

Dobór materiałów z uwzględnieniem cyklu życia

Tam, gdzie aluminium się wygrywa

Gdy wybierasz metal na projekt, pytanie nie brzmi tylko „czy aluminium jest odporne na korozję?” – chodzi o to, jak każdy materiał będzie się sprawował przez cały okres użytkowania. Wyobraź sobie budowę konstrukcji, pojazdu czy urządzenia zewnętrznego. Chcesz, aby był trwały, wymagał minimalnej konserwacji i był opłacalny na dłuższą metę. W wielu przypadkach aluminium wyróżnia się jako metal, który nie rdzewieje, dzięki swojemu naturalnemu barierowemu tlenkowemu pokryciu. Ta samonaprawiająca się warstwa oznacza, że aluminium jest odporne na rdzę w większości warunków środowiskowych i wymaga znacznie mniejszej konserwacji niż stal. Jego niska waga – około jedna trzecia wagi stali – czyni go idealnym do zastosowań, gdzie redukcja masy odgrywa kluczową rolę, jak np. w przemyśle lotniczym, transportowym czy przy konstrukcjach przenośnych.

Aluminium jest również łatwy w formowaniu i ekstruzji do skomplikowanych kształtów, umożliwiając zintegrowane funkcje i nowoczesne projekty. Jego wysoka przewodność cieplna i elektryczna umożliwia zastosowanie w everything od radiatorów po linie przesyłowe energii. Gdy zaś chodzi o zrównoważony rozwój, recykling aluminium jest trudny do pobicia – aż około 75% całego wyprodukowanego aluminium nadal jest dziś używane, co czyni go najlepszym wyborem dla projektów przyjaznych środowisku.

Gdy stal nierdzewna lub stal powlekana mogą być lepszym wyborem

Ale co, jeśli potrzebujesz maksymalnej wytrzymałości lub Twoja aplikacja napotyka ekstremalne temperatury? Wtedy stal nierdzewna bierze górę. Stal nierdzewna jest wyjątkowo wytrzymała i zapewnia znakomitą odporność na korozję w wielu agresywnych środowiskach, takich jak zakłady chemiczne czy warunki morskie. Mimo że stal nie jest metalem, który nie rdzewieje, to gatunki nierdzewne są zaprojektowane tak, aby oprawiać się korozji dzięki warstwom tlenku chromu. W przypadku konstrukcji obciążonych dużymi siłami wyższa wytrzymałość stali na rozciąganie i jej twardość czynią ją preferowanym wyborem, zwłaszcza gdy waga nie odgrywa kluczowej roli.

Stal powlekana lub ocynkowana może również stanowić mądre i opłacalne rozwiązanie do zastosowań w pomieszczeniach lub na zewnątrz w mniej wymagających warunkach. Dzięki odpowiednim powłokom i regularnej konserwacji stal może służyć długo za stosunkowo niską początkową cenę. Należy jednak pamiętać, że powłoki te mogą wymagać odnowienia w czasie, a konstrukcje stalowe zazwyczaj wymagają częstszych kontroli i utrzymania niż aluminium.

Jak porównać wartość cyklu życia

Więc, jaki metal nie rdzewieje lub nie wymaga ciągłego nadzoru? Aluminium jest dość bliskie, ale właściwa odpowiedź zależy od Twojego środowiska, projektu i strategii konserwacji. Aby pomóc Ci ocenić dostępne opcje, poniżej znajduje się porównanie obok siebie:

| Kryteria | Aluminium | Stal nierdzewna | Stal ocynkowana/pokryta powłoką |

|---|---|---|---|

| Koszt początkowy | Wyższa cena za funt, ale mniej potrzebna ze względu na niską wagę | Wysoka (szczególnie dla wysokich gatunków) | Najniższy |

| Odporność na korozję | Naturalna warstwa tlenkowa; czy aluminium jest odporne na korozję? Tak, w większości środowisk | Doskonała (szczególnie w trudnych warunkach lub w środowisku morskim) | Dobra (zależy od spójności powłoki) |

| Nakład konserwacyjny | Minimalny (warstwa tlenkowa utrzymuje się sama) | Niski (ale nadal wymaga czyszczenia i inspekcji) | Umiarkowany do wysokiego (pokrycia należy utrzymywać) |

| Waga | Najlżejszy (1/3 masy stali) | Cięższych | Najcięższe |

| Wyprodukowalność | Łatwy do wyciskania, formowania i obróbki mechanicznej | Dobry, ale trudniejszy do obróbki mechanicznej i formowania | Dobry, zwłaszcza w typowych kształtach |

| Możliwość recyklingu | Wyśmienny (najbardziej recyklingowa metala, zachowuje wartość) | Wyśmienny (szeroko recyklingowany) | Wyśmienny (szczególnie z rdzeniem stalowym) |

Pamiętaj, że najlepszy wybór nie polega tylko na tym, która metal nie rdzewieje, ale na tym, który materiał najlepiej odpowiada Twoim konkretnym potrzebom i warunkom środowiskowym. Na przykład wyższy początkowy koszt aluminium często jest rekompensowany niższymi kosztami utrzymania i oszczędnościami eksploatacyjnymi w czasie. W rejonach morskich lub przybrzeżnych jego odporność na korozję i możliwość recyklingu mogą przesądzić o jego wyborze. Natomiast w projektach wymagających dużych obciążeń, wysokiej temperatury lub ograniczonego budżetu bardziej odpowiednie mogą być stal nierdzewna lub stal powlekana.

- Zmapuj swoje środowisko: Czy jest nadmorskie, przemysłowe, czy wnętrzowe?

- Przeanalizuj metale kontaktowe: Czy różne metale będą się ze sobą stykać, tworząc ryzyko korozji?

- Zaplanuj strategię natrysku: Czy istotna jest dodatkowa ochrona czy łatwe nanoszenie poprawek?

- Ustal plan konserwacji: Jak często możesz sprawdzać lub konserwować materiał?

Wybór odpowiedniego materiału to kwestia zrównoważenia odporności na korozję, wagi, kosztu i konserwacji – warto spojrzeć dalej niż cena początkowa, by ocenić rzeczywistą wartość cyklu życia.

Dalej dowiemy się, jakie kroki skutecznie chronią aluminium przed korozją – od przygotowania powierzchni po powłoki – dzięki czemu maksymalnie wykorzystasz inwestycję, niezależnie od wybranego metalu.

Zapobieganie korozji dzięki sprawdzonym metodom ochrony aluminium

Przygotowanie powierzchni, które naprawdę działa

Czy kiedyś zastanawiałeś się, dlaczego niektóre elementy aluminiowe trwają dziesięciolecia, a inne pojawiają się na nich białawe plamy lub wgłębienia już po kilku porach roku? Sekret leży w przygotowaniu. Jeśli chcesz uzyskać skuteczną ochronę przed korozją aluminium, wszystko zaczyna się od starannego, krok po kroku przygotowania powierzchni. Oto jak zapobiec korozji aluminium – niezależnie od tego, czy pracujesz nad kadłubem łodzi, ramą okienną, czy elementem przemysłowym:

- Odżelazienie: Użyj środka czyszczącego bezpiecznego dla aluminium, aby usunąć oleje, smary i brud z warsztatu. Unikaj agresywnych zasad lub krzemianów, które mogą atakować powierzchnię. Pękanie mechaniczne może pomóc w usunięciu trudnych zabrudzeń.

- Przepłucz dokładnie: Wielokrotne płukanie, w tym podwójne lub potrójne płukanie przeciwbieżne, pomaga usunąć wszystkie ślady środka czyszczącego i brudu. Czyste, przepłukane powierzchnie są kluczowe dla kolejnych etapów.

- Trawienie lub szlifowanie: Mechanicznie przetrawiać (piaskować, szlifować) lub chemicznie wytrawiać, aby usunąć naturalną warstwę tlenkową i naświetlić świeży metal. Dobierz łagodne lub intensywne wytrawianie w zależności od stopu i potrzebnego wykończenia. Wytrawiacze kwasowe są łagodniejsze dla powierzchni polerowanych, podczas gdy wytrawiacze zasadowe mogą być bardziej agresywne w trudnych przypadkach.

- Usuwanie zanieczyszczeń: Dla stopów o dużej zawartości tlenków lub pierwiastków stopowych zastosuj roztwór do usuwania zanieczyszczeń (często na bazie kwasu azotowego), aby usunąć nierozpuszczalne reszty. Ten krok pozostawia powierzchnię czystą i gotową do powlekania.

- Powłoka konwersyjna (opcjonalnie): Zastosuj powłokę chromatową lub bezchromatową w celu poprawienia przyczepności oraz zwiększenia odporności na korozję aluminium, szczególnie przed malowaniem lub natryskiem proszkowym.

- Ostateczne płukanie i suszenie: Upewnij się, że powierzchnia jest całkowicie czysta i sucha przed nałożeniem jakiegokolwiek wykończenia.

- Zastosuj wykończenie ochronne: Wybierz anodyzowanie, malowanie lub natrysk proszkowy, postępując zgodnie z instrukcjami producenta, aby osiągnąć najlepsze rezultaty. Każdy system ma własne wymagania dotyczące grubości powłoki, utwardzania i środowiska aplikacji.

Opcje powłokowe i anodowania

Który wykończenie wybrać, aby osiągnąć maksymalną odporność aluminium na korozję? Oto szybki przegląd:

- Anodyzowanie: Ten proces elektrochemiczny powoduje pogrubienie naturalnej warstwy tlenkowej, w wyniku czego powstaje aluminium odporne na korozję, które wytrzymuje działanie czynników ścierających i agresywnych środowisk. Wykończenia anodowane mogą być przezroczyste lub kolorowe i są szczególnie trwałe w zastosowaniach morskich i architektonicznych. Uszczelnienie warstwy anodowanej dodatkowo zwiększa ochronę przed plamieniem i powstawaniem ubytków [ChemResearchCo] .

- Malowanie: Powłoki organiczne, takie jak poliuretan, farba epoksydowa lub akrylowa, stanowią dekoracyjną i ochronną barierę. Świetnie sprawdzają się w dopasowaniu kolorów i zapewniają dobrą ochronę w większości środowisk, ale mogą się łuszczyć i wymagać czasem dotychczasowych napraw.

- Powłoka proszkowa: Ten proces wykorzystuje suchy proszek wypalany w podwyższonej temperaturze, tworząc twardą, jednolitą warstwę. Aluminium pokryte proszkowo jest bardzo odporne na odpryskiwanie i wypalanie koloru, dlatego jest popularne w meblach ogrodowych, balustradach i urządzeniach.

Zalety i wady każdego wykończenia

-

Anodowanie

- Zalety: Doskonała ochrona przed korozją aluminium, trwała, nie łuszczy się ani nie odpada, odpowiednia do zastosowań wymagających dużej wytrzymałości lub w środowisku morskim

- Wady: Ograniczone opcje kolorystyczne, może być kosztowna, czasem wymaga uszczelnienia, trudna naprawa

-

Malarstwo

- Zalety: Szeroki wybór kolorów, łatwe dotykowe naprawy, odpowiednie do zastosowań dekoracyjnych

- Wady: Może się wyszczerbić, czasem wymaga nanoszenia od nowa, kluczowe jest pokrycie krawędzi

-

Malowanie proszkowe

- Zalety: Trwały, jednolity wykończenie, odporny na UV i warunki atmosferyczne, niski poziom konserwacji

- Wady: Dostosowanie koloru przy naprawach może być trudne, przygotowanie powierzchni musi być idealne

Typowe tryby uszkodzeń i sposób ich unikania

Martwisz się o uszkodzenia powłok? Większość problemów wynika z zaniedbań w przygotowaniu lub drobnych błędów. Oto na co należy zwracać uwagę:

- Słabe pokrycie krawędzi – powłoki robią się cieńsze w narożnikach i wokół otworów pod elementy mocujące, co staje się miejscem podatnym na korozję.

- Nieuszczelne warstwy anodowe – jeśli nie zostaną uszczelnione, nawet najlepsze anodowanie z czasem może dopuścić wilgoć.

- Zatrzymana wilgoć lub zanieczyszczenia – szczeliny i przerwy mogą pokonać nawet najbardziej wytrzymałe powłoki, prowadząc do zlokalizowanego ataku.

- Niewłaściwe czyszczenie powierzchni – pozostałości lub tlenki pozostawione na powierzchni mogą spowodować odspajanie się powłok lub tworzenie się pęcherzy.

Przygotowanie to 80% sukcesu w nanoszeniu powłok – powłoki nie wytrzymują tam, gdzie przygotowanie zawodzi, szczególnie przy krawędziach i otworach pod wkręty.

W przypadku prac krytycznych rozważ użycie standaryzowanych testów, takich jak ASTM B117 lub ISO 9227 (badanie odporności na mgłę solną), aby porównać skuteczność powłok. W przypadku wątpliwości sprawdź karta danych technicznych dostarczonych przez producenta powłok, aby uzyskać konkretne rekomendacje dotyczące odporności aluminium na korozję.

Dzięki tym krokom i opcjom maksymalnie zwiększy się odporność na korozję aluminium w Twoim projekcie. Następnie: poznaj bezpieczne i skuteczne sposoby czyszczenia i naprawy powierzchni aluminiowych – dzięki czemu nawet jeśli pojawi się korozja, możesz ją szybko naprawić i chronić swoją inwestycję.

Czyszczenie i naprawa utlenionego aluminium

Czyszczenie aluminium bez uszkodzeń

Gdy zauważysz na częściach szarawy, pudrowaty nalot lub uporczywe plamy po aluminium, możesz się zastanawiać: jak skutecznie oczyścić zkorodowane aluminium, nie pogarszając sytuacji? Odpowiedzią jest ostrożne, krok po kroku podejście – takie, które zachowa metal i zapobiegnie przyszłym problemom, takim jak rdzewiejące aluminium czy powstawanie ubytków.

- Oględziny i przygotowanie: Zacznij od zbadania powierzchni pod kątem utlenienia, plam lub ubytków. Ustal, czy masz do czynienia z lekkim zabarwieniem (białawy lub szary nalot) czy też z zaawansowaną korozją. Upewnij się, że część jest oczyszczona z luźnego brudu i zanieczyszczeń.

- Przepłucz dokładnie: Użyj czystej wody, aby usunąć sole, kurz i luźne zabrudzenia. Usunięcie zanieczyszczeń powierzchniowych jest niezbędne przed głębszą obróbką usuwania korozji aluminium.

- Delikatne czyszczenie: Przygotuj łagodny, zbalansowany pH środek do mycia naczyń, mieszając go z ciepłą wodą. Używając miękkiej szmatki lub sponża bez zdrapki, delikatnie potrzyj powierzchnię. W przypadku szczelin lub szczegółowych miejsc zastosuj szczoteczkę z miękkimi włosiami lub szczoteczkę do zębów. Unikaj zdrapki do czyszczenia, ponieważ może ona zadrapać aluminium i uszkodzić ochronne powłoki.

- Usuwanie upartych plam i lekkiego matowienia: Jeśli zauważysz miejsca, w których występuje matowienie aluminium – białe lub szare plamy – nałóż roztwór wody z octem destylowanym lub sokiem z cytryny w równych proporcjach. Pozwól, by roztwór działał przez kilka minut, a następnie delikatnie pocieraj miejsce ściereczką. Ten łagodny kwas pomaga rozpuścić lekką utlenę i matowienie aluminium, nie uszkadzając metalu bazowego.

- Płukać i suszyć: Po oczyszczeniu dokładnie spłucz powierzchnię czystą wodą, aby usunąć resztki środka czyszczącego lub kwasu. Wysusz dokładnie chusteczką mikrofibrową, aby zapobiec plamom po wodzie i dalszemu utlenianiu.

-

NIE WOLNO stosować:

- Pianki stalowej lub szczotek stalowych (mogą one wprowadzać cząstki żelaza i powodować korozję galwaniczną lub rdzę na aluminium)

- Srogo zasadowych lub żrących środków czyszczących (mogą one atakować aluminium i usuwać warstwy ochronne)

- Chlorku sodowego (może powodować ubytki i dalszą korozję)

- Płytka ściernej lub papieru ściernego, chyba że przygotowujesz powierzchnię do naprawy (patrz poniżej)

Usuwanie utleny i leczenie ubytków

Co jeśli masz do czynienia z głębszą korozją lub ubytkami – małymi otworami, które czasem pojawiają się na aluminiowych elementach zewnętrznych lub morskich? Oto jak usunąć korozję z aluminium i naprawić uszkodzenia:

- Zeszlifuj lub zmatowij uszkodzone miejsca: W przypadku silnej utleniacji lub ubytków użyj papieru ściernego o drobnej granulacji (zacznij od 400–600) lub ściereczki ścielającej niemetalicznej, aby delikatnie usunąć warstwę utlenioną. Pracuj ruchem okrężnym i rozprowadź krawędzie, aby wtopić się w sąsiedni metal. W razie potrzeby powtórz z papierem o drobniejszej granulacji, by uzyskać gładką powierzchnię. [BoatLife] .

- Oczyść i zobojętnij: Po zeszlifowaniu przetrzyj powierzchnię wilgotną szmatką. Jeśli wcześniej użyłeś octu lub soku z cytryny, upewnij się, że powierzchnia została zobojętniona i dokładnie spłukana.

- Napraw i zabezpiecz: W przypadku głębszych ubytków może być konieczne wypełnienie ich masą dopasowaną do aluminium. Po utwardzeniu wypełniacza, przeszlifuj powierzchnię, by była gładka. Następnie nałóż warstwę podkładową (jeśli jest wymagana dla danego zastosowania), aby poprawić przyczepność i zapobiec przyszłej korozji.

- Podkład i warstwa wykończeniowa: Aby zapewnić długotrwałą ochronę, zagruntuj naprawiony obszar odpowiednim podkładem aluminiowym, a następnie zakończ warstwą powłoki wierzchniej lub bezbarwnym uszczelnieniem. Nie tylko przywraca to wygląd, ale także pomaga zapobiec konieczności usuwania korozji aluminium w przyszłości.

Ochrona naprawy, aby trwała

Po oczyszczeniu i naprawie ważne jest, aby utrzymać aluminiowy wygląd i sprawność działania. Czy aluminium ponownie się przetarni? Dzięki regularnej pielęgnacji możesz to zminimalizować. Oto jak to zrobić:

- Nałóż ochronny wosk lub warstwę przezroczystą, aby stworzyć barierę przeciw wilgoci i powietrzu.

- Utrzymuj powierzchnie suche i czyste – szczególnie po ekspozycji na wodę zasolną lub trudne warunki.

- Regularnie sprawdzaj, czy nie ma nowych plam lub oznak korozji i usuń je na wczesnym etapie.

- Postępuj zgodnie z wytycznymi producenta lub branżowymi dotyczącymi czyszczenia zmatowiałego aluminium w zastosowaniach specjalistycznych (np. w przemyśle morskim, motoryzacyjnym lub przetwórstwa spożywczego).

Zawsze przeprowadzaj testy środków czyszczących na małym, niewidocznym fragmencie i postępuj zgodnie z kartami danych bezpieczeństwa. Należy nosić rękawiczki i używać ochrony oczu, a zużyte materiały należy usuwać zgodnie z lokalnymi przepisami.

Postępując zgodnie z tymi krokami, nie tylko usuniesz korozję z aluminium i przywrócisz jego połysk, ale także wydłużysz jego trwałość i poprawisz właściwości. W kolejnym kroku omówimy, w jaki sposób dobór stopów i świadome decyzje projektowe mogą dodatkowo zmniejszyć ryzyko korozji i sprawić, że Twoje aluminiowe części będą wyglądały jak nowe przez wiele lat.

Dobór stopu i projektowanie wyciskania w celu zapewnienia trwałości

Wpływ serii stopów na zachowanie w zakresie odporności na korozję

Czy kiedyś zastanawiałeś się, dlaczego niektóre aluminiowe części samochodowe przez wiele lat nie mają żadnych uszkodzeń, podczas gdy inne pokazują plamy lub ślady? Odpowiedź często tkwi w wyborze stopu aluminium. Choć czyste aluminium jest dość odporne na korozję, większość rzeczywistych komponentów wykorzystuje stopy – mieszanki aluminium z pierwiastkami takimi jak magnez, krzem, miedź czy cynk – w celu zwiększenia wytrzymałości, podatności na obróbkę lub innych właściwości. Ale tu pojawia się problem: nie wszystkie stopy jednakowo odpierają korozję, a wybór odpowiedniego stopu może znacząco wpłynąć na trwałość aluminium w trudnych warunkach.

Podzielmy je według serii, skupiając się na tych najczęściej używanych do wytłaczania:

| Seria stopów | Typowe zastosowanie | Odporność na korozję | Wykształcalność | Zgodność powłoki |

|---|---|---|---|---|

| 1000/3000 | Ogólne blachy, podstawowe wytłoczniki | Bardzo dobrze. | Doskonały | Wysoka (lakiery, anodowanie) |

| 5000 | Stosowane w przemyśle morskim, transportowe, konstrukcyjne | Doskonała (zawartość Mg) | Dobre | Wysoki |

| 6000 (np. 6061, 6063, 6005) | Wytłoczniki samochodowe, ramy | Bardzo dobrze. | Bardzo dobrze. | Doskonała (anodowanie, farba proszkowa) |

| 7000 | Lotnicze, części obciążone | Niższy (wymaga ochrony) | Umiarkowany | Wymaga ostrożnej obróbki |

| 2000 | Lotnictwo, specjalistyczne | Niższy (zawartość miedzi) | Umiarkowany | Może wymagać dodatkowego wykończenia |

Zauważysz, że seria 6000 – zwłaszcza stopy takie jak 6061 i 6063 – cieszy się dużym zainteresowaniem w przypadku aluminiowych profili wytłaczanych stosowanych w motoryzacji. Dlaczego? Dają silny balans: wysoka odporność na korozję stopów aluminium, dobra wytrzymałość, łatwe formowanie oraz doskonała kompatybilność z powłokami ochronnymi, takimi jak anodowanie czy malowanie proszkowe. Seria 5000, bogata w magnez, jest najlepszym wyborem do zastosowań morskich lub transportowych, gdzie występuje ekspozycja na sól lub trudne warunki. Tymczasem seria 7000 i 2000 oferuje wyższą wytrzymałość, ale wymaga dodatkowej ostrożności, aby zapobiec korozji – zwłaszcza jeśli zastanawiasz się, czy stop aluminium rdzewieje – w wymagających środowiskach.

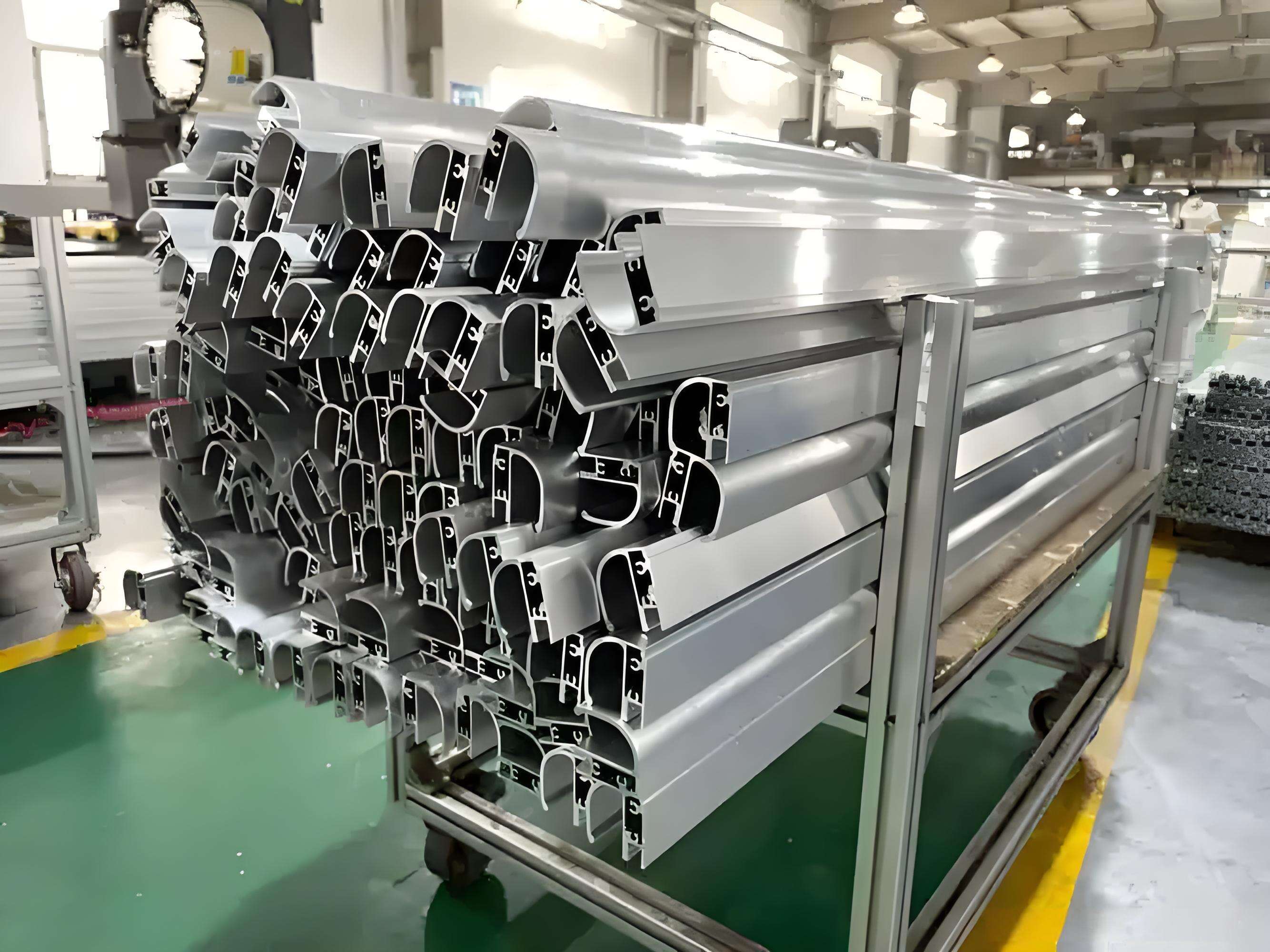

Wybieranie stopów do wytłaczania profili aluminiowych dla części samochodowych

Projektując wyciskane elementy pojazdów – takie jak elementy podwozia, obudowy baterii czy konstrukcje do wchłaniania uderzeń – odpowiedni stop może decydować o długoterminowej niezawodności lub przedwczesnym uszkodzeniu. Wyobraź sobie samochód, który spędza życie w mieście nadmorskim: chciałbyś, by użyty w nim stop był nie tylko wytrzymały, ale także odporny na korozję aluminiową i łatwy do ochrony powłokami. Stopy takie jak 6061 czy 6005 cenione są właśnie z tych powodów, oferując dobre właściwości spawalności oraz stabilną pracę po anodyzowaniu czy malowaniu. W przypadku widocznych listew lub elementów wymagających idealnego wyglądu, wyróżnia się stop 6063 dzięki swojej doskonałej powierzchni oraz reakcji na anodyzowanie.

Czy jednak stop aluminium może rdzewieć lub korodować? Choć prawdziwa rdza (tlenek żelaza) się nie tworzy, niektóre stopy – zwłaszcza zawierające więcej miedzi lub cynku – mogą wykazywać ubytki (piaskowanie) lub białe plamy, jeśli nie zostały odpowiednio wykończone lub zostały narażone na uwięzioną wilgoć. Dlatego tak ważne jest dobranie odpowiedniego stopu do środowiska oraz wykończenia.

Wskazówki projektowe zmniejszające ryzyko korozji

Opracowanie inteligentnego projektu idzie w parze z odpowiednim stopem. Oto praktyczne kroki, które zwiększą trwałość:

- Unikaj miejsc gromadzenia wilgoci: Projektuj profile o gładkich, otwartych kształtach, które umożliwiają odpływ wody i cyrkulację powietrza.

- Używaj dużych promieni zaokrąglenia: Zaokrąglone narożniki zmniejszają gromadzenie się brudu i wody, ułatwiając czyszczenie i ograniczając korozję szczelinową.

- Zadbaj o ścieki: Dodaj otwory lub pochylenia do spływu wody (zalecane minimum 8 mm), aby zapobiec jej staniu wewnątrz profili wyciskanych.

- Izoluj różne metale: Zapobiegaj korozji galwanicznej, oddzielając aluminium od części stalowych lub miedzianych, szczególnie w wilgotnych warunkach.

- Dobierz odpowiednie powłoki: Dopasuj wykończenie do stopu i środowiska — anodowanie dla zastosowań morskich lub architektonicznych, malowanie proszkowe dla miejsc narażonych na intensywny użytek, malowanie zwykłe dla potrzeb dekoracyjnych.

Jeśli chodzi o odporność na korozję, dobrze dobrany stop i mądre zaprojektowanie konstrukcji to Twoja najlepsza obrona — nie pozwól, aby ukryte pułapki czy słabe wykończenie zniweczyły Twoją pracę.

Dobierając odpowiedni stop, projekt oraz wykończenie, możesz z pełnym przekonaniem odpowiedzieć na pytanie „czy stopy aluminium rdzewieją?” w kontekście swojego kolejnego projektu – i upewnić się, że Twoje komponenty wytrzymają wiele lat intensywnej eksploatacji. W następnej sekcji podsumujemy najważniejsze wnioski oraz zapewnimy pomocne listy kontrolne, które pozwolą Ci wdrożyć te spostrzeżenia w życie.

Najważniejsze wnioski oraz sprawdzone źródła dostawców w zakresie zapobiegania korozji aluminium

Główne wnioski, które możesz zastosować od razu

Wybierając materiały lub konserwując istniejące części, naturalnie pojawia się pytanie: czy aluminium rdzewieje i co to oznacza dla Twojego projektu? Oto istota sprawy – aluminium nie rdzewieje jak stal czy żeliwo, jednak może może ulegać korozji w określonych warunkach. Zrozumienie dlaczego aluminium nie rdzewieje (dzięki swojej samonaprawiającej się warstwie tlenkowej) oraz kiedy ta ochrona może przestać działać, jest kluczowe dla uzyskania trwałych rezultatów, niezależnie od tego, czy Twoje komponenty są używane w pomieszczeniach, na zewnątrz, czy nawet w wilgotnych środowiskach.

- Glin nie rdzewieje —tworzy zamiast rdzy w kolorze czerwonawobrązowym ochronną warstwę tlenkową.

- Korozja jest nadal możliwa , szczególnie jeśli warstwa tlenkowa zostanie uszkodzona przez sól, chemikalia lub kontakt z innym metalem.

- Projektowanie pod kątem pasywacji : Gładkie kształty, odpływ i unikanie miejsc gromadzenia wilgoci pomagają warstwie tlenkowej w pełnieniu jej funkcji.

- Korozja galwaniczna może wystąpić, gdy aluminium dotyka metali takich jak stal lub miedź w obecności wody.

- Pokrycia i regularna konserwacja to Twój najlepszy środek ochrony – wybierz wykończenie i procedury czyszczenia dostosowane do środowiska pracy.

- Testowanie i inspekcja (takie jak testy pod działaniem mgły solnej) pomagają zweryfikować wybór środków ochrony, szczególnie dla kluczowych lub zewnętrznych elementów.

Lista kontrolna projektu i konserwacji

| Stopień | Co zrobić |

|---|---|

| 1. Oceń środowisko | Czy Twój aluminium jest narażony na działanie wody, soli lub warunków atmosferycznych? Jeśli tak, zwiększ ochronę oraz częstotliwość inspekcji. |

| 2. Wybierz odpowiedni stop | Wybierz stopy o udowodnionej odporności na korozję w Twoim zastosowaniu (np. seria 5000 lub 6000 do części morskich lub samochodowych). |

| 3. Izoluj połączenia | Stosuj nieprzewodzące podkładki, uszczelki lub powłoki, aby oddzielić aluminium od stali lub miedzi – szczególnie tam, gdzie występuje woda. |

| 4. Dobierz powłoki ochronne | Dopasuj wykończenie do środowiska: anodowanie do trudnych warunków, malowanie proszkowe na trwałość oraz farbę do ochrony dekoracyjnej. |

| 5. Zaplanuj konserwację | Ustal harmonogram czyszczenia i inspekcji – wykrywanie wczesnych objawów korozji (takich jak biały proszek czy ubytki) zapobiega poważniejszym problemom. |

Gdzie zdobyć fachową pomoc

Nadal masz pytania, czy aluminium ulegnie korozji w Twoim konkretnym zastosowaniu, albo nie wiesz, jak wybrać odpowiedni stop i ochronny wykończenie? Być może projektujesz części samochodowe i chcesz mieć pewność, że Twoje komponenty nie będą ulegać atakowi galwanicznemu ani nie zawiodą w trudnych warunkach. Właśnie w takich przypadkach wsparcie eksperta może wszystko zmienić.

Najlepsza kontrola korozji zaczyna się na etapie projektowania i jest utrzymywana dzięki prostym i spójnym czynnościom konserwacyjnym.

Dla wsparcia inżynieryjnego, doboru materiałów i pozyskiwania precyzyjnych części ekstruzji aluminiowej , rozważ konsultację z Dostawca Części Metalowych Shaoyi . Ich zespół specjalizuje się w rozwiązaniach dla komponentów samochodowych z aluminium – pomagając odpowiadać na pytania takie jak „czy aluminium rdzewieje”, „dlaczego aluminium nie rdzewieje” i „czy aluminium ulega korozji w wodzie” – przy użyciu praktycznych i sprawdzonych metod. Niezależnie od tego, czy potrzebujesz porady przy wyborze stopu, projektowaniu złączy czy ochronnym wykończeniu, Shaoyi oferuje zasoby i wsparcie produkcyjne, aby Twoje części zapewniały maksymalną trwałość i odporność na korozję.

Dzięki tym konkretnym krokom i ekspertowskim materiałom masz wszystko, co potrzebne, by podejmować świadome decyzje – dzięki czemu Twoje aluminiowe części pozostaną trwałe, estetyczne i niezawodne, niezależnie od miejsca i sposobu ich użytkowania.

Często zadawane pytania dotyczące rdzy i korozji aluminium

1. Czy aluminium rdzewieje tak jak stal czy żelazo?

Nie, aluminium nie rdzewieje w taki sposób jak stal czy żelazo. Rdza odnosi się konkretnie do brązowo-czerwonawego tlenku żelaza powstającego na metalach zawierających żelazo. Aluminium zamiast tego tworzy ochronną warstwę tlenkową, która zapobiega powstawaniu typowej rdzy widywanej na stali. Niemniej jednak, aluminium może ulegać korozji w pewnych warunkach, szczególnie przy ekspozycji na sól, agresywne chemikalia lub kontakt z różnymi metalami.

2. Co powoduje korozję aluminium, jeśli nie rdzewieje ono w typowy sposób?

Aluminium ulega korozji, gdy jego naturalna warstwa tlenkowa zostanie uszkodzona lub zaburzona. Typowymi przyczynami są ekspozycja na chlorki (np. woda morska), substancje kwaśne lub zasadowe, uwięziona wilgoć oraz kontakt z innymi metalami, takimi jak stal czy miedź. Te czynniki mogą niszczyć barierę tlenkową, prowadząc do powstawania ubytków, białego proszkowatego osadu lub matowienia powierzchni.

3. Jak mogę zapobiec korozji części aluminiowych?

Aby zapobiec korozji aluminium, należy zapewnić odpowiednią przygotowę powierzchni, nałożyć powłoki ochronne, takie jak anodowanie, farbowanie lub malowanie proszkowe, oraz odizolować aluminium od innych metali, stosując nieprzewodzące podkładki lub uszczelki. Dobre praktyki konstrukcyjne, takie jak zapewnienie odpływu wody i unikanie miejsc zatrzymywania wilgoci, w połączeniu z regularnym czyszczeniem i inspekcją, znacznie zmniejszają ryzyko korozji.

4. Czy aluminium może ulegać korozji w wodzie lub w warunkach zewnętrznych?

Aluminium jest zazwyczaj odporne na korozję w wodzie i na zewnątrz dzięki samonaprawiającej się warstwie tlenkowej. Jednak długotrwałe narażenie na wodę morską, zanieczyszczone powietrze lub stojącą wodę może powodować korozję lokalną, zwłaszcza jeśli warstwa tlenkowa zostanie uszkodzona. Wybór odpowiedniego stopu oraz zastosowanie odpowiednich obróbek powierzchniowych pomaga zachować trwałość w trudnych warunkach.

5. Które stopy aluminium oferują najlepszą odporność na korozję w częściach samochodowych?

W zastosowaniach samochodowych popularne są stopy aluminium serii 5000 i 6000, takie jak 6061 i 6063, które cechują się doskonałą odpornością na korozję, wytrzymałością oraz kompatybilnością z powłokami ochronnymi. Stopy te są idealne do wyciskania i części konstrukcyjnych, szczególnie gdy są łączone z zaawansowanymi obróbkami powierzchniowymi, takimi jak anodyzacja czy malowanie proszkowe, jak je oferuje specjalistyczny dostawca taki jak Shaoyi.

Małe partie, wysokie standardy. Nasza usługa szybkiego prototypowania sprawia, że weryfikacja jest szybsza i łatwiejsza —

Małe partie, wysokie standardy. Nasza usługa szybkiego prototypowania sprawia, że weryfikacja jest szybsza i łatwiejsza —