Przewodnik po doborze materiałów do kucia w przemyśle motoryzacyjnym

Przewodnik po doborze materiałów do kucia w przemyśle motoryzacyjnym

STRESZCZENIE

Wybór odpowiednich materiałów do kucia w przemyśle motoryzacyjnym polega na doborze metali takich jak stal węglowa, stal stopowa, aluminium i tytan, w oparciu o kluczowe czynniki wydajności. Decyzja ta balansuje stosunek wytrzymałości do masy, odporność na ciepło, kowalność oraz koszt, aby zapewnić trwałość i niezawodność elementom takim jak wały korbowe i przekładnie. Prawidłowy wybór materiału jest podstawą produkcji wysokowydajnych, bezpiecznych i efektywnych części pojazdów.

Podstawy kucia w przemyśle motoryzacyjnym

Kucie to proces produkcyjny, w którym kształtowanie metalu odbywa się za pomocą zlokalizowanych sił ściskających, wywieranych poprzez kucie młotem, prasowanie lub walcowanie. W przeciwieństwie do odlewnictwa, polegającego na wlewaniu stopionego metalu do formy, kucie odkształca bryłę metalu w stanie stałym, ulepszając jego wewnętrzną strukturę ziarnową. Proces ten dopasowuje kierunek przebiegu ziarna do kształtu elementu, co znacząco zwiększa jego wytrzymałość, odporność na pękanie oraz odporność na zmęczenie materiału. To właśnie dzięki takiej integralności strukturalnej kucie jest preferowaną metodą wytwarzania kluczowych części samochodowych, które muszą wytrzymywać ogromne obciążenia oraz obciążenia cykliczne.

W branży motoryzacyjnej zapotrzebowanie na pojazdy lżejsze, mocniejsze i bardziej oszczędne w zużyciu paliwa sprawiło, że kucie stało się nieodzowne. Skuwane komponenty charakteryzują się lepszym stosunkiem wytrzymałości do masy w porównaniu z częściami wyprodukowanymi innymi metodami, co przyczynia się do redukcji całkowitej masy pojazdu bez kompromitowania bezpieczeństwa czy wydajności. Kluczowe elementy silnika, skrzyni biegów oraz układu zawieszenia są często wykuwane, aby zagwarantować niezawodność w trudnych warunkach pracy.

Proces kucia można ogólnie sklasyfikować według temperatury, w której jest on prowadzony: kucie gorące, ciepłe lub zimne. Kucie gorące odbywa się w temperaturach powyżej punktu rekrystalizacji metalu, co czyni materiał bardzo plastycznym i ułatwia nadanie mu złożonych kształtów. Kucie zimne przeprowadza się w temperaturze pokojowej lub bliskiej jej, co zwiększa wytrzymałość metalu poprzez umocnienie odkształceniowe, jednak wymaga użycia potężniejszego sprzętu. Kucie ciepłe stanowi kompromis między tymi dwiema metodami, oferując równowagę pomiędzy precyzją a możliwością kształtowania.

Kluczowe kryteria doboru materiałów

Wybór odpowiedniego materiału na aplikację kucie samochodowe to decyzja o kluczowym znaczeniu, która bezpośrednio wpływa na wydajność, trwałość i koszt elementu. Proces selekcji wymaga starannego zrównoważenia wymagań inżynieryjnych i uwarunkowań produkcyjnych. Należy ocenić kilka głównych kryteriów, aby zagwarantować, że końcowa część spełni stawiane jej eksploatacyjne wymagania.

- Stosunek wytrzymałości do masy: Jest to najważniejsze w nowoczesnym projektowaniu samochodów, gdzie redukcja masy pojazdu ma kluczowe znaczenie dla poprawy efektywności zużycia paliwa i właściwości jezdnych. Materiały takie jak stopy aluminium i tytanu oferują doskonałą wytrzymałość przy niewielkiej wadze, co czyni je idealnym wyborem w zastosowaniach związanych z osiągami i inspirowanych przemysłem lotniczym.

- Odporność na ciepło: Elementy znajdujące się w silniku i systemie wydechowym są narażone na skrajne temperatury. Materiały muszą zachować integralność strukturalną i wytrzymałość w warunkach wysokich temperatur. Stale stopowe i tytan są często wybierane ze względu na ich zdolność do wytrzymywania wysokich temperatur bez degradacji.

- Kowalność i odporność na pękanie: Kowalność odnosi się do zdolności materiału do odkształcania się pod wpływem naprężeń rozciągających bez pękania, natomiast odporność na pękanie to jego zdolność do pochłaniania energii i plastycznego odkształcania się bez pęknięcia. Oba te parametry są kluczowe dla elementów narażonych na nagłe udary lub duże obciążenia, takich jak komponenty zawieszenia czy drążki połączeniowe.

- Odporność na korozję: Części samochodowe są narażone na wilgoć, sól drogową oraz inne substancje żrące. Stale nierdzewne, aluminium oraz pewne stale stopowe z powłokami ochronnymi są wybierane ze względu na ich odporność na rdzę i degradację środowiskową, co zapewnia długotrwałą niezawodność.

- Przetwarzalność: Po kucie wiele komponentów wymaga dodatkowego obróbki skrawaniem w celu osiągnięcia końcowych, precyzyjnych wymiarów. Obrabialność materiału wpływa na czas i koszt tych operacji wykańczających. Niektóre stopy są specjalnie formułowane w celu ułatwienia cięcia i kształtowania.

- Koszty: Cena surowców oraz złożoność procesu kucia to istotne czynniki. Choć stopy o wysokiej wydajności, takie jak tytan, oferują lepsze właściwości, stale węglowe i mikrostale stopowe często stanowią najbardziej opłacalne rozwiązanie dla produkcji seryjnej, nie oferując przy tym wymaganej wydajności.

Zarządzanie tymi kompromisami wymaga głębokiej wiedzy specjalistycznej. Dla firm dążących do optymalizacji produkcji komponentów, współpraca ze specjalistą może być nieoceniona. Na przykład dostawcy zaawansowanych rozwiązań kucia mogą doradzać w zakresie doboru materiałów i optymalizacji procesów, począwszy od prototypowania, aż po produkcję masową, zapewniając zgodność komponentów z rygorystycznymi standardami branżowymi, takimi jak IATF 16949.

Przewodnik po popularnych materiałach kowalnych i ich zastosowaniach

Przemysł motoryzacyjny polega na niewielkiej grupie metali znanych ze swoich unikalnych właściwości i charakterystyki wydajności pod obciążeniem. Wybór materiału zależy od konkretnego zastosowania, od elementów silnika po komponenty szkieletonu.

Stal węglowa

Stal węglowa jest podstawowym materiałem w przemyśle kucia ze względu na doskonałą wytrzymałość, odporność na zużycie i korzystny stosunek jakości do ceny. Jej właściwości są przede wszystkim zależne od zawartości węgla. Stal niskowęglowa jest łatwo obrabialna i stosowana do części takich jak elementy łączące, podczas gdy stal średnio węglowa oferuje zrównoważone parametry dla wałów korbowych i tłoków. Stal wysokowęglowa jest używana w zastosowaniach wymagających maksymalnej twardości i odporności na zużycie, takich jak sprężyny i narzędzia o dużej wytrzymałości.

Zalety:

- Kosztownie efektywna dla produkcji seryjnej

- Dobra równowaga wytrzymałości i kowalności

- Odporna na zużycie i ścieranie

Wady:

- Podatna na korozję bez ochronnych powłok

- Niższy stosunek wytrzymałości do masy w porównaniu z nowoczesnymi stopami

Stali stopowej

Stal stopowa powstaje przez dodanie pierwiastków takich jak chrom, nikiel, molibden i mangan do stali węglowej. Te dodatki poprawiają właściwości takie jak wytrzymałość, twardość, odporność na pękanie oraz odporność na działanie ciepła i korozji. Ta uniwersalność czyni stal stopową niezbędna w zastosowaniach wymagających wysokiej wydajności, takich jak przekładnie, osie i sprzęgła uniwersalne, które wymagają doskonałych właściwości mechanicznych.

Zalety:

- Wyższa wytrzymałość i odporność na pękanie

- Poprawiona odporność na działanie ciepła i korozji

- Wysoki stopień dostosowania właściwości poprzez różne pierwiastki stopowe

Wady:

- Wyższy koszt niż stal węglowa

- Może wymagać bardziej złożonych procesów obróbki cieplnej

Stal nierdzewna

Ze względu na zawartość co najmniej 10,5% chromu znana jest z wyjątkowej odporności na korozję; stal nierdzewna jest stosowana w elementach narażonych na surowe warunki środowiskowe. W sektorze motoryzacyjnym znajduje zastosowanie w systemach wydechowych, zaworach i łożyskach. Zachowuje swoją wytrzymałość w wysokich temperaturach i oferuje czysty, wykończony wygląd.

Zalety:

- Doskonała odporność na rdzę i korozję

- Trwały i odporny na skrajne temperatury

- Długa żywotność przy niskim poziomie konserwacji

Wady:

- Bardziej kosztowny niż węgiel i większość stali stopowych

- Może być trudniejszy w obróbce mechanicznej

Aluminium

Aluminium jest cenione za swoją niską gęstość i doskonałą odporność na korozję. Kucanie aluminium zwiększa jego wytrzymałość, czyniąc go odpowiednim do zastosowań, w których redukcja masy jest najwyższym priorytetem, takich jak elementy zawieszenia (ramiona sterujące, piasty), koła oraz niektóre części silnika, np. tłoki. Stopowanie z pierwiastkami takimi jak miedź i magnez dalszych poprawia jego właściwości mechaniczne.

Zalety:

- Lekki, co poprawia oszczędność paliwa i dynamikę pojazdu

- Wysoka odporność na korozję

- Dobra przewodność cieplna i elektryczna

Wady:

- Niższa wytrzymałość w porównaniu ze stalą

- Wyższy koszt materiału

Tytan

Tytan ma najwyższy stosunek wytrzymałości do wagi spośród powszechnie stosowanych metali. Wykazuje również wyjątkową odporność na korozję i wysokie temperatury. W branży motoryzacyjnej jego zastosowanie jest zazwyczaj ograniczone do pojazdów wysokoprężnych i wyścigowych ze względu na wysoką cenę. Typowymi zastosowaniami są korbowody, zawory oraz elementy układu wydechowego, gdzie zysk wydajności uzasadnia wydatek.

Zalety:

- Wyjątkowy stosunek siły do masy

- Nadzwyczajna odporność na korozję i wysokie temperatury

- Doskonała trwałość zmęczeniowa

Wady:

- Znacznie droższy niż stal czy aluminium

- Trudny w obróbce i przetwarzaniu

Elementy kute w nowoczesnych pojazdach: od silnika po podwozie

Kucie odgrywa kluczową rolę w bezpieczeństwie, niezawodności i wydajności nowoczesnych pojazdów. Proces ten służy do wytwarzania szerokiej gamy krytycznych komponentów w każdym głównym systemie samochodu, tam gdzie wytrzymałość i trwałość są niezastąpione. Analizując te systemy, możemy zauważyć, jak elementy kute stanowią podstawę inżynierii motoryzacyjnej.

W ramach Silnik , niektóre z najbardziej obciążonych elementów są wykute. Wały korbowe, które przekształcają ruch posuwisty tłoków w ruch obrotowy, są wykute ze stali węglowej lub mikrostali stopowej, aby wytrzymać stałe obciążenia skręcające i zginające. Korbowody, które łączą tłoki z wałem korbowym, są również wykute, aby wytrzymać ogromne obciążenia ściskające i rozciągające podczas każdego cyklu spalania. W silnikach wysokoprężnych stosuje się stal stopową kowaną lub tytan do tych elementów, aby zwiększyć wytrzymałość przy jednoczesnym zminimalizowaniu masy.

The Napęd i skrzynia biegów zależą w dużej mierze od kowanych elementów do przekazywania mocy z silnika na koła. Koła zębate, wały i sprzęgła muszą wytrzymać wysoki moment obrotowy i zużycie. Koła zębate ze stali kowanej lub stali stopowej oferują lepszą odporność na pękanie i zmęczenie materiału w porównaniu z odlewanymi lub frezowanymi kołami zębatymi, zapewniając długą i niezawodną pracę. Ta wytrzymałość zapobiega pękaniu zębów i gwarantuje płynne przekazywanie mocy w różnych warunkach jazdy.

W Podwieszenie i podwozie , bezpieczeństwo jest głównym priorytetem. Komponenty takie jak wahacze, przeguby kulowe, piasty kół oraz belki osi są stale narażone na uderzenia pochodzące z nawierzchni drogowej. Kucie tych elementów ze stali lub stopów aluminium zapewnia niezbędną wytrzymałość i odporność na obciążenia udarowe, zapobiegając katastrofalnemu uszkodzeniu. Udoskonalona struktura ziarna kowanych części czyni je znacznie bardziej trwałe i odporno na zmęczenie spowodowane milionami cykli obciążeniowych w całym okresie eksploatacji pojazdu.

Projektowanie pod kątem technologii produkcji (DFM) w procesie kucia

Chociaż wybór odpowiedniego materiału jest kluczowy, projekt samej części odgrywa równie ważną rolę w powodzeniu procesu kucia. Projektowanie pod kątem technologii produkcji (DFM) to zbiór zasad mających na celu zoptymalizowanie projektu pod względem łatwości produkcji, co z kolei redukuje koszty, poprawia jakość i skraca czas produkcji. W przypadku kucia, DFM koncentruje się na sposobie przepływu metalu w matrycy, aby wytworzyć wytrzymałый, wolny od wad komponent.

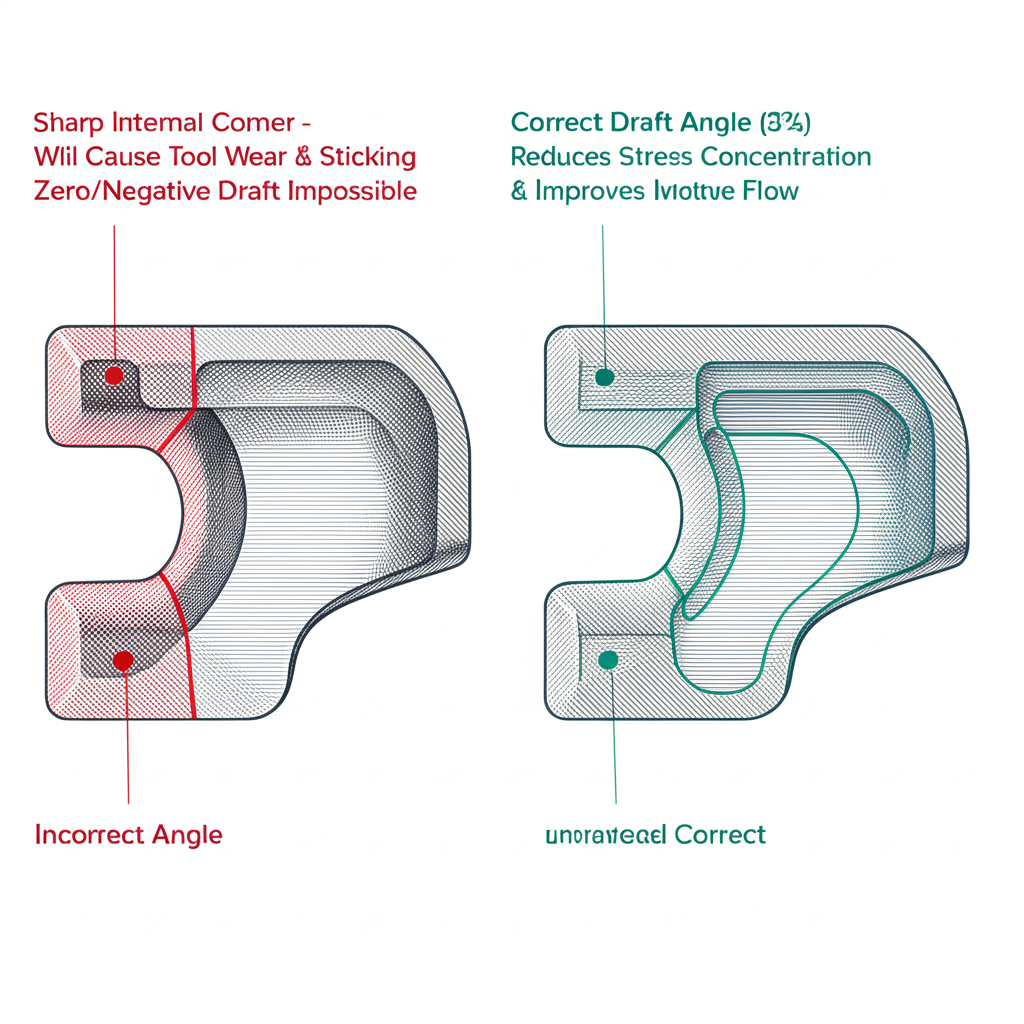

Jedną z podstawowych zasad DFM dotyczących kucia jest stosowanie hojnych promienie narożników i zaokrągleń . Ostre wewnętrzne narożniki mogą utrudniać przepływ metalu, powodować koncentrację naprężeń oraz prowadzić do wad, takich jak pęknięcia czy niepełne wypełnienie matrycy. Projektując elementy ze sprawnymi, zaokrąglonymi przejściami, inżynierowie zapewniają swobodny i jednolity ruch materiału przez całą wnękę matrycy, co skutkuje silniejszym elementem o bardziej spójnej strukturze ziarnistej. Podobnie należy unikać gwałtownych zmian grubości przekroju, aby zapobiec problemom z przepływem materiału.

Kolejnym ważnym aspektem jest kąt wyboju , co oznacza niewielki pochylenie boków elementu. Takie pochylenie jest niezbędne, aby ułatwić wyjęcie elementu z matrycy kucia po jego ukształtowaniu. Bez odpowiednich kątów wykroju elementy mogą utknąć w matrycy, co prowadzi do opóźnień w produkcji oraz potencjalnych uszkodzeń zarówno elementu, jak i narzędzi. Linia rozdziału – płaszczyzna, w której spotykają się dwie połowy matrycy kucia – musi być również starannie zaprojektowana, aby zminimalizować nadmiar materiału (tzw. fason) i uprościć kolejne operacje obróbki skrawaniem.

Na koniec, DFM polega na projektowaniu pod kątem optymalnego półwyrobu lub zagęszczenia . Początkowy kawałek metalu jest często kształtowany w przybliżoną formę końcowej części przed główną operacją kucia. Skutecznie zaprojektowana forma wstępna minimalizuje ilość potrzebnego materiału i zmniejsza liczbę etapów kucia, co bezpośrednio wpływa na koszty i efektywność produkcji. Współpraca z ekspertami od kucia w fazie projektowania to najlepszy sposób, aby uwzględnić te zasady i zagwarantować, że komponent będzie idealnie przystosowany do niezawodnej produkcji seryjnej.

Małe partie, wysokie standardy. Nasza usługa szybkiego prototypowania sprawia, że weryfikacja jest szybsza i łatwiejsza —

Małe partie, wysokie standardy. Nasza usługa szybkiego prototypowania sprawia, że weryfikacja jest szybsza i łatwiejsza —