Steel Sheet Laser Cut Secrets: Fiber Vs CO2 And When Each Wins

What Steel Sheet Laser Cutting Actually Means for Modern Manufacturing

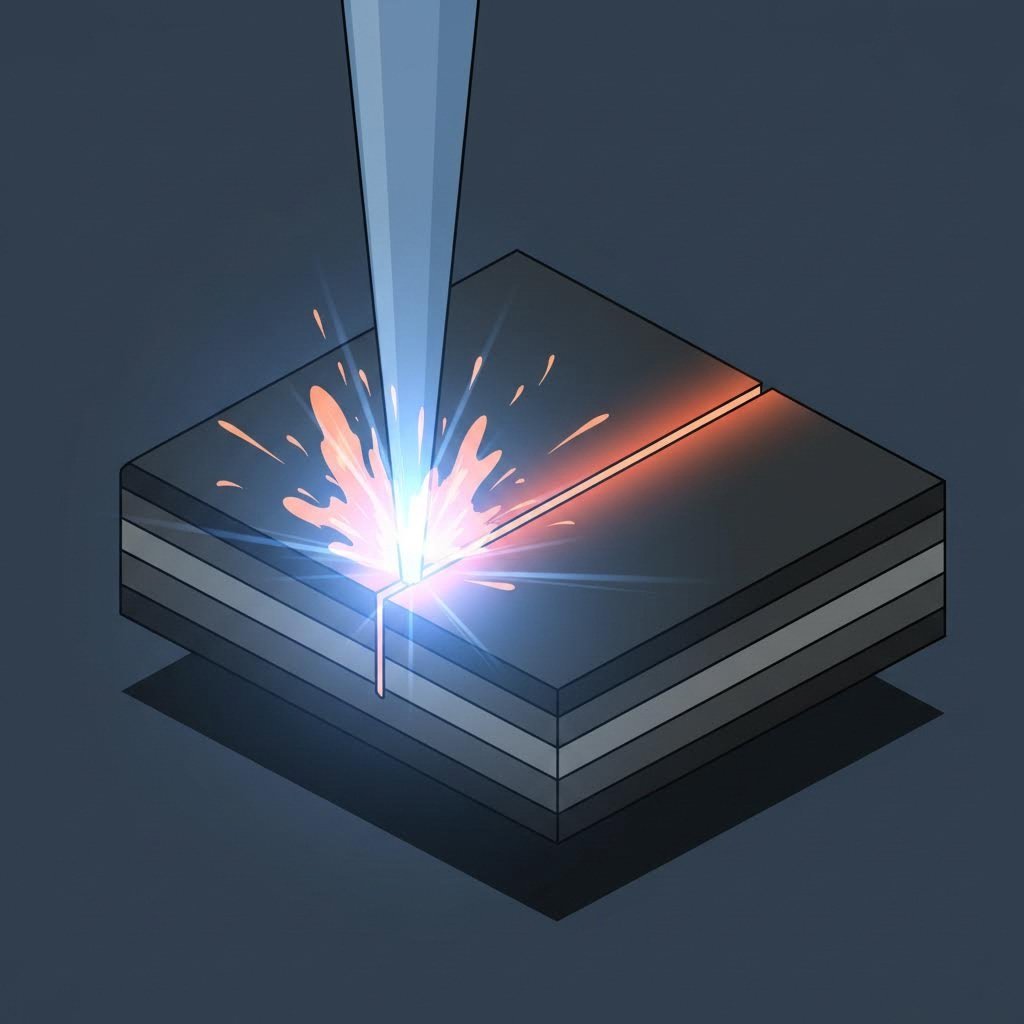

Ever watched a beam of concentrated light slice through solid steel like a hot knife through butter? That's exactly what happens during steel sheet laser cut operations—and it's transforming how manufacturers approach precision metal fabrication.

Steel sheet laser cutting is a precision thermal cutting process that uses a high-powered, focused laser beam to melt, burn, or vaporize material along a programmed path, while assist gases blow away molten material to create exceptionally clean and accurate cuts.

This process has become the gold standard for steel fabrication across countless industries. But what makes it so revolutionary? Let's break down the science and discover why precision matters more than ever in today's manufacturing landscape.

The Science Behind Laser Beam Steel Cutting

Imagine concentrating the energy of thousands of light bulbs into a beam narrower than a human hair. That's essentially what a laser cutter does when processing a metal sheet. The term "laser" itself stands for Light Amplification by Stimulated Emission of Radiation—a technology that has evolved dramatically since its invention in 1960.

Here's how the process works in practice:

- A laser resonator generates a high-powered beam of concentrated light

- Mirrors and focusing lenses direct and concentrate this beam to an incredibly small focal point

- The focused beam rapidly heats the steel to its melting or vaporization point

- Assist gases (typically oxygen or nitrogen) blow away the molten material

- CNC-controlled movement guides the laser along the programmed cutting path

The result? Cuts with tolerances less than +/- 0.01 inches—precision that traditional cutting methods simply cannot match. This level of accuracy makes laser technology ideal for sheet metal fabrication projects requiring intricate geometries and tight specifications.

Two primary laser types dominate the steel cutting landscape: fiber lasers and CO2 lasers. Fiber lasers use optical fiber doped with rare-earth elements to amplify light, producing a wavelength of 1.06 microns. CO2 lasers, developed by Kumar Patel at Bell Labs in 1964, use gas discharge to generate an infrared beam at 10.6 microns. Each wavelength interacts differently with steel surfaces—a distinction that becomes crucial when selecting the right metal cutter for specific applications.

Why Precision Matters in Modern Fabrication

You might wonder: does a fraction of a millimeter really make that much difference? In modern manufacturing, absolutely yes.

Consider automotive components where parts must fit together with microscopic tolerances, or aerospace applications where structural integrity depends on exact specifications. Traditional cutting methods like plasma or mechanical shearing introduce variations that can cascade into significant problems during assembly.

Laser cutting eliminates these concerns through several key advantages:

- Consistency: Every cut follows the exact same programmed path

- Minimal material distortion: The focused heat zone reduces warping

- Complex geometry capability: Intricate patterns that would be impossible with mechanical cutting

- Reduced secondary processing: Clean edges often require no additional finishing

This precision directly translates to cost savings. When parts fit correctly the first time, manufacturers eliminate rework, reduce scrap rates, and accelerate production timelines. For metal fabrication operations competing in today's demanding marketplace, these efficiencies aren't just nice to have—they're essential for survival.

As we explore the differences between fiber and CO2 lasers in the following sections, you'll discover that choosing the right technology depends on factors including material thickness, production volume, and desired edge quality. Understanding these nuances is the first step toward mastering steel fabrication with laser technology.

Fiber Laser vs CO2 Laser Performance on Steel Sheets

So you've decided laser cutting is right for your steel project—but which type of laser should you choose? This question has sparked countless debates in fabrication shops worldwide, and for good reason. The difference between fiber and CO2 lasers isn't just technical jargon; it directly impacts your cutting speed, operating costs, and final edge quality.

Let's cut through the confusion and examine exactly when each technology wins.

Fiber Laser Advantages for Steel Sheet Processing

Fiber lasers have revolutionized how manufacturers approach metal laser cutting over the past decade. Their secret weapon? A wavelength of approximately 1.06 microns that steel absorbs incredibly efficiently. This shorter wavelength allows for tighter beam focus and deeper material penetration—translating to cleaner cuts and faster processing speeds.

When working with a metal laser cutting machine powered by fiber technology, you'll notice several distinct advantages:

- Energy efficiency: Fiber lasers convert up to 30% of input power into usable laser output, compared to just 10-15% for CO2 systems—potentially cutting your electricity costs in half

- Superior speed on thin materials: When processing steel sheets under 6mm thick, fiber lasers can operate 2-3 times faster than comparable CO2 units

- Minimal maintenance: The solid-state design eliminates mirror alignments and gas refills, reducing weekly maintenance from 4-5 hours (CO2) to less than 30 minutes

- Extended lifespan: Fiber laser cutters can operate reliably for 25,000 to 100,000 hours before requiring significant service

The beam delivery system tells much of this story. Fiber lasers transmit their beam through protected fiber optic cables, completely shielding the optics path from contaminants. This monolithic configuration means fewer moving parts, reduced wear, and consistent output quality—even in challenging shop environments.

For shops processing high volumes of thin to medium-gauge steel, a laser cutter for metal using fiber technology often delivers the best return on investment. The speed advantage compounds with every sheet processed, while lower operating costs continue saving money year after year.

When CO2 Lasers Still Make Sense

Don't count CO2 technology out just yet. Despite fiber lasers capturing headlines, CO2 systems remain valuable workhorses in specific applications.

CO2 lasers generate their beam through an electrically stimulated gas mixture, producing infrared light at 10.6 microns. While this longer wavelength doesn't absorb as efficiently into steel as fiber's shorter wavelength, it offers unique characteristics worth considering:

- Power scalability: High-power CO2 lasers can deliver tens of kilowatts, sometimes exceeding what fiber technology offers at competitive price points

- Material versatility: The same CO2 laser metal cutting machine can process non-metallic materials like wood, acrylic, and textiles—ideal for shops with diverse material needs

- Established technology: Decades of refinement mean CO2 systems are well-understood, with abundant operator expertise available

However, CO2 lasers require more attention. Their beam delivery relies on bend mirrors contained within bellows that accumulate contamination over time. Temperature fluctuations can distort mirrors, reducing power delivery and potentially misaligning the beam. The most costly issue occurs when reflected laser light damages the expensive oscillator—a risk that fiber systems largely avoid.

For operations already owning CO2 equipment with paid-off capital costs, continuing to use these machines for appropriate applications often makes financial sense. Similarly, shops requiring a desktop fiber laser for small-scale work alongside a larger cutter machine metal setup for production might find hybrid approaches worthwhile.

| Performance Category | Fiber Laser | CO2 Laser |

|---|---|---|

| Cutting Speed (Thin Steel <3mm) | 2-3x faster | Baseline speed |

| Cutting Speed (Thick Steel >12mm) | Comparable to slightly faster | Traditionally stronger, gap now closed |

| Operating Costs | Up to 50% lower electricity consumption | Higher energy use, gas refills required |

| Edge Quality on Steel | Excellent, minimal heat-affected zone | Good, slightly wider heat-affected zone |

| Material Versatility | Optimized for metals | Processes metals and non-metals |

| Maintenance Time | <30 minutes weekly | 4-5 hours weekly |

| Expected Lifespan | 25,000-100,000 hours | 10,000-20,000 hours |

The wavelength difference ultimately determines how each laser interacts with your steel sheet. Fiber's 1.06 micron wavelength is readily absorbed by metallic materials, producing minimal heat-affected zones and precise cuts. CO2's 10.6 micron wavelength requires more energy to achieve similar results on steel but excels when versatility across material types matters most.

Understanding these distinctions helps you match the right technology to your specific steel grade and thickness requirements—which is exactly what we'll explore next.

Choosing the Right Steel Grade for Laser Cutting Success

Here's a question that separates amateur fabricators from seasoned professionals: does the steel you choose actually matter for laser cutting? The answer might surprise you—material selection can make or break your entire project before the laser even fires up.

Not all steel is created equal when it comes to laser processing. Understanding the difference between "laser quality" steel and standard material is your first step toward consistent, high-quality cuts every time.

Carbon Steel vs Stainless Steel Cutting Characteristics

When cutting stainless steel sheets, you're dealing with a fundamentally different material than carbon steel—and your laser parameters need to reflect that difference.

Carbon steel remains the workhorse of laser cutting operations. Its predictable composition and relatively low reflectivity make it forgiving for operators still learning parameter optimization. Oxygen assist gas reacts exothermically with carbon steel during cutting, actually adding energy to the process and enabling faster cutting speeds on thicker sections.

Stainless steel sheet metal presents unique challenges that demand respect:

- High reflectivity: Austenitic grades like 304 stainless sheet metal and 316 stainless steel reflect up to 70% of fiber laser energy—significantly more than carbon steel

- Increased melt viscosity: Chromium and nickel content creates a thicker, stickier melt pool that resists being blown away by assist gas

- Slag formation tendency: The viscous melt can form "teardrop" slag on the underside of cuts if parameters aren't optimized

- Composition sensitivity: Under extreme laser heat, low-boiling-point elements like zinc and manganese can preferentially evaporate, potentially affecting edge corrosion resistance

So how do you cut stainless steel sheet metal successfully? The key lies in parameter adjustment. Higher laser power compensates for reflectivity losses, while nitrogen assist gas prevents oxidation and produces silver-white edges that maintain the material's aesthetic appeal. For brushed stainless steel sheet metal applications where surface appearance matters, this oxidation prevention becomes even more critical.

Galvanized sheet metal introduces another variable: the zinc coating. This protective layer vaporizes at lower temperatures than the base steel, creating zinc fumes and potentially affecting cut quality. Many fabricators find that slightly slower cutting speeds and increased ventilation help manage these challenges while maintaining edge quality.

Surface Preparation Requirements Before Cutting

Imagine trying to cut through steel that's warped, covered in mill scale, or contaminated with oils. Even the most powerful laser struggles under these conditions—and the resulting cuts show it.

"Laser quality" steel exists for exactly this reason. According to Steel Warehouse, laser quality material undergoes specialized processing through a temper pass line that includes a temper mill, flattener, leveler, and continuous rotary shear. This eliminates coil memory and ensures the material lies absolutely "table flat" during processing.

Why does flatness matter so much? The laser's focal point is calibrated to a specific distance from the material surface. When steel warps or retains coil memory, that focus distance varies across the sheet—producing inconsistent cut quality, wider kerfs in some areas, and potential cutting failures in others.

Before any steel sheet laser cut operation, evaluate your material against these key selection criteria:

- Composition verification: Confirm the steel grade matches your parameter settings—cutting 316 stainless with 304 parameters can produce substandard results

- Surface condition assessment: Check for mill scale, rust, oils, or protective coatings that might interfere with laser absorption

- Thickness uniformity: Variations in thickness across a single sheet can cause focus issues and inconsistent edge quality

- Storage considerations: Steel stored in humid conditions may develop surface oxidation that affects cutting performance

Mill scale deserves special attention. This oxide layer forms during hot rolling and can significantly affect laser absorption characteristics. Some operations specifically request pickled and oiled steel to ensure clean, scale-free surfaces. Others factor mill scale into their parameter calculations, though this typically requires slightly higher power settings.

The interaction between steel thickness and material grade determines your optimal cutting approach. Thinner stainless steel sheets cut cleanly with nitrogen assist at moderate powers, while thicker sections may require oxygen assist despite the resulting oxidized edge—a tradeoff between cut quality and processing capability. Carbon steel follows similar scaling principles but generally tolerates wider parameter windows.

Getting material selection right sets the foundation for everything that follows. With the proper steel grade and surface preparation established, the next consideration becomes understanding exactly what thickness ranges your equipment can handle—and what parameters will deliver the best results.

Steel Sheet Thickness Capabilities and Cutting Parameters

You've selected the perfect steel grade and your material lies table-flat. Now comes the critical question: can your laser actually cut through it? Understanding thickness capabilities and parameter relationships separates successful steel sheet laser cut operations from frustrating trial-and-error sessions.

Whether you're processing thin gauge material at 14 gauge steel thickness (approximately 1.9mm) or heavier 11 gauge steel thickness (around 3mm), the principles remain consistent—but the parameters change dramatically.

Understanding Thickness Limits and Power Requirements

Think of laser power like water pressure in a garden hose. A gentle stream works perfectly for watering delicate flowers, but you'll need a pressure washer to clean concrete. Similarly, thin steel sheets require modest power levels, while thick steel plates demand significantly more energy to achieve clean through-cuts.

Modern fiber lasers have expanded thickness capabilities considerably. Today's high-powered systems can process:

- Ultra-thin gauges (under 1mm): Cut at extremely high speeds, often exceeding 1000 inches per minute, requiring careful power modulation to prevent burn-through

- Thin to medium sheets (1-6mm): The sweet spot for most laser sheet metal cutter operations, offering optimal balance of speed and edge quality

- Medium to thick plates (6-20mm): Slower cutting speeds required, with assist gas selection becoming increasingly critical

- Heavy plates (20mm+): Achievable with high-power systems (10kW+), though edge quality may require secondary processing

The relationship between power and thickness isn't linear. Doubling your material thickness might require tripling your laser power to maintain acceptable cutting speeds. According to DW Laser's technical guidelines, factors including focal length, nozzle diameter, and lens quality all influence how efficiently power translates into cutting capability.

Speed adjustments work hand-in-hand with power settings. Higher speeds distribute heat more evenly across the cut path, preventing excessive melting or burning. Slower speeds concentrate heat more intensely—necessary for thicker materials but potentially damaging for thin sheets. Finding the optimal balance requires understanding your specific steel sheet cutting machine's capabilities and limitations.

Assist Gas Selection for Different Steel Types

Here's where sheet metal laser cutting becomes genuinely interesting. The gas blowing alongside your laser beam isn't just clearing debris—it's actively participating in the cutting process.

For carbon steel, oxygen creates an exothermic reaction that actually adds energy to your cut. According to Isotema's comprehensive guide, this combustion effect accelerates cutting speed dramatically, making oxygen the preferred choice for thicker carbon steel plates above 6mm. The tradeoff? Oxidized edges that may require cleaning or post-processing.

Stainless steel and aluminum demand nitrogen for different reasons:

- Oxidation prevention: Nitrogen creates an inert atmosphere that protects the cut edge from discoloration

- Clean aesthetics: Silver-white edges require no secondary finishing for visible applications

- Pressure requirements: Higher nitrogen pressures (up to 25 bar) ensure complete molten material evacuation

Compressed air offers a budget-friendly middle ground for laser cutting metal sheet operations where edge quality isn't critical. While less expensive than pure nitrogen or oxygen, air's 21% oxygen content can cause some oxidation and rougher edges—particularly on stainless steel where burrs may form.

| Steel Thickness | Recommended Laser Power | Carbon Steel Assist Gas | Stainless Steel Assist Gas | Typical Cutting Speed |

|---|---|---|---|---|

| Under 1mm | 1-2 kW | Oxygen or Nitrogen | Nitrogen (high pressure) | 500-1000+ in/min |

| 1-3mm | 2-4 kW | Oxygen | Nitrogen | 200-500 in/min |

| 3-6mm | 4-6 kW | Oxygen | Nitrogen | 80-200 in/min |

| 6-12mm | 6-10 kW | Oxygen | Nitrogen | 30-80 in/min |

| 12-20mm | 10-15 kW | Oxygen | Nitrogen or Air | 10-30 in/min |

| 20mm+ | 15+ kW | Oxygen | Application-dependent | 1-10 in/min |

What about dimensional accuracy? Professional laser cutting typically achieves tolerances of approximately +/- 0.002 inches—far tighter than waterjet or plasma alternatives. According to Approved Sheet Metal's comparison data, laser beam widths can shrink to just 0.001 inches, enabling precision that mechanical cutting methods simply cannot match.

The heat-affected zone (HAZ) presents your final parameter consideration. This narrow band of material adjacent to the cut experiences thermal changes that can affect hardness and microstructure. Faster cutting speeds minimize HAZ width by limiting heat exposure time, while slower speeds on thick steel plates inevitably create wider affected zones. For critical structural applications, understanding this thermal impact helps you specify appropriate post-cut treatments or design around affected areas.

With thickness capabilities and parameter relationships now clear, the natural next question becomes: what kind of edge quality should you actually expect from these cuts?

Evaluating Cut Quality and Edge Finish Standards

You've dialed in your parameters and completed your first steel sheet laser cut—but how do you know if it's actually good? Cut quality evaluation goes far beyond a simple visual inspection. Understanding what separates a premium edge from one requiring secondary processing can save you hours of rework and significant material costs.

Let's examine the specific quality indicators that professionals use to evaluate laser cut metal sheets and discover how to achieve consistently excellent results.

Edge Quality Factors and Surface Finish Expectations

Imagine running your finger along a freshly laser cut stainless steel edge. What should you feel? The answer depends on your parameters, material, and intended application—but certain quality markers remain universal.

According to Senfeng Laser's technical analysis, surface smoothness is often the first quality indicator customers notice when evaluating laser cut sheet metal. A high-quality cut should leave a smooth, uniform edge requiring little to no post-processing.

Four critical quality indicators define professional laser cutting steel sheet results:

- Edge perpendicularity: How straight the cut edge stands relative to the material surface—critical for mechanical assemblies where parts must fit precisely

- Surface roughness: The microscopic texture of the cut face, ranging from mirror-smooth to visibly striated depending on parameters

- Dross presence: Any molten material solidified on the bottom of the cut that requires removal

- HAZ width: The extent of heat-affected material adjacent to the cut edge

So what exactly determines these quality outcomes? Three primary variables interact to produce your final edge characteristics:

Cutting speed directly influences smoothness and thermal effects. Too slow, and excessive heat creates rough surfaces with visible striations. Too fast, and incomplete material ejection leaves burrs and inconsistent edges. According to SendCutSend's edge quality guide, thinner materials generally produce cleaner edges right off the laser but are more sensitive to changes in cutting conditions.

Laser power must match your material thickness precisely. Excessive power over-burns the cut zone, creating wider kerfs and potentially damaging edges. Insufficient power produces incomplete cuts with excessive dross formation. Finding the sweet spot requires balancing speed and power for each specific material grade and thickness.

Focus position determines how concentrated laser energy reaches your workpiece. Slight misalignment—even fractions of a millimeter—reduces accuracy and degrades edge quality. Regular calibration ensures the focal point remains precisely positioned throughout production runs.

Different steel grades produce distinctly different edge characteristics. Carbon steel cut with oxygen assist typically shows a slightly oxidized, dark edge with excellent perpendicularity. Laser cut stainless steel processed with nitrogen produces silver-white edges that maintain the material's aesthetic appeal but may show slightly more pronounced striations on thicker sections.

Minimizing Dross and Heat-Affected Zones

Here's a term every laser operator needs to understand: dross. To define dross simply, it's the molten metal that re-solidifies on the bottom edge of your cut rather than being completely blown away by assist gas. Think of it as unwanted metal icicles clinging to your finished parts.

Why does dross form? According to Halden's quality control analysis, dross appears when cutting speed is too slow, laser power is too high, or assist gas pressure is insufficient. The molten material doesn't evacuate completely before re-solidifying—leaving deposits that require grinding, tumbling, or vibratory finishing to remove.

Minimizing dross requires systematic parameter optimization:

- Increase assist gas pressure: Higher pressure more effectively blows molten material clear of the cut zone

- Optimize cutting speed: Faster speeds reduce the time molten material has to re-attach

- Adjust focal position: Proper focus ensures maximum energy concentration for complete material removal

- Match gas type to material: Nitrogen for stainless steel, oxygen for carbon steel—each produces optimal results for its intended application

The heat-affected zone presents related but distinct challenges. This narrow band of thermally altered material surrounds every laser cut, potentially affecting hardness, microstructure, and corrosion resistance. According to Senfeng's research, HAZ occurs because of excessive laser power, slow cutting speeds, or improper gas flow—essentially any condition that allows heat to conduct into surrounding material.

Reducing HAZ width involves the same fundamental approach: use appropriate laser power for your thickness, maintain optimal cutting speeds, and select proper assist gases that cool the cutting zone while protecting against oxidation. High cutting speeds inherently limit heat exposure time, producing narrower affected zones. For laser cut metal applications where material properties must remain consistent to the edge, these considerations become especially critical.

Burn marks—another common defect—result from excessive heat concentrated in specific areas. Lowering laser power, increasing cutting speed, and ensuring adequate assist gas flow all help prevent the discoloration and surface damage these marks cause.

What should you realistically expect from professional laser cutting? Premium-quality laser cut metal sheets typically show smooth, uniform edges with minimal visible striations, perpendicular faces suitable for precision assembly, and virtually no dross requiring secondary processing. Achieving these results consistently requires the right combination of equipment capability, optimized parameters, and quality input materials—fundamentals that apply whether you're processing thin gauge decorative panels or thick structural components.

With quality expectations now clearly defined, the natural question becomes: what kinds of parts and projects actually benefit most from this precision cutting capability?

Real-World Applications Across Industries

Where does all this precision actually matter? Steel sheet laser cut technology has moved far beyond specialized manufacturing facilities into virtually every industry where metal components play a role. From the car you drive to the building you work in, laser-cut steel surrounds us—often in ways you'd never notice.

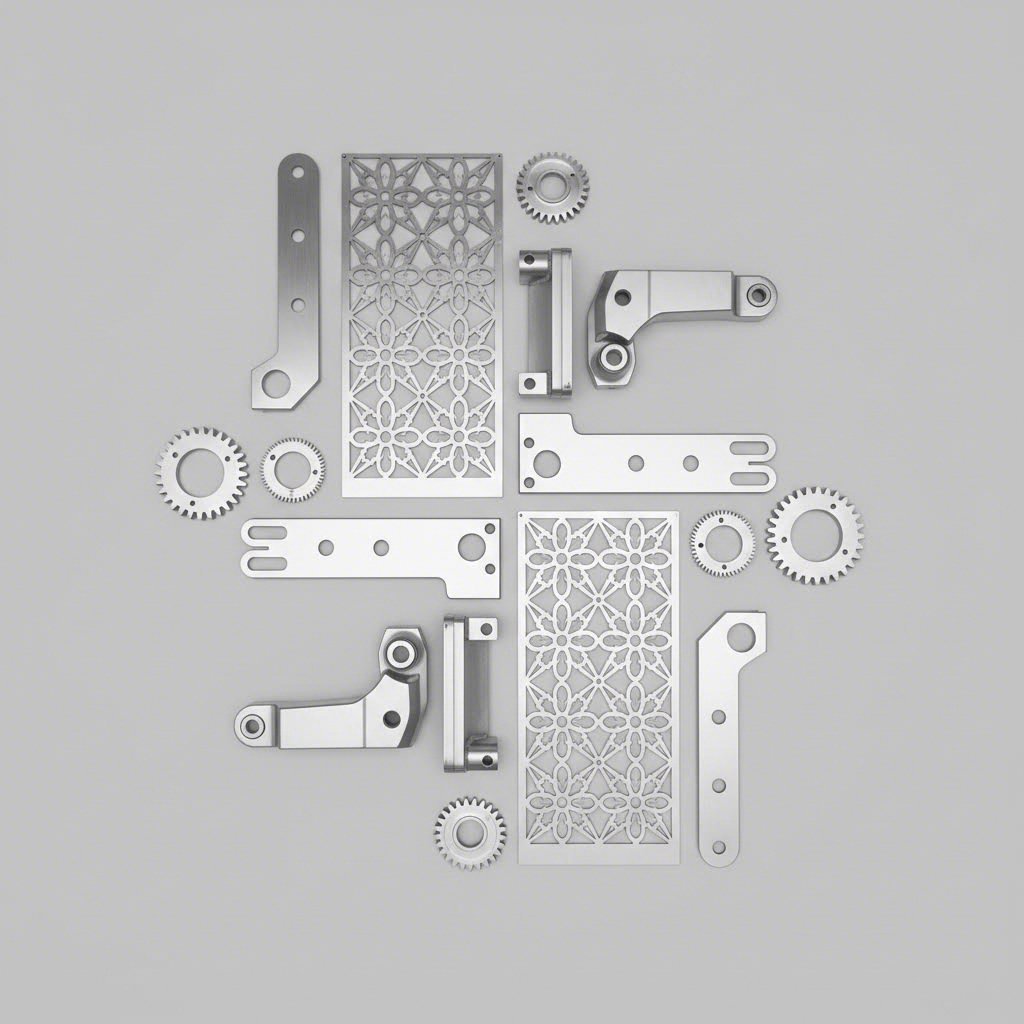

The versatility of laser cutting stems from its unique combination of capabilities: complex geometries that would be impossible to achieve mechanically, tight nesting that maximizes material efficiency, and rapid prototyping speeds that compress development timelines from weeks to days. Let's explore where these advantages create the most impact.

Automotive and Industrial Manufacturing Applications

Ever wondered how modern vehicles achieve such precise fit and finish? According to Great Lakes Engineering's industry analysis, precision laser cutting plays a vital role in producing high-quality automotive components efficiently. Manufacturers use this technique to create chassis parts, body panels, engine components, and intricate fittings from metals like steel and aluminum.

The automotive sector demands speed and consistency that traditional cutting methods simply cannot deliver. Consider what laser cutting enables:

- Chassis components: Structural brackets, mounting plates, and reinforcement members cut to tolerances under 0.002 inches

- Body panels: Complex curves and precise edges that eliminate costly secondary finishing operations

- Engine parts: Heat shields, gasket blanks, and mounting brackets requiring exact specifications

- Suspension elements: Control arm blanks and structural components where strength-to-weight ratios matter

Industrial equipment manufacturing benefits equally from laser technology's precision. Think about the machines that build other machines—CNC equipment frames, conveyor system components, agricultural machinery parts, and construction equipment brackets all rely on laser-cut steel for their structural integrity.

The process's high speed and accuracy allow for rapid production of parts that meet tight tolerances, supporting high-volume manufacturing while minimizing waste. Reduced part distortion and minimal need for post-processing enhance productivity, making steel sheet laser cutting the preferred method for durable components that contribute directly to equipment performance and longevity.

Custom Fabrication and Prototyping Possibilities

Imagine needing a single custom bracket for a specialized application. Traditional tooling would cost thousands and take weeks. Laser cutting? You could have your part in days—sometimes hours—with no tooling investment whatsoever.

This flexibility revolutionizes how designers and engineers approach product development. Rather than committing to expensive production tooling before testing concepts, teams can iterate rapidly through physical prototypes, testing fit and function with actual parts rather than digital simulations alone.

Common application categories span an impressive range:

- Architectural elements: Laser cut steel panels, decorative screens, facade cladding, and custom metal signs that transform building aesthetics

- Artistic installations: Laser cut decorative metal panels for public spaces, galleries, and corporate environments

- Signage and branding: Precise lettering, logos, and dimensional graphics impossible to achieve with traditional methods

- Furniture components: Table bases, chair frames, shelving brackets, and decorative accents

- HVAC and mechanical systems: Custom ductwork, mounting brackets, and equipment enclosures

- Electronics enclosures: Chassis, panels, and structural components for instrumentation

According to AMICO Architectural's application guide, architectural metals offer tremendous creative flexibility—from sunshades that reduce heat gain and improve visual comfort to equipment screens that dampen sound while maintaining ventilation. Exterior facades, interior wall cladding, and even vertical garden supports all benefit from the precision and design freedom laser cutting provides.

The laser cut metal panel has become particularly significant in modern architecture. These panels can feature intricate patterns impossible to achieve economically through mechanical means, creating dynamic visual effects as lighting conditions change throughout the day. Whether functioning as privacy screens, decorative accents, or structural cladding, laser-cut panels offer architects unprecedented design latitude.

Tight nesting capabilities maximize material utilization across all these applications. Advanced software arranges parts like puzzle pieces, minimizing the scrap material between cuts. For high-volume production runs, this optimization can reduce material costs by 15-25% compared to less efficient cutting methods—savings that compound significantly across large projects.

The contrast between high-volume and custom work highlights laser cutting's versatility. The same equipment that produces thousands of identical automotive brackets can, with a simple program change, create one-of-a-kind architectural elements or prototype parts. This flexibility eliminates the traditional tradeoff between production efficiency and customization capability.

Whether you're designing decorative laser cut metal panels for a flagship retail location or producing structural components for industrial machinery, the fundamental advantages remain consistent: precision that ensures proper fit, speed that meets demanding timelines, and flexibility that accommodates changing requirements without retooling penalties.

Understanding these applications naturally raises a practical question: should you invest in your own cutting equipment, or partner with a professional service provider? The answer depends on factors we'll examine next.

Making the Build vs Buy Decision for Steel Cutting Capabilities

You've seen the applications and understand the technology—but here's the question that keeps manufacturing managers awake at night: should you invest in your own steel sheet laser cut equipment, or partner with professional fabrication services? This decision impacts everything from your cash flow to your production flexibility.

The answer isn't one-size-fits-all. Some operations thrive with in-house capabilities, while others find outsourcing strategically superior. Let's break down the real costs and benefits so you can make a decision based on data rather than gut feeling.

In-House Equipment vs Professional Cutting Services

Imagine you're spending $6,000 monthly on outsourced laser cutting. That's $72,000 annually flowing to someone else's bottom line. Sounds like buying a machine makes obvious sense, right? Not so fast.

According to Arcus CNC's cost analysis, the capital expenditure for a standard 3kW fiber laser system ranges from $30,000 to $60,000—plus installation, auxiliary equipment, and training. But the real surprise? For operations spending more than $1,500-$2,000 monthly on outsourced parts, in-house equipment often pays for itself in 6-8 months.

Here's how the math works for a typical scenario:

- Outsourcing 2,000 steel plates monthly at $6 each: $144,000 annual cost

- In-house production with same volume: Approximately $54,000 annually (material + operating costs)

- Annual savings: Nearly $90,000—meaning a $50,000 machine pays for itself in under 7 months

But equipment ownership brings responsibilities. Your operational expenses include electricity (roughly $2 per hour for fiber lasers), assist gases ($2-$15 hourly depending on nitrogen vs air), consumables, and most significantly—labor. The good news? Modern systems don't require PhD-level expertise. According to industry research, existing welders or shop personnel can typically operate fiber lasers competently after just 2-3 days of training.

Professional cutting services offer a fundamentally different value proposition. When you search for "sheet metal near me" or contact metal fabricators near me, you're accessing capabilities without capital commitment:

- Zero upfront investment: No machine purchase, no financing payments

- Scalability on demand: Increase or decrease volume without capacity constraints

- Advanced equipment access: High-powered systems you couldn't justify purchasing

- Complementary services: Many fabrication shops near me offer powder coating services, bending, welding, and assembly under one roof

According to Selmach Machinery's analysis, once external laser cutting spend approaches £1,500 monthly (approximately $1,900 USD), investing in your own equipment becomes financially advantageous. However, this calculation changes when you factor in the hidden costs of outsourcing: material markups, transportation expenses, lead time delays, and quality control disputes.

| Decision Factor | In-House Equipment | Professional Cutting Services |

|---|---|---|

| Initial Investment | $30,000-$60,000+ for complete system | Zero capital outlay |

| Production Flexibility | Immediate turnaround; cut parts in minutes | Subject to supplier scheduling; typical 1-2 week lead times |

| Expertise Access | Requires internal training and experience development | Immediate access to specialized knowledge and certified processes |

| Scalability | Limited by machine capacity and operator availability | Virtually unlimited; pay only for what you need |

| Quality Control | Direct supervision and immediate feedback | Dependent on supplier standards and certifications |

| Maintenance Burden | Your responsibility; budget for parts and downtime | Included in service pricing |

What to Look for in a Fabrication Partner

If outsourcing makes sense for your situation—or you're adopting a hybrid approach where metal fab specialists handle overflow and specialty work—choosing the right partner becomes critical. Not all steel fabricators deliver equal value.

Start with certifications. For automotive and precision component work, IATF 16949 certification represents the gold standard. According to IATF 16949 supplier selection criteria, proper evaluation includes assessing the supplier's risk to product conformity, quality and delivery performance, quality management system maturity, and manufacturing capability.

Beyond baseline qualifications, evaluate these differentiators when selecting metal fabrication near me providers:

- Turnaround capabilities: Can they deliver rapid prototyping when you need design validation quickly? Some certified manufacturers offer 5-day prototype turnaround with automated mass production capabilities for scaling up

- Design for Manufacturing (DFM) support: Will they help optimize your designs for laser cutting before you commit to production? This collaborative approach prevents costly revisions and ensures manufacturability

- Quote responsiveness: Extended quote cycles delay your projects. Look for partners offering 12-hour quote turnaround or faster

- Material expertise: Do they understand the nuances of cutting stainless steel versus carbon steel versus galvanized materials?

- Secondary operations: Can one partner handle cutting, bending, welding, and finishing—or will you manage multiple vendors?

For automotive supply chain applications specifically, partnering with an IATF 16949-certified manufacturer ensures quality systems that meet OEM requirements. These certifications require multidisciplinary decision-making processes, robust change management, and documented manufacturing capabilities—protections that matter when your components become critical vehicle parts.

The hybrid approach deserves consideration too. Many smart operations purchase mid-range equipment to handle 80-90% of their daily cutting needs—standard steel thicknesses and common materials—while outsourcing specialty work to metal fabricators near me with ultra-high-power systems or specialized capabilities. This strategy captures the cost savings of in-house production without requiring investment in equipment you'd rarely use.

Whether you're evaluating equipment purchases or vetting fabrication partners, the fundamental question remains: what delivers the best value for your specific production requirements and growth trajectory? The answer shapes not just your cutting capabilities, but your competitive position in an increasingly demanding manufacturing landscape.

Putting Steel Sheet Laser Cutting Knowledge Into Action

You've absorbed a wealth of information about steel sheet laser cut technology—from wavelength differences to assist gas selection to edge quality expectations. But knowledge without action is just trivia. Let's translate everything you've learned into concrete steps that move your projects forward.

Whether you're specifying parts for an upcoming project, evaluating equipment investments, or fine-tuning existing operations, the path forward requires applying these fundamentals strategically.

Key Takeaways for Successful Steel Laser Cutting

Before diving into next steps, let's crystallize the essentials that separate successful laser cutting of metal sheets from frustrating trial-and-error experiences.

The single most critical success factor for steel sheet laser cutting projects is matching your material selection, parameter settings, and quality expectations before the first cut—not troubleshooting after problems appear.

According to Steelway Laser Cutting's expert analysis, the most common mistakes stem from overlooking fundamentals: ignoring material properties, misconfiguring machine settings, neglecting design file preparation, skipping surface cleaning, and failing to inspect finished products properly. Every one of these errors is preventable with proper planning.

Here's what matters most:

- Material selection drives everything: Laser quality steel, proper grade matching, and clean surfaces eliminate variables before cutting begins

- Fiber lasers dominate thin-to-medium steel: For most applications under 12mm, fiber technology delivers superior speed and lower operating costs

- Parameter optimization is non-negotiable: Power, speed, focus, and assist gas selection must align with your specific material and thickness

- Quality expectations should be defined upfront: Edge finish, dross tolerance, and HAZ requirements influence every parameter decision

Your Next Steps Based on Project Requirements

Ready to move forward? Your path depends on where you stand today.

If you're specifying parts for a cutting service: Start with clean, properly formatted design files—vector-based with no overlapping lines or incomplete paths. According to SendCutSend's design guidelines, verifying dimensions by printing at 100% scale and converting all text to outlines prevents costly revisions. Specify your material grade precisely and communicate edge quality expectations clearly.

If you're evaluating equipment purchases: Calculate your actual monthly cutting spend and compare it against true ownership costs—including electricity, gases, consumables, maintenance, and labor. For operations exceeding $1,500-$2,000 monthly in outsourced cutting, equipment ownership often pays for itself within 6-8 months. Consider a laser metal cutter sized for 80-90% of your daily needs, outsourcing specialty work to partners with specialized capabilities.

If you're optimizing existing processes: Document your current parameters and systematically test variations. Small adjustments in cutting speed, focus position, or gas pressure can dramatically improve edge quality and reduce dross formation. Track results methodically—what works for 304 stainless may fail on carbon steel.

For automotive, chassis, and precision structural component projects requiring certified quality, working with experienced manufacturing partners provides immediate access to optimized processes without learning-curve delays. Readers seeking IATF 16949-certified manufacturing partners offering comprehensive DFM support and rapid quote turnaround can explore options at Shaoyi Metal Technology.

Common mistakes to avoid as you proceed:

- Don't skip material verification—cutting 316 stainless with 304 parameters produces substandard results

- Don't assume flatness—warped material causes inconsistent focus and variable cut quality

- Don't ignore assist gas selection—oxygen for carbon steel speed, nitrogen for stainless steel aesthetics

- Don't rush prototyping—validate designs with test cuts before committing to production volumes

The laser cutting machine for metal you choose—or the metal cutting laser machine your fabrication partner operates—represents just one variable in a complex equation. Success comes from understanding how material, parameters, and quality expectations interact. You now have that understanding.

Your steel sheet laser cutting journey starts with a single well-informed decision. Make it count.

Frequently Asked Questions About Steel Sheet Laser Cutting

1. What is the difference between fiber and CO2 lasers for steel sheet cutting?

Fiber lasers operate at 1.06 microns wavelength and excel at cutting thin to medium steel sheets with 2-3x faster speeds and up to 50% lower electricity costs. CO2 lasers use 10.6 microns wavelength and offer material versatility for both metals and non-metals. Fiber lasers require less than 30 minutes weekly maintenance versus 4-5 hours for CO2 systems, making fiber technology the preferred choice for dedicated steel cutting operations.

2. How thick of steel can a laser cutter cut?

Modern fiber lasers can process steel from ultra-thin gauges under 1mm up to plates exceeding 20mm. Thin sheets under 1mm cut at speeds over 1000 inches per minute with 1-2 kW lasers. Medium thicknesses of 6-12mm require 6-10 kW systems cutting at 30-80 inches per minute. Heavy plates above 20mm need 15+ kW lasers and may require secondary edge processing to achieve optimal quality.

3. What assist gas should I use for laser cutting steel?

For carbon steel, oxygen creates an exothermic reaction that adds energy to the cut, enabling faster processing on thicker sections above 6mm but producing oxidized edges. For stainless steel, nitrogen prevents oxidation and produces clean silver-white edges ideal for visible applications. Compressed air offers a budget-friendly option but may cause some oxidation and rougher edges, particularly on stainless steel.

4. Should I buy laser cutting equipment or outsource to a service?

If your monthly outsourced cutting spend exceeds $1,500-$2,000, in-house equipment typically pays for itself within 6-8 months. A 3kW fiber laser system costs $30,000-$60,000 but can reduce per-part costs by over 60% at volume. However, outsourcing provides zero capital outlay, scalability on demand, and access to advanced equipment. For automotive applications, partnering with IATF 16949-certified manufacturers ensures quality standards while offering rapid prototyping and DFM support.

5. What causes dross on laser cut steel and how do I prevent it?

Dross forms when molten metal re-solidifies on the cut edge instead of being blown away by assist gas. Common causes include cutting speed too slow, laser power too high, or insufficient gas pressure. Prevention requires increasing assist gas pressure for better material evacuation, optimizing cutting speed to reduce re-attachment time, adjusting focal position for maximum energy concentration, and matching gas type to material—nitrogen for stainless steel and oxygen for carbon steel.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —