- Riduci i Costi di Estrusione dell'Alluminio con 5 Fondamentali Consigli DFM

- Il vero ROI degli stampi di estrusione personalizzati per la produzione di massa

- Prototipazione in Metallo per l'Automotive: Una Guida per un'Innovazione più Rapida

- Ricambi per Aria Condizionata Auto: Dal Compressore all'Evaporatore Svelati

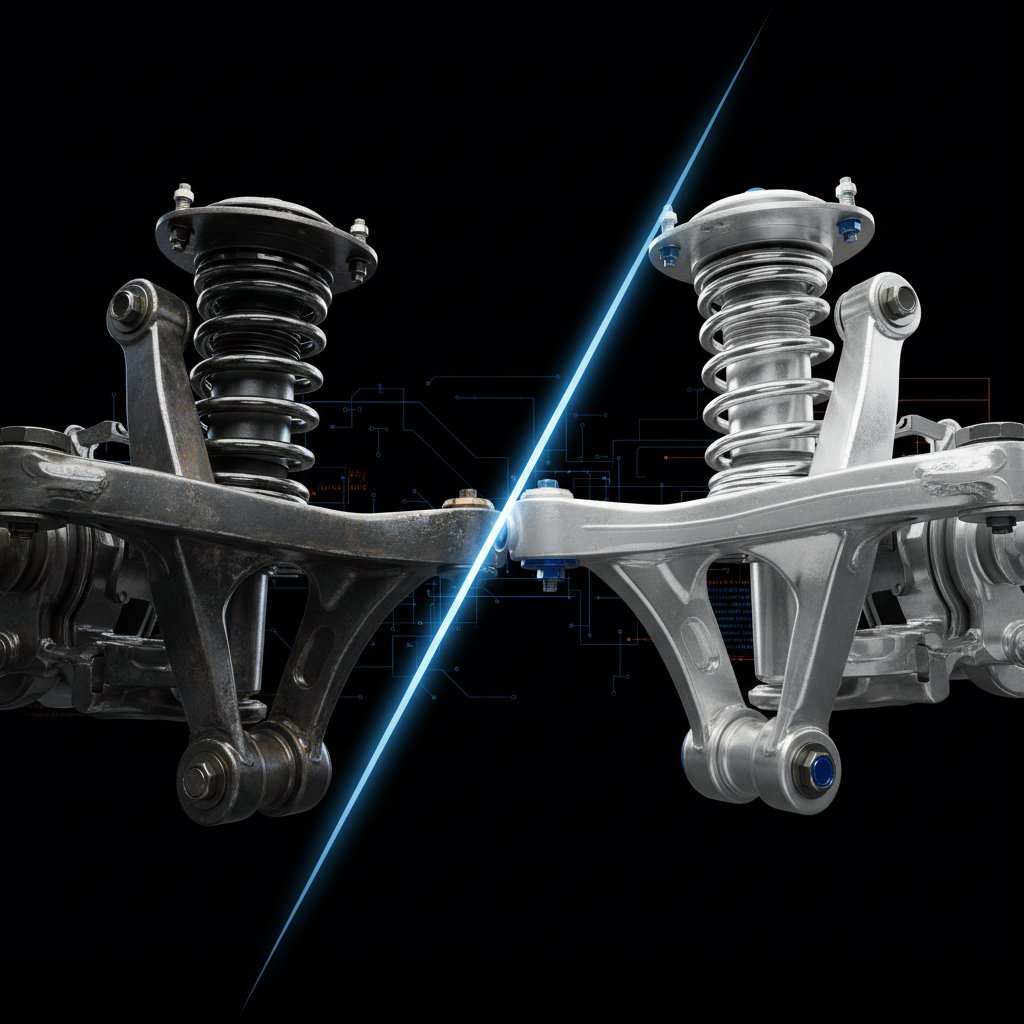

Acciaio stampato contro alluminio billet: la scelta essenziale per i bracci oscillanti

Time : 2025-12-15

TL;DR

La scelta tra bracci di controllo in acciaio stampato e in alluminio billet si riduce a un compromesso tra durata economica ed elevata resistenza prestazionale. I bracci in acciaio stampato sono lo standard accessibile, robusto e affidabile per la maggior parte delle auto di uso quotidiano e per le sostituzioni OEM. I bracci in alluminio billet sono notevolmente più leggeri, più resistenti rispetto al loro peso e resistenti alla corrosione, rendendoli la scelta premium per applicazioni ad alte prestazioni, fuoristrada e veicoli personalizzati in cui ridurre il peso e massimizzare la resistenza è fondamentale, anche se con un costo molto più elevato.

Comprensione dei materiali: cosa caratterizza l'acciaio stampato e l'alluminio billet?

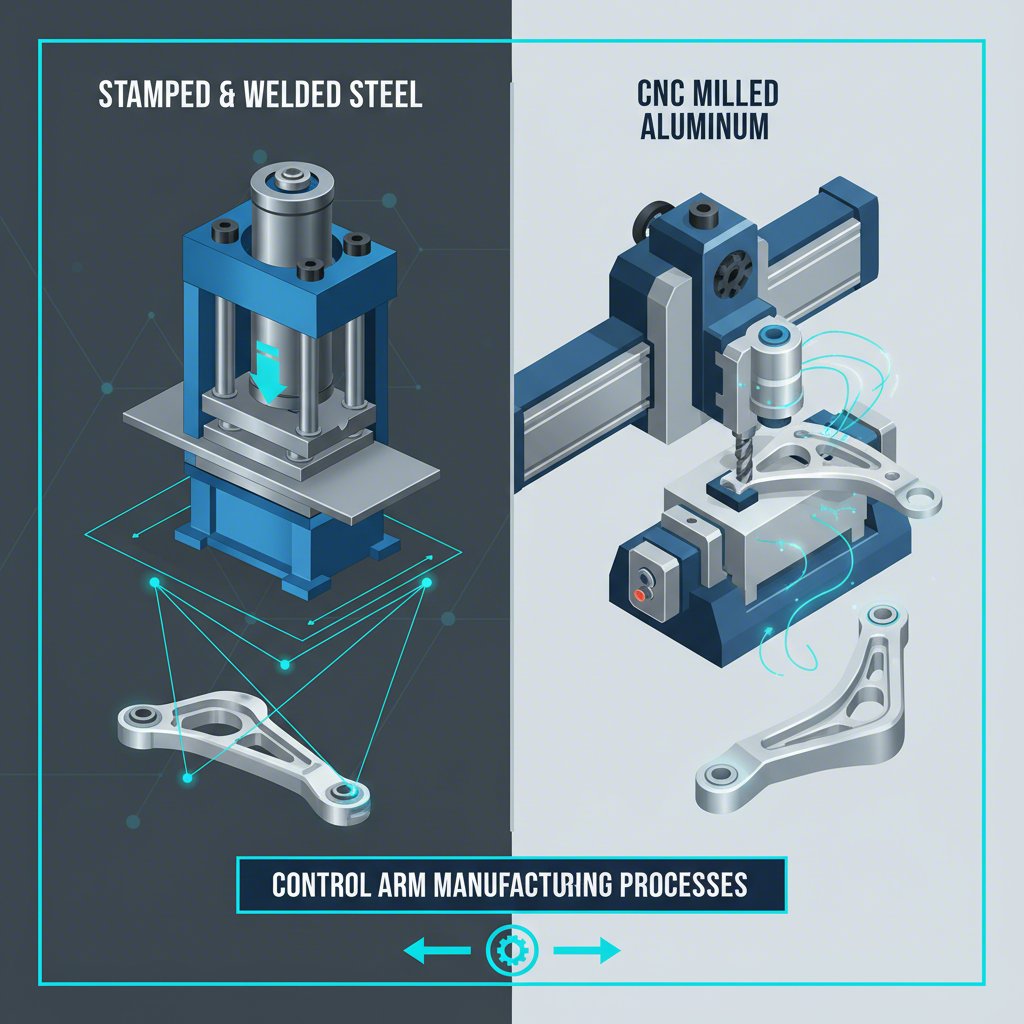

Prima di confrontare le prestazioni, è essenziale comprendere come vengono realizzati questi due tipi di bracci oscillanti, poiché il loro processo produttivo ne determina le proprietà. Essi sono fondamentalmente diversi nella creazione, nell'aspetto e nell'applicazione. L'acciaio stampato punta sulla affidabilità della produzione di massa, mentre l'alluminio ricavato dal pieno (billet) si concentra su prestazioni progettate con precisione.

I bracci oscillanti in acciaio stampato sono il tipo più comune montato sui veicoli di serie, specialmente su camion e auto per uso quotidiano. Vengono prodotti stampando fogli di acciaio ad alta resistenza in una forma desiderata, quindi saldando insieme le parti per formare il componente finale. Questo processo è altamente efficiente ed economico, rendendolo ideale per la produzione su larga scala. Per i costruttori automobilistici che si affidano a questo metodo, la precisione è fondamentale. Ad esempio, specialisti del settore come Shaoyi (Ningbo) Metal Technology Co., Ltd. forniscono soluzioni complete per la stampatura automobilistica, garantendo che componenti di questo tipo rispettino rigorosi standard industriali, dal prototipo alla produzione di massa.

Le balestre in alluminio billet, al contrario, rappresentano la gamma alta dei componenti per sospensioni. Ogni braccio viene lavorato con precisione da un unico blocco massiccio (billet) di alluminio mediante una macchina CNC (Controllo Numerico Computerizzato). Questo processo rimuove il materiale superfluo per creare un componente finale senza saldature, giunti o cuciture. Il risultato è un elemento eccezionalmente resistente e leggero, con una finitura lavorata di alta qualità. Questo metodo richiede molto più tempo ed è più costoso, motivo per cui i bracci in alluminio billet si trovano tipicamente su veicoli ad alte prestazioni, da corsa o fuoristrada dedicati.

Come fare quindi a riconoscere la differenza sul proprio veicolo? Ecco alcuni indicatori chiari:

- Aspetto visivo: I bracci in acciaio stampato hanno generalmente una superficie liscia con una finitura verniciata nera lucida per prevenire la ruggine. I bracci in alluminio billet presentano tipicamente una finitura metallica argentata naturale che mostra le linee sottili lasciate dal processo di lavorazione CNC.

- Giunture: Il segno più evidente di un braccio in acciaio stampato è una saldatura visibile lungo il giunto dove le parti stampate sono state unite. Un braccio in alluminio ricavato da un unico blocco, essendo lavorato da un pezzo unico, non presenta assolutamente saldature.

- Il Test con la Calamita: Come prova semplice ed efficace, un magnete aderirà saldamente a un braccio in acciaio, ma non aderirà a uno in alluminio.

Confronto diretto: acciaio stampato vs. alluminio ricavato da un blocco

Mettendo a confronto questi due bracci laterali, le differenze in termini di prestazioni, durata e costo risultano evidenti. La scelta giusta dipende interamente dall'uso previsto per il veicolo, dagli obiettivi di prestazioni e dal budget disponibile. Mentre l'acciaio offre resistenza robusta e convenienza economica, l'alluminio ricavato da un blocco garantisce resistenza progettata e significativi vantaggi in termini di prestazioni.

Il vantaggio prestazionale più significativo dell'alluminio è la riduzione del peso. Bracci oscillanti più leggeri riducono il "peso non sospeso" di un veicolo, ovvero il peso di tutti i componenti non sostenuti dal sistema di sospensione. Ridurre questo peso permette alla sospensione di reagire più rapidamente a dossi e variazioni della superficie stradale, migliorando il comportamento in curva, l'aderenza e la qualità complessiva della guida. L'acciaio è molto più denso e pesante, il che può rendere la sospensione meno reattiva in condizioni di guida sportiva.

Per quanto riguarda la resistenza pura, l'acciaio è un materiale estremamente resistente e durevole, perfettamente in grado di sopportare i carichi pesanti e gli urti derivanti dalla guida quotidiana e persino dall'uso intensivo. Tuttavia, il processo produttivo mediante tornitura da barra consente di ottenere un componente in alluminio con un rapporto resistenza-peso superiore. Si tratta di un materiale eccezionalmente resistente e rigido, senza il sovrappeso tipico dell'acciaio. Inoltre, l'alluminio resiste naturalmente alla ruggine e alla corrosione, mentre i bracci in acciaio richiedono rivestimenti protettivi per prevenire la ruggine, specialmente in climi umidi o con presenza di sale.

Ecco una suddivisione dettagliata delle principali differenze:

| Caratteristica | Acciaio stampato | Alluminio Billet |

|---|---|---|

| Processo di fabbricazione | Lamiere d'acciaio sono stampate e saldate insieme. | Fresato a CNC da un unico blocco solido di alluminio. |

| Peso | Pesante | Significativamente più leggero |

| Resistenza | Alta durabilità e resistenza grezza. | Rapporto eccezionale tra resistenza e peso; molto rigido. |

| Resistenza alla corrosione | Soggetto a ruggine; richiede rivestimenti protettivi (ad esempio, vernice). | Naturalmente resistente alla ruggine e alla corrosione. |

| Prestazioni e Guidabilità | Sufficiente per l'uso standard; un peso non sospeso più elevato può limitare la reattività. | Migliora la risposta della sospensione, il comportamento stradale e l'aderenza grazie al minore peso non sospeso. |

| Applicazione tipica | OEM sulla maggior parte di auto e camion, veicoli di uso quotidiano, ricambi per utenti attenti al budget. | Auto da corsa ad alte prestazioni, fuoristrada da competizione, veicoli personalizzati da esposizione. |

| Costo relativo | Basso / Economico | Molto alto / Premium |

Applicazione e casi d'uso: quale braccio oscillante è adatto al tuo veicolo?

Tradurre i dettagli tecnici in una decisione pratica è l'ultimo passo. Il "migliore" materiale per il braccio oscillante non è universale; dipende interamente dalle tue esigenze specifiche, dalle abitudini di guida e dal tipo di veicolo. Rispondere a poche domande chiave può indirizzarti rapidamente verso la scelta più adatta alla tua situazione.

Per la stragrande maggioranza dei conducenti, l'acciaio stampato è la scelta ideale. Se utilizzi il tuo veicolo per gli spostamenti quotidiani, per il trasporto familiare o per lavori generici di utilità e devi sostituire una parte usurata, un braccio oscillante in acciaio stampato offre il perfetto equilibrio tra durata, affidabilità ed economicità. Rispetta o supera le specifiche originali del costruttore e garantirà prestazioni affidabili per anni.

Tuttavia, se stai realizzando un veicolo per uno scopo specifico in cui le prestazioni sono la priorità assoluta, l'alluminio ricavato dal pieno diventa un aggiornamento molto interessante. Per gli appassionati di fuoristrada che affrontano percorsi desertici ad alta velocità o arrampicate su roccia, la combinazione di leggerezza ed elevata resistenza migliora l'articolazione e il comportamento del sistema di sospensione. Allo stesso modo, per vetture da pista o veicoli stradali ad alte prestazioni, la riduzione del peso non sospeso apporta un miglioramento tangibile nell'efficienza in curva e nella reattività. Marche come Icon e Camburg si specializzano in bracci oscillanti di alta gamma, offrendo opzioni sia in alluminio ricavato dal pieno che in acciaio tubolare ad alta resistenza per applicazioni gravose.

È inoltre fondamentale considerare la compatibilità. Sebbene sia possibile sostituire bracci in acciaio con altri in alluminio (o viceversa), non sempre si tratta di una sostituzione semplice. Come evidenziano gli esperti di Maxtrac Suspension , materiali diversi per i bracci oscillanti possono essere abbinati a dimensioni specifiche dei giunti sferici e dei mozzi sterzanti. L'installazione di un braccio incompatibile può causare un montaggio improprio e condizioni di guida pericolose. Verificare sempre che qualsiasi braccio oscillante aftermarket sia progettato per funzionare con l'assetto specifico del proprio veicolo.

Per prendere la decisione migliore, porsi le seguenti domande:

- Qual è l'utilizzo principale del veicolo? (uso quotidiano contro gare/fuoristrada)

- Qual è il mio budget? (Sto cercando una soluzione economica oppure un aggiornamento prestazionale premium?)

- Do priorità al comportamento stradale e alla reattività rispetto al costo?

- Le mie condizioni di guida sono così difficili da giustificare la superiore resistenza alla corrosione dell'alluminio?

Le tue risposte indicheranno chiaramente la strada da seguire. Per la maggior parte degli utenti, l'acciaio stampato è la soluzione pratica e logica. Per chi spinge al limite le prestazioni, l'alluminio billet è un investimento degno.

Domande frequenti

1. Qual è il materiale migliore per i bracci oscillanti?

Non esiste un unico materiale "migliore"; la scelta ideale dipende dall'uso del veicolo e dal tuo budget. L'acciaio stampato è il migliore per la guida quotidiana e le sostituzioni standard OEM grazie all'elevata durata e al basso costo. L'alluminio è la scelta superiore per applicazioni ad alte prestazioni, da corsa o fuoristrada impegnative, dove il suo peso leggero e il rapporto elevato tra resistenza e peso migliorano il comportamento stradale e la reattività della sospensione.

2. Come capire se i bracci oscillanti sono in acciaio o in alluminio?

Ci sono tre modi semplici per identificare i bracci oscillanti. Primo, osservate la finitura: i bracci in acciaio stampato sono generalmente verniciati in nero lucido, mentre quelli in alluminio hanno spesso un aspetto argentato grezzo e lavorato al tornio. Secondo, controllate la presenza di giunture: i bracci in acciaio stampato sono saldati insieme e presenteranno una saldatura visibile, mentre i bracci in alluminio billet sono ricavati da un blocco unico e non hanno giunture. Infine, utilizzate un magnete; questo aderirà all'acciaio ma non all'alluminio.

Piccole partite, alti standard. Il nostro servizio di prototipazione rapida rende la validazione più veloce e facile —

Piccole partite, alti standard. Il nostro servizio di prototipazione rapida rende la validazione più veloce e facile —