- Riduci i Costi di Estrusione dell'Alluminio con 5 Fondamentali Consigli DFM

- Il vero ROI degli stampi di estrusione personalizzati per la produzione di massa

- Prototipazione in Metallo per l'Automotive: Una Guida per un'Innovazione più Rapida

- Ricambi per Aria Condizionata Auto: Dal Compressore all'Evaporatore Svelati

Bracci oscillanti in acciaio stampato: difetti chiave da conoscere

Time : 2025-12-15

TL;DR

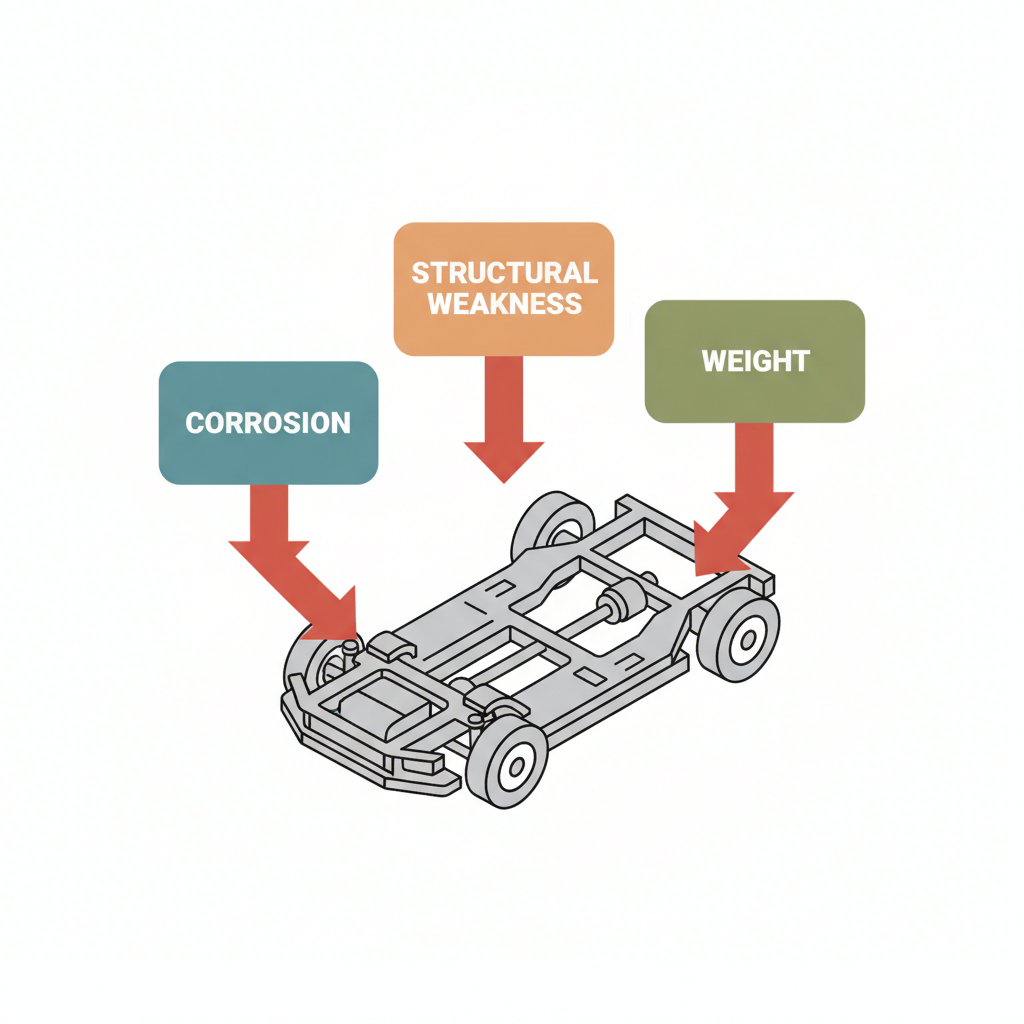

I bracci di controllo in acciaio stampato, un componente comune in molti veicoli economici, presentano diversi svantaggi significativi. Le loro principali debolezze sono l'elevata suscettibilità alla ruggine e alla corrosione, specialmente in climi umidi con sale stradale. Sono anche strutturalmente meno resistenti rispetto alle alternative fuse o forgiare, il che li rende più soggetti a flessioni o danni sotto stress intensi. Infine, sono più pesanti dei bracci in alluminio, il che può influire negativamente sulla guida e sulla reattività della sospensione del veicolo.

I principali svantaggi dei bracci oscillanti in acciaio stampato spiegati

Un braccio oscillante è un componente fondamentale del sistema di sospensione che collega il telaio del veicolo all'insieme della ruota, consentendo alle ruote di muoversi verso l'alto e verso il basso seguendo l'irregolarità della strada mantenendo al contempo la stabilità. I bracci oscillanti in acciaio stampato vengono prodotti stampando fogli di acciaio in una forma desiderata e successivamente saldandoli insieme. Questo metodo consente una produzione di massa economicamente vantaggiosa, motivo per cui sono spesso presenti sulle autovetture standard. Per i produttori automobilistici, ottenere precisione in questo processo è fondamentale, e aziende specializzate come Shaoyi (Ningbo) Metal Technology Co., Ltd. forniscono soluzioni complete, dalla prototipazione alla produzione di massa, per questo tipo di componenti.

Nonostante il loro ampio utilizzo, i bracci in acciaio stampato presentano svantaggi intrinseci che i proprietari dei veicoli dovrebbero conoscere. Questi svantaggi rientrano principalmente in tre categorie: suscettibilità alla corrosione, integrità strutturale e peso. Ognuno di questi fattori può influire sulla durata, sicurezza e prestazioni del veicolo a lungo termine, rendendo la scelta del materiale del braccio oscillante una considerazione importante durante la manutenzione o gli aggiornamenti.

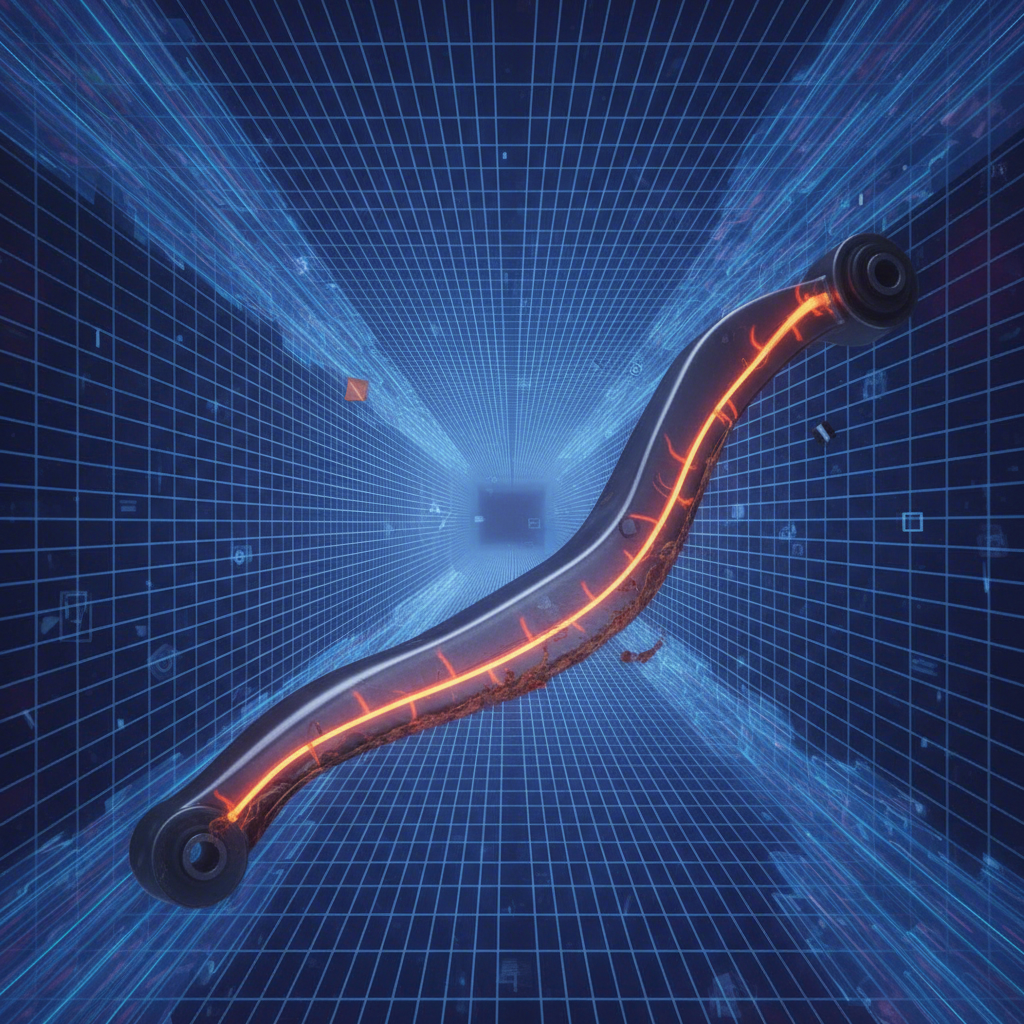

Lo svantaggio più significativo e frequentemente citato è la loro vulnerabilità alla ruggine. L'acciaio stesso è soggetto ad ossidazione, e questo problema è spesso aggravato dal processo produttivo. Le saldature possono trattenere umidità, e i rivestimenti applicati in fabbrica possono scheggiarsi o usurarsi nel tempo, esponendo il metallo allo stato grezzo agli agenti atmosferici. Secondo un articolo pubblicato da CarParts.com , questa debolezza è particolarmente evidente perché i componenti della sospensione sono costantemente esposti a umidità, sale stradale e detriti, accelerando il processo di corrosione e indebolendo potenzialmente il componente nel tempo.

Un'altra preoccupazione importante riguarda la loro resistenza strutturale rispetto ad altri materiali. Poiché sono tipicamente cavi e realizzati mediante saldatura di pezzi separati anziché essere un unico blocco di metallo, i bracci in acciaio stampato possono flettersi, piegarsi o creparsi sotto stress estremi, come quando si colpisce una grossa buca o in condizioni fuoristrada. Questa mancanza di rigidità può influire sull'allineamento e sulla tenuta di strada. Al contrario, i bracci in ghisa solida o in acciaio forgiato offrono una resistenza superiore e sono più adatti per applicazioni gravose, come osservato da Metrix Premium Parts .

Infine, il peso è un fattore critico nelle prestazioni della sospensione. L'acciaio stampato è più denso e pesante dell'alluminio. Questo peso aggiuntivo "non sospeso" (la massa della sospensione, delle ruote e di altri componenti non supportati dalle molle) può rendere la sospensione meno reattiva agli imperfezioni della strada, causando una guida più dura e un controllo meno preciso. In applicazioni orientate alle prestazioni, ridurre al minimo il peso non sospeso è un obiettivo primario.

- Alta suscettibilità alla ruggine: Le saldature e l'acciaio rivestito sono vulnerabili alla corrosione, specialmente in climi umidi o nevosi.

- Debolezza strutturale: La struttura cava e saldata è meno rigida e più soggetta a flessioni o danni da impatti rispetto a parti solide fuse o forgiati.

- Peso Aumentato: Più pesante dell'alluminio, il che può influire negativamente sulla reattività del sistema di sospensione, sul comportamento in marcia e sulla qualità complessiva della guida.

Acciaio stampato vs. Alternative: Uno scontro tra materiali e resistenza

Comprendere gli svantaggi dell'acciaio stampato è più semplice confrontandolo direttamente con le alternative comuni: ghisa, alluminio fuso e acciaio forgiato. La scelta migliore dipende spesso dall'uso del veicolo, dall'ambiente di guida e dal budget del proprietario. Ogni materiale deriva da un diverso processo produttivo: lo stampaggio prevede la formatura e la saldatura di lamiere d'acciaio, la fusione consiste nel versare metallo fuso in uno stampo, mentre la forgiatura implica la formatura del metallo riscaldato sotto pressione estrema, allineando la struttura cristallina del metallo per una resistenza superiore.

La ghisa è la scelta più comune per molti camion e SUV. Come spiegato da GMT Rubber , il suo principale vantaggio è l'elevata resistenza e durata, rendendola ideale per veicoli pesanti sottoposti a condizioni difficili. Sebbene sia pesante e soggetta a ruggine se il rivestimento protettivo viene compromesso, la sua robustezza ne fa un'opzione affidabile per veicoli da lavoro in cui il peso è una preoccupazione secondaria rispetto alla resistenza.

La ghisa alluminata è diventata un'opzione popolare, specialmente nei veicoli sportivi e di lusso. Il suo principale vantaggio è la significativa riduzione del peso. Secondo Aldan American , i bracci di controllo in alluminio possono essere dal 40% al 50% più leggeri rispetto ai loro equivalenti in acciaio. Questa drastica riduzione del peso non sospeso permette alla sospensione di reagire più rapidamente, migliorando il comportamento stradale e il comfort di guida. Inoltre, l'alluminio è naturalmente resistente alla corrosione, un vantaggio significativo per i veicoli nelle regioni con piogge abbondanti o uso di sale stradale. Il compromesso è generalmente un costo più elevato e una minore resistenza alla rottura catastrofica in caso di impatti intensi rispetto all'acciaio.

L'acciaio forgiato (o l'alluminio forgiato) rappresenta il massimo in termini di resistenza. Il processo di forgiatura crea un componente estremamente denso e robusto, rendendolo la scelta migliore per applicazioni automobilistiche ad alte prestazioni e fuoristrada estreme, dove il cedimento dei componenti non è ammissibile. Combina la resistenza dell'acciaio con un processo produttivo che elimina le debolezze presenti nei componenti stampati o fusi, anche se questo comporta il costo più elevato.

| Materiale | Vantaggio principale | Svantaggio principale | Migliore per |

|---|---|---|---|

| Acciaio stampato | Basso costo | Soggetto a ruggine e deformazioni | Veicoli economici per uso quotidiano |

| Ghisa | Alta resistenza | Molto pesante | Autocarri e SUV pesanti |

| Alluminio fuso | Leggero e resistente alla corrosione | Costo più elevato e minore resistenza agli urti | Prestazioni e climi piovosi |

| Acciaio forgiato/Alluminio | Massima resistenza e durata | Costo più elevato | Gare ed fuoristrada estremo |

Identificazione e ispezione dei bracci di controllo

Conoscere il tipo di bracci di controllo montati sul veicolo è essenziale per ordinare i ricambi corretti e comprendere i potenziali punti di rottura. L'identificazione visiva è spesso semplice. Come descritto da Switch Suspension , i bracci in acciaio stampato possono essere generalmente identificati dalla loro costruzione; appaiono come due pezzi di metallo stampati e saldati insieme, con una saldatura visibile lungo i bordi. Di solito presentano una superficie liscia e verniciata. Al contrario, i bracci in ghisa o alluminio sono realizzati in un unico pezzo di metallo e hanno una finitura più ruvida e texturizzata, senza saldature.

L'ispezione regolare è fondamentale, specialmente per i bracci in acciaio stampato in ambienti difficili. I punti di guasto più comuni non sono sempre il braccio stesso, ma i componenti a esso collegati: boccoli e giunti sferici. I boccoli sono inserti in gomma o poliuretano che isolano le vibrazioni e permettono al braccio di oscillare. Col tempo, possono creparsi, degradarsi e rompersi, causando rumori metallici, cattivo allineamento e usura irregolare dei pneumatici. Analogamente, il giunto sferico, che collega il braccio di controllo al mozzo dello sterzo, può usurarsi, provocando uno sterzo molle e rumori.

Durante l'ispezione dei bracci di controllo, prestare particolare attenzione alle saldature e alle zone soggette ad alto stress per individuare eventuali segni di crepe o distacco avanzato della ruggine. Una corrosione significativa può compromettere l'integrità strutturale del braccio molto prima che si rompa. Una semplice lista di controllo può guidare un'ispezione fai-da-te.

- Sollevare e Sostenere il Veicolo in Sicurezza: Utilizzare cavalletti per assicurarsi che il veicolo sia stabile prima di posizionarsi al di sotto.

- Identificazione Visiva: Cerca il caratteristico cordone di saldatura di un braccio in acciaio stampato rispetto alla costruzione monoblocco di un braccio fuso.

- Controlla la presenza di crepe e corrosione: Esamina attentamente l'intero braccio, prestando particolare attenzione alle saldature e alle zone intorno ai boccoli e al giunto sferico per individuare eventuali crepe o ruggine significativa.

- Ispezionare le boccole: Cerca crepe visibili, strappi o degrado della gomma nei boccoli in cui il braccio di controllo si collega al telaio del veicolo.

- Ascolta gli indizi udibili: Durante la guida, ascolta rumori di scatti, scoppi o colpi, specialmente quando si passa su dossi o si sterza. Questi sono spesso i primi segnali di usura di un componente del braccio di controllo.

Domande frequenti

1. Qual è il materiale migliore per i bracci oscillanti?

Non esiste un unico "materiale migliore", poiché la scelta ideale dipende dal veicolo e dal suo utilizzo. Per la maggior parte delle autovetture usate quotidianamente in climi asciutti, l'acciaio stampato rappresenta una soluzione economicamente vantaggiosa. Per i veicoli che circolano in zone con piogge abbondanti e sale stradale, l'alluminio offre una superiore resistenza alla corrosione e migliori prestazioni. La ghisa è la migliore per camion e SUV pesanti che richiedono la massima resistenza, mentre l'acciaio forgiato o l'alluminio sono riservati ad applicazioni ad alte prestazioni e da corsa, dove resistenza e leggerezza sono fondamentali.

2. La sua vita. Qual è la differenza tra braccia di controllo stampate e falsificate?

La differenza principale risiede nel processo produttivo e nella resistenza risultante. Le braccia oscillanti stampate sono realizzate da lamiere d'acciaio pressate in forma e saldate insieme, il che le rende economiche ma più deboli nei punti di saldatura. Le braccia oscillanti forgiati vengono create riscaldando un pezzo solido di metallo e comprimendolo in uno stampo sotto pressione estrema. Questo processo allinea la struttura interna del grano metallico, producendo un componente significativamente più resistente, più duraturo e più resistente alla fatica rispetto alle controparti stampate o addirittura fuse.

Piccole partite, alti standard. Il nostro servizio di prototipazione rapida rende la validazione più veloce e facile —

Piccole partite, alti standard. Il nostro servizio di prototipazione rapida rende la validazione più veloce e facile —