Custom Cut Sheet Metal: From First Measurement To Finished Part

Understanding Custom Cut Sheet Metal and Why Precision Matters

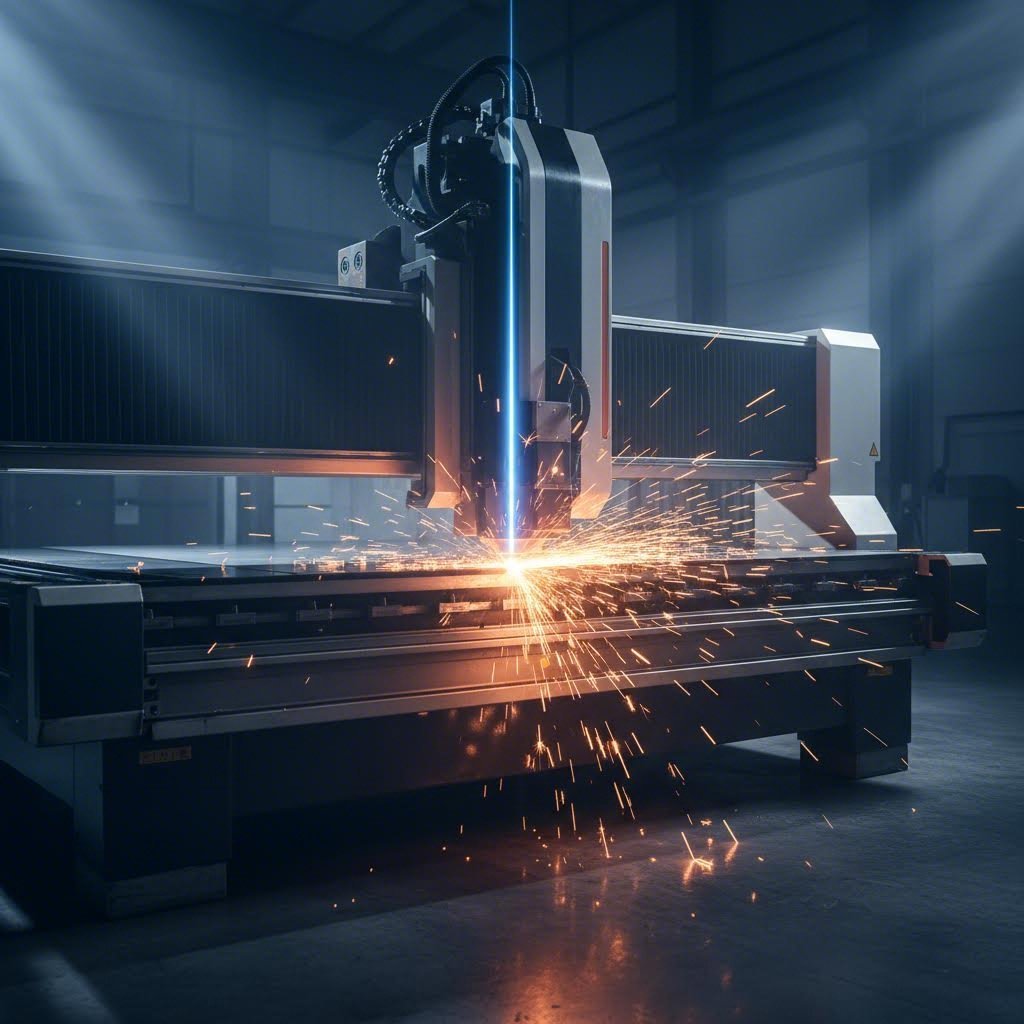

Ever stared at a standard metal sheet and wondered how manufacturers transform it into perfectly sized components for everything from aircraft panels to custom garage projects? That transformation happens through custom cut sheet metal—a process that takes raw material and shapes it into exactly what you need, nothing more, nothing less.

Custom cut sheet metal refers to the manufacturing process where flat metal sheets are cut to precise dimensions and shapes based on specific customer requirements. Unlike purchasing pre-sized stock that rarely matches your exact needs, this approach delivers components ready for immediate use in your application. The result? Less material waste, minimal secondary processing, and parts that fit perfectly the first time.

What Makes Sheet Metal Custom Cut Different

Standard metal sheets come in predetermined sizes—4x8 feet, 4x10 feet, and similar industry-standard dimensions. When your project calls for a 7.25-inch by 12.5-inch bracket with specific hole placements, you're left with two choices: buy oversized material and waste what you don't need, or order custom cut pieces that arrive ready to install.

The difference comes down to precision. Modern sheet metal fabrication employs computerized cutting tools—lasers, waterjets, and plasma systems—that follow CAD files with remarkable accuracy. According to manufacturing experts, these computerized cutting tools cut sheet metal to precise shapes, enabling tolerances that manual methods simply cannot achieve.

This precision matters whether you're an industrial manufacturer producing thousands of identical parts or a hobbyist building a single custom enclosure. Both audiences benefit from receiving components that match their specifications exactly.

From Raw Material to Precision Part

Think of custom cutting as the critical bridge between raw materials and finished components. A flat metal sheet holds potential, but it's the cutting process that unlocks its usefulness for your specific application.

Custom metal fabrication transforms standard sheet metal stock into components that meet exact specifications—eliminating waste, reducing secondary processing, and delivering ready-to-use parts that fit perfectly into the intended application.

The benefits extend beyond simple convenience:

- Waste elimination: You pay only for the material you actually need, not oversized sheets that end up in the scrap bin

- Reduced labor: Parts arrive ready for assembly or installation without additional trimming or modification

- Consistency: When ordering multiple pieces, each one matches the others precisely—critical for assemblies requiring interchangeable components

- Design flexibility: Complex shapes, curves, and cutouts become achievable without specialized in-house equipment

For industrial applications, custom cut metal enables efficient production of brackets, enclosures, panels, and structural components across sectors from HVAC to aerospace. Medical device manufacturers rely on precision-cut stainless steel for surgical instruments. Automotive suppliers need identical stamped parts by the thousands.

Hobbyists and DIY enthusiasts benefit equally. Building a custom electronics enclosure? Restoring a vintage vehicle? Fabricating art installations? Custom cutting provides access to professional-grade precision without requiring expensive equipment investments. You submit your specifications, and fabricators deliver finished metal sheets cut exactly to your design—ready for bending, welding, or direct installation.

Understanding this foundational concept sets the stage for making informed decisions about cutting methods, materials, and specifications—all of which we'll explore in the sections ahead.

Comparing Laser Waterjet Plasma and Shear Cutting Methods

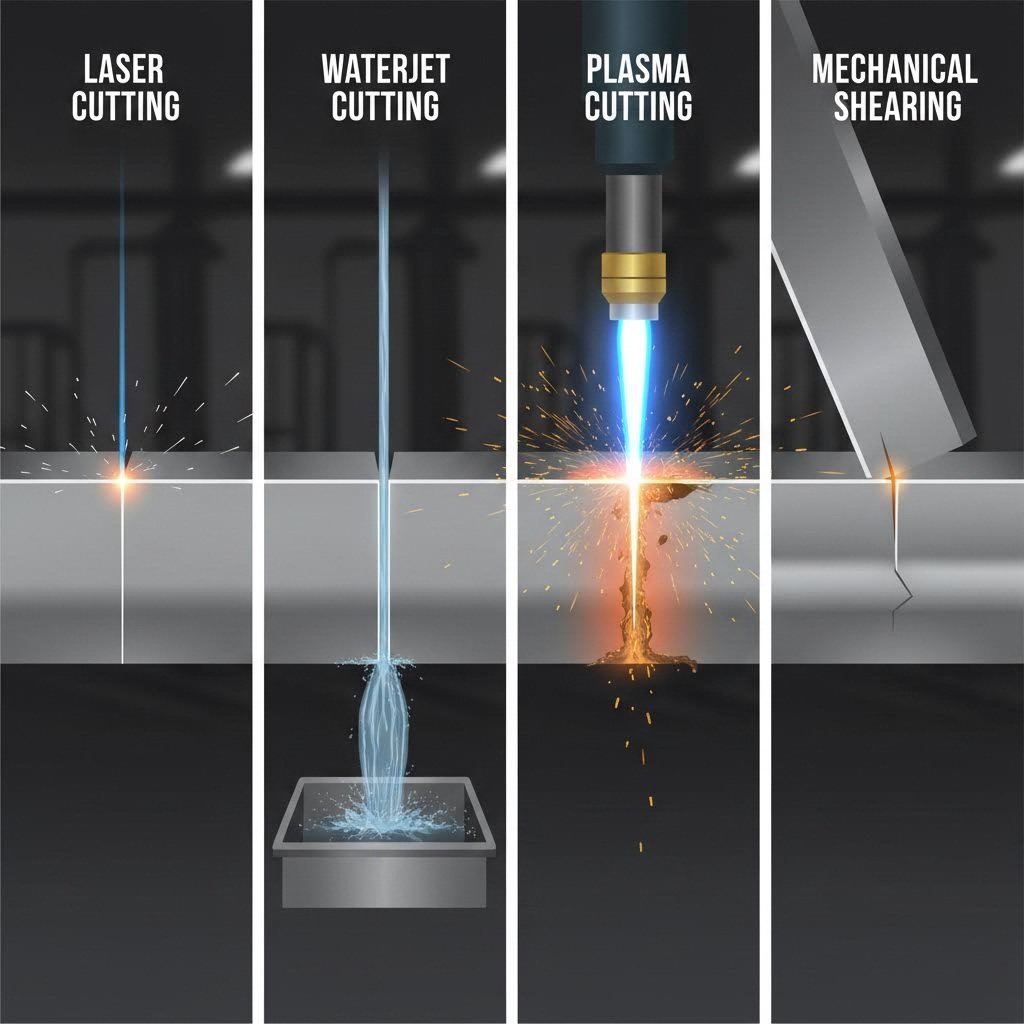

So you've decided custom cut sheet metal is the right approach for your project. Now comes the critical question: which cutting method should you specify? The answer significantly impacts your part quality, cost, and timeline. Each technology—laser, waterjet, plasma, and mechanical shearing—brings distinct strengths to the table, and understanding these differences helps you make smarter decisions.

Think of it this way: choosing a cutting method is like selecting the right tool from your toolbox. A hammer works brilliantly for nails but terribly for screws. Similarly, a laser cutter excels at intricate thin-material work but struggles with 2-inch steel plate. Let's break down what each method does best.

Laser Cutting for Fine Detail Work

Laser cutting uses a focused beam of intense light to melt, burn, or vaporize metal along a precisely controlled path. If your project demands intricate patterns, tight tolerances, or exceptionally clean edges, this is often your best bet.

The laser cutter shines when working with thin to medium-thickness materials—typically up to about 1 inch for steel. According to industry testing, laser cutting is far superior for parts requiring small holes, sharp corners, and fine details. Medical device manufacturers, electronics enclosure fabricators, and decorative metalwork producers rely heavily on this technology.

What makes laser cutting special?

- Exceptional precision: Tolerances as tight as ±0.005 inches are achievable on many materials

- Minimal finishing required: The focused beam creates smooth edges that often need no secondary processing

- Small kerf width: The cut itself removes minimal material, maximizing your usable sheet area

- Repeatability: CNC-controlled systems produce identical parts cut after cut

However, laser technology isn't perfect for every application. Equipment and operational costs run high, and efficiency drops significantly when cutting very thick metals. If you're wondering how to cut plexiglass or how to cut acrylic sheet, laser cutting handles these materials beautifully—though power settings must be carefully controlled to prevent melting or burning.

Waterjet Versus Plasma Trade-offs

When projects involve thicker materials or heat-sensitive alloys, waterjet and plasma cutting step into the spotlight—each with fundamentally different approaches.

Waterjet cutting uses high-pressure water (often mixed with abrasive particles) to slice through material without generating heat. This cold-cutting process means zero heat-affected zone, making it ideal for aerospace components, specialty alloys, and materials that would warp or harden under thermal stress. The technology handles virtually any material—metals, stone, glass, composites—with the same machine setup.

Plasma cutting takes the opposite approach, using an electrically ionized gas stream heated to extreme temperatures to melt and blast through conductive metals. What plasma sacrifices in precision it gains in speed and cost-effectiveness, particularly for thicker steel plate applications.

Consider these trade-offs when deciding between them:

- Heat sensitivity: Waterjet wins when material properties must remain unchanged; plasma creates a heat-affected zone that can alter metal characteristics near the cut

- Speed: Plasma cutting operates 3-4 times faster than waterjet on 1-inch steel

- Operating costs: Plasma systems cost roughly half as much per foot to operate compared to waterjet

- Material versatility: Waterjet cuts non-conductive materials; plasma works only with conductive metals

For those asking how do you cut perspex or similar plastics, waterjet provides a clean option without the heat concerns that can melt or discolor these materials.

Mechanical Shearing for Economical Straight Cuts

Don't overlook the simplest method in the metal cutter arsenal. Mechanical shearing uses a blade to apply shearing force, breaking material along straight lines. It's fast, economical, and highly effective for its intended purpose.

Shearing makes sense when your parts require only straight-line cuts without complex shapes. High-volume production of rectangular blanks, strips, or simple profiles benefits from shearing's speed and low operational costs. The equipment investment is significantly lower than thermal or waterjet systems.

The limitations? Shearing typically handles materials up to about 6mm thickness. Edge quality can include slight burrs requiring secondary finishing. And forget intricate patterns—this technology cuts straight lines only.

Cutting Method Comparison at a Glance

Matching the right cutting method to your project requirements becomes easier when you compare key factors side by side. This table summarizes what each technology delivers:

| Factor | Laser Cutting | Waterjet Cutting | Plasma Cutting | Mechanical Shearing |

|---|---|---|---|---|

| Material Compatibility | Metals, plastics, wood, ceramics | Nearly any material (metals, stone, glass, composites) | Conductive metals only (steel, aluminum, copper) | Sheet metals (steel, aluminum, stainless) |

| Thickness Range | Best for thin to medium (up to ~1") | Excellent for thick materials (6"+ possible) | Optimal for 1/2" to 2"+ steel | Typically up to 1/4" (6mm) |

| Edge Quality | Excellent; smooth, minimal finishing needed | Very good; smooth with minimal burrs | Rougher; often requires post-processing | Fair; may have slight burrs |

| Heat-Affected Zone | Small but present | None (cold cutting process) | Large; can cause material distortion | None (mechanical process) |

| Precision Tolerance | ±0.005" or better | ±0.005" to ±0.010" | ±0.020" to ±0.030" | ±0.010" to ±0.020" |

| Relative Cost | High equipment/operating costs | High equipment/operating costs | Moderate; most affordable thermal option | Low; economical for simple cuts |

| Best Application | Intricate patterns, precision parts | Heat-sensitive materials, thick stock | Thick steel, structural components | Straight cuts, high-volume blanks |

Matching Method to Project Requirements

How do you choose? Start with three fundamental questions:

- What material and thickness are you cutting? Thick structural steel points toward plasma or waterjet. Thin stainless with intricate patterns screams for laser. Simple rectangular aluminum blanks suit shearing.

- What precision and edge quality do you need? Tight-tolerance parts for die cut machine assemblies or medical devices demand laser or waterjet. Structural components with less critical dimensions can tolerate plasma's rougher finish.

- What's your budget and timeline? Plasma delivers speed at lower cost for appropriate applications. Waterjet and laser cost more but eliminate finishing steps.

Many fabrication shops operate multiple cutting technologies precisely because different projects have different requirements. Understanding these trade-offs helps you communicate effectively with fabricators and ensure your custom cut sheet metal arrives optimized for your specific application.

Sheet Metal Gauge Chart and Thickness Standards Explained

You've selected your cutting method. Now comes another decision that confuses countless buyers: what thickness do you actually need? Here's where things get counterintuitive. Sheet metal thickness often gets specified using gauge numbers—and a higher gauge number means thinner material. Sounds backwards? You're not alone in thinking so.

Understanding the sheet metal gauge chart transforms you from someone guessing at specifications to someone ordering exactly what your project demands. Let's decode this system so you can confidently specify the right metal gauge thickness for any application.

Decoding the Gauge System

Why do higher numbers mean thinner metal? The answer lies in 19th-century wire manufacturing. According to industry experts, the gauge system originated from wire production, where the gauge number represented how many times a wire was drawn through progressively smaller dies. More drawing operations meant thinner wire—and a higher gauge number.

Think of it like this: imagine stretching pizza dough. Each time you stretch it, the dough gets thinner. If you stretched it 10 times, you'd have thicker dough than if you stretched it 16 times. That's essentially how gauge sizing works for steel gauge thickness and other metals.

This historical quirk persists today because the industry standardized around it. The result? A 10-gauge steel sheet is substantially thicker than a 16 gauge steel thickness measurement—even though 16 is a bigger number. Once you internalize this reverse logic, gauge charts become intuitive.

Here's another important detail: the change between gauge numbers isn't linear. The difference from 3 gauge to 4 gauge stainless is 0.016 inches, while the jump from 24 to 25 gauge measures only 0.003 inches. This non-linear progression means small gauge number changes matter more for thicker materials.

Steel Versus Aluminum Gauge Differences

Here's where many buyers make costly mistakes: the same gauge number produces different thicknesses depending on the metal type. A 14 gauge steel thickness is not identical to 14 gauge aluminum.

Why the discrepancy? Gauge sizing relates to material density and weight per square foot. Since aluminum weighs roughly one-third as much as steel, a 14-gauge aluminum sheet measures thinner than its steel counterpart—both weigh approximately the same per square foot, but the aluminum achieves that weight at reduced thickness.

This difference catches people off guard when switching between materials. If you've designed a project around 11 gauge steel thickness specifications, don't assume aluminum in the same gauge will perform identically. The aluminum version will be thinner and may lack the structural rigidity your application requires.

Common Gauge Sizes Comparison Table

This gauge size chart covers the most frequently ordered specifications. Use it to translate between gauge numbers and actual dimensional measurements:

| Gauge | Steel (inches) | Steel (mm) | Stainless Steel (inches) | Stainless Steel (mm) | Aluminum (inches) | Aluminum (mm) |

|---|---|---|---|---|---|---|

| 10 Gauge | 0.1345 | 3.42 | 0.1406 | 3.57 | 0.1019 | 2.59 |

| 11 Gauge | 0.1196 | 3.04 | 0.1250 | 3.18 | 0.0907 | 2.30 |

| 12 Gauge | 0.1046 | 2.66 | 0.1094 | 2.78 | 0.0808 | 2.05 |

| 14 Gauge | 0.0747 | 1.90 | 0.0781 | 1.98 | 0.0641 | 1.63 |

| 16 Gauge | 0.0598 | 1.52 | 0.0625 | 1.59 | 0.0508 | 1.29 |

Notice how aluminum runs consistently thinner across all gauge numbers? That 10-gauge aluminum at 0.1019 inches falls closer to what you'd get from 12-gauge steel. Always verify the actual dimensional thickness when precision matters.

Matching Gauge to Your Application

Different gauge sizes suit different purposes. Selecting too thin risks structural failure; too thick wastes money and adds unnecessary weight. Here's how common gauge ranges typically get applied:

- 10-11 Gauge (Heavy Duty): Structural components, heavy equipment panels, trailer floors, industrial machinery guards. This range handles significant loads and abuse. A 10-gauge metal sheet at roughly 3.4mm provides excellent rigidity for demanding applications.

- 12-14 Gauge (Medium Duty): Automotive body panels, HVAC ductwork, appliance housings, storage tanks. These gauges balance strength with workability—thick enough for durability yet manageable for bending and forming operations.

- 16-18 Gauge (Light to Medium): Electrical enclosures, decorative panels, light brackets, residential ductwork. This range offers sufficient strength for many applications while keeping material costs reasonable and weight manageable.

- 20-24 Gauge (Light Duty): Flashing, gutters, decorative trim, light covers, hobby projects. These thinner gauges bend easily and cost less per square foot, but lack the strength for structural applications.

When in doubt, err slightly thicker rather than thinner—especially for structural applications. Material costs typically represent a small fraction of total project expense, while replacing failed components costs far more.

Pro Tips for Specifying Gauge

Want to avoid confusion when ordering custom cut sheet metal? Consider these practical guidelines:

- Specify dimensional thickness, not just gauge: Telling a fabricator you need "14 gauge steel" leaves room for interpretation. Stating "0.0747-inch steel" removes all ambiguity.

- Confirm the gauge chart being used: Different suppliers occasionally reference slightly different standards. When tolerance matters, verify the exact thickness you'll receive.

- Account for manufacturing tolerances: Sheet metal gauge measurements provide reliable thickness indications, but variations occur due to manufacturing tolerances. For critical applications, specify acceptable tolerance ranges.

- Remember the 6mm rule: Metal thicker than approximately 6mm (about 1/4 inch) is typically classified as plate rather than sheet metal, and may be priced and processed differently.

With gauge standards now demystified, you're equipped to specify thickness accurately. But thickness represents just one variable—the material itself matters equally. Different metals offer vastly different properties, and choosing wisely impacts everything from corrosion resistance to weight to weldability.

Material Selection Guide for Custom Metal Projects

You've mastered gauge specifications and cutting methods. Now comes arguably the most consequential decision for your custom cut sheet metal project: which material should you actually use? The answer shapes everything—how long your part lasts, what environments it can handle, how much it weighs, and what your final costs look like.

Think of material selection like choosing the right ingredient for a recipe. You wouldn't use butter where you need olive oil, even though both are fats. Similarly, aluminum sheet metal excels in applications where carbon steel would fail miserably—and vice versa. Let's explore your options so you can make confident choices.

Choosing Between Steel Stainless and Aluminum

Three material families dominate custom sheet metal fabrication: carbon steel, stainless steel, and aluminum. Each brings distinct advantages to the table, and understanding these differences prevents costly mistakes.

Carbon steel remains the workhorse of metal fabrication. It's strong, affordable, and welds beautifully. According to Xometry's material guide, grades like DC01 offer excellent durability with good formability, making them ideal for indoor structural applications. The catch? Carbon steel rusts readily when exposed to moisture unless protected by paint, powder coating, or galvanization.

Stainless steel sheets solve the corrosion problem through chemistry. The chromium content (at least 10.5%) forms a protective oxide layer that shields the underlying metal from environmental damage. This self-healing barrier makes stainless steel the go-to choice for food processing equipment, medical devices, and outdoor installations. However, you'll pay a premium—typically 3-5 times more than carbon steel.

Aluminum offers a compelling third option. As noted by industry specialists, aluminum is highly corrosion-resistant because it naturally forms a protective oxide layer without additional coatings. Add its exceptional strength-to-weight ratio—roughly one-third the weight of steel—and aluminum becomes essential for aerospace, transportation, and any application where weight matters.

304 vs 316 Stainless Steel: When the Difference Matters

Not all stainless steel performs equally. The two most common grades—304 and 316—look identical but behave differently in demanding environments.

Type 304 stainless steel sheet is the general-purpose workhorse. It resists corrosion well in typical indoor and outdoor environments, machines easily, and costs less than its premium cousin. Kitchen equipment, architectural trim, and industrial enclosures commonly use 304 grade.

Type 316 stainless adds molybdenum to its alloy composition. According to material specifications, this addition improves corrosion resistance, particularly against chlorides and non-oxidizing acids. Marine environments, chemical processing plants, and pharmaceutical facilities specify 316 stainless steel precisely because salt spray and aggressive chemicals would pit and corrode 304 over time.

The price difference between these grades can reach 20-30%. For most applications, 304 delivers excellent performance at lower cost. Reserve 316 for genuinely corrosive environments where the extra protection justifies the investment.

Specialty Metals for Demanding Applications

Beyond the big three material families, specialty options address specific challenges:

Galvanized steel takes carbon steel and applies a protective zinc coating. This treatment dramatically improves corrosion resistance at a fraction of stainless steel's cost. For outdoor structural applications, HVAC ductwork, and agricultural equipment, galvanized steel plate often provides the sweet spot between performance and budget.

AR500 abrasion-resistant steel handles punishment that would destroy ordinary materials. Mining equipment, conveyor systems, and shooting targets benefit from its exceptional hardness. However, this toughness makes fabrication more challenging—expect higher cutting costs and limited forming options.

Aluminum alloys vary significantly in properties. The 5000-series (like 5052 and 5083) excels in marine applications with outstanding corrosion resistance. The 6000-series (6061, 6082) offers excellent machinability and weldability for structural components. Aluminum 7075 delivers high strength and fatigue resistance for aerospace applications—though at premium pricing.

Material Properties Comparison

Selecting the right material becomes easier when you compare key properties side by side:

| Material | Corrosion Resistance | Strength | Weight | Weldability | Typical Applications |

|---|---|---|---|---|---|

| Carbon Steel | Poor (requires coating) | High | Heavy | Excellent | Structural components, machinery, indoor equipment |

| 304 Stainless Steel | Very Good | High | Heavy | Good | Food equipment, architectural, general industrial |

| 316 Stainless Steel | Excellent (chloride resistant) | High | Heavy | Good | Marine, chemical processing, pharmaceutical |

| Aluminum (5052/6061) | Excellent | Moderate | Light (1/3 of steel) | Good (TIG/MIG) | Aerospace, transportation, enclosures |

| Galvanized Steel | Good | High | Heavy | Fair (zinc fumes) | Outdoor structures, HVAC, agricultural |

| AR500 Steel | Poor | Very High (hardened) | Heavy | Requires preheat | Wear plates, targets, mining equipment |

Key Questions for Material Selection

Before specifying material for your custom cut sheet metal order, work through these essential questions:

- What environment will the part encounter? Indoor climate-controlled spaces tolerate carbon steel; outdoor or marine exposure demands stainless or aluminum.

- What structural loads must it handle? Heavy loads favor steel's superior strength; weight-sensitive applications benefit from aluminum's lighter profile.

- Will the part require welding? Carbon steel welds most easily; aluminum requires specialized equipment; galvanized steel produces toxic zinc fumes requiring proper ventilation.

- What's your budget constraint? Carbon steel costs least; stainless runs 3-5x higher; specialty alloys command premium pricing.

- Does appearance matter? Stainless steel and aluminum maintain attractive finishes; carbon steel requires painting or coating for aesthetic applications.

- Are there regulatory requirements? Food contact, medical devices, and certain industrial applications mandate specific material grades.

Answering these questions narrows your options quickly. A decorative indoor panel might use economical carbon steel with powder coating. A boat component demands marine-grade aluminum or 316 stainless. An industrial machine guard balances galvanized steel's corrosion protection against its budget-friendly pricing.

With material selected, you're ready to tackle the next challenge: communicating your exact specifications to fabricators in a language they understand. Proper measurement and documentation prevent costly errors and ensure your custom parts arrive exactly as intended.

How to Measure and Specify Custom Cut Requirements

You've selected your material and cutting method. Now comes the step that separates successful projects from frustrating do-overs: properly communicating your requirements to the fabricator. Sounds straightforward? Here's the reality—unclear specifications cause more custom cut sheet metal problems than any other factor.

Think of your specification package as a conversation with someone who can't ask clarifying questions. Every dimension, tolerance, and finish requirement must be crystal clear before metal meets cutting beam. Get this right, and your parts arrive ready to use. Get it wrong, and you're paying twice for the same job.

Creating Accurate Dimensional Specifications

Precision starts with measurement. Before touching CAD software or sketching drawings, you need accurate numbers to work from. Whether you're designing from scratch or replicating an existing part, these fundamentals apply.

For sheet metal cut to size applications, always measure with calibrated tools. A quality digital caliper handles thickness and smaller dimensions; a steel tape measure works for larger profiles. Avoid fabric measuring tapes—they stretch and introduce errors that compound quickly.

When specifying custom size sheet metal, document these critical elements:

- Overall dimensions: Length, width, and material thickness in consistent units (all inches or all millimeters—never mix)

- Hole locations: Reference from consistent datum points, typically a corner or edge. According to precision fabrication guidelines, hold position tolerances of ±0.15–0.25mm for laser-cut hole centers on thin sheet

- Critical dimensions: Identify which measurements absolutely cannot vary versus those with more flexibility

- Tolerance notation: Express allowable variation using plus-minus notation (±0.25mm) rather than vague terms like "close" or "tight"

Tolerance specifications deserve special attention. As fabrication experts explain, tolerances are often noted with plus-minus notations indicating the allowable range for deviations—these help standardize what's acceptable and avoid unnecessary rework or part rejection.

Not every dimension needs tight tolerances. Over-specifying increases cost without improving function. A structural bracket might need ±0.5mm on overall length but ±0.1mm on mounting hole positions. Communicate this hierarchy clearly.

File Formats and Drawing Standards

Modern fabricators rely on digital files to drive their cutting equipment. Understanding accepted formats prevents conversion headaches and ensures your design translates accurately to finished parts.

DXF (Drawing Exchange Format) remains the most universally accepted file type for custom cut metal sheets. According to industry design guides, DXF files created in CAD programs like Fusion 360 or SolidWorks are most likely to be manufacturing-ready. The format contains pure geometry—lines, arcs, and curves that define your part outline.

DWG files work similarly but are native to AutoCAD. Most fabricators can convert these, though DXF remains more universally compatible.

Vector formats (SVG, AI) from programs like Adobe Illustrator or Inkscape also work for many shops. However, these files can contain non-manufacturable elements. Your drawing should only outline the part, containing lines, curves, circles, and splines to define part edges—features like embedded images and text won't translate properly.

Critical rule: your drawing file should contain only the part outline. Don't submit prints with dimension tables, notes, or other annotations cluttering the geometry. Those belong on a separate ship drawing or specification sheet—the cutting file itself must be clean.

Step-by-Step Specification Process

From initial concept to fabricator submission, follow this sequence to minimize errors and rework:

- Measure and document all dimensions using calibrated tools. Double-check critical measurements. Record material thickness requirements.

- Create or obtain CAD geometry representing your exact part outline. Use closed contours with no gaps or overlapping lines.

- Account for kerf width in your design. Laser cutting typically removes 0.15–0.30mm of material; small holes will effectively shrink by this amount unless compensated. Discuss with your fabricator whether you're providing nominal dimensions (they apply compensation) or pre-offset geometry.

- Specify tolerance requirements for critical features. Not everything needs tight tolerances—identify what matters functionally and communicate those priorities.

- Define edge finish requirements explicitly. Do you need deburred edges? Specific corner radii? Smooth versus acceptable roughness? Fabricators won't assume—tell them what you need.

- Export clean geometry files in DXF or other accepted formats. Verify no stray lines, duplicate contours, or open paths exist.

- Prepare a separate specification document listing material type, thickness, quantity, tolerances, finish requirements, and any special instructions.

- Submit files with clear naming conventions that identify the part, revision level, and material. "Bracket_Rev2_16ga_Steel.dxf" beats "final_version_new.dxf" every time.

Common Specification Mistakes to Avoid

These errors appear constantly in custom metal shapes orders—and they're all preventable:

- Ignoring kerf width: A 10mm hole designed without kerf compensation might measure 9.7mm after cutting. For interference fits or close tolerances, this matters enormously.

- Unspecified edge requirements: Laser-cut edges differ from waterjet edges. If your application needs smooth, deburred edges, say so explicitly.

- Mixed units: Submitting drawings with some dimensions in inches and others in millimeters invites conversion errors.

- Missing material thickness: "Steel sheet" isn't a specification. "16-gauge cold-rolled steel (0.0598 inch)" leaves no room for interpretation.

- Overlapping or unclosed geometry: Clean DXF practices require keeping contours closed with no overlaps—problems here cause cutting errors or rejected files.

- Unrealistic tolerances: Specifying ±0.01mm on every dimension when ±0.2mm would function perfectly increases cost dramatically without adding value.

When Professional CAD Services Make Sense

Not everyone has CAD expertise—and that's perfectly fine. Knowing when to invest in professional file preparation saves money compared to repeated fabrication errors.

Consider professional CAD services when:

- Your project involves complex geometries beyond simple rectangles and holes

- Tight tolerances require precise compensation calculations

- You're working from hand sketches or physical samples rather than existing digital files

- The order quantity justifies upfront investment in manufacturing-ready files

- Previous DIY attempts resulted in rejected or incorrect parts

For simple custom metal shapes—rectangular blanks, basic brackets, straightforward hole patterns—most people can produce adequate specifications themselves using free tools like Inkscape or Fusion 360's free tier.

Complex parts with multiple bend operations, compound curves, or critical mating surfaces benefit from professional preparation. Many fabrication shops offer design-for-manufacturing (DFM) support that catches issues before cutting begins—taking advantage of this expertise often costs less than fixing problems after the fact.

With specifications properly documented and files prepared correctly, you've eliminated the most common source of custom cut sheet metal project failures. Next comes understanding what precision levels are actually achievable—and when tighter tolerances justify their additional cost.

Tolerances Precision and Edge Quality Considerations

You've submitted your specifications. But here's a question that trips up even experienced buyers: when a fabricator promises "precision cutting," what does that actually mean for your finished parts? The answer lies in understanding tolerances—the permissible variation between your design intent and manufacturing reality.

Tolerances aren't just technical jargon. They directly impact whether your parts fit together, function properly, and meet quality standards. And here's the kicker—tighter isn't always better. Specifying unnecessarily tight tolerances inflates costs without improving function. Let's decode what these numbers mean in practical terms.

What Tolerance Numbers Actually Mean

When you see a tolerance specification like ±0.1mm, it defines the acceptable range of variation from your nominal dimension. A 100mm part with ±0.1mm tolerance means anything between 99.9mm and 100.1mm passes inspection. Outside that window? The part gets rejected or reworked.

According to precision fabrication specialists, tolerances serve two critical functions: they give manufacturers clear, unambiguous goals regarding design requirements, and they provide designers control over features critical to fit and functionality.

But here's what most buyers miss: achieving tighter tolerances costs exponentially more. As industry data shows, moving from a standard tolerance (±0.2mm) to a tight tolerance (±0.1mm) might increase cost by 25%—while jumping to precision tolerance (±0.05mm) could double or triple the price. This cost explosion stems from slower cutting speeds, more frequent machine calibration, additional quality checks, and higher rejection rates.

The practical lesson? Assign tight tolerances only to dimensions that genuinely require them. Hole positions for alignment pins need precision. Overall panel length on a decorative cover probably doesn't. This selective approach delivers functional parts without budget-busting specifications.

Tolerance Capabilities by Cutting Method

Different cutting technologies deliver different precision levels. Understanding these capabilities helps you match method to requirement—and avoid specifying tolerances that a particular process simply cannot achieve.

| Cutting Method | Linear Dimension Tolerance | Hole Diameter Tolerance | Position Tolerance | Notes |

|---|---|---|---|---|

| Laser Cutting | ±0.05mm to ±0.1mm (small features) ±0.1mm to ±0.5mm (larger dimensions) |

±0.05mm to ±0.1mm | ±0.05mm to ±0.15mm | Tightest tolerances on thin materials; precision decreases with thickness |

| Waterjet Cutting | ±0.1mm to ±0.25mm | ±0.1mm to ±0.2mm | ±0.1mm to ±0.25mm | No heat distortion; excellent for heat-sensitive materials |

| Plasma Cutting | ±0.5mm to ±1.5mm | ±0.5mm to ±1.0mm | ±0.5mm to ±1.0mm | Best for thicker materials where speed matters more than precision |

| CNC Punching | ±0.1mm to ±0.5mm | ±0.1mm to ±0.2mm | ±0.13mm to ±0.25mm | Cumulative error possible across multiple punch operations |

| Mechanical Shearing | ±0.25mm to ±1.0mm | N/A (straight cuts only) | N/A | Economical for straight-line cuts; manual operations less precise |

Notice how laser cutting achieves the tightest tolerances on small features—but that precision varies with dimension size. Fabrication data confirms that smaller linear dimensions (below 100mm) hold ±0.05mm to ±0.1mm, while larger dimensions above 100mm may widen to ±0.5mm due to machine travel variations.

Heat-Affected Zones and Why They Matter

Thermal cutting methods—laser, plasma, and flame cutting—generate intense heat that changes material properties near the cut edge. This region, called the heat-affected zone (HAZ), can significantly impact your part's performance in certain applications.

When does HAZ actually matter?

- Subsequent welding: If your custom cut sheet metal requires welding, the HAZ from cutting can interact unpredictably with weld zones. For critical welds in structural or pressure applications, this interaction requires attention.

- Hardened materials: Heat exposure can alter the hardness profile of treated steels, potentially softening or embrittling the edge zone.

- Fatigue-sensitive applications: Parts subject to cyclic loading may experience crack initiation at HAZ boundaries where material properties transition.

According to welding specialists, the HAZ from laser cutting is minimal compared to plasma, but both introduce localized property changes. For applications involving aluminum welding or welding aluminum alloys, HAZ effects require particular attention since aluminum's thermal conductivity spreads heat extensively.

When HAZ concerns apply, waterjet cutting eliminates the issue entirely—cold cutting means no thermal effects whatsoever. For spot welding applications or parts requiring consistent material properties right to the edge, waterjet often justifies its higher operating cost.

Edge Quality and Surface Finish Options

The cut edge itself varies dramatically between methods. Imagine comparing a surgical incision to a rough saw cut—that's roughly the difference between laser-cut and plasma-cut edges.

Laser cutting produces the smoothest edges on thin to medium materials. The focused beam creates clean, oxide-free surfaces that often require no secondary finishing. For decorative applications or parts that mate closely with other components, this edge quality proves invaluable.

Waterjet cutting delivers good edge quality with a characteristic matte texture from abrasive action. Edges are burr-free and require minimal finishing. The slight taper inherent to waterjet cutting (where the exit side cuts slightly wider than the entry) can be minimized through process parameter control.

Plasma cutting produces rougher edges with noticeable dross (resolidified metal) and oxidation. For structural applications where the cut edge gets welded or hidden, this roughness is acceptable. Visible edges typically require grinding or machining to meet aesthetic standards.

Post-Processing Options for Edge Quality

When as-cut edges don't meet your requirements, post-processing options bridge the gap. As deburring specialists explain, proper edge finishing extends beyond aesthetics—unremoved burrs can cause assembly problems, create safety hazards, interfere with proper part function, and lead to premature wear in mechanical systems.

Common edge finishing operations include:

- Deburring: Removes sharp edges and burrs that could cause handling injuries or assembly interference. Methods range from manual filing to automated tumbling systems.

- Grinding: Smooths rough plasma or flame-cut edges to consistent profiles. Essential when edges will be visible or require close fits.

- Edge breaking: Creates consistent small chamfers or radii that improve safety and paint adhesion without removing significant material.

- Polishing: Produces mirror or satin finishes for decorative applications. Common on stainless steel architectural components.

For high-volume production, automated deburring systems deliver uniform results independent of operator skill or fatigue—a critical advantage for consistent quality across large orders.

Matching Tolerance and Finish to Application

Before specifying tolerances and edge requirements, ask yourself these practical questions:

- Will this edge be visible? Hidden edges don't need polishing. Decorative panels do.

- Does this part mate with others? Alignment holes need position accuracy. Ventilation slots probably don't.

- What's the assembly method? Parts joined by spot welding tolerate rougher edges than those requiring precise slip fits.

- Is post-processing already planned? If parts will be ground or machined anyway, paying premium for laser-smooth edges wastes money.

This practical assessment prevents over-specification while ensuring genuinely critical features receive appropriate attention. The goal isn't perfection everywhere—it's adequate precision where function demands it and cost-effective production everywhere else.

With tolerances and edge quality understood, you're ready to tackle the business side of custom cut sheet metal: what drives costs, how to plan realistic budgets, and what lead times to expect for your project.

Cost Factors and Lead Time Planning for Custom Orders

You've specified your material, tolerances, and edge requirements. Now comes the question every project manager dreads: how much will this actually cost—and when will it arrive? Custom cut sheet metal pricing isn't a simple per-square-foot calculation. Multiple variables interact in ways that can double your costs or slash them in half depending on your choices.

Understanding these price drivers transforms you from someone accepting quotes blindly to someone negotiating intelligently. Let's break down what actually determines your final invoice.

Understanding Price Drivers for Custom Cuts

When fabricators calculate quotes, they're balancing several interconnected factors. Changing one variable often ripples through others. Here are the primary cost drivers that shape your custom cut sheet metal pricing:

- Material type and thickness: Raw material costs vary dramatically. According to industry pricing data, steel runs approximately $0.50–$1.50 per pound, aluminum reaches $2.00–$3.50 per pound, while stainless steel commands $2.50–$5.00 per pound. Specialty metals like brass, copper, and titanium cost even more—and their cutting difficulty adds labor expense on top of material premiums.

- Cutting method complexity: Laser and waterjet operations cost more per hour than plasma or shearing. As noted by fabrication specialists, machine time for some materials simply takes longer and needs to be factored into estimates. Intricate patterns with small cutouts and fine details slow cutting speeds significantly.

- Quantity ordered: Setup costs get distributed across your order quantity. A single prototype absorbs the entire programming and setup expense; a hundred pieces spread that fixed cost thin.

- Tolerance requirements: Tighter tolerances demand slower cutting speeds, more frequent calibration, and additional quality inspection. Each step adds labor and machine time to your invoice.

- Finishing options: Post-processing like deburring, powder coating, or anodizing adds separate cost layers. Powder coat services typically charge based on part size and complexity, while anodized aluminum finishes vary by coating thickness and color requirements.

Beyond these primary factors, don't overlook hidden cost contributors. Industry experts warn that hardware, accessories, and material markups can accumulate—if the fabricator provides materials rather than working with customer-supplied stock, expect sourcing and handling charges added to raw material costs.

How Order Quantity Affects Per-Piece Pricing

Imagine paying $50 for a single custom bracket—then discovering the same bracket costs just $8 each when ordering 100 pieces. What changed? Not the metal plate material or cutting complexity. The difference lies entirely in setup cost distribution.

Every custom order involves fixed costs before any cutting begins:

- Programming the cutting path from your CAD files

- Setting up material on the cutting bed

- Calibrating equipment for your specific material and thickness

- First-article inspection and quality verification

These setup activities might consume an hour of skilled labor regardless of whether you're cutting one piece or fifty. Order a single part, and that entire hour lands on your invoice. Order fifty parts, and each piece carries just 1/50th of the setup burden.

According to fabrication pricing guidance, small orders may have minimum charges specifically due to programming and setup costs—fabricators can't operate profitably if setup time exceeds cutting time.

This economics creates a practical question: should you order extras while you're paying for setup anyway? For production parts likely to need replacement or spares, ordering 10-20% additional units during initial production often makes financial sense. The marginal cost of additional pieces drops dramatically once setup is complete.

Material Availability and Supply Chain Realities

Your ideal material specification means nothing if it's sitting in a warehouse three states away with a six-week backlog. Material availability directly impacts both cost and timeline.

Common materials like standard carbon steel, popular aluminum alloys (6061, 5052), and 304 stainless steel typically remain in stock at major distributors. Fabricators with their own material inventory can often start cutting within days.

Specialty materials tell a different story. Alu sheets in unusual alloys, exotic metals like Inconel or titanium, and non-standard thicknesses may require special ordering. As supply chain experts note, the costs of raw materials can experience volatility when supply chains are disrupted—and your fabricator can provide insights into those markets.

Pro tip: when timeline matters, ask your fabricator what materials they stock versus what requires procurement. Designing around readily available stock can shave weeks off your delivery schedule.

Balancing Speed Quality and Budget

Here's the uncomfortable truth about custom fabrication: you can optimize for two of three variables—speed, quality, and cost—but rarely all three simultaneously. Understanding these trade-offs helps you make realistic decisions.

Standard turnaround typically runs 1-3 weeks for straightforward cutting jobs, depending on shop workload and material availability. This timeline allows fabricators to batch similar jobs, optimize cutting layouts, and schedule work efficiently. Standard turnaround usually delivers the best per-piece pricing.

Rush orders accelerate delivery but at premium pricing. Expedited work disrupts planned schedules, may require overtime labor, and often prevents the batching efficiencies that reduce standard pricing. Expect 25-50% rush premiums—sometimes more for extreme timelines.

When do rush orders actually make sense?

- Production line down-time costs exceed rush premiums

- Missed project deadlines carry contractual penalties

- Prototype timing affects critical development milestones

- Customer commitments cannot be renegotiated

When should you plan ahead instead?

- Regular production runs with predictable demand

- Projects with flexible installation schedules

- Development work where timeline pressure is artificial

- Budget-constrained projects where cost matters most

Lead Time Factors Beyond Cutting

Cutting represents just one step in many custom orders. Your total lead time accumulates across multiple stages:

- Quote and approval: 1-3 days for standard requests; complex projects may require engineering review

- Material procurement: Same-day to 4+ weeks depending on availability

- Cutting queue position: 3-10 business days typical for standard priority

- Post-processing: Deburring adds 1-2 days; powder coat or anodizing adds 3-7 days

- Quality inspection: Standard checks add minimal time; certified inspections may add days

- Shipping: Local delivery same-day possible; cross-country freight adds 3-7 days

According to fabrication ordering guides, understanding the turnaround time for custom parts ensures your production schedule remains on course—discuss deadlines with your fabricator upfront to confirm they can meet your expectations.

For projects requiring anodized aluminum or powder coat finishes, build finishing lead times into your planning from the start. These processes often occur at separate facilities, adding both time and coordination complexity.

Practical Budget Planning Strategies

Armed with cost factor knowledge, you can approach budget planning strategically rather than reactively:

- Get multiple quotes: As industry guidance suggests, comparing quotes from multiple providers often highlights competitive pricing. Different shops have different equipment and workload situations.

- Question your specifications: Could a slightly thicker standard gauge work instead of custom thickness? Would 304 stainless serve adequately where you specified 316? Small specification changes sometimes yield significant savings.

- Consider design modifications: Fabrication experts recommend reviewing plans with a design-for-manufacturability approach—what looks good on paper may cost more to produce than slightly modified alternatives.

- Bundle related orders: If you need multiple different parts, ordering together often reduces total setup costs versus separate orders.

- Plan for shipping: Shipping costs can be an unexpected last-minute expense if not factored into initial budgets. Larger metal plate orders and heavier parts incur higher freight charges.

The most important budget strategy? Communicate openly with your fabricator. They've seen thousands of projects and often suggest cost-saving alternatives you'd never consider. A good fabrication partner wants your business long-term—helping you optimize costs builds that relationship.

With cost factors and lead times understood, one major decision remains: choosing the right fabrication partner who can deliver the quality, pricing, and reliability your project demands.

Choosing a Reliable Custom Metal Fabrication Partner

You've nailed down your specifications, selected materials, and understand what tolerances you need. Now comes a decision that can make or break your entire project: which fabricator actually gets your business? Searching for "sheet metal near me" or "sheet metal fabrication near me" returns dozens of options—but not all fabricators deliver equal results.

The right partner transforms your CAD files into precision parts that fit perfectly. The wrong one sends you scrambling to find a replacement mid-project while explaining delays to stakeholders. Let's explore how to evaluate fabricators systematically so you choose confidently the first time.

Evaluating Fabricator Capabilities and Certifications

Not every shop handles every job. Some specialize in high-volume production runs; others excel at one-off prototypes. Some maintain comprehensive in-house capabilities; others outsource critical operations. Understanding these differences prevents costly mismatches.

According to metal fabrication experts, full-service integrated facilities streamline the entire process under one roof—providing tighter control over production, faster turnaround times, and consistent quality standards. When operations get outsourced, delays multiply and communication gaps widen.

Before committing to any fabricator, evaluate these critical capability areas:

- Equipment capabilities: Does the shop operate the cutting technology your project requires? Laser, waterjet, plasma, and shearing each serve different needs. A shop lacking laser cutting can't deliver the precision your intricate bracket design demands.

- Material inventory: Fabricators with substantial stock can start immediately. Those requiring special orders add procurement delays to your timeline.

- In-house finishing: Can they handle deburring, powder coating, or other post-processing internally? Outsourced finishing adds time, cost, and coordination complexity.

- Production capacity: A small shop producing your thousand-piece order might take months. An oversized facility might treat your prototype as low priority.

- Quality certifications: ISO 9001 demonstrates basic quality management systems. Industry-specific certifications signal deeper commitment to rigorous standards.

Why Certifications Matter for Critical Applications

For general-purpose parts, basic quality processes suffice. But automotive, aerospace, medical, and other demanding applications require certified quality systems that document every step from raw material to finished component.

IATF 16949 certification represents the gold standard for automotive supply chain quality. This certification isn't optional window dressing—for many major automotive OEMs, it's a mandatory prerequisite for doing business. The standard embeds defect prevention, risk analysis, and continuous improvement into every production process.

What does IATF 16949 certification actually mean for your custom cut sheet metal orders?

- Documented traceability: Every material lot, process parameter, and inspection result gets recorded. Problems can be traced to root causes.

- Risk-based thinking: Potential failure modes get identified and addressed before they become costly problems.

- Continuous improvement: The certification requires ongoing process refinement—not just meeting minimum standards.

- Customer-focused outcomes: The entire system orients around meeting customer requirements and preventing defects.

Manufacturers like Shaoyi (Ningbo) Metal Technology demonstrate this commitment through IATF 16949 certification for their chassis, suspension, and structural component production. Their combination of rapid prototyping capabilities—turning around prototypes in as few as 5 days—with automated mass production systems shows how certified quality and operational speed can coexist.

Questions to Ask Before Placing Your Order

Don't accept marketing claims at face value. As industry veterans recommend, dig deeper with pointed questions that reveal true capabilities:

- How long have you been in business? Experience translates into deeper material knowledge, refined processes, and the ability to anticipate challenges before they become costly problems.

- Do you have experience with my specific application? A fabricator experienced in automotive components understands tolerances and quality requirements that might surprise someone focused on architectural work.

- What's your quality control process? Look for first-article inspection, in-process dimensional checks, and final verification procedures. Shops without documented quality processes rely on luck rather than systems.

- How do you handle supply chain disruptions? The ability to pivot when materials become scarce separates reliable partners from single-source operations vulnerable to delays.

- What's your typical turnaround time—and can you meet my specific deadline? Vague promises mean nothing. Confirm they can realistically deliver when you need parts.

- Do you provide engineering or DFM support? Design for manufacturability guidance catches costly design issues before cutting begins. Shaoyi's comprehensive DFM support exemplifies how proactive collaboration improves outcomes.

Evaluating Responsiveness and Communication

How quickly a fabricator responds to your initial inquiry predicts how they'll communicate throughout your project. A shop that takes a week to return quote requests will likely frustrate you with slow updates and delayed problem resolution.

Quote turnaround time serves as a practical litmus test. Some manufacturers, including Shaoyi, commit to 12-hour quote turnaround—demonstrating both operational efficiency and customer prioritization. Compare this to competitors requiring multiple days for basic estimates.

Beyond speed, evaluate communication quality:

- Do they ask clarifying questions about your requirements, or just quote whatever you submitted?

- Can they explain trade-offs and alternatives, or just accept orders without input?

- Do they proactively identify potential issues, or wait for problems to surface?

As fabrication specialists emphasize, a reliable fabricator will provide clear timelines, project updates, and realistic expectations—strong communication prevents costly surprises and keeps projects aligned from start to finish.

The Value of Problem-Solving Partners

The best metal fabricators near me don't just execute orders—they improve them. According to industry experience, successful fabrication companies understand that fulfilling customer requests is just the starting point—true excellence lies in proactively addressing potential issues and actively problem-solving throughout the process.

What does problem-solving partnership look like practically?

- Suggesting material alternatives that reduce cost without compromising function

- Recommending design modifications that simplify production

- Identifying tolerance specifications that may be unnecessarily tight

- Proposing cutting methods better suited to your specific requirements

This collaborative approach often yields lower costs, simpler production methods, or faster delivery—without sacrificing quality. A fabricator who just processes orders misses opportunities that a true partner would catch.

With these evaluation criteria in hand, you're equipped to distinguish capable steel fabricators from those who'll disappoint. The final step? Consolidating everything you've learned into an actionable plan for your custom cut sheet metal project.

Taking Action on Your Custom Sheet Metal Project

You've absorbed a lot of information—cutting methods, gauge charts, material properties, tolerance specifications, and fabricator evaluation criteria. Now it's time to transform that knowledge into action. Whether you're ordering a custom steel plate for industrial equipment or a stainless steel sheet custom cut for a precision assembly, success depends on systematic preparation rather than guesswork.

The difference between projects that sail through production and those that stall? Informed decisions made upfront. Let's consolidate everything into a practical framework you can follow for any custom metal cutting project.

Your Custom Cut Project Checklist

Before contacting fabricators, work through this comprehensive checklist. Completing each step prevents costly revisions and ensures your specifications communicate exactly what you need:

- Define your application requirements: What loads, environments, and stresses will your part encounter? Document functional requirements before selecting materials or tolerances.

- Select appropriate material: Match corrosion resistance, strength, and weight characteristics to your application. Carbon steel for indoor structural work, stainless for corrosive environments, aluminum when weight matters.

- Specify thickness using actual dimensions: Translate gauge numbers to inches or millimeters. Confirm your fabricator's gauge chart matches your expectations—especially when ordering custom cut steel plate in specific alloys.

- Choose the optimal cutting method: Laser for precision and intricate patterns, waterjet for heat-sensitive materials, plasma for thick steel at lower cost, shearing for economical straight cuts.

- Document dimensional specifications: Create clean CAD files with closed contours. Reference all hole positions from consistent datum points. Account for kerf width where precision matters.

- Assign tolerances strategically: Tight tolerances only where function demands them. Over-specifying inflates costs without improving outcomes.

- Define edge finish requirements: Specify deburring, grinding, or polishing needs explicitly. Fabricators won't assume your requirements.

- Evaluate fabricator capabilities: Confirm they operate appropriate equipment, stock your material, and can meet your timeline.

- Verify quality certifications: For demanding applications, confirm ISO 9001 or IATF 16949 certification as appropriate.

- Get multiple quotes: Compare pricing, lead times, and included services across at least two or three qualified fabricators.

Moving from Planning to Production

When does custom cut sheet metal make sense versus alternative approaches? The answer depends on your specific situation.

Custom cutting excels when:

- Standard stock sizes don't match your requirements

- Complex shapes or cutouts are needed

- Precision tolerances matter for assembly or function

- Quantities are too small for dedicated tooling investment

- Material waste from oversized stock exceeds cutting costs

Consider alternatives when:

- Standard sizes work with minor adaptation

- High volumes justify stamping dies or progressive tooling

- Simple cuts can be made in-house with basic equipment

For automotive and precision applications requiring certified quality, manufacturers like Shaoyi (Ningbo) Metal Technology offer comprehensive solutions spanning rapid prototyping through mass production—with IATF 16949-certified processes for chassis, suspension, and structural components. Their 5-day prototyping capability and 12-hour quote turnaround demonstrate how certified quality and operational speed can work together.

Whatever your custom metal plate requirements, the principles remain consistent: specify clearly, select appropriate methods and materials, and partner with fabricators whose capabilities match your needs. The knowledge you've gained transforms you from someone accepting whatever arrives to someone who ensures precision parts the first time—saving money, time, and frustration across every project you undertake.

Frequently Asked Questions About Custom Cut Sheet Metal

1. Where can I get metal cut near me?

Local metal fabrication shops, industrial suppliers, and online services all offer custom cutting. Search for 'sheet metal fabrication near me' to find regional options, or use online platforms like SendCutSend, Xometry, or Cut2Size Metals for convenient ordering. When evaluating local shops, verify their equipment capabilities match your cutting method requirements and confirm they stock your preferred material. For automotive or precision applications requiring IATF 16949-certified quality, specialized manufacturers like Shaoyi offer rapid prototyping and mass production solutions with 12-hour quote turnaround.

2. How much does custom metal cutting cost?

Custom metal cutting costs depend on material type, thickness, cutting method, quantity, and tolerance requirements. Steel typically runs $0.50–$1.50 per pound raw material, aluminum $2.00–$3.50, and stainless steel $2.50–$5.00. Setup costs get distributed across order quantity—single prototypes absorb full programming expenses while larger orders reduce per-piece pricing significantly. Tighter tolerances, complex patterns, and finishing operations like deburring or powder coating add additional costs. Request quotes from multiple fabricators to compare total pricing.

3. What is the difference between laser cutting and plasma cutting?

Laser cutting uses focused light to achieve exceptional precision (±0.05mm tolerances) with smooth edges, ideal for thin to medium materials and intricate patterns. Plasma cutting uses ionized gas at extreme temperatures, operating 3-4 times faster than waterjet on thick steel but with rougher edges and larger heat-affected zones. Laser excels for detailed work on materials up to 1 inch thick, while plasma provides cost-effective cutting for thicker structural steel where precision is less critical. Choose based on material thickness, required tolerances, and budget constraints.

4. What gauge sheet metal should I use for my project?

Gauge selection depends on structural requirements and application. For heavy-duty structural components, 10-11 gauge (approximately 3mm thick) provides excellent rigidity. Medium-duty applications like automotive panels and HVAC ductwork typically use 12-14 gauge. Light-duty projects including electrical enclosures and decorative panels work well with 16-18 gauge. Remember that higher gauge numbers mean thinner material, and aluminum gauges measure thinner than equivalent steel gauges. Always specify actual dimensional thickness rather than gauge alone to avoid confusion.

5. How do I submit specifications for custom sheet metal orders?

Submit clean DXF or DWG files containing only part geometry—closed contours with no gaps or overlapping lines. Reference hole positions from consistent datum points and specify tolerances using plus-minus notation for critical dimensions. Include a separate specification document listing material type, thickness, quantity, edge finish requirements, and any special instructions. Account for kerf width in your design and clarify whether you're providing nominal dimensions or pre-offset geometry. Many fabricators offer DFM support to catch issues before cutting begins.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —