- Riduci i Costi di Estrusione dell'Alluminio con 5 Fondamentali Consigli DFM

- Il vero ROI degli stampi di estrusione personalizzati per la produzione di massa

- Prototipazione in Metallo per l'Automotive: Una Guida per un'Innovazione più Rapida

- Ricambi per Aria Condizionata Auto: Dal Compressore all'Evaporatore Svelati

Cuscinetti a sfera vs boccoli guida lisci: quale salva il tuo mandrino?

Time : 2026-01-13

La scelta corretta del boccolo guida per applicazioni di precisione

Ogni fresatore conosce quella sensazione: trovarsi al banco lavoro, guardare la specifica di uno stampo e chiedersi se optare per boccoli a sfere o boccoli lisci. Non si tratta solo di una decisione tecnica. È una scelta che influisce direttamente sulla durata dell'albero motore, sulla qualità dei pezzi e, in ultima analisi, sul proprio margine di guadagno.

Quando si lavora con applicazioni di utensileria di precisione, comprendere il dibattito tra boccoli e cuscinetti non è una questione accademica. È una questione pratica. Una selezione errata porta a usura precoce, fastidiosi problemi di allineamento e tempi di fermo costosi che nessuno ha previsto nel bilancio. Ma cos'è un boccolo e come si differenzia da una soluzione a cuscinetto nelle prestazioni reali?

Perché la scelta del boccolo guida determina le prestazioni dello stampo

Il significato di boccola va ben oltre quello di un semplice componente cilindrico. Le boccole di guida fungono da interfaccia critica tra i componenti mobili dello stampo, controllando l'allineamento con precisione microscopica. Che si scelga un design con elementi volventi o una superficie di scorrimento liscia, tale decisione si ripercuote su ogni corsa del vostro torchio.

Pensatela in questo modo: il vostro sistema di guida assorbe le forze di disallineamento, gestisce l'espansione termica e mantiene la precisione posizionale per migliaia, a volte milioni, di cicli. La scelta tra cuscinetto e boccola influisce sulle caratteristiche di attrito, sulla generazione di calore e sui modelli di usura. Scegliete bene, e il vostro utensile funzionerà senza problemi per anni. Scegliete male, e dovrete pianificare manutenzioni non programmate entro pochi mesi.

I Costi Nascosti della Scelta Errata

Cosa vi costano effettivamente cuscinetti e boccole oltre al prezzo d'acquisto? Considerate queste conseguenze reali derivanti da componenti di guida non compatibili:

- Usura accelerata dell'albero portautensile dovuta ad attrito eccessivo o a una distribuzione del carico inadeguata

- Deterioramento della qualità del pezzo poiché le tolleranze di allineamento variano nel tempo

- Fermi imprevisti per riparazioni urgenti e sostituzione di componenti

- Aumento dei tassi di scarto quando la precisione scende al di fuori dei limiti accettabili

Questa guida adotta un approccio pratico alla scelta tra boccoli e cuscinetti. Anziché addentrarsi in formule teoriche di ingegneria, troverete schemi decisionali applicabili basati su condizioni operative reali. Valuteremo le opzioni secondo cinque criteri fondamentali: capacità di carico, requisiti di velocità, esigenze di precisione, fattori ambientali e costo totale di possesso.

Che siate alle prese con la selezione di componenti per un nuovo punzonatrice progressiva o con la risoluzione di usura prematura su attrezzature esistenti, avrete a disposizione linee guida chiare per abbinare la scelta dei boccoli alle specifiche esigenze della vostra applicazione.

Criteri di valutazione per il confronto delle opzioni di boccoli guida

Prima di passare a raccomandazioni specifiche sui prodotti, è necessario un framework sistematico per valutare le proprie opzioni. Troppi ingegneri si affidano a ciò che ha funzionato nell'ultimo progetto o, peggio ancora, a ciò che il fornitore ha in magazzino. Questo approccio ignora la realtà per cui applicazioni diverse richiedono soluzioni diverse.

Quando si confrontano cuscinetti e boccole per applicazioni di guida, cinque fattori interconnessi determinano quale soluzione garantisce prestazioni ottimali. Comprendere per quali utilizzi le boccole sono più adatte e in quali ambiti invece i design con elementi volventi eccellono richiede di esaminare ogni criterio nel contesto dell'ambiente operativo specifico.

Cinque fattori critici di selezione per le boccole di guida

I seguenti criteri di valutazione costituiscono la base di ogni decisione relativa alle boccole di guida. Nessun singolo fattore prevale sugli altri; piuttosto, la combinazione unica di requisiti della vostra applicazione indica la soluzione corretta.

- Requisiti di capacità di carico: Quanta forza assorbirà il tuo sistema di guida? Considera sia i carichi statici durante i periodi di pausa che i carichi dinamici durante i cicli ad alta velocità. Diversi tipi di boccola e opzioni di materiali per le boccole gestiscono i carichi radiali, assiali e momento con efficienza variabile. Operazioni di stampaggio pesante richiedono elevate capacità di carico, mentre applicazioni leggere possono dare priorità ad altri fattori.

- Velocità e Frequenza di Ciclo: Quali velocità di corsa e cicli al minuto richiede la tua operazione? Presse progressive ad alta velocità che superano i 200 colpi al minuto creano sfide diverse in termini di attrito e calore rispetto a operazioni con matrice transfer più lente. I tipi di boccole che si distinguono a 50 cicli al minuto potrebbero guastarsi precocemente a 500.

- Requisiti di Precisione Tolleranziale: Quanto stringenti sono i tuoi requisiti di accuratezza posizionale? Alcune applicazioni tollerano alcune migliaia di variazione, mentre altre richiedono ripetibilità sub-micronica. Il tuo sistema di guida deve mantenere tali tolleranze in modo costante attraverso cicli termici e lunghi cicli produttivi.

- Condizioni ambientali: Quali contaminanti, temperature e condizioni operative dovranno affrontare i componenti della guida? Gli ambienti di stampaggio spesso introducono trucioli metallici, nebbie di lubrificante e fluttuazioni termiche che mettono alla prova diversi tipi di boccole in modi unici. Una soluzione che funziona perfettamente in un impianto climatizzato potrebbe avere difficoltà in una sala produzione polverosa.

- Richieste di manutenzione e accessibilità: Quanta manutenzione puoi effettivamente garantire? Alcune boccole e cuscinetti richiedono piani di lubrificazione regolari, mentre altre funzionano senza necessità di manutenzione. Considera non solo il piano di manutenzione ideale, ma ciò che il tuo team può effettivamente eseguire in modo costante.

Come le condizioni operative influenzano la tua scelta

Ecco cosa sanno bene i produttori di utensili esperti: il contesto determina tutto. Una guida a bocce che offre risultati eccezionali in un'applicazione potrebbe avere prestazioni scadenti in un'altra. Allo stesso modo, boccole lisce che sembrano obsolete sulla carta spesso superano alternative più sofisticate quando abbinati alle condizioni adatte.

La chiave sta nella valutazione onesta. Quando si analizza la propria applicazione, bisogna resistere alla tentazione di esagerare i requisiti o inseguire specifiche effettivamente non necessarie. Un punzone che opera per 100.000 cicli all'anno ha esigenze radicalmente diverse rispetto a uno che ne esegue 10 milioni. Abbinare la scelta della guida alle reali condizioni operative — non a quelle teoriche — evita sia una spesa eccessiva sia prestazioni insufficienti.

Il costo totale di proprietà merita un'attenzione particolare. Il prezzo iniziale di acquisto racconta solo una parte della storia. È necessario considerare la complessità dell'installazione, la manodopera per la manutenzione, gli intervalli di sostituzione e il costo produttivo dei fermi non pianificati. Un boccolo a basso costo che richiede sostituzione ogni sei mesi potrebbe rivelarsi molto più costoso rispetto a un'opzione premium che dura tre anni.

Con questi criteri di valutazione stabiliti, siete in grado di valutare le diverse opzioni di boccole guida in base ai loro meriti reali piuttosto che alle semplici affermazioni di marketing. Le sezioni seguenti esaminano ciascuna delle principali categorie, partendo dalle boccole guida a cuscinetti a sfera per applicazioni ad alta precisione.

Boccole guida a cuscinetti a sfera per applicazioni ad alta precisione

Quando l'applicazione richiede velocità massima senza rinunciare all'accuratezza, le boccole guida a cuscinetti a sfera si pongono come chiare leader. Questi componenti di precisione trasformano il modo in cui i gruppi stampo gestiscono operazioni ad alto ciclo, offrendo caratteristiche prestazionali che superfici scorrevoli semplici non possono eguagliare.

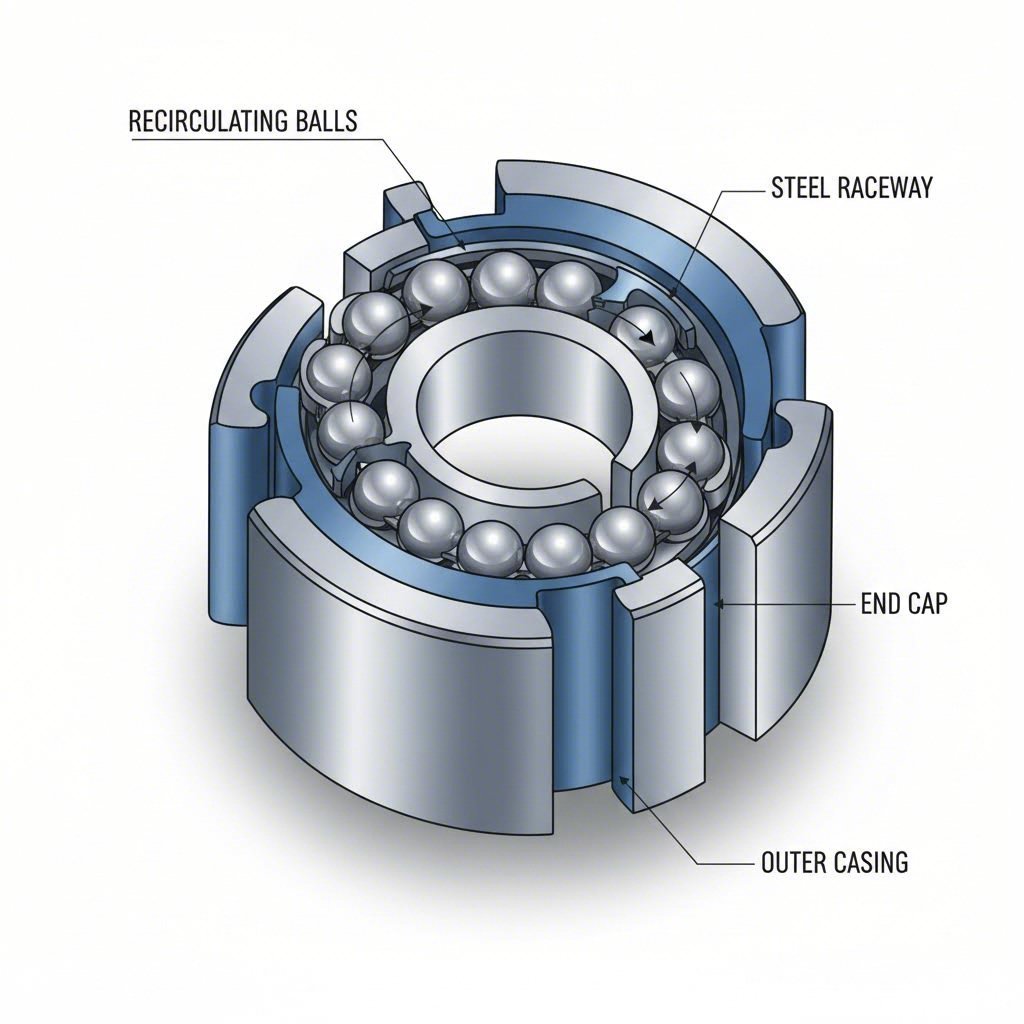

Cosa fa quindi effettivamente la tecnologia a cuscinetti a sfera all'interno del tuo sistema di guida? A differenza dei semplici boccoli in cui le superfici scorrono l'una contro l'altra, un cuscinetto a sfere utilizza elementi volventi – piccole sfere disposte su piste di ricircolo – per supportare e guidare il movimento. Questa differenza fondamentale nel tipo di contatto modifica completamente comportamenti relativi a attrito, calore e usura.

Quando i cuscinetti a sfere offrono prestazioni insuperabili

La funzione dei cuscinetti a sfere nelle applicazioni di guida si basa su un vantaggio fondamentale: il contatto volvente elimina l'attrito radente. Quando una sfera del cuscinetto rotola tra piste temprate, genera una frazione dell'attrito che si avrebbe quando due superfici scivolano l'una rispetto all'altra. Tale differenza diventa particolarmente marcata a velocità elevate.

Immagina di far funzionare il tuo punzone a 300 corsa al minuto. Con boccole lisce, il contatto metallo contro metallo genera un calore significativo ad ogni ciclo. Questa energia termica si accumula, causando dilatazione che compromette la precisione di allineamento. Le guide a cuscinetti volventi evitano completamente questo problema. L'attrito volvente produce calore minimo, consentendo al sistema di guida di mantenere tolleranze strette anche durante lunghi cicli ad alta velocità.

Le capacità di precisione vanno oltre la stabilità termica. Gli assiemi di boccole a sfera di qualità raggiungono giochi estremamente ridotti—spesso misurati in micron piuttosto che millesimi di millimetro. Ciò si traduce direttamente in una qualità superiore dei pezzi, specialmente per matrici progressive che producono componenti con tolleranze ristrette, dove conta la ripetibilità della posizione.

Applicazioni ideali per le guide a cuscinetti volventi

Comprendere a cosa servono i cuscinetti volventi nelle applicazioni di utensileria ti aiuta a identificare i casi in cui offrono il massimo valore. Valuta l'uso di guide a cuscinetti quando la tua operazione prevede:

- Punzoni progressivi che funzionano a oltre 150-200 colpi al minuto dove il calore generato dall'attrito diventa problematico con alternative a strisciamento

- Stampaggio ad Alta Precisione che richiedono una ripetibilità posizionale inferiore al millesimo di millimetro durante le produzioni

- Cicli produttivi prolungati in cui prestazioni costanti su milioni di colpi giustificano un investimento iniziale più elevato

- Applicazioni con carichi uniformi e costanti piuttosto che condizioni di sovraccarico o urto pesante

- Ambienti puliti o controllati dove la contaminazione può essere efficacemente gestita

Le operazioni con punzoni progressivi traggono particolare vantaggio dalla tecnologia a cuscinetti a sfera. Questi punzoni richiedono un allineamento preciso attraverso molteplici stazioni di formatura, e ogni deriva posizionale si accumula avanzando del nastro. La superiore ripetibilità dei sistemi di guida a elementi volventi contribuisce a mantenere la qualità dalla prima all'ultima stazione.

Punti di forza e debolezza dei sistemi a cuscinetti a sfera

Ogni soluzione di guida comporta dei compromessi. I sistemi a cuscinetti a sfera offrono prestazioni eccezionali nelle condizioni giuste, ma non sono universalmente superiori. Ecco una valutazione onesta:

Punti a favore

- Attrito drasticamente ridotto: Il contatto volvente riduce i coefficienti d'attrito dell'80-90% rispetto al contatto strisciante, consentendo velocità di ciclo più elevate senza surriscaldamento

- Velocità raggiungibili più elevate: Progettati per funzionare in modo continuo a velocità che distruggerebbero i plain bushings entro poche ore

- Vita Servizio Prolungata: In condizioni ottimali — ambiente pulito, precarico corretto, lubrificazione adeguata — le guide a cuscinetti a sfera possono avere una durata significativamente superiore rispetto alle alternative a strisciamento

- Precisione di posizionamento superiore: Gioco minimo e comportamento costante in rotolamento garantiscono un'eccezionale ripetibilità corsa dopo corsa

- Minori esigenze di lubrificazione: Molti design incorporano elementi sigillati e prelubrificati che riducono le esigenze di manutenzione

Punti deboli

- Investimento Iniziale Maggiore: I cuscinetti a sfera di precisione hanno generalmente un costo da 3 a 5 volte superiore rispetto ai normali boccoli equivalenti

- Sensibilità alla contaminazione: I cuscinetti a sfera di piccole dimensioni e le piste di precisione sono vulnerabili ai danni causati da trucioli metallici, polvere e detriti: una singola particella può innescare un guasto precoce

- Importanza dell'allineamento: Le guide con cuscinetti a sfera richiedono un allineamento preciso del montaggio; un errore di allineamento che un normale bocco potrebbe tollerare può causare un rapido deterioramento del cuscinetto

- Complessità dell'Installazione: La corretta regolazione del precarico e la verifica dell'allineamento richiedono maggiore competenza e tempo rispetto al semplice inserimento di un bocco a manicotto

- Limitata tolleranza ai carichi d'urto: I carichi d'impatto possono danneggiare gli elementi volventi e le piste, rendendo queste guide meno adatte per operazioni pesanti di tranciatura o punzonatura

La decisione dipende spesso dalla corrispondenza tra la tecnologia della guida e le effettive condizioni operative. Le guide a cuscinetti a sfera giustificano il loro costo superiore in applicazioni ad alta velocità e ad alta precisione che operano in ambienti ragionevolmente puliti. Tuttavia, quando la contaminazione è inevitabile o i carichi d'urto sono predominanti, i vantaggi si riducono e il sovrapprezzo diventa più difficile da giustificare.

Per le officine che valutano le proprie opzioni, la domanda successiva diventa: quando ha più senso utilizzare boccole di guida lisce? La risposta richiede di comprendere come le moderne boccole lisce di precisione si siano evolute per soddisfare le esigenze impegnative degli stampi da tranciatura.

Boccole di Guida Lisce di Precisione per l'Eccellenza negli Stampi da Tranciatura

Mentre i sistemi a guide con cuscinetti a sfera dominano le applicazioni ad alta velocità, i boccoli di guida lineari di precisione rimangono la soluzione principale per la stragrande maggioranza delle operazioni di stampaggio. Questi componenti apparentemente semplici, quando progettati secondo standard rigorosi, offrono prestazioni notevoli in un'ampia gamma di condizioni, superiore a quanto molti ingegneri ritengano.

Che cosa rende un boccole metallica moderna fondamentalmente diversa dai semplici boccoli cilindrici del passato? La risposta risiede nella precisione produttiva, nella scienza dei materiali e in una progettazione accurata. I boccoli di guida lineari di oggi non sono semplici tubi cilindrici; sono strumenti di precisione lavorati con tolleranze paragonabili a quelle delle alternative con elementi volventi.

Perché i boccoli di guida lineari eccellono nello stampaggio

Considera l'ambiente tipico di stampaggio: schegge di metallo in volo, nebbia di lubrificante nell'aria, escursioni termiche tra i turni e qualche volta un pezzo che non viene espulso correttamente. Questa è la realtà sul pavimento produttivo — ed è proprio qui che i boccoli cilindrici con flangia si distinguono.

A differenza dei cuscinetti a sfera, con i loro piccoli elementi rotolanti e le piste strette, un boccole ben progettato non offre alla contaminazione spazi in cui nascondersi e causare danni. Le particelle che distruggerebbero un cuscinetto a sfera di precisione vengono semplicemente rimosse o incorporate in modo innocuo nei materiali più morbidi della boccola. Questa tolleranza alla contaminazione si traduce direttamente in un funzionamento affidabile nelle condizioni reali.

La progettazione compatta dei boccoli lisci offre un altro vantaggio pratico. Quando i vincoli di spazio limitano le opzioni, una guida di tipo manicotto occupa radialmente uno spazio significativamente inferiore rispetto a un cuscinetto a sfera con capacità di carico equivalente. Questo aspetto è rilevante nei punzoni progressivi con stazioni ravvicinate o in situazioni di retrofit, dove la geometria esistente dello stampo non può ospitare componenti di guida più grandi.

L'ingegneria alla base dei boccoli lisci superiori

Non tutti i boccoli lisci offrono prestazioni uguali. La differenza tra un componente standard e un boccolo di guida progettato con precisione dipende da diversi fattori critici.

Primo, l'accuratezza dimensionale. I boccoli piani di alta qualità vengono rettificati e lucidati per raggiungere tolleranze sui diametri interno ed esterno misurate in micron. Questa precisione garantisce un gioco costante con i perni guida, riducendo al minimo l'oscillazione senza causare inceppamenti. Pensatelo come la differenza tra un boccolo in plastica prodotto in serie e uno in metallo lavorato con precisione: entrambi potrebbero apparire simili, ma le prestazioni differiscono notevolmente.

Secondo, la qualità della finitura superficiale. Un foro correttamente finito presenta una superficie scorrevole liscia e uniforme che favorisce una distribuzione omogenea del lubrificante e modelli di usura prevedibili. Tecniche avanzate di finitura creano microtexture capaci di trattenere film lubrificanti anche sotto carichi elevati.

In terzo luogo, la selezione dei materiali. Le boccole piane moderne utilizzano leghe specializzate, polimeri tecnici e materiali compositi progettati per specifiche condizioni operative. Che si necessiti di una boccola per trapano per un posizionamento preciso dei fori o di una boccola filettata per un posizionamento regolabile, la scelta del materiale giusto garantisce un equilibrio tra resistenza all'usura, caratteristiche di attrito e capacità di carico.

La progettazione della flangia della boccola richiede particolare attenzione nelle applicazioni di stampaggio. Una boccola flangiata correttamente progettata assicura il fermo assiale senza l'uso di elementi di fissaggio aggiuntivi, semplifica l'allineamento durante l'installazione e può includere caratteristiche come scanalature per lubrificazione o guarnizioni anti-contaminazione. Questi elementi integrati riducono la complessità di assemblaggio migliorando al contempo le prestazioni.

Abbinare la qualità della boccola agli standard OEM

Ecco una realtà che i produttori esperti di stampi conoscono bene: le boccole guida sono buone quanto il processo produttivo che le genera. Tolleranze strette sulla carta non significano nulla se il processo produttivo non riesce a mantenerle in modo costante su migliaia di pezzi.

È in questo contesto che gli standard di certificazione assumono un reale significato, andando oltre semplici requisiti di marketing. La certificazione IATF 16949, ad esempio, stabilisce rigorosi requisiti di gestione della qualità specificamente per i componenti della catena di fornitura automobilistica. I produttori che operano secondo questo standard devono dimostrare l'adozione del controllo statistico dei processi, di sistemi di prevenzione dei difetti e di protocolli di miglioramento continuo, garantendo che ogni boccola soddisfi le specifiche tecniche, non solo i campioni presentati per l'approvazione.

Per applicazioni di stampaggio automotive in cui la precisione delle boccole guida influisce direttamente sulla qualità del pezzo, collaborare con fornitori certificati IATF 16949 come Shaoyi fornisce la garanzia che i componenti di guida soddisfino le tolleranze rigorose richieste dai vostri stampi. Le avanzate capacità di simulazione CAE aiutano a convalidare i progetti degli stampi prima dell'asportazione del metallo, identificando precocemente eventuali problemi del sistema di guida quando le correzioni costano pochi centesimi invece che dollari.

Punti a favore

- Costo Iniziale Inferiore: I boccoli lisci costano tipicamente il 60-80% in meno rispetto agli equivalenti gruppi a cuscinetti a sfera, liberando budget per altri miglioramenti degli utensili

- Superiore tolleranza alle contaminazioni: Tolleranti nei confronti di trucioli, polvere e detriti che inevitabilmente entrano negli ambienti di stampaggio

- Installazione più semplice: Il montaggio a pressione o scorrevole richiede meno abilità e tempo rispetto all'allineamento dei sistemi di guida a cuscinetti a sfera di precisione

- Opzioni autolubrificanti disponibili: Materiali compositi e impregnati eliminano completamente la necessità di lubrificazione esterna

- Ingombro compatto: Dimensioni radiali inferiori rispetto alle alternative a cuscinetti a sfera a parità di capacità di carico

- Capacità di carico d'urto: Maggiore tolleranza ai carichi d'impatto comuni nelle operazioni di tranciatura e foratura

Punti deboli

- Attrito maggiore a velocità elevate: Il contatto strisciante genera più attrito e calore rispetto al contatto volvente, limitando i tassi di ciclo praticabili

- Richiede una corretta pianificazione della lubrificazione: La maggior parte dei bronzini richiede un approvvigionamento costante di lubrificante per una durata ottimale; una lubrificazione trascurata accelera significativamente l'usura

- L'usura è inevitabile: Anche i migliori bronzini subiscono un'usura graduale che alla fine richiede sostituzione o regolazione

- Limitazioni di velocità: Non adatto alle applicazioni ad altissima velocità in cui i vantaggi dei cuscinetti a sfera in termini di attrito diventano critici

Il punto fondamentale? I boccoli piani di precisione rappresentano la scelta ottimale per la maggior parte delle applicazioni di stampi. Quando prodotti con tolleranze rigorose da fornitori certificati, garantiscono l'accuratezza richiesta dai vostri utensili offrendo al contempo vantaggi pratici in termini di resistenza alla contaminazione, semplicità di installazione e costo totale di possesso.

Per applicazioni che richiedono una maggiore tolleranza alla contaminazione o che operano in ambienti corrosivi, i boccoli piani in bronzo offrono un'affidabilità collaudata nel tempo con vantaggi unici del materiale da esplorare.

Boccoli Piani in Bronzo per Prestazioni Moderatamente Affidabili

A volte la soluzione migliore non è quella più recente. I boccoli in bronzo supportano macchinari rotanti e scorrevoli da secoli — e continuano a essere utilizzati con successo nelle moderne operazioni di stampaggio. Quando avete bisogno di un boccole che resista a condizioni difficili senza richiedere un'attenzione costante, il bronzo merita una seria considerazione.

Cosa rende questa antica lega così duratura? Il bronzo combina l'eccellente conducibilità termica del rame con il miglioramento della durezza apportato dall'elemento stagno, creando un materiale per boccole che resiste naturalmente all'usura, dissipa efficacemente il calore e sviluppa nel tempo caratteristiche superficiali vantaggiose. Questi non sono solo vantaggi teorici: si traducono in prestazioni affidabili e prevedibili in applicazioni gravose.

Boccole in Bronzo per Affidabilità Tradizionale

Le proprietà meccaniche del bronzo lo rendono particolarmente adatto per applicazioni di boccola guida. Secondo del settore , le boccole in bronzo offrono elevata durezza per resistere all'usura fisica, eccellente resistenza alla compressione sotto carichi pesanti e naturale resistenza alla corrosione grazie alla formazione di uno strato ossidato.

Pensi a cosa accade all'interno di un boccolo meccanico durante il funzionamento. Le superfici di scorrimento generano attrito, che produce calore. La superiore conducibilità termica del bronzo smaltisce efficacemente questo calore dalla zona di contatto, prevenendo l'accumulo termico che accelera l'usura nei materiali meno conduttivi. Questa naturale dissipazione del calore risulta particolarmente preziosa nei coni che eseguono cicli produttivi continui.

Il basso coefficiente di attrito intrinseco del bronzo riduce le perdite energetiche e diminuisce la necessità di lubrificazione rispetto al contatto acciaio su acciaio. Nel tempo, le superfici dei cuscinetti in bronzo effettivamente migliorano, sviluppando uno strato levigato e indurito per lavorazione che ne potenzia le prestazioni. Questa caratteristica di rodaggio significa che i vostri boccole spesso funzionano meglio dopo un uso iniziale piuttosto che subito dopo l'installazione.

Gli alleati di bronzo sono disponibili in diverse formulazioni, ciascuna ottimizzata per specifiche condizioni:

- Leghe di bronzo stagno: Durezza moderata con eccellente resistenza alla corrosione e lavorabilità — ideale per applicazioni generali

- Bronzo stagno al piombo: Migliorata lavorabilità e resistenza all'usura per bocce piane soggette a carichi moderati

- Bronzo Alluminio: Resistenza ultra-elevata e resistenza alla corrosione per ambienti con carichi pesanti e condizioni corrosive

- Bronzo Fosforo: Eccellente resistenza all'usura e alla fatica per applicazioni in macchinari di precisione

- Bronzo grafite: Proprietà autolubrificanti che riducono la manutenzione in situazioni ad alta temperatura o difficili da lubrificare

Quando il bronzo supera le alternative moderne

I boccoli in bronzo non sono la scelta giusta per ogni applicazione — ma in determinate condizioni, superano alternative considerate superiori. Comprendere questi scenari permette di abbinare intelligentemente materiale e applicazione.

Si consideri un'applicazione con boccola a barile in una matrice per tranciatura pesante. Ogni corsa genera carichi d'urto significativi quando il punzone entra in contatto con il materiale. I cuscinetti a sfera, dotati di elementi volventi a contatto puntiforme, possono subire danni alle piste sotto carichi ripetuti di tipo impulsivo. Il bronzo, grazie al contatto superficiale distribuito e alla sua intrinseca tenacità, assorbe questi urti senza degradarsi.

Gli ambienti contaminati rappresentano un altro scenario in cui il bronzo eccelle. Nelle operazioni di stampaggio in cui schegge metalliche, prodotti derivanti dalla degradazione dei lubrificanti e polvere ambientale sono inevitabili, la natura tollerante del bronzo evita i guasti catastrofici che la contaminazione provoca negli accoppiamenti di precisione dei cuscinetti a sfera. Le particelle che distruggerebbero cuscinetti a sfera di piccole dimensioni semplicemente si incorporano nella matrice più morbida del bronzo o vengono spostate durante il funzionamento.

Le opzioni in bronzo autolubrificante, in particolare le varianti impregnate di grafite e di olio, risolvono una delle limitazioni del bronzo tradizionale. Queste alternative a boccole con portacarboni forniscono lubrificazione continua direttamente dal materiale stesso, riducendo o eliminando la necessità di lubrificazione esterna. Per applicazioni in cui l'accesso alla lubrificazione è difficoltoso o dove è fondamentale un funzionamento pulito, queste formulazioni autolubrificanti offrono l'affidabilità del bronzo con minori esigenze di manutenzione.

Punti a favore

- Comprovato successo: Secoli di applicazione con successo in settori che vanno dalla marina all'aerospaziale fino alla produzione automobilistica

- Eccellente dissipazione del calore: Elevata conducibilità termica che previene l'accumulo di calore, responsabile dell'accelerazione dell'usura in altri materiali

- Lavorabile per adattamenti personalizzati: Il bronzo è facilmente lavorabile, consentendo un adattamento preciso e una personalizzazione senza l'uso di utensili specializzati

- Economico per applicazioni standard: Costi inferiori di materiale e produzione rispetto alle alternative con cuscinetti a sfera di precisione

- Resistenza naturale alla corrosione: Forma strati ossidici protettivi che resistono al degrado in ambienti aggressivi

- Tolleranza ai carichi d'urto: Resiste a sollecitazioni d'impatto e vibrazioni che danneggiano i cuscinetti a rotolamento

- Opzioni autolubrificanti disponibili: Le formulazioni con tappo di grafite e impregnate di olio riducono notevolmente le esigenze di manutenzione

Punti deboli

- Più pesanti delle alternative: La densità del bronzo aggiunge peso rispetto alle opzioni in alluminio o compositi, un aspetto da considerare nelle applicazioni sensibili al peso

- Limitata capacità di velocità: L'attrito radente genera più calore ad alte velocità rispetto al contatto volvente, limitandone la velocità pratica

- Richiede lubrificazione periodica: Le comuni formulazioni in bronzo necessitano di regolare reintegrazione del lubrificante per garantire prestazioni ottimali e lunga durata

- L'usura graduale è intrinseca: Tutte le superfici di contatto scorrevoli si usurano nel tempo, richiedendo alla fine sostituzione o regolazione

I bocchetti in bronzo trovano il loro ambiente ideale nelle applicazioni con matrici a bassa velocità, nelle operazioni con carichi d'urto significativi e negli ambienti in cui la contaminazione rende impraticabili i cuscinetti di precisione. Sono particolarmente adatti per matrici che funzionano al di sotto di 100 corsie al minuto, operazioni con trasferimento di stampo con carichi più pesanti e ambienti produttivi in cui le risorse di manutenzione sono limitate.

Quando anche il ridotto fabbisogno di lubrificazione del bronzo sembra eccessivo, i bocchetti compositi autolubrificanti offrono un'alternativa valida—eliminando completamente la lubrificazione esterna pur mantenendo prestazioni di guida affidabili.

Bocchetti Compositi Autolubrificanti per un Funzionamento a Bassa Manutenzione

E se potessi eliminare del tutto le schedulazioni della lubrificazione? Per operazioni in cui l'accesso alla manutenzione è difficoltoso o in cui la contaminazione da lubrificante crea problemi, i boccoli compositi autolubrificanti offrono una soluzione elegante. Questi componenti avanzati ribaltano completamente l'equazione tradizionale della manutenzione dei boccoli.

Capire cosa fa un boccolo in una configurazione autolubrificante rivela un'ingegneria intelligente al lavoro. Piuttosto che dipendere da un apporto esterno di lubrificante, questi compositi contengono materiali lubrificanti incorporati direttamente nella loro struttura. Durante il funzionamento del boccolo, microscopiche quantità di lubrificante migrano verso la superficie scorrevole, mantenendo un film protettivo senza alcun intervento da parte del vostro team di manutenzione.

Eliminare i Problemi di Lubrificazione con Boccoli Compositi

La tecnologia alla base delle boccole autolubrificanti varia a seconda del produttore e dell'applicazione, ma il concetto fondamentale rimane lo stesso. Lubrificanti solidi — tipicamente PTFE, grafite, disolfuro di molibdeno o miscele proprietarie — vengono incorporati in un materiale matrice di base. Questo materiale per boccole in plastica o composito metallo-polimero rilascia continuamente lubrificante durante tutta la vita utile del componente.

Come funzionano le boccole quando sono autolubrificanti? Immaginate migliaia di minuscoli serbatoi di lubrificante distribuiti in tutta la struttura della boccola. Sotto carico e movimento, questi serbatoi trasferiscono il lubrificante sulla superficie del cuscinetto attraverso una combinazione di azione meccanica ed effetti termici. Il risultato è una lubrificazione costante che non dipende dal rispetto perfetto dei programmi di manutenzione.

Questo approccio con lubrificante incorporato offre diversi vantaggi pratici oltre alla riduzione della manutenzione:

- Caratteristiche di attrito costanti: A differenza dei boccoli lubrificati esternamente che possono rimanere a secco tra un intervallo di manutenzione e l'altro, i composti autolubrificanti mantengono coefficienti di attrito stabili per tutta la loro vita operativa

- Funzionamento pulito: L'assenza di lubrificante in eccesso elimina gocciolamenti, contaminazioni dei pezzi lavorati e disordine sul pavimento del reparto produttivo

- Inventario semplificato: L'eliminazione della selezione e dello stoccaggio del lubrificante riduce la complessità degli approvvigionamenti

- Minori preoccupazioni ambientali: Nessun problema di smaltimento del lubrificante né rischi di contaminazione da versamenti

Dove le soluzioni autolubrificanti sono vantaggiose

Non tutte le applicazioni traggono ugualmente beneficio dalla tecnologia autolubrificante. Comprendere a cosa servono i boccoli in specifici ambienti aiuta a identificare dove questi componenti offrono il massimo valore

Gli ambienti produttivi per alimenti rappresentano un'applicazione ovvia. Quando la contaminazione da lubrificanti potrebbe compromettere la sicurezza del prodotto, le boccole autolubrificanti eliminano completamente il rischio. Molte formulazioni composite sono conformi alla FDA per contatto accidentale con alimenti, rendendole adatte per matrici utilizzate nella produzione di imballaggi alimentari o componenti per attrezzature di lavorazione.

Anche le operazioni in prossimità di camere bianche traggono benefici simili. Sebbene la vostra operazione di stampaggio possa non richiedere protocolli completi di camera bianca, la produzione di componenti per elettronica, dispositivi medici o apparecchiature per semiconduttori richiede un controllo della contaminazione. Guide autolubrificanti impediscono la migrazione di lubrificanti sui pezzi destinati a applicazioni sensibili a valle.

Considera anche le applicazioni in cui l'accesso per la lubrificazione è fisicamente difficoltoso. Matrici con geometrie complesse, guide posizionate in spazi ristretti o zone ad alta temperatura in cui il lubrificante si degrada rapidamente presentano tutte sfide di manutenzione. Quando ci si chiede a cosa serve un boccolo in queste situazioni, i compositi autolubrificanti offrono affidabilità senza necessità di manutenzione.

Un altro caso d'uso significativo è rappresentato dal funzionamento intermittente. Le apparecchiature che rimangono ferme per lunghi periodi possono subire migrazione o degradazione del lubrificante. I boccole autolubrificanti mantengono la loro capacità lubrificante indipendentemente dal programma operativo, garantendo prestazioni affidabili all'avvio dopo giorni o settimane di fermo.

Punti a favore

- Intervalli di manutenzione drasticamente ridotti: Molte boccole autolubrificanti funzionano senza manutenzione per tutta la durata del servizio

- Funzionamento pulito: Ideali per applicazioni in cui la contaminazione da lubrificante è inaccettabile o problematica

- Buona resistenza alla contaminazione: Le matrici di lubrificante solido non vengono lavate via dai refrigeranti né compromesse dai detriti come i film oleosi

- Prestazioni Costanti: Le caratteristiche di attrito rimangono stabili invece di variare in base alle condizioni di lubrificazione

- Logistica semplificata: Nessuna necessità di selezionare, immagazzinare o smaltire lubrificanti

- Resistenza alla corrosione: Molte formulazioni composite resistono a sostanze chimiche e umidità che degradano i componenti metallici

Punti deboli

- Limitazioni di Temperatura: I compositi a base polimerica hanno limiti di temperatura massima che tipicamente variano tra 250-500°F a seconda della formulazione—superare questi limiti accelera l'usura e può causare il guasto

- Vincoli di capacità di carico: I compositi autolubrificanti generalmente non riescono a eguagliare le capacità di carico dei boccioli in bronzo o acciaio di dimensioni equivalenti

- Costo unitario più elevato: I materiali compositi avanzati hanno un costo superiore rispetto al bronzo base, anche se la ridotta manutenzione spesso ne determina un costo totale di proprietà più vantaggioso

- Limitata capacità di velocità elevata: La generazione di calore a velocità elevate può superare la capacità termica di alcuni materiali compositi

- Considerazioni sulla compatibilità dei materiali: Alcuni compositi possono reagire con sostanze chimiche o lubrificanti specifici presenti nell'ambiente

Cosa fanno i boccoli quando sono correttamente abbinati ai requisiti dell'applicazione? Forniscono anni di funzionamento senza problemi. I compositi autolubrificanti si distinguono nelle applicazioni a carico moderato e velocità moderata in cui la riduzione della manutenzione giustifica il prezzo più elevato, soprattutto quando la sensibilità alla contaminazione o le limitazioni di accesso rendono impraticabile la lubrificazione convenzionale.

Per applicazioni che richiedono la massima capacità di carico nello spazio minimo, i sistemi di guida a rullini offrono un ulteriore approccio alla sfida dei boccoli di guida.

Sistemi di Guida a Rullini per Alte Sollecitazioni

Cosa succede quando hai bisogno delle prestazioni di un cuscinetto a sfere ma non puoi permetterti lo spazio radiale? O quando i requisiti di carico superano ciò che gli elementi volventi convenzionali possono gestire nello spazio disponibile? È in questi casi che entrano in gioco i sistemi di guida con cuscinetti a rullini, soluzioni specializzate per applicazioni in cui le opzioni standard risultano insufficienti.

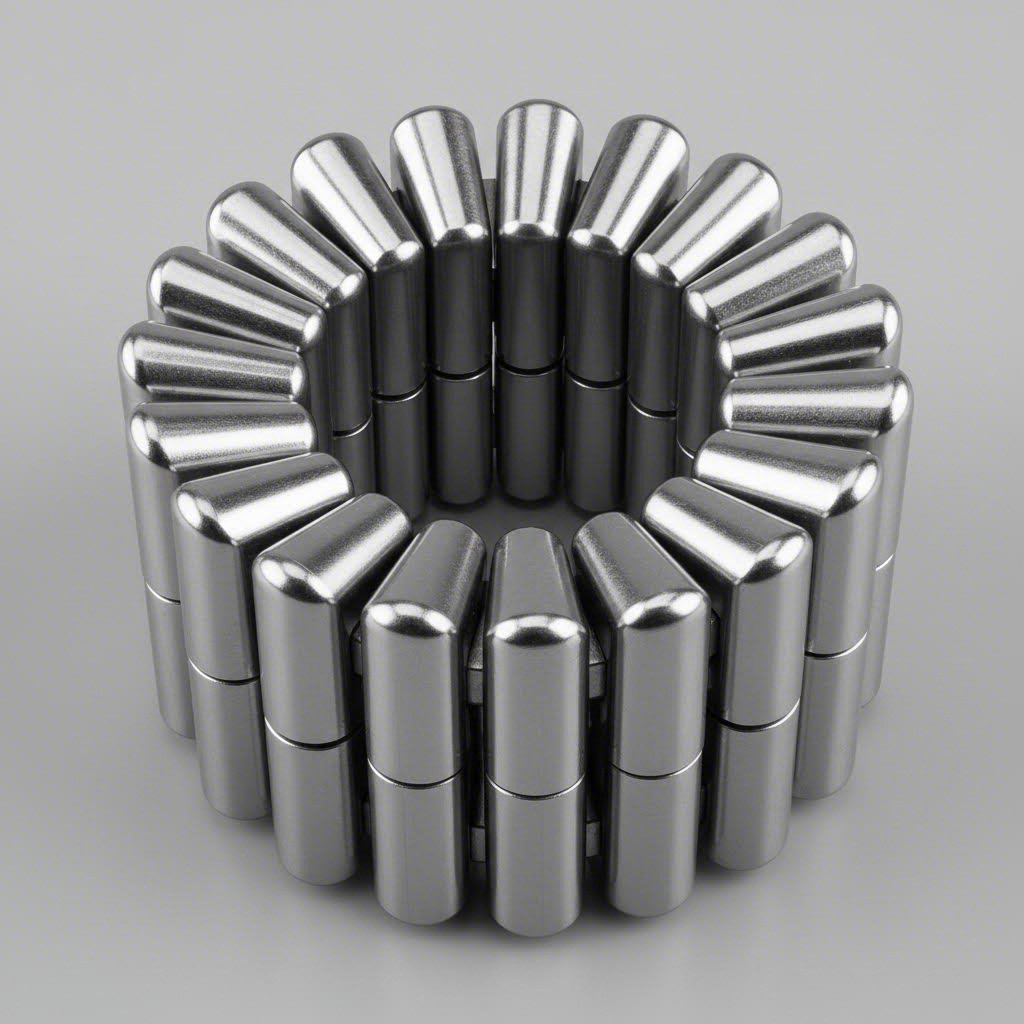

Confrontando i progetti con cuscinetti a rullini e quelli a sfere, la differenza è immediatamente evidente. Invece di elementi volventi sferici, i cuscinetti a rullini utilizzano rulli cilindrici allungati con rapporto tra lunghezza e diametro tipicamente superiore a 4:1. Questa geometria offre una capacità di carico notevolmente maggiore in ogni millimetro di spazio radiale.

Cuscinetti a rullini per applicazioni con carichi estremi

Pensi alla fisica per un momento. Un cuscinetto a boccole liscio o un cuscinetto a sfere entra in contatto con la superficie abbinata in aree relativamente piccole: punti nel caso delle sfere, linee strette per la superficie dell'albero. I rulli a ago, al contrario, presentano un contatto lineare esteso lungo tutta la loro lunghezza. Questo contatto distribuito diffonde i carichi su aree più ampie, riducendo le concentrazioni di sollecitazione e consentendo classi di carico più elevate.

Qual è il risultato pratico? Un supporto a rulli a ago può sostenere da due a tre volte il carico radiale di un cuscinetto a sfere che occupa lo stesso spazio. Per operazioni di stampaggio pesante in cui le forze dello stampo spingono i sistemi guida convenzionali ai loro limiti, questo vantaggio in termini di capacità diventa fondamentale.

Le applicazioni con movimento oscillante beneficiano in particolare della tecnologia a rulli aghiformi. A differenza dei cuscinetti a sfera, che preferiscono una rotazione continua, i cuscinetti a rulli tollerano il movimento avanti e indietro comune in molte applicazioni di stampaggio senza sviluppare i fenomeni di usura che possono colpire altre soluzioni con elementi volventi. La configurazione con boccola a rulli gestisce questi cicli di rotazione parziale mantenendo i vantaggi di basso attrito propri del contatto volvente.

Gli scenari con carichi combinati—nei quali forze radiali si associano a carichi assiali—rappresentano un ulteriore punto di forza dei cuscinetti a rulli. Alcune configurazioni di boccole includono facce assiali o disposizioni di rulli inclinati capaci di gestire combinazioni complesse di carico. Quando lo stampo genera forze simultanee in più direzioni, queste soluzioni integrate semplificano l'architettura del sistema di guida.

Potenza Compatta in Spazi Ristretti

I vincoli di spazio determinano molte scelte dei cuscinetti a rullini. Le matrici progressive con stazioni molto ravvicinate, le applicazioni di retrofit in basi esistenti o i progetti in cui altri componenti limitano lo spazio disponibile traggono vantaggio dalla straordinaria densità di potenza offerta dai cuscinetti a rullini.

Si consideri uno scenario in cui l'analisi del carico indica la necessità di un cuscinetto a sfere con foro da 50 mm, ma si dispone soltanto di 35 mm di spazio radiale. Una soluzione con boccola a rullini potrebbe offrire una capacità di carico equivalente in questo ingombro ridotto, trasformando un problema di progettazione impossibile in una specifica semplice.

Operazioni pesanti di punzonatura e formatura generano forze elevate che mettono alla prova sistemi di guida di portata leggera. I carichi concentrati durante il taglio del materiale possono superare quanto i normali sistemi di guida a cuscinetti a sfera possono sopportare senza cedimenti prematuri. I cuscinetti a rullini, grazie ai loro più elevati valori di carico ammissibile, offrono il margine necessario per queste applicazioni gravose.

Punti a favore

- Straordinaria capacità di carico rispetto alle dimensioni: Due o tre volte la capacità di carico radiale rispetto ai cuscinetti a sfere con foro equivalente, consentendo progetti compatti sotto carichi elevati

- Eccellente per il moto oscillante: Tolleranza ai movimenti parziali e alternati migliore rispetto ai cuscinetti a sfere, ideale per schemi tipici delle matrici

- Gestisce efficacemente i carichi combinati: Le configurazioni disponibili gestiscono forze radiali e assiali simultanee senza cuscinetti di spinta separati

- Ingombro radiale compatto: Sezioni sottili adatte dove assemblaggi più grandi di cuscinetti a sfere non possono essere installati, risolvendo sfide complesse di ingombro

- Alta rigidezza: Contatti multipli lineari creano sistemi di guida più rigidi con minore deformazione sotto carico rispetto alle alternative a contatto puntuale

Punti deboli

- Opzione con costo più elevato: Il prezzo premium riflette i requisiti di produzione di precisione: prevedere un costo significativamente superiore rispetto ai cuscinetti a sfere o alle boccole lisce

- Richiede un allineamento preciso: I rulli a ago sono meno tolleranti rispetto ai cuscinetti a sfera in caso di cattivo allineamento; anche piccoli errori angolari accelerano l'usura e riducono la durata

- Sensibile alla contaminazione: Gli stretti giochi tra rulli e piste rendono i cuscinetti a rulli a ago vulnerabili ai danni causati dalle particelle, forse ancora di più rispetto ai cuscinetti a sfera

- Installazione complessa: Il montaggio corretto richiede conoscenze specialistiche e spesso attrezzature specifiche; un'installazione errata provoca un rapido guasto

- Limitata capacità di velocità: Nonostante siano elementi volventi, i cuscinetti a rulli a ago hanno tipicamente velocità ammesse inferiori rispetto a progetti equivalenti con cuscinetti a sfera, a causa della dinamica dei rulli

- Lubrificazione fondamentale: Richiedono una lubrificazione costante e appropriata; i guasti dovuti a lubrificazione insufficiente si verificano rapidamente e in modo catastrofico

I sistemi di guida a rullini occupano una nicchia specializzata. Non rappresentano la soluzione adatta per la maggior parte delle applicazioni di stampaggio, ma quando è necessaria la massima capacità di carico nello spazio minimo, risolvono problemi che altre boccole per cuscinetti semplicemente non possono affrontare. Stampo pesanti, utensili progressivi con limitazioni di spazio e applicazioni con carichi oscillanti gravosi rappresentano tutti ambiti in cui l'impiego di rullini può risultare vantaggioso.

Dopo aver esaminato tutte le principali categorie di boccole di guida, sei ora pronto a confrontare direttamente le diverse opzioni, abbinando caratteristiche prestazionali specifiche ai requisiti della tua applicazione.

Tabella completa di confronto per la selezione delle boccole di guida

Hai esplorato in profondità ciascuna categoria di boccola di guida; ora è il momento di metterle a confronto. Quando si valutano le differenze tra opzioni con boccola o cuscinetto, un quadro comparativo completo aiuta a superare la complessità e indica chiaramente quale soluzione si adatta meglio alla situazione specifica.

Le tabelle seguenti riassumono tutto quanto trattato in strumenti di riferimento pratici. Che tu stia definendo componenti per la realizzazione di un nuovo stampo o che tu stia risolvendo problemi su un sistema esistente, questi confronti forniscono il supporto decisionale di cui hai bisogno.

Confronto comparativo delle prestazioni

Comprendere la differenza tra soluzioni a cuscinetti e a boccole richiede l'analisi simultanea di più dimensioni prestazionali. La tabella seguente confronta tutte le opzioni esaminate rispetto ai criteri critici di selezione stabiliti in precedenza.

Quando si analizza questo confronto, ricordare che "boccola e cuscinetto" non è una scelta esclusiva. Ciascuna categoria eccelle in condizioni specifiche: il tuo compito consiste nell'abbinare questi punti di forza alle esigenze della tua applicazione.

| Tipo guida | Capacità di Carico | Adatto alla velocità | Capacità di precisione | Tolleranza alle contaminazioni | Requisiti di manutenzione | Costo relativo | Applicazioni più adatte |

|---|---|---|---|---|---|---|---|

| Boccole lisce di precisione | Alto | Bassa a moderata (fino a 150 SPM) | Alta (con lavorazione di precisione) | Eccellente | Moderata (lubrificazione regolare) | Basso ($) | Stoccaggio generico, stampi transfer, ambienti contaminati |

| Guide a cuscinetti a sfera | Moderato | Molto elevata (300+ SPM) | Eccellente | Scarso | Bassa (design sigillati) | Elevato ($$$) | Stampe progressive ad alta velocità, stampaggio di precisione |

| Bussola in bronzo liscia | Alto | Bassa (sotto i 100 SPM) | Da moderato ad alto | Eccellente | Moderata (lubrificazione periodica) | Basso ($) | Sbavatura pesante, carichi d'urto, ambienti corrosivi |

| Compositi autolubrificanti | Da basso a moderato | Da basso a moderato | Moderato | Buono | Molto bassa (senza manutenzione) | Medio ($$) | Per alimenti, operazioni pulite, posizioni di difficile accesso |

| Guide a rullini | Molto elevato | Moderato | Eccellente | Scarso | Alto (lubrificazione critica) | Molto Alto ($$$$) | Stampaggio pesante, applicazioni con carico elevato e spazio limitato |

Osserva come nessuna opzione risulti dominante in tutte le categorie. La scelta tra cuscinetti e bocce torna sempre al contesto applicativo. Una boccola, in termini meccanici, funge da interfaccia scorrevole — e quando tale interfaccia scorrevole è adatta alle tue condizioni, spesso supera soluzioni più sofisticate.

Abbinare il tipo di guida alle condizioni operative

Il confronto prestazionale riportato sopra indica cosa può fare ciascun tipo di guida. Questa tabella successiva inverte la prospettiva — partendo dai parametri della tua applicazione e indicando la soluzione raccomandata.

Pensa a questo strumento come a un ausilio rapido per prendere decisioni. Identifica il tipo di punzonatrice, la gamma di velocità e le condizioni ambientali, quindi segui orizzontalmente per trovare la tecnologia di guida appropriata. Comprendere i requisiti meccanici delle boccole nel tuo contesto specifico porta a scelte migliori rispetto all'uso automatico di soluzioni familiari.

| Tipo di dado | Intervallo di Velocità del Ciclo | Ambiente di funzionamento | Carico Primario | Soluzione Guida Consigliata |

|---|---|---|---|---|

| Morso progressivo | 200-400+ SPM | Pulito, climatizzato | Leggeri a moderati | Guide a cuscinetti a sfera |

| Morso progressivo | 100-200 SPM | Pavimento standard di produzione | Moderato | Boccole lisce di precisione |

| Stampo a trasferimento | 20-80 SPM | Contaminazione pesante | Carichi pesanti con urti | Bussola in bronzo liscia |

| Morra di staccaggio | 50-150 SPM | Produzione standard | Impatto violento | Bocce in bronzo o boccole di precisione |

| Stampo per formatura pesante | 20-60 SPM | Spazio limitato | Molto pesante | Guide a rullini |

| Stampo per imballaggio alimentare | 50-150 SPM | Adiacente a camera bianca | Leggeri a moderati | Compositi autolubrificanti |

| Stampo per componenti medicali | 100-250 SPM | Sensibile alla contaminazione | Luce | Cuscinetti a sfera sigillati o compositi autolubrificanti |

| Punzone per uso generico | Sotto i 100 SPM | Condizioni tipiche del laboratorio | Moderato | Boccole lisce di precisione |

Considerazioni sull'installazione e sull'allineamento

La differenza tra un cuscinetto e una boccola va oltre le prestazioni operative, includendo anche i requisiti di installazione. Questo fattore spesso viene trascurato durante la specifica, ma incide notevolmente sul costo totale di possesso e sull'affidabilità del sistema.

- Boccole lisce (tutti i tipi): Installazione più semplice: montaggio con accoppiamento forzato o scorrevole, con minima sensibilità all'allineamento. Tollerano piccoli errori di montaggio che danneggerebbero alternative con elementi volventi. Tempo tipico di installazione: 15-30 minuti per ogni set di guide.

- Guide a cuscinetti a sfera: Richiedono un preciso allineamento parallelo tra il perno guida e il foro della boccola. Un'allineamento errato superiore a 0,001" per pollice di corsa accelera l'usura. Spesso necessitano di regolazione del precarico per ottenere prestazioni ottimali. Tempo tipico di installazione: 45-90 minuti per ogni set di guide.

- Guide a rullini: Requisiti di installazione più rigorosi. Richiedono tecniche di assemblaggio specializzate e spesso attrezzature specifiche. La tolleranza ai disallineamenti è più stretta rispetto ai cuscinetti a sfera. Un'installazione errata provoca guasti rapidi, talvolta catastrofici. Tempo tipico di installazione: 60-120 minuti per set di guide.

Per applicazioni di retrofit, queste differenze di installazione diventano particolarmente significative. L'aggiornamento da boccole lisce a guide con cuscinetti a sfera può richiedere modifiche per garantire che le tolleranze di allineamento possano essere raggiunte e mantenute. Al contrario, la conversione da installazioni problematiche con cuscinetti a sfera a boccole lisce di qualità spesso risolve i guasti legati all'allineamento riducendo al contempo la complessità.

Con questo quadro di confronto completo a disposizione, sei in grado di effettuare scelte informate sulle boccole di guida basandoti sulle tue reali condizioni operative, piuttosto che su ipotesi o raccomandazioni del fornitore.

Raccomandazioni finali e selezione del tuo partner per gli utensili

Hai valutato le caratteristiche di prestazione, confrontato i carichi nominali ed esaminato la tolleranza alla contaminazione in ogni principale categoria di boccola guida. Ora arriva il passaggio cruciale: tradurre questa conoscenza in una decisione consapevole per la tua specifica applicazione. La domanda boccola contro cuscinetto a sfera si risolve da sé quando si applica un processo di valutazione sistematico.

Cosa distingue le scelte corrette di boccole guida dagli errori costosi? Raramente si tratta di scegliere l'opzione più costosa o seguire ciò che ha funzionato nell'ultimo progetto. Il successo deriva dalla valutazione onesta delle condizioni operative e dal collegamento con la tecnologia giusta. Vediamo esattamente come fare.

La tua mappa decisionale basata sulle esigenze dell'applicazione

Segui questi cinque passaggi in sequenza. Ognuno si basa sul precedente, creando un quadro completo delle tue esigenze prima di impegnarti in una soluzione specifica. Affrettarsi o saltare dei passaggi porta spesso a specifiche che sembrano valide sulla carta ma hanno prestazioni scadenti in produzione.

- Definisci i requisiti di velocità e ciclo: Inizia con le tue corse obiettivo al minuto. Stai gestendo un punzonatura progressiva ad alta velocità a oltre 300 corse al minuto, oppure un'operazione di trasferimento moderata sotto le 100 corse al minuto? Questo singolo fattore spesso riduce significativamente le opzioni disponibili. La scelta tra cuscinetti a sfera e boccole dipende frequentemente dal fatto che le frequenze di ciclo generino calore d'attrito che superfici lisce non riescono a dissipare. Documenta non solo i tuoi requisiti attuali, ma anche le esigenze future previste: progettare per il domani evita aggiornamenti prematuri.

- Valuta le condizioni di carico: Calcola le forze che il tuo sistema di guida deve assorbire. Considera i carichi radiali derivanti da forze laterali dello stampo, i carichi assiali dovuti a componenti verticali e i carichi flettenti causati da forze eccentriche. Non dimenticare i carichi d'impatto durante le operazioni di tranciatura e punzonatura: questi colpi improvvisi possono superare le forze in condizioni stazionarie anche di tre volte o più. Per applicazioni pesanti e soggette a impatti, spesso è preferibile ricorrere a boccole lisce o cuscinetti a rulli piuttosto che a soluzioni con cuscinetti a sfera sensibili agli urti.

- Valuta i fattori ambientali: Ispeziona il tuo reparto produttivo con occhio critico. Quanto contaminante entra effettivamente nell'area dello stampo? Trucioli metallici, nebbia di lubrificante, polvere in sospensione e fluttuazioni termiche influiscono tutti sulle prestazioni del sistema di guida. Il confronto tra boccole e cuscinetti a sfera cambia drasticamente in presenza di elevati livelli di contaminazione: il vantaggio dei cuscinetti a sfera in termini di attrito perde significato se le particelle distruggono le piste di rotolamento entro pochi mesi.

- Considera le capacità di manutenzione: Siate onesti riguardo a ciò che il vostro programma di manutenzione può effettivamente garantire. I sistemi guida sofisticati, che richiedono programmi precisi di lubrificazione e regolazioni periodiche del precarico, necessitano di tecnici qualificati e procedure rigorose. Se le risorse per la manutenzione sono limitate, compositi autolubrificanti o boccole in bronzo più tolleranti possono offrire risultati migliori a lungo termine rispetto a cuscinetti a sfera di precisione che si deteriorano senza un'adeguata manutenzione.

- Calcolare il Costo Totale di Proprietà: Il prezzo iniziale di acquisto rappresenta solo una parte della storia. Considerate il costo della manodopera per l'installazione (i cuscinetti a sfera richiedono da 2 a 3 volte il tempo di installazione delle boccole lisce), i costi di manutenzione durante la vita utile prevista, le spese per la sostituzione dei componenti e, soprattutto, il costo produttivo delle fermate impreviste. Una guida su boccole e cuscinetti che ignora i costi del ciclo di vita fornisce indicazioni incomplete.

La precisione dei tuoi manicotti guida non potrà mai superare la precisione dell'intera progettazione dello stampo. Specificare guide a sfere di alta qualità tollerando al contempo giochi eccessivi in altre parti crea un disallineamento costoso, sprecando denaro per prestazioni che non puoi sfruttare.

Quando effettuare un aggiornamento e quando invece ridimensionare

Gli scenari di retrofit presentano opportunità decisionali uniche. Se stai risolvendo problemi di usura prematura delle guide o stai valutando aggiornamenti degli utensili esistenti, la scelta tra cuscinetti a sfera e boccole può differire rispetto alle specifiche per nuove realizzazioni.

Valuta di passare da boccole lisce a cuscinetti a sfera quando:

- La velocità di produzione è aumentata oltre i valori originariamente previsti, generando problemi termici

- I requisiti di precisione si sono ristretti a causa di richieste qualitative più stringenti a valle

- Il tuo stabilimento ha migliorato i controlli ambientali rispetto all'installazione iniziale

- Le capacità di manutenzione si sono ampliate per supportare sistemi più sofisticati

Valuta di passare da cuscinetti a sfera a boccole lisce di qualità quando:

- I guasti dei cuscinetti legati alla contaminazione si verificano ripetutamente nonostante le misure di tenuta

- I problemi di allineamento nelle vecchie scanalature delle matrici causano un'usura accelerata dei cuscinetti a sfera

- Le velocità di produzione effettive sono inferiori rispetto a quelle inizialmente previste

- Le risorse per la manutenzione non riescono a garantire le cure necessarie ai cuscinetti a sfera

La scelta tra cuscinetto pilota e boccola nelle applicazioni di trasmissione offre un parallelo utile. Gli ingegneri effettuano questa scelta in base alle condizioni operative reali, non a una superiorità teorica. Applica la stessa pragmaticità alle tue guide per matrici da stampaggio

Collaborare con il giusto fornitore di utensili

Ecco la realtà che i costruttori esperti di matrici conoscono bene: l'uso di una boccola va ben oltre il semplice guidaggio del movimento. Il tuo sistema di guida si integra con l'allineamento tra punzone e matrice, i meccanismi estrattori, i sistemi di alimentazione del materiale e l'integrità strutturale complessiva della matrice. Ottimizzare le boccole di guida in modo isolato, ignorando queste interconnessioni, limita i risultati ottenibili

Questa prospettiva integrata spiega perché la selezione della boccola di guida merita attenzione durante la progettazione dello stampo, e non come considerazione successiva durante la costruzione. Gli strumenti di simulazione CAE possono prevedere il comportamento del sistema di guida sotto carichi operativi reali, identificando potenziali problemi prima dell'asportazione del metallo. Un'analisi accurata convalida che la tecnologia di guida scelta funzionerà come previsto all'interno della specifica architettura dello stampo.

Per applicazioni di stampaggio automobilistico in cui le tolleranze sono strette e i volumi produttivi elevati, collaborare con fornitori che comprendono questo approccio olistico offre vantaggi misurabili. Le soluzioni per stampi da tranciatura certificate IATF 16949 di Shaoyi integrano una corretta specifica del sistema di guida con avanzate simulazioni CAE, convalidando i progetti prima dell'inizio della prototipazione. Il loro tasso di approvazione al primo tentativo del 93% riflette una disciplina ingegneristica che si estende dalla selezione delle boccole di guida fino all'ottimizzazione completa del sistema stampo.

Che si tratti di specificare guide a cuscinetti a sfera per applicazioni di precisione ad alta velocità o di scegliere boccole lisce resistenti per ambienti contaminati, il principio fondamentale rimane costante: le prestazioni di una boccola guida sono buone quanto l'intero progetto dello stampo che la supporta. Abbinare la scelta della guida alle effettive condizioni operative, verificarla mediante un'analisi adeguata e collaborare con fornitori che comprendono come l'eccellenza degli utensili richieda attenzione a ogni componente, comprese le boccole guida che proteggono il vostro mandrino.

Domande frequenti sui cuscinetti a sfera rispetto alle boccole guida lisce

1. Qual è la differenza tra una boccola e un cuscinetto a sfera?

Un boccolo è un manicotto liscio che fornisce una superficie scorrevole uniforme per il movimento dell'albero, mentre un cuscinetto a sfera utilizza elementi rotolanti (sfere) alloggiati in piste per ridurre l'attrito. I boccoli si basano sul contatto strisciante e sono più adatti per ambienti contaminati, velocità inferiori e carichi d'urto. I cuscinetti a sfera offrono un attrito notevolmente inferiore—fino al 90% in meno—rendendoli ideali per applicazioni ad alta velocità superiori a 200 SPM dove la generazione di calore è un fattore critico. La scelta dipende dalle specifiche condizioni operative, incluse velocità, carico, ambiente e capacità di manutenzione.

2. Quando devo utilizzare guide con cuscinetti a sfera invece di boccoli lisci?

Scegliete i sistemi di guida a cuscinetti a sfera quando l'applicazione prevede punzonatrici progressive ad alta velocità che operano oltre 150-200 colpi al minuto, richiedono una ripetibilità posizionale inferiore al millesimo di pollice, funzionano in ambienti puliti o controllati e implicano carichi uniformi e costanti piuttosto che impatti pesanti. I cuscinetti a sfera si distinguono in cicli produttivi prolungati, dove la loro precisione superiore e l'attrito ridotto giustificano i costi iniziali più elevati. Tuttavia, non sono adatti per ambienti contaminati, operazioni di tranciatura con forti sollecitazioni d'urto o applicazioni in cui non è possibile mantenere un corretto allineamento.

3. Quali sono i vantaggi dei boccoli in bronzo rispetto ad altre opzioni di guida?

Le boccole in bronzo offrono un'affidabilità comprovata grazie a secoli di utilizzo industriale con successo. I principali vantaggi includono un'eccellente conducibilità termica per la dissipazione del calore, una naturale resistenza alla corrosione grazie alla formazione di un ossido protettivo, una superiore tolleranza ai carichi d'urto per matrici pesanti, e una facile lavorabilità per adattamenti personalizzati. Le opzioni in bronzo autolubrificante con grafite incorporata riducono le esigenze di manutenzione. Il bronzo è ideale per matrici a bassa velocità inferiori a 100 SPM, applicazioni con contaminazione inevitabile e ambienti che richiedono resistenza alla corrosione. I principali limiti sono il peso e la capacità di velocità rispetto alle alternative moderne.

4. Come si calcola il costo totale di possesso delle boccole di guida?

Il costo totale di proprietà va oltre il prezzo di acquisto e include la manodopera per l'installazione (i cuscinetti a sfera richiedono da 2 a 3 volte in più rispetto ai semplici boccoli), i costi di manutenzione durante la vita utile, le spese per componenti di ricambio e le perdite produttive dovute a fermi imprevisti. Un boccole più economico che richiede sostituzione ogni sei mesi potrebbe costare di più rispetto a un'opzione premium che dura tre anni. Considerate anche le capacità di manutenzione del vostro team: sistemi sofisticati a cuscinetti a sfera che necessitano di programmi precisi di lubrificazione potrebbero prestare meno bene se non viene garantita una corretta manutenzione costante. Fornitori certificati IATF 16949 come Shaoyi contribuiscono a ridurre i costi totali grazie a una produzione di precisione che prolunga la vita dei componenti.

5. Posso modificare il mio stampo passando da boccoli semplici a guide con cuscinetti a sfera?

Sì, ma la modifica richiede una valutazione accurata. Passare ai cuscinetti a sfera quando le velocità di produzione sono aumentate oltre le specifiche originali causando problemi termici, i requisiti di precisione si sono ristretti, i controlli ambientali sono migliorati o le capacità di manutenzione si sono ampliate. Tuttavia, si consiglia di passare da cuscinetti a sfera a boccole lisce di qualità quando si verificano ripetutamente guasti legati alla contaminazione, problemi di allineamento nei vecchi supporti dello stampo causano usura accelerata, le velocità effettive sono inferiori al previsto o le risorse di manutenzione sono limitate. Verificare sempre che la geometria dello stampo esistente possa ospitare dimensioni diverse dei componenti di guida e che siano raggiungibili le tolleranze di allineamento.

Piccole partite, alti standard. Il nostro servizio di prototipazione rapida rende la validazione più veloce e facile —

Piccole partite, alti standard. Il nostro servizio di prototipazione rapida rende la validazione più veloce e facile —