Metal CNC Cutting Decoded: From Raw Stock To Precision Parts

What Metal CNC Cutting Actually Means for Modern Manufacturing

Ever wondered how manufacturers transform a simple digital sketch into a flawless metal component? The answer lies in a technology that has fundamentally changed how we work with metal. Metal CNC cutting bridges the gap between imagination and reality, turning computer designs into tangible parts with remarkable accuracy.

CNC stands for Computer Numerical Control - a manufacturing process where pre-programmed computer software dictates the movement of cutting tools to shape metal with precision measured in thousandths of an inch.

Breaking Down the CNC Acronym

Understanding the CNC meaning starts with its three components. "Computer" refers to the digital brain controlling operations. "Numerical" describes the coded instructions (G-code and M-code) that guide every movement. "Control" represents the system's ability to execute these commands with unwavering consistency.

When you combine these elements with a machine to cut metal, you get a system that follows exact digital pathways without deviation. Unlike a human operator who might fatigue or introduce slight variations, CNC metal cutting delivers identical results whether it's the first part or the thousandth.

From Digital Design to Physical Metal Parts

The journey from concept to completed part follows a streamlined path. First, engineers create a 3D model using CAD (Computer-Aided Design) software. This digital blueprint then converts into machine-readable instructions through CAM (Computer-Aided Manufacturing) programs.

Once loaded into the CNC system, these instructions command the cutting tools along precise coordinates based on a three-dimensional Cartesian system. The machine knows exactly where to position itself, how fast to move, and how deep to cut. This digital-to-physical workflow enables rapid iteration - design changes can be tested through additional CNC runs without tooling adjustments or mold creation.

Why Computer Control Revolutionized Metal Cutting

The contrast between manual and CNC-controlled cutting reveals why this technology transformed manufacturing. Manual machining relies heavily on the operator's skill, coordination, and experience. Even skilled machinists introduce slight variations through hand-controlled movements.

CNC machining and CNC technology eliminates this variability. According to industry experts, CNC machines incorporate advanced features like feedback mechanisms, tool monitoring systems, and automatic tool changers that enhance precision far beyond manual capabilities. Multi-axis machining enables complex three-dimensional cuts that would be nearly impossible by hand.

The benefits extend across the spectrum - from hobbyists crafting custom projects to industrial facilities producing aerospace components. For small workshops, metal CNC offers affordable entry points with desktop machines. For manufacturers, it means consistent quality across thousands of parts. Whether you're exploring CNC cuts for a personal project or evaluating industrial solutions, the fundamental advantage remains the same: unmatched repeatability and precision that manual methods simply cannot match.

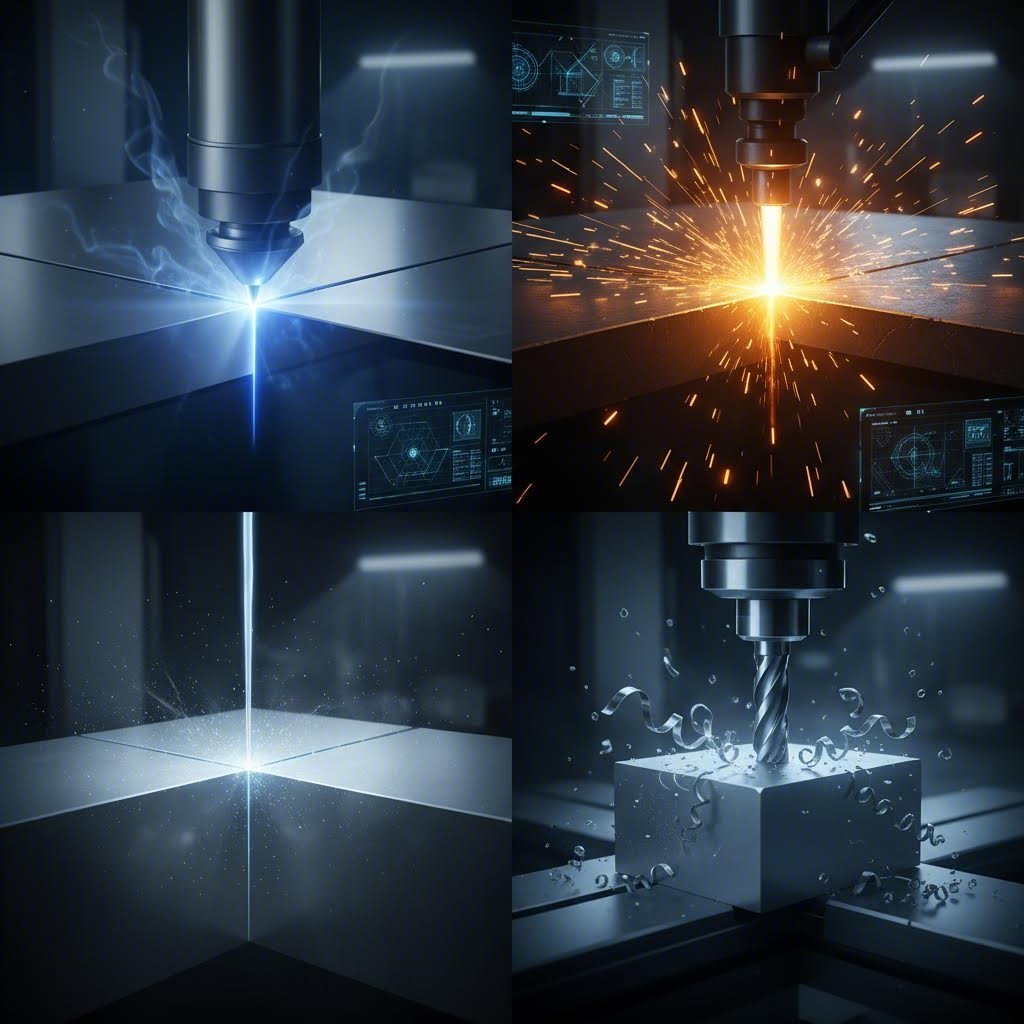

Comparing CNC Metal Cutting Methods Side by Side

Choosing the wrong metal cutter can cost you thousands in wasted material and lost time. With four primary CNC cutting technologies available, matching the right method to your specific application becomes critical for success. Let's break down each approach so you can make an informed decision.

Laser Cutting Precision and Speed Advantages

Imagine focusing intense light energy into a beam thin enough to cut intricate patterns with surgical precision. That's exactly what a laser cutter does. This technology excels when working with thin metal sheet materials, particularly when fine details or precise holes are needed.

Key advantages of laser cutting include:

- Exceptional edge quality requiring minimal post-processing

- Ability to cut small holes and intricate shapes with sharp corners

- High-speed processing on materials under 1/4 inch thick

- Precise kerf width control for tight-tolerance parts

- Excellent performance on stainless steel sheet and aluminum sheet materials

Best applications include electronics enclosures, medical devices, and precision parts manufacturing where clean edges matter most.

Plasma Cutting for Thick Plate Applications

When you're working with thick conductive metals, plasma cutting dominates. This technology uses an electrical arc and compressed gas to melt and blast through steel, aluminum, and copper with impressive speed and cost efficiency.

According to Wurth Machinery's testing, plasma cutters show excellent performance on steel plates over 1 inch thick - territory where laser cutters struggle to penetrate. The advantages become clear:

- Handles materials from 1/2 inch to several inches thick

- Fastest cutting speed for thick conductive metals

- Lower operating costs compared to laser and waterjet

- Complete plasma systems cost approximately $90,000 versus $195,000 for comparable waterjet systems

Structural steel fabrication, heavy equipment manufacturing, and shipbuilding rely heavily on plasma cutting for these reasons.

Waterjet Technology for Heat-Sensitive Metals

What if you need to cut metal without introducing any heat? Waterjet cutting uses high-pressure water mixed with abrasive particles to slice through virtually any material - from steel to stone - without thermal effects. The waterjet market is growing rapidly, projected to reach over $2.39 billion by 2034.

This technology shines when:

- Heat damage must be avoided (no warping, hardening, or heat-affected zones)

- Material versatility matters - cuts metals, composites, glass, and stone

- Thick materials up to 12 inches need precise cutting

- Sensitive alloys require cold-cutting processes

Aerospace components and precision applications where metallurgical properties must remain unchanged benefit most from waterjet technology.

CNC Milling and Router Capabilities

Unlike the other methods that cut through material, CNC milling and CNC router systems remove material through rotating cutting tools. This approach offers unique advantages - particularly the ability to create 3D contours, pockets, and complex geometries impossible with 2D cutting methods.

However, you'll notice speed limitations when using a CNC router for metal compared to dedicated cutting systems. Forum discussions frequently highlight this reality: routers designed primarily for wood and plastics require significant parameter adjustments and slower feeds when processing metals.

CNC milling excels for:

- Complex 3D geometries and contoured surfaces

- Precision hole-making and threading operations

- Parts requiring multiple machining operations in one setup

- Tight tolerances on critical dimensions

Complete Method Comparison at a Glance

This comparison table helps you quickly identify which technology fits your specific requirements:

| Factor | Laser Cutting | Plasma Cutting | Waterjet Cutting | CNC Milling/Routing |

|---|---|---|---|---|

| Material Thickness Range | 0.001" - 1" | 0.5" - 6"+ | 0.001" - 12" | Limited by tool reach |

| Precision Tolerances | ±0.001" - 0.005" | ±0.015" - 0.030" | ±0.003" - 0.010" | ±0.0005" - 0.005" |

| Edge Quality | Excellent, minimal finishing | Good, may need grinding | Very good, slight texture | Excellent with proper tooling |

| Cutting Speed | Very fast (thin materials) | Fast (thick materials) | Slow to moderate | Moderate |

| Operating Costs | Moderate to high | Low to moderate | High (abrasive consumption) | Moderate (tooling wear) |

| Best Applications | Thin sheets, intricate designs, electronics | Thick plate, structural steel, heavy fabrication | Heat-sensitive materials, aerospace, mixed materials | 3D parts, precision components, multi-operation work |

| Heat-Affected Zone | Small | Moderate to large | None | Minimal with coolant |

Matching Thickness to Technology

Your material thickness often determines the optimal cutting method:

- Thin gauge metal sheet (under 1/4"): Laser cutting delivers the best combination of speed, precision, and edge quality

- Medium thickness (1/4" to 1"): All methods work; choose based on precision needs and heat sensitivity

- Thick plate (over 1"): Plasma offers the best speed and cost efficiency for conductive metals; waterjet handles non-conductive or heat-sensitive materials

Many successful fabrication shops eventually incorporate multiple technologies, starting with the system that addresses their most common projects. As capabilities expand, adding complementary cutting methods covers more ground and opens new opportunities.

Understanding these fundamental differences prepares you to select cutting parameters specific to your chosen material - which requires careful attention to each metal's unique properties and behaviors.

Material-Specific Cutting Parameters for Every Metal Type

Ever loaded a beautiful piece of titanium into your CNC machine only to destroy your cutting tool within seconds? Material-specific parameters make the difference between precision parts and expensive scrap. Each metal brings unique challenges - from aluminum's tendency to gum up tools to stainless steel's work-hardening behavior. Let's dive into what actually works for each material.

Aluminum Cutting Parameters and Challenges

Aluminum sheet metal ranks among the most CNC-friendly materials you'll encounter. Its relatively low tensile strength (typically 70-700 MPa depending on alloy) allows aggressive cutting speeds that would destroy tools in harder metals. However, don't let this ease fool you into carelessness.

Recommended parameters for aluminum cutting:

- Cutting speed: 200-400 meters per minute - significantly higher than steel

- Feed rate: Aggressive feeds work well; calculate using chip load of 0.05-0.15mm per tooth

- Tooling: Two or three-flute end mills maximize chip evacuation

- Coolant: Flood coolant or mist prevents built-up edge formation

Common pitfalls with aluminum include:

- Chip welding: Aluminum's softness causes it to stick to cutting edges, creating built-up edge that degrades surface finish

- Insufficient chip evacuation: Using too many flutes traps chips in the cut, causing re-cutting and heat buildup

- Wrong alloy assumptions: 6061-T6 machines differently than cast aluminum - verify your specific alloy's properties

For aluminum welding applications where cut edges will be joined, prioritize edge quality over speed. Slower feeds with sharp, coated tools produce cleaner surfaces that weld more reliably.

Steel and Stainless Steel Machining Considerations

Steel demands respect. Its higher tensile strength requires reduced speeds and careful attention to heat management. When working with stainless steel sheet metal, the challenges multiply due to work-hardening behavior.

Standard carbon steel parameters:

- Cutting speed: 60-120 meters per minute for mild steel

- Feed rate: Moderate feeds prevent excessive heat generation

- Tooling: Carbide end mills with TiAlN coating resist wear

- Coolant: Essential for heat control and tool life extension

316 stainless steel requires special attention. According to machining experts, this austenitic grade work-hardens rapidly, meaning hesitation or dwelling creates a hardened surface layer that accelerates tool wear dramatically.

Critical stainless steel guidelines:

- Cutting speed: 40-80 meters per minute - lower than carbon steel

- Feed rate: Maintain consistent engagement; never let the tool rub

- Depth of cut: Take deeper passes rather than multiple light passes to cut below work-hardened layers

- Tool sharpness: Replace tools before they dull; worn edges generate excessive heat

Post-processing options for stainless include brushing, electropolishing, mechanical polishing, and sandblasting - each affecting corrosion resistance and aesthetic appearance differently.

Working with Titanium and Exotic Alloys

Titanium CNC machining represents the pinnacle of cutting challenges. This aerospace favorite combines high strength-to-weight ratio with notoriously difficult machinability. Its low thermal conductivity means heat concentrates at the cutting edge rather than dissipating through the workpiece.

Titanium machining parameters:

- Cutting speed: 30-70 meters per minute - significantly slower than aluminum or steel

- Feed rate: Maintain adequate chip load to prevent rubbing and work-hardening

- Tooling: Sharp carbide tools with specialized coatings; consider end mills designed specifically for titanium

- Coolant: High-pressure coolant delivery directly to the cutting zone is essential

Common titanium machining mistakes:

- Excessive speed: Generates heat that rapidly degrades tool coatings

- Dwelling: Creates work-hardened spots that destroy subsequent tool passes

- Inadequate rigidity: Titanium's springback tendency amplifies any machine or workholding flex

- Ignoring chip color: Blue or purple chips indicate excessive heat - reduce speed immediately

Inconel, Hastelloy, and other nickel-based superalloys present similar challenges with even stricter requirements for tool quality and cutting parameters.

Brass and Copper Soft Metal Strategies

Soft metals like brass and copper offer excellent machinability but introduce their own quirks. When comparing brass vs bronze, brass typically machines more easily due to its zinc content, while bronze's tin content increases hardness.

According to TFG USA's brass machining research, recent studies show brass is capable of far more intensive machining than previously thought possible. The material's softness and stability make it ideal for precision parts.

Brass cutting parameters:

- Cutting speed: High speeds work well; brass handles aggressive parameters

- Feed rate: Adjusting feed rate controls chip formation - critical for preventing long, ribbon-shaped chips that damage machines

- Tooling: Carbide tools with positive rake angles minimize burr formation

- Coolant: Often optional; many brass alloys cut well dry

Copper machining considerations:

- Gummy behavior: Pure copper tends to stick to tools more than brass

- Tool geometry: Sharp edges with polished flutes reduce material adhesion

- Feed rate adjustment: Higher feeds can help break chips rather than creating strings

- Surface finish: Achieve excellent finishes with proper speeds and sharp tooling

Both brass and copper benefit from positive rake angles that shear material cleanly rather than pushing it. Burr formation remains a common challenge - solved through proper cutting speed selection and sharp, high-quality tooling.

Understanding these material-specific parameters sets the foundation, but selecting the right cutting tools and coatings amplifies your results significantly.

Selecting the Right Cutting Tools and Coatings

You've dialed in your material parameters perfectly - but are you sabotaging your results with the wrong tooling? The cutting tool you select determines everything from surface finish quality to how many parts you'll produce before replacing that expensive end mill. Let's decode the tooling decisions that separate amateur results from professional-grade CNC metal milling.

End Mill Types and When to Use Each

Not all end mills are created equal. The material your tool is made from directly impacts performance, tool life, and which metals you can successfully machine.

High Speed Steel (HSS) provides good wear resistance at the lowest cost. According to MSC's end mill guide, HSS works well for general-purpose milling of both ferrous and nonferrous materials. It's your entry point for hobbyist projects and light-duty applications.

Cobalt (M-42: 8% Cobalt) steps up performance significantly. This material offers higher wear resistance, hot hardness, and toughness than standard HSS. You can run cobalt tools approximately 10% faster than HSS equivalents, making them ideal for machining cast iron, steel, and titanium alloys when budget constraints prevent carbide investment.

Solid Carbide represents the professional standard for CNC milling metals. These tools offer superior rigidity and heat resistance, running 2-3 times faster than HSS in many applications. Carbide square end mills excel at precision slotting and profiling in cast iron, nonferrous metals, plastics, and tough materials. However, heavy feed rates are better suited to HSS or cobalt tools due to carbide's brittleness under shock loading.

Powdered Metal (PM) bridges the gap between HSS and solid carbide. More durable and cost-effective than solid carbide with high resistance to breakage, PM tools perform excellently in materials under 30 RC hardness and in high-shock roughing applications.

- General purpose work: HSS or cobalt for budget-conscious shops

- High-speed aluminum machining: Solid carbide with polished flutes

- Steel and stainless: Coated carbide for optimal tool life

- Heavy roughing: Powdered metal or cobalt for shock resistance

- Finishing passes on anodized aluminum: Sharp carbide with appropriate coatings prevents coating damage

Coating Technologies Explained

Think of tool coatings as armor for your cutting edges. The right coating can extend tool life dramatically while enabling higher cutting speeds. But choosing incorrectly wastes money or limits performance.

According to coating performance research, proper coating selection improves production efficiency by 20% to 70%, raises machining accuracy by 0.5 to 1 grade, and reduces tool wear costs by 20% to 50%.

TiN (Titanium Nitride) - The gold-colored classic coating with hardness around 2000-2500 HV. TiN works well for general machining at low to medium speeds but wears faster during high-speed cutting. It's your versatile, cost-effective default choice for mixed production including steel, aluminum, and plastics.

TiAlN (Titanium Aluminum Nitride) - The high-performance option with hardness exceeding 3000 HV. At elevated temperatures, TiAlN forms a protective aluminum oxide layer that significantly enhances thermal stability. This coating tolerates temperatures above 800°C, making it ideal for high-speed cutting and dry machining of steel and hard alloys. TiAlN delivers multiple times longer cutting life than TiN when machining challenging materials.

DLC (Diamond-Like Carbon) - Features extremely low friction coefficient (approximately 0.1-0.15), making it perfect for non-ferrous metals. DLC greatly reduces cutting resistance and achieves smoother surface finishes. However, it degrades above 350°C, making it unsuitable for prolonged steel machining. Choose DLC for high-speed aluminum and copper work where surface quality matters most.

- High-volume steel machining: TiAlN coating for heat resistance and longevity

- Aluminum and copper: DLC coating for low friction and excellent finish

- Multi-purpose mixed production: TiN coating for balanced performance and cost

- Parts requiring powder coat finish: DLC-coated tools minimize burrs that show through final coating

Flute Count Selection for Different Metals

How many flutes should your end mill have? This seemingly simple question dramatically affects chip evacuation, surface finish, and feed rates. Getting it wrong means either clogged cuts or unnecessarily slow production.

According to CNC Cookbook's comprehensive analysis, the general rule is to use 4 flutes for machining steel and harder alloys, while 2 flutes work best for aluminum and non-ferrous materials.

2-Flute End Mills: Designed for softer materials like aluminum and plastics. The larger flute valleys provide superior chip evacuation and higher material removal rates. Solid carbide 2-flute end mills offer excellent performance for slotting operations where chips need to escape efficiently. These also work well when machining delrin and other engineering plastics.

3-Flute End Mills: A performance-enhancing alternative to 2-flute designs. The extra flute enables faster feed rates for a given surface speed, making them ideal for aluminum roughing applications where you want maximum material removal.

4-Flute End Mills: Built for harder materials like steel, stainless steel, and iron. More flutes mean a larger core and increased tool strength. Four-flute designs deliver smoother finishes and handle high-speed cutting of hard materials efficiently. They're your go-to choice for general-purpose cutting and finishing work in ferrous metals.

High Flute Count (5+ flutes): Reserved for really tough materials such as titanium, high-temperature nickel alloys, and stainless steels. Since these materials can't be spun fast without burning cutters, having more flutes keeps feedrates up so material removal rates remain acceptable despite lower spindle speeds.

Here's a sneaky trick for text milling and peripheral operations in aluminum: you may get away using 4 flutes when only the side of the end mill engages the material. Since chips aren't trapped in a tight slot, evacuation remains adequate while feed rates increase.

Kerf Width and Dimensional Accuracy

Every cutting tool removes material - and that removal width (kerf) directly affects your final part dimensions. Understanding kerf compensation prevents undersized or oversized parts.

Tool diameter determines kerf width in milling operations. A 1/4" end mill creates cuts approximately 1/4" wide, but tool deflection under cutting forces can widen this slightly. Worn tools also cut wider as edges degrade.

Program your toolpaths accounting for:

- Tool radius offset: CAM software compensates automatically when properly configured

- Tool wear allowance: Build in tolerance for gradual diameter reduction

- Material springback: Some metals flex during cutting, affecting final dimensions

Coolant and Lubrication Strategies

Proper coolant application extends tool life, improves surface finish, and enables faster cutting parameters. Different operations demand different approaches.

- Flood coolant: Best for steel and stainless steel machining; continuous stream removes heat and flushes chips

- Mist coolant: Suitable for aluminum; provides lubrication without thermal shock concerns

- Minimum quantity lubrication (MQL): Environmentally friendly option applying precise lubricant amounts directly to cutting zones

- Dry machining: Viable for brass and some aluminum alloys; requires TiAlN-coated tools designed for high temperatures

- High-pressure coolant: Essential for titanium and exotic alloys; delivers coolant directly to cutting edge for maximum heat extraction

With proper tooling selected and coated for your specific materials, the next critical factor becomes how you hold that workpiece securely during cutting operations.

Workholding Solutions That Ensure Cutting Accuracy

Have you ever watched a perfectly programmed cut go wrong because the material shifted mid-operation? Workholding failures account for more scrapped parts than most machinists care to admit. The reality is simple: even the best tooling and parameters mean nothing if your metal plate moves during cutting. Let's explore the fixturing strategies that keep your workpiece exactly where it needs to be.

Clamping Strategies for Sheet Metal

Traditional edge clamping creates immediate problems with thin materials. According to DATRON's machining research, thin sheets are inherently less rigid, making edge clamping nearly impossible without the sheet lifting or shifting during machining. The end mill's cutting forces tend to pull material upward, causing movement and inaccuracies.

Operators often compensate by running machines at slower speeds - sacrificing productivity to manage workholding limitations. This isn't solving the problem; it's just working around it poorly.

Effective clamping strategies for different thicknesses:

- Thin gauge sheet (under 3mm): Avoid point-loading with traditional clamps; distributed holding methods work better

- Medium thickness (3-12mm): Toe clamps with soft jaws or stepped clamps positioned strategically

- Thick steel plates (12mm+): Standard mechanical clamping with adequate torque works reliably

- Galvanized sheet metal: Use protective pads to prevent coating damage at clamp contact points

The bending and warping challenges multiply when improper clamping introduces stress into thin materials. Research from thin-wall machining studies shows that traditional hard jaws concentrate load at a few points, causing local distortion under the clamp that remains as permanent bow or twist after release.

Vacuum Tables and Magnetic Fixtures

When you need uniform holding pressure across an entire steel plate or sheet, vacuum fixtures deliver remarkable results. These systems - typically aluminum chucks with meandering grooves - hold sheets quickly and firmly when connected to adequate vacuum pressure.

One aerospace shop machines 1.2mm thick aluminum skins on vacuum chucks, achieving flatness within 0.03mm after roughing and finishing - compared to 0.15mm with edge clamps. That's a five-fold improvement in accuracy simply by changing the holding method.

However, vacuum tables have a critical limitation: you cannot cut completely through the material within the sealed area without losing vacuum. This requires either secondary operations or alternative approaches for through-cutting.

Advanced vacuum solutions now overcome this limitation. Systems featuring permeable sacrificial layers allow complete profile cutting while maintaining hold on small parts. The vacuum pulls through the permeable material, securing the sheet regardless of whether cuts penetrate completely through.

Magnetic fixtures offer another solution for ferrous steel plates. These provide instant clamping without setup time, but work only with magnetic materials - eliminating aluminum, brass, and stainless steels from consideration.

Custom Jig Design Principles

Sometimes standard solutions don't fit your specific geometry. Conformal fixtures that follow the exact shape of your part distribute holding forces across large contact areas, keeping point loads low.

A medical device manufacturer using epoxy-filled conformal fixtures for titanium implant housings with 0.8mm walls reduced distortion from 0.12mm to 0.02mm - an 83% improvement in dimensional accuracy.

Follow this step-by-step fixturing setup process for optimal results:

- Analyze your part geometry - Identify thin sections, tall features, and areas prone to deflection during cutting

- Select primary holding method - Choose vacuum, mechanical, or magnetic based on material and thickness

- Design support locations - Position supports directly beneath cutting zones to minimize deflection

- Verify clamping force distribution - Ensure no single point receives excessive pressure that causes local deformation

- Test with trial cuts - Run sample parts and measure for distortion before production

- Monitor during production - Check vacuum levels, clamp torque, or magnetic hold periodically

Modular pin-type fixtures allow quick adjustment for varying geometries. Adjustable pins with spherical tips support ribs and webs at multiple points, with force per pin limited to 10-20N. An automotive supplier machines aluminum battery trays this way, holding ±0.025mm on 1.5mm walls after full contouring.

Temporary supports - sacrificial webs or tabs left in place during roughing - add stiffness exactly where needed. Remove them during finishing operations. This staged approach prevents distortion during aggressive material removal while maintaining precision for final dimensions.

With your workpiece properly secured, understanding the precision tolerances each cutting method actually achieves helps set realistic expectations for your finished parts.

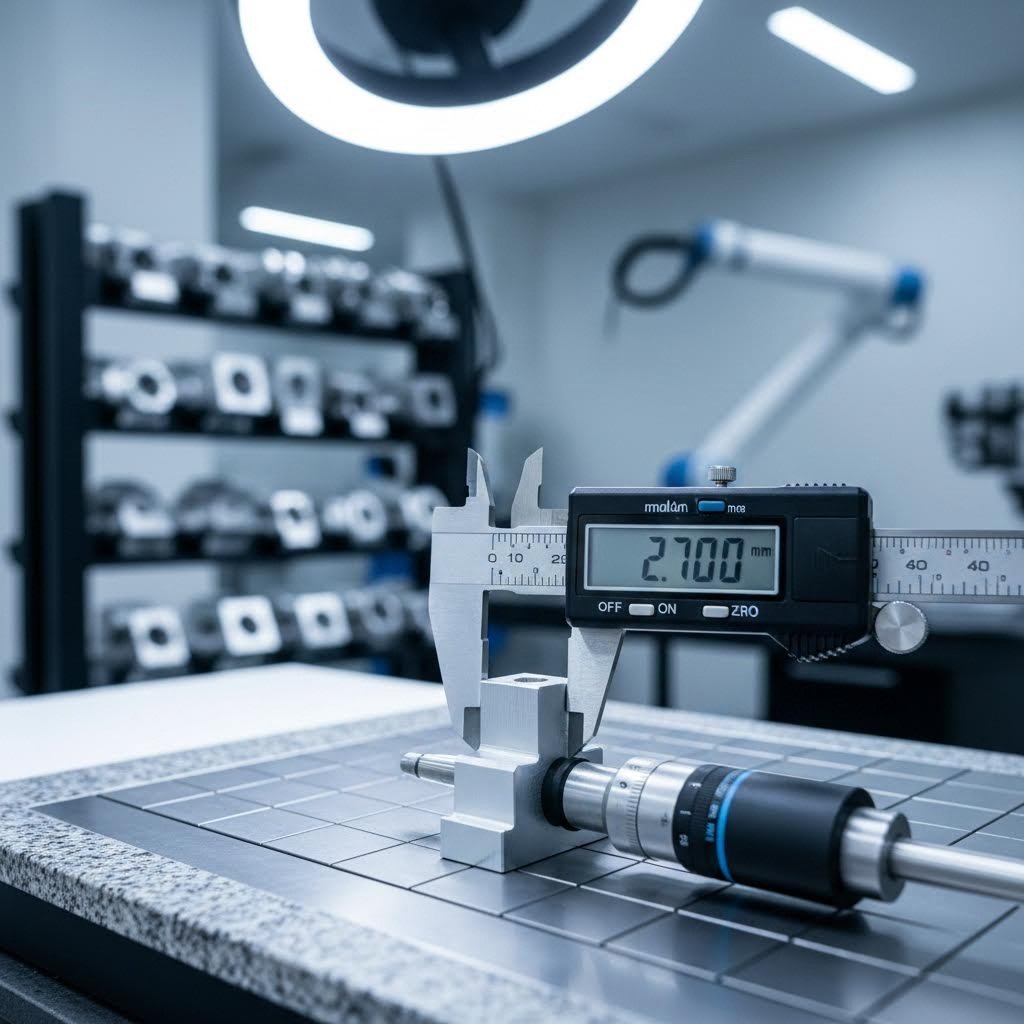

Understanding Precision and Tolerance Capabilities

What tolerance do you actually need - and can your chosen cutting method deliver it? This question determines whether your parts fit perfectly or end up as expensive scrap. Understanding achievable tolerances before committing to a cutting approach saves time, money, and frustration.

Tolerances define the acceptable deviation from a desired dimension in a manufactured part. The tighter the tolerance, the more precise the machining process needs to be - and the higher the associated costs.

Achievable Tolerances by Cutting Method

Each CNC cutting technology delivers different precision levels based on its fundamental operating principles. According to Fabricast's tolerance research, the choice of cutting method directly affects how tight tolerances can be, depending on tool wear, machine control, material type, and process variables.

| Cutting Method | Typical Tolerance Range | Best-Case Tolerance | Notes |

|---|---|---|---|

| Laser Cutting | ±0.003" - 0.005" | ±0.001" | Heat-affected zone may influence thin materials |

| Plasma Cutting | ±0.015" - 0.030" | ±0.010" | Better suited for thick plate than precision work |

| Waterjet Cutting | ±0.003" - 0.010" | ±0.001" | No thermal distortion; excellent for heat-sensitive metals |

| CNC Milling | ±0.001" - 0.005" | ±0.0005" | Highest precision available; requires proper setup |

| EDM/Wire EDM | ±0.0002" - 0.001" | ±0.0001" | Ultra-precision for micro-scale components |

When reviewing a sheet metal gauge chart to determine material thickness, remember that gauge sizes affect achievable tolerances. For example, 14 gauge steel thickness (approximately 0.075") responds differently to cutting forces than heavier 11 gauge steel thickness (approximately 0.120"). Thinner materials deflect more easily, potentially widening tolerance bands.

Factors That Affect Dimensional Accuracy

Even with high-precision CNC machines, maintaining tight tolerances isn't always straightforward. According to industry tolerance analysis, small deviations can accumulate and cause major issues in part functionality, fit, and assembly.

Critical factors influencing your results include:

- Material properties: Softer or more ductile materials may deform during cutting, affecting final dimensions

- Machine rigidity: Vibration or backlash in mechanical components introduces variation

- Tool wear: Gradual degradation of tool sharpness increases dimensional variation over production runs

- Thermal effects: Heat from laser or plasma cutting causes warping or expansion

- Operator skill and setup: Proper calibration and fixturing remain crucial regardless of machine quality

Temperature deserves special attention. Metal expands when heated - a phenomenon that affects both the workpiece during cutting and measurements afterward. A part measured immediately after laser cutting may read differently once cooled to room temperature. Professional shops control ambient temperature and allow parts to stabilize before final inspection.

Just as a drill bit size chart helps you select the right tool for hole-making operations, understanding tolerance capabilities helps you match cutting methods to project requirements.

When Precision Matters Most

Not every application demands ultra-tight tolerances. Matching precision requirements to actual functional needs prevents overspending on unnecessary accuracy.

Decorative applications - Custom metal signs, artistic pieces, and architectural elements typically accept wider tolerances (±0.030" or looser). Visual appearance matters more than dimensional precision, making plasma cutting a cost-effective choice.

General fabrication - Structural components, brackets, and enclosures usually require ±0.010" to ±0.015" tolerances. Laser cutting or waterjet handles these applications efficiently.

Precision assemblies - Parts that must fit together or interface with other components need ±0.005" or tighter. CNC milling typically delivers these results reliably.

Critical components - Aerospace, medical, and automotive parts often require tolerances below ±0.001". These applications justify EDM processes or precision CNC milling with extensive quality control measures.

Industry standards provide guidance for specific sectors. ISO 2768 sets standard tolerance ranges based on part size and precision level required. ASME Y14.5 structures geometric tolerancing for complex assemblies. Aerospace (AS9100) and medical (ISO 13485) components follow strict protocols where dimensional accuracy directly affects safety.

Understanding what tolerances you actually need - and which cutting methods reliably achieve them - sets realistic expectations and guides smarter manufacturing decisions. With these precision fundamentals established, you're ready to match your specific project requirements to the optimal CNC cutting approach.

Choosing the Right CNC Cutting Approach for Your Project

You understand the cutting methods, material parameters, and tolerance capabilities - but how do you actually decide which approach fits your specific situation? This is where many projects stall. The best cnc machine for metal work isn't necessarily the most expensive or most capable option; it's the one that matches your unique requirements for precision, volume, and budget.

Think of this decision like choosing transportation. A sports car, pickup truck, and delivery van all move you from point A to B - but selecting the wrong vehicle for your specific task creates problems. The same logic applies when selecting a cnc machine for metal projects.

Matching Your Project to the Right Method

Start by asking the right questions about your specific application. According to Zintilon's fabrication research, selecting the appropriate cutting method dictates final product quality, production efficiency, cost-effectiveness, and material utilization.

Use this decision criteria checklist to narrow your options:

- Material type and thickness: What metal are you cutting, and how thick is it? Thin aluminum sheet points toward laser cutting, while 1-inch steel plate favors plasma.

- Precision requirements: Do you need ±0.001" tolerances for aerospace components, or will ±0.030" work for structural brackets?

- Heat sensitivity: Will thermal cutting methods damage your material's properties? Heat-treated alloys and certain stainless steels may require waterjet's cold-cutting process.

- Edge quality needs: Must edges be weld-ready immediately, or can you budget for secondary finishing operations?

- Design complexity: Simple profiles cut efficiently with plasma, while intricate patterns and small features demand laser precision.

- Downstream operations: Consider how cut edges affect subsequent bending, welding, or finishing processes.

A cnc metal cutting machine excels when you need repeatability across identical parts. But if you're cutting one-off prototypes with frequent design changes, the flexibility of your chosen method matters more than raw cutting speed.

Budget Considerations and Cost Factors

The true cost of CNC cutting extends far beyond the initial equipment investment. According to Wurth Machinery's analysis, choosing the wrong technology can cost thousands in wasted material and lost time.

Factor these economic considerations into your decision:

- Initial capital investment: Complete plasma systems run approximately $90,000, while comparable waterjet systems cost around $195,000. Laser systems fall somewhere between depending on power and features.

- Operating costs per foot: Plasma cutting thick steel costs roughly half as much per foot as waterjet cutting the same material.

- Consumable expenses: Waterjet consumes abrasive media continuously; plasma uses electrodes and nozzles; laser requires gas and optics maintenance.

- Material waste: Kerf width varies by method - laser's narrow kerf maximizes material yield compared to plasma's wider cut.

- Secondary operation costs: Rough plasma edges may require grinding before welding, adding labor and time.

- Energy consumption: Laser cutting generally operates more energy-efficiently than plasma or oxy-fuel processes.

Don't solely focus on per-cut cost. Factor in setup time, potential material waste due to errors, and expenses for required secondary operations like deburring or cleaning. A machine cutter metal system that produces clean edges at moderate speed often beats a faster alternative requiring extensive post-processing.

Production Volume and Turnaround Needs

Your production quantity dramatically influences which cnc machines for metal make economic sense. According to Prototech Laser's manufacturing research, the scale of production directly influences the economic viability of various cutting methods.

Prototype and low-volume production (1-50 parts):

- Flexibility matters more than raw speed

- Setup time represents a larger percentage of total project cost

- Waterjet and manual plasma offer versatility without extensive programming

- CNC machining eliminates expensive tooling - the same machine produces completely different parts by changing the digital program

Medium-volume production (50-500 parts):

- Balance between setup investment and per-part efficiency

- Automated laser cutting maximizes throughput while maintaining precision

- Consider dedicated fixturing to reduce setup time between batches

High-volume production (500+ parts):

- Per-unit cost optimization becomes critical

- Automated systems with rapid material handling justify higher capital investment

- High-speed punching or laser cutting with automatic sheet loading maximizes productivity

- Setup time becomes negligible when amortized across thousands of parts

When Dual-Functionality Makes Sense

Should you invest in one versatile cnc machine metal system or multiple dedicated solutions? This question deserves careful analysis based on your typical project mix.

Consider dual-functionality machines when:

- Your projects span multiple material types and thicknesses

- Shop floor space limits equipment footprint

- Capital budget restricts multiple equipment purchases

- Job variety prevents consistent utilization of specialized equipment

Dedicated cutting solutions make more sense when:

- You specialize in specific material types or thickness ranges

- Production volume justifies equipment running near capacity

- Precision requirements exceed what combination machines achieve

- Downtime for maintenance on one function shouldn't stop all production

Many successful fabrication shops start with one technology addressing their most common projects. As business grows, adding complementary cutting methods expands capabilities and client base. Plasma and laser often pair well - plasma handles thick structural work while laser delivers precision on thin sheet. Waterjet adds versatility for heat-sensitive materials and non-metals that neither plasma nor laser can address.

The right choice ultimately aligns technology with your specific requirements - material types, thickness ranges, precision needs, and budget constraints. With the right CNC cutting approach selected, your next consideration becomes the equipment scale that matches your production environment and growth trajectory.

Equipment Options from Hobbyist to Industrial Scale

You've selected your cutting method and understand the parameters - but what equipment actually delivers results at your scale? The gap between a desktop cnc machine for metal and an industrial production system spans not just price tags but capabilities, space requirements, and realistic expectations. Let's explore what each equipment tier actually offers.

Desktop CNC Options for Small Shops

Can a home cnc machine for metal really produce quality parts? The honest answer: it depends on your expectations and material choices. According to CanCam's metal cutting research, CNC routers can certainly cut metal - but not all routers are well-suited to this task.

A metal cnc router designed for woodworking requires significant adjustments when processing metals. These machines typically feature lighter frames, smaller spindles, and cooling systems optimized for dust rather than metal chips. However, purpose-built desktop systems now bridge this gap effectively.

What desktop metal cnc machine systems deliver:

- Aluminum and brass machining: Soft metals machine well on quality desktop units with proper feeds and speeds

- Light steel work: Thin gauge steel possible with carbide tooling and conservative parameters

- Prototype development: Excellent for testing designs before committing to production runs

- Small batch production: Cost-effective for quantities under 50 parts

Realistic limitations include:

- Rigidity constraints: Lighter frames deflect under cutting forces, limiting depth of cut and precision

- Spindle power: Typically 1-3 HP motors restrict material removal rates

- Work envelope: Smaller tables limit maximum part size

- Speed trade-offs: Forum discussions frequently highlight that cnc router for metal applications run significantly slower than dedicated milling machines

According to CNC Cookbook's equipment guide, a high-quality CNC router can be acquired for less than $2,000 - making entry-level cnc metal work accessible to hobbyists and small shops. However, expect to spend $5,000-$15,000 for machines specifically designed to handle metal reliably.

Industrial-Grade Cutting Systems

When production demands consistent output across thousands of parts, industrial sheet metal cnc machine systems justify their higher investment. These machines feature robust construction, powerful spindles, and automation capabilities that desktop units simply cannot match.

Industrial CNC milling centers offer spindles ranging from 10-50+ HP with rigid machine frames weighing thousands of pounds. This mass absorbs vibration and maintains accuracy under aggressive cutting conditions. Multi-axis configurations enable complex geometries impossible on simpler machines.

Plasma and laser cutting systems scale similarly. Entry-level CNC plasma cutting machines start around $5,000 according to industry sources, while production-grade systems with automated material handling reach $50,000-$150,000. Laser cutting equipment spans an even wider range - from $5,000 for basic CO2 systems to $300,000+ for high-power fiber lasers with automated loading.

Industrial advantages include:

- Continuous operation: Built for multi-shift production without overheating or wear issues

- Precision maintenance: Rigid construction holds tolerances across production runs

- Automation integration: Robotic loading, pallet changers, and automatic tool changers minimize operator intervention

- Material handling: Larger tables accommodate full sheet sizes and heavy plates

Equipment Comparison by Capability

This comparison helps you identify which equipment tier matches your requirements:

| Factor | Desktop/Hobbyist | Small Shop/Professional | Industrial Production |

|---|---|---|---|

| Investment Range | $2,000 - $15,000 | $15,000 - $75,000 | $75,000 - $500,000+ |

| Typical Materials | Aluminum, brass, thin steel | Steel, stainless, aluminum | All metals including titanium |

| Work Envelope | 12" x 12" to 24" x 36" | 24" x 48" to 48" x 96" | Full sheet capacity and larger |

| Production Volume | Prototypes, 1-50 parts | Small batches, 50-500 parts | High volume, 500+ parts |

| Space Required | Garage corner, small room | Dedicated shop space | Industrial facility |

| Power Requirements | Standard 110V/220V outlets | 220V dedicated circuits | 3-phase industrial power |

| Skill Level Needed | Beginner to intermediate | Intermediate to advanced | Professional operators |

| Typical Applications | Hobby projects, custom parts | Job shop work, small production | OEM manufacturing, high-volume |

Scaling Up Your Metal Cutting Capabilities

Growth rarely happens overnight - and neither should equipment investment. Smart scaling matches capability expansion to actual demand rather than anticipated needs.

Consider this progression path:

- Start with versatility: A quality metal cnc machine handling multiple materials beats specialized equipment sitting idle

- Identify bottlenecks: Track where your current equipment limits throughput or capability before investing

- Add complementary technology: If your cnc metal router handles aluminum well but struggles with steel, adding plasma cutting expands capability without replacing existing assets

- Invest in automation incrementally: Automatic tool changers, probing systems, and material handling improve productivity on existing machines before requiring new capital equipment

Space planning matters as much as budget. A metal cnc machine requires not just its footprint but clearance for material loading, chip management, and operator access. Industrial equipment often needs dedicated ventilation, compressed air systems, and coolant management infrastructure.

Power requirements escalate with machine capability. Desktop systems run on standard household circuits, but industrial CNC milling centers demand three-phase power that may require electrical service upgrades costing thousands before the machine even arrives.

Skill development parallels equipment investment. A $100,000 machine in unskilled hands produces expensive scrap. Many manufacturers offer training programs, and local community colleges provide CNC programming courses that build operator competence before equipment exceeds capabilities.

Whether you're outfitting a garage workshop or expanding an industrial facility, matching equipment to realistic production needs prevents both underinvestment that limits capability and overinvestment that strains budgets. With the right equipment selected and operating, you're ready to take your metal cutting projects from concept to completion.

Taking Your Metal Cutting Projects to the Next Level

You've absorbed the fundamentals of metal CNC cutting - from material parameters and tooling selection to equipment options and tolerance capabilities. Now comes the exciting part: putting this knowledge into action. Whether you're launching your first project or scaling an existing operation, the path forward requires strategic decisions about where your capabilities end and where professional partnerships begin.

Getting Started with Your First Metal Cutting Project

Ready to make chips? Before loading material into your machine, follow this systematic approach to maximize your chances of first-part success. According to CNC Cookbook's beginner resources, understanding the complete workflow from design to finished part prevents costly mistakes that frustrate newcomers.

- Define your project requirements clearly - Document material type, thickness, required tolerances, and quantity needed before touching any equipment

- Create or obtain a proper CAD model - Ensure your digital design accounts for manufacturing realities like bend radii, kerf width, and tool access

- Select your cutting method based on project needs - Match material thickness and precision requirements to the appropriate technology as covered earlier

- Calculate feeds and speeds for your specific material - Use manufacturer recommendations as starting points, then adjust based on actual cutting conditions

- Set up proper workholding - Secure your material adequately to prevent movement during cutting operations

- Run a simulation or air cut first - Verify toolpaths before committing to actual material removal

- Start with test cuts on scrap material - Dial in parameters on inexpensive material before cutting your actual workpiece

- Inspect and measure results - Compare finished dimensions against specifications before proceeding to production quantities

For those creating custom metal signs or decorative pieces, tolerance requirements relax considerably. These projects make excellent starting points for developing CNC skills without the pressure of tight specifications. More demanding applications like precision brackets or assemblies require the systematic approach outlined above.

When to Partner with Professional Fabricators

Here's a truth many DIY enthusiasts resist: some projects simply exceed what home or small shop equipment can deliver. Recognizing when to partner with professional metal fabrication resources isn't admitting defeat - it's making smart manufacturing decisions.

According to Wiley Metal's analysis, outsourcing metal fabrication work offers significant advantages that go beyond simple capability matching. Professional fabricators invest in sophisticated machinery for cutting, bending, and welding - equipment costing six or even seven figures that they amortize across orders from a large customer base.

Consider professional sheet metal fabrication partnerships when:

- Tolerances exceed your equipment capability - Precision requirements below ±0.005" often demand industrial-grade machines

- Material thickness surpasses your machine's capacity - Thick steel plates require plasma or waterjet systems beyond typical shop equipment

- Volume exceeds practical in-house production - Production runs of hundreds or thousands justify professional efficiency

- Certified quality standards apply - Aerospace, automotive, and medical applications require documented quality systems

- Exotic materials present challenges - Titanium, Inconel, and specialized alloys demand experience and equipment most shops lack

Searching for "fabrication shops near me" or "metal fabricators near me" connects you with local resources. However, geographic proximity matters less than capability matching. A steel fabrication specialist across the country may serve your steel plate project better than a general shop around the corner.

Experience particularly matters when selecting fabrication partners. According to industry experts, an experienced fabricator can often look at part prints and suggest ways to improve appearance, cut costs, or raise quality - experience developed by working on a large number of different jobs for different customers using different materials.

For automotive applications requiring certified quality standards, partnering with IATF 16949-certified manufacturers ensures your chassis, suspension, and structural components meet industry requirements. Manufacturers like Shaoyi (Ningbo) Metal Technology offer comprehensive DFM support and rapid prototyping capabilities - delivering quotes within 12 hours and prototypes in as few as 5 days. This accelerates development cycles for complex metal cutting projects where design iteration and certified quality both matter.

Optimizing Your Manufacturing Workflow

Whether you're handling projects in-house or coordinating with external partners, workflow optimization maximizes results while minimizing waste and frustration.

According to Fictiv's prototyping research, applying Design for Manufacturability (DFM) principles early ensures both prototype and final production run smoothly. Use consistent bend radii, minimize tight tolerances where they aren't functionally necessary, and avoid overly complex geometries that increase cost without adding value.

For cnc machine for metal fabrication operations, consider these workflow enhancements:

- Standardize material procurement - Use common sheet sizes and standard thicknesses to reduce inventory complexity

- Nest parts efficiently - Maximize material utilization by optimizing part arrangement on sheet stock

- Document successful parameters - Create material-specific setup sheets for repeatable results on future jobs

- Build prototype-to-production pathways - Establish processes that scale from single prototypes to volume production without starting over

- Implement quality checkpoints - Catch issues early rather than discovering problems after completing entire batches

The prototype-to-production transition deserves special attention. According to sheet metal prototyping research, when enough prototypes are made, the line between prototyping and small-batch production starts to blur. Sheet metal prototyping eliminates the need for complex, expensive tooling, making it a practical and affordable option for low-volume production after final design approval.

Metal fabrication success ultimately comes down to matching capabilities with requirements - knowing when your equipment and skills handle a project confidently, and recognizing when professional partnerships deliver better results. The knowledge you've gained about cutting methods, material parameters, tooling selection, and precision capabilities positions you to make these decisions intelligently.

Your next step? Pick a project that matches your current capabilities, apply the systematic approach outlined above, and start making parts. Each completed project builds experience that expands what you can tackle confidently. And when projects exceed your practical limits, you now understand exactly what professional fabricators offer - and how to evaluate whether they're the right fit for your specific needs.

Frequently Asked Questions About Metal CNC Cutting

1. Can you cut metal with a CNC?

Yes, CNC machines cut metal effectively using multiple methods including milling, plasma, laser, and waterjet cutting. The best approach depends on your material type, thickness, and precision requirements. Softer metals like aluminum and brass work well on CNC routers with proper tooling, while harder metals like steel and titanium require more rigid machines, powerful spindles, and appropriate coolant systems. For automotive and industrial applications requiring certified quality, partnering with IATF 16949-certified manufacturers ensures precision across chassis, suspension, and structural components.

2. How much does CNC cutting usually cost?

CNC cutting costs vary based on complexity, materials, and production volume. Simple parts in small runs typically range from $10 to $50 per part, while complex precision-engineered components may cost $160 or more, especially for low-volume orders. Operating costs also differ by method - plasma cutting thick steel costs roughly half as much per foot as waterjet cutting the same material. Complete plasma systems run approximately $90,000 versus $195,000 for comparable waterjet systems, affecting your long-term cost structure.

3. Is CNC hard to learn?

CNC has a learning curve but isn't inherently difficult. The process involves three layers: creating designs in CAD software, converting designs to machine instructions via CAM programs, and operating the physical machine. Hobbyists can create simple parts within hours or days using tutorials and beginner-friendly software like Fusion 360. However, mastering CNC for professional production takes years of experience in programming, setup, and problem-solving. Starting with small machines and simple projects while utilizing online communities accelerates the learning process.

4. How much does a metal CNC machine cost?

Metal CNC machine prices span a wide range based on capability. Entry-level desktop CNC routers for hobbyists start around $2,000-$5,000, while purpose-built metal cutting desktop machines run $5,000-$15,000. Professional small shop equipment costs $15,000-$75,000. Entry-level CNC plasma cutting machines range from $10,000-$30,000, with mid-range systems at $30,000-$100,000. Industrial production systems with automation capabilities can exceed $500,000 depending on features and capacity.

5. What is the best CNC cutting method for thick metal plates?

For thick metal plates over 1 inch, plasma cutting dominates due to its speed and cost efficiency on conductive metals. Plasma handles materials from 0.5 inch to over 6 inches thick with operating costs significantly lower than laser or waterjet alternatives. However, if heat sensitivity is a concern or you need tighter tolerances, waterjet cutting works for materials up to 12 inches thick without thermal effects. For structural steel fabrication and heavy equipment manufacturing, plasma offers the best balance of speed, capability, and cost-effectiveness.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —