Hagyományos acéllap karok: igazi szilárdságuk feltárása

TL;DR

A sajtolt acél karok az autóipar alapértelmezett választása egy jó okból: kiváló szilárdságot nyújtanak, és költséghatékonyan előállíthatók, így tökéletesen tartósak a legtöbb gyári jármű számára normál üzemeltetési körülmények között. Azonban fő hátrányaik a jelentős súlyuk az alternatívákhoz képest, valamint az idővel kialakuló rozsdásodási hajlamuk, amely miatt a teljesítmény-rajongók és a kemény klímájú területeken élők gyakran könnyebb, rozsdamentesebb alumíniumot vagy erősebb, tuningolt acél megoldásokat fontolgatnak igénybevételt jelentő alkalmazásokhoz.

Az alapvonal szabványa: sajtolt acél lengéscsillapító karok megértése

Ha a legtöbb személygépkocsi és teherautó futóművét nézzük, amelyek az alapítósoron készülnek, valószínűleg laposacélból készült lengéscsillapító karokat találunk. Ezek az alkatrészek a jármű alvázának elismert munkásai, összekötik a keretet a kerekekkel, és biztosítják a stabilitást minden egyes bukkanón és kanyarban. A laposacélból készült lengéscsillapító kart úgy gyártják, hogy egy acélötvözet lemezt sablon segítségével adott formára sajtolnak. Ezt az eljárást, amelyet hidegalakításnak neveznek, nemcsak az alkatrész formálására használják, hanem anyagának szilárdságát is növeli, amit gyakran emlegetnek a mérnöki viták során.

A tervezés nem önkényes; a fémben kialakított görbék és csatornák merevséget biztosítanak, és megszüntetik az elhajlást, lehetővé téve, hogy egy viszonylag vékony fémlemez is kiválóan ellenálljon nagy erőknek. Ez a gyártási módszer költséghatékony megoldást jelent az autógyártók számára, és sok szakértő szerint elegendő szilárdságot nyújt a járművek szokásos alkalmazásaihoz. Napi használatra ezek az OEM alkatrészek úgy készültek, hogy megbízhatóan működjenek a jármű élettartama alatt, sőt maga az alkatrész gyakran túléli a benne lévő gumibelsőket.

Ez a folyamat rendkívül nagy pontosságot és speciális berendezéseket igényel, hogy minden alkatrész szigorú biztonsági és teljesítményszabványoknak megfeleljen. A jelen lévő vállalatok, mint például Shaoyi (Ningbo) Metal Technology Co., Ltd. , a jármipari ellátási lánc magas szintű gerincét képviselik, és mindenféle prototípustól kezdve a gyártók tömeggyártású sajtolt alkatrészeiig mindent szállítanak. Az összetett, tartós alkatrészek létrehozásában szerzett szakértelmük teszi lehetővé, hogy a sajtot acél megbízható, tömeges megoldásként funkcionáljon.

Népszerűségük ellenére a sajtolt acél alkatrészeket néha költségvetésbarát választásként érzékelik. Bár igaz, hogy olcsóbbak a nyomott alumíniumnál vagy az űrtött acélnál, ezeket erősre tervezték. Az átlagautóst illetően a sajtolt acél lengéscsillapító karok szilárdsága és tartóssága nem jelent problémát; úgy készültek, hogy kibírják a gödröket és a napi kopást hibásodás nélkül. A fő jellemzők a következőképpen foglalhatók össze:

- Költséghatékony: A sajtolt acél gazdaságos módja az erős, megbízható alkatrészek nagy mennyiségben történő előállításának.

- Magas nyers szilárdság: A hidegalakító eljárás és a tervezett forma jelentős merevséget és tartósságot biztosít az OEM igényeinek.

- Eredeti Gyári Szabvány: Ez az új járművek karosszériáinak leggyakoribb anyaga a kiegyensúlyozott tulajdonságai miatt.

- Nehezebb az alternatíváknál: Fő teljesítménybeli hátránya a súlya, ha összehasonlítjuk más anyagokkal, például az alumíniummal.

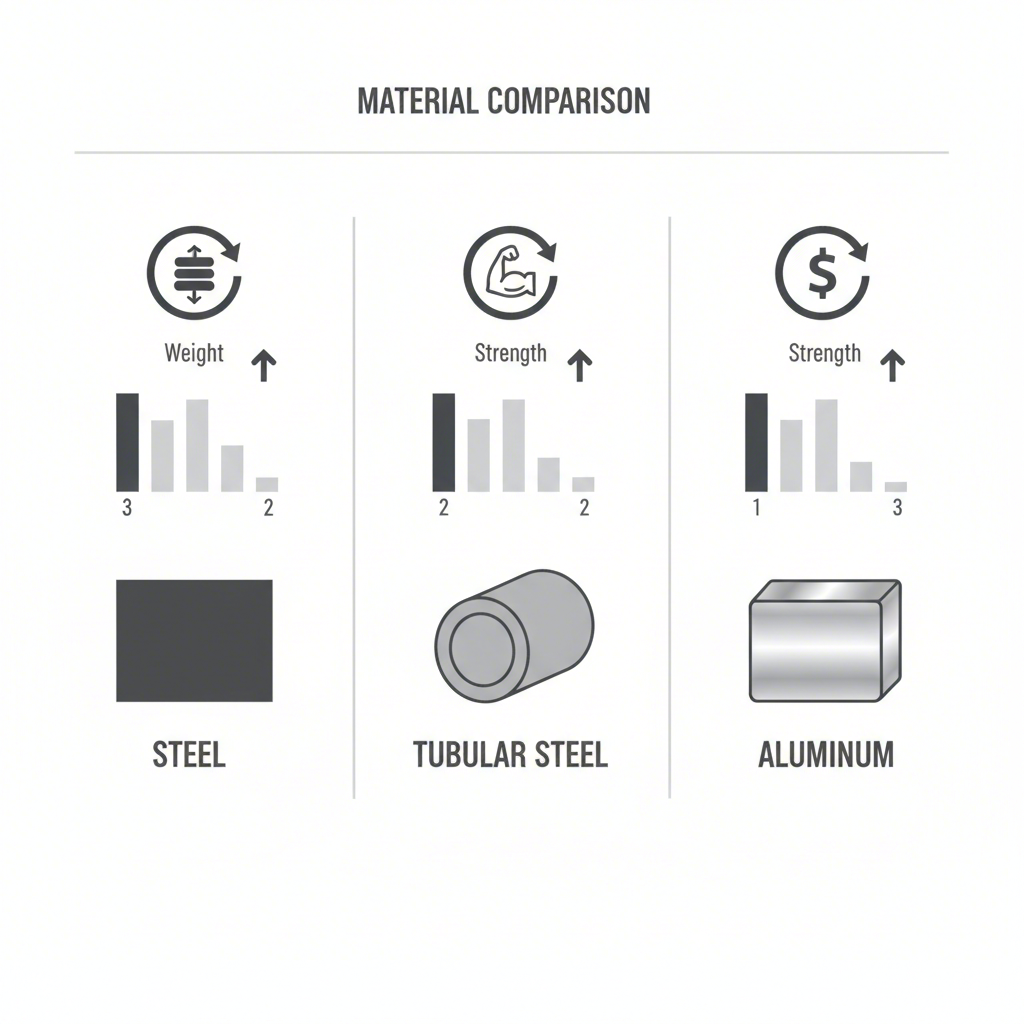

Anyagok összehasonlítása: Sajtolt acél vs. Alumínium és az utángyártott lehetőségek

Bár a sajtolt acél az üzemben használt alapanyag, az utángyártott piacon számos más anyag is elérhető, melyek mindegyikének megvannak az előnyei és hátrányai. A leggyakoribb összehasonlítás az acél és az alumínium között történik, de más lehetőségek, mint a csöves és a kovácsolt acél is léteznek, melyek speciális teljesítményigényeket elégítenek ki. A döntés végül is a járművön, a vezetési stíluson és a prioritásokon múlik.

A különféle formájú acél az erősségéért és tartósságáért kedvelt. Képes ellenállni ismétlődő terhelésnek és nagy súlyoknak, ezért a nehéz teherautók, csúszásos versenyautók és extrém erőhatások mellett történő használat esetén elsődleges választás. Emellett hőállósága is jobb, ami fontos tényező lehet a nagy teljesítményű fékrendszerek közelében. Az acél minden változatának fő hátránya a súly. Ez a többlettömeg, különösen az „nem rugózott tömeg” (a felfüggesztés által nem megtámasztott tömeg), csökkentheti a felfüggesztés reakciókészségét az út egyenetlenségei esetén.

Az alumínium a könnyűsúlyú bajnokként lép be a beszélgetésbe. Az alumínium irányítókarok 40–50 százalékkal könnyebbek lehetnek acéltársaiknál, ami jelentős tömegcsökkentést eredményez, javítja a kormányozhatóságot, növeli a futómű reakciókészségét, és jobb utazási komfortot biztosít. Ezért az alumínium különösen kedvelt a teljesítményorientált utcai használatban, autókeresztező versenyeken és országúti pályák alkalmazásainál, ahol a fürgeség kiemelten fontos. Egy másik nagy előnye a természetes korrózióállóság. Ellentétben az acéllal, amely védőréteget igényel a rozsdásodás megelőzéséhez, az alumínium védelmet nyújtó oxidréteget képez, így ideális választás olyan járművekhez, amelyek nedves vagy hóval borított éghajlaton közlekednek, ahol gyakori az útsó használata.

A különbségek tisztázása érdekében itt egy közvetlen összehasonlítás a leggyakoribb irányítókar-anyagok között:

| Anyag | Fontos előny | Fő hátrány | Legjobb használati eset |

|---|---|---|---|

| Sajtolással gyártott acél | Alacsony költség, magas termelési mennyiség, megfelelő alapvető szilárdság. | Nagy tömegű, rozsdásodásra hajlamos, alapvető teljesítmény. | Gyári alkalmazások, napi közlekedés, költségtudatos javítások. |

| Csöves acél | Erősebb és merevebb, mint a sajtolt acél, gyakran javított geometriával. | Még mindig nehéz az alumíniumhoz képest, és továbbra is rozsdásodhat. | Terepjárás, emelt raktári gépkocsik, nehézüzemű alkalmazások. |

| Tömör alumínium | Kiváló szilárdság-súly arány, kiváló korrózióállóság, javítja a kezelhetőséget. | Magasabb költség, extrém ütközés esetén kevésbé tartós, mint az acél. | Utcai teljesítmény, pályahasználat, kiállítási járművek, kemény klímájú területek. |

Végül is a döntés elsősorban a prioritások egyensúlyozásán múlik. Egy klasszikus izomautónál, amely nagy teljesítményű motorral rendelkezik, az acél szilárdsága lehet a legjobb választás. Egy modern sportautó esetében, amelyet hétvégenként használnak pályán, az alumínium súlycsökkentése érezhető teljesítménybeli előnyt jelent.

Tartósság és meghibásodási pontok: Élettartam és mikor érdemes frissíteni

Bár a préselt acél lengéscsillapító karokat normál körülmények között hosszú élettartamra tervezték, azok nem sérthetetlenek. Tartósságuk két fő tényező miatt csökkenhet: anyagfáradás és mechanikai igénybevétel módosított használat során. Ezeknek a gyenge pontoknak a megértése kulcsfontosságú ahhoz, hogy tudjuk, mikor nem elegendő egyszerű cserével pótolni, és szükség van fejlesztésre.

A legjelentősebb hosszú távú veszély, amely a acélt fenyegeti, a korrózió. A gyári védőbevonat ellenére az útról származó törmelék okozta karcolások és cikkek lehántolhatják a védelmet, így kivonva a nyers fémet. Olyan területeken, ahol erős esőzések vannak, vagy télen útsót használnak – az úgynevezett „Sóöv” – a rozsda megtelepedhet, és idővel gyengítheti a kar szerkezeti integritását. Rendszeres rozsdakeresés ésszerű karbantartási gyakorlat, mivel a haladott korrózió egyértelmű jele annak, hogy cserére van szükség.

A mechanikai hiba a másik fő aggály. Egyes járműtulajdonosok által megjegyzett konkrét gyengeség, hogy bizonyos szegecselt acél felső vezérlőkarok nem biztosítanak elegendő támaszt a gömbcsuklónak, ha az meghibásodik, ami súlyosabb felfüggesztési problémához vezethet. Továbbá, a jármű felfüggesztésének módosítása túlterhelheti a gyári karokat, és meghaladhatja azok tervezett működési határait. Egy teherautó vagy terepjáró emelése például megváltoztatja a felfüggesztés geometriáját. A gyári vezérlőkaroknak lehet, hogy nincs elegendő mozgástartománya az új szögek kiszolgálásához, ami megkötést, korai kopást okozhat a csapszegeknél és gömbcsuklóknál, valamint rossz futóképet eredményezhet. Egy útmutató szerint Shock Surplus , a felső vezérlőkarok cseréje gyakran szükséges a jármű felemelésekor, hogy kijavítsák a futóképet és helyreállítsák a megfelelő felfüggesztési mozgást.

Tehát mikor érdemes elgondolkodni a gyári acéltartók cseréjén? Egy frissítés akkor válik elengedhetetlenné, amikor a felfüggesztésre nehezedő igénybevétel meghaladja az eredeti tervezési paramétereket. Ha bármelyik alábbi jelenséget észleli, ideje lehet komolyabb utángyártott megoldásba fektetni.

Jelek, hogy szüksége van frissített lengéscsillapító karokra

- Jármű felemelése után: A legtöbb szakértő új felső vezérlőkarokat javasol 5 cm-nél nagyobb emelésnél, hogy kijavítsa a nyom és kúpszegelet beállítását.

- Nagyobb gumiabroncsok felszerelése: Nagyobb, nehezebb abroncsok növelik a felfüggesztés alkatrészeire ható terhelést, és szükségessé tehetik az utángyártott kar által biztosított korrigált geometriát.

- Gyakori terepen vagy pályán való használat: Az intenzív és ismétlődő terhelés, amely a nagy teljesítményű vezetésből adódik, erősebb anyagokat igényel, mint például csöves acél vagy könnyűfém.

- Látható sérülés vagy korrózió: Bármilyen repedés, hajlás vagy jelentős rozsdásodás azonnali jelzés, hogy az alkatrész megsérült.

- Gyenge kormányzás vagy igazítási problémák: Ha járműve imbolyog, a kormányzás laza érzetű, vagy nem tudja megtartani az igazítást, akkor a hibás vagy nem megfelelő kormányzókarok lehetnek az ok.

A Jogi Döntés a Járművéhez

A sajtolt acél, az alumínium vagy más utángyártott kormányzókarok közötti választás végül is a jármű felhasználási céljának és teljesítményelvárásainak őszinte mérlegelésén múlik. A legtöbb sofőr számára az eredeti sajtolt acél alkatrészek bizonyított erősségükkel és tartósságukkal egy egész élettartamra megbízható szolgáltatást nyújtanak. Ezek költséghatékony, mérnöki megoldások, amelyek minden probléma nélkül kielégítik a mindennapi vezetés igényeit.

Azonban amikor járművét speciális feladatokra kezdi módosítani – legyen szó javított pályaképességről, durva terepjáró képességekről vagy egyszerűen csak a kemény klímában való túlélésről – a sajtolt acél korlátai nyilvánvalóvá válnak. Ezekben az esetekben kerül előtérbe az utángyártott alkatrészek előnye. Egy alumínium kar élesebb kormányzási reakciókat biztosíthat és ellenáll a korróziónak, míg egy erős csöves acélkar brutális szilárdságot nyújthat extrém körülmények között.

A döntés meghozatala előtt fontolja meg költségvetését, vezetési szokásait és járművével kapcsolatos hosszú távú terveit. A megfelelő lengéscsillapító kar nem csupán egy cseredarab; ez egy fejlesztés, amelynek összhangban kell lennie konkrét igényeivel, így biztosítva a biztonságot és a teljesítményt a további úton.

Gyakran Ismételt Kérdések

1. Mágnesesek-e a hengerelt acélból készült lengéscsillapító karok?

Igen, a sajtolt acél lengéscsillapító karok mágnesesek. Mivel acélötvözetből készülnek, amely vasalapú fém, a mágnes hozzá tapad. Ezt gyakran használják egyszerű tesztként az alumínium lengéscsillapító karoktól való megkülönböztetésre, amelyek nem mágnesesek.

Kis szeletek, magas szabványok. Gyors prototípuskészítési szolgáltatásunk gyorsabbá és egyszerűbbé teszi az ellenőrzést —

Kis szeletek, magas szabványok. Gyors prototípuskészítési szolgáltatásunk gyorsabbá és egyszerűbbé teszi az ellenőrzést —