Bélyegzett acél lengőkar csere költsége: Részletes útmutató

Bélyegzett acél lengőkar csere költsége: Részletes útmutató

TL;DR

A bélyegzett acél vezérlőkar cseréjének költsége általában 400 és 1000 dollár felett mozog karonként. Ez az összeg magában foglalja a tartozékot, a munkadíjat, valamint a kötelező kerékbeállítást a beépítés után. A végső számla nagyban függ járműve márkájától és típusától, a helyi munkadíjakról, valamint attól, hogy egy hivatalos márkakereskedést vagy független szerelőt választ-e.

A bélyegzett acél vezérlőkar cseréjének költségeinek részletezése

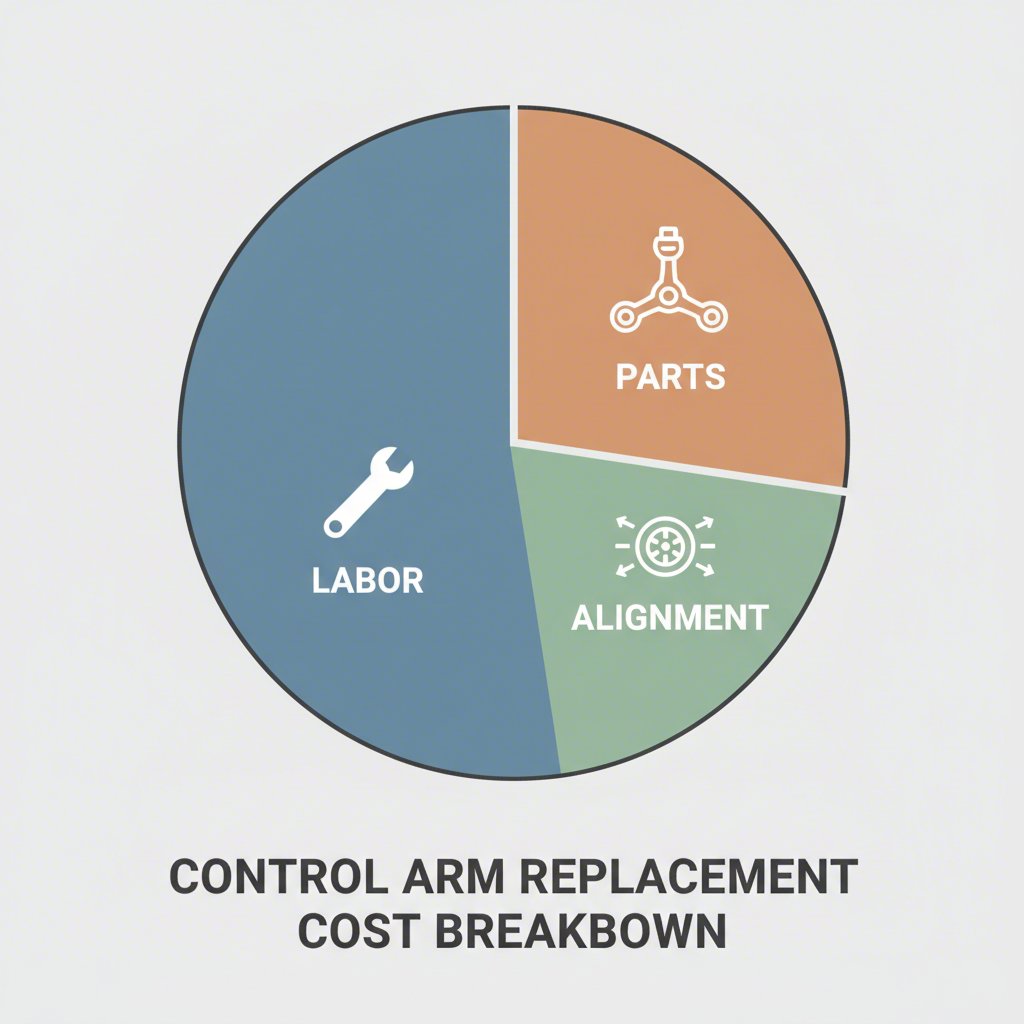

A vezérlőkar cseréjének végső árához három különálló összetevőt kell figyelembe venni: a tartozék, a munkadíj és a szükséges követő szolgáltatás. Mindegyik elem jelentősen hozzájárul a teljes költséghez, és az, hogy pontosan tudja, mire költi a pénzét, segíthet a hatékony költségvetésben és váratlan kiadások elkerülésében. A költség nem csupán egy darab fémre vonatkozik; hanem az egész folyamatra, amely járműve biztonságának és vezethetőségének helyreállítását szolgálja.

A karépítés maga az első jelentős változó. Gyakori járművek esetén egy minőségi utángyártott acéllemez kar meglehetősen megfizethető lehet. Azonban a luxus-, teljesítmény- vagy nehézüzemű járművek alkatrészei magasabb árat fognak igényelni. A munkadíj gyakran a számla legnagyobb részét teszi ki. A szerelők egy szabványos útmutatót, az úgynevezett „könyvidőt” használnak a munkához szükséges órák becslésére, amely általában 2–3 óra karéntként. Ez az óradíj jelentősen eltérhet a műhely helyétől és hírnevétől függően. Végül a kerekek beállítása nem egy opcionális felár; elengedhetetlen lépés. A kar cseréje alapvetően megváltoztatja a felfüggesztés geometriáját, és ha kihagyjuk a beállítást, az rossz vezérlést és gyors, egyenetlen gumiabroncskopást eredményez.

Hogy világosabb képet kapjon, itt egy részletes áttekintés a lemezacél kar egy darabjának cseréjével járó költségekről:

| Költségkomponens | Tipikus Árkeret | Megjegyzések |

|---|---|---|

| Lemezacél Kar | $80 - $400+ | Az ár az OEM és az utángyártott, valamint a jármű márkájától/modelljétől függ. |

| Munkadíj | $225 - $330+ | Tipikus 2–3 órás felszerelési idő alapján darabkarhoz. |

| Kerékigazítás | $100 - $125 | Kötelező a futómű beavatkozás után, a biztonság érdekében és a gumiabroncs-használat megelőzése végett. |

| Becsült teljes összeg (karanként) | $405 - $855+ | A teljes költség meghaladhatja az 1000 dollárt prémium járművek esetén vagy márkakereskedői árakon. |

Amikor árajánlatot kap, győződjön meg róla, hogy részletezett legyen. Ez az átláthatóság lehetővé teszi, hogy pontosan lássa, hová kerül a pénze. Ne habozzon megkérni szerelőjét, hogy magyarázza el az egyes tételeket. Egy megbízható műhely képes lesz indokolni a költségeket, és megerősíteni, hogy a cserét követő állásbeállítás szerepel az ajánlatban.

Sajtolt acél vs. egyéb anyagok: Hogyan hat a választása a költségre és a teljesítményre

A „kivágott acél” kifejezés a javítási árajánlatban jelentős, mivel meghatározza járműve karfogó típusát. A kivágott acél karfogókat acéllemezek adott alakra préselésével gyártják. Ez a módszer rendkívül költséghatékony, így ez a széles körben elterjedt választás személygépkocsik és teherautók többsége számára. Megbízható egyensúlyt kínál az erősség és az ár között mindennapi vezetési körülmények között. Ha bizonytalan abban, hogy járműve milyen típusú karfogóval rendelkezik, a mechanikusok által említett egyszerű teszt a mágneses teszt: ha a mágnes tapad a karfogóhoz, akkor az acélból készült.

Bár a sajtolt acél az elterjedt, ez nem az egyetlen elérhető lehetőség. Más anyagok, például öntött alumínium, öntött vas és kovácsolt acél különböző járműalkalmazásokban kerülnek felhasználásra, mindegyik különböző kompromisszumokat jelentve ár, súly és tartósság tekintetében. Az öntött alkatrészeket úgy készítik, hogy olvadt fémet öntenek formába, amely összetettebb és merevebb alakzatok kialakítását teszi lehetővé. A kovácsolt alkatrészeket extrém nyomás alatt alakítják ki, így keletkeznek a legerősebb és legtartósabb, ugyanakkor legdrágább alkatrészek. Ezek gyártási folyamatok pontossága kritikus fontosságú a biztonság és a teljesítmény szempontjából. Azok számára, akik az autóiparban dolgoznak, olyan vállalatok, mint a Shaoyi (Ningbo) Metal Technology Co., Ltd. összetett sajtolt alkatrészek nagy sorozatú gyártására specializálódott, és biztosítja, hogy a prototípusoktól a tömeggyártásig szigorú IATF 16949 minőségi szabványoknak megfeleljenek.

A legtöbb sofőr számára a kopott, sajtolt acélkar kicserélése ugyanolyan típusúra a legpraktikusabb és leggazdaságosabb megoldás. Ha azonban módosított járművel rendelkezik, például emelt teherautóval, vagy nehézüzemű célokra használja járművét, akkor érdemes lehet mechanikusával egy erősebb anyagú alkatrészre való frissítést megvitatni, amely hosszú távon megnöveli a tartósságot.

| Anyag típusa | Átlagos költség | Hosszútartamú használhatóság | Súly | Legjobb Használati Eset |

|---|---|---|---|---|

| Sajtolással gyártott acél | Alacsony közepesig | Jó | Mérsékelt | A legtöbb személygépkocsi és könnyű teherautó. |

| Öntött alumínium/vas | Mérsékelt és magas | Nagyon jó. | Könnyebb (alumínium) vagy nehezebb (vas) | Luxusjárművek, teljesítményautók és néhány teherautó. |

| Fém-alumínium kovácsolt | Magas | Kiváló | Közepes vagy kis terhelés | Magas teljesítményű, terepen használt és nehézüzemű alkalmazások. |

A végső számlára ható kulcsfontosságú tényezők

A karcsere széles költségtartománya nem véletlenszerű; számos konkrét tényező határozza meg, amelyek jelentősen befolyásolhatják a végső számlát. Ezeknek a változóknak az ismerete segít előre jelezni az adott helyzetben felmerülő költségeket, és megalapozott döntéseket hozni a javítás helyéről és módjáról.

Először is, az Ön a jármű gyártója és modellje a alkatrészárak fő meghatározója. Egy közönséges hazai szedánhoz tartozó alkatrészek lényegesen olcsóbbak, mint egy európai luxusautó vagy egy teherbíró pickup teherautó alkatrészei. Például a(z) RepairPal adatai szerint a Chevrolet Silverado 1500 átlagos cseréköltsége 732 és 850 dollár között mozog, ami tükrözi a teherautókhoz szükséges erősebb alkatrészeket.

Másodszor, a szerelő választása nagyon fontos szerepet játszik. A márkakereskedések általában a legmagasabb munkadíjat számítják fel, és kizárólag az eredeti felszerelést gyártó (OEM) alkatrészeket használják, amelyek drágábbak. Egy független autószerelő műhely majdnem mindig alacsonyabb munkadíjat kínál, és lehetőséget ad arra, hogy minőségi, de olcsóbb utángyártott alkatrészeket használjon. A kompromisszum az, hogy a márkakereskedés hosszabb garanciát nyújthat, vagy speciális eszközökkel rendelkezhet az Ön konkrét járművéhez.

Egyéb fontos tényezők:

- Földrajzi helyszín: A munkadíjak magasabbak a nagyvárosokban, ahol az életköltségek magasabbak, mint a vidéki városokban.

- A munka terjedelme: Ha a korrózió vagy elhasználódás az oka, a mechanikusok gyakran azt javasolják, hogy párban cseréljék le a vezérlőkarokat (például mindkét első oldalt, bal és jobb oldali). Ez biztosítja az egyenletes futást, és megakadályozza, hogy néhány hónap múlva vissza kelljen jönnie a másik oldal javítására. Ez azonban majdnem megduplázza a teljes javítási költséget.

- További sérülések: Néha egy hibás vezérlőkar károsíthat más alkatrészeket is, például gömbfejeket, kormánypillangókat vagy akár az tengelyt is. Ha további alkatrészeket is ki kell cserélni, a költség ennek megfelelően növekszik.

Megéri lecserélni a vezérlőkart? Tünetek és a halogatás kockázatai

Amikor egy olyan számlával szembesülünk, amely közel ezer dollárra rúghat, természetes feltenni a kérdést: „Ez feltétlenül szükséges?” A vezérlőkar esetében a válasz egyértelmű igen. Ez az alkatrész kritikus kapcsolódási pont a jármű felfüggesztési rendszerében, összekötve a kerékagyat a jármű vázával. A meghibásodása nem jelent csekély kellemetlenséget – komoly biztonsági kockázatot jelent.

A hibás vezérlőkar figyelmeztető jeleinek figyelmen kívül hagyása veszélyezteti Önt, utasait és más közlekedőket. Ezek a tünetek járműve módja annak, hogy jelezze: egy kritikus rendszer meghibásodott. Figyeljen ezekre az indikátorokra:

- Koppanó vagy ütődő zajok: Gyakran bukdácsolás, gyorsítás vagy fékezés közben hallható hang, amely kopott gumibelső vagy gömbcsuklóból származik, ami túlzott mozgást enged.

- Kormánykerék rezgése: Egy laza vezérlőkar rezgéseket okozhat, amelyeket közvetlenül a kormánykeréken keresztül érezhet, különösen magasabb sebességeknél.

- Precíziótalan vagy lusta kormányzás: A jármű instabilnak tűnhet, ide-oda billeghet, vagy késleltetett választ adhat a kormányzási beavatkozásokra.

- Egyenetlen gumiabronzolódás: Egy rossz vezérlőkar elrontja a kerekek állását, aminek következtében a gumi belső vagy külső széle sokkal gyorsabban kopik, mint a futófelület többi része.

Ezen javítás elhalasztása veszélyes kockázat. A kontrollkarban lévő elkopott gömbcsukló teljesen szétválhat, ami a kerék részleges leválását okozhatja a járműről. A szerint, ez teljes kormányzási ellenőrzésvesztést és balesetveszélyt eredményezhet. Továbbá a javítás halogatása későbbi többletköltségekhez vezet. A sérült kontrollkar jelentős terhelést helyez a környező alkatrészekre, felgyorsítva a gumiabroncsok, rugók és fékberendezések kopását. A kezdeti cseréköltség befektetés a katasztrofális meghibásodás és más drága javítások sorozatának megelőzésében. autóipari alkatrészgyártók ez

Gyakran Ismételt Kérdések

1. Mennyibe kerül általában egy kontrollkar cseréje?

Egy kontrollkar egyoldalú cseréjének ára általában 400 és 1000 dollár felett mozog. A végső ár függ a jármű márkájától és típusától, az alkatrészek költségétől (OEM vagy utángyártott), valamint a helyi munkadíjtól. A teljes becslés mindig tartalmaznia kell egy kormányutánállítást, amely elengedhetetlen a javítás után.

2. Honnan tudhatom, hogy lenyomott acélkarjaim vannak-e?

A legegyszerűbb módja annak, hogy egy autótulajdonos ellenőrizze, egy mágnessel próbálkozzon. Ha a mágnes biztosan tapad a lengéscsillapító karhoz, akkor az acélból készült. Az alumíniumból készült lengéscsillapító karok nem vonzzák a mágnest. A préselt acél a leggyakoribb anyag a lengéscsillapító karokhoz szabványos személygépkocsiknál.

3. Megéri kicserélni egy lengéscsillapító kart?

Igen, feltétlenül megéri, és biztonsági szempontból elengedhetetlen. Egy hibás lengéscsillapító kar elveszítheti a kormányzási kontrollt, ami súlyos balesetet okozhat. A javítás késleltetése továbbá felgyorsított kopást okozhat más drága alkatrészeknél, például a gumiabroncsoknál, fékeknél és lengéscsillapítóknál, ami hosszú távon magasabb költségekhez vezet. Ha egy szerelő hibás lengéscsillapító kart állapít meg, azt haladéktalanul ki kell cserélni.

Kis szeletek, magas szabványok. Gyors prototípuskészítési szolgáltatásunk gyorsabbá és egyszerűbbé teszi az ellenőrzést —

Kis szeletek, magas szabványok. Gyors prototípuskészítési szolgáltatásunk gyorsabbá és egyszerűbbé teszi az ellenőrzést —