Repedt lengéscsillapító kar hegesztése: súlyos biztonsági figyelmeztetés

TL;DR

Egy repedt sajtolt acél kar hegesztése rendkívül veszélyes, és határozottan ellene szól a javaslat. A hegesztés során keletkező intenzív hő alapvetően gyengíti a fém szerkezetét, olyan rideg területet létrehozva, amely hajlamos a hirtelen, katasztrofális meghibásodásra, ami teljes járműirányítás-vesztést okozhat. Az Ön és mások biztonsága érdekében az egyetlen helyes és megbízható megoldás a sérült alkatrész lecserélése egy új, tanúsított alkatrészre.

Szakértők véleménye: Miért jelent nagy biztonsági kockázatot egy lengéscsillapító kar hegesztése

A jármű vezérlőkarja egy kritikus felfüggesztési alkatrész, amely a váz és a kerékagy közötti lényeges kapcsolatot biztosítja. Forgó mozgást végez, lehetővé téve a felfüggesztés számára, hogy áthaladjon a bumpokon, miközben a kereket stabilan tartja és megfelelően igazítja. Emiatt az alkatrész folyamatosan hatalmas dinamikus erők hatása alatt áll – gyorsítás, fékezés, kanyarodás és az úttestről származó ütések. Amikor ezen nagy terhelésű alkatrészen repedés keletkezik, az egész felfüggesztési rendszer szerkezeti épsége romlik, így a jármű vezetése biztonságtalanná válik.

Az autóipari fórumokon és szakértői véleményeken átívelő konzensus egyöntetűen világos: a repedt, sajtolt acélból készült lengéscsillapító kar roncsolása súlyos biztonsági kockázatot jelent. Ahogy egy fórum tömören fogalmazott: „A HEGESZTÉS ROSSZ, ÉS ELGYENGEÍTI A LENGÉSCSILLAPÍTÓ KAROKAT.” Ez nem csupán egy vélemény; ez figyelmeztetés, amely a anyagtudományra épül. A hegesztéshez szükséges hő megváltoztatja a sajtolt acél tulajdonságait, amelyet gyárilag hőkezelték és formáztak, hogy meghatározott szilárdság- és rugalmassági arányt érjenek el. A hegesztés olyan jelentős változót vezet be, amelyet az eredeti tervezés nem vesz figyelembe, így új, előre nem látható töréspont keletkezik.

A repedt vezérműkar messze nem jelent csekély problémát; vörös zászló egy hamarosan bekövetkező, súlyos meghibásodásra. Ha a kar elszakad, miközben a jármű mozgásban van, a sofőr azonnal elveszítheti a kormányzási képességét, ami miatt a kerék beszorulhat a keréknyílásba, vagy kiszámíthatatlanul kilendülhet. Ennek következménye komoly baleset, sérülés, vagy annál is rosszabb lehet. Ezért minden repedést, akármilyen kicsinek is tűnik, azonnali intézkedésnek kell követnie – és ez az intézkedés a cserének kell legyen, nem pedig kockázatos javításnak.

A hibásodás tudománya: Hőhatásra megváltozott zónák (HAZ) hidegen hengerelt acélból készült alkatrészeknél

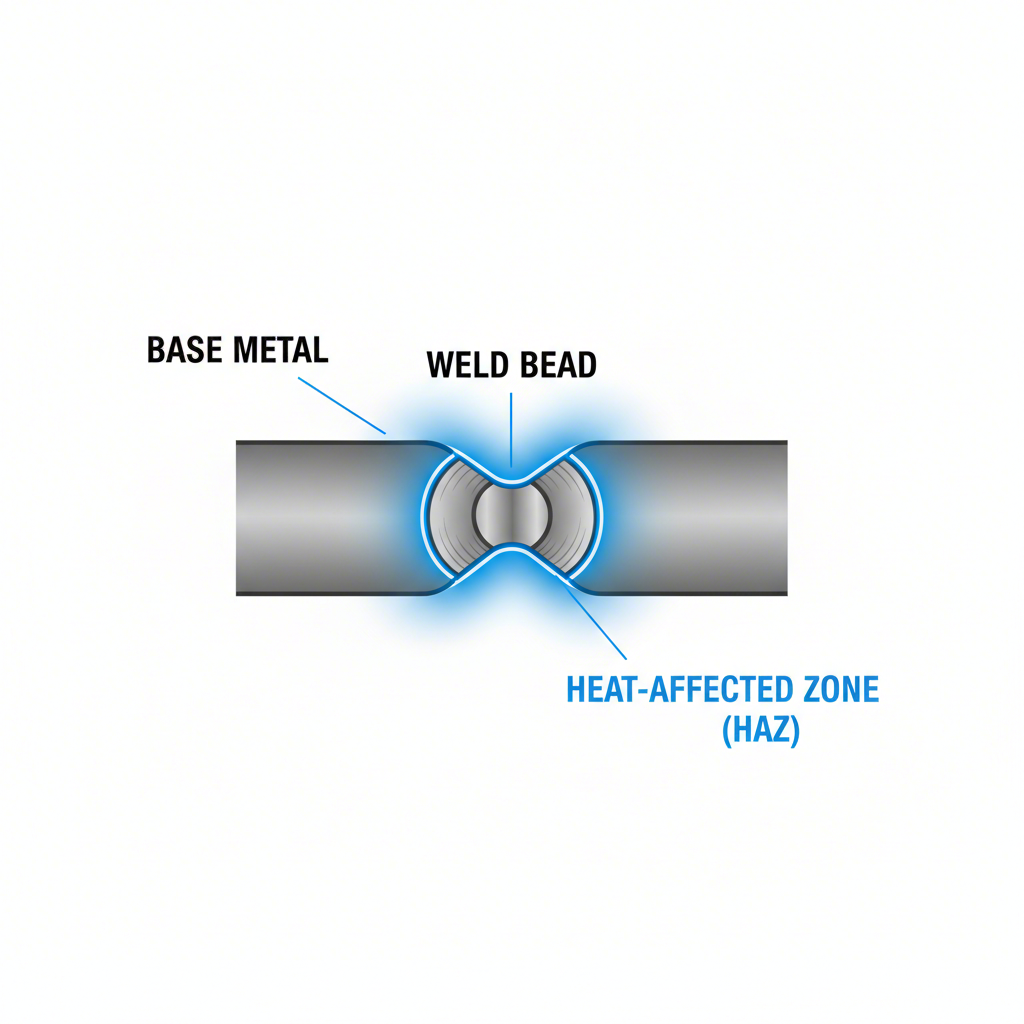

Ahhoz, hogy megértsük, miért olyan veszélyes egy lengéscsillapító kar hegesztése, fontos szemügyre venni, mi történik a fémmel mikroszkopikus szinten. A probléma nem maga a hegesztési varrat, hanem a környező terület, amelyet hőhatásra érzékeny zónának (HAZ) neveznek. A sajtolt acélt meghatározott tulajdonságokkal tervezték, de amikor a hegesztő ívet üt, az intenzív hő nemcsak az adalékanyagot olvasztja meg, hanem a varrat melletti fémréteget is felmelegíti. Ez a folyamat visszafordíthatatlanul megváltoztatja az acél szemcsestruktúráját.

A HAZ-ban a gondosan kialakított acéltulajdonságok elpusztulnak. A fém gyakran keményebbé válik, ugyanakkor lényegesen ridegebbé. Bár a keménység jónak tűnhet, a lengéscsillapító alkatrész ridegsége katasztrófára hív. Egy normál lengéscsillapító kart úgy tervezték, hogy terhelés hatására enyhén deformálódjon, ám egy rideg HAZ nem képes kezelni ezeket a dinamikus igénybevételeket. Ahelyett, hogy deformálódna, repedések és váratlan eltörések jelentkezhetnek, különösen akkor, ha gödröt ütünk vagy éles kanyarban haladunk.

Ezenkívül egy ilyen alkatrész megfelelő hegesztése rendkívül nehéz feladat. Számos próbált javítás olyan ún. "hideg hegesztéshez" vezet, amikor a hegesztési varrat a kiinduló fémfelület tetején helyezkedik el anélkül, hogy mély, szerkezeti összeköttetést hozna létre. Ez kizárólag kosmetikai kötést eredményez, amely gyakorlatilag semmiféle szilárdsággal nem rendelkezik. Szakmai anyagtechnológiai ismeretek, előmelegítésre szolgáló speciális berendezések és az acél normalizálását biztosító szabályozott utómelegítés nélkül szinte lehetetlen egy laikus számára kezelni a hőhatásövezetet (HAZ) és olyan javítást végezni, ami nem csupán egy időzített bomba.

A 'szakértői kivétel': Mikor és hogyan lehetséges *esetleg* egy hegesztett javítás

Bár a túlnyomó tanács az, hogy soha ne hevessék meg a kormányzott hídat, egyes források említik, hogy elméletileg lehetséges a javítás – de kizárólag rendkívül szigorúan meghatározott és ellenőrzött körülmények között, mesteri szintű szakember által. Ez nem olyan feladat, amit egy otthoni barkácsoló vagy akár egy általános autószerelő vállalhatna. A szükséges eljárás lényegesen összetettebb annál, mint egyszerűen végigfutni egy varratot a repedés felett; gondos, specializált lépéseket igényel, amelyek gyakran alkalmazhatatlanok és költségességgel járóak.

Egy igazi szerkezeti javítás több kritikus szakaszt is magában foglal. Először a repedést teljesen ki kell csiszolni egy 'V' alakú horonyba, amely jól túlnyúlik a látható végpontokon, hogy eltávolítsa a feszültség alatt álló fém minden nyomát. Az egész alkatrészt ezután előmelegíteni kell egy meghatározott hőmérsékletre, hogy megelőzzük a hő sokkhatását. A hegesztés során olyan speciális betöltő pálcát kell használni, amely kompatibilis az alapfémmel, és biztosítja a teljes, mély behatolást. A legfontosabb, de gyakran kihagyott lépés a hegesztést követő hőkezelés. Az egész lengőkart speciális kemencébe kell helyezni, és pontos hőmérsékletre kell emelni, hogy feloldja a hegesztés által okozott feszültségeket, és részben visszaállítsa az eredeti tulajdonságait.

Ez a munkaszint inkább hasonlít az autóversenyekhez készült egyedi gyártásra, semmint egy repedt gyári alkatrész javítására. Még akkor is, ha több szakember is visszautasítaná a munkát az óriási felelősség miatt. Ha figyelembe vesszük ennek a speciális munkának az árát és a továbbra fennálló bizonytalanságot, világossá válik, hogy ez a „szakértői kivétel” inkább elméleti gyakorlat, semmint gyakorlati megoldás. A hibalehetőség zéró, és a tét egyszerűen túl magas.

Az okos és biztonságos alternatíva: Miért a cserélés az egyetlen valódi megoldás

A hegesztett javítás súlyos kockázatait és összetettségét figyelembe véve az egyetlen logikus, biztonságos és felelős megoldás a repedt futómű-kar cseréje. Egy új alkatrész garantálja a járműgyártó által előírt szerkezeti integritást és teljesítményt. Ez nem csupán egy javítás; ez a jármű biztonsági rendszerének gyári előírások szerinti helyreállítása.

Egy új, szakmailag gyártott alkatrész pontosan megfelel az eredeti gyártó (OEM) szilárdságra, illeszkedésre és tartósságra vonatkozó előírásainak. Ezeket az alkatrészeket olyan szakosodott gyártók állítják elő, mint a Shaoyi Metal Technology , akik fejlett, IATF 16949 tanúsítvánnyal rendelkező gyártási folyamatokat alkalmaznak, hogy minden sajtolt acél lengéscsillapító kar megfeleljen a gyári szintű szerkezeti integritás követelményeinek – ezt a garanciát egy hegesztett javítás soha nem tudja biztosítani. Ha összehasonlítjuk az új lengéscsillapító kar viszonylag alacsony árát egy baleset, biztosítási igények és személyi sérülések potenciális költségeivel, a cserének egyértelműen a leggazdaságosabb megoldásnak bizonyul.

A biztonságos döntéshez kövesse az alábbi egyértelmű, azonnal alkalmazható lépéseket:

- Azonnal hagyja abba a jármű vezetését. Ne próbálja meg a javítóműhelyhez vezetni a járművet. Egy repedt lengéscsillapító kar bármikor teljesen eltörhet.

- Járműt vontasson. Szervezzen vontatást egy minősített, szakmai szerelőhöz alapos ellenőrzés céljából.

- Rendeljen új alkatrészt. Vásároljon nagy minőségű OEM vagy tanúsított utángyártott karosszériarészt. Ne használjon bontott alkatrészt, mivel az láthatatlan feszültséget vagy sérülést tartalmazhat.

- Gondoskodjon szakmai beszerelésről. A új alkatrész beszerelését hitelesített szakember végezze, aki teljes kerekesszabályozást is el tud végezni, ami ezen típusú felfüggesztési munkák után szükséges.

Végül is a cserére való választás nyugalmat biztosít. Bizalommal vezethet, tudván, hogy járműve felfüggesztésének egyik kritikus alkatrésze ép, megbízható, és megfelel az olyan szervezetek által előírt összes biztonsági szabványnak, mint a National Highway Traffic Safety Administration (NHTSA) .

| Gyár | Hegesztett javítás | Új alkatrész csere |

|---|---|---|

| Biztonság | Rendkívül magas kockázat | Garantált OEM biztonság |

| Megbízhatóság | Kiszámíthatatlan / hajlamos a meghibásodásra | Magas / Megfelel a gyári előírásoknak |

| Költség | Alacsony kezdeti költség, de baleset esetén potenciálisan végtelen költség | Mérsékelt, kiszámítható költség |

| Békés lelkendezés | Nincs. Folyamatos aggodalom a meghibásodás miatt. | Teljes bizalom a jármű biztonságában |

Gyakran Ismételt Kérdések

1. Hegeszthető sajtolt acél?

Igen, a hengerelt acél hegeszthető, és a gyártás során gyakori eljárás a hengerelt alkatrészek nagyobb egységgé való összeépítésére. Azonban a hegesztés hője megváltoztatja a fém tulajdonságait. Egy nagy igénybevételű, biztonságtechnikailag kritikus alkatrész, mint például egy kormányzott lengéscsillapító kar esetében, ez a változás törékeny, gyenge pontot hoz létre, amely elfogadhatatlan javítási célból anélkül, hogy speciális, többfokozatú hőkezelést alkalmaznának.

2. Mennyire súlyos egy repedt kormányzott lengéscsillapító kar?

Egy repedt kormányzott lengéscsillapító kar rendkívül súlyos, és a járművet vezethetetlenné teszi. A kormányzott lengéscsillapító kar a felfüggesztési rendszer kulcsfontosságú eleme, és meghibásodása hirtelen kormányzási ellenőrzésvesztéshez, a kerék járműről való leválásához és potenciálisan halálos balesethez vezethet. Ha repedést gyanít, azonnal hagyja abba a vezetést.

3. Melyik acélalkatrészek javíthatók normál esetben hegesztéssel?

A hegesztési javításokat általában nem szerkezeti jellegű vagy alacsony igénybevételű alkatrészeknél, például kipufogó-tartóknál vagy kisebb karosszérialemez-repedéseknél alkalmazzák. A nagy szén tartalmú vagy különlegesen hőkezelt acélból készült kritikus, magas igénybevételű alkatrészeket, mint a felfüggesztési karok, meghajtótengelyek vagy kormányzuhanyok, szinte soha nem lehet biztonságosan hegeszteni, és ezeket mindig ki kell cserélni a biztonság érdekében.

Kis szeletek, magas szabványok. Gyors prototípuskészítési szolgáltatásunk gyorsabbá és egyszerűbbé teszi az ellenőrzést —

Kis szeletek, magas szabványok. Gyors prototípuskészítési szolgáltatásunk gyorsabbá és egyszerűbbé teszi az ellenőrzést —