Fontos stratégiák az alumínium korróziójának megelőzésére autóalkatrészeknél

TL;DR

Az alumínium autóalkatrészek hatékony korrózióvédelméhez tartós gátat kell létrehozni a nedvességgel, útsóval és galvános reakciókkal szemben. A legmegbízhatóbb stratégiák közé tartozik védőrétegek, például átlátszó bevonatok vagy kerámia tömítőszerek felvitele, az anódolás alkalmazása kiváló tartósság érdekében, valamint rendszeres tisztításból és ellenőrzésből álló rutin betartása, hogy eltávolítsa a káros korróziót okozó szennyeződéseket, mielőtt kárt tehetnének.

Az alumínium korróziójának gyökérokainak megértése

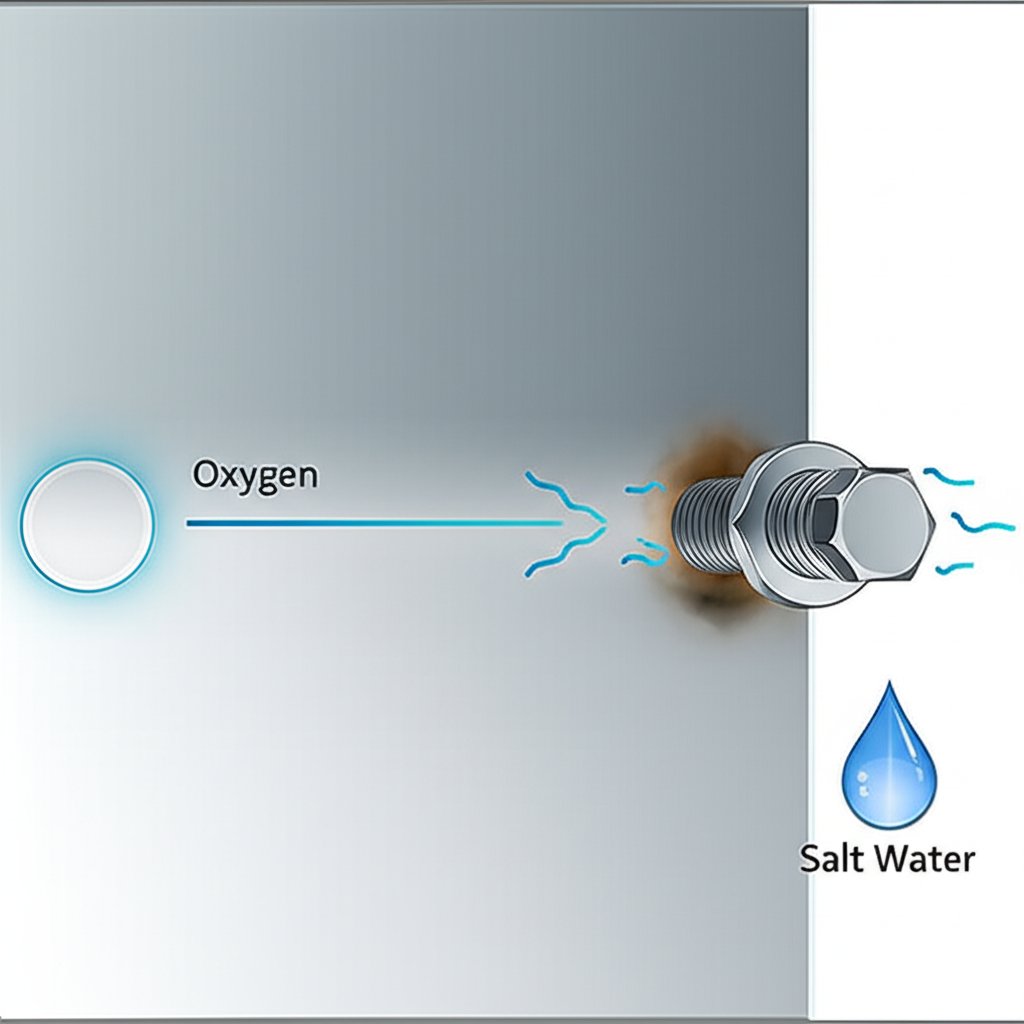

Mielőtt hatékonyan védené járműve alumínium alkatrészeit, fontos megérteni, mi okozza azok degradációját. Az acélon képződő vörös, pelyhes rozsdától eltérően az alumínium korróziója általában fehér, krétaszerű por vagy felületi pitting formájában jelentkezik. Ez több fő folyamat révén következhet be. A leggyakoribb a légköri korrózió, más néven oxidáció. Bár az alumínium természetes módon kialakít egy vékony, kemény alumínium-oxid réteget, amely védi azt, ez a réteg sérülhet például útsó, savas eső vagy állandó nedvesség hatására.

Egy agresszívebb és gyakran félreértett lebomlási forma az érintkezési (galvánelemes) korrózió. Egy járműipari alkalmazásokról szóló jelentés szerint a Aluminum Association , ez az elektrokémiai reakció akkor következik be, amikor az alumínium közvetlen kapcsolatban áll egy másik, nemesebb fémmel (például acéllal) elektrolit jelenlétében, mint például a téli utakról származó sósvíz. Ebben a helyzetben a két fém gyakorlatilag egy akkumulátort hoz létre, aminek következtében az alumínium alkatrész – a kevésbé nemes, vagyis aktívabb fém – felgyorsult ütemben korródik. Egy klasszikus példa az autóiparban, amikor egy acélcsavar közvetlenül egy alumínium szívókollektorhoz van rögzítve, és a nedvesség felhalmozódhat, ezzel kiváltva a korróziós folyamatot.

Alapvető megelőzés: Védőbevonatok és tömítőanyagok alkalmazása

A legközvetlenebb módja a korrózió megelőzésének az, hogy fizikai gátat hozunk létre, amely elszigeteli az alumínium felületét a környezettől. Ez a legkönnyebben elérhető módszer a legtöbb autótulajdonos számára, és helyes alkalmazás esetén nagyon hatékony lehet. Ezek a bevonatok megakadályozzák, hogy nedvesség, só és egyéb szennyeződések elérjék magát a fémet.

Többféle védőbevonat létezik, mindegyiknek megvannak a saját előnyei:

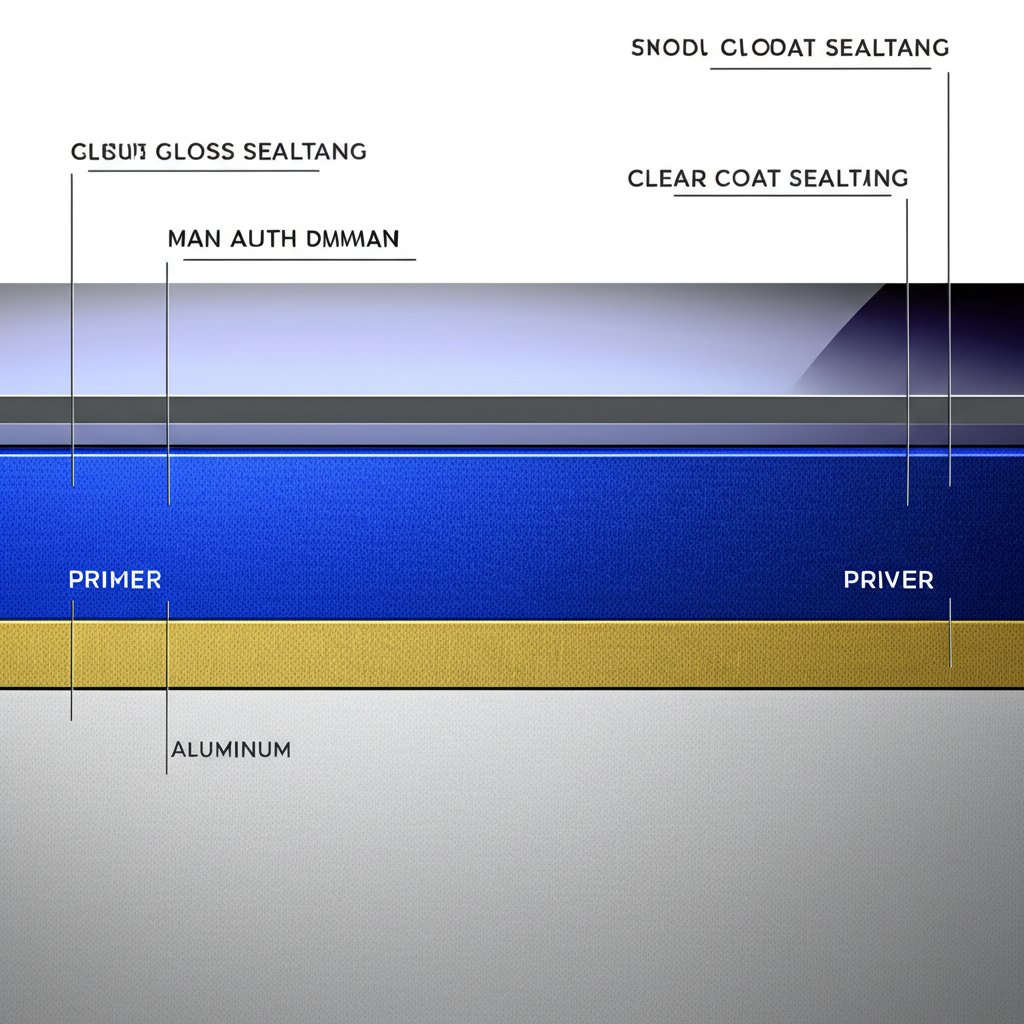

- Lakkok és átlátszó bevonatok: Pontosan úgy, ahogy az autó karosszériáját védik, az autóipari lakk vagy átlátszó réteg bizonyított védelmet nyújt. A nyers alumínium alkatrészekhez egy minőségi, önmagában maró alapozó felvitele, majd erre egy tartós átlátszó bevonat alkalmazása kiváló védelmet biztosít, és megőrzi a fém megjelenését. Ahogyan az AvalonKing szakértői is kiemelik, az alumínium védelem legelterjedtebb formája a védő átlátszó bevonat felhordása.

- Korróziógátló permetek és viaszok: A kevésbé látható alkatrészekhez, különösen az alvázhoz, a ragadós viasz vagy olajalapú korróziógátló permetek ideálisak. Ezek a termékek képesek behatolni az illesztésekbe és repedésekbe, kiszorítva a nedvességet, és rugalmas, vízlepergető, öngyógyuló filmet képeznek. Rugalmasak maradnak, nem repednek vagy repedeznek, így hosszú távú védelmet nyújtanak az útsó és szennyeződés ellen.

- Kerámia bevonatok: Egy modernabb és rendkívül tartós lehetőség a nano-kerámia bevonat, amely mikroszkopikus, szuperhidrofób üvegréteget képez a felületen. Ez a védőréteg rendkívül ellenálló vegyi anyagokkal, piszkozattal és vízzel szemben, így sokkal nehezebbé téve a korrózió kialakulását. Kiváló választás magas láthatóságú alkatrészekhez, például kovácsolt alumíniumkerékhez vagy fényezett díszítőelemekhez.

Haladó megoldások: szakmai kezelések és anódos oxidálás

A legmagasabb szintű védelem érdekében a szakmai kémiai kezelések olyan állandóbb megoldást nyújtanak, amely az alumínium felületét magát változtatja meg. Bár ezek a módszerek gyakran speciális felszerelést igényelnek, olyan tartósságot biztosítanak, amelyet a felületi bevonatok nem tudnak felülmúlni.

A legkiválóbb kezelés az anódos oxidálás. Ahogyan a Light Metals Coloring , az anodizálás egy elektrokémiai folyamat, amely jelentősen megvastagítja az alumínium természetes oxidrétegét. Ez a szabályozott oxidáció egy új felületet hoz létre, amely sokkal keményebb, tartósabb, valamint jóval ellenállóbb a korrózióval és kopással szemben, mint a nyers alumínium. Gyakori bevonat nagy teljesítményű és OEM alkatrészek esetén, kiváló élettartama miatt.

Egy másik szakmai lehetőség a kromátátalakító bevonatok alkalmazása (gyakran kereskedelmi neveken, például Alodine néven ismert). Ezek a kémiai kezelések vékony, védőfóliát hoznak létre az alumínium felületén, amely gátolja a korróziót, és kiváló alapozóként is szolgál, javítva a következő festéssel történő tapadást. Ezt a módszert széles körben használják az űrrepülési iparban és olyan járműipari alkatrészeknél, amelyek erős, többrétegű védőrendszert igényelnek.

Olyan projekteknél, ahol a korrózió megelőzése az elejétől kritikus fontosságú, az alapvetően tartósságra tervezett alkatrészekkel való kezdés kulcsfontosságú. Például olyan szolgáltatások, amelyek testre szabott alumíniumprofilokat biztosítanak, mint Shaoyi Metal Technology , mérnöki alkatrészeket gyárt szigorú minőségi rendszerek, például az IATF 16949 szerint, hogy eleget tegyenek az autóipari igényeknek a szilárdság és korrózióállóság tekintetében.

Az alap: Proaktív karbantartás és rendszeres tisztítás

Egyetlen bevonat vagy kezelés sem lehet teljesen hatékony anélkül, hogy ne lenne meg a folyamatos karbantartás alapja. A korrózió egy fokozatos folyamat, és a proaktív gondozás a legjobb védekezés ahhoz, hogy megakadályozzuk kialakulását. Egy egyszerű, de szisztematikus rutin jelentősen meghosszabbíthatja alumínium alkatrészei élettartamát.

Kövesse ezeket a lépéseket hosszú távú védelem érdekében:

- Rendszeresen mossa meg: Rendszeresen mossuk le járművét, különös figyelmet fordítva az alumínium alkatrészekre. Ez elsősorban téli hónapokban vagy tengerparti területeken kritikus fontosságú, ahol az útsó – amely erős katalizátora a galvános és atmoszférikus korróziónak – eltávolítása szükséges.

- Teljesen szárítsa fel: A víz és a nedvesség elengedhetetlen összetevői a korróziónak. A mosás után vagy nedves körülmények közötti vezetést követően szánjon időt arra, hogy alaposan megszárítsa az alumínium alkatrészeket, különösen az összetett felépítésű keréktárcsákat vagy motoralkatrészeket, ahol a víz összegyűlhet.

- Gyakori ellenőrzés: Szokássá váljon az alumínium alkatrészek átnézése. Keressen korai figyelmeztető jeleket, mint példárl a pittálódás, elszíneződés vagy buborékok a lakkréteg alatt. Ha időben észreveszi ezeket a problémákat, sokkal könnyebben javíthatók.

- Azonnali érintetlenítés: Ha egy védőrétegen repedést vagy karcolást talál, azonnal intézkedjen. A kis sérülés nyitott meghívó a nedvességnek és szennyeződéseknek, hogy aláhatoljanak a réteg alá, és károkat okozzanak.

Hosszú távú stratégia rozsda-mentes alumíniumért

Az autója alumínium alkatrészeinek védelme a korrózió ellen nem egyszeri beavatkozás, hanem folyamatos stratégia. A minőségi védőrétegek azonnali védelmének és a rendszeres, alapos tisztítás alapvető gyakorlatának kombinálásával hatékonyan védekezhet az elemek hatása ellen. Azok számára, akik a legnagyobb tartósságot keresik, a professzionális kezelések, mint például az anódolás, igen tartós, hosszú távú megoldást kínálnak. A korrózió okainak megértésével és ezek megelőző intézkedések aktív alkalmazásával járműve alumínium alkatrészei évekig makulátlan külsejűek maradhatnak, és megbízhatóan működhetnek.

Gyakran ismétlődő kérdések az alumíniumkorrócióról

1. Mi az alumínium legjobb korróziógátlója?

Nincs egyetlen "legjobb" inhibitor minden helyzetben; az ideális választás a alkatrész elhelyezkedésétől és céljától függ. Az alváz alatti alkatrészekhez, amelyek durva körülményeknek vannak kitéve, egy vastag, viasz- vagy olajalapú permetezhető inhibitor tartós, önkihegülő hatást biztosít. Látható alkatrészekhez, például kerékhez vagy díszítéshez, egy kemény, átlátszó védőréteg, mint például egy kerámia bevonat, kiváló védelmet nyújt, miközben megőrzi az esztétikai megjelenést. Egyes speciális alapozók kémiai inhibitort is tartalmaznak, amelyek aktívan akadályozzák a korróziós folyamatot.

2. Megállítja-e a WD-40 az alumínium korróziót?

A WD-40 ideiglenes védelmet nyújt az alumínium korróziójától. Elsődleges funkciója a víz elmozdítása, és olyan korróziósellenes szereket tartalmaz, amelyek vékony, védő filmet alkotnak a fémfelületen. Bár rövid távú használatra vagy a könnyű felület oxidációjának eltávolítására hatékony, nem tartós megoldás. A védőréteg viszonylag gyorsan elhasználódik, és gyakran kell újrahelyezni, hogy hatékonynak maradjon, ellentétben a speciális tömítőanyagokkal, viaszokkal vagy festékekkel, amelyeket tartós védelemre terveztek.

Kis szeletek, magas szabványok. Gyors prototípuskészítési szolgáltatásunk gyorsabbá és egyszerűbbé teszi az ellenőrzést —

Kis szeletek, magas szabványok. Gyors prototípuskészítési szolgáltatásunk gyorsabbá és egyszerűbbé teszi az ellenőrzést —