Steel Cutting Services Decoded: Methods, Costs, And Quality Secrets

Understanding Steel Cutting Services and Their Manufacturing Impact

When you need raw steel transformed into precise components for your project, professional steel cutting services become your essential partner. These specialized services encompass everything from straightforward linear cuts to intricate custom shapes, delivering the exact dimensions your manufacturing, construction, or engineering project demands.

But what exactly are you getting when you work with a metal cutting services provider? At its core, this process involves dividing steel workpieces into multiple parts using advanced technologies that ensure accuracy, clean edges, and minimal material waste. Whether you're preparing structural beams for a building project, fabricating machine components, or creating custom metal cutting solutions for specialized equipment, these services bridge the gap between raw material and functional parts.

What Steel Cutting Services Actually Deliver

Imagine receiving steel plates or sheets that fit together perfectly during assembly, with edges smooth enough for immediate welding. That's the value professional cutting brings to your project. Modern cutting operations use advanced machinery including high-definition plasma cutters, laser systems, waterjet equipment, and oxy-fuel torches to achieve cuts meeting exact specifications.

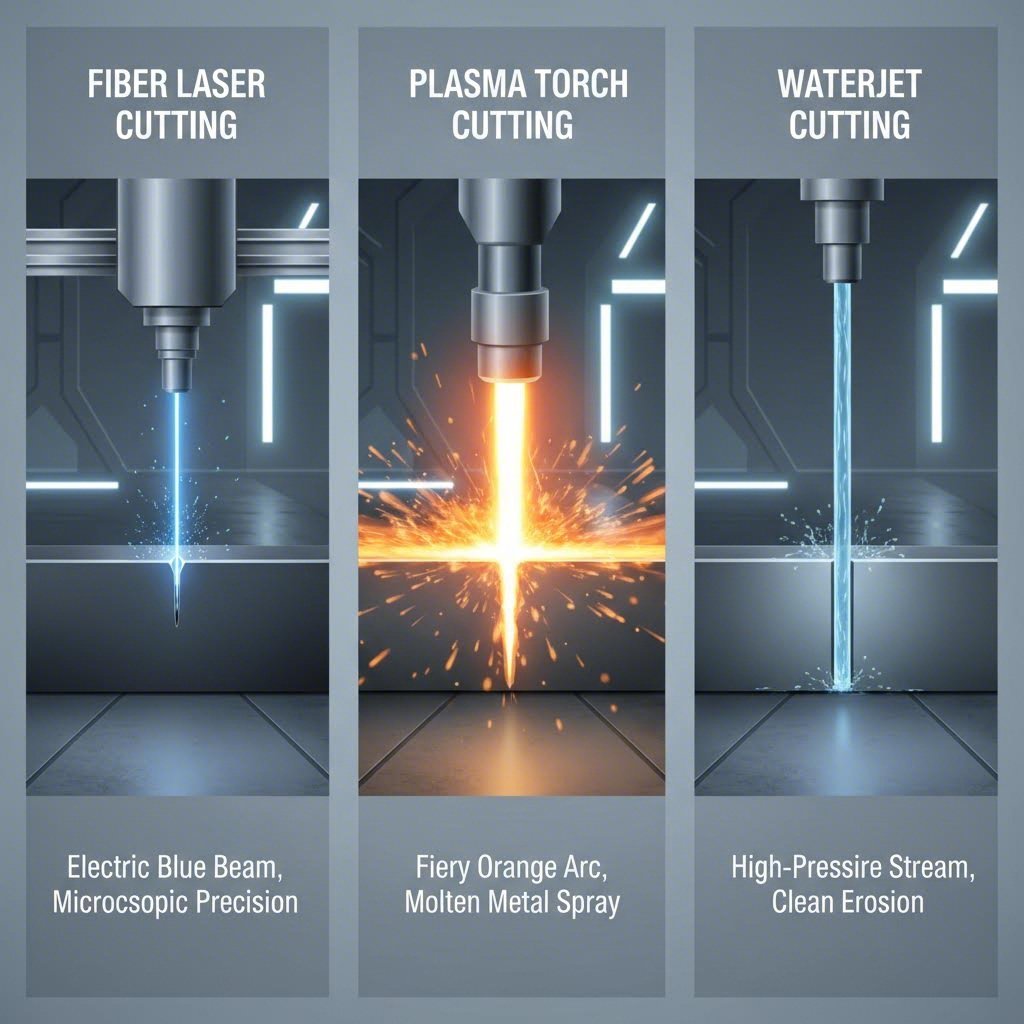

The services available fall into three primary categories you'll encounter throughout your search:

- Thermal Cutting: Methods like laser, plasma, and oxy-fuel that use heat to melt through steel

- Mechanical Cutting: Techniques including sawing, shearing, and punching that use physical force

- Abrasive Cutting: Processes such as waterjet cutting that erode material through friction and pressure

Each category offers distinct advantages depending on your material thickness, tolerance requirements, and project timeline.

Why Precision Cutting Matters for Your Project

Even slight measurement errors during the cutting phase can cascade into significant problems. Misaligned components, compromised structural integrity, and costly rework often trace back to imprecise cuts. Professional services eliminate these risks by delivering tolerances as tight as +/- 0.001" with methods like waterjet cutting, ensuring your welded or bolted components fit together effortlessly.

Throughout this guide, you'll discover how different cutting methods compare, which techniques suit specific industries and materials, and what factors influence pricing. You'll also learn how to prepare project specifications that get accurate quotes and how to evaluate service providers effectively. By the end, you'll have the knowledge to make confident decisions about your steel cutting needs.

Complete Guide to Steel Cutting Methods and Technologies

Choosing the right cutting method can make or break your project's success. Each technology brings unique strengths to the table, and understanding these differences helps you match your specific requirements to the ideal solution. Let's break down every major cutting method you'll encounter when exploring steel cutting services.

Thermal Cutting Technologies Explained

Thermal cutting methods use concentrated heat to melt, vaporize, or oxidize steel along a precise path. These processes dominate industrial applications because they handle thick materials efficiently while maintaining respectable accuracy.

Laser Cutting

Fiber laser technology has revolutionized precision cutting over the past decade. These systems generate intense laser beams by amplifying light within optical fibers doped with rare-earth elements like ytterbium. The result? Exceptionally focused energy that melts through steel with remarkable accuracy.

What makes fiber lasers particularly impressive is their scalability. Low-power systems up to 500W handle materials up to 3mm thick, perfect for electronics and medical device components. Mid-power lasers between 500W and 2kW cut stainless steel up to 8mm and carbon steel up to 18mm. High-power systems from 2kW to 10kW tackle materials up to 40mm thick, while ultra-high-power lasers exceeding 10kW process carbon steel over 80mm thick.

For projects requiring laser cutting in Minneapolis or laser cutting in Minnesota, you'll find this technology delivers exceptionally tight tolerances with minimal heat-affected zones. The digitally controlled beam path eliminates human error, ensuring every cut meets exact specifications.

Plasma Cutting

Steel plasma cutting services offer an excellent balance between speed and cost-effectiveness. This method forces electrically ionized gas through a constricted opening at high velocity, creating temperatures exceeding 20,000°F that melt through steel rapidly.

Plasma excels at cutting thicker materials where laser becomes less economical. You'll typically find plasma systems handling steel from 1/4" to several inches thick, making them workhorses for structural fabrication and heavy industrial applications. The edge quality, while good, typically requires more post-processing than laser cuts for precision applications.

Oxy-Fuel Cutting

This traditional method combines oxygen with fuel gases like acetylene or propane to create intense heat that oxidizes steel along the cut line. While less precise than laser or plasma, oxy-fuel remains invaluable for cutting very thick carbon steel plates, sometimes exceeding 12 inches. It's particularly cost-effective for straight cuts on heavy structural materials where edge refinement isn't critical.

Mechanical and Abrasive Cutting Alternatives

Not every project requires thermal methods. Mechanical and abrasive technologies offer distinct advantages, especially when heat-affected zones must be avoided or when working with specialized materials.

Waterjet Cutting

Imagine cutting steel with a stream of water moving at three times the speed of sound. Waterjet systems mix high-pressure water with abrasive particles, creating a cutting force that erodes through virtually any material without generating heat. This cold-cutting process preserves material properties near the cut edge, making it ideal for heat-sensitive applications.

Waterjet handles steel thicknesses from thin sheet metal to slabs over 8 inches thick. The absence of thermal distortion makes it popular for aerospace components and precision parts where metallurgical integrity matters.

Shearing

When you need rapid, consistent cuts across sheet metal, shearing delivers exceptional productivity. This process applies pressure between two metal blades, causing the material to yield and separate along the cutting line. Shearing works across a wide range of thicknesses and produces parts quickly, though edge quality may be rougher than other methods.

Sawing

Band saws and circular saws remain essential for cutting bar stock, tubes, and structural shapes. Laser tube cutting in Minneapolis and similar specialized services handle cylindrical materials, but traditional sawing offers cost-effective solutions for straightforward cuts on solid sections where tight tolerances aren't required.

Steel Cutting Methods Comparison

| Cutting Method | Precision Tolerance | Thickness Range | Material Compatibility | Edge Quality | Typical Applications |

|---|---|---|---|---|---|

| Fiber Laser | +/- 0.001" to 0.005" | 0.03" to 3"+ (power dependent) | Carbon steel, stainless, aluminum, brass, copper | Excellent, minimal burr | Precision parts, electronics, automotive, aerospace |

| Plasma | +/- 0.015" to 0.030" | 0.25" to 6"+ | All conductive metals | Good, may require grinding | Structural steel, heavy fabrication, shipbuilding |

| Oxy-Fuel | +/- 0.030" to 0.060" | 0.5" to 12"+ | Carbon steel, some alloys | Moderate, oxidized edge | Thick plate cutting, demolition, scrap processing |

| Waterjet | +/- 0.001" to 0.005" | 0.030" to 8"+ | Any material including hardened steel | Excellent, no heat zone | Aerospace, precision tooling, heat-sensitive parts |

| Shearing | +/- 0.010" to 0.030" | Up to 0.5" (typical) | Sheet metals, mild steel | Fair, may have burr | High-volume sheet blanking, HVAC, general fabrication |

| Sawing | +/- 0.030" to 0.060" | Limited by blade/machine | All steel types, bar stock, tubes | Fair, requires deburring | Bar stock prep, structural shapes, tube cutting |

Understanding these distinctions positions you to have informed conversations with service providers. Your project's material thickness, required precision, edge finish needs, and budget constraints will guide you toward the optimal cutting method. Next, we'll dive deeper into specific thickness capabilities and tolerance specifications that help you match project requirements to the right technology.

Thickness Capabilities and Precision Tolerances Explained

You've seen what each cutting method can do, but here's where the rubber meets the road: can your chosen technology actually handle your specific material at the thickness you need? And once it does, how precisely will those cuts match your specifications? These questions determine whether your custom cut metal project succeeds or requires costly rework.

Thickness Ranges by Cutting Technology

Every cutting method has a sweet spot where it performs optimally. Push beyond these limits, and you'll encounter slower speeds, degraded edge quality, or outright inability to complete the cut. The table below breaks down realistic thickness ranges you can expect from professional sheet metal cutting services.

| Cutting Method | Minimum Thickness | Optimal Range | Maximum Thickness | Best Material Match |

|---|---|---|---|---|

| Fiber Laser | 0.03" | 0.125" - 0.75" | 1.25" (mild steel) | Carbon steel, stainless steel, aluminum |

| Plasma (X-Definition) | 0.125" | 0.25" - 1.5" | 6"+ | All conductive metals |

| Oxy-Fuel | 0.25" | 1" - 6" | 36" - 48" | Mild steel only |

| Waterjet | 0.03" | 0.5" - 4" | 8"+ | Any material including hardened steel |

| Shearing | 24 gauge | 16 gauge - 0.25" | 0.5" (typical) | Sheet metals, mild steel |

Notice how each technology claims specific territory? Oxy-fuel cutting dominates heavy plate work beyond 1 inch, with some operations handling steel up to 48 inches thick. Meanwhile, laser cutting finds its sweet spot in materials up to around 1.25 inches, where it delivers exceptional edge quality and precision that thicker-capable methods simply can't match.

When evaluating custom sheet metal cutting providers, ask specifically about their equipment's power ratings. A 6kW fiber laser handles different thickness limits than a 15kW system. The same principle applies across all thermal methods—higher power translates to thicker cutting capability.

Understanding Precision Tolerances

Here's where material type significantly impacts your results. Cutting carbon steel, stainless steel, and aluminum at identical thicknesses produces different tolerance outcomes because each material responds uniquely to heat, abrasion, and mechanical force.

Carbon Steel Tolerances

Carbon steel offers the most predictable cutting behavior. Laser systems typically hold tolerances under 0.01" (0.25mm) on carbon steel plates, while X-Definition plasma systems achieve approximately 0.02" (0.5mm). The material's consistent composition and thermal properties make it the benchmark against which other materials are measured.

Stainless Steel Considerations

Stainless steel's higher chromium content creates challenges. The material reflects more laser energy and conducts heat differently than carbon steel, often requiring slower cutting speeds to maintain the same tolerance. Expect slightly wider tolerances when cutting stainless compared to carbon steel at equivalent thicknesses.

Aluminum Behavior

Aluminum's high thermal conductivity and reflectivity make it particularly demanding for thermal cutting methods. The heat dissipates quickly, requiring higher power settings. Fiber lasers handle aluminum well, but tolerances typically run looser than carbon steel. Waterjet excels here since it eliminates thermal variables entirely.

When Tight Tolerances Actually Matter

Sounds expensive, right? Tighter tolerances do cost more—but not every project needs them. Consider this practical framework:

- Tight tolerances (+/- 0.005" or less): Precision assemblies, aerospace components, parts requiring no secondary machining, mating surfaces with close fits

- Standard tolerances (+/- 0.015" to 0.030"): Welded assemblies, structural components, parts receiving subsequent machining, general fabrication

- Loose tolerances (+/- 0.060" or more): Rough blanks for heavy machining, scrap processing, non-critical structural elements

The tolerance difference between laser and plasma—about the thickness of a business card—may not justify the cost differential for your application. If your parts go directly from the cutting table to welding, where weld tolerances far exceed cut tolerances, you're paying for precision that disappears in the next operation.

Smart project planning matches tolerance requirements to functional needs. Over-specifying tolerances creates unnecessary costs through higher equipment investment, more frequent inspection, increased scrap rates, and reduced throughput. Before requesting laser quality on every part, ask yourself whether the form, fit, or function truly demands that precision.

With thickness and tolerance fundamentals clarified, you're ready to explore how different industries apply these capabilities to their specific manufacturing challenges.

Industry Applications and Method Recommendations

Ever wonder why an automotive manufacturer chooses laser cutting while a shipyard relies on plasma? Different industries face unique challenges that demand specific cutting solutions. Understanding these distinctions helps you communicate more effectively with your metal cutting shop and ensures your project receives the appropriate technology from the start.

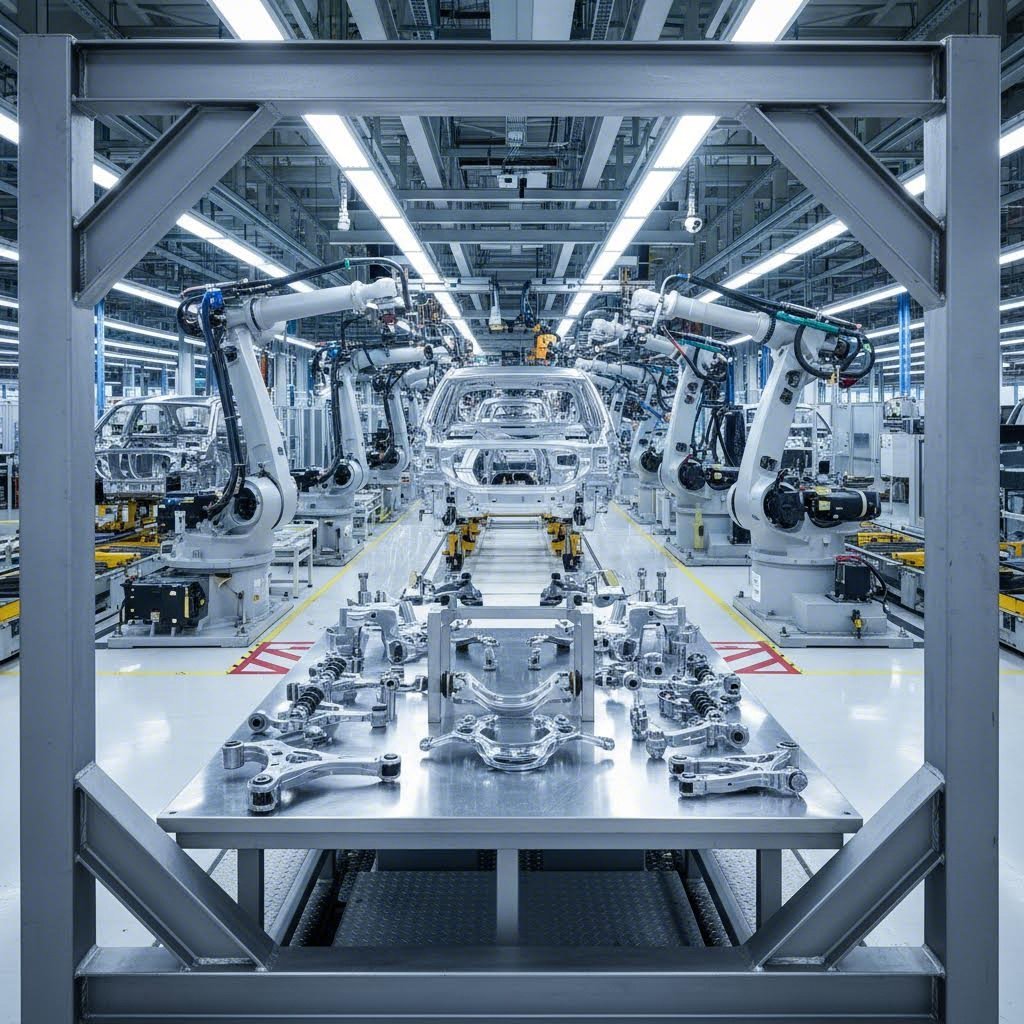

Automotive and Transportation Applications

The automotive sector demands a precise balance between lightweight construction and structural integrity. Modern vehicles rely on fabricated sheet metal for everything from body panels to safety-critical chassis components. This industry prioritizes tight tolerances, high-volume production capability, and strict material certification.

According to Prototek's analysis of automotive manufacturing, sheet metal fabrication is essential for creating strong, lightweight vehicle parts that contribute to safety, appearance, and performance. The outer parts of vehicles—doors, hoods, roofs, and fenders—require cutting methods that deliver both precision and production speed.

Common automotive cutting applications include:

- Chassis and frame components: High-strength steel requiring laser or plasma cutting with tolerances under 0.015"

- Suspension brackets and mounts: Often demand custom metal cuts with excellent edge quality for subsequent welding

- Body panels and structural reinforcements: Sheet metal parts needing clean edges without heat distortion

- Engine compartment components: Precision parts including brackets, shields, and covers requiring tight dimensional control

- Interior structural elements: Dashboard mounts, seat frames, and airbag supports where consistency matters

Recommended cutting methods for automotive:

- Fiber laser: Ideal for high-volume production of body panels and precision brackets (0.03" to 0.75" thickness)

- Plasma cutting: Cost-effective for thicker chassis components and structural elements

- Waterjet: Preferred when heat-affected zones must be avoided on safety-critical parts

Automotive manufacturers increasingly focus on lightweight materials to reduce emissions and improve fuel efficiency. This shift toward aluminum and high-strength steel alloys demands cutting technologies capable of handling these materials without compromising structural properties.

Aerospace and Industrial Manufacturing Needs

When lives depend on component integrity, aerospace applications demand the highest precision available. Aerospace sheet metal fabrication involves cutting, bending, and assembling metal structures for aircraft, satellites, and spacecraft where failure simply isn't an option.

This industry prioritizes precision above all else, followed closely by material traceability and certification. Turnaround time matters, but never at the expense of quality. Aerospace manufacturers typically work with titanium alloys, aluminum alloys like 6061 and 7075, and specialty stainless steels that require specific cutting parameters.

Critical aerospace cutting applications:

- Fuselage skin panels: Large curved panels requiring stretch forming after precision cutting

- Wing structural components: High-strength aluminum and titanium parts with tight tolerances

- Engine mounting brackets: Heat-resistant alloys demanding cold-cutting methods

- Control surface elements: Precision parts where weight savings directly impact fuel efficiency

- Satellite and spacecraft structures: Custom copper fabrication and specialty alloy work for thermal management

Recommended cutting methods for aerospace:

- Laser cutting: Achieves tolerances within ±0.05 mm for high-precision components

- Waterjet cutting: Handles materials up to 300 mm thick without heat-affected zones—ideal for titanium and heat-sensitive alloys

- Plasma cutting: Suitable for thicker structural components where tolerances allow

Marine and Construction Industry Requirements

Marine fabrication presents unique challenges: large-scale components, corrosion-resistant materials, and outdoor cutting environments. Shipyards typically process thick steel plates for hulls, decks, and structural members where production volume and material handling capabilities outweigh ultra-tight tolerances.

Marine industry priorities:

- Handling large plate sizes (often 10' x 40' or larger)

- Cutting thick materials efficiently (1" to 4" common)

- Processing corrosion-resistant alloys and marine-grade aluminum

- Achieving adequate tolerances for welded assemblies

Construction and structural steel applications:

- Beam and column preparation: Straight cuts on heavy structural shapes using oxy-fuel or plasma

- Connection plates and gussets: Plasma cutting delivers adequate precision at lower cost

- Decorative architectural elements: Laser cutting for intricate designs in thinner materials

- Bridge components: High-definition plasma for thicker structural elements with certified materials

Recommended cutting methods for marine and construction:

- Oxy-fuel: Most economical for straight cuts on thick carbon steel plates

- Plasma: Balances speed, cost, and quality for structural fabrication

- Laser: Reserved for precision architectural work and thinner decorative elements

General Industrial Manufacturing Considerations

Beyond specialized sectors, general industrial applications span equipment manufacturing, agricultural machinery, material handling systems, and countless other uses. These projects typically balance cost efficiency with functional requirements rather than pushing precision limits.

How industries prioritize cutting factors:

| Industry | Primary Priority | Secondary Priority | Typical Tolerance Range | Volume Expectation |

|---|---|---|---|---|

| Automotive | Volume & Consistency | Precision | ±0.010" to ±0.020" | High volume production runs |

| Aerospace | Precision & Certification | Material Integrity | ±0.005" or tighter | Low to medium volume |

| Marine | Thick Material Capability | Cost Efficiency | ±0.030" to ±0.060" | Project-based |

| Construction | Speed & Cost | Material Handling | ±0.030" to ±0.125" | Variable, often high |

| General Industrial | Cost Optimization | Turnaround Time | ±0.015" to ±0.030" | Prototype to production |

Understanding where your project fits within this framework helps you communicate requirements clearly and avoid over-specifying tolerances that drive up costs unnecessarily. A metal cutting shop experienced in your industry already knows these priorities and can guide you toward the most appropriate solution.

Now that you understand how different industries approach cutting requirements, let's focus on preparing your specific project for success with clear specifications that get accurate quotes.

How to Prepare Your Steel Cutting Project for Success

You've identified the right cutting method and understand your industry's requirements. Now comes the critical step that separates smooth projects from frustrating delays: communicating your needs clearly to service providers. Whether you're wondering where to get metal cut for a prototype or seeking a metal cut service near me for production runs, proper preparation ensures accurate quotes and results that match your expectations.

Preparing Your Cutting Project Specifications

Think of your project specifications as the blueprint for success. Incomplete information leads to back-and-forth emails, delayed quotes, and sometimes costly misunderstandings once cutting begins. Metal fabrication experts emphasize that precision plays a major role in quality—even minor measurement errors can lead to delays, wasted material, or misaligned assemblies.

Before reaching out to any provider, gather these essential details:

- Material specifications: Include the exact alloy or grade (such as 304 stainless steel, A36 carbon steel, or 6061 aluminum), along with thickness and any required certifications

- Quantity needs: Specify exact quantities for each part, including whether this is a one-time prototype or recurring production order

- Dimensional requirements: Provide complete measurements for all cut dimensions, including critical tolerances where precision matters most

- Finish expectations: Note whether you need raw mill finish, deburred edges, specific surface treatments, or preparation for subsequent welding

- Drawing format: CAD files (DXF, DWG, or STEP formats) deliver the clearest communication, though detailed hand sketches with dimensions can work for simpler jobs

- Deadline requirements: Include both your ideal timeline and any hard deadlines that cannot be missed

When working with a cutting service, providing detailed blueprints and maintaining open communication throughout production helps keep the project on track and aligned with your exact specifications. Most local shops use advanced cutting technologies like laser or plasma systems that rely on accurate input data to guarantee precision.

Essential Information for Accurate Quotes

Wondering where can I get metal cut without the hassle of multiple quote revisions? The answer lies in upfront clarity. Industry research indicates that missing information can result in unexpected costs or project delays if fabricators need to request clarifications.

Your project specification checklist should include:

- Part geometry details: All dimensions, bend lines (if applicable), hole locations, and critical features clearly marked

- Material grade and thickness: Specific alloy designations, not just "steel" or "aluminum"

- Tolerance callouts: Indicate which dimensions require tight control and which can accept standard shop tolerances

- Surface finish requirements: Specify any coating, treatment, or edge preparation needed

- Quantity breakdown: Differentiate between sample, pilot, and production quantities if applicable

- Delivery location and timeline: Include shipping address and any scheduling constraints

- Secondary operations: Note if you need bending, welding, assembly, or other post-cut processes

Troubleshooting Common Specification Issues

Even experienced buyers encounter challenges when preparing cutting projects. Here's how to address the most frequent stumbling blocks:

Unclear drawings: If you don't have CAD files, detailed hand sketches with clear dimensions can suffice—but always aim for clarity. Include all relevant details such as materials, dimensions, tolerances, and any special features or finishes required. An incomplete drawing can lead to price swings or delays.

Material selection questions: Unsure which steel grade fits your application? Discuss your project goals with the fabricator. Skilled providers can recommend materials that balance cost efficiency with long-term reliability. The type of metal directly affects performance, durability, and cost.

Tolerance uncertainty: When you're not sure how tight to specify tolerances, consider the part's function. Will it mate directly with other precision components? Does it require machining after cutting? Parts heading straight to welding rarely need laser-level precision, while close-fit assemblies demand tighter control.

Prototype vs. Production Considerations

Your approach should differ based on project scale. For prototypes and small batches, expect higher per-unit costs due to setup and programming efforts that get spread across fewer pieces. Single prototypes may cost significantly more per part than production runs of 1,000 units.

When preparing prototype orders:

- Clearly label the order as a prototype or sample run

- Ask about design feedback before committing to production tooling

- Consider slightly relaxed tolerances if the goal is form and fit verification

- Request material certificates if you're validating performance characteristics

For production-scale projects:

- Provide accurate volume projections to unlock quantity pricing

- Establish delivery schedules and blanket order arrangements if applicable

- Discuss quality inspection protocols and documentation requirements

- Lock in material pricing when possible to avoid cost fluctuations

Clear communication remains the cornerstone of successful projects at any scale. By preparing thorough specifications upfront, you minimize quote revisions, reduce production surprises, and build a productive relationship with your cutting service provider. With your project properly documented, the next consideration becomes ensuring your chosen provider meets appropriate quality standards and certifications.

Quality Standards and Certifications That Matter

You've prepared thorough specifications and identified potential providers—but how do you know they'll deliver consistent results? Certifications serve as your assurance that a cutting service provider follows proven processes, maintains documented quality systems, and submits to regular third-party audits. Understanding what these credentials mean helps you distinguish between shops that promise quality and those that prove it.

Understanding ISO and Industry Certifications

When evaluating steel cutting services, certifications provide objective evidence of a provider's commitment to quality management. These aren't just plaques on the wall—they represent systematic approaches to process control, continuous improvement, and customer satisfaction.

Key certifications and their significance:

- ISO 9001:2015: This globally recognized standard ensures an organization's quality management system consistently meets customer requirements while driving continuous improvement. According to Ameritex's certification documentation, ISO 9001:2015 certification demonstrates commitment to providing reliable, high-quality products manufactured through efficiency, innovative technology, and dedication.

- IATF 16949: Built on ISO 9001 requirements, this automotive-specific certification goes further by ensuring compliance with lean manufacturing, defect prevention, variance reduction, and waste elimination. OGS Industries explains that IATF 16949 certification emphasizes strong customer focus, prioritizes top management alignment, and optimizes procedures for consistent service delivery.

- AS9100: The aerospace industry's quality standard addresses unique requirements for flight-critical components, including traceability, risk management, and configuration control.

- AWS D1.1/D1.6: Welding certifications relevant when your cutting project includes welded assemblies, ensuring proper procedures and welder qualifications.

- NADCAP: National Aerospace and Defense Contractors Accreditation Program certification for special processes like heat treatment or non-destructive testing.

What does certification actually mean for your project? Certified providers maintain documented procedures for every step—from receiving your order to final inspection. They track calibration of measuring equipment, train personnel on quality standards, and maintain records that prove each part meets specifications. When problems arise, their corrective action systems prevent recurrence.

Quality Inspection and Documentation

Beyond certifications, understanding a provider's inspection capabilities tells you whether they can verify the precision your project demands. Different cutting technologies deliver different baseline precision levels, and quality systems ensure consistency across every part.

Precision expectations by cutting method:

- Fiber laser cutting: Tolerances of ±0.001" to ±0.005" achievable with proper equipment calibration and quality control

- High-definition plasma: Expect ±0.015" to ±0.020" with certified processes and regular equipment maintenance

- Waterjet cutting: Delivers ±0.001" to ±0.005" when operators follow documented procedures

- Oxy-fuel cutting: Standard tolerances of ±0.030" to ±0.060" for thick plate applications

Certified shops use coordinate measuring machines (CMMs), optical comparators, and calibrated measuring instruments to verify dimensions. They provide inspection reports documenting actual measurements against your specifications—evidence that your parts meet requirements before they ship.

Turnaround Times and Production Timeline Expectations

Quality certifications also address delivery reliability. A certified quality system includes production planning, capacity management, and on-time delivery tracking. But what realistic timelines should you expect?

Typical turnaround by cutting method and order size:

- Laser cutting (small batch, under 50 parts): 3-7 business days depending on material availability and shop loading

- Laser cutting (production runs): 1-3 weeks with established blanket orders potentially reducing lead times

- Plasma cutting (structural components): 5-10 business days for standard orders; expedited service often available

- Waterjet cutting (precision parts): 5-10 business days due to slower cutting speeds on thick materials

- Oxy-fuel cutting (heavy plate): 1-2 weeks depending on plate availability and complexity

Several factors influence actual delivery timelines beyond the cutting operation itself:

- Material procurement: Standard alloys ship quickly; specialty grades may add 1-3 weeks

- Nesting efficiency: Complex part geometries require more programming time

- Secondary operations: Deburring, bending, or surface treatment extends lead times

- Inspection requirements: First article inspection and documentation add processing time

- Current shop capacity: Peak seasons may extend standard lead times by 25-50%

When timeline matters most, ask potential providers about their current backlog and expedite options. IATF 16949-certified shops, in particular, maintain production planning systems designed to meet automotive industry's demanding just-in-time delivery requirements. This discipline often translates to more predictable lead times across all customer projects.

Armed with knowledge of quality standards and realistic timeline expectations, you're now positioned to evaluate the final piece of the puzzle: understanding what drives cutting costs and how to optimize your project budget.

Pricing Factors and Cost Optimization Strategies

What will your steel cutting project actually cost? This question keeps many buyers guessing because pricing varies dramatically based on factors that aren't always obvious upfront. Whether you're searching for a steel cutter near me or comparing quotes from multiple providers, understanding these cost drivers helps you budget accurately and identify opportunities to save without sacrificing quality.

Key Factors That Influence Cutting Costs

Every quote you receive reflects a complex calculation involving materials, machine time, labor, and overhead. According to industry pricing research, laser cutting costs alone can range from $0.10 to $1.00 per inch depending on material type and thickness. Let's break down each factor so you can anticipate costs before requesting quotes.

Material type and cost:

- Mild steel: The most economical option at approximately $0.50-$1.00/kg ($0.23-$0.45/lb), making it the baseline for pricing comparisons

- Stainless steel: Expect to pay $1.50-$3.00/kg ($0.68-$1.36/lb) due to its durability and corrosion resistance

- Aluminum: Runs $2.00-$4.00/kg ($0.91-$1.81/lb) and requires specific cutting parameters that may affect machine time

- Specialty alloys: Custom pricing based on material availability and cutting difficulty

Thickness impact on pricing:

Thicker materials require more power, slower cutting speeds, and increased consumable wear. A 2mm mild steel sheet cuts significantly faster than 10mm plate, directly affecting machine time charges. CNC plasma systems can cut 1/2" mild steel at speeds exceeding 100 inches per minute, while waterjet systems typically operate at 5-20 inches per minute—a difference that translates directly into cost per part.

Design complexity:

- Simple shapes: Approximately 1 hour of design/programming time at $20-$100

- Complex geometries: 2-4 hours of preparation time, costing $40-$400

- Custom prototypes: 5+ hours at $100-$500 or more for intricate designs

Quantity considerations:

Setup and programming costs get distributed across your order quantity. A single prototype might cost $50-$100 in setup alone, while that same setup spread across 500 parts becomes negligible per unit. High-volume orders often qualify for material discounts and batch processing efficiencies that lower overall costs by 15-30%.

Tolerance requirements:

Tighter tolerances demand slower cutting speeds, more frequent quality checks, and potentially different cutting methods. Requesting ±0.005" precision when ±0.030" would suffice increases costs without adding functional value. Match your tolerance specifications to actual requirements.

Turnaround time:

- Standard lead time (5-10 days): Base pricing with no premium

- Rush orders (2-3 days): Expect 25-50% surcharges for priority scheduling

- Same-day or next-day: Premium pricing of 50-100% above standard rates

Post-cutting operations:

Deburring, polishing, bending, or painting add significant costs. A 1 m² laser-cut part might cost an additional $5-$15 for deburring and $10-$30 for painting, potentially doubling the base cutting cost for finished parts.

Optimizing Your Project for Cost Efficiency

Smart buyers don't just accept quotes—they optimize projects before requesting them. Metal fabrication experts recommend several strategies that reduce costs without compromising results.

Simplify your design:

Avoid overly complex cuts, unnecessary welds, and intricate detailing that require extensive labor and time. Using standard material sizes reduces waste and eliminates premium charges for custom sheet dimensions. Sometimes a slight design modification saves 20-30% on cutting costs.

Leverage nesting efficiency:

Advanced software arranges parts on sheet metal to maximize material usage. Partnering with a metal cutter near me that utilizes nesting technology reduces scrap and lowers material costs. Ask potential providers about their nesting capabilities—this single factor can significantly impact per-part pricing.

Plan for batch production:

Producing components in bulk rather than as one-off custom pieces significantly cuts costs. Batch production reduces setup time, labor, and overall expenses while maintaining quality consistency. If possible, consolidate multiple orders or plan ahead to take advantage of volume pricing.

Choose appropriate cutting methods:

Don't pay for laser precision when plasma delivers adequate quality for your application. CNC plasma tables offer the lowest cost per inch of cut with consumable costs of $0.10-$0.50 per inch, compared to laser systems at $0.15-$0.75 per inch. Match the technology to your actual requirements.

Consider material alternatives:

While stainless steel offers strength and corrosion resistance, aluminum may be more cost-effective for lightweight applications. Discuss your project goals with fabricators who can recommend materials balancing cost efficiency with long-term reliability.

Local vs. Online Service Economics

When you search for steel cutting near me, you're weighing convenience against potentially lower prices from distant providers. Both approaches have merit depending on your specific situation.

Advantages of local services:

- Face-to-face communication for complex projects reduces misunderstandings

- Lower or eliminated shipping costs for heavy materials

- Faster turnaround without transit time

- Ability to inspect first articles before full production

- Easier to address issues or make changes mid-project

When online/remote services make sense:

- Specialized capabilities not available locally

- Significantly lower pricing that offsets shipping costs

- Simple, well-defined projects with clear specifications

- Non-urgent timelines that accommodate shipping

For thick steel plates, shipping costs can quickly exceed any savings from distant providers. A single 4×8 ft mild steel sheet at 2mm thickness costs approximately $60-$120 for material alone—shipping that same sheet across the country might add $50-$150 depending on distance and carrier.

Calculate your total landed cost before making decisions. A local shop charging 15% more for cutting might still deliver lower total project cost when shipping and transit time are factored in. With pricing fundamentals understood, you're ready to evaluate providers and select the right partner for your project.

Selecting the Right Steel Cutting Service Provider

You've mastered the technical details and understand your project costs—now comes the decision that ties everything together. Finding a metal cutting shop near me that matches your specific requirements demands more than a quick online search. The right provider becomes a strategic partner who delivers consistent quality, meets deadlines, and communicates proactively when challenges arise.

Evaluating Service Provider Capabilities

Before committing to any provider, conduct a thorough assessment of their capabilities against your project needs. According to TMCO's industry guidance, a fabricator's experience is one of the strongest indicators of their capabilities—years in business often translate into deeper material knowledge, refined processes, and the ability to anticipate challenges before they become costly problems.

Provider evaluation checklist:

- Equipment capabilities: Verify they have the specific cutting technology (laser, plasma, waterjet) suited to your material and thickness requirements

- Material expertise: Confirm experience with your specific steel grades, whether carbon steel, stainless, or specialty alloys

- Certifications: Look for ISO 9001 at minimum; IATF 16949 for automotive applications; AS9100 for aerospace work

- In-house capabilities: Full-service shops offering cutting, bending, welding, and finishing under one roof reduce handoffs and quality variations

- Production capacity: Ensure they can scale from prototypes to production volumes without quality degradation

- Engineering support: Providers offering Design for Manufacturability (DFM) guidance help optimize designs before cutting begins

- Inspection equipment: CMMs, optical comparators, and documented quality processes ensure dimensional accuracy

- Communication responsiveness: Note how quickly they respond to initial inquiries—this predicts project communication quality

Not all fabrication shops offer the same level of capability. Some only cut metal, while others outsource machining, finishing, or assembly—which can lead to delays, communication gaps, and inconsistencies in quality. Industry experts emphasize that modern equipment and technology play important roles in custom sheet metal fabrication, as advanced machinery allows for accurate cutting, bending, and assembly essential for achieving precise designs.

When searching for sheet metal cutters near me or steel cutters near me, prioritize shops that demonstrate transparency about their equipment, processes, and quality systems. A provider confident in their capabilities will readily share this information.

Questions to Ask Before Committing

The questions you ask during initial conversations reveal whether a provider fits your needs. Industry research confirms that a supplier's reliability is just as important as the quality of their products—reliable suppliers ensure timely delivery and consistent product availability critical for maintaining project timelines.

Essential questions for potential providers:

- How long have you been fabricating complex metal parts, and do you have experience with similar applications?

- What cutting technologies do you operate, and what are their thickness and tolerance capabilities?

- Can you provide references or case studies from projects similar to mine?

- What certifications do you hold, and can you provide documentation?

- What is your typical lead time for projects of my size and complexity?

- Do you offer expedited services, and what are the associated costs?

- How do you handle design changes or issues discovered during production?

- What inspection processes ensure parts meet specifications before shipping?

- Do you provide material certifications and inspection reports with deliveries?

- What is your quote turnaround time, and how detailed are your estimates?

Pay attention to how providers answer these questions. Experienced custom metal fabricators understand variations in metals and how each performs during cutting, forming, and welding. They should confidently explain their quality processes without hesitation.

When Local Services Matter Most

Geographic proximity offers tangible advantages for certain project types. If you're asking where can I get metal cut near me, consider these scenarios where local providers deliver clear benefits:

- Complex or evolving projects: Face-to-face communication resolves ambiguities faster than email exchanges

- Heavy materials: Shipping thick steel plates adds significant cost; local pickup eliminates freight charges

- Tight timelines: Eliminating transit time provides additional working days for production

- First article inspection: Visiting the shop to approve initial samples before full production prevents costly mistakes

- Iterative prototyping: Rapid design-test-modify cycles benefit from geographic proximity

- Ongoing relationships: Regular orders build rapport and often unlock preferential treatment during capacity crunches

Local metal fabrication shops also understand regional market conditions, building codes, and industry norms that may affect your project. This contextual knowledge proves valuable for construction, architectural, and infrastructure applications.

When Remote or Online Services Work Well

Distance becomes less relevant when projects meet certain criteria:

- Well-defined specifications: Clear drawings and requirements minimize communication needs

- Specialized capabilities: Unique cutting technologies may not exist locally

- High-volume production: Significant per-unit savings can offset shipping costs

- Lightweight parts: Thin sheet metal ships economically

- Flexible timelines: Non-urgent projects accommodate shipping transit without pressure

- Established relationships: Once you've verified a remote provider's quality, ongoing orders become routine

For automotive and precision metal stamping applications, the calculation shifts toward finding providers with specific certifications and integrated capabilities regardless of location. Manufacturers like Shaoyi (Ningbo) Metal Technology exemplify this approach, offering IATF 16949-certified quality for chassis, suspension, and structural components with 5-day rapid prototyping capabilities and 12-hour quote turnaround. Their comprehensive DFM support streamlines the complete manufacturing process from cutting to finished assemblies—capabilities that may not exist within your local market.

When evaluating distant providers for automotive applications, prioritize those demonstrating:

- IATF 16949 certification ensuring automotive-grade quality systems

- Rapid prototyping capabilities for fast design validation

- Automated mass production capacity for volume scaling

- Comprehensive engineering support reducing design iterations

- Quick quote responsiveness indicating operational efficiency

Building Long-Term Provider Relationships

The best cutting service relationships extend beyond transactional orders. Trusted providers become extensions of your engineering team, offering insights that improve designs and reduce costs over time. They prioritize your orders during capacity constraints because they value the ongoing relationship.

Start with a trial project to verify capabilities before committing to larger orders. Evaluate not just the finished parts, but the entire experience—quote accuracy, communication quality, on-time delivery, and issue resolution. Transparent communication prevents costly surprises and keeps projects aligned from start to finish.

A reliable fabricator will provide clear timelines, project updates, and realistic expectations. Strong communication skills indicate a provider who values partnership over short-term profit. These relationships deliver compounding value as providers learn your preferences, anticipate needs, and proactively suggest improvements.

With provider selection criteria established, you're ready to synthesize everything you've learned and take confident action on your steel cutting project.

Making Informed Steel Cutting Decisions

You've navigated the complete landscape of steel cutting services—from understanding thermal and mechanical technologies to evaluating providers and optimizing costs. Now it's time to distill this knowledge into actionable decisions that move your project forward with confidence.

Matching Your Project to the Right Cutting Method

Choosing the optimal cutting technology doesn't require becoming a metallurgical expert. Instead, focus on three fundamental questions that guide every successful project:

The right cutting method balances your material thickness, required precision, and budget constraints. Over-specifying tolerance wastes money; under-specifying risks costly rework.

Consider your material first. Carbon steel offers the widest range of cutting options, while stainless steel and aluminum demand specific parameters. Next, evaluate thickness—laser excels under 1.25 inches, plasma handles mid-range plates efficiently, and oxy-fuel tackles the heaviest sections. Finally, match tolerance requirements to functional needs rather than aspirational precision.

Professional steel cutting solutions succeed when specifications align with reality. A trusted fabrication partner can guide you toward the cutting method that maximizes your project's success while respecting budget boundaries.

Key decision factors at a glance:

- For precision under 0.75" thickness: Fiber laser delivers excellent edge quality and tight tolerances

- For structural components over 1" thick: Plasma or oxy-fuel provides cost-effective results

- For heat-sensitive materials: Waterjet eliminates thermal distortion concerns

- For high-volume sheet metal: Shearing offers rapid throughput at lower cost

Taking the Next Step with Confidence

Ready to move forward? This industrial metal cutting guide has equipped you with the knowledge to communicate effectively with providers and evaluate their responses intelligently. Clear communication remains the foundation of successful projects—incomplete specifications lead to quote revisions, production delays, and results that miss expectations.

Remember that project management best practices emphasize setting specific goals, defining scope clearly, and maintaining open communication channels. These principles apply directly to your cutting project, regardless of size or complexity.

Your steel fabrication cutting methods action plan:

- Document your requirements completely: Gather material specifications, quantities, tolerances, and deadline constraints before contacting providers

- Prepare professional drawings: CAD files in DXF, DWG, or STEP formats communicate specifications most effectively—detailed sketches work for simpler jobs

- Request quotes from multiple providers: Compare at least three shops to understand market pricing and capability differences

- Verify certifications: Confirm ISO 9001 at minimum; require IATF 16949 for automotive or AS9100 for aerospace applications

- Ask about lead times and capacity: Understand current backlog and expedite options before committing

- Start with a trial order: Test provider capabilities with a smaller project before committing to production volumes

- Evaluate the complete experience: Assess quote accuracy, communication quality, and on-time delivery—not just finished part quality

The knowledge you've gained transforms you from a passive buyer into an informed partner. You understand steel fabrication cutting methods well enough to ask the right questions, recognize quality certifications that matter, and optimize projects for cost efficiency without sacrificing results.

Whether you need a wood laser cutter service for specialized applications or heavy plate processing for structural steel, the fundamentals remain consistent: clear specifications, appropriate technology selection, and verified provider capabilities lead to successful outcomes. Take that first step by documenting your project requirements—the path from raw steel to precision components begins with clarity about what you need to achieve.

Frequently Asked Questions About Steel Cutting Services

1. How much does metal cutting cost?

Metal cutting costs vary based on material type, thickness, complexity, and cutting method. Laser cutting typically ranges from $0.10 to $1.00 per inch, while plasma cutting offers lower costs at $0.10-$0.50 per inch. Mild steel costs approximately $0.50-$1.00/kg, stainless steel runs $1.50-$3.00/kg, and aluminum ranges $2.00-$4.00/kg. Setup fees for simple shapes cost $20-$100, while complex designs may reach $100-$500. Rush orders add 25-100% surcharges, and secondary operations like deburring or painting can double base cutting costs.

2. Can you cut steel at home?

Yes, you can cut mild steel up to about 3/8 inch thick at home using ferrous-metal-cutting blades with circular saws or angle grinders. Carbide-tooth blades last longer than steel-tooth options. Tin snips work for thin sheet metal, and regular scissors handle very thin materials. However, for precision cuts, complex shapes, or thicker materials, professional steel cutting services using laser, plasma, or waterjet technologies deliver superior accuracy, cleaner edges, and tolerances as tight as +/- 0.001 inch.

3. What is the best cutting method for thick steel plates?

For thick steel plates, oxy-fuel cutting handles materials from 0.5 inch to over 36 inches thick, making it ideal for heavy structural work. Plasma cutting efficiently processes steel from 0.25 inch to 6+ inches with better edge quality than oxy-fuel. Waterjet cutting handles up to 8+ inches without heat-affected zones, preserving material properties. Choose oxy-fuel for straight cuts on heavy carbon steel, plasma for balanced speed and quality on structural components, and waterjet when heat distortion must be avoided on precision parts.

4. What certifications should I look for in a steel cutting service provider?

Key certifications include ISO 9001:2015 for quality management systems, IATF 16949 for automotive applications requiring lean manufacturing and defect prevention, and AS9100 for aerospace components demanding traceability and configuration control. AWS D1.1/D1.6 certifications matter when projects include welding. NADCAP accreditation applies to special processes like heat treatment. These certifications ensure documented procedures, calibrated equipment, trained personnel, and consistent quality through third-party audits.

5. How do I prepare specifications for a steel cutting project?

Prepare complete specifications including exact material grade and alloy (such as 304 stainless or A36 carbon steel), thickness, quantities, and dimensional requirements with critical tolerances marked. Provide CAD files in DXF, DWG, or STEP formats for clearest communication. Include finish expectations, deadline requirements, and any secondary operations needed. Specify which dimensions require tight control versus standard tolerances. Clear specifications prevent quote revisions, reduce production delays, and ensure results match expectations.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —