खराब हो रहा है नियंत्रण आर्म? आपकी ब्रेकिंग के लिए छिपा खतरा

संक्षिप्त में

एक दोषपूर्ण या क्षतिग्रस्त स्टैम्प्ड स्टील नियंत्रण भुजा (कंट्रोल आर्म) आपके वाहन के ब्रेकिंग प्रदर्शन को गंभीर रूप से कमजोर कर देती है। यह व्हील संरेखण में बदलाव पैदा करती है, जिससे ब्रेक लगाते समय ड्राइविंग व्हील में खतरनाक कंपन, गाड़ी का एक तरफ खिंचना और समग्र अस्थिरता होती है। ये लक्षण एक गंभीर सुरक्षा समस्या को दर्शाते हैं जो वाहन को संचालित करने के लिए असुरक्षित बना देती है।

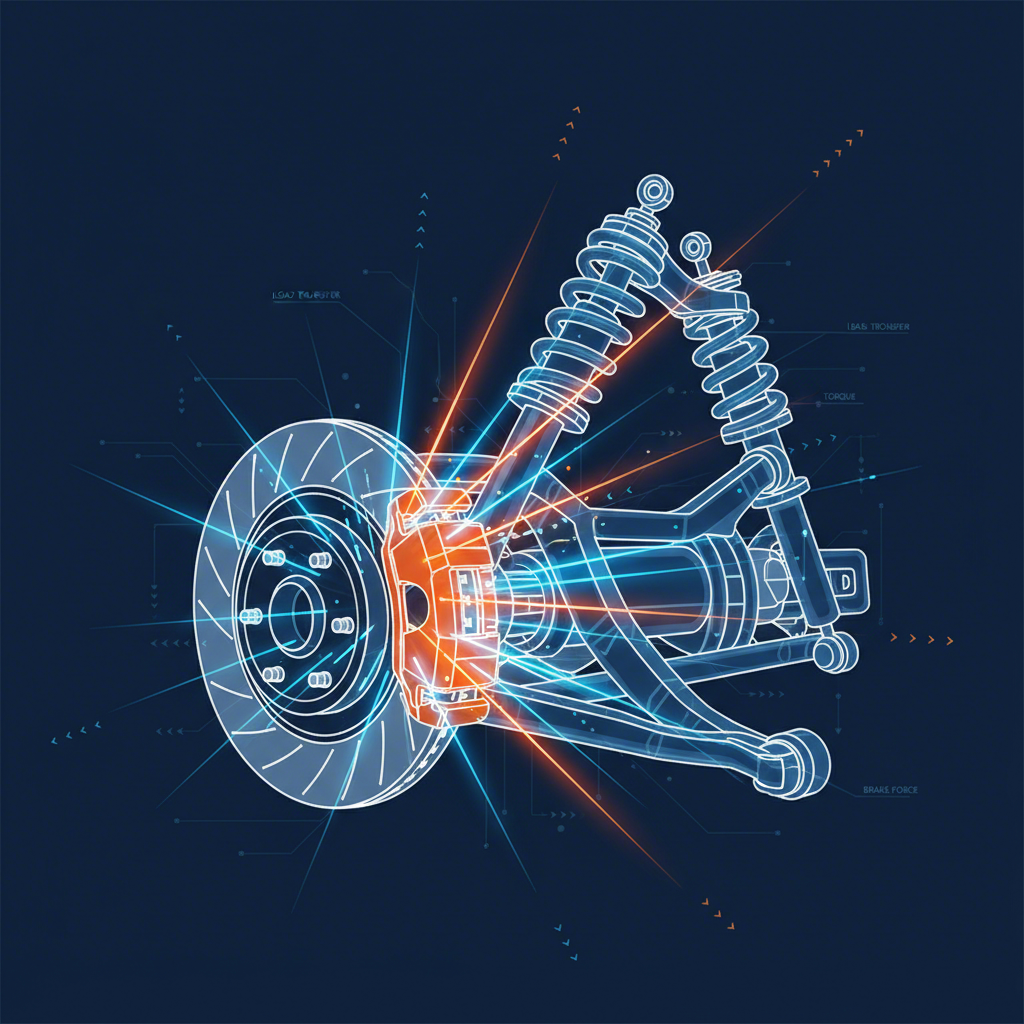

सस्पेंशन और ब्रेकिंग में नियंत्रण भुजा की महत्वपूर्ण भूमिका

आपके वाहन के सस्पेंशन प्रणाली के गहरे भीतर, नियंत्रण भुजा (कंट्रोल आर्म) नामक घटकों का एक सेट सुरक्षा और स्थिरता के लिए पूर्णतः आवश्यक कार्य करता है। एक नियंत्रण भुजा एक मजबूत, कब्जेदार लिंक है जो आपके वाहन के फ्रेम को स्टीयरिंग नकल या व्हील हब से जोड़ती है। इसे एक महत्वपूर्ण कनेक्शन के रूप में समझें जो आपके पहियों को उबड़-खाबड़ सड़कों पर ऊपर-नीचे हिलने की अनुमति देता है, साथ ही स्टीयरिंग करते समय घूमने की भी अनुमति देता है। बिना इस घटक के, आपकी गाड़ी के पास उचित व्हील संरेखण बनाए रखने या ड्राइविंग और ब्रेकिंग के दौरान उत्पन्न विशाल बलों को अवशोषित करने का कोई तरीका नहीं होगा।

कंट्रोल आर्म का प्राथमिक कार्य सड़क के संबंध में आपके पहियों की स्थिति और कोण को नियंत्रित करना है। जैसे-जैसे आप गाड़ी चलाते हैं, कंट्रोल आर्म यह सुनिश्चित करते हैं कि टायर लगातार सड़क के संपर्क में बने रहें, जो ट्रैक्शन, हैंडलिंग और प्रभावी ब्रेकिंग के लिए महत्वपूर्ण है। इनमें लचीले रबर या पॉलियूरेथेन बुशिंग्स होते हैं जहां वे फ्रेम से जुड़ते हैं, जो कंपन को अवशोषित करते हैं और शोर को कम करते हैं। पहिये के सिरे पर, एक बॉल जॉइंट एक घूर्णन बिंदु प्रदान करता है, जो स्टीयरिंग के लिए आवश्यक सुचारु, नियंत्रित गति की अनुमति देता है।

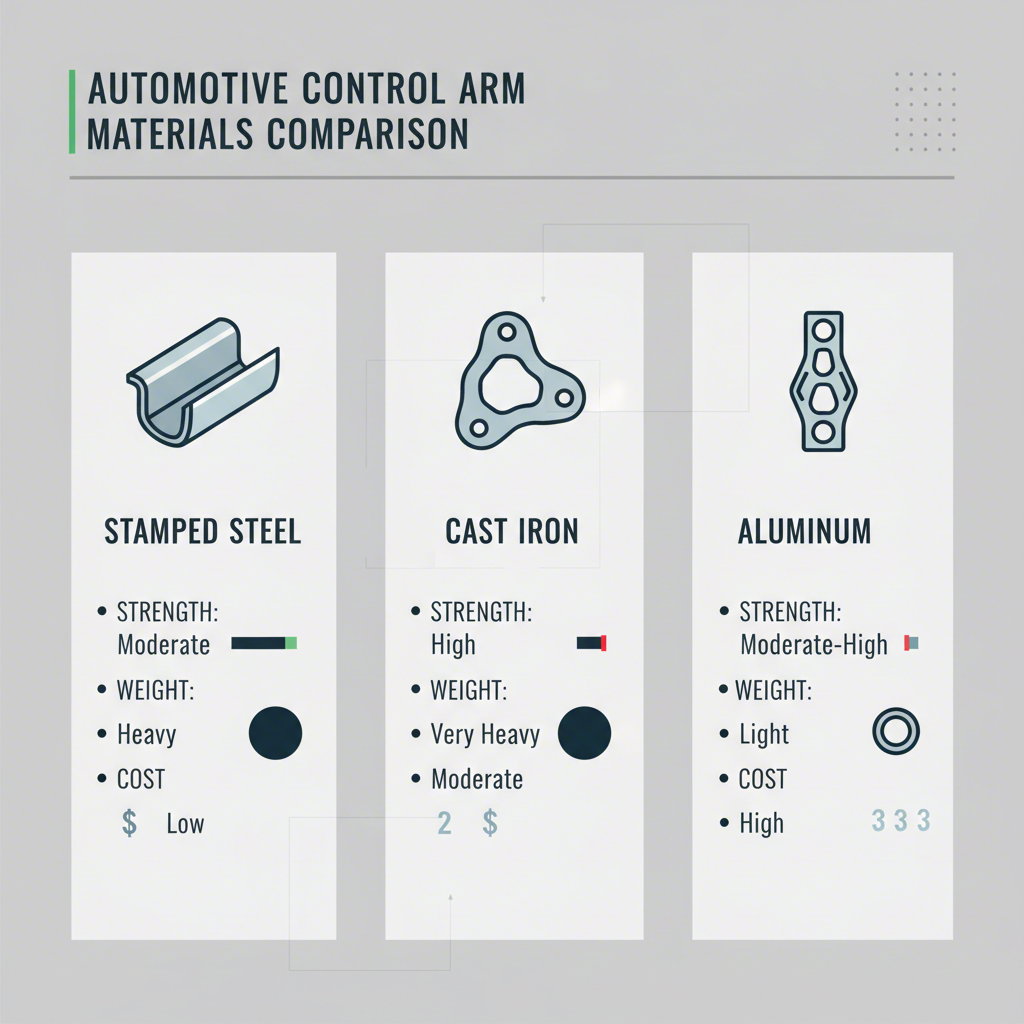

कंट्रोल आर्म आमतौर पर तीन सामग्रियों में से एक—स्टैम्प्ड स्टील, ढलवां लोहा या ढलवां एल्युमीनियम से बनाए जाते हैं। प्रत्येक के अलग-अलग गुण होते हैं:

- स्टैम्प्ड स्टील: यह यात्री कारों में पाया जाने वाला सबसे आम प्रकार है। यह कम उत्पादन लागत पर मजबूती और टिकाऊपन का अच्छा संतुलन प्रदान करता है। एल्युमीनियम की तुलना में भारी होने के बावजूद, इसकी विश्वसनीयता इसे विभिन्न वाहनों के लिए लोकप्रिय विकल्प बनाती है।

- ढलवां लोहा: अपनी असाधारण मजबूती और कठोरता के लिए जाना जाता है, ढलवां लोहे का उपयोग अक्सर ट्रकों और एसयूवी जैसे भारी वाहनों में किया जाता है। यह कंपन को दबाने में उत्कृष्ट है, लेकिन सबसे भारी विकल्प है और यदि उचित रूप से लेपित नहीं किया गया तो जंग लगने के प्रति संवेदनशील हो सकता है।

- ढलाई किया हुआ एल्यूमीनियम: यह सबसे हल्के विकल्प है, जो ईंधन दक्षता और निलंबन प्रतिक्रियाशीलता में सुधार करने में मदद करता है। एल्युमीनियम प्राकृतिक रूप से जंगरोधी भी होता है। हालाँकि, यह आमतौर पर स्टील या लोहे की तुलना में सबसे महंगी सामग्री होती है और उच्च-तनाव अनुप्रयोगों के लिए उसी स्तर की मजबूती प्रदान नहीं कर सकती है।

इन भागों के निर्माण प्रक्रिया उनके प्रदर्शन और सुरक्षा के लिए महत्वपूर्ण है। उच्च परिशुद्धता और टिकाऊपन पर निर्भर रहने वाले ऑटोमोटिव निर्माताओं के लिए, शाओयी (निंगबो) मेटल टेक्नोलॉजी कंपनी लिमिटेड जैसी कंपनियां व्यापक धातु स्टैम्पिंग समाधान प्रदान करती हैं। उन्नत, IATF 16949 प्रमाणित सुविधाओं के साथ, वे नियंत्रण भुजाओं जैसे जटिल ऑटोमोटिव घटकों के उत्पादन में विशेषज्ञता रखते हैं, जिससे आधुनिक वाहनों के लिए आवश्यक कठोर गुणवत्ता और सुरक्षा मानकों को पूरा किया जाता है। अंततः, सामग्री के बावजूद, अच्छी तरह से इंजीनियर की गई नियंत्रण भुजा पूरे निलंबन और ब्रेकिंग प्रणाली की अखंडता के लिए मौलिक है।

एक खराब हो रहे स्टैम्प्ड स्टील नियंत्रण भुजा का ब्रेकिंग प्रदर्शन पर सीधा नकारात्मक प्रभाव

एक खराब कंट्रोल आर्म केवल एक मामूली परेशानी नहीं है; यह आपके वाहन के सुरक्षित ढंग से रुकने की क्षमता पर सीधा और खतरनाक प्रभाव डालता है। जब एक स्टैम्प्ड स्टील कंट्रोल आर्म या उसके बुशिंग घिस जाते हैं, तो आपकी निलंबन की सटीक ज्यामिति बिगड़ जाती है। ब्रेक लगाते समय, वाहन का वजन आगे की ओर स्थानांतरित होता है, जिससे सामने के निलंबन पर भारी बल पड़ता है। एक स्वस्थ कंट्रोल आर्म इस बल के खिलाफ पहिया असेंबली को स्थिर रखता है। हालांकि, एक क्षतिग्रस्त कंट्रोल आर्म पहिया की स्थिति बदलने देता है, जिससे ठीक उसी क्षण जब आपको अधिकतम स्थिरता की आवश्यकता होती है, पहिया की संरेखण और टो कोण बदल जाता है।

इस अवांछित गति कई खतरनाक ब्रेकिंग लक्षणों का मूल कारण है। सबसे आम और चिंताजनक लक्षण है ब्रेक लगाते समय स्टीयरिंग व्हील में मजबूत कंपन या झटका यह तब होता है जब ढीला या गलत तरीके से संरेखित पहिया ब्रेकिंग बल के तहत सीधा नहीं चल पाता, जिससे वह डगमगाता है। यह कंपन हल्के कांपन से लेकर हिंसक हिलने तक का हो सकता है, जिससे वाहन को नियंत्रित करना मुश्किल हो जाता है।

एक अन्य खतरनाक लक्षण वाहन का होना है ब्रेक लगाते समय एक तरफ तेजी से खिंचना ब्रेक लगाते समय, उदाहरण के लिए, यदि दाईं ओर का कंट्रोल आर्म खराब हो रहा है, तो उस पहिए में पीछे की ओर खिसकाव या कोण में परिवर्तन हो सकता है, जिससे कार दाईं ओर मुड़ जाती है। इससे ड्राइवर को कार को सीधा रखने के लिए लगातार स्टीयरिंग सुधार करने पड़ते हैं, जो आपातकालीन रोक या फिसलन भरी सतहों पर विशेष रूप से खतरनाक होता है। स्पष्ट रूप से, घिसे बुशिंग अक्सर मुख्य दोषी होते हैं, क्योंकि वे आर्म को दृढ़ता से जगह पर रखने की क्षमता खो देते हैं।

स्पष्ट रूप से, खराब कंट्रोल आर्म ब्रेकिंग में महत्वपूर्ण समस्याएं पैदा करता है। ब्रेक लगाते समय आपको निम्नलिखित सामान्य लक्षण अनुभव हो सकते हैं:

- स्टीयरिंग व्हील का कंपन: स्टीयरिंग व्हील के माध्यम से महसूस होने वाला कंपन या झटके, विशेष रूप से मध्यम या तीव्र ब्रेकिंग के दौरान ध्यान देने योग्य।

- एक तरफ खिंचना: बिना ड्राइवर द्वारा स्टीयरिंग इनपुट के वाहन स्पष्ट रूप से बाईं या दाईं ओर मुड़ जाता है।

- खरोंच या झनझनाहट की आवाज़: घिसे हुए घटक धातु-पर-धातु संपर्क का कारण बन सकते हैं, जिससे निलंबन पर ब्रेक लगाने के दबाव में आने पर तेज़ आवाज़ें आती हैं।

- अस्थिर या "भटकती हुई" अनुभूति: कार का अगला हिस्सा सड़क से ढीला या अलग लग सकता है, जिससे ड्राइवर के आत्मविश्वास और नियंत्रण में कमी आती है।

- ब्रेकिंग प्रभावशीलता में कमी: चूंकि टायर सड़क के साथ इष्टतम संपर्क बनाए नहीं रखता है, आपके वाहन की रुकने की दूरी बढ़ सकती है।

इन लक्षणों को नज़रअंदाज़ करना अत्यंत खतरनाक है। एक क्षतिग्रस्त नियंत्रण भुजा स्टीयरिंग नियंत्रण के पूर्ण नुकसान या यहां तक कि घातक निलंबन विफलता का कारण बन सकती है, जिसके कारण तुरंत निदान और मरम्मत आपकी सुरक्षा के लिए आवश्यक है।

पूर्ण नैदानिक मार्गदर्शिका: खराब नियंत्रण भुजा के सभी लक्षणों को पहचानना

जबकि ब्रेक की समस्याएं एक महत्वपूर्ण लाल झंडा हैं, एक विफल नियंत्रण हाथ अक्सर खुद को विभिन्न अन्य लक्षणों के माध्यम से प्रकट करता है जो स्टीयरिंग, हैंडलिंग और टायर पहनने को प्रभावित करते हैं। इस तरह के लक्षणों को पहचानने में सक्षम होने से आपको समस्या का पता लगाने में मदद मिल सकती है। एक गहन जांच में असामान्य आवाज़ों की ओर ध्यान देना, स्टीयरिंग में बदलाव महसूस करना और टायर और सस्पेंशन के घटकों का नेत्रहीन निरीक्षण करना शामिल है।

सबसे आम संकेतों में से एक शोर है। आप एक स्पष्ट आवाज सुन सकते हैं घंटों तक की आवाज , विशेष रूप से जब आप ढलानों, गड्ढों या तेज मोड़ पर चलते हैं। यह शोर आमतौर पर पहने हुए बुशिंग या ढीले गोले के जोड़ के कारण होता है, जो अत्यधिक आंदोलन और धातु के भागों को एक दूसरे के खिलाफ टक्कर देने की अनुमति देता है। एक अन्य प्रमुख लक्षण सामान्य भावना है स्टीयरिंग अस्थिरता . शायद स्टीयरिंग ढीली, अस्पष्ट या अनुत्तरित लग रही हो या फिर आप कार को बिना किसी संकेत के बहते हुए देख सकते हैं। यह दर्शाता है कि नियंत्रण बांह अब पहिया संयोजन को सही संरेखण में मजबूती से नहीं पकड़ रहा है।

दृश्य रूप से, आपके टायर सबसे अच्छे नैदानिक उपकरणों में से एक हैं। एक घुमाया या पहना नियंत्रण हाथ पहिया संरेखण फेंक देगा, कारण असमान और समय से पहले टायर पहनना . टायर के अंदर या बाहर के किनारों पर पहनने की तलाश करें, जो यह बताता है कि पहिया सड़क के लंबवत नहीं है जैसा कि यह होना चाहिए। चूंकि नियंत्रण बांह को बदलने के लिए पहियों को संरेखित करना आवश्यक है, इसलिए असमान पहनने की जांच करना एक महत्वपूर्ण कदम है।

समस्या के स्रोत को अलग करने में मदद करने के लिए, यह समझने के लिए उपयोगी है कि विभिन्न घटक विफलताएं खुद को कैसे प्रस्तुत करती हैं। नीचे एक तालिका है जो खराब नियंत्रण हाथ बुशिंग, एक विफल गेंद जोड़, और एक घुमावदार नियंत्रण हाथ के सामान्य लक्षणों की तुलना करती है।

| घटक की विफलता | प्राथमिक लक्षण |

|---|---|

| पहने हुए नियंत्रण बांह के बुशिंग | टक्कर के दौरान टक्कर लगने की आवाज, स्टीयरिंग व्हील के कंपन, स्टीयरिंग में ढीलापन की भावना और ब्रेक लगाते समय एक तरफ खींचने की आवाज। सबसे आम विफलता बिंदु। |

| असफल गेंद जोड़ | जब स्टीयरिंग व्हील घुमाया जाए या ढलानों पर चढ़ाई की जाए तो जोर से धड़कने या चिल्लाने की आवाजें। यह स्टीयरिंग भटकने और टायर के असमान पहनने का कारण भी बन सकता है। पूर्ण विफलता के कारण पहिया अलग हो सकता है। |

| घुमावदार या टूटी हुई नियंत्रण बांह | आमतौर पर एक महत्वपूर्ण प्रभाव (गड्ढे, बेंचमार्क) के कारण होता है। इसके परिणामस्वरूप गंभीर संरेखण समस्याएं होती हैं, जिससे कार एक तरफ से काफी हद तक खींचती है। पहिया स्पष्ट रूप से झुका हुआ दिखाई दे सकता है। यह एक महत्वपूर्ण सुरक्षा खतरा है। |

यदि आपको नियंत्रण बांह की समस्या का संदेह है, तो आप एक बुनियादी जांच कर सकते हैं। सुरक्षित रूप से पार्क किए हुए वाहन के साथ, बस्टिंग्स को देखने की कोशिश करें कि क्या कोई दरारें या आंसू दिखाई दे रहे हैं। आप व्हील को आगे बढ़ाने का प्रयास करके भी वाहन को अत्यधिक खेल की जाँच के लिए एक पेशेवर लिफ्ट कर सकते हैं। किसी भी प्रकार की ढीली होने की स्थिति एक समस्या का संकेत है।

अक्सर पूछे जाने वाले प्रश्न

1. क्या नियंत्रण बांह से ब्रेक लगने में समस्या हो सकती है?

हाँ, बिल्कुल। खराब नियंत्रण बांह या इसके बुशिंग पहियों के संरेखण को प्रभावित करके महत्वपूर्ण ब्रेक समस्याएं पैदा कर सकते हैं। जब बुशिंग्स पहनते हैं, तो वे नियंत्रण बांह को स्थानांतरित करने की अनुमति देते हैं, जिससे पहिया अस्थिर हो जाता है। इससे कंपन, हिलना और एक तरफ खींचना होता है, खासकर जब आप ब्रेक लगाते हैं।

2. नियंत्रण बांह टूटने का कारण क्या हो सकता है?

नियंत्रण बांह की विफलता के सबसे आम कारण बड़े गड्ढे से टकराने, फुटपाथ पर टकराने या टक्कर में शामिल होने के प्रभाव हैं। समय के साथ, रबर या पॉलीयूरेथेन बुशिंग भी पहन सकते हैं, दरारें, और आंसू, जो एक अधिक क्रमिक विफलता का रूप है। सड़क नमक के भारी उपयोग वाले क्षेत्रों में गंभीर जंग भी धातु को कमजोर कर सकती है और टूटने का कारण बन सकती है।

3. कैसे पता चलेगा कि आपके पास स्टील से मुहर लगी है?

सामग्री की पहचान करने का एक सरल तरीका चुंबक से है। यदि चुंबक नियंत्रण बांह पर दृढ़ता से चिपके रहता है, तो यह या तो स्टैम्प्ड स्टील या कास्ट आयरन से बना होता है। यदि चुंबक चिपके नहीं है, तो यह एल्यूमीनियम है। दृश्य रूप से, स्टैम्प्ड स्टील के हथियार अक्सर ऐसा दिखते हैं जैसे वे एक साथ वेल्डेड शीट धातु के दो टुकड़ों से बने हों, जबकि कास्ट घटकों में आमतौर पर एकल, ठोस दिखने वाले टुकड़े होते हैं।

4. कास्ट आयरन और स्टील नियंत्रण हथियारों के बीच क्या अंतर है?

स्टैम्प्ड स्टील कंट्रोल आर्म आमतौर पर हल्के और कम महंगे होते हैं, जिससे वे आधुनिक यात्री कारों में आम हो जाते हैं। कास्ट आयरन नियंत्रण हथियार भारी और मजबूत होते हैं, आमतौर पर भारी शुल्क वाले वाहनों जैसे ट्रकों और एसयूवी में उपयोग किए जाते हैं क्योंकि वे कठिन परिस्थितियों का बेहतर सामना कर सकते हैं। जबकि दोनों मजबूत हैं, कास्ट आयरन उत्कृष्ट कंपन को कम करता है लेकिन यदि इसे लेपित नहीं किया जाता है तो यह जंग के लिए अधिक प्रवण होता है।

छोटे पर्चे, उच्च मानदंड। हमारी तेजी से प्रोटोटाइपिंग सेवा मान्यता को तेजी से और आसानी से बनाती है —

छोटे पर्चे, उच्च मानदंड। हमारी तेजी से प्रोटोटाइपिंग सेवा मान्यता को तेजी से और आसानी से बनाती है —