Sheet Metal Stamping Die Secrets: From Design Flaws To Flawless Parts

What Is a Sheet Metal Stamping Die and Why It Matters

Ever wondered how manufacturers produce thousands of identical metal parts with razor-sharp precision? The answer lies in a specialized tool that sits at the heart of modern metalworking. Understanding what is metal stamping and the dies that make it possible unlocks the secret behind everything from automotive panels to tiny electronic components.

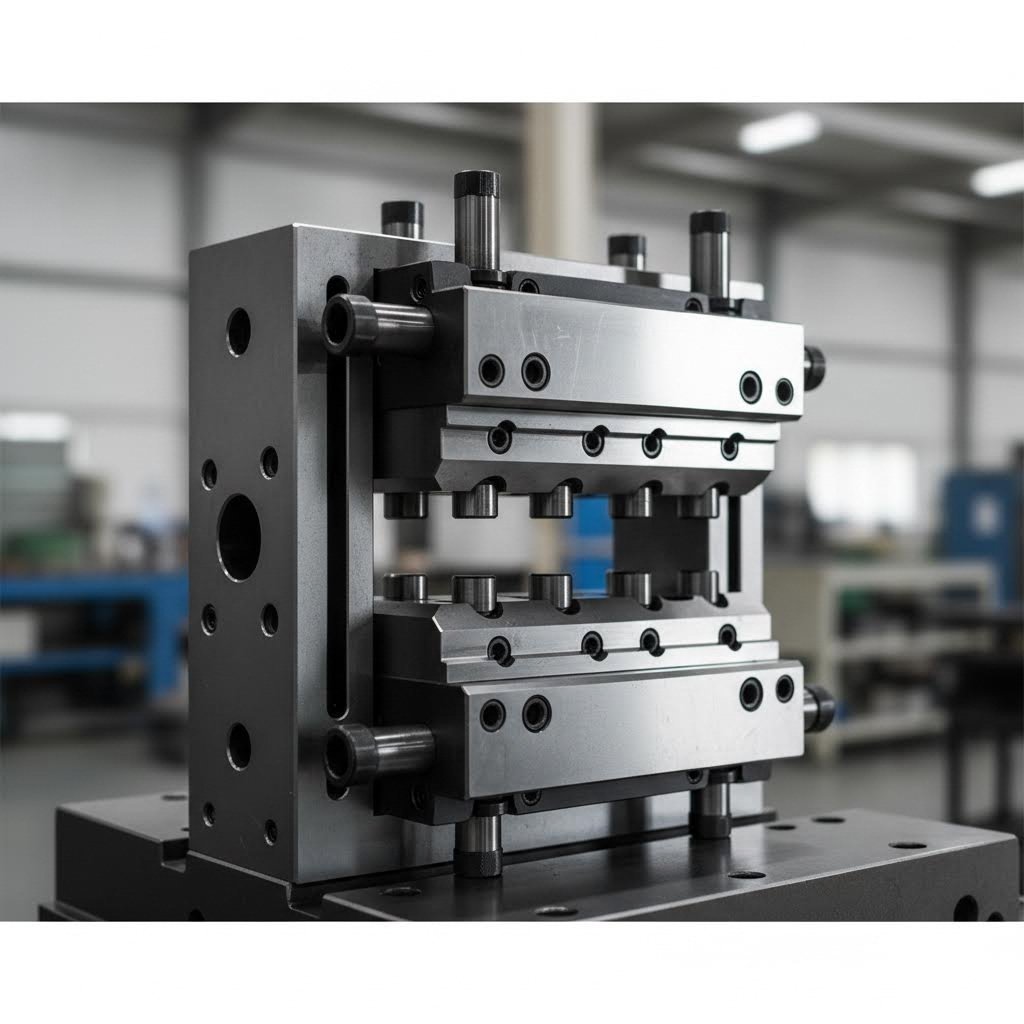

A sheet metal stamping die is a precision tool made from hardened tool steel that cuts, shapes, and forms flat metal sheets into specific three-dimensional parts through controlled pressure applied by a stamping press.

So, what are dies exactly? In manufacturing, stamping dies are specialized tools designed to perform specific cutting and forming operations on sheet metal. They work in pairs - an upper and lower component - that come together under immense force to transform raw material into finished parts. Unlike hand tools or general-purpose equipment, these dies are engineered for one specific part geometry and cannot function without the power of a stamping press.

The Core Function of Stamping Dies in Metal Fabrication

What is stamping in practical terms? It's a cold forming process that uses dies to shape metal without heating it first. When you ask what is stamped metal, you're looking at components created through this precise mechanical transformation. According to The Phoenix Group, a stamping die performs four essential functions during operation:

- Locating - Positioning the sheet metal precisely within the die

- Clamping - Securing the material in place during forming

- Working - Performing the actual cutting, bending, or shaping operations

- Releasing - Freeing the finished part from the tooling

The working phase is where the real magic happens. During this stage, the die performs value-added operations like cutting, bending, piercing, embossing, forming, drawing, stretching, coining, and extruding. Each operation transforms the flat blank into something more complex and useful.

Why Dies Are the Heart of High-Volume Production

Imagine trying to hand-craft 10,000 identical brackets for an automotive assembly line. It would take forever, and consistency would be nearly impossible. This is precisely why dies matter so much in manufacturing.

What is a stamping operation without proper tooling? Simply put - inefficient and impractical. As noted by Dynamic Die Supply, stamping dies enable mass production of affordable, high-precision parts with consistent quality and dimensional accuracy. While developing these tools requires significant investment in computer-aided design and skilled craftsmanship, they prove invaluable when production volumes justify the upfront cost.

The real power of a sheet metal stamping die lies in repeatability. Once properly designed and manufactured, it can produce identical parts cycle after cycle - sometimes running at speeds exceeding 1,000 strokes per minute. This combination of speed, precision, and consistency makes stamping dies indispensable across industries from aerospace to consumer electronics.

Types of Stamping Dies and When to Use Each

Now that you understand what a stamping die does, the next question becomes: which type fits your project? Selecting the wrong die type can mean wasted budget, production delays, or parts that simply don't meet specifications. Let's break down the major types of stamping dies and explore exactly when each one makes the most sense for real-world manufacturing.

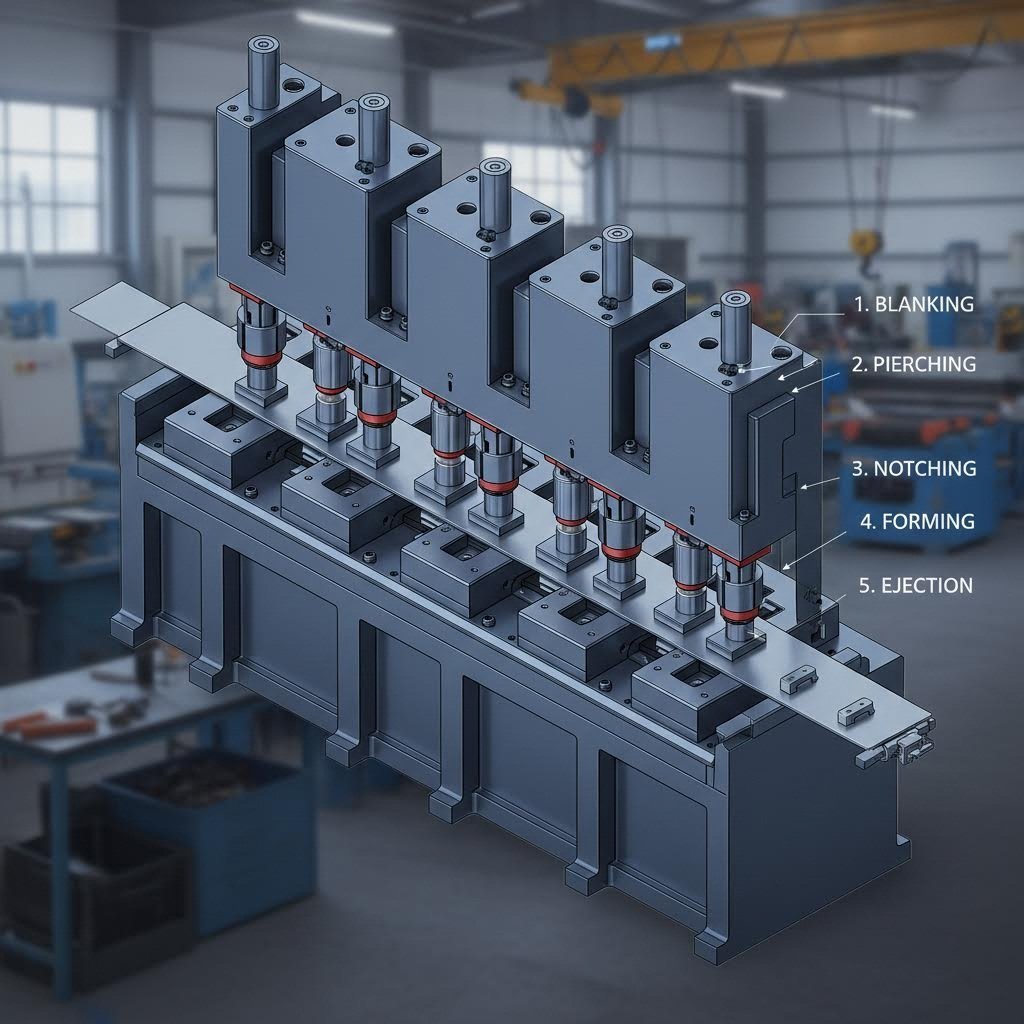

Progressive Dies for High-Speed Continuous Production

Picture a metal coil feeding continuously through a press while multiple stations work simultaneously - that's progressive die stamping in action. According to Durex Inc., progressive dies consist of multiple stations arranged in sequence, with each performing a specific operation as the metal sheet advances through the press.

What makes this stamping die configuration so powerful? The workpiece stays attached to the base strip from start to finish. Separating individual parts from the carrier strip happens only at the final station. This continuous flow eliminates handling time between operations and maximizes throughput.

Progressive dies excel when you need:

- High-volume production - Ideal for runs requiring thousands or millions of identical parts

- Complex geometries through simple steps - Each station handles one operation, building complexity incrementally

- Strict tolerance specifications - The continuous strip maintains alignment throughout processing

- Fast cycle times - Parts are produced rapidly with high repeatability

However, progressive dies require significant upfront investment in permanent steel tooling. They're also not suitable for parts requiring deep drawing operations, where the forming depth exceeds what the attached strip can accommodate.

Transfer Dies Versus Compound Dies in Complex Part Manufacturing

When progressive dies don't fit the bill, manufacturers typically choose between transfer dies and compound dies. Understanding their differences helps you match the right die for press to your specific application.

Transfer die stamping separates the part from the metal strip at the very first operation. From there, mechanical "fingers" transport each individual piece through multiple stations that perform separate operations. As Engineering Specialties Inc. notes, this method is ideal for parts with intricate design elements like knurls, ribs, and threading.

Transfer dies shine in scenarios involving:

- Deep-draw components where forming depth exceeds strip limitations

- Tube applications and complex assemblies

- Parts requiring operations on multiple sides

- Larger components that progressive dies cannot handle efficiently

Compound die stamping takes a different approach entirely. Instead of multiple strokes across stations, compound dies perform all cutting, punching, and bending operations in a single stroke. This makes them exceptionally fast for simpler parts. According to Worthy Hardware, compound dies are particularly cost-effective for medium to high-volume production of flat parts like washers.

The trade-off? Compound dies cannot handle complex three-dimensional shapes. They work best when part geometry remains relatively simple and flat.

Comparing Die Types: A Practical Selection Guide

When evaluating forming dies for your next project, several factors determine which type delivers the best results. Dies and stamping processes must align with your part requirements, budget, and production goals. The following comparison breaks down the key selection criteria:

| Die Type | Part Complexity | Production Volume | Setup Time | Typical Applications |

|---|---|---|---|---|

| Progressive Die | Moderate to high (built incrementally) | High volume (thousands to millions) | Moderate initial; fast changeover | Automotive brackets, clips, electronic components |

| Transfer Die | High (intricate designs, deep draws) | Short to long runs (flexible) | Longer setup; requires precision alignment | Aerospace parts, heavy machinery, tube components |

| Compound Die | Low to moderate (flat parts only) | Medium to high volume | Quick setup; single-stroke operation | Washers, gaskets, simple flat components |

| Combination Die | Moderate (cutting and forming together) | Medium volume | Moderate setup complexity | Parts requiring both blanking and forming in one press cycle |

Beyond these four primary categories, specialized dies like blanking dies, coining dies, and embossing dies serve targeted functions. Blanking dies cut specific shapes from sheet metal as a preparatory step. Coining dies create high-precision detailed components for jewelry or medical devices. Embossing dies add raised or recessed patterns for aesthetic or functional purposes.

The right choice ultimately depends on balancing part complexity against production economics. High-volume simple parts favor compound or progressive approaches, while complex assemblies benefit from transfer die flexibility. Understanding these distinctions prepares you for the next critical consideration: what materials and components make up the die itself.

Stamping Die Components and Material Selection

You've selected the right die type for your project - but what actually goes inside that tooling? Understanding stamping die components separates engineers who troubleshoot problems from those who prevent them entirely. Let's cut open a typical metal stamping die and examine the critical parts that determine whether you produce flawless parts or fight constant quality issues.

Essential Die Components From Punch to Stripper Plate

Think of a metal die as a precisely engineered assembly where every component serves a specific purpose. According to U-Need's stamping die components guide, the design, material, and integrity of individual parts determine more than 90 percent of overall tool performance and operational lifespan.

Here are the core components you'll find in most sheet metal dies:

- Die Shoes (Upper and Lower) - The heavy base plates forming the top and bottom halves of the die set. The lower shoe mounts to the press bed while the upper shoe attaches to the ram. These provide the structural foundation holding everything in alignment.

- Guide Pins and Bushings - Precision-ground hardened pins on one die shoe that slide into equally precise bushings on the other. They ensure perfect alignment between upper and lower halves during every press stroke.

- Punches - The male components that perform piercing, blanking, or forming operations. These directly contact the workpiece and experience the greatest stress during operation.

- Die Buttons - The female counterparts to punches in cutting operations. Each button features a precision-ground hole matching the punch profile with specific clearance allowances.

- Stripper Plates - Critical for removing material from punches after piercing or blanking. Without proper stripping force, parts stick to tooling and production halts.

- Backing Plates - Hardened plates positioned behind punches and die buttons that absorb impact forces and prevent tool deflection.

- Pilots - Precision pins that locate the strip material accurately at each station, especially critical in progressive steel stamping dies.

A small error of just a few micrometers in any component can trigger a chain reaction of failures: wrong part dimensions, premature tool wear, expensive unscheduled downtime, and elevated scrap rates. This is why understanding each part's function matters so much.

Material Selection for Durability and Precision

Why do some metal forming dies last 500,000 cycles while others fail at 50,000? Material selection is often the deciding factor. Choosing the right tool steel or specialty alloy for each stamp die component requires balancing hardness, toughness, wear resistance, and thermal stability.

According to Neway's tool and die materials guide, here's what each property contributes:

- Hardness - Tool steels should possess 44-52 HRC (Rockwell hardness) for general stamping, or up to 60 HRC for demanding cold work applications

- Toughness - Protects against chipping and cracking during repetitive mechanical impact; Charpy V-notch values greater than 20 J are desirable for complex dies

- Wear Resistance - Determines how long cutting edges and forming surfaces maintain their geometry

- Dimensional Stability - Low-distortion materials maintain accuracy after heat treatment; volumetric shrinkage below 0.3% is typically acceptable

Common materials used in stamping die components include:

| Material | Hardness Range | Best Applications | Key Advantages |

|---|---|---|---|

| D2 Tool Steel | 58-62 HRC | Blanking dies, trim dies, thin sheet metal cutting | High chromium content (~12%) provides excellent wear resistance |

| A2 Tool Steel | 56-60 HRC | General-purpose dies, forming tools, inserts | Good dimensional stability and balanced toughness |

| S7 Tool Steel | 54-56 HRC | Trim dies, impact-intensive applications | Exceptional impact resistance without brittleness |

| Tungsten Carbide | >80 HRC | High-wear inserts, long-life shearing tools | Extreme compressive strength and wear life |

| H13 Hot Work Steel | 44-52 HRC | Dies exposed to elevated temperatures | Excellent balance of strength, toughness, and heat resistance |

D2 tool steel remains a popular choice for cold work stamping operations due to its exceptional abrasion resistance. However, it lacks the toughness needed for high-impact applications. For components facing repetitive shock loading, S7 steel delivers superior performance despite lower hardness numbers.

Carbide inserts represent the premium option when die life justifies the investment. While more brittle than tool steels, carbide components routinely outlast steel alternatives by 5-10 times in abrasive stamping applications. Many manufacturers use carbide strategically - placing inserts only at high-wear locations rather than fabricating entire components from this expensive material.

Specialized coatings like titanium nitride (TiN) or diamond-like carbon (DLC) extend tool life further by reducing friction and improving surface hardness. These treatments prove especially valuable when stamping stainless steel, aluminum, or other materials prone to galling.

Achievable tolerances depend heavily on both component materials and die configuration. Precision-ground components can hold tolerances of +/- 0.001mm according to industry standards, while standard tooling typically operates at +/- 0.025mm or looser. Progressive dies generally achieve tighter tolerances than single-station setups because the continuous strip maintains consistent positioning throughout processing.

With components and materials understood, the next logical step involves exploring how engineers design these complex assemblies - from initial CAD models through simulation-validated production tooling.

The Die Design Process From Concept to Production

You've selected the right die type and understand the materials involved - but how does a stamping die design actually come to life? The journey from initial concept to production-ready tooling involves sophisticated software, careful analysis, and iterative refinement. Getting this die process right determines whether your first production run yields perfect parts or expensive scrap.

From CAD Model to Production-Ready Die Design

Modern metal stamping die design begins long before any metal gets machined. The stamping process starts digitally, with engineers translating part geometry into manufacturable tooling through a structured workflow.

The typical design sequence follows these stages:

- Part Analysis - Engineers examine the finished part geometry, identifying forming requirements, critical dimensions, and potential problem areas

- Process Planning - Determining the sequence of operations, number of stations, and overall die configuration needed to produce the part

- Blank Development - Calculating the optimal flat pattern size and shape that will form into the final geometry with minimal waste

- Die Layout - Creating the overall arrangement of punches, forming surfaces, and material handling features within the die set

- Detail Design - Engineering individual components including punches, die buttons, strippers, and guide systems

- CAM Programming - Generating toolpaths for CNC machining of die components

CAD/CAM integration has transformed how engineers approach this workflow. Today's design platforms allow seamless transition from 3D solid models to machining instructions without manual data translation. Parametric modeling enables rapid design iterations - change a punch diameter in the CAD model, and all related components update automatically.

What makes a manufacturing die design truly production-ready? Beyond geometric accuracy, engineers must account for material springback, press deflection, thermal expansion, and wear allowances. These factors rarely appear in textbook examples but dominate real-world tooling performance.

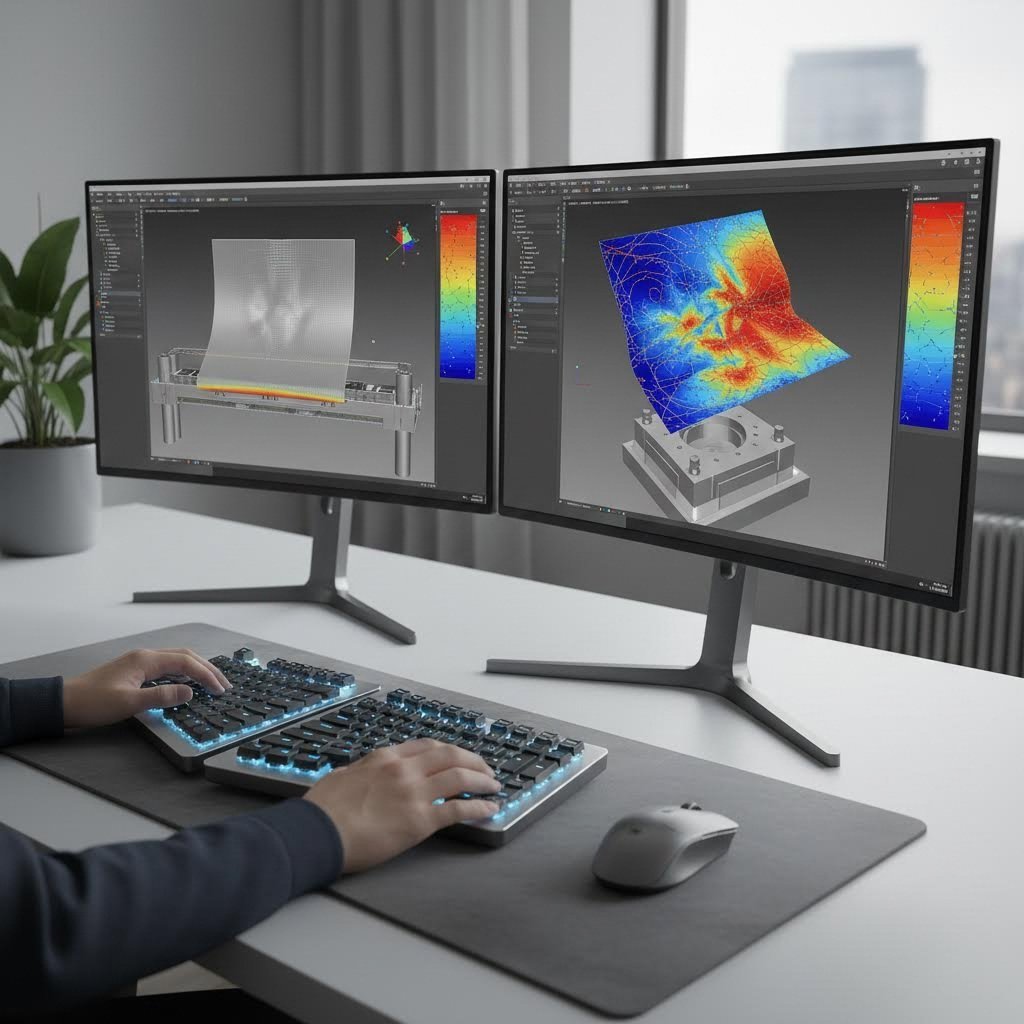

How Simulation Prevents Costly Design Errors

Imagine discovering that your newly machined tooling produces wrinkled parts - after spending weeks and thousands of dollars on fabrication. This scenario played out regularly before simulation software revolutionized stamping die design.

According to Dutton Simulation, press tool simulation has been widely used since the early 1990s with one clear goal: "to take the uncertainty out of the die design process by predicting splitting, wrinkling, thinning, surface defects and springback problems before any metal is cast." International benchmarks like NUMISHEET have repeatedly validated the accuracy of these methods.

Modern CAE (Computer-Aided Engineering) simulation identifies critical issues that would otherwise surface only during physical tryouts:

- Springback Prediction - As Keysight's engineering team explains, advanced high-strength steels and aluminum alloys exhibit significant elastic recovery after forming. Simulation predicts this behavior, allowing engineers to compensate tooling geometry before fabrication.

- Wrinkling Analysis - Excess material in compression zones causes wrinkles that ruin part quality. Simulation reveals where blankholder pressure adjustments or addendum geometry changes prevent these defects.

- Thinning and Splitting Risk - Overly aggressive stretching thins material beyond acceptable limits, eventually causing splits. Simulation maps thickness distribution across the entire part surface.

- Surface Quality Assessment - For visible components, simulation can evaluate aesthetic quality through digital stoning contours or virtual lightroom analysis that mimics shopfloor inspection techniques.

Software packages like eta/DYNAFORM and FASTFORM Advanced represent the current state of the art for die for manufacturing applications. These tools incorporate detailed finite element models that account for blankholder curvature, drawbead geometry, lubrication conditions, and even material property variations within the same batch.

The business case for simulation is compelling. Physical die tryouts consume weeks of press time, require skilled technicians, and often demand multiple correction cycles. Virtual tryouts compress this timeline dramatically while identifying problems that physical testing might miss entirely. As Keysight notes, simulation helps "predict and prevent defects early in the design phase, streamlining operations and ensuring that parts meet stringent quality standards from the outset."

Perhaps most valuable is springback compensation - the semi-automatic adjustment of tool surfaces to counteract material elastic recovery. Without simulation, engineers rely on experience-based rules that work inconsistently across different materials and geometries. With simulation, compensation becomes systematic and predictable, reducing iteration cycles from many to few.

The iterative refinement process typically follows this pattern: simulate initial design, identify defects, modify tooling geometry or process parameters, re-simulate, and repeat until results meet specifications. Each virtual cycle takes hours rather than the days or weeks required for physical iterations. This acceleration fundamentally changes project economics - enabling more design exploration within the same timeline and budget.

Understanding simulation capabilities prepares you for the next critical relationship in stamping operations: matching your die design to press equipment specifications.

Press and Die Relationship in Metal Stamping Operations

You've designed the perfect die - now what? Without the right press to power it, even flawless tooling produces nothing but frustration. The relationship between stamping dies and metal stamping presses determines whether your operation runs smoothly or grinds to a halt. Let's explore the practical selection criteria that ensure your die and press work together as intended.

Matching Die Requirements to Press Capabilities

Think of your sheet metal stamping press as the engine and your die as the specialized tool attachment. Mismatch them, and you'll either lack the power to form parts or overwhelm delicate tooling with excessive force. Several critical factors must align for successful stamping and pressing operations.

Key press-die compatibility factors include:

- Tonnage Capacity - The press must deliver sufficient force to complete all forming and cutting operations. Calculate required tonnage based on material thickness, tensile strength, and total cutting perimeter. Always include a 20-30% safety margin above theoretical requirements.

- Bed Size (Bolster Dimensions) - The press bed must accommodate the complete die footprint with adequate clearance for clamping and material handling. Oversized dies on undersized beds create alignment problems and safety hazards.

- Stroke Length - Sufficient ram travel ensures punches fully clear the workpiece during retraction. Deep draw operations require longer strokes than simple blanking applications.

- Shut Height - The distance between bed and ram at bottom dead center must match die closed height. Adjustable shut heights provide flexibility across different tooling configurations.

- Speed Capabilities - Production rates depend on strokes per minute (SPM). Progressive dies often run at 200-1,000+ SPM, while complex transfer operations may require slower speeds for material handling accuracy.

- Feed System Compatibility - Coil-fed progressive operations need servo feeds synchronized with press motion. Transfer dies require mechanical fingers or robotic handling matched to press timing.

Getting tonnage calculations wrong creates immediate problems. Insufficient force results in incomplete forming, dimensional errors, or stalled production. Excessive force accelerates die wear and risks catastrophic tooling failure.

Critical Press Specifications for Successful Stamping Operations

Beyond basic compatibility, several press specifications directly impact part quality and production efficiency. Understanding these parameters helps you select equipment that maximizes your die investment.

The die stamping machine must provide:

- Parallelism and Rigidity - Ram-to-bed parallelism within 0.001 inches per foot prevents uneven wear and dimensional drift. Frame rigidity minimizes deflection under load.

- Slide Velocity Profile - Servo-driven presses offer programmable velocity curves that slow the ram during critical forming phases, reducing impact stress on tooling.

- Counterbalance Systems - Proper counterbalancing prevents slide drop and ensures consistent bottom dead center positioning.

- Quick Die Change Capability - For operations running multiple part numbers, rapid changeover systems minimize downtime between production runs.

The metal stamping process follows a consistent flow regardless of die type. Material feeds into position - either as individual blanks or from continuous coil stock. Pilots or locating pins precisely position the workpiece. The press ram descends, engaging upper die components with lower tooling. Forming and cutting operations complete at bottom dead center. The ram retracts while strippers remove the part from punches. Finally, ejection systems or mechanical transfers move finished parts clear before the next cycle begins.

Sheet metal pressings quality depends heavily on this synchronized dance between press motion and die function. Timing errors measured in milliseconds can cause misfeed jams, incomplete operations, or damaged tooling. Modern press controls monitor dozens of parameters in real-time, stopping production instantly when sensors detect abnormal conditions.

Die design must account for these press specifications from the earliest concept stages. A die engineered for a 200-ton mechanical press won't perform identically in a 200-ton hydraulic unit - the force application curves differ significantly. Similarly, tooling designed for high-speed progressive operation requires different clearances and stripper configurations than slower transfer applications.

With press and die properly matched, the focus shifts to maintaining consistent production quality - and knowing how to diagnose problems when they inevitably arise.

Troubleshooting Common Stamping Die Problems

Your press is running, your die is installed - but something isn't right. Maybe parts show excessive burrs, or dimensions keep drifting out of tolerance. Every stamping operation eventually encounters problems that threaten production quality. Knowing how to diagnose and solve these issues separates experienced engineers from those scrambling for answers. Let's explore the most common sheet metal stamping dies problems and the systematic approaches that fix them.

Diagnosing Common Stamping Defects at the Die Level

When stamped parts start failing quality checks, the root cause often traces back to the metal stamping die itself. According to DGMF Mold Clamps, uneven wear patterns on punch cores represent one of the most frequent issues - particularly pronounced on thin, narrow rectangular dies. Understanding the sheet metal stamping process helps pinpoint where things go wrong.

The primary causes behind inconsistent die wear include:

- Machine tool alignment issues - Upper and lower turntable mounting seats that aren't properly aligned create uneven stress distribution across cutting edges

- Inadequate mold precision - Design or manufacturing accuracy that fails to meet requirements leads to premature failure

- Guide bushing problems - Worn or imprecise guide bushings allow lateral movement during press strokes

- Improper clearance settings - Clearances too tight or too loose accelerate wear on specific punch areas

- Long-term component degradation - Mold mounts and guide bushings wear over extended production runs

Stamped sheet metal quality directly reflects die condition. When you notice scratches, inconsistent edges, or dimensional variations across parts, start your investigation at the tooling level before blaming material or press settings.

Understanding Bypass Notches in Sheet Metal Stamping Dies

Ever wondered about the bypass notches sheet metal forming purpose? These intentional relief features cut into die surfaces serve a critical function: controlling material flow during forming operations.

Bypass notches in sheet metal stamping dies allow excess material to escape rather than bunching up and causing wrinkles or cracks. During deep drawing or complex forming, metal needs somewhere to go as it stretches and compresses. Without proper bypass notches, material flow becomes unpredictable - leading to surface defects and dimensional inconsistencies in stamped parts.

Think of bypass notches as pressure relief valves for your forming process. They're strategically positioned based on simulation analysis to manage material movement exactly where problems would otherwise develop.

Solving Dimensional Accuracy and Surface Quality Issues

When dimensional drift or surface defects appear, systematic troubleshooting saves hours of guesswork. The following table organizes common problems with their likely causes and proven corrective actions:

| Problem | Likely Causes | Corrective Actions |

|---|---|---|

| Excessive Burring | Worn cutting edges; insufficient punch-to-die clearance; dull tooling | Sharpen or replace punches; verify and adjust clearances to 5-10% of material thickness; inspect die buttons for wear |

| Part Cracking | Material too hard or brittle; excessive forming radius; insufficient lubrication | Verify material specifications; increase bend radii; improve lubrication; consider annealing material |

| Wrinkling | Insufficient blankholder pressure; improper bypass notch design; excessive material in compression zones | Increase blankholder force; redesign material flow features; adjust drawbead configuration |

| Dimensional Drift | Thermal expansion during production; progressive die wear; inconsistent material thickness | Allow warm-up cycles before measuring; implement regular sharpening schedules; verify incoming material specifications |

| Premature Die Wear | Misaligned turret; worn guide bushings; incorrect material hardness; contaminated lubricant | Use alignment mandrels for regular checks; replace worn guides; verify tool steel hardness; change lubrication system filters |

| Parts Sticking to Punches | Worn or weak strippers; insufficient spring pressure; surface finish issues | Replace stripper springs; increase stripping force; polish punch surfaces; apply appropriate coatings |

Prevention beats correction every time. DGMF recommends several principles to avoid stamping problems before they occur:

- Perform direction checks during die installation to ensure convex and concave components align correctly

- Limit stamping depth adjustments to no more than 0.15mm per change

- Use lower punching speeds when working with challenging materials or complex geometries

- Verify plate flatness before processing - warped material causes unpredictable results

- Position forming operations away from clamps where material movement is restricted

- Complete common stamping operations before using forming dies in progressive setups

Regularly using alignment mandrels to check and adjust machine turret positioning prevents the cascade of wear problems that stem from misalignment. Timely guide bushing replacement and proper clearance selection extend die life significantly.

When troubleshooting feels overwhelming, remember that most stamping defects trace to just a handful of root causes: alignment, clearance, lubrication, and wear. Address these fundamentals first, and you'll solve the majority of production quality issues before they become costly problems. Maintaining these solutions over time, however, requires systematic maintenance practices that we'll explore next.

Die Maintenance and Life Extension Best Practices

You've diagnosed the problem and fixed the immediate defect - but how do you prevent it from happening again tomorrow? Reactive maintenance keeps you constantly chasing issues while production suffers. Smart manufacturers flip this equation entirely. Proper die processing through systematic maintenance extends tool life dramatically while keeping part quality consistent run after run.

According to Kaishuo Mold, preventive maintenance costs 12-18% less than emergency repairs - and every dollar invested saves five dollars in future costs. This strategic approach cuts unexpected downtime by over 70%. Let's explore exactly how to implement these practices in your stamping tooling operations.

Preventive Maintenance Schedules for Maximum Die Life

Think of your die stamp as a precision instrument requiring regular care. Waiting until something breaks means accepting costly production interruptions and accelerated wear on surrounding components. A structured maintenance program addresses potential issues during planned downtime rather than during critical production runs.

Effective metal stamping tooling maintenance follows this essential checklist:

- Post-Run Cleaning - Clean dies thoroughly after every production run. Residual metal dust and lubricant burn-on act as abrasives that accelerate wear on critical surfaces. According to industry data, proper cleaning alone can reduce abrasive wear by up to 20%.

- Lubrication Verification - Confirm proper lubrication before each run. The right lubricant forms a protective film between die and sheet metal, reducing friction by over 80%. This simple step can increase service life by 30-50% before major servicing becomes necessary.

- Visual Inspection Protocol - Train operators to inspect key wear areas after every run. Look for early signs of cracking, chipping, or galling. This proactive measure successfully identifies over 75% of developing issues before they cause failures.

- Alignment Checks - Verify guide pin and bushing alignment weekly or after every 10,000 cycles. Misalignment causes uneven wear patterns that compound rapidly.

- Clearance Measurement - Check punch-to-die clearances monthly using appropriate gauges. Worn clearances lead to excessive burring and accelerated edge degradation.

- Spring Tension Testing - Test stripper and pressure pad springs quarterly. Weak springs cause parts sticking and inconsistent forming pressure.

- Cycle Counting and Logging - Track production cycles for each die set. This data enables predictive maintenance - replacing parts at 80% of their predicted lifespan rather than waiting for failure.

As JVM Manufacturing notes, well-maintained equipment reduces the likelihood of unexpected breakdowns and prevents costly production halts. Addressing minor issues during planned downtimes ensures continuous workflow rather than emergency scrambles.

When to Sharpen, Repair, or Replace Die Components

Not every worn component needs immediate replacement - but waiting too long transforms minor maintenance into major repairs. Understanding the decision points helps you optimize both die life and maintenance budgets.

Sharpening intervals depend on material being stamped, production volume, and observed edge condition. General guidelines suggest:

- Mild steel stamping: Sharpen every 50,000-100,000 hits

- Stainless steel or high-strength materials: Sharpen every 20,000-40,000 hits

- When burr height exceeds 10% of material thickness

- Whenever visual inspection reveals edge chipping or rounding

Addressing a minor sharpening task in two hours avoids a 16-hour breakdown later. The grinding and honing processes restore original geometry and sharpness, maintaining the desired tolerances and surface finishes your parts require.

Repair becomes necessary when components show wear beyond what sharpening can address but remain structurally sound. Guide bushings, stripper springs, and locating pins often fall into this category. Replace these wear items on schedule rather than waiting for failure - the production interruption costs far more than the replacement parts.

Component replacement timing follows predictable patterns when you track cycle counts. Dies manufacturing operations benefit from data-driven replacement schedules that swap components at 80% of expected lifespan. This approach reduces component costs by 8-12% compared to arbitrary replacement intervals while virtually eliminating surprise failures.

Storage Requirements That Protect Your Investment

Die stamps face threats even when sitting idle. Humidity causes rust and pitting on precision surfaces - damage that's expensive to correct and often impossible to fully reverse. Proper storage protects your tooling investment between production runs.

Essential storage practices include:

- Climate control - Store tools in dry environments with humidity below 50%. This single precaution slashes corrosion rates by 99%.

- Anti-corrosion coatings - Apply protective oils or vapor corrosion inhibitors to all exposed tool steel surfaces before storage.

- Proper support - Store die sets on appropriate racks that prevent warping or damage to alignment features.

- Identification and documentation - Label each die clearly and maintain accessible records of maintenance history, cycle counts, and known issues.

The relationship between maintenance practices and production quality becomes obvious over time. Shops that invest in systematic care consistently produce parts within specification while spending less on emergency repairs and replacement tooling. Those that defer maintenance face escalating quality problems, unpredictable downtime, and frustrated customers.

Consistent stamping tooling maintenance isn't a cost - it's performance insurance that protects your capital investment while guaranteeing the quality your customers expect. With maintenance practices established, the next consideration becomes understanding the full economics of die investment and calculating true cost per part over the tooling lifetime.

Cost Considerations and ROI for Die Investments

You've maintained your tooling perfectly - but how do you know whether that die investment made financial sense in the first place? Many manufacturers fixate on initial quotes while overlooking the real economics that determine profitability. Understanding die stamping costs requires looking beyond the purchase price to evaluate total project economics over the entire production lifetime.

According to Jeelix's comprehensive cost analysis, equating a mold's purchase price with its total cost is one of the most common traps in manufacturing. The initial price often represents just the tip of the iceberg - with massive, project-defining costs hidden beneath the surface.

Key Factors Driving Stamping Die Investment Costs

Why do quotes for seemingly similar dies vary by 50% or more between suppliers? As The Fabricator explains, multiple factors drive this variance - and understanding them transforms you from a passive price-taker into a strategic decision-maker.

The primary cost drivers for custom metal stamping dies include:

- Part Geometry and Complexity - In mold engineering, complexity and cost rarely follow a linear relationship. Instead, the relationship is often exponential. Even small design details can have significant ripple effects on manufacturing expenses.

- Material Selection - Parts made from specialty materials like titanium, aluminum, or high-strength steel require higher grades of tool steel and carbide, increasing tooling costs substantially.

- Tolerance Requirements - Tighter tolerances demand more precise machining, better materials, and additional quality verification steps - all adding to the final price.

- Expected Production Volume - Higher volumes justify investment in multi-cavity designs and premium materials that reduce per-part costs over time.

- Vendor Capabilities and Location - Labor rates for diemakers, designers, and engineers vary significantly by geography. A tool built in California typically costs more than one built in Wisconsin due to cost-of-living differences.

The process used to make your part represents perhaps the largest factor in tool cost. One stamping dies manufacturer might quote a 10-station progressive die with a 5-inch pitch, while another quotes a 15-station die with a 5.250-inch pitch. This processing method difference results in significant cost variations - yet both may produce acceptable parts.

Calculating True Cost Per Part Over Die Lifetime

Smart procurement professionals understand that the initial fabrication cost often represents only 70-80% of total cost of ownership over the first few years. According to Glencoyne's ROI guide, calculating the "all-in" cost requires accounting for lifecycle expenses rarely included in initial quotes.

These hidden costs fall into several categories:

| Cost Category | Description | Budget Impact |

|---|---|---|

| Design Modifications | T1 sample corrections and engineering changes | 10-15% of initial quote |

| Scheduled Maintenance | Sharpening, component replacement, preventive care | 5-10% annually |

| Unplanned Repairs | Emergency fixes for unexpected failures | Variable but significant |

| Iteration Cycles | Multiple tryout rounds before production approval | Weeks of press time per cycle |

A practical rule: budget a 15-25% contingency on top of initial quotes to cover lifecycle costs over the first 24 months. For an $80,000 custom metal stamping die, this means earmarking an additional $12,000-$20,000 for modifications and maintenance.

To calculate true cost per part, divide total die investment (including contingencies) by expected lifetime production volume. A $100,000 die producing 1 million parts costs $0.10 per piece for tooling amortization alone. That same investment producing only 100,000 parts jumps to $1.00 per piece - a tenfold difference in economics.

The Business Case for Manufacturer Selection

Here's where metal stamping die manufacturers truly differentiate themselves. The cheapest quote often becomes the most expensive project when iteration cycles multiply and approval timelines stretch.

Consider what happens with first-pass approval rates. If a supplier achieves only 60% approval on initial samples, you're looking at multiple correction cycles - each consuming weeks of calendar time and thousands in modification costs. Compare this to working with experienced stamping die manufacturers who achieve approval rates above 90% on first submissions.

Rapid prototyping capabilities further compress project timelines. Traditional stamping die manufacturing might require 8-12 weeks for initial samples. Manufacturers like Shaoyi offer rapid prototyping in as little as 5 days, dramatically accelerating your time-to-market while reducing development costs. Combined with their 93% first-pass approval rate, this engineering expertise translates directly into project savings.

When evaluating suppliers, assess these value-creating capabilities:

- Engineering Expertise - Experienced teams identify cost-saving opportunities during design that less capable suppliers miss entirely

- Simulation Capabilities - Advanced CAE analysis prevents costly physical iteration cycles

- First-Pass Approval Rates - Higher rates mean fewer corrections and faster production start

- Prototyping Speed - Rapid sample delivery compresses development timelines

- Quality Certifications - IATF 16949 and similar standards indicate robust processes that deliver consistent results

The lowest quoted price rarely delivers the lowest total cost. Strategic die investment means selecting partners whose capabilities reduce iteration cycles, accelerate timelines, and deliver right-first-time tooling. This approach optimizes the cost-quality balance that determines true project profitability - and positions your operation for the demanding quality requirements we'll explore next in automotive and high-precision applications.

Automotive and High-Precision Stamping Die Applications

You've mastered die economics and maintenance - but what happens when your customer demands zero defects across millions of parts? Automotive applications represent the ultimate proving ground for sheet metal stamping technology. In this demanding environment, a single flawed component can trigger recalls costing hundreds of millions of dollars. Understanding how automotive stamping dies differ from general industrial tooling prepares you for the industry's most rigorous quality requirements.

According to Kenmode's automotive quality analysis, suppliers must deliver metal stamped parts with zero defects while complying with constantly evolving international industry standards. The stakes couldn't be higher - and the quality systems required reflect that reality.

Meeting Automotive OEM Standards in Die Manufacturing

What separates automotive stamping die requirements from general metal stamping applications? The answer lies in systematic quality management that touches every aspect of design, production, and verification.

Automotive OEMs require their metal parts stamping suppliers to implement the Automotive Quality Core Tools developed by the Automotive Industry Action Group (AIAG). As the AIAG states, "The Automotive Quality Core Tools are the building blocks of an effective quality management system. Today, most automotive manufacturers and suppliers require use of one or more of the Core Tools."

These mandatory frameworks include:

- Advanced Product Quality Planning (APQP) - A structured process monitoring more than 20 areas before production begins, including design robustness, testing protocols, inspection standards, and packaging requirements. Through APQP, manufacturers and their stamping suppliers collaborate on every step from initial development through product launch.

- Production Part Approval Process (PPAP) - The generic part qualification process ensuring all customer requirements are understood and the manufacturing process can produce conforming parts consistently. PPAP represents the critical first step for quality verification.

- Failure Modes and Effects Analysis (FMEA) - Systematic identification of possible failures in design, manufacturing, and assembly. Process FMEA specifically rates what could go wrong during metal stamping operations and identifies ways to reduce failure probability.

- Measurement System Analysis (MSA) - Standardized procedures managing measurement error and ensuring quality in both manufacturing processes and resulting products. Components include bias, stability, linearity, and gauge repeatability and reproducibility (GR&R).

- Statistical Process Control (SPC) - Real-time monitoring using control charts to analyze process variability and track manufacturing in real time. Variances from specifications trigger immediate investigation and corrective action.

As Die-Matic's quality management guide emphasizes, implementing these systems "requires attention to detail through every step of the process, every minute of every working day." The emphasis on quality at the source empowers operators to catch and address potential concerns as the first line of defense.

Quality Certifications That Matter for Precision Stamping

When sourcing automotive stamping dies, certification status provides immediate insight into supplier capability. The IATF 16949 standard represents the benchmark that serious automotive suppliers must meet.

IATF 16949 certification indicates a supplier has demonstrated:

- Robust Quality Management Systems - Documented processes covering design, production, installation, and service of automotive-related products

- Continuous Improvement Culture - Systematic approaches to defect prevention and reduction of variation and waste

- Complete Traceability - The ability to track every component, material batch, and process parameter throughout production

- Customer-Specific Requirements - Integration of individual OEM specifications beyond baseline standards

- Supply Chain Management - Controls extending quality requirements to sub-tier suppliers

Beyond certification, automotive OEMs often impose additional specifications covering dimensional tolerances, surface finish requirements, material testing protocols, and documentation standards. These customer-specific requirements may exceed IATF 16949 baseline expectations significantly.

Traceability requirements deserve special attention in automotive applications. Every part must be traceable to specific material lots, production dates, machine settings, and operator identifications. When problems emerge - even years after production - this traceability enables rapid root cause analysis and targeted containment actions.

Working with IATF 16949-certified manufacturers like Shaoyi delivers the quality assurance automotive OEMs require. Their advanced CAE simulation capabilities ensure defect-free results before physical tooling is cut, while their engineering team's expertise in high-volume manufacturing with OEM-standard tooling represents industry-leading capability for demanding applications.

How Automotive Dies Differ in Precision and Quality Control

Automotive stamping dies face demands that general industrial tooling rarely encounters. The combination of tight tolerances, high volumes, and zero-defect expectations creates unique engineering challenges.

Key differentiators include:

- Tighter Dimensional Tolerances - Automotive components often require tolerances of ±0.05mm or tighter, compared to ±0.1mm typical in general industrial applications

- Surface Finish Requirements - Visible exterior panels demand Class A surface quality with no detectable defects under controlled lighting conditions

- Higher Production Volumes - Automotive stamping die life expectations often exceed 1 million cycles, requiring premium materials and robust construction

- Material Complexity - Increasing use of advanced high-strength steels and aluminum alloys demands specialized tooling knowledge

- In-Process Verification - Real-time monitoring systems including vision inspection, in-die sensors, and automated measurement ensure consistent quality throughout production runs

Quality-minded metal stampers implement in-die sensors for tonnage monitoring, misfeeds, and slug retention. Vision systems verify part presence and orientation. Laser measurement confirms critical dimensions without stopping production. These stamping technology investments enable the real-time quality verification that automotive applications demand.

Design for Manufacturability (DFM) collaboration early in the development process helps ensure automotive stamping dies are optimized from the start. As quality experts note, although a component stamping may seem small in the overall product design, it can make a significant difference in reliability, cost, and production efficiency. Early engineering involvement reduces failure risk while containing costs - exactly what automotive OEMs require from their supply base.

Frequently Asked Questions About Sheet Metal Stamping Dies

1. How much does a metal stamping die cost?

Metal stamping die costs range from $500 to $15,000 for simple tooling, while complex automotive dies can exceed $100,000. Key cost drivers include part geometry complexity, material selection, tolerance requirements, and expected production volume. Remember to budget an additional 15-25% contingency for design modifications, scheduled maintenance, and iteration cycles. Per-part costs decrease dramatically with higher volumes - a $100,000 die producing 1 million parts costs just $0.10 per piece for tooling amortization.

2. What is sheet metal stamping dies?

Sheet metal stamping dies are precision tools made from hardened tool steel that cut, shape, and form flat metal sheets into specific three-dimensional parts. They work in pairs - upper and lower components - that come together under immense force from a stamping press. These dies perform four essential functions: locating the material, clamping it in place, performing working operations like cutting and bending, and releasing the finished part. Once properly manufactured, dies can produce identical parts at speeds exceeding 1,000 strokes per minute.

3. What is the difference between die cut and stamping?

Die cutting and stamping are distinct metal forming processes. Die casting uses ingots or billets heated past their melting point, while stamping uses sheet metal blanks or coils in a cold working process. Stamping dies mechanically cut, bend, and form material at room temperature through controlled pressure. The stamping process offers faster cycle times for high-volume production and works with a wider range of sheet metal thicknesses, making it ideal for automotive components, brackets, and precision parts.

4. What are the main types of stamping dies and when should I use each?

The four main types are progressive dies, transfer dies, compound dies, and combination dies. Progressive dies excel at high-volume production of moderately complex parts, keeping workpieces attached to a strip through multiple stations. Transfer dies handle intricate designs and deep draws by separating parts early and moving them mechanically. Compound dies perform all operations in a single stroke, ideal for simpler flat parts like washers. Choose based on part complexity, production volume, and budget constraints.

5. How can I extend the lifespan of my stamping dies?

Implement systematic preventive maintenance including post-run cleaning, lubrication verification, and regular visual inspections. Sharpen cutting edges every 50,000-100,000 hits for mild steel or 20,000-40,000 hits for high-strength materials. Check guide pin alignment weekly and measure punch-to-die clearances monthly. Store dies in climate-controlled environments below 50% humidity with anti-corrosion coatings applied. This approach reduces unexpected downtime by over 70% and costs 12-18% less than reactive emergency repairs.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —