संरचनात्मक ऑटोमोटिव भागों के लिए सटीक डाई डिज़ाइन

संक्षिप्त में

संरचनात्मक ऑटोमोटिव भागों के लिए डाई डिज़ाइन एक विशेष इंजीनियरिंग अनुशासन है, जो मजबूत, हल्के और सटीक वाहन घटकों जैसे चेसिस फ्रेम और बॉडी पैनलों को आकार देने के लिए धातु को आकार देने वाले मजबूत उपकरणों (डाई) बनाने पर केंद्रित है। यह प्रक्रिया, जो मुख्य रूप से शीट धातु के लिए स्टैम्पिंग या गलित धातु के लिए डाई कास्टिंग का उपयोग करती है, आधुनिक वाहन निर्माण के लिए मौलिक है क्योंकि यह अंतिम भाग की संरचनात्मक बनावट, गुणवत्ता और प्रदर्शन को निर्धारित करती है। इष्टतम टिकाऊपन और सुरक्षा प्राप्त करने के लिए विधि के चयन और डिज़ाइन की परिशुद्धता महत्वपूर्ण है।

ऑटोमोटिव उद्योग में डाई डिज़ाइन के मूल सिद्धांत

डाई डिज़ाइन एक मूलभूत प्रक्रिया है जो एक डिजिटल अवधारणा को स्पष्ट, बड़े पैमाने पर उत्पादित ऑटोमोटिव वास्तविकता में बदल देती है। इसमें विशेष उपकरणों की जटिल इंजीनियरिंग शामिल है जो भारी दबाव के तहत धातु को काटते और आकार देते हैं, जो घटक की अंतिम गुणवत्ता, सटीकता और संरचनात्मक अखंडता को पहले से निर्धारित करते हैं। एक ऐसे उद्योग में जहां सुरक्षा और प्रदर्शन सर्वोच्च प्राथमिकता है, डाई स्वयं इन मानकों की रक्षक के रूप में कार्य करती है, यह सुनिश्चित करते हुए कि पहले से लेकर लाखवें तक प्रत्येक उत्पादित भाग समान हो और कठोर विनिर्देशों को पूरा करे। वाहन की स्केलेटन बनाने वाले चिकने बॉडी पैनल से लेकर महत्वपूर्ण चेसिस घटकों तक सब कुछ निर्माण के लिए यह प्रक्रिया महत्वपूर्ण है।

डाई डिज़ाइन का प्राथमिक उद्देश्य एक ऐसा उपकरण बनाना है जो उच्च गुणवत्ता वाले भागों का विश्वसनीय ढंग से उत्पादन कर सके, जबकि कई महत्वपूर्ण विनिर्माण लक्ष्यों के बीच संतुलन बनाए रखे। संरचनात्मक भागों के निर्माण में दो प्रमुख विधियाँ उभरती हैं: शीट धातु के लिए स्टैम्पिंग और गलित धातु के लिए डाई कास्टिंग। स्टैम्पिंग चपटी धातु की चादरों को दरवाजों और फेंडर जैसे भागों के लिए आदर्श जटिल त्रि-आयामी आकृतियों में आकार देने के लिए अत्यधिक बल का उपयोग करती है। डाई कास्टिंग में एल्युमीनियम या मैग्नीशियम मिश्र धातु जैसी गलित धातु को इंजन ब्लॉक और ट्रांसमिशन केस जैसे जटिल, हल्के घटक बनाने के लिए एक साँचे के कोष्ठ में इंजेक्ट किया जाता है। दोनों विधियों को ऐसे भागों का उत्पादन करने के लिए अनुकूलित किया गया है जो दोनों स्थायी और ईंधन दक्षता और वाहन गतिकी में सुधार के लिए यथासंभव हल्के हों।

किसी भी संरचनात्मक ऑटोमोटिव भाग की सफलता मोल्ड डिज़ाइन द्वारा निर्धारित गुणों के सटीक संतुलन पर निर्भर करती है। इसमें आंतरिक तनाव, धातु की संरचना और सतह की परिष्कृतता जैसे कारकों को नियंत्रित करना शामिल है। उदाहरण के लिए, एक अच्छी तरह से डिज़ाइन किया गया डाई-कास्टिंग मोल्ड यह प्रबंधित करेगा कि पिघली धातु खाली जगह को कैसे भरती है और ठंडी होती है, जिसका प्रभाव सीधे अंतिम भाग की पारगम्यता और शक्ति पर पड़ता है। डाई डिज़ाइन प्रक्रिया के अंतिम लक्ष्य यह सुनिश्चित करना हैं:

- सटीकता और संगति: लाखों उत्पादन चक्रों में कसे हुए सहिष्णुता की प्राप्ति करना।

- संरचनात्मक पूर्णता: ऐसे भागों का उत्पादन करना जो मजबूत, टिकाऊ हों और वाहन संचालन के तनाव का सामना कर सकें।

- वजन अनुकूलन: उच्च-शक्ति वाले स्टील और एल्यूमीनियम मिश्र धातुओं जैसी सामग्री का उपयोग करके वाहन के वजन को कम करना बिना सुरक्षा गंवाए।

- लागत प्रभावीता: प्रति इकाई लागत को कम रखने के लिए सामग्री की बर्बादी को कम करना और उत्पादन को सरल बनाना।

मुख्य पद्धतियाँ: स्टैम्पिंग डाई डिज़ाइन बनाम संरचनात्मक डाई कास्टिंग

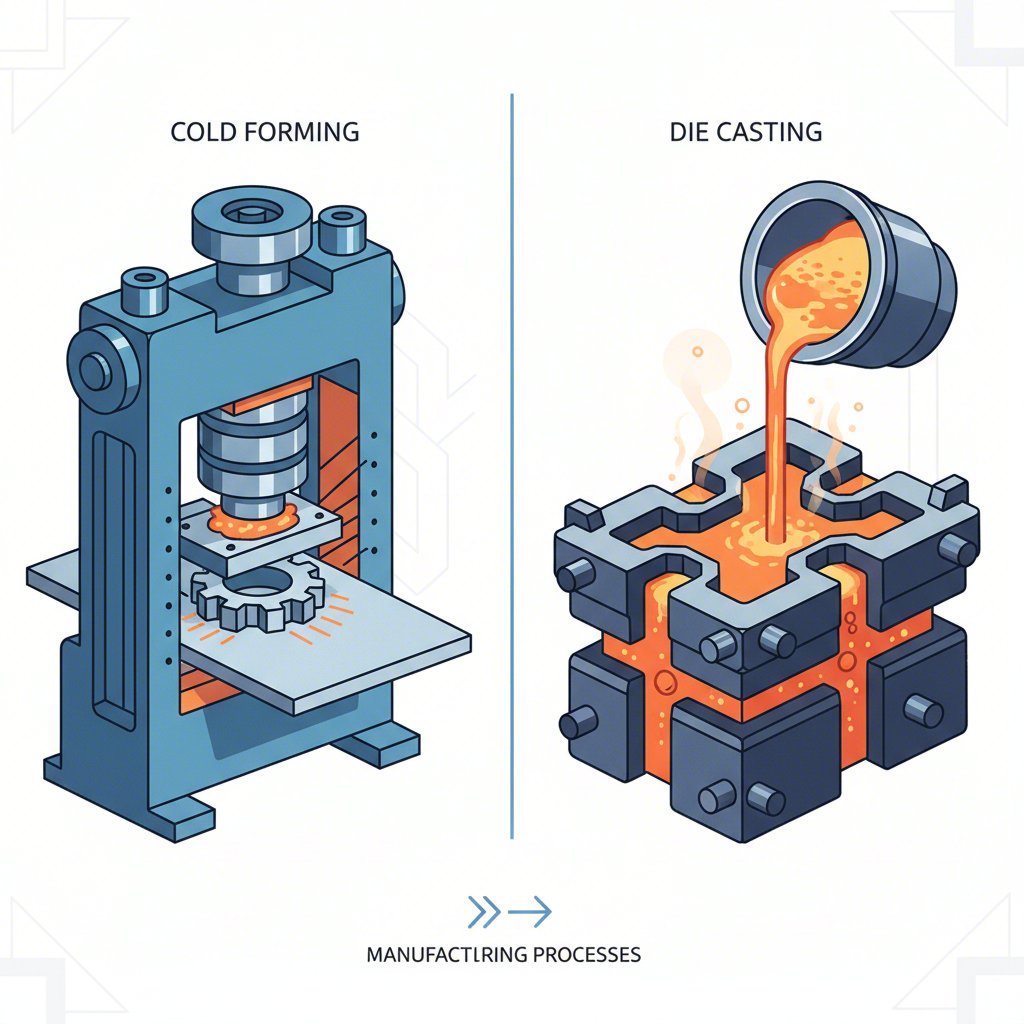

स्टैम्पिंग और संरचनात्मक डाई कास्टिंग के बीच अंतर को समझना आवश्यक है, क्योंकि प्रत्येक विधि विभिन्न ऑटोमोटिव अनुप्रयोगों के लिए अद्वितीय लाभ प्रदान करती है। स्टैम्पिंग डाई डिज़ाइन ठोस शीट धातु को आकार देने पर केंद्रित होता है, जबकि संरचनात्मक डाई कास्टिंग मोल्टन धातु से भागों का निर्माण करती है। इनके बीच चयन भाग की जटिलता, आवश्यक सामग्री गुणों और उत्पादन मात्रा पर निर्भर करता है।

स्टैम्पिंग डाय डिजाइन धातु की चादरों को काटने, मोड़ने और वांछित आकृतियों में आकार देने के लिए उपकरण बनाने की प्रक्रिया है। इसे अक्सर प्रगतिशील डाइज़ का उपयोग करके किया जाता है, जहाँ सामग्री की कुंडली को एक के बाद एक कई स्टेशनों के माध्यम से खिलाया जाता है, जिनमें से प्रत्येक एक विशिष्ट संचालन करता है, जब तक कि एक पूर्ण भाग उत्पादित नहीं हो जाता। ऑटोमोटिव पार्ट्स निर्माता अलसेट , इस विधि उच्च मात्रा में बॉडी पैनल और ब्रैकेट जैसे जटिल घटकों के उत्पादन के लिए अत्यधिक कुशल है। स्टैम्पिंग स्टील और एल्यूमीनियम जैसी सामग्री के लिए आदर्श है और पारंपरिक कार बॉडी निर्माण की रीढ़ है।

स्ट्रक्चरल डाई कास्टिंग , दूसरी ओर, उच्च दबाव में कठोर इस्पात के साँचे (डाई) में गलित धातु को डालने की प्रक्रिया शामिल करता है। KDM Fabrication द्वारा वर्णित, यह तकनीक जटिल, नेट-शेप भागों के उत्पादन में उत्कृष्ट है जिनमें न्यूनतम द्वितीयक मशीनीकरण की आवश्यकता होती है। यह एल्युमीनियम और मैग्नीशियम मिश्र धातुओं से हल्के लेकिन मजबूत घटक बनाने के लिए विशेष रूप से मूल्यवान है। जैसा कि Zetwerk नोट्स करता है, इससे भार में महत्वपूर्ण कमी आती है, जो ईंधन दक्षता और इलेक्ट्रिक वाहनों की रेंज में सुधार के लिए महत्वपूर्ण है। ऐसे भागों के उदाहरणों में इंजन क्रैडल, शॉक टावर और बैटरी एन्क्लोज़र शामिल हैं।

अंतर स्पष्ट करने के लिए, यहाँ दोनों पद्धतियों की सीधी तुलना दी गई है:

| विशेषता | स्टैम्पिंग डाय डिजाइन | स्ट्रक्चरल डाई कास्टिंग |

|---|---|---|

| प्रक्रिया प्रकार | दबाव के तहत ठोस शीट धातु का आकार देना। | एक साँचे की गुहा में गलित धातु को डालना। |

| सामान्य सामग्री | इस्पात, उच्च-सामर्थ्य इस्पात, एल्युमीनियम शीट। | एल्युमीनियम मिश्रधातु, मैग्नीशियम मिश्रधातु, जस्ता मिश्रधातु। |

| खंड जटिलता | समतल चादरों से जटिल 3D आकृतियों के लिए उपयुक्त। | अलग-अलग दीवार की मोटाई वाले जटिल, नेट-आकार के भागों के लिए उत्कृष्ट। |

| विशिष्ट ऑटोमोबाइल पार्ट्स | बॉडी पैनल, दरवाजे, फेंडर, चेसिस घटक, ब्रैकेट। | इंजन ब्लॉक, ट्रांसमिशन केस, शॉक टावर, बैटरी हाउसिंग। |

| मुख्य फायदे | उच्च मात्रा के लिए उच्च-गति उत्पादन, उत्कृष्ट सतह परिष्करण। | उच्च शक्ति वाले हल्के भाग बनाता है, कई घटकों को एक में एकीकृत करता है। |

अंततः, चयन रणनीतिक होता है। एक इंजीनियर बड़ी, चिकनी सतह और उच्च उत्पादन गति की आवश्यकता के कारण एक कार के दरवाजे के लिए स्टैम्पिंग का चयन करेगा। इसके विपरीत, एक जटिल ट्रांसमिशन हाउसिंग के लिए जिसमें आंतरिक चैनल और माउंटिंग बिंदुओं की आवश्यकता होती है, डाई कास्टिंग श्रेष्ठ विकल्प है क्योंकि यह एक हल्के टुकड़े में इन जटिल विशेषताओं को बना सकती है।

डाई डिजाइन और निर्माण प्रक्रिया के चरण

कार्यात्मक और कुशल मरने का निर्माण एक व्यवस्थित प्रक्रिया है जो एक भाग अवधारणा को उत्पादन के लिए तैयार उपकरण में बदल देती है। इस कार्यप्रवाह के लिए विश्लेषणात्मक कठोरता, रचनात्मक समस्या-समाधान और उन्नत सॉफ्टवेयर उपकरण का मिश्रण आवश्यक है ताकि यह सुनिश्चित हो सके कि अंतिम मरने से लाखों चक्रों में सटीक और विश्वसनीय रूप से भागों का उत्पादन हो। प्रत्येक चरण पिछले चरण पर आधारित होता है, व्यापक व्यवहार्यता जांच से लेकर घटक स्तर पर बारीकी से विवरण तक।

अवधारणा से निर्माण तक की यात्रा को स्पष्ट, अनुक्रमिक कार्यप्रवाह में विभाजित किया जा सकता हैः

- भाग विश्लेषण एवं व्यवहार्यता अध्ययन: यह प्रक्रिया भाग के डिजाइन को तोड़कर शुरू होती है। जैसा कि एक शुरुआती गाइड में समझाया गया है Jeelix , डिजाइनरों को अत्यधिक तेज कोनों, अपर्याप्त मोड़ त्रिज्या, या सुविधाओं है कि बनाने के लिए मुश्किल हो जाएगा की तरह संभावित मुद्दों की पहचान करने के लिए विनिर्माण के लिए डिजाइन (DFM) समीक्षा का संचालन। सामग्री गुणों का विश्लेषण किया जाता है ताकि यह सुनिश्चित किया जा सके कि वे इच्छित ढालने की प्रक्रिया के लिए उपयुक्त हैं।

- प्रक्रिया योजना (स्ट्रिप या मोल्ड लेआउट): स्टैम्पिंग के लिए, इंजीनियर एक स्ट्रिप लेआउट बनाते हैं जो प्रगतिशील मरने के प्रत्येक स्टेशन पर संचालन के अनुक्रम (जैसे, छेद, झुकने, बनाने) का नक्शा बनाता है। यह योजना सामग्री के उपयोग को अनुकूलित करने और सुनिश्चित करने के लिए महत्वपूर्ण है कि स्ट्रिप प्रेस के माध्यम से खिलाए जाने के लिए पर्याप्त कठोर बनी रहे। डाई कास्टिंग के लिए, इस चरण में यह योजना शामिल है कि कैसे पिघले हुए धातु को दोषों को रोकने के लिए मोल्ड गुहा में बहने और भरने के लिए।

- सीएडी डिजाइन और सिमुलेशनः उन्नत सीएडी सॉफ्टवेयर का उपयोग करके, डिजाइनर पूरे डाई असेंबली का विस्तृत 3 डी मॉडल बनाते हैं, जिसमें ऊपरी और निचले जूते, पंच, डाई ब्लॉक और गाइड सिस्टम शामिल हैं। इस चरण में, वर्चुअल ट्रायल करने के लिए अक्सर शक्तिशाली सिमुलेशन सॉफ्टवेयर (CAE) का उपयोग किया जाता है। यह किसी भी स्टील को काटने से पहले सामग्री प्रवाह की भविष्यवाणी कर सकता है, संभावित तनाव बिंदुओं की पहचान कर सकता है, और किसी भी स्टील को काटने से पहले दरार या झुर्रियों जैसी समस्याओं की भविष्यवाणी कर सकता है, जिससे महत्वपूर्ण समय और लागत की बचत होती है।

- मरने के घटक और सामग्री का चयनः पंच और इंसेप्टर जैसे व्यक्तिगत घटकों को सावधानीपूर्वक डिजाइन किया गया है। इन घटकों के लिए सामग्री का चयन उन ताकतों के आधार पर किया जाता है जो वे सहन करेंगे। उच्च पहनने वाले भागों को आमतौर पर दीर्घायु सुनिश्चित करने के लिए D2 या SKD11 जैसे कठोर उपकरण स्टील्स से बनाया जाता है। मानक घटक जैसे गाइड पिन और स्प्रिंग्स को अक्सर विश्वसनीयता सुनिश्चित करने के लिए विशेष आपूर्तिकर्ताओं से प्राप्त किया जाता है।

- मरने के निर्माण और विधानसभाः एक बार डिजाइन को अंतिम रूप देकर समीक्षा कर लेने के बाद, विस्तृत 2 डी चित्र उपकरण निर्माताओं को भेजे जाते हैं। सटीक सीएनसी मशीनिंग, पीसने और ईडीएम प्रक्रियाओं का उपयोग करके, प्रत्येक घटक को तंग सहिष्णुता के साथ निर्मित किया जाता है। अंत में, प्रत्येक भाग को सावधानीपूर्वक इकट्ठा किया जाता है, संरेखित किया जाता है और परीक्षण किया जाता है ताकि यह सुनिश्चित किया जा सके कि पूरी तरह से मरम्मत के कार्य डिजाइन के अनुसार हों। जटिल परियोजनाओं के लिए, एक विशेषज्ञ के साथ साझेदारी करना जैसे शाओयी (निंगबो) मेटल तकनीकी कंपनी, लिमिटेड. महत्वपूर्ण हो सकता है। वे CAE सिमुलेशन और प्रोटोटाइपिंग से लेकर ऑटोमोटिव स्टैम्पिंग डाइज़ के बड़े पैमाने पर उत्पादन तक व्यापक सेवाएं प्रदान करते हैं, जिससे OEMs और टियर 1 आपूर्तिकर्ताओं के लिए उच्च गुणवत्ता और दक्षता सुनिश्चित होती है।

महत्वपूर्ण डिज़ाइन नियम और गुणवत्ता नियंत्रण कारक

सफल डाइज़ डिज़ाइन इंजीनियरिंग के मौलिक सिद्धांतों के एक समूह पर आधारित होता है जो यह सुनिश्चित करते हैं कि अंतिम भाग न केवल आयामी रूप से सटीक हो, बल्कि संरचनात्मक रूप से भी मजबूत हो। ये नियम धातु के दबाव के तहत व्यवहार को नियंत्रित करने के लिए महत्वपूर्ण हैं, जिससे छिद्रता, दरारें और विरूपण जैसे सामान्य दोषों को रोका जा सके। ऑटोमोटिव उद्योग के कठोर सुरक्षा और प्रदर्शन मानकों को पूरा करने वाले उच्च गुणवत्ता वाले संरचनात्मक घटकों के उत्पादन के लिए इन दिशानिर्देशों का पालन करना आवश्यक है।

ये सिद्धांत संरचनात्मक डाइ कास्टिंग में विशेष रूप से महत्वपूर्ण हैं, जहां गलित धातु का प्रवाह और ठोसीकरण भाग की आंतरिक अखंडता को निर्धारित करता है। जैसा कि एक मार्गदर्शिका में विस्तार से बताया गया है Inox Cast , डाई की ज्यामिति सीधे छिद्रता और आंतरिक तनाव जैसे कारकों को नियंत्रित करती है। इन नियमों की अनदेखी करने से कमजोर जगहें हो सकती हैं जो भार के तहत भाग के प्रदर्शन को कमजोर कर देती हैं।

यहाँ कुछ सबसे महत्वपूर्ण डिज़ाइन नियम और गुणवत्ता कारक दिए गए हैं:

- पार्टिंग लाइन निर्धारण: पार्टिंग लाइन वह स्थान है जहाँ डाई के दो हिस्से मिलते हैं। इसकी स्थिति महत्वपूर्ण है क्योंकि यह निर्धारित करती है कि भाग को कैसे बाहर निकाला जाएगा, फ्लैश (अतिरिक्त सामग्री) की संभावना, और घटक की अंतिम उपस्थिति। एक अच्छी तरह से स्थित पार्टिंग लाइन उपकरण के निर्माण को सरल बनाती है और भाग की गुणवत्ता में सुधार करती है।

- गेटिंग और रनर सिस्टम डिज़ाइन: डाई कास्टिंग में, गेटिंग सिस्टम चैनलों का एक नेटवर्क होता है जिसके माध्यम से गलित धातु मोल्ड गुहा में प्रवेश करती है। इन गेटों और रनरों के डिज़ाइन को यह सुनिश्चित करना चाहिए कि गुहा बिना जल-मल के सुचारु रूप से और पूरी तरह से भर जाए, जो हवा को फंसा सकता है और छिद्रता का कारण बन सकता है।

- ओवरफ्लो और वायु वेंट का स्थान: ओवरफ्लो छोटे-छोटे आवरण होते हैं जो धातु के प्रारंभिक, ठंडे प्रवाह और किसी भी अशुद्धि को समाए रखने के लिए डिज़ाइन किए गए होते हैं। वायु निकास छोटे-छोटे चैनल होते हैं जो खोल के भरने के दौरान फंसी हवा और गैसों को बाहर निकलने की अनुमति देते हैं। गैस की अपर्याप्त निकासी गैसीय छिद्रता का प्रमुख कारण है, जो भाग के भीतर बुलबुले बनाती है और इसे गंभीर रूप से कमजोर कर देती है।

- निष्कासक पिन रणनीति: ठोस भाग को साँचे से बाहर निकालने के लिए निष्कासक पिन का उपयोग किया जाता है। भाग के सम्पूर्ण क्षेत्र में समान बल लागू करने के लिए उनकी स्थिति और आकार की सावधानीपूर्वक योजना बनाई जानी चाहिए, ताकि निष्कासन के दौरान विरूपण या क्षति से बचा जा सके। अंतिम घटक पर अक्सर उनके निशान दिखाई देते हैं, इसलिए आमतौर पर उन्हें गैर-सौंदर्य स्थानों पर रखा जाता है।

- ड्राफ्ट कोण: साँचे के खुलने की दिशा के समानांतर सभी सतहों में थोड़ा कोण होना चाहिए, जिसे ड्राफ्ट कहा जाता है। यह ढलान भाग को साँचे से साफ तरीके से निकालने में सक्षम बनाता है। अपर्याप्त ड्राफ्ट के कारण भाग चिपक सकता है, जिससे निष्कासन के दौरान सतह पर खींचे गए निशान या टूटने की समस्या हो सकती है।

इन नियमों को बारीकी से लागू करके डिज़ाइनर निर्माण से जुड़ी संभावित समस्याओं को पहले से ही दूर कर सकते हैं। उदाहरण के लिए, उचित ढंग से डिज़ाइन की गई गेटिंग प्रणाली और प्रभावी वायु वेंट का संयोजन आंतरिक खाली स्थानों से मुक्त एक सघन, ठोस ढलवां भाग सुनिश्चित करता है। इस स्तर के नियंत्रण के कारण ही एक उच्च-प्रदर्शन संरचनात्मक घटक, एक दोषपूर्ण घटक से अलग होता है।

छोटे पर्चे, उच्च मानदंड। हमारी तेजी से प्रोटोटाइपिंग सेवा मान्यता को तेजी से और आसानी से बनाती है —

छोटे पर्चे, उच्च मानदंड। हमारी तेजी से प्रोटोटाइपिंग सेवा मान्यता को तेजी से और आसानी से बनाती है —