Custom Metal Laser Cutting Decoded: From CAD File To Finished Part

What Custom Metal Laser Cutting Actually Means for Your Projects

Ever watched a magnifying glass focus sunlight into a single, intense point? Custom metal laser cutting takes that same principle and amplifies it to an extraordinary degree. At its core, this process uses a highly concentrated beam of light to vaporize or melt metal along computer-programmed paths, creating shapes with remarkable accuracy that traditional cutting methods simply cannot match.

Unlike mechanical cutting techniques that rely on physical contact between a blade and material, laser metal cutting is a non-contact process. This means no tool wear, no mechanical stress on the workpiece, and no need for clamping or fixturing that might distort thin materials. The result? Cleaner edges, tighter tolerances, and the ability to create intricate designs that would be impossible with saws, shears, or punches.

How Laser Beams Transform Raw Metal into Precision Parts

When you submit a design for custom metal laser cutting, here's what actually happens. The laser cutter generates an incredibly focused beam—typically from either a CO2 or fiber laser source—that is directed through a series of mirrors and lenses. This focusing system concentrates the beam into an extraordinarily small point, creating temperatures that can exceed 20,000 degrees Celsius.

The moment this intense energy contacts the metal surface, the material at the point of impact rapidly heats, melts, or vaporizes. Simultaneously, a high-pressure assist gas—typically nitrogen or oxygen—blows away the molten material, leaving behind a clean, smooth cut. A CNC (Computer Numerical Control) system guides the laser head with extreme precision, following your exact digital design specifications.

The non-contact nature of precision laser cutting eliminates blade wear entirely, meaning the ten-thousandth cut is just as accurate as the first—something no mechanical cutting method can claim.

The Science Behind Thermal Metal Separation

Understanding the physics of laser-material interaction helps you appreciate why this technology delivers such consistent results. When photons from the laser beam strike metal, they're absorbed by free electrons in the material's surface. This absorption happens in mere femtoseconds to picoseconds, rapidly converting light energy into thermal energy.

Several scientific principles make metal laser cutting particularly effective:

- Absorption efficiency: Different metals absorb laser wavelengths differently. Fiber lasers, for instance, are preferentially absorbed by steel and aluminum, making them the go-to choice for metal cutting applications.

- Thermal conductivity: Metals conduct heat quickly away from the cut zone, which actually helps maintain clean edges by preventing excessive heat buildup in surrounding areas.

- Gas assist dynamics: The assist gas not only removes molten material but also prevents re-solidification and oxidation, resulting in smoother finishes.

- Kerf width consistency: The laser beam creates a narrow cut width (kerf) that remains consistent throughout the cutting process, enabling precise nesting of parts and minimal material waste.

For engineers and designers evaluating manufacturing options, understanding these fundamentals reveals why custom metal laser cutting has become indispensable across industries—from automotive and aerospace to electronics and architectural detailing. The technology's combination of speed, precision, and versatility makes it an ideal solution for everything from rapid prototyping to high-volume production runs.

Fiber vs CO2 vs Nd YAG Laser Technologies Explained

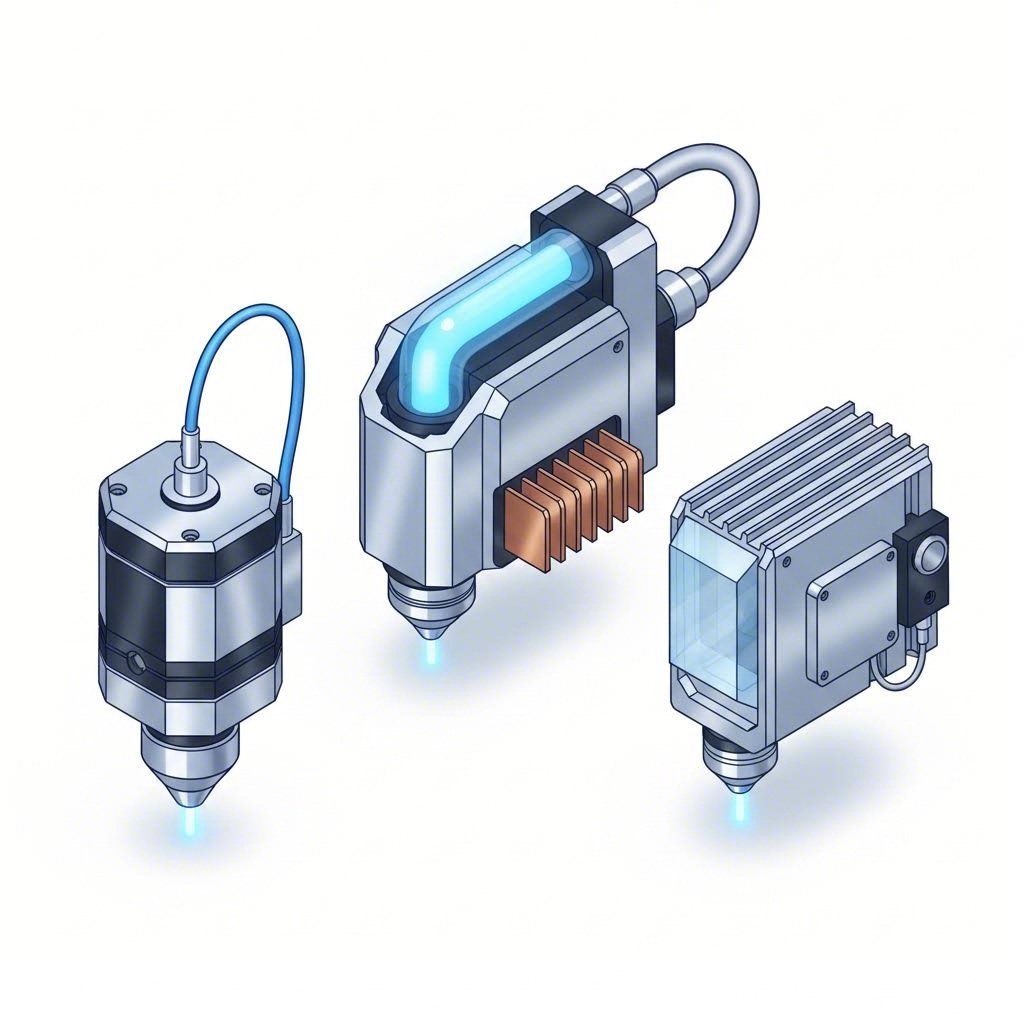

So you understand how lasers cut metal—but which laser technology should you actually care about? This is where things get interesting. Three main laser systems dominate the metal cutting landscape, and each brings distinct advantages depending on your project requirements. Let's break down the technology behind each one.

The fundamental difference between these systems lies in how they generate their laser beams and the wavelengths they produce. These wavelengths directly affect how efficiently different metals absorb the laser energy—and ultimately, how clean and fast your cuts will be.

Fiber Lasers and Their Dominance in Metal Processing

Fiber lasers have revolutionized metal cutting laser machine capabilities over the past decade. Unlike older technologies, fiber lasers use optical fibers doped with rare-earth elements as their gain medium. The result? A wavelength of 1.064 micrometers—roughly one-tenth the wavelength of CO2 lasers.

Why does this matter to you? That shorter wavelength allows the beam to focus into an exceptionally small spot size, enabling:

- Faster cutting speeds: Fiber lasers can cut thin metals at speeds up to 20 meters per minute—approximately three times faster than comparable CO2 systems

- Higher efficiency: With electrical-to-optical conversion rates around 35%, fiber lasers consume significantly less power than alternatives

- Excellent reflective metal handling: Aluminum, copper, and brass that challenge other laser types are processed reliably with fiber technology

- Minimal maintenance: Solid-state design means no gas-filled tubes or optical mirrors requiring regular replacement, with lifespans reaching 100,000 hours

For laser cutting of metal sheets in the thin-to-medium range (up to 25mm for steel), fiber lasers deliver the best combination of speed, precision, and operating cost. This explains why most modern metal laser cutter installations choose fiber technology.

When CO2 Lasers Still Make Sense for Mixed Materials

Don't write off CO2 laser cut metal machines entirely. Operating at a wavelength of 10.6 micrometers, these gas-based lasers interact with materials differently than their fiber counterparts.

CO2 lasers generate their beam by electrically stimulating a gas-filled tube containing carbon dioxide. This longer wavelength is absorbed more efficiently by organic and non-metallic materials, making CO2 systems the preferred choice when your workflow includes:

- Mixed-material cutting (metals plus wood, acrylic, plastics, textiles)

- Thicker material applications exceeding 20-40mm

- Projects prioritizing edge smoothness over cutting speed

- Lower initial investment requirements

The trade-off? CO2 laser cutting machine for metal applications requires more maintenance, consumes more power (10-20% conversion efficiency), and struggles with reflective metals. For dedicated metal fabrication, fiber typically wins—but shops handling diverse materials may find CO2's versatility compelling.

Nd:YAG Lasers for Specialized Precision Applications

Nd:YAG (neodymium-doped yttrium aluminum garnet) lasers occupy a specialized niche. These solid-state systems share the 1.06μm wavelength with fiber lasers but use crystal-based gain media and flash lamp pumping.

Where do Nd:YAG lasers shine? Precision applications requiring exceptional detail:

- Medical device manufacturing with intricate geometries

- Aerospace components demanding tight tolerances

- Jewelry and fine metalwork

- Applications requiring material versatility (some plastics and ceramics)

However, Nd:YAG technology comes with limitations: higher maintenance requirements due to flash lamp replacement, lower overall power output compared to fiber systems, and larger physical footprints. For most general metal cutting applications, fiber lasers have largely superseded Nd:YAG installations.

Comprehensive Laser Technology Comparison

Choosing the right laser technology requires weighing multiple factors against your specific project needs. The following comparison synthesizes the key performance characteristics:

| Characteristic | Fiber Laser | CO2 Laser | Nd:YAG Laser |

|---|---|---|---|

| Wavelength | 1.064 μm | 10.6 μm | 1.06 μm |

| Best Metal Applications | Steel, stainless steel, aluminum, copper, brass | Steel, stainless steel (thicker gauges); excels on non-metals | Precision work on steel, aluminum; some ceramics/plastics |

| Optimal Thickness Range | Up to 25mm (highest efficiency on thin materials) | Up to 40mm+ (better relative performance on thick stock) | Best for thin materials requiring high detail |

| Cutting Speed | Fastest on thin metals (up to 3x faster than CO2) | Slower on metals; competitive on thick non-metals | Moderate; optimized for precision over speed |

| Edge Quality | Excellent on thin materials; may roughen on thick cuts | Superior smoothness on thick materials and non-metals | Excellent for detailed, intricate work |

| Energy Efficiency | ~35% conversion efficiency | 10-20% conversion efficiency | ~20% conversion efficiency |

| Maintenance Requirements | Minimal; no consumables; ~100,000 hour lifespan | Higher; gas tubes and mirrors need periodic replacement | Moderate to high; flash lamp replacement required |

| Reflective Metal Handling | Excellent | Challenging; risk of back-reflection damage | Good |

| Typical Use Cases | Automotive, fabrication, electronics, high-volume production | Signage, mixed-material shops, woodworking with metal components | Medical devices, aerospace, jewelry, micro-cutting |

When evaluating a laser cutting machine for metal applications, consider both your current needs and future direction. Fiber lasers dominate modern custom metal laser cutting for good reason—but understanding all three technologies helps you ask the right questions when selecting a service provider or investing in equipment.

Of course, the laser technology is only part of the equation. The material you're cutting plays an equally critical role in determining optimal results, which brings us to an essential consideration: how different metals behave under laser cutting conditions.

Material Selection Guide for Laser Cut Metal Parts

Now that you understand laser technologies, here's the critical question: how does your material choice affect the final result? Not all metals behave the same under a laser beam. Some absorb energy efficiently and cut like butter. Others reflect the beam back, conduct heat away too quickly, or produce edge characteristics that may—or may not—meet your project requirements.

Understanding these differences before you submit your design can save you time, money, and frustration. Let's walk through the most common metals used in custom metal laser cutting and what you should expect from each.

Aluminum and Its Reflectivity Challenges

Aluminum sheet metal presents a fascinating paradox. It's lightweight, corrosion-resistant, and widely available—making it ideal for countless applications. Yet its high reflectivity and thermal conductivity create genuine challenges during laser cutting.

When a laser beam strikes an aluminum sheet, a significant portion of that energy bounces back rather than being absorbed. According to industry fabrication experts, this reflection causes three major issues: incomplete cuts, poor edge quality, and potential damage to laser optics from back-reflection.

Modern fiber lasers have dramatically improved aluminium laser cutting capabilities thanks to their shorter wavelength (1.064 μm), which aluminum absorbs more readily than CO2 laser wavelengths. However, operators still need to account for aluminum's behavior:

- Thermal conductivity: Aluminum pulls heat away from the cut zone rapidly, requiring higher power settings to maintain the stable melt pool needed for clean cuts

- Reflectivity management: Some fabricators apply temporary surface coatings or protective films that increase energy absorption and reduce back-reflection risks

- Assist gas selection: Nitrogen is typically preferred for laser cut aluminum applications, as it prevents oxidation and produces smooth, bright edges

- Edge characteristics: Expect slightly rougher edges compared to steel; post-processing like deburring may be necessary for critical applications

- Thickness considerations: Thin aluminum (under 6mm) cuts efficiently; thicker gauges require progressively more power and slower speeds

For applications requiring excellent edge quality on aluminum—such as visible architectural components or precision enclosures—discuss your expectations with your service provider before production begins.

Stainless Steel Edge Quality Expectations

Stainless steel represents the sweet spot for laser cutting. Its physical properties allow for excellent energy absorption, manageable heat distribution, and consistently clean edges across a wide range of thicknesses.

According to Xometry's technical resources, stainless steel laser cutting offers distinct advantages: it reduces the risk of work hardening, introduces minimal heat-affected zones, and often eliminates post-processing requirements entirely.

However, "stainless steel" encompasses a spectrum of alloys—austenitic, ferritic, martensitic, and duplex—each with unique characteristics:

- Austenitic grades (304, 316): Most commonly laser cut; non-magnetic with excellent corrosion resistance; produce clean, fused edges with proper settings

- Ferritic grades: Magnetic, lower cost; cut similarly to mild steel with slightly different parameter requirements

- Martensitic grades: Harder and stronger; may require power adjustments to prevent edge hardening

- Heat-affected zone: Highly localized due to laser precision; properly optimized cuts show minimal discoloration or structural changes outside the immediate cut area

- Edge finish: Smooth, often mirror-like edges possible; can be cut with nitrogen for oxide-free results or oxygen for faster processing with slight surface oxidation

Stainless steel sheet thicknesses up to approximately 25mm can be processed efficiently with high-power fiber lasers, though specific capabilities vary by equipment. For thicker gauges or critical applications, always confirm capabilities with your provider.

Mild Steel: The Workhorse Material

If stainless steel is the precision athlete, mild steel (low-carbon steel) is the reliable workhorse. It absorbs laser energy efficiently, conducts heat predictably, and produces excellent edge quality across virtually all common thicknesses.

- Processing speed: Among the fastest metals to laser cut; excellent production efficiency

- Edge quality: Typically produces clean, burr-free edges requiring minimal finishing

- Oxygen assist cutting: Often used with oxygen as the assist gas, which creates an exothermic reaction that adds heat and increases cutting speed

- Thickness range: Can be cut at substantial thicknesses (specifications vary by equipment)

- Cost-effectiveness: Lower material cost combined with efficient processing makes mild steel economical for many applications

Mild steel's predictable behavior makes it an excellent choice for structural components, brackets, enclosures, and general fabrication work where maximum corrosion resistance isn't required.

Brass vs Bronze and Copper: The Reflective Metal Challenge

Brass and copper occupy the challenging end of the laser cutting spectrum. Both are highly reflective, and copper specifically has exceptional thermal conductivity that makes it notoriously difficult to process.

Understanding the differences between brass vs bronze and copper is essential for realistic expectations:

Copper characteristics:

- Extremely high thermal conductivity—pulls heat away from the cut zone faster than almost any other metal

- High reflectivity creates back-reflection risks even with fiber lasers

- Requires higher power settings, slower speeds, and often negative focus positioning

- Nitrogen assist gas produces bright, oxide-free edges essential for electrical conductivity applications

- Dross (burr) formation on bottom edges is common; viscous molten copper resists ejection from the kerf

Brass characteristics:

- Contains 30-40% zinc, which has a lower boiling point than copper

- Zinc vaporization during cutting creates vapor pressure that actually assists material ejection

- Generally easier and faster to cut than pure copper despite similar appearance

- Safety consideration: cutting brass releases zinc oxide fumes; proper ventilation and filtration are essential

- Edge quality can be excellent with proper parameter optimization

In the battle of laser cutting copper vs brass, copper is the heavyweight champion of difficulty—requiring more power, sharper focus, and steadier nerves.

How Material Choice Affects Your Project Outcomes

Your material selection directly impacts three critical project factors:

- Cut quality: Materials like stainless and mild steel produce consistently clean edges. Reflective metals like copper and aluminum may require additional finishing.

- Processing speed: Mild steel cuts fastest; copper cuts slowest. This directly affects production timelines and cost.

- Overall cost: Beyond material price, consider processing time, assist gas requirements, and potential post-processing when budgeting your project.

Remember that specific thickness capabilities and tolerances vary significantly by equipment configuration and service provider expertise. Always confirm that your chosen fabricator has experience with your specific material and thickness combination before committing to production.

With your material selected, the next critical step is preparing your design files correctly—a process that directly determines whether your parts come out right the first time.

Design File Preparation and Optimization Best Practices

You've selected your material and understand the laser technology. Now comes the step that separates successful projects from costly revisions: preparing your design files correctly. Think of your CAD file as a set of instructions for the laser—any ambiguity, error, or oversight gets translated directly into wasted material, delayed timelines, and unexpected charges.

The good news? Proper file preparation isn't complicated once you understand what the laser sheet metal cutter actually needs from your design. Let's walk through the complete workflow that ensures your laser cut parts come out exactly as intended.

Preparing Your CAD Files for Clean Laser Cuts

Every sheet metal laser cutting project starts with a vector file—typically a DXF (Drawing Interchange Format). Unlike image files that store pixels, DXF files contain precise mathematical paths that CNC laser cutting machines interpret as cutting instructions. Here's your step-by-step workflow for getting it right:

- Start with clean 2D geometry: Create or export your design as a flat, 2D drawing. Remove any 3D elements, construction lines, or reference geometry that isn't part of your actual cut path. The laser only understands closed vector paths—everything else creates confusion.

- Verify your units and scale: This sounds basic, but it's the source of countless errors. Before exporting, confirm your CAD software is set to the correct units (millimeters or inches) and that your geometry matches real-world dimensions. A bracket designed at 100mm that exports at 100 inches creates obvious problems.

- Convert all elements to polylines or splines: Arcs, circles, and curves should be converted to smooth polylines. Some older laser software interprets complex curves differently—converting them eliminates interpretation errors.

- Organize layers logically: Separate cut lines, engraving paths, and bend lines onto distinct layers. Use consistent naming conventions (e.g., "CUT," "ENGRAVE," "SCORE"). This helps operators immediately understand your intent.

- Eliminate duplicate lines: Overlapping or duplicate geometry causes the laser to cut the same path twice—wasting time and potentially over-burning your material. Run a cleanup command to merge coincident lines.

- Close all contours: Every shape that needs to be cut out must form a completely closed path. Even microscopic gaps in your geometry can cause cutting failures or unexpected results.

- Export as DXF and verify: After exporting, open your DXF file in a separate viewer or CAD program to confirm everything translated correctly. Import the file into your laser cutting software and set appropriate speed and power parameters based on your material and thickness.

For software options, you have several paths. Inkscape offers a free, user-friendly option compatible with Windows, Mac, and Linux. Fusion 360 provides cloud-based collaboration features at approximately $70 monthly, while Adobe Illustrator works well at $20.99 monthly and includes iPad compatibility. Each has trade-offs between cost, learning curve, and features.

Common Design Mistakes That Increase Costs

Even experienced designers make errors that drive up project costs. Here's what to avoid:

Ignoring kerf width: The laser beam itself has width—typically ranging from 0.1mm to 1.0mm depending on material and cutting parameters. This "kerf" is the material removed by the cut itself. If you're designing interlocking parts or precise assemblies, you'll need to account for kerf in your dimensions. Parts designed without kerf compensation will be slightly smaller than intended.

Features too small for your material: Every material has minimum feature size limits. Attempting to cut holes smaller than the material thickness typically produces poor results. Thin internal webs between cuts can warp or melt. As a general guideline, internal features should be at least as wide as the material is thick—though this varies by specific material and equipment.

Sharp internal corners: Lasers can't create perfectly sharp inside corners. The beam has a physical diameter, which translates to a minimum radius on internal features. Designing with small corner radii (often 0.5mm minimum) produces cleaner results and reduces stress concentration in finished parts.

Geometry too close to edges: Holes placed too close to sheet edges risk tearing or deforming, especially if parts undergo subsequent forming operations. Similarly, space cutting geometry at least two times the sheet thickness apart to prevent heat-related distortion between adjacent features.

Non-standard material thicknesses: Choosing a 3.2mm sheet when 3mm is standard can dramatically impact both cost and lead time. Non-standard thicknesses often require minimum order quantities, special sourcing, and custom machine calibration. Whenever possible, design around readily available standard gauges.

Proper file preparation doesn't just reduce errors—it directly accelerates production. Clean files require less operator intervention, which means faster turnaround and lower costs for your project.

Design Optimization Checklist

Before submitting your files, run through these final verification points:

- All contours closed: No gaps in any cut paths

- No duplicate geometry: Each line exists only once

- Correct scale verified: Dimensions match intended real-world size

- Layers organized: Cut, engrave, and score operations separated

- Kerf compensation applied: If required for your application

- Minimum feature sizes respected: Based on your material thickness

- Corner radii specified: Especially for internal corners

- Standard material thickness selected: To avoid sourcing delays

- Adequate spacing between features: At least 2x material thickness

- File format confirmed: DXF exported and independently verified

Taking twenty minutes to optimize your design files can eliminate days of back-and-forth revisions. The sheet metal laser cutter will faithfully execute whatever instructions you provide—so make sure those instructions are exactly what you intend.

With your files prepared correctly, you're ready to evaluate whether laser cutting is the right process for your specific application—or whether alternative methods might better serve your needs.

Laser Cutting vs Waterjet vs Plasma vs CNC Routing

Your design files are ready, your material is selected—but is laser cutting actually the right process for your project? This is the question many engineers and designers skip, jumping straight to the technology they know best rather than evaluating all options objectively.

The truth is, a laser that cuts metal brilliantly on 3mm stainless steel might be completely wrong for 25mm aluminum plate. Similarly, the fastest cutting method isn't always the most cost-effective when you factor in secondary finishing requirements. Let's break down how laser cutting metal compares to the major alternatives—waterjet, plasma, and CNC routing—so you can make an informed decision.

When Waterjet Beats Laser for Thick Materials

Imagine cutting through virtually any material—metal, stone, glass, composites—without generating any heat whatsoever. That's the fundamental advantage of waterjet cutting. Operating at pressures up to 60,000 to 90,000 PSI, waterjet systems use high-pressure water mixed with abrasive particles to erode material along programmed paths.

Where does waterjet genuinely outperform laser? Consider these scenarios:

- Thick material processing: Waterjet can handle materials up to 24 inches thick for rough cuts—far beyond what any metal cutting laser can achieve. When your project involves thick plate work, waterjet becomes the only viable option.

- Heat-sensitive applications: Because waterjet is a cold-cutting process, there's zero heat-affected zone. This preserves material properties completely—critical for hardened steels, tempered materials, or components where metallurgical changes are unacceptable.

- Material versatility: A waterjet cuts steel, aluminum, titanium, stone, glass, carbon fiber, and rubber with essentially the same setup. If your workflow involves diverse materials, this versatility eliminates equipment changes.

- No secondary finishing: Waterjet produces a satin-smooth edge without burn marks, discoloration, or heat-induced stress. For visible components or assemblies requiring immediate use, this eliminates finishing operations.

The trade-off? Speed. According to industry testing data, waterjet systems typically cut at 5-20 inches per minute depending on material and thickness—significantly slower than laser or plasma alternatives. Equipment costs are also substantially higher, with complete systems running approximately $195,000 compared to around $90,000 for comparable plasma installations.

Plasma Cutting Trade-offs for Budget Projects

If you're searching for "plasma cutting near me" for thick steel fabrication, there's good reason. Plasma cutting uses an electrical arc and compressed gas to create superheated plasma—reaching temperatures up to 45,000°F (25,000°C)—that melts and blows away conductive metals with impressive speed.

When does plasma make sense over laser? Consider these factors:

- Thick conductive metals: Modern CNC plasma tables excel on materials from 0.018" to 2" thick. For 1-inch steel plate, plasma cuts approximately 3-4 times faster than waterjet at roughly half the operating cost per foot.

- Budget constraints: Plasma represents the lowest initial investment among CNC cutting technologies. If capital is limited but you need thick metal cutter capabilities, plasma delivers exceptional value.

- Speed requirements: A high-powered plasma system can cut 1/2" mild steel at speeds exceeding 100 inches per minute—making it the fastest option for medium to thick metal plates.

- Structural fabrication: Shipbuilding, heavy equipment manufacturing, and structural steel work rely heavily on plasma for thick plate processing with excellent bevel cutting capabilities.

However, plasma has genuine limitations you should understand:

- Heat-affected zone: The high-temperature arc creates significant heat input, potentially causing warping, hardening, or discoloration near cut edges

- Edge quality: Plasma produces slag or dross that often requires secondary grinding or finishing—adding labor and time

- Precision limits: While modern high-definition plasma approaches laser quality on thick materials, it cannot match laser precision for intricate designs or small features

- Material restrictions: Plasma only works on electrically conductive materials—no wood, plastics, glass, or ceramics

For laser cut steel requirements under 1/4" thick where precision matters, laser typically wins. For structural steel over 1" where speed and cost dominate, plasma is hard to beat.

CNC Routing for Non-Metallic Alternatives

CNC routing occupies a different niche entirely. Using spinning cutting tools rather than thermal or erosive processes, routers excel at softer materials—wood, plastics, foams, and soft metals like aluminum. For metal fabrication specifically, routing generally applies only to aluminum sheet and soft alloys where tool wear remains manageable.

Routing advantages include lower equipment costs, no thermal effects, and excellent edge finish on appropriate materials. However, for most custom metal laser cutting applications, routing simply doesn't compete—tool wear on steel makes it impractical, and precision on thin metals rarely matches laser capabilities.

Comprehensive Cutting Method Comparison

Choosing the right metal cutter technology requires weighing multiple factors against your specific project requirements. This comparison synthesizes key performance characteristics across all four methods:

| Factor | Laser Cutting | Waterjet Cutting | Plasma Cutting | CNC Routing |

|---|---|---|---|---|

| Material Compatibility | Most metals; limited non-metals | Virtually any material including stone, glass, composites | Conductive metals only (steel, aluminum, copper) | Soft metals, wood, plastics, composites |

| Optimal Thickness Range | Best under 25mm; efficiency drops on thick materials | Up to 24" for rough cuts; maintains quality at all thicknesses | 0.018" to 2"; excels on thick plate | Thin to medium gauges; tool wear limits thick processing |

| Cutting Speed | Fastest on thin materials (up to 20m/min) | Slowest (5-20 inches/min typically) | Fastest on thick materials (100+ in/min on 1/2" steel) | Moderate; depends on material hardness |

| Edge Quality | Excellent; often requires no finishing | Satin-smooth; no heat marks | Good; may require slag removal | Good on soft materials; tool marks possible |

| Heat-Affected Zone | Minimal but present; localized to cut edge | None (cold process) | Significant; may cause warping or hardening | None (mechanical process) |

| Precision Level | Highest for thin materials; tight tolerances achievable | High; excellent for thick materials | Moderate; HD plasma approaches laser on thick stock | Moderate; tool deflection limits precision |

| Relative Equipment Cost | Moderate to high (fiber systems) | Highest (~$195,000 for complete system) | Lowest (~$90,000 for comparable system) | Low to moderate |

| Operating Cost | Low (fiber lasers highly efficient) | Highest (abrasive consumption, pump maintenance) | Lowest cost per inch of cut | Low (tooling wear primary expense) |

Making the Right Choice for Your Project

So which method wins? The honest answer: it depends entirely on your specific requirements.

Choose laser cutting when:

- Working with thin to medium thickness metals (under 25mm)

- Precision and edge quality are priorities

- Your design includes intricate details, small holes, or tight tolerances

- Production speed matters for high-volume runs

Choose waterjet when:

- Processing thick materials beyond laser capabilities

- Heat effects are absolutely unacceptable

- Working with mixed material types in the same workflow

- Edge finish must be perfect without secondary operations

Choose plasma when:

- Budget is the primary constraint

- Cutting thick conductive metals at high speed

- Secondary finishing is acceptable or already planned

- Structural fabrication work with less demanding tolerances

Many successful fabrication shops eventually incorporate multiple cutting technologies, starting with the system that addresses their most common projects and expanding as capabilities and customer demands grow.

Understanding these trade-offs helps you specify the right process upfront—saving both time and money. With your cutting method selected, the next step is understanding exactly what factors drive project costs so you can budget accurately.

Understanding Custom Laser Cutting Cost Factors

You've selected your cutting method, prepared your files, and chosen your material. Now comes the question that ultimately shapes every project decision: what will this actually cost? Unlike commodity products with fixed price tags, custom metal laser cutting involves multiple interconnected variables—and understanding how each factor influences your final invoice puts you in control of your budget.

The truth is, two seemingly similar projects can have dramatically different costs based on design decisions you might not even realize you're making. Let's break down exactly what drives laser cutting charges so you can optimize your project from the start.

How Cut Complexity Multiplies Your Project Cost

Imagine two parts cut from identical material and thickness. One is a simple rectangle. The other features intricate internal cutouts, tight radius curves, and decorative perforations. Which costs more? The answer reveals how complexity compounds expenses.

According to industry pricing analysis, every cutout requires a pierce point where the laser initiates the cut. More pierce points mean more cutting time, more energy consumption, and greater wear on consumables. Here's how complexity factors break down:

- Number of pierce points: Each hole, slot, or internal feature requires the laser to pierce the material fresh. A part with 50 small holes takes significantly longer than a simple outline cut, even if the total cut length is similar.

- Total cut path length: Intricate designs with detailed contours accumulate more linear inches of cutting. This directly increases machine time—the primary driver of laser cutting charges.

- Corner and curve density: Sharp corners require the cutting head to decelerate, change direction, and accelerate again. Designs with numerous tight radii or complex curves process slower than those with long, straight runs.

- Feature proximity: Closely spaced cuts require careful heat management to prevent warping. Operators may need to adjust parameters or sequence cuts strategically, adding programming time.

A real-world example illustrates this clearly: an intricate 5052 aluminum part with complex geometry was priced at $27 each, while simpler designs in the same material cost significantly less to produce. The lesson? Simplifying your design where possible—without compromising function—directly reduces your laser cutting quote.

Volume Discounts and Batch Optimization Strategies

Here's where smart ordering transforms your project economics. The first part of any production run is always the most expensive—setup time, machine calibration, and program verification happen whether you're cutting one piece or one thousand.

The numbers are striking. According to fabrication cost studies, a small zinc-plated G90 steel part costs approximately $29 when ordering just one. Order ten identical parts? The price drops to just $3 per unit. That's an 86% reduction simply by spreading fixed costs across more pieces.

Batch optimization strategies that maximize your savings include:

- Consolidate orders: Combine multiple part designs into single production runs when possible. This spreads setup costs and qualifies for volume pricing tiers.

- Efficient nesting: Quality providers use advanced nesting software to arrange your parts tightly on material sheets, minimizing waste. Better nesting means less raw material cost passed to you.

- Standard material selection: Ordering parts from readily available standard sheet sizes and thicknesses avoids special sourcing fees and minimum order requirements.

- Plan ahead for prototypes: If you're prototyping, consider ordering slightly more units than needed for testing. The marginal cost of additional pieces is often minimal compared to reordering later.

Material and Finishing Cost Multipliers

Your material choice affects more than just the raw material line item. Different metals require different cutting parameters, assist gases, and processing speeds—all of which influence machine time and consumable costs.

- Material type: Cutting stainless steel generally requires more energy and slower speeds than mild steel, increasing processing costs. Reflective metals like copper demand even more careful parameter management.

- Thickness impact: Thicker materials require more energy, slower cutting speeds, and generate more wear on equipment. According to industry sources, thickness is one of the most significant cost drivers—doubling thickness can more than double cutting time.

- Material waste: Larger parts or inefficient geometries that don't nest well create more scrap material. While providers optimize nesting, fundamentally wasteful designs carry higher material costs.

Finishing processes add another cost layer that's easy to underestimate. Powder coating services transform raw cut parts with durable, attractive finishes—but add significant per-part expense. That same $27 aluminum part mentioned earlier? With a powder coat finish, it jumps to $43. Similarly, anodized aluminum provides excellent corrosion resistance and aesthetic options, but the electrochemical process adds both time and specialized processing costs.

Common finishing add-ons to budget for include:

- Deburring: Removing sharp edges left by the cutting process

- Powder coating: Durable, decorative finish in various colors and textures

- Anodizing: Electrochemical treatment for aluminum providing corrosion resistance and color options

- Plating: Zinc, nickel, or chrome plating for corrosion protection

- Grinding and polishing: Achieving specific surface finish requirements

Getting Accurate Quotes: What Information to Prepare

The accuracy of your laser cutting quote depends entirely on the information you provide upfront. Vague requests generate rough estimates; detailed specifications yield precise pricing. Before requesting quotes, prepare the following information:

- Complete design files: DXF or other vector formats with verified dimensions and clean geometry

- Material specifications: Exact material type, grade, and thickness

- Quantity requirements: Total pieces needed, including any prototype quantities

- Tolerance requirements: Any critical dimensions that need tighter-than-standard precision

- Finishing specifications: Required surface treatments, coatings, or post-processing

- Delivery timeline: Standard lead time versus rush requirements

Quality providers offering rapid quote turnaround—some within 12 hours—help you budget accurately and compare options efficiently. This responsiveness often indicates well-organized operations that translate to reliable delivery and consistent quality.

The more detailed your quote request, the more accurate your pricing will be. Surprises in manufacturing almost always cost more than planning ahead.

Understanding these cost dynamics empowers you to make informed trade-offs between design complexity, material selection, finishing requirements, and budget constraints. With pricing factors clear, the next consideration is ensuring your finished parts meet the quality standards your application demands.

Quality Standards and Tolerance Specifications

You've optimized your design, selected your material, and budgeted accurately. But here's the question that separates acceptable parts from exceptional ones: how do you know if your laser cut metal sheets actually meet spec? Understanding quality standards isn't just academic—it's the difference between parts that fit perfectly in your assembly and components that require costly rework or rejection.

For engineers and designers evaluating custom metal laser cutting services, quality benchmarks provide the language for communicating expectations clearly. Let's decode what these standards mean for your projects.

Industry Tolerances: What You Can Realistically Expect

Every cutting process produces minor deviations from nominal dimensions—that's simply the nature of manufacturing. According to TEPROSA's technical documentation, these variations result from minute inaccuracies in laser system movement, irregularities in base material, and beam shaping variations. The key is ensuring these deviations stay within acceptable limits.

The international standard DIN ISO 2768 establishes general manufacturing tolerances that most laser cutting operations reference. Within this framework, four tolerance classes define increasing levels of precision:

- Fine (f): Tightest tolerances for precision applications

- Medium (m): Standard manufacturing tolerance—most laser cut sheet metal parts default to this class

- Coarse (c): Relaxed tolerances for non-critical dimensions

- Very coarse (v): Widest acceptable variation for rough components

Most quality providers manufacture according to DIN ISO 2768-1 m (medium tolerance class) unless you specify tighter requirements. Here's what that means practically: tolerance depends heavily on material thickness. Thicker materials present greater challenges for maintaining tight geometric tolerances—something to consider when designing precision assemblies from heavy gauge stock.

For thermal cutting processes specifically, DIN EN ISO 9013 defines additional standards addressing stainless laser cutting and steel laser cutting applications. This standard covers perpendicularity, angularity, and surface quality characteristics unique to laser, plasma, and oxyfuel processes.

Edge Quality Grades and What They Mean

When you examine a laser cut stainless steel edge, what should you actually look for? Edge quality encompasses several characteristics that affect both aesthetics and functionality.

Surface roughness: Measured in Ra (roughness average), this indicates how smooth the cut edge appears. Fiber lasers typically produce excellent surface finish on thin materials, with roughness increasing as thickness grows.

Perpendicularity: How square is the cut edge relative to the material surface? Slight angular deviation is normal, particularly on thicker materials where the laser beam diverges slightly as it penetrates.

Striation patterns: The characteristic lines visible on cut edges result from the pulsing nature of the laser and assist gas dynamics. Finer striations generally indicate optimized cutting parameters.

What about dross? To define dross clearly: it's the resolidified molten material that adheres to the bottom edge of a cut. According to quality control research, dross forms when molten material doesn't eject cleanly from the kerf during cutting. The viscosity of the molten metal, assist gas pressure, and cutting speed all influence dross formation.

Dross appears most commonly on:

- Reflective metals like copper and brass where molten material is viscous

- Thick materials where the assist gas struggles to clear the full depth

- Cuts made with suboptimal parameters (wrong speed, power, or focus)

Inspection Points for Critical Components

Whether you're inspecting incoming parts or establishing quality requirements with your provider, these checkpoints ensure laser cut metal sheets meet your specifications:

- Dimensional accuracy: Verify critical dimensions against your design using calibrated measuring equipment. Check multiple locations—variations can occur across large parts.

- Edge quality assessment: Examine for burrs, dross, and surface roughness. Run your finger along edges to detect sharpness requiring deburring.

- Heat discoloration: Blue or straw-colored zones adjacent to cuts indicate excessive heat input. While often cosmetic, significant discoloration may signal metallurgical changes in heat-sensitive alloys.

- Flatness verification: Particularly important for thin materials prone to warping. Place parts on a flat surface and check for gaps or rocking.

- Hole and feature geometry: Measure critical holes for diameter and roundness. Check slot widths and internal feature dimensions.

- Surface contamination: Look for spatter, oxide deposits, or protective film residue that may affect subsequent processes.

Quality isn't just about meeting specifications—it's about consistency. The best laser cutting operations produce parts that are virtually identical whether you're inspecting the first piece or the thousandth.

Troubleshooting Common Quality Issues

Understanding what causes quality problems helps you communicate effectively with providers and design parts that cut cleanly the first time.

Warping and distortion: Thermal stress from the cutting process can cause thin materials or parts with asymmetric geometry to warp. Prevention strategies include:

- Designing with balanced geometry where possible

- Using appropriate cutting sequences that distribute heat evenly

- Selecting materials with lower thermal expansion coefficients for critical applications

- Allowing parts to cool gradually rather than rapid quenching

Burr formation: Burrs occur when cutting speed is too slow or laser power too high, causing molten material to resolidify before cleanly separating. Optimizing cutting parameters and ensuring proper beam focus minimizes burr formation. When burrs do occur, deburring methods including mechanical grinding, tumbling, or vibratory finishing can restore edge quality.

Burn marks: Excessive heat around the cutting area causes discoloration or surface damage. Solutions include lowering laser power, increasing cutting speed, and using appropriate assist gases like nitrogen that cool the cutting zone while preventing oxidation.

Inconsistent cuts: If quality varies across a production run, root causes typically include material inconsistency, machine calibration drift, or consumable wear. Regular maintenance, proper calibration, and material verification prevent these issues.

Why Certifications Matter for Critical Applications

For automotive, aerospace, and medical applications, quality standards aren't suggestions—they're requirements. This is where certifications like IATF 16949 become essential.

IATF 16949:2016 represents the global automotive quality management standard, built on ISO 9001:2015 with additional automotive-specific requirements. Developed by the International Automotive Task Force—including BMW, Ford, General Motors, Volkswagen, and other major manufacturers—this certification demonstrates that a supplier has implemented rigorous quality systems specifically designed for automotive supply chain requirements.

What does IATF 16949 certification mean for your parts?

- Documented quality systems: Every process is controlled, measured, and continuously improved

- Traceability: Materials and processes can be traced throughout production

- Defect prevention: Systems focus on preventing problems rather than just detecting them

- Consistent production: Standardized processes ensure repeatability across production runs

- Supply chain integration: Certified suppliers meet requirements accepted by major automotive OEMs

For aerospace applications, similar certifications like AS9100 establish equivalent quality frameworks. Medical device manufacturing references ISO 13485. When your application demands these standards, working with certified providers isn't optional—it's the foundation of compliant manufacturing.

Understanding quality standards positions you to specify requirements clearly, evaluate incoming parts effectively, and select providers capable of meeting your application demands. With quality expectations established, the next step is exploring how different industries apply these capabilities to solve specific manufacturing challenges.

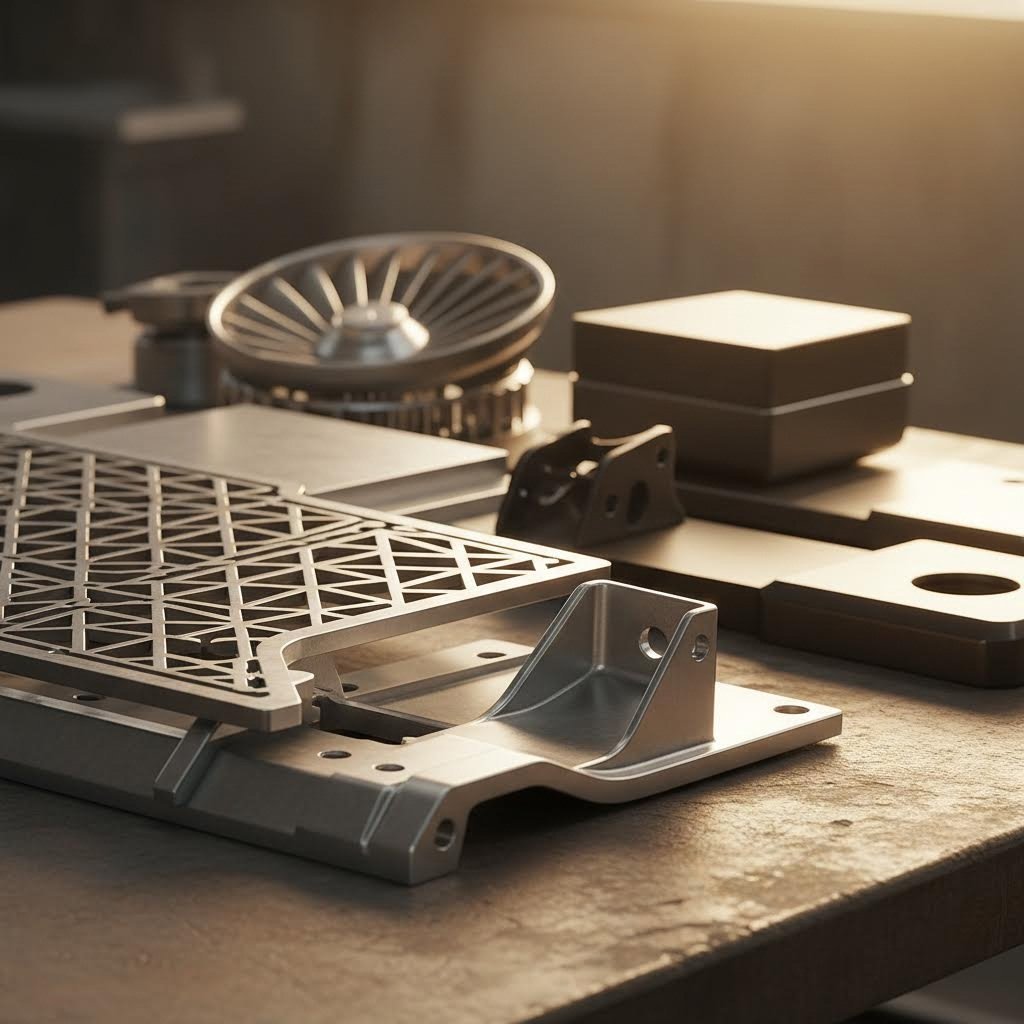

Industry Applications from Automotive to Architecture

Now that you understand quality standards, here's where everything comes together: real-world applications. Custom metal laser cutting isn't a one-size-fits-all technology—different industries leverage its capabilities in remarkably different ways. Understanding these sector-specific requirements helps you evaluate whether your project aligns with proven applications and identify best practices from industries that have refined laser fabrication for decades.

From chassis components requiring micron-level precision to custom metal signs demanding aesthetic perfection, each application brings unique challenges. Let's explore how major industries apply this technology—and what you can learn from their approaches.

Automotive Component Applications and Requirements

The automotive industry represents one of the most demanding environments for metal fabrication. According to industry analysis, traditional stamping and die-cutting methods couldn't keep pace with rapidly rising demand—which is precisely why laser cutting became essential to modern auto manufacturing.

Today's automotive applications span virtually every vehicle system:

- Chassis and structural components: Floor pans, crossmembers, and reinforcement brackets require consistent precision across high-volume production runs. Laser cutting delivers the repeatability that automated assembly lines demand.

- Suspension parts: Control arms, mounting brackets, and subframe components benefit from clean edges that reduce stress concentrations and improve fatigue life.

- Body panels and trim: Precision cut edges enable tighter panel gaps and better fit-and-finish that distinguishes quality vehicles.

- Electronic enclosures: Modern vehicles contain dozens of electronic control units, each requiring precisely cut metallic housings that protect sensitive electronics while managing heat dissipation.

- Lightweighting applications: The industry's push toward fuel efficiency drives adoption of lighter materials like aluminum and advanced high-strength steels—materials that laser cutting handles exceptionally well.

What makes automotive applications particularly demanding? The combination of tight tolerances, high volumes, and absolute quality consistency. A chassis component that's acceptable on 99 out of 100 parts isn't acceptable at all—every single piece must meet specification.

This is why automotive manufacturers increasingly seek partners offering integrated capabilities. When a supplier provides both laser cutting and metal stamping under one roof, component solutions become streamlined. For example, Shaoyi (Ningbo) Metal Technology combines custom metal stamping with precision assemblies, offering 5-day rapid prototyping alongside automated mass production. Their IATF 16949 certification—the global automotive quality standard—ensures chassis, suspension, and structural components meet the exacting requirements major OEMs demand. With comprehensive DFM support and 12-hour quote turnaround, manufacturers can optimize both design and production timeline simultaneously.

Aerospace and Defense: Where Precision Is Non-Negotiable

If automotive is demanding, aerospace raises the stakes exponentially. According to McKiney Manufacturing, precision isn't just a preference in aerospace—it's a necessity, since a single flaw can compromise entire systems.

Fiber laser cutting proves particularly valuable for aerospace applications:

- Turbine components: Precision-cut turbine blades are essential for maintaining engine efficiency and safety. Each blade must meet exacting standards to reduce failure risk.

- Airframe structures: From wing sections to fuselage panels, structural components must be both lightweight and strong. Laser cutting achieves necessary precision while maintaining structural integrity.

- Avionics enclosures: Increasingly sophisticated electronics require durable enclosures with fine details that protect sensitive systems in extreme environments.

- Defense equipment: Military vehicles, weapons systems, and communication equipment demand rigorous standards that fiber laser cutting reliably delivers.

The aerospace industry also benefits from fiber lasers' ability to process diverse materials—titanium, stainless steel, aluminum, and advanced composites all appear in modern aircraft. This versatility, combined with minimal post-processing requirements, reduces both production time and cost.

Electronics: Miniaturization Meets Precision

From pocket-sized smartphones to ultra-thin laptops, consumer electronics continue shrinking while increasing in capability. This miniaturization trend creates perfect conditions for laser cutting applications.

Key electronics applications include:

- Printed circuit board (PCB) components: The precision and efficiency of fiber laser cutters enables manufacturers to quickly cut tiny yet intricate components while maintaining the cleanest, most accurate cuts.

- Device enclosures: Sheet metal fabrication for electronic housings requires tight tolerances and clean edges that won't interfere with sensitive internal components.

- Heat sinks and thermal management: Complex geometries for heat dissipation benefit from laser cutting's ability to create intricate internal structures.

- Connector shields and brackets: Small, precise components that position and protect electronic connections throughout devices.

- Solder stencils: Laser-cut stencils allow machines to quickly cover PCB pads with solder without targeting each pad individually.

When searching for metal fabricators near me for electronics work, prioritize providers with experience in thin-gauge materials and fine-feature capabilities. The tolerances acceptable for structural steel fabrication are far too loose for electronics applications.

Architectural and Decorative Metal Projects

Architecture and decorative applications occupy the opposite end of the spectrum from aerospace—here, aesthetics often matter as much as precision. Yet laser cutting excels in both dimensions.

Laser cutting serves architectural applications including:

- Decorative panels and screens: Intricate patterns impossible with traditional cutting methods become straightforward with laser technology. From geometric designs to organic motifs, the only limit is imagination.

- Façade elements: Building exteriors increasingly feature laser-cut metal panels that combine weather resistance with visual impact.

- Interior partitions: Custom metal signs and room dividers create dramatic visual statements while serving functional purposes.

- Railings and balustrades: Precision-cut baluster patterns enable both safety compliance and aesthetic distinction.

- Lighting fixtures: Complex lamp shades and light diffusers that control and shape illumination while serving as design elements.

According to industry sources, both CO2 and fiber laser cutters serve architectural applications well, since many building projects use various materials. Fiber cutters handle metal components while CO2 systems address wood, acrylic, and other decorative materials.

The metal fab sector also produces attention-grabbing signage for businesses—from clear and legible safety signage to eye-catching displays that draw customers. Whether compliance-driven or marketing-focused, laser cutting delivers the precision and repeatability these applications demand.

Signage and Branding: Making Statements in Metal

Custom metal signs represent one of the most visible applications of laser cutting. When you see a precision-cut metal logo on a building entrance or a directional sign in a hospital corridor, you're witnessing laser fabrication at work.

- Corporate signage: Logos and branding elements cut from stainless steel, aluminum, or brass create lasting impressions at building entrances.

- Wayfinding systems: Hospitals, airports, and large facilities rely on durable metal signage that withstands heavy traffic and cleaning.

- Retail displays: Point-of-sale elements and product displays benefit from laser cutting's ability to create intricate, eye-catching designs.

- Safety and compliance signage: Industrial facilities require clear, durable signage that meets regulatory requirements.

Manufacturing and Industrial Applications

Beyond specific industries, steel fabrication and sheet metal fabrication serve countless manufacturing applications:

- Machine guards and covers: Safety enclosures that protect workers while allowing visibility and airflow.

- Control panels: Precisely cut openings for instruments, switches, and displays in industrial equipment.

- Gaskets and seals: Non-metallic gaskets cut with CO2 lasers; metal gaskets processed with fiber systems.

- Prototyping: Rapid iteration on new product designs before committing to production tooling.

- Replacement parts: Custom one-off components for equipment repair when OEM parts are unavailable or cost-prohibitive.

Marine and Shipbuilding

The marine industry presents unique requirements combining precision with corrosion resistance. According to industry sources, shipbuilders and marine manufacturers must stay within tight tolerances and regulations to operate legally.

Marine applications include:

- Hull components: Structural elements requiring both precision and durability in harsh saltwater environments.

- Deck fittings: Cleats, chocks, and hardware that must withstand continuous exposure to salt spray.

- Interior panels: Cabin components combining aesthetics with marine-grade durability.

- Custom replacement parts: Fiber laser cutters enable custom replacement components for older vessels when original parts are no longer available.

The same laser cutting technology that produces a precision aerospace turbine blade can create a decorative architectural screen or a custom marine fitting. Understanding your industry's specific requirements helps you specify the right process and find providers with relevant experience.

Whether you're producing chassis components for automotive assembly lines or custom metal signs for a retail installation, the fundamental technology remains consistent—only the specifications and quality requirements change. With applications understood, the final piece of the puzzle is finding the right service partner to bring your projects to life.

Choosing the Right Custom Laser Cutting Service Partner

You've mastered the technology, selected your materials, optimized your design files, and understand quality requirements. Now comes perhaps the most consequential decision of all: who will actually manufacture your parts? The difference between an exceptional service partner and a mediocre one extends far beyond price—it determines whether your project succeeds on schedule or becomes a cascade of delays, rework, and frustration.

When searching for laser cutting near me or metal laser cutting services, you'll find no shortage of options. But how do you distinguish providers who genuinely deliver from those who simply promise? Let's walk through a systematic evaluation framework that separates world-class partners from risky choices.

Evaluating Equipment Capabilities and Certifications

The foundation of any quality laser cutting services near me search starts with hardware. According to industry experts at LS Precision Manufacturing, low-end or aging laser machines produce poor dynamic performance—cutting head oscillation at high speeds leads to shape errors that render precision parts unusable.

Here's what to evaluate in priority order:

- Equipment vintage and capability: Modern fiber laser systems deliver tolerances of ±0.1mm with smooth, dross-free surfaces. Ask about equipment age, power ratings, and bed sizes. Providers investing in current technology demonstrate commitment to quality outcomes.

- Quality certifications: For automotive applications, IATF 16949 certification is non-negotiable—it signals documented quality systems, traceability, and defect prevention processes accepted by major OEMs. For aerospace, look for AS9100. General manufacturing should meet ISO 9001 at minimum.

- Material expertise: According to Pinnacle Precision's guidance, an experienced metal fabrication partner brings knowledge of different materials, fabrication processes, and industry standards. Ask specifically about experience with your material and thickness combinations.

- Facility inspection: The simplest verification method is visiting their factory or requesting video tours. Observe equipment brands, workshop organization, and operational standards—these directly indicate capability.

- Sample evaluation: Request actual samples of different materials they've processed. Examine cutting accuracy, surface quality, minimum hole spacing, and absence of scorch marks or distortion.

When evaluating metal fabrication near me options, remember that reputation matters enormously. As Pinnacle Precision emphasizes, don't take risks with cheaper fabricators—a well-established company with a proven track record beats a low-cost unknown every time.

What Quote Turnaround Times Reveal About Operations

Here's an insight many buyers overlook: how quickly a provider responds to your quote request reveals volumes about their operational efficiency. A company that takes a week to return a simple estimate likely operates with the same sluggishness throughout production.

Quality cnc laser cutting services providers demonstrate responsiveness that reflects internal organization:

- Rapid quote turnaround: Leading providers return detailed quotes within hours, not days. For example, Shaoyi (Ningbo) Metal Technology offers 12-hour quote turnaround—a capability that requires streamlined intake processes, experienced estimators, and efficient communication systems.

- Detailed cost breakdowns: Quality quotes itemize costs, process recommendations, and realistic delivery timelines rather than providing single-number estimates that hide surprises.

- Proactive communication: According to LS Precision, professional project engineers should provide preemptive technical reviews—identifying potential issues before they become production problems.

When fabrication shops near me compete for your business, responsiveness becomes a reliable proxy for overall operational excellence.

DFM Support and Rapid Prototyping Capabilities

Design for Manufacturability (DFM) support separates transactional vendors from true manufacturing partners. The best providers don't simply cut what you send—they actively improve your designs to reduce costs, eliminate production issues, and enhance outcomes.

What does comprehensive DFM support look like?

- Free design analysis: Quality providers examine your drawings for aspects affecting cut quality or cost—sharp edges, narrow slits, minimum apertures—and offer optimization recommendations before production begins.

- Cost-reduction suggestions: Experienced engineers identify opportunities to simplify geometry, optimize material utilization, or adjust tolerances without compromising function.

- Risk identification: Problems caught during design review cost far less to fix than problems discovered during production.

Rapid prototyping capabilities prove equally valuable for design validation. Before committing to mass production tooling or high-volume runs, you need to verify that your design performs as intended in the real world. Leading providers like Shaoyi offer 5-day rapid prototyping that enables fast iteration—testing designs, identifying improvements, and confirming fit and function before scaling up.

This prototyping capability becomes critical when you consider the alternative: discovering design flaws after ordering thousands of parts. The cost difference is dramatic.

Evaluating End-to-End Capabilities

When searching for laser cutter service near me, consider whether your project benefits from integrated capabilities beyond cutting alone. According to LS Precision, the value of a quality provider extends far beyond delivering cut parts—true value comes from integration into your production process as a one-stop facility.

Comprehensive providers offer:

- Post-processing services: Bending, welding, deburring, and assembly under one roof eliminates supplier coordination headaches and reduces error opportunities.

- Surface finishing: Powder coating, electroplating, and anodizing capabilities mean finished parts—not just cut blanks—ship from a single source.

- Volume flexibility: From single-piece prototypes to automated mass production, capacity should match your current needs and growth trajectory.

For automotive applications specifically, partners offering both laser cutting and metal stamping capabilities—like Shaoyi's combination of custom metal stamping parts and precision assemblies—provide complete component solutions that streamline supply chain management.

Your Evaluation Checklist

Before committing to any provider, systematically verify these criteria:

- Equipment capability: Modern fiber laser systems appropriate for your materials and thicknesses

- Quality certifications: IATF 16949 for automotive; AS9100 for aerospace; ISO 9001 minimum

- Material expertise: Documented experience with your specific material and thickness

- Quote responsiveness: 12-24 hour turnaround indicates operational efficiency

- DFM support: Free design analysis and optimization recommendations

- Rapid prototyping: 5-day or faster prototype capability for design validation

- References: Customer contacts willing to discuss their experience

- Facility verification: On-site visit or video tour confirming capabilities

- Sample quality: Physical samples demonstrating actual cutting quality

- Integrated services: Post-processing and finishing capabilities matching your requirements

Choosing the right laser cutting supplier isn't a question of price comparison—it's a strategic decision that can make or break your project.

The investment you make in properly evaluating partners pays dividends throughout your project lifecycle. A provider meeting these criteria becomes more than a vendor—they become an extension of your manufacturing capabilities, helping transform designs into precision components efficiently and reliably.

Frequently Asked Questions About Custom Metal Laser Cutting

1. How much does it cost to get a metal laser cut?

Custom metal laser cutting costs depend on several interconnected factors: material type and thickness, cut complexity and total path length, number of pierce points, quantity ordered, and finishing requirements. A simple rectangular part costs significantly less than intricate designs with numerous internal cutouts. Volume dramatically affects per-unit pricing—ordering 10 identical parts instead of one can reduce costs by up to 86% by spreading setup fees across more pieces. For accurate budgeting, prepare complete design files, specify exact material requirements, and request quotes from IATF 16949-certified providers offering rapid quote turnaround.

2. Is there a laser that can cut metal?

Yes, fiber lasers are specifically designed for metal cutting and have become the industry standard. Operating at a 1.064 micrometer wavelength, fiber lasers focus into exceptionally small spot sizes that metals absorb efficiently. They cut steel, stainless steel, aluminum, copper, and brass with excellent precision and speed. Modern fiber systems achieve cutting speeds up to 20 meters per minute on thin materials, with minimal maintenance requirements and lifespans reaching 100,000 hours. CO2 lasers can also cut metals but are less efficient for dedicated metal fabrication.

3. What is the difference between fiber and CO2 lasers for metal cutting?

Fiber lasers operate at 1.064μm wavelength with approximately 35% energy efficiency, cutting thin metals up to three times faster than CO2 systems. They excel at processing reflective metals like aluminum and copper with minimal maintenance requirements. CO2 lasers operate at 10.6μm wavelength with 10-20% efficiency, making them better suited for mixed-material shops cutting metals alongside wood, acrylic, and plastics. For dedicated metal fabrication under 25mm thickness, fiber lasers deliver superior speed, precision, and operating cost advantages.

4. What materials can be laser cut and what are their challenges?

Common laser-cut metals include mild steel (fastest processing, excellent edges), stainless steel (clean cuts, minimal finishing needed), aluminum (requires fiber lasers due to reflectivity), and copper and brass (most challenging due to thermal conductivity and reflectivity). Each material behaves differently under laser energy. Stainless steel represents the sweet spot with consistent results across thicknesses. Aluminum requires higher power settings and nitrogen assist gas. Copper demands specialized parameters and often produces bottom-edge dross requiring post-processing.

5. How do I prepare design files for laser cutting?

Start with clean 2D vector geometry in DXF format, verifying units and scale match intended dimensions. Convert all curves to smooth polylines, organize layers logically (CUT, ENGRAVE, SCORE), eliminate duplicate lines, and ensure all contours are completely closed. Account for kerf width in precision assemblies, design features at least as wide as material thickness, add small corner radii to internal corners, and maintain adequate spacing between features. Before submitting, open your exported DXF in a separate viewer to confirm everything translated correctly.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —