द फोर्ज के अंदर: कस्टम फोर्ज्ड व्हील निर्माण चरणों का खुलासा

कस्टम फोर्ज्ड व्हील निर्माण उत्कृष्टता की समझ

उच्च-प्रदर्शन फोर्ज्ड व्हील को एक सामान्य व्हील से क्या अलग करता है? उत्तर स्वयं निर्माण प्रक्रिया में गहराई में निहित है। कस्टम फोर्ज्ड व्हील ऑटोमोटिव व्हील इंजीनियरिंग की चरम सीमा का प्रतिनिधित्व करते हैं, जहां उत्पादन के दौरान किया गया प्रत्येक निर्णय सीधे आपके वाहन के त्वरण, हैंडलिंग और सड़क या ट्रैक की मांगों को सहने के तरीके को आकार देता है।

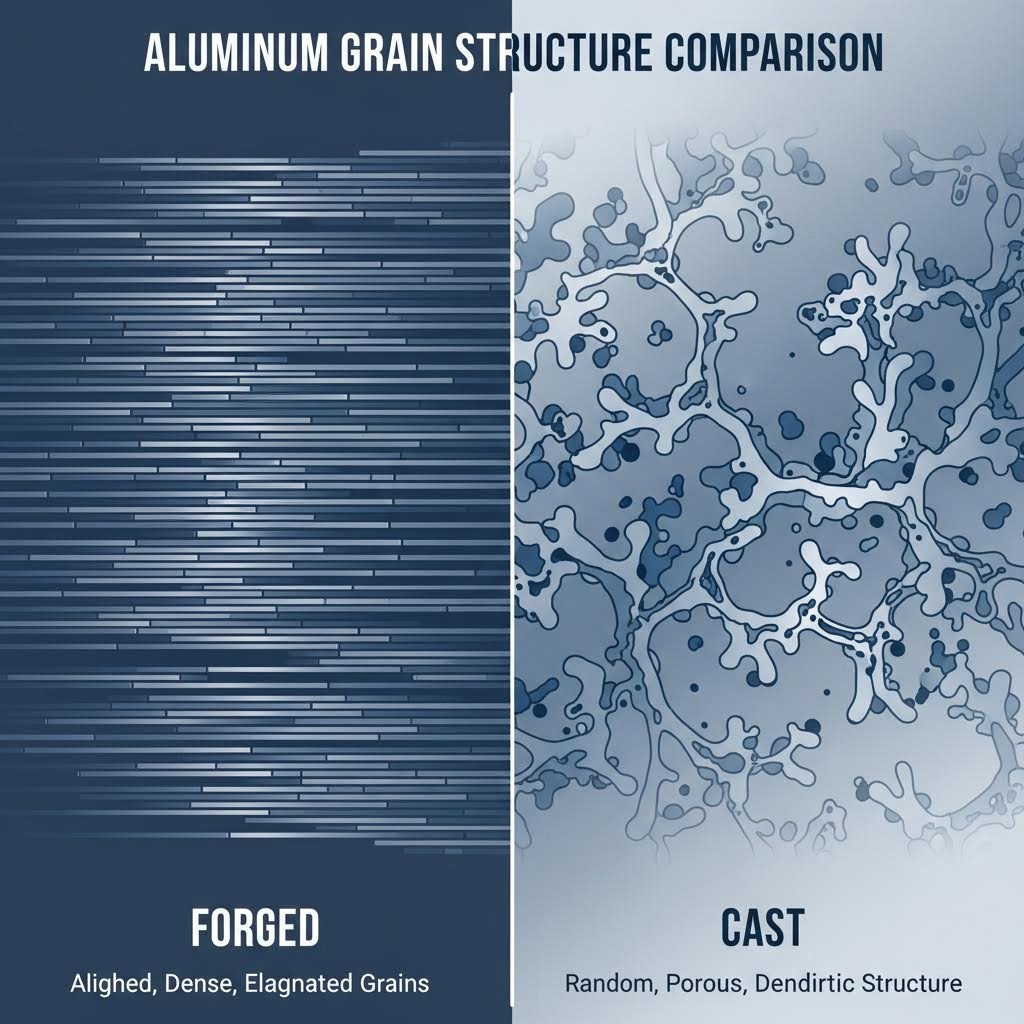

तो, फोर्ज्ड व्हील्स वास्तव में क्या हैं? फोर्ज्ड व्हील्स की परिभाषा के अनुसार, इन घटकों को उच्च-ग्रेड एल्युमीनियम के एकल ब्लॉक से बनाया जाता है, जिस पर अत्यधिक गर्मी और दबाव लगाया जाता है, जिससे एक ऐसा व्हील बनता है जिसमें वजन के मुकाबले अद्वितीय मजबूती की विशेषताएँ होती हैं। ढलाई विकल्पों के विपरीत, वन पीस फोर्ज्ड व्हील्स में घनी और एकरूप धात्विक संरचना होती है जो आंतरिक कमजोरियों को खत्म कर देती है, जिसके परिणामस्वरूप उत्कृष्ट टिकाऊपन और प्रदर्शन मिलता है।

फोर्जिंग प्रक्रिया धातु को संपीड़ित करती है, जिससे एक घनी धात्विक संरचना बनती है जो व्हील्स को मजबूती बनाए रखते हुए वजन कम करने में सक्षम बनाती है। सिर्फ यह निर्माण निर्णय तय करता है कि क्या आपके व्हील्स उच्च तनाव वाली ड्राइविंग परिस्थितियों का सामना कर सकते हैं या समय के साथ धातु की थकान के कारण खराब हो जाएंगे।

व्हील खरीदारों के लिए निर्माण ज्ञान क्यों महत्वपूर्ण है

चाहे आप उच्चतम प्रदर्शन की तलाश में एक ऑटोमोटिव उत्साही हों, आपूर्तिकर्ताओं का आकलन कर रहे एक खरीद विशेषज्ञ हों, या गुणवत्ता वाले घटकों में निवेश करने वाले एक प्रदर्शन-उन्मुख खरीदार हों, फोर्ज्ड व्हील्स के अर्थ को समझना सतही विनिर्देशों से परे का अर्थ रखता है। कच्चे एल्युमीनियम बिलेट से लेकर तैयार पहिया तक की निर्माण यात्रा में तन्य शक्ति, थकान प्रतिरोध और समग्र दीर्घायु को निर्धारित करने वाले महत्वपूर्ण चरण शामिल होते हैं।

यह तकनीकी संदर्भ सतही अवलोकन और अप्राप्य उद्योग दस्तावेज़ीकरण के बीच की खाई को पाटता है। आप यह जान पाएंगे कि प्रत्येक उत्पादन चरण पहिये की चरम बलों को संभालने की क्षमता को कैसे प्रभावित करता है, आक्रामक कोनिंग से लेकर ऊबड़-खाबड़ इलाके की नेविगेशन तक।

प्रत्येक कस्टम फोर्ज्ड व्हील के पीछे इंजीनियरिंग सटीकता

इस मार्गदर्शिका के सभी चरणों में, आप निर्माण की पूर्ण यात्रा का अनुसरण करेंगे, जिसमें कच्चे माल का चयन, फोर्जिंग प्रक्रिया स्वयं, ऊष्मा उपचार प्रोटोकॉल, सटीक सीएनसी मशीनिंग, सतह परिष्करण और कठोर गुणवत्ता नियंत्रण परीक्षण शामिल है। प्रत्येक चरण यह बताता है कि फोर्ज्ड व्हील्स की प्रीमियम कीमत क्यों होती है और गंभीर ड्राइवरों द्वारा मांगे जाने वाले अतुल्य प्रदर्शन लक्षण कैसे प्राप्त होते हैं।

कच्चे माल का चयन और एल्युमीनियम बिलेट की तैयारी

क्या आपने कभी सोचा है कि फोर्ज्ड व्हील को अत्यधिक बलों को संभालने में सक्षम बनाने के बावजूद भी इतनी हल्की कैसे रखा जाता है? इसका उत्तर धातु के किसी फोर्जिंग प्रेस को छूने से बहुत पहले का है। यह सही एल्युमीनियम मिश्र धातु के चयन के साथ शुरू होता है, और इस निर्णय से निर्माण प्रक्रिया में आगे आने वाली हर चीज आकार लेती है।

तो, मिश्र धातु व्हील किससे बनी होती है? प्रीमियम फोर्ज्ड व्हील्स का आधार एयरोस्पेस-ग्रेड एल्युमीनियम होता है, विशेष रूप से ऐसे मिश्र धातु जो अनावश्यक भार के बिना अद्वितीय शक्ति प्रदान करने के लिए डिज़ाइन किए गए होते हैं। उच्चतम प्रदर्शन स्तर पर पहिया किससे बना होता है, यह पूछने पर उत्तर लगभग हमेशा 6xxx श्रृंखला के एल्युमीनियम मिश्र धातु की ओर इशारा करता है, जिसमें 6061-T6 उद्योग का उदगामी मानक है।

एयरोस्पेस-ग्रेड एल्युमीनियम चयन मापदंड

क्या फोर्ज्ड व्हील्स एल्युमीनियम की होती हैं? हाँ, लेकिन कोई भी एल्युमीनियम नहीं। 6061-T6 मिश्र धातु एक सावधानीपूर्वक इंजीनियर की गई संरचना का प्रतिनिधित्व करती है जहाँ मैग्नीशियम और सिलिकॉन मुख्य मिश्र धातु तत्व के रूप में कार्य करते हैं। उद्योग विनिर्देश , एक विशिष्ट 6061-T6 संरचना उन गुणों का एक इष्टतम संतुलन प्रदान करती है जो निर्माता शुद्ध एल्युमीनियम या कम ग्रेड के मिश्र धातुओं के साथ प्राप्त नहीं कर सकते।

अनुकूलित फोर्ज्ड व्हील उत्पादन में 6061-T6 क्यों प्रभुत्व स्थापित करता है? तकनीकी तर्क तीन महत्वपूर्ण कारकों पर केंद्रित है:

- तन्यता शक्ति अनुकूलन: लगभग 290-310 MPa की अंतिम तन्य ताकत और लगभग 250-260 MPa की उपज ताकत के साथ, 6061-T6 मोड़ने के बल, सड़क प्रभावों और ब्रेक की गर्मी का स्थायी विरूपण के बिना सामना करने के लिए आवश्यक संरचनात्मक अखंडता प्रदान करता है।

- ऊष्मा उपचार योग्यता: T6 टेम्पर नामकरण इंगित करता है कि मिश्र धातु को समाधान ऊष्मा उपचार के बाद कृत्रिम उम्र के अधीन किया गया है, जिससे सामग्री में कठोरता और ताकत को अधिकतम करने वाले सूक्ष्म Mg₂Si अवक्षेप प्राप्त होते हैं।

- गर्म से गर्म तापमान सीमा में प्रसाध्यता: 350-500°C के तापमान के बीच, 6061 आसानी से पुन: क्रिस्टलीकृत हो जाता है, जिससे निर्माता एक सूक्ष्म, समदैशिक दाने की संरचना प्राप्त कर सकते हैं जो एक्सट्रूडेड या ढलवां विकल्पों की तुलना में थकान जीवन में 10-15% का सुधार करती है।

इन ताकत विशेषताओं के साथ 2.70 ग्राम/सेमी³ के संयोजन से वह उच्च विशिष्ट ताकत अनुपात बनता है जिसे इंजीनियर कहते हैं। इसका अर्थ है कि भारी विकल्पों की भार-वहन क्षमता को बनाए रखते हुए, या उससे भी अधिक करते हुए, फोर्ज किए गए पहियों में महत्वपूर्ण वजन कम किया जा सकता है।

पहियों के प्रदर्शन को निर्धारित करने वाले सामग्री गुण

धातुकर्म स्तर पर पहियों के निर्माण में उपयोग होने वाली सामग्री की समझ यह बताती है कि सामग्री के चयन को क्यों नजरअंदाज नहीं किया जा सकता। 6061-T6 मिश्र धातु एक व्यापक गुण प्रोफ़ाइल प्रदान करती है जो सीधे तौर पर सड़क पर प्रदर्शन में अनुवादित होती है:

- जंग प्रतिरोध: मैग्नीशियम-सिलिकॉन आव्यूह ऑक्सीकरण और आम वातावरणीय तत्वों के खिलाफ अंतर्निहित सुरक्षा प्रदान करता है, जिससे अतिरिक्त प्रसंस्करण उपचारों की आवश्यकता कम होती है और पहिये के सेवा जीवन को बढ़ाया जा सकता है।

- थर्मल चालकता: लगभग 167 W/m·K पर, यह मिश्र धातु ब्रेक लगाने के दौरान उत्पन्न ऊष्मा को तेजी से विघटित कर देती है, जिससे पहिये की संरचना और आसन्न घटकों को तापीय क्षति से सुरक्षा मिलती है।

- मध्यम कार्य-कठोरता: उन मिश्र धातुओं के विपरीत जो तनाव के तहत अत्यधिक कठोर हो जाती हैं, 6061-T6 डालने के दौरान भविष्य कहने योग्य व्यवहार बनाए रखती है, जिससे उत्पादन के दौरान सतत गुणवत्ता सुनिश्चित होती है।

- वेल्डिंग क्षमता: विलग डिजाइन वाले बहु-भाग पहियों के लिए जहां वेल्डेड जोड़ों की आवश्यकता होती है, उचित तैयारी और उपचार के बाद मिश्र धातु TIG, MIG और घर्षण मिश्रण वेल्डिंग विधियों को स्वीकार करती है।

हालांकि, निर्माताओं को सीमाओं का भी ध्यान रखना चाहिए। लंबे समय तक एक्सपोजर के दौरान 150°C से अधिक समय तक पीक-एज हार्डनेस खोना शुरू हो जाता है और इसकी थकान सीमा लगभग 95-105 एमपीए के लिए अत्यधिक चक्रवात, उच्च भार अनुप्रयोगों के लिए सावधानीपूर्वक डिजाइन विचार की आवश्यकता होती है।

किसी भी बैलेट के उत्पादन में प्रवेश करने से पहले, गुणवत्ता पर केंद्रित निर्माता कठोर इनकमिंग सामग्री सत्यापन लागू करते हैं। इसमें आमतौर पर मिश्र धातु विनिर्देशों की पुष्टि करने के लिए रासायनिक संरचना विश्लेषण, बिलेट स्टॉक के आयामी निरीक्षण और प्रमाणीकृत मिलों तक सामग्री का पता लगाने वाले दस्तावेज की समीक्षा शामिल होती है। कुछ सुविधाएं आंतरिक रिक्तियों या समावेशनों का पता लगाने के लिए अल्ट्रासोनिक परीक्षण करती हैं जो तैयार पहिया की संरचनात्मक अखंडता को खतरे में डाल सकती हैं।

जिस बिलेट की गुणवत्ता के साथ आप शुरुआत करते हैं, वह सीधे उस पहिये की गुणवत्ता को निर्धारित करती है जिसके साथ आप समाप्त करते हैं। उच्च-गुणवत्ता वाली प्रक्रिया द्वारा खराब कच्चे माल को ठीक नहीं किया जा सकता—इसे केवल मूल्यवान उत्पादन संसाधनों को बर्बाद करने से पहले अस्वीकार किया जा सकता है। इसीलिए प्रमुख निर्माता कठोर आपूर्तिकर्ता योग्यता कार्यक्रम बनाए रखते हैं और लागत के दबाव बढ़ने पर भी सामग्री के स्रोत पर समझौता करने से इनकार कर देते हैं।

उचित रूप से सत्यापित एयरोस्पेस-ग्रेड एल्युमीनियम बिलेट प्राप्त करने के बाद, निर्माण यात्रा रूपांतरकारी फोर्जिंग चरण की ओर बढ़ती है, जहाँ तीव्र दबाव और ऊष्मा कच्चे माल को एक पहिया ब्लैंक में ढाल देती है जिसमें असाधारण संरचनात्मक विशेषताएँ होती हैं।

फोर्जिंग प्रक्रिया: बिलेट से पहिया ब्लैंक तक

कल्पना कीजिए कि एयरोस्पेस-ग्रेड एल्युमीनियम के एक ठोस सिलेंडर को मात्र कुछ सेकंड में एक पहिये के पहचाने जाने योग्य आकार में बदल दिया जाता है। यही वह है जो एक फोर्जिंग प्रेस के अंदर होता है, जहाँ अत्यधिक दबाव और सावधानीपूर्वक नियंत्रित ऊष्मा एक साथ काम करके ऐसी चीज़ बनाते हैं जो कच्ची सामग्री से कहीं अधिक मजबूत होती है। यह समझने के लिए कि फोर्ज्ड व्हील्स कैसे बनते हैं, उन सटीक मापदंडों में गहराई से जाना आवश्यक है जो उत्कृष्ट व्हील्स को मामूली व्हील्स से अलग करते हैं।

एल्युमीनियम व्हील फोर्जिंग प्रक्रिया तब शुरू होती है जब एक पूर्व-तापयुक्त बिलेट, जिसे आमतौर पर 350-500°C के तापमान तक बढ़ाया जाता है, फोर्जिंग प्रेस में प्रवेश करता है। इस तापमान सीमा में, एल्युमीनियम दबाव के तहत आकार लेने के लिए पर्याप्त लचीला हो जाता है, जबकि वह धातुकर्म गुण बरकरार रखता है जो इसे उच्च-प्रदर्शन अनुप्रयोगों के लिए आदर्श बनाते हैं। यदि बहुत ठंडा हो, तो सामग्री आकार देने का विरोध करती है और दरारें विकसित करती है। यदि बहुत गर्म हो, तो आप दाने के बढ़ने का जोखिम उठाते हैं जो अंतिम उत्पाद को कमजोर कर देता है।

के अनुसार फोर्ज्ड व्हील उत्पादन पर उद्योग दस्तावेज़ीकरण , फोर्जिंग रिम्स प्रक्रिया में एकल संचालन के बजाय कई दबाव चरण शामिल होते हैं। प्रारंभिक दबाव द्वारा व्हील का चेहरा आकार में आता है क्योंकि प्रेस कई हजार टन के बल को लागू करता है। इस क्रमिक दृष्टिकोण से धातु की संरचना में लगातार सुधार होता है, जिससे एकल विशाल दबाव से प्राप्त उत्पाद की तुलना में मजबूत अंतिम उत्पाद बनता है।

ओपन डाई और क्लोज्ड डाई फोर्जिंग तकनीक

जब निर्माता फोर्जिंग विधियों पर चर्चा करते हैं, तो दो प्रमुख दृष्टिकोण वार्तालाप को प्रभावित करते हैं। प्रत्येक तकनीक व्हील डिज़ाइन आवश्यकताओं, उत्पादन मात्रा और सटीकता की आवश्यकताओं के आधार पर विशिष्ट उद्देश्यों की सेवा करती है।

खुले डाई फोर्जिंग में एल्यूमीनियम को सामग्री को पूरी तरह से घेरे बिना समतल या सरल आकार की डाई के बीच रखा जाता है। इसे नियंत्रित आकार देने के रूप में समझें, जहाँ धातु कई दिशाओं में प्रवाहित हो सकती है। यह विधि प्रारंभिक व्हील प्रीफॉर्म बनाने या बड़े, अपेक्षाकृत सरल व्हील ब्लैंक बनाने में उत्कृष्ट है। खुले डाई फोर्जिंग की लचीलापन छोटे बैच के अनुकूलित कार्य के लिए लागत प्रभावी बनाता है, जहाँ जटिल डाई बनाना अत्यधिक महंगा होगा।

बंद डाई फोर्जिंग, जिसे इम्प्रेशन डाई फोर्जिंग भी कहा जाता है, एक मौलिक रूप से भिन्न दृष्टिकोण अपनाती है। एल्यूमीनियम बिलेट को एक डाई गुहा के भीतर रखा जाता है जो वांछित व्हील प्रोफ़ाइल के ठीक आकार से मेल खाती है। जब प्रेस बल लगाता है, तो धातु को गुहा के हर आकार को भरने के लिए बाध्य किया जाता है, जिससे एक ही संचालन में जटिल स्पोक पैटर्न और सटीक आयाम उत्पन्न होते हैं।

| विधि | अनुप्रयोग | लाभ | सीमाएं |

|---|---|---|---|

| खुली ढलाई | प्रारंभिक प्रीफॉर्म, बड़े सरल आकार, अनुकूलित कम-मात्रा वाले पहिये, रिंग ब्लैंक | कम टूलिंग लागत, डिज़ाइन में परिवर्तन के लिए लचीलापन, बड़े भागों के लिए उपयुक्त, अच्छा धान का विकास | कम आयामी सटीकता, खुरदरी सतह का फ़िनिश, धीमी उत्पादन दर, कुशल ऑपरेटर्स की आवश्यकता |

| सीले ढलाई | जटिल स्पोक पैटर्न, उच्च मात्रा में उत्पादन, सटीक व्हील फेस, अंतिम व्हील आकृतियाँ | कसे हुए टॉलरेंस, उत्कृष्ट सतह फ़िनिश, तेज़ उत्पादन, बेहतर सामग्री उपयोग, दोहराई जा सकने वाली गुणवत्ता | उच्च डाई लागत, आकार सीमाएँ, डिज़ाइन में परिवर्तन के लिए कम लचीलापन, टूलिंग के लिए लंबे समय तक लीड टाइम |

कई प्रीमियम व्हील निर्माता दोनों विधियों को क्रमिक रूप से अपनाते हैं। वे अनुकूलित धान प्रवाह वाला प्रीफॉर्म बनाने के लिए ओपन डाई फोर्जिंग का उपयोग कर सकते हैं, और फिर सटीक स्पोक ज्यामिति के लिए बंद डाई में व्हील फेस को पूरा कर सकते हैं। यह संकर दृष्टिकोण दोनों तकनीकों के लाभों को जोड़ता है।

फोर्जिंग प्रेस ऑपरेशन और टनेज आवश्यकताएँ

यहां पर फोर्जिंग ऑपरेशन के पैमाने का महत्व स्पष्ट होता है। जबकि एक सामान्य घरेलू दुकान का हाइड्रोलिक प्रेस 10-20 टन बल उत्पन्न कर सकता है, एल्युमीनियम व्हील फोर्जिंग में उपयोग किए जाने वाले प्रेस पूरी तरह से अलग दायरे में काम करते हैं। Rays व्हील निर्माण प्रलेखन के अनुसार, उनके उत्पादन प्रेस 10,000 टन का दबाव उत्पन्न करने में सक्षम हैं।

व्हील की गुणवत्ता के लिए प्रेस टनेज का महत्व क्यों है? उच्च क्षमता वाले प्रेस कई महत्वपूर्ण लाभ प्रदान करते हैं:

- पूर्ण डाई भरना: पर्याप्त बल सुनिश्चित करता है कि जटिल डाई गुहाओं के हर कोने में एल्युमीनियम प्रवाहित हो, जिससे स्पोक डिज़ाइन में खाली स्थान या अधूरी संरचना रोकी जा सके।

- दान सुधार: उच्च दबाव एल्युमीनियम को और अधिक ठीक से संकुचित करता है, मोटी धान की संरचना को तोड़ता है और उच्च थकान प्रतिरोधकता प्रदान करने वाली सूक्ष्म संरचना बनाता है।

- तेज़ साइकिल समय: उच्च टनेज वाले प्रेस बनावट की प्रक्रिया को सेकंडों में पूरा कर देते हैं, जिसमें कई हल्के स्ट्रोक की आवश्यकता नहीं होती, जिससे उत्पादन दक्षता और स्थिरता में सुधार होता है।

- कम किया गया अवशिष्ट तनाव: समान दबाव वितरण आंतरिक तनाव को कम करता है जिसके कारण बाद में ऊष्मा उपचार या मशीनीकरण के दौरान विकृति हो सकती है।

जिस दौरान धातुकर्म में अनाज संरचना का संरेखण होता है, वही बुनियादी कारण है कि क्यों ढलाई विकल्पों की तुलना में धातुकर्म वाले पहिये बेहतर प्रदर्शन करते हैं। जब एक ढलाई साँचे में पिघला हुआ एल्यूमीनियम ठोस होता है, तो अनाज संरचना यादृच्छिक रूप से बनती है और इसमें पूरे क्षेत्र में छिद्रता और कमजोर बिंदु फैले होते हैं। धातुकर्म इन अनाजों को संपीड़ित करता है और उन्हें पहिए के सेवा के दौरान अनुभव किए जाने वाले तनाव मार्गों के अनुरूप पुनः संरेखित करता है।

इस संरेखित अनाज प्रवाह से आंतरिक खाली स्थान और छिद्रता समाप्त हो जाती है जो ढलाई घटकों में समस्या बनी रहती है। परिणाम? समतुल्य मजबूती वाले ढलाई वाले पहियों की तुलना में धातुकर्म वाले पहियों में लगभग 32% तक वजन कम किया जा सकता है। धातुकर्मीय तर्क सीधा-सादा है: आंतरिक दोषों के कारण अतिरिक्त सामग्री की आवश्यकता नहीं होती, इसलिए इंजीनियर पतले क्रॉस-सेक्शन के डिजाइन कर सकते हैं जो संरचनात्मक अखंडता बनाए रखते हैं।

रोटरी फोर्ज्ड तकनीक एक विशेष विविधता है, जहाँ रोलर्स प्रारंभिक फेस फोर्जिंग के बाद धीरे-धीरे व्हील बैरल को पतला और मजबूत करते हैं। यह प्रक्रिया रिम खंड को कार्य-कठोर बनाती है, जबकि फोर्ज किए गए फेस के संरचनात्मक लाभों को बनाए रखती है, जो पूर्ण फोर्जिंग के लाभों और उत्पादन दक्षता के बीच संतुलन प्रदान करती है।

हजारों टन दबाव के केवल कुछ सेकंड के अधीन, एक साधारण एल्युमीनियम सिलेंडर से क्लासिक व्हील आकृति उभरती है। फिर किनारों को गोल किया जाता है ताकि तनाव वृद्धि से बचा जा सके—ये छोटे दरार या मोड़ जो बार-बार भार डालने पर दरारों में बदल सकते हैं। इस चरण में एक खुरदरे व्हील ब्लैंक की तरह दिखने वाली वस्तु पहले से ही वह आंतरिक दाने की संरचना रखती है जो वर्षों तक सेवा के दौरान इसके प्रदर्शन लक्षणों को परिभाषित करेगी।

जब फोर्जिंग पूरी हो जाती है और व्हील ब्लैंक की ग्रेन संरचना को अनुकूलित कर दिया जाता है, तो अगला महत्वपूर्ण चरण शुरू होता है: ऊष्मा उपचार प्रक्रियाएँ जो एल्युमीनियम की आणविक संरचना में बंद संपूर्ण शक्ति क्षमता को सक्षम करती हैं।

अधिकतम शक्ति के लिए ऊष्मा उपचार और टेम्परिंग

वास्तविक शक्ति के संदर्भ में फोर्ज्ड व्हील का क्या अर्थ है? फोर्जिंग प्रक्रिया आधार बनाती है, लेकिन ऊष्मा उपचार एल्युमीनियम की वास्तविक क्षमता को सक्षम करता है। उचित तापीय प्रसंस्करण के बिना, यहां तक कि सर्वोत्तम फोर्ज्ड व्हील ब्लैंक भी मांग वाले प्रदर्शन अनुप्रयोगों के लिए आवश्यक यांत्रिक गुणों से वंचित रहेगा। यह महत्वपूर्ण चरण एल्युमीनियम की आणविक संरचना को परिवर्तित करता है, जिससे एक ऐसा व्हील बनता है जो कठोर सड़क स्थितियों के वर्षों का सामना करने में सक्षम होता है।

धातुकर्म स्तर पर फोर्ज्ड रिम्स क्या हैं, यह समझने का अर्थ है कि फोर्ज्ड रिम्स की अवधारणा केवल आकार देने की प्रक्रिया तक सीमित नहीं है। प्रीमियम फोर्ज्ड व्हील्स पर देखी जाने वाली T6 टेम्पर उपनाम एक सटीक दो-चरणीय ऊष्मीय उपचार को इंगित करती है जो मजबूती, कठोरता और थकान प्रतिरोध में महत्वपूर्ण सुधार करती है।

अधिकतम मजबूती के लिए ऊष्मा उपचार चक्र

T6 ऊष्मा उपचार प्रक्रिया सावधानीपूर्वक नियंत्रित तापन और शीतलन क्रम के माध्यम से सामान्य एल्यूमीनियम को उच्च-मजबूती वाले घटकों में बदल देती है। एल्यूमीनियम ऊष्मा उपचार पर तकनीकी प्रलेखन , यह प्रक्रिया वजन बढ़ाए बिना एल्यूमीनियम की मजबूती को दोगुना या तिगुना कर सकती है, जिससे यह एयरोस्पेस, ऑटोमोटिव और संरचनात्मक अनुप्रयोगों के लिए अत्यंत आवश्यक बन जाती है जहां मजबूती और वजन दोनों मायने रखते हैं।

पूर्ण ऊष्मा उपचार चक्र एक सटीक क्रम का अनुसरण करता है:

- सॉल्यूशन हीट ट्रीटमेंट: ढाला हुआ व्हील ब्लैंक को लगभग 530°C (6061 मिश्र धातु के लिए) तक कई घंटों तक गर्म किया जाता है। इस तापमान पर, मिश्र धातु के तत्व—मुख्य रूप से मैग्नीशियम और सिलिकॉन—एल्यूमीनियम मैट्रिक्स में पूरी तरह से घुल जाते हैं, जिससे एक अतिसंतृप्त ठोस विलयन बनता है। यह चरण धातु संरचना भर में मजबूती वाले तत्वों के समान वितरण को सुनिश्चित करता है।

- विस्तारित शीतलन: समाधान उपचार के तुरंत बाद, व्हील को आमतौर पर पानी या पॉलिमर घोल में तेजी से ठंडा किया जाता है। भाग को भट्ठी से निकालने के 10 सेकंड के भीतर इस चरण को पूरा कर लेना चाहिए ताकि अतिसंतृप्त संरचना बनी रहे। इसका उद्देश्य उन घुले हुए तत्वों को अनियंत्रित ढंग से अवक्षेपित होने से पहले फँसाना है।

- कृत्रिम उम्र बढ़ाना: क्वेंच किए गए पहिये को फिर कम तापमान पर—6061 एल्युमीनियम के लिए लगभग 175°C—पर लगभग 8 घंटे तक रखा जाता है। इस नियंत्रित एजिंग अवधि के दौरान, धातु संरचना में सूक्ष्म Mg₂Si अवक्षेप बनते हैं। ये सूक्ष्म कण धातु के भीतर दोषों की गति को रोकते हैं, जिससे कठोरता और सामर्थ्य में भारी वृद्धि होती है।

प्रत्येक मिश्र धातु के लिए समय और तापमान का होना आवश्यक है। छोटे-से-छोटे उतार-चढ़ाव भी धातु के अंतिम गुणों को प्रभावित कर सकते हैं। पहियों के अनुप्रयोगों में आमतौर पर उपयोग किए जाने वाले A356 एल्युमीनियम के लिए, अंतर्राष्ट्रीय जर्नल ऑफ फैटीग में प्रकाशित अनुसंधान इस बात की पुष्टि करता है कि T6 स्थिति में मिश्र धातुओं में सबसे अच्छा थकान व्यवहार देखा गया है, विशेष रूप से लो-साइकिल थकान परिदृश्यों में जो वास्तविक दुनिया की ड्राइविंग तनाव का अनुकरण करते हैं।

टेम्परिंग प्रक्रियाएँ जो टिकाऊपन को अधिकतम करती हैं

यदि निर्माता ऊष्मा उपचार चरणों को छोड़ देते हैं या उन्हें गलत तरीके से करते हैं तो क्या होता है? इसके परिणाम सीधे पहिये की सुरक्षा और दीर्घायु पर प्रभाव डालते हैं:

- अपूर्ण समाधान उपचार: यदि मिश्र धातु तत्व पूरी तरह से घुल नहीं जाते हैं, तो उम्र बढ़ने की बाद की प्रक्रिया समान मजबूती उत्पन्न नहीं कर सकती। पहिया में कठोरता के असमान क्षेत्र हो सकते हैं, जिससे तनाव के तहत विफलता के संभावित बिंदु उत्पन्न हो सकते हैं।

- शमन विलंब: विलयन उपचार और शमन के बीच बहुत अधिक समय तक प्रतीक्षा करने से अनियंत्रित अवक्षेपण शुरू हो जाता है। गुणों पर इसका काफी नकारात्मक प्रभाव पड़ता है, और बाद के एजिंग के बावजूद पहिया निर्दिष्ट ताकत के स्तर तक नहीं पहुंच पाता।

- अति-उम्र बढ़ना: भागों को एजिंग तापमान पर बहुत अधिक समय तक छोड़ देने से वास्तव में ताकत कम हो जाती है। अवक्षेपित पदार्थ इष्टतम आकार से अधिक बढ़ जाते हैं और दोष के स्थानांतरण को रोकने की अपनी प्रभावशीलता खो देते हैं। निर्माताओं को एजिंग समय की सावधानीपूर्वक निगरानी करनी चाहिए और नमूना भागों का नियमित रूप से परीक्षण करना चाहिए।

- विरूपण और विकृति: अनुचित शमन तकनीक या अपर्याप्त फिक्सचर के कारण आकार में परिवर्तन हो सकता है, जिससे पहिया उपयोग करने योग्य नहीं रह जाता या ठीक करने के लिए अत्यधिक मशीनीकरण की आवश्यकता होती है।

जलवायु और संचालन वातावरण के विचार ऊष्मा उपचार प्रोटोकॉल को भी प्रभावित करते हैं। कठोर वातावरण के लिए निर्धारित पहिये तनाव संक्षारण दरार प्रतिरोध में सुधार के लिए थोड़े से अतिप्रायुक्त हो सकते हैं, जिससे शीर्ष ताकत की थोड़ी सी मात्रा की कमी के बदले दीर्घकालिक स्थायित्व में वृद्धि होती है। यह T7-समीपवर्ती दृष्टिकोण एक अधिक स्थिर सूक्ष्मसंरचना बनाता है जो चुनौतीपूर्ण परिस्थितियों के तहत गुणों को बेहतर ढंग से बनाए रखती है।

गुणवत्ता पर केंद्रित निर्माता ऊष्मा उपचार दोषों को रोकने के लिए कठोर प्रक्रिया नियंत्रण लागू करते हैं। तापमान रिकॉर्डर प्रत्येक उत्पादन बैच के पूरे तापीय इतिहास को दस्तावेजीकृत करते हैं। कठोरता परीक्षण—उचित रूप से उपचारित 6061-T6 के लिए 95-105 HB (ब्रिनल कठोरता) की अपेक्षा—सफल उपचार की त्वरित पुष्टि प्रदान करता है। चालकता परीक्षण मशीनिंग में आगे बढ़ने से पहले अनुचित रूप से उपचारित भागों की पहचान करने के लिए एक अविनाशी विधि प्रदान करता है।

परिवर्तन उल्लेखनीय है: ऊष्मा उपचार के बाद, 6061 एल्युमीनियम अपरिमित सामग्री की तुलना में लगभग 30% तक यील्ड सामर्थ्य में सुधार प्राप्त करता है। थकान प्रतिरोध में उल्लेखनीय सुधार होता है, जिससे T6 उपचारित भाग विफल होने से पहले कई अधिक लोड चक्रों का सामना कर सकते हैं। इससे उन्हें प्रदर्शन वाले पहियों के लिए आवश्यक दैनिक गतिशील, उच्च-तनाव अनुप्रयोगों के लिए उपयुक्त बनाता है।

एल्युमीनियम के यांत्रिक गुणों को अब सटीक तापीय प्रसंस्करण द्वारा अनुकूलित किया गया है, और पहिया ब्लैंक उच्च-सटीक सीएनसी मशीनिंग संचालन के लिए तैयार है, जो इसे एक मोटे फोर्जिंग से एक पूर्ण पहिया में बदल देगा जिसमें बोल्ट पैटर्न, ऑफसेट और स्पोक प्रोफाइल के लिए सटीक विनिर्देश होंगे।

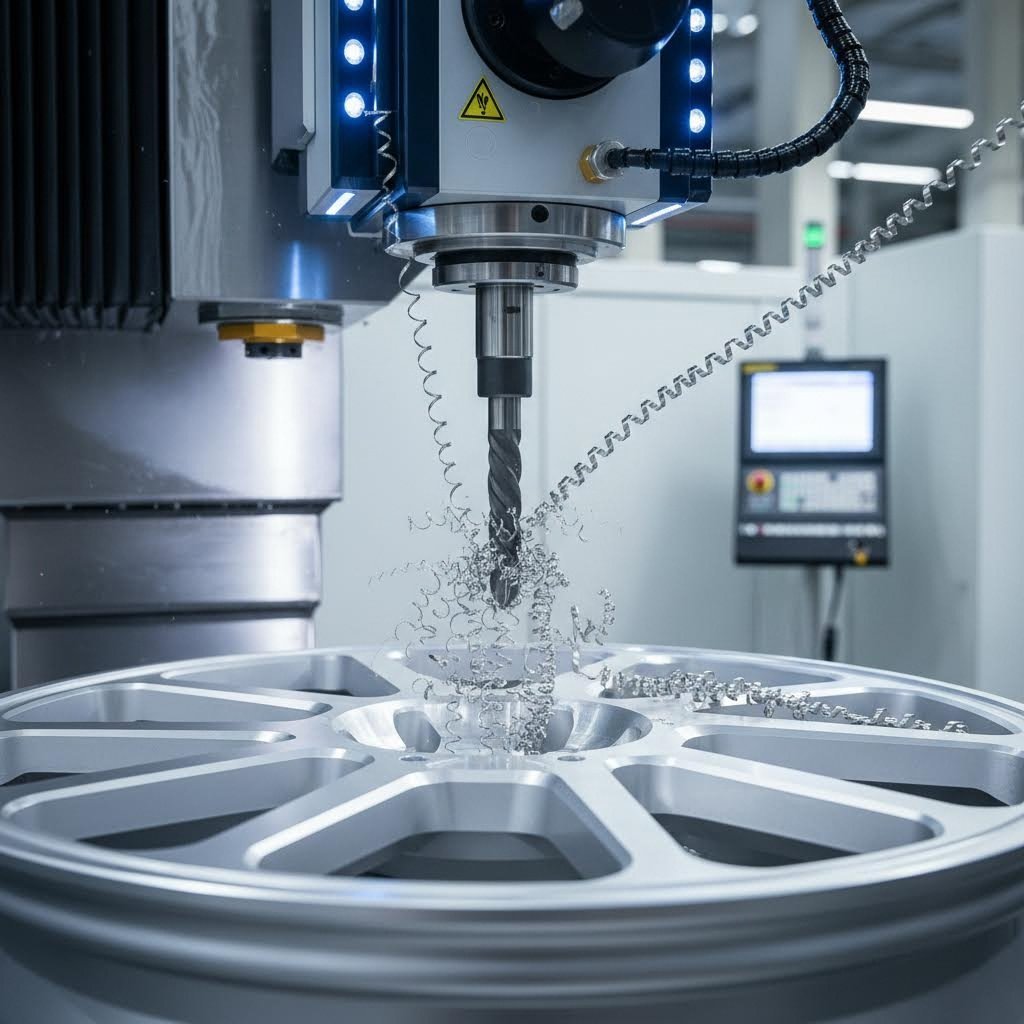

उच्च-सटीक सीएनसी मशीनिंग और प्रोफाइल निर्माण

थर्मल रूप से अनुकूलित, लेकिन अभी भी कच्चे और अपरिभाषित टेम्परिंग प्रक्रिया से बाहर आते हुए एक ऊष्मा-उपचारित पहिया ब्लैंक की कल्पना करें। यह कच्ची फोर्जिंग आपके वाहन पर लगाए जाने वाले बिल्कुल सटीक इंजीनियर व्हील निर्माण में कैसे बदलती है? उत्तर कंप्यूटर न्यूमेरिकल कंट्रोल मशीनिंग में निहित है, जहां मल्टी-एक्सिस कटिंग उपकरण मिलीमीटर के बजाय माइक्रॉन में मापी गई सटीकता के साथ एल्युमीनियम को आकार देते हैं।

व्हील प्रोफाइल के निर्माण के लिए ऐसी मशीनरी की आवश्यकता होती है जो पर्याप्त सामग्री को हटाते समय असाधारण सटीकता बनाए रखने में सक्षम हो। साधारण टर्निंग ऑपरेशन के विपरीत, आधुनिक फोर्ज्ड व्हील मशीनिंग में जटिल त्रि-आयामी ज्यामिति शामिल होती है: जटिल स्पोक पैटर्न, सटीक बोल्ट पैटर्न और हब बोर जो वाहन हब के साथ बिल्कुल सही ढंग से फिट होने चाहिए। यही वह जगह है जहां उन्नत उपकरणों में निवेश प्रीमियम निर्माताओं को अन्य सभी से अलग करता है।

मल्टी-एक्सिस सीएनसी मशीनिंग ऑपरेशन

प्रत्येक निर्माण चरण में उपयोग की जाने वाली विशिष्ट मशीनरी उपलब्ध सटीकता और अनुकूलन विकल्पों की सीमा दोनों को निर्धारित करती है। आधुनिक फोर्ज्ड व्हील उत्पादन कई विशेष मशीनों पर निर्भर करता है जो क्रम में काम करती हैं।

सीएनसी ऊर्ध्वाधर टर्निंग लेथ व्हील ब्लैंक की प्रारंभिक कच्ची मशीनिंग को संभालते हैं। ये विशाल मशीनें फोर्ज्ड ब्लैंक को पकड़ती हैं और इसे घुमाती हैं, जबकि कटिंग उपकरण बैरल, रिम फ्लैंज और केंद्र खंड से अतिरिक्त सामग्री को हटा देते हैं। लेथ मुख्य व्हील प्रोफाइल को स्थापित करता है, जिसमें ड्रॉप सेंटर शामिल है जो टायर माउंटिंग की अनुमति देता है और रिम चौड़ाई जो टायर फिटमेंट निर्धारित करती है।

मल्टी-अक्सिस सीएनसी मशीनिंग सेंटर विस्तृत कार्य करते हैं जो प्रत्येक व्हील को उसकी विशिष्ट उपस्थिति प्रदान करता है। सटीक मशीनिंग विनिर्देशों के अनुसार , उन्नत सीएनसी उपकरण आमतौर पर ±0.002" से ±0.0004" (±0.050 मिमी से ±0.010 मिमी) तक की सहनशीलता बनाए रखते हैं। पांच-अक्ष मशीनिंग केंद्र व्हील उत्पादन के लिए विशेष रूप से मूल्यवान हैं क्योंकि वे कार्यपृष्ठ के लगभग किसी भी कोण से जुड़ सकते हैं, जिससे जटिल स्पोक डिज़ाइन को एकल सेटअप में काटा जा सकता है, बजाय बार-बार पुनः स्थापना के जिससे संभावित त्रुटियाँ उत्पन्न हो सकती हैं।

बहु-भाग व्हील डिज़ाइन और दो-भाग व्हील विन्यास के लिए, अतिरिक्त विशेषीकृत संचालन लागू होते हैं। बैरल खंडों और केंद्र डिस्क को ऐसे मिलान प्रोफ़ाइल के साथ मशीन किया जाना चाहिए जो बोल्ट या वेल्ड द्वारा बिना किसी अंतर के जुड़ जाएँ। इसके लिए असेंबली के बाद कंपन या वायु रिसाव को रोकने के लिए मिलने वाली सतहों पर और भी कड़ी सहनशीलता की आवश्यकता होती है।

व्हील प्रोफ़ाइल में माइक्रॉन-स्तरीय परिशुद्धता प्राप्त करना

अग्रिम कटिंग से अंतिम प्रोफ़ाइल तक मशीनिंग के क्रमिक संचालन एक सावधानीपूर्वक संगठित प्रगति का अनुसरण करते हैं:

- कच्चा टर्निंग: सीएनसी लेथ, फोर्ज किए गए ब्लैंक से अतिरिक्त सामग्री का अधिकांश हिस्सा हटा देते हैं, और फिनिशिंग पास के लिए 1-2 मिमी स्टॉक छोड़ते हुए लगभग पहिया प्रोफ़ाइल स्थापित करते हैं। इस आक्रामक सामग्री हटाने से बैरल, रिम खंड और केंद्र डिस्क को तेजी से आकार दिया जाता है, जबकि स्वीकार्य सतह की गुणवत्ता बनी रहती है।

- अर्ध-पूर्ण टर्निंग: एक दूसरा लेथ ऑपरेशन पहिया ज्यामिति को सुधारता है, शेष अधिकांश स्टॉक को हटाते हुए और 0.1 मिमी के भीतर आयामी सटीकता प्राप्त करता है। सतह की गुणवत्ता में काफी सुधार होता है, जो पहिये को अंतिम संचालन के लिए तैयार करता है।

- बोल्ट पैटर्न ड्रिलिंग: सटीक ड्रिलिंग संचालन लग होल्स बनाते हैं जो पहिये को वाहन हब से जोड़ते हैं। बोल्ट सर्कल व्यास की सटीकता महत्वपूर्ण है—0.1 मिमी की त्रुटि भी असमान लग टोक़ और संभावित ढीलापन पैदा कर सकती है। अधिकांश निर्माता प्रत्येक छेद की स्थिति की पुष्टि करने के लिए समर्पित ड्रिलिंग फिक्सचर या पांच-अक्ष मशीनिंग सेंटर के साथ प्रोबिंग क्षमताओं का उपयोग करते हैं।

- हब बोर मशीनिंग: वाहन हब पर फिट होने वाले केंद्र बोर पर सावधानीपूर्वक ध्यान दिया जाता है। हब-केंद्रित व्हील्स को 0.02 मिमी के भीतर विशिष्ट वाहन विनिर्देशों के अनुरूप बोर व्यास की आवश्यकता होती है ताकि उचित केंद्रण सुनिश्चित हो सके और कंपन खत्म हो सके।

- स्पोक प्रोफ़ाइल मशीनिंग: पाँच-अक्षीय सीएनसी सेंटर प्रत्येक व्हील के सौंदर्य चरित्र को परिभाषित करने वाले स्पोक पैटर्न को तराशते हैं। जटिल अंडरकट, छेनियाँ, और आकृति वाली सतहें कटिंग उपकरणों द्वारा प्रोग्राम किए गए टूलपाथ पर चलने से उभरती हैं। जटिल ज्यामिति के कारण इस चरण में अक्सर सबसे लंबा मशीनिंग चक्र होता है।

- फ़िनिश टर्निंग: टायर बीड सीटिंग और उचित सीलिंग के लिए आवश्यक आयामी परिशुद्धता प्राप्त करने के लिए रिम की सतहों पर अंतिम पास किए जाते हैं। सीलिंग सतहों पर सतह की खुरदरापन विशिष्टताओं में आमतौर पर Ra मान 3.2 माइक्रॉन से कम की आवश्यकता होती है।

- वाल्व स्टेम छेद ड्रिलिंग: एक सटीक कोण वाला छेद टायर वाल्व को समायोजित करता है, जिसे ब्रेक घटकों से बचाते हुए और टायर को हवा भरने के लिए आसान पहुँच सुनिश्चित करने के लिए स्थित किया जाता है।

मशीनिंग सटीकता और पहिया संतुलन के बीच संबंध को विशेष ध्यान देने की आवश्यकता होती है। सामग्री की असममिति का प्रत्येक ग्राम असंतुलन पैदा करता है जो गति पर कंपन के रूप में प्रकट होता है। जब सीएनसी संचालन स्थिर दीवार की मोटाई और सममित स्पोक प्रोफ़ाइल बनाए रखते हैं, तो माउंट करने के बाद पहिया को न्यूनतम संतुलन भार की आवश्यकता होती है—कभी-कभी केवल 10-15 ग्राम, कम सटीक रूप से मशीन किए गए विकल्पों के 50+ ग्राम की तुलना में।

ऑफसेट और चौड़ाई विनिर्देश जैसे अनुकूलन विकल्प सीधे सीएनसी प्रोग्रामिंग समायोजन के माध्यम से लागू किए जाते हैं। ऑफसेट—पहिया माउंटिंग सतह और रिम केंद्र रेखा के बीच की दूरी—बैरल के सापेक्ष केंद्र खंड की गहराई को बदलकर प्रारंभिक टर्निंग संचालन के दौरान स्थापित किया जाता है। प्रीमियम व्हील निर्माताओं के विनिर्माण प्रलेखन के अनुसार , ग्राहक अनुकूलित आकार, ऑफसेट और परिष्करण चुन सकते हैं, जिन्हें सीएनसी मशीनिंग के दौरान प्रत्येक वाहन की विशिष्ट आवश्यकताओं के अनुरूप प्रोग्राम किया जाता है।

चौड़ाई में समायोजन भी रिम फ्लैंज को अलग-अलग दूरी पर स्थित करने के लिए लेथ ऑपरेशन के पुनः प्रोग्रामिंग की आवश्यकता होती है। सीएनसी निर्माण का लाभ यह है कि इन परिवर्तनों के लिए केवल सॉफ्टवेयर संशोधन की आवश्यकता होती है, भौतिक टूलिंग में परिवर्तन की नहीं, जिससे बेस्पोक निर्माण की पारंपरिक लागत पेनाल्टी के बिना वास्तविक अनुकूलन संभव हो जाता है।

मशीनिंग अनुक्रम के दौरान सम्पूर्ण गुणवत्ता सत्यापन होता है। समन्वय मापन मशीन (सीएमएम) विशिष्ट आयामों की विशिष्टताओं के विरुद्ध जाँच करती हैं, जबकि गतिशील संतुलन परीक्षण आयामी जाँच में छूट जाने वाली किसी भी असममितता की पहचान करता है। इन निरीक्षणों में विफल पहियों को या तो सुधार के लिए पुनः मशीनिंग के लिए लौटा दिया जाता है या पूरी तरह से खारिज कर दिया जाता है—सुरक्षा पर निर्भर पहिया निर्माण में सटीकता के लिए कोई समझौता नहीं होता।

अब पहिया बिल्कुल सटीक विशिष्टताओं के अनुसार मशीन किया गया है, अगले चरण का ध्यान सतह समापन और सुरक्षात्मक कोटिंग्स पर केंद्रित है जो तैयार उत्पाद की सौंदर्य आकर्षकता और दीर्घकालिक टिकाऊपन दोनों को निर्धारित करेंगे।

सतह समापन और सुरक्षात्मक कोटिंग अनुप्रयोग

आपके पास परिष्कृत रूप से मशीनीकृत फोर्ज्ड व्हील है जिसके आदर्श आयाम और अनुकूलित ग्रेन संरचना है। लेकिन इसके बाद क्या होता है, यह तय करता है कि क्या व्हील वर्षों तक ध्यान खींचता रहेगा या महीनों में ही क्षरण का शिकार हो जाएगा। सतह समापन वह जगह है जहाँ इंजीनियरिंग कला से मिलती है—और जहाँ फोर्ज्ड व्हील और मिश्र धातु व्हील के बीच का अंतर दृष्टिगत रूप से स्पष्ट हो जाता है।

जब खरीदार पूछते हैं कि मिश्र धातु या फोर्ज्ड व्हील में क्या बेहतर है, तो उत्तर का एक हिस्सा फिनिशिंग क्षमताओं में निहित है। प्रीमियम फोर्ज्ड व्हील उच्च-गुणवत्ता वाले अधिक विविध फिनिश स्वीकार करते हैं क्योंकि उनकी सघन, रिक्तता-मुक्त सतह कोटिंग के लिए उत्कृष्ट आधार प्रदान करती है। फिनिशिंग चरण में फोर्ज्ड रिम्स क्या हैं, इसे समझने से यह स्पष्ट होता है कि विकल्पों की तुलना में ये व्हील अपनी उपस्थिति को लंबे समय तक क्यों बनाए रखते हैं।

सतह समापन के विकल्प और तकनीकें

फिनिशिंग चरण आपकी पसंद के अनुसार अंतिम उत्पाद को प्रभावित करने के लिए उल्लेखनीय अनुकूलन के अवसर प्रदान करता है। अनुसार प्रीमियम व्हील निर्माता , टेलर-मेड फोर्ज्ड व्हील बनाने का अर्थ है आप जो भी फिनिश चाहते हैं, उसका चयन करना—बाजार में उपलब्ध ढलाई विकल्पों पर देखी जाने वाली सामान्य रंग विकल्पों से कहीं आगे।

उपलब्ध फिनिश प्रकार शामिल हैं:

- सॉलिडटोन रंग फिनिश: एकल-चरण फिनिश जो रंग की पाउडर कोटिंग की परत लगाकर प्राप्त की जाती है, जिसमें चमक या सैटिन क्लियर कोट के साथ विभिन्न स्तरों की चमक प्राप्त की जाती है। यह टिकाऊ, रखरखाव में आसान विकल्प अधिकांश व्हील के लिए मानक के रूप में कार्य करता है।

- पॉलिश फिनिश: कच्चे एल्युमीनियम रंग में दर्पण जैसी सूक्ष्म पॉलिश सतह, जो मशीन और हाथ से पॉलिश के संयोजन से प्राप्त की जाती है। एल्युमीनियम को सील करने के लिए क्लियर टॉप कोट लगाया जाता है, जिससे चमक बनाए रखने के लिए लगातार पॉलिश करने की आवश्यकता नहीं होती। परिणाम क्रोम जैसा दिखता है लेकिन इसमें फोर्ज्ड एल्युमीनियम के वजन के लाभ होते हैं।

- पारदर्शी/अर्धपारदर्शी (कैंडी) फिनिश: एक बहु-स्तरीय प्रक्रिया जिसमें पहले चक्कों को प्रतिबिंबित सब्सट्रेट तक पॉलिश किया जाता है, फिर गहन सफाई और कुल्ला करने के बाद एक रंगीन पारदर्शी ऊपरी कोट दिया जाता है। परिणाम एक आकर्षक कैंडी फिनिश होता है जिसे चमकदार या सैटिन क्लियर कोट्स द्वारा और भी बेहतर बनाया जा सकता है।

- ब्रश किया गया फिनिश: सबसे अधिक श्रम-गहन विकल्प, जिसमें डिज़ाइन की जटिलता के आधार पर प्रति चक्के के लिए लगभग 8 घंटे तक प्रत्येक स्पोक और चक्के की सतह के लिए कलाकार द्वारा हाथ से ब्रशिंग की आवश्यकता होती है। पारदर्शी रंग के ऊपरी कोट के नीचे ब्रश की गई बनावट अद्वितीय दृश्य प्रभाव उत्पन्न करती है जो प्रत्येक कोण से प्रकाश को अलग तरीके से प्रतिबिंबित करता है। यह प्रीमियम अपग्रेड ऑफ-द-शेल्फ चक्कों पर नहीं बनाया जा सकता।

प्रत्येक फिनिश प्रकार का प्रभाव केवल दिखावट तक नहीं सीमित होता। पॉलिश की गई सतहों को ऑक्सीकरण रोकने के लिए सील किए गए क्लियर कोट्स की आवश्यकता होती है। पाउडर कोटेड फिनिश दैनिक उपयोग वाले वाहनों के लिए उत्कृष्ट चिप प्रतिरोध प्रदान करते हैं। पारदर्शी ऊपरी कोट के साथ ब्रश किए गए फिनिश दोनों की बेहतरीन विशेषताएं प्रदान करते हैं—अलग पहचान वाली सौंदर्य बनावट के साथ मजबूत सुरक्षा।

लंबे समय तक की टिकाऊपन के लिए सुरक्षित कोटिंग

सौंदर्य से परे, सुरक्षात्मक कोटिंग्स एक महत्वपूर्ण कार्य करती हैं: वातावरणीय क्षति से एल्युमीनियम सब्सट्रेट की रक्षा करना। पेशेवर कोटिंग विशेषज्ञ पुष्टि करते हैं कि उच्च-गुणवत्ता वाली सुरक्षात्मक परतें समय के साथ धातु की सतहों के साथ पानी, सड़क नमक और रसायनों की प्रतिक्रिया को रोकती हैं।

सिरेमिक कोटिंग्स पहिया सुरक्षा के क्षेत्र में शीर्ष पर हैं। ये उन्नत कोटिंग्स एक जल-प्रतिकारी परत बनाती हैं जो पानी, ब्रेक डस्ट और सड़क के प्रदूषकों को विकर्षित करती है, साथ ही स्क्रैच की संभावना को कम करती है। सिरेमिक कोटिंग्स के ऊष्मा-प्रतिरोधी गुण ब्रेक की गर्मी और पराबैंगनी (UV) त्वचा के कारण ऑक्सीकरण और रंग फीकापन को कम करते हैं। उचित ढंग से लगाए जाने पर पेशेवर सिरेमिक पहिया सुरक्षा 2 से 5 वर्षों तक चलती है, जो ड्राइविंग की स्थिति पर निर्भर करती है।

फिनिशिंग के दौरान गुणवत्ता नियंत्रण चेकपॉइंट्स सुसंगत परिणामों को सुनिश्चित करते हैं:

- प्री-ट्रीटमेंट निरीक्षण: ऐसे मशीनिंग निशान, सम्भरकता या दूषण के लिए सतहों की जांच की जाती है जो कोटिंग अटकाव को कमजोर कर सकते हैं।

- सफाई सत्यापन: बहु-स्तरीय सफाई प्रक्रिया कोटिंग लगाने से पहले तेल, धातु संसाधन द्रव और कणों को हटा देती है।

- लेपन मोटाई माप: विशेष गेज पाउडर कोट या पेंट की मोटाई की पुष्टि करते हैं जो मानक अनुप्रयोगों के लिए आमतौर पर 60-80 माइक्रोन के विनिर्देशों के अनुसार होती है।

- अधिग्रहण परीक्षण: क्रॉस-हैच या पुल-ऑफ परीक्षण यह सुनिश्चित करते हैं कि कोटिंग सही ढंग से सब्सट्रेट से बंधित हो, भविष्य में छिलने या टूटने को रोका जा सके।

- दृश्य जाँच: प्रशिक्षित निरीक्षक नियंत्रित प्रकाश व्यवस्था के तहत प्रत्येक व्हील की ऑरेंज पील बनावट, धाराओं, झूलाव या रंग असंगति की जांच करते हैं।

उद्योग प्रमाणन मानक पूरी फिनिशिंग प्रक्रिया को नियंत्रित करते हैं। एसएई (सोसाइटी ऑफ ऑटोमोटिव इंजीनियर्स) और जेडब्ल्यूएल (जापान लाइट एलॉय व्हील) मानक कोटिंग की स्थायित्व, संक्षारण प्रतिरोध और दिखावट की सुसंगति के लिए न्यूनतम आवश्यकताओं को निर्दिष्ट करते हैं। निर्माता दस्तावेजीकृत प्रक्रियाओं, कैलिब्रेटेड उपकरणों और नियमित तीसरे पक्ष के लेखा परीक्षण के माध्यम से अनुपालन प्राप्त करते हैं जो सुनिश्चित करते हैं कि प्रक्रिया नियंत्रण प्रभावी बने रहें।

सतह की गुणवत्ता के निरीक्षण मानदंड केवल दृश्य जांच तक सीमित नहीं हैं। लवण धुंध परीक्षण में पूर्ण व्हील्स को त्वरित संक्षारण परिस्थितियों के अधीन किया जाता है, जिससे सुरक्षात्मक कोटिंग्स के निर्दिष्ट अनुसार कार्य करने की पुष्टि होती है। पराबैंगनी (UV) त्वचा परीक्षण सूर्य के प्रकाश के वर्षों के अनुकरण के दौरान रंग के स्थायित्व की पुष्टि करता है। ये कठोर प्रोटोकॉल आपके अनुकूलित फोर्ज्ड व्हील्स को सड़क के नमक, गर्मी की उमस और दैनिक ड्राइविंग के कठोर उपयोग के बावजूद उनकी परिष्कृत सतह बनाए रखना सुनिश्चित करते हैं।

सतह परिष्करण पूर्ण होने और सुरक्षात्मक कोटिंग्स लगाए जाने के बाद, निर्माण यात्रा अपने अंतिम महत्वपूर्ण चरण में प्रवेश करती है: व्यापक गुणवत्ता नियंत्रण परीक्षण, जो आपके वाहन तक पहुंचने से पहले व्हील के निर्माण के हर पहलू की पुष्टि करता है।

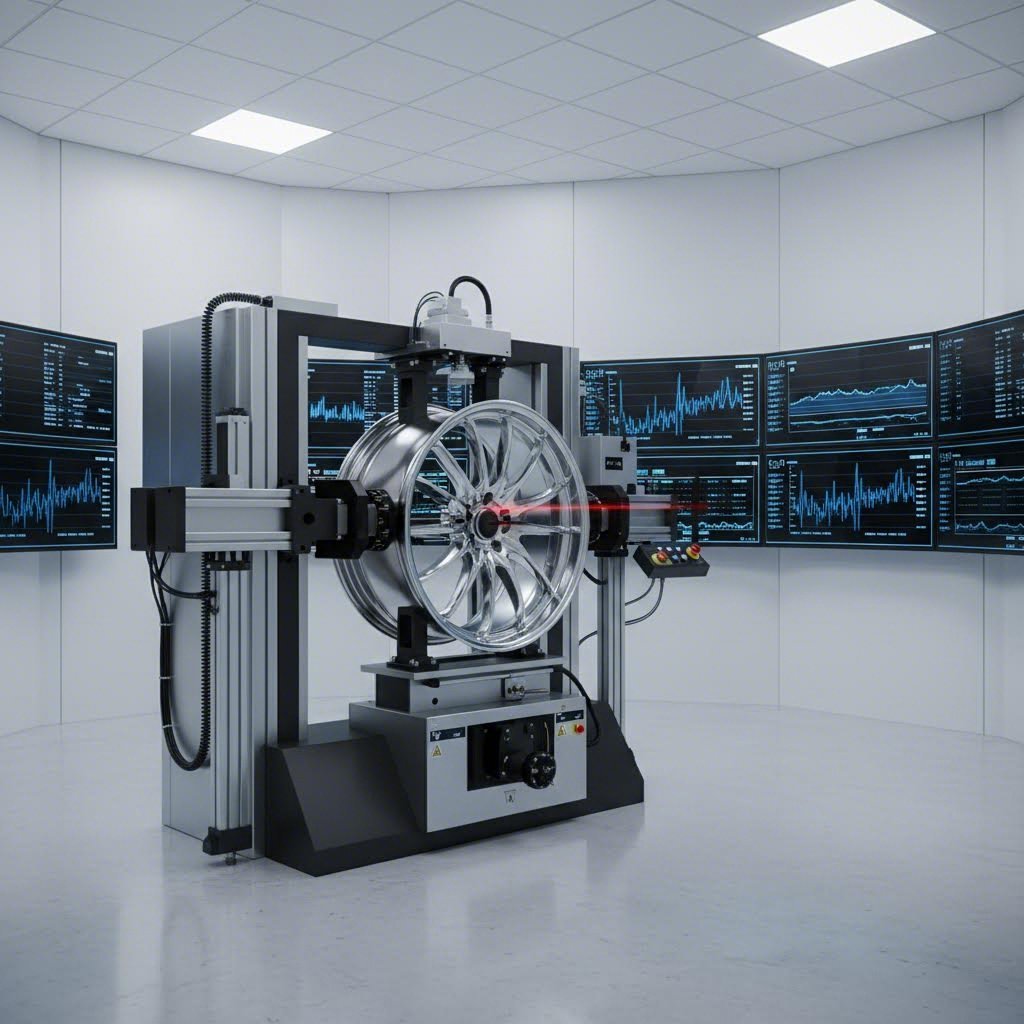

गुणवत्ता नियंत्रण परीक्षण और प्रमाणन मानक

यदि एक फोर्ज्ड व्हील वास्तविक सड़क परिस्थितियों के कठोर परिणाम सहन नहीं कर सकता, तो वह वास्तव में क्या है? यदि गुणवत्ता नियंत्रण पहियों के आपके वाहन तक पहुँचने से पहले दोषों को पकड़ने में विफल रहता है, तो सटीक फोर्जिंग, ऊष्मा उपचार और मशीनीकरण का कोई अर्थ नहीं होता। यह महत्वपूर्ण चरण उन निर्माताओं को अलग करता है जो लगातार उत्कृष्टता प्रदान करते हैं और उनसे जो आपकी सुरक्षा के साथ जुआ खेलते हैं।

जाँच प्रक्रियाओं पर खुलासा किए बिना सामान्य अवलोकनों के विपरीत, विस्तृत गुणवत्ता जाँच बिंदु की जानकारी समझने से यह स्पष्ट हो जाता है कि प्रीमियम निर्माता प्रत्येक पहिये को कठोर मानकों के अनुरूप सत्यापित कैसे करते हैं। चाहे आप सर्वश्रेष्ठ 3 पीस व्हील ब्रांड्स का आकलन कर रहे हों या सिंगल-पीस फोर्ज्ड विकल्प, गुणवत्ता नियंत्रण प्रक्रियाओं की गहराई आपको पहिये की विश्वसनीयता के बारे में बाजार दावों से कहीं अधिक बताती है।

महत्वपूर्ण गुणवत्ता नियंत्रण चेकपॉइंट्स

गुणवत्ता सत्यापन उत्पादन के अंत में एकल चरण नहीं है—यह पूरी निर्माण यात्रा में गूंथा हुआ है। उद्योग गुणवत्ता नियंत्रण प्रलेखन के अनुसार , प्रभावी फोर्जिंग गुणवत्ता नियंत्रण में पूर्व-फोर्जिंग सामग्री सत्यापन, प्रक्रिया के दौरान निगरानी और व्यापक उत्तर-फोर्जिंग निरीक्षण शामिल है। प्रत्येक जाँच बिंदु विशिष्ट दोष प्रकारों को उस समय पकड़ता है जब वे अंतिम उत्पादों में फैलने से पहले होते हैं।

पहिया ढलाई प्रक्रियाओं के साथ तुलना महत्वपूर्ण है। ढलाई प्रक्रिया के अंतर्निहित पारगम्यता और सिकुड़न दोषों के लिए ढाले गए पहियों का व्यापक निरीक्षण आवश्यक होता है। फोर्ज्ड पहिये इन चिंताओं को समाप्त कर देते हैं, लेकिन धान्य प्रवाह, आयामी सटीकता और ऊष्मा उपचार सत्यापन पर केंद्रित अलग निरीक्षण प्राथमिकताएँ पेश करते हैं।

| विनिर्माण चरण | परीक्षण प्रकार | स्वीकृति मानदंड | विफलता के परिणाम |

|---|---|---|---|

| आगमन सामग्री | रासायनिक संरचना विश्लेषण, अल्ट्रासोनिक निरीक्षण | विशिष्टता के भीतर मिश्र धातु संरचना, आंतरिक खाली स्थान या अशुद्धियाँ नहीं | सामग्री अस्वीकृत, आपूर्तिकर्ता को सूचित किया गया, बैच को अलग रखा गया |

| उत्तर-फोर्जिंग | दृश्य निरीक्षण, आयामी जाँच, धान्य प्रवाह सत्यापन | सतह दरारें, लैप्स या फोल्ड्स नहीं; आयाम 1 मिमी सहिष्णुता के भीतर | यदि मामूली है तो पुनः कार्य करें, यदि संरचनात्मक दोष मौजूद हैं तो अपशिष्ट |

| उत्तर-ऊष्मा उपचार | कठोरता परीक्षण, चालकता परीक्षण | 6061-T6 के लिए 95-105 HB कठोरता, निर्दिष्ट सीमा के भीतर चालकता | यदि पुनः उपचार योग्य हो तो पुनः उपचार, यदि अति प्राचीन या क्षतिग्रस्त हो तो अपशिष्ट |

| मशीनिंग के बाद | सीएमएम आयामी निरीक्षण, सतह की खुरदरापन माप | महत्वपूर्ण आयाम 0.05 मिमी के भीतर, सीलिंग सतहों पर Ra 3.2 माइक्रन से कम | यदि स्टॉक अनुमति देता है तो मशीनिंग पुनः करें, यदि आकार से कम हो तो अपशिष्ट |

| उपरांत-समापन | कोटिंग मोटाई, चिपकाव परीक्षण, दृश्य निरीक्षण | 60-80 माइक्रन कोटिंग, क्रॉस-हैच चिपकाव पास, कोई दृश्य दोष नहीं | स्ट्रिप और रीकोट करें, या यदि सब्सट्रेट क्षतिग्रस्त है तो स्क्रैप करें |

| अंतिम जांच | गतिशील संतुलन, अरीय/पार्श्व रनआउट, लीक परीक्षण | 30 ग्राम के भीतर संतुलन, 0.5 मिमी से कम रनआउट, वायु रिसाव नहीं | यदि संभव हो तो पुनः संतुलित या पुनः मशीनिंग करें, अन्यथा स्क्रैप करें |

सामान्य निर्माण दोष और उनके निवारण के लिए मूल कारणों को समझना आवश्यक है। दरारें, लैप्स और फोल्ड जैसे सतही दोष आमतौर पर अनुचित फोर्जिंग तापमान या डाई के क्षरण से उत्पन्न होते हैं। आंतरिक दोष कच्चे माल की गुणवत्ता की समस्याओं या अपर्याप्त फोर्जिंग दबाव से उत्पन्न होते हैं। आयामी दोष डाई डिजाइन की समस्याओं, नियंत्रित ठंडा न करने या मशीनिंग त्रुटियों के कारण होते हैं। गुणवत्ता नियंत्रण विशेषज्ञ इस बात पर जोर दें कि सटीक पैरामीटर नियंत्रण के माध्यम से निवारण, सदैव संसूचन-और-अस्वीकृति दृष्टिकोण की तुलना में बेहतर होता है।

संरचनात्मक अखंडता सुनिश्चित करने वाले परीक्षण प्रोटोकॉल

आयामी सत्यापन से परे, संरचनात्मक अखंडता परीक्षण पहियों को सामान्य सेवा भारों से काफी अधिक परिस्थितियों के अधीन करते हैं। JWL प्रमाणन आवश्यकताओं के अनुसार, प्रमाणन चिह्न प्राप्त करने के लिए पहियों को तीन प्राथमिक थकान परीक्षणों में उत्तीर्ण होना चाहिए।

गतिशील कोने की थकान परीक्षण आक्रामक कोने की स्थिति के दौरान अनुभव किए गए झुकाव तनाव का अनुकरण करता है। परीक्षण पहिया एक घूर्णन टेबल पर माउंट किया जाता है, जबकि एक आघूर्ण भुजा पहिये के बाहरी माउंटिंग पैड पर निरंतर बल लगाती है। जैसे पहिया थकान परीक्षण पर प्रकाशित शोध समझाता है, यह परीक्षण वास्तविक कोने की स्थिति के बहुत करीब के तनाव पैटर्न को पुनः उत्पन्न करता है। पहिये को डाई पेनीट्रेंट निरीक्षण के तहत दिखाई देने वाले दरार बिना निर्दिष्ट घूर्णन चक्रों—अक्सर लाखों—को पूरा करना चाहिए।

गतिशील अरीय थकान परीक्षण टायर-पहिया असेंबली को एक घूर्णन ड्रम के विरुद्ध स्थित करता है जबकि निरंतर अरीय भार लगाया जाता है। यह सीधी रेखा में ड्राइविंग के दौरान अनुभव किए गए निरंतर भारण का अनुकरण करता है। JWL मानकों के अनुसार, पहियों को विफलता के बिना न्यूनतम 400,000 परीक्षण चक्रों का सामना करना चाहिए। परीक्षण पैरामीटरों में अधिकतम वाहन भार से गणना किए गए विशिष्ट टायर दबाव और भार शामिल हैं, जिनमें सुरक्षा मार्जिन लागू किए जाते हैं।

आघात परीक्षण अचानक झटका भारों के प्रति प्रतिरोध का मूल्यांकन करता है, जो सड़क के गड्ढों या कर्ब के टकराव की नकल करता है। यात्री कारों के लिए JWL मानक एक 13-डिग्री इम्पैक्ट परीक्षण के लिए निर्दिष्ट करते हैं, जिसमें सटीक वायु दबाव और स्ट्राइकर भार की आवश्यकताएं होती हैं। JWL परीक्षण प्रलेखन के अनुसार, पहिये तब पास होते हैं जब उनमें वायु रिसाव या दरारें नहीं होतीं, हालांकि JWL मानकों के तहत दरार के बिना मुड़ना स्वीकार्य है। ट्रक पहियों के लिए अधिक कठोर JWL-T मानक ध्यान देने योग्य विरूपण दिखाने वाले किसी भी पहिये को फेल कर देता है।

SAE (सोसाइटी ऑफ ऑटोमोटिव इंजीनियर्स) प्रमाणन उत्तर अमेरिका विशिष्ट आवश्यकताओं के साथ समान परीक्षण दर्शन का अनुसरण करता है। SAE और JWL दोनों मानक यह आवश्यकता करते हैं कि अंतिम, उत्पादन-प्रतिनिधि पहियों का परीक्षण किया जाए—पूर्व-उत्पादन नमूनों या अधूरे खाली स्थानों का नहीं। जैसा कि JWL प्रलेखन विशेष रूप से बताता है, प्लेट किए गए पहियों को प्लेटिंग के बाद, पहले नहीं, परीक्षण किया जाना चाहिए, जिससे पूरी निर्माण प्रक्रिया की पुष्टि सुनिश्चित होती है।

प्रक्रिया विवरण के आधार पर निर्माता की गुणवत्ता का आप कैसे आकलन करते हैं? इन संकेतकों को देखें:

- दस्तावेजीकृत निरीक्षण आवृत्ति: गुणवत्ता वाले निर्माता यह बताते हैं कि प्रत्येक परीक्षण कितनी बार किया जाता है—प्रत्येक भाग, सांख्यिकीय प्रतिचयन या बैच परीक्षण के लिए।

- कैलिब्रेशन कार्यक्रम: उपकरण कैलिब्रेशन अनुसूचियों के संदर्भ से पता चलता है कि माप सटीकता को समय के साथ बनाए रखा जाता है।

- ट्रेसेबिलिटी सिस्टम: किसी भी पहिए को उसके कच्चे माल के बैच, ऊष्मा उपचार लॉट और निरीक्षण रिकॉर्ड तक ट्रेस करने की क्षमता गुणवत्ता के प्रति गंभीर प्रतिबद्धता को दर्शाती है।

- तृतीय-पक्ष प्रमाणन: ISO 9001, IATF 16949, या NADCAP प्रमाणन बाहरी लेखा परीक्षा की आवश्यकता होती है जो यह सत्यापित करती है कि गुणवत्ता प्रणाली वास्तव में दस्तावेजीकृत अनुसार कार्य कर रही है।

- विफलता प्रतिक्रिया प्रोटोकॉल: असफल भागों के संबंध में कैसे निपटा जाता है, मूल कारणों की जांच कैसे की जाती है, और सुधारात्मक कार्रवाई कैसे लागू की जाती है—इसके विवरण से पता चलता है कि गुणवत्ता प्रतिक्रियात्मक है या प्राक्कल्पिक।

JWL प्रमाणन के भीतर निगरानी परीक्षण आवश्यकताएँ एक अतिरिक्त सत्यापन परत जोड़ती हैं। प्रारंभिक पंजीकरण के बाद भी, VIA (वाहन निरीक्षण संघ) प्रोटोकॉल निरंतर निगरानी परीक्षणों को निर्दिष्ट करें। यदि कोई उत्पाद निगरानी परीक्षण में विफल हो जाता है, तो उस श्रेणी के अंतर्गत पंजीकृत सभी उत्पादों को पूर्ण पुनः परीक्षण से गुजरना होगा। यह निरंतर जवाबदेही यह सुनिश्चित करती है कि निर्माता प्रारंभिक प्रमानन के बहुत बाद तक गुणवत्ता मानकों को बनाए रखें।

गुणवत्ता सत्यापन पूर्ण होने और प्रमाणन आवश्यकताओं को पूरा करने के बाद, निर्माण समयसीमा और लागत कारकों पर ध्यान केंद्रित किया जाता है—यह समझना कि मूल्य निर्धारण को क्या प्रेरित करता है, आपको यह मूल्यांकन करने में मदद करता है कि उद्धृत लागतें वास्तविक गुणवत्ता निवेश को दर्शाती हैं या केवल अधिक मार्जिन को।

निर्माण समयसीमा और लागत पर विचार

आपने कच्चे एल्युमीनियम बिलेट से लेकर फोर्जिंग, ऊष्मा उपचार, सटीक मशीनीकरण, फिनिशिंग और गुणवत्ता परीक्षण तक की पूरी यात्रा का अनुसरण किया है। अब वह प्रश्न आता है जो हर खरीदार अंततः पूछता है: यह वास्तव में कितना समय लेता है, और कस्टम फोर्ज्ड व्हील्स की कीमत क्यों इतनी होती है? ये व्यावहारिक पहलू अक्सर निर्माण प्रक्रिया के सबसे अस्पष्ट पहलू बने रहते हैं, फिर भी ये सीधे तौर पर आपके खरीद प्रबंधन को प्रभावित करते हैं।

चाहे आप ट्रकों के लिए फोर्ज्ड व्हील्स की आपूर्ति कर रहे हों, विभिन्न आफ्टरमार्केट व्हील आपूर्तिकर्ताओं का आकलन कर रहे हों, या मार्टिनी वर्क्स व्हील्स जैसे विशिष्ट निर्माताओं से प्रीमियम विकल्पों की खोज कर रहे हों, समयरेखा और लागत कारकों को समझने से आपको अतिरंजित मूल्य निर्धारण से वास्तविक मूल्य के बीच अंतर करने में मदद मिलती है।

ऑर्डर से लेकर डिलीवरी तक निर्माण समयरेखा

कस्टम फोर्ज्ड व्हील के पूरे उत्पादन चक्र में कई सप्ताह लगते हैं, जिसमें प्रत्येक निर्माण चरण को गुणवत्ता के बलिदान के बिना संक्षिप्त नहीं किया जा सकता। भंडारगृहों में रखे तैयार उत्पादों के विपरीत, वास्तविक कस्टम निर्माण का अर्थ है कि आपके ऑर्डर के उत्पादन शुरू करने तक आपके लिए व्हील मौजूद नहीं होते।

| विनिर्माण चरण | आम अवधि | मुख्य गतिविधियाँ |

|---|---|---|

| डिजाइन और इंजीनियरिंग | 3-7 दिन | CAD मॉडलिंग, FEA सिमुलेशन, फिटमेंट सत्यापन, ग्राहक स्वीकृति |

| सामग्री खरीद | 5-10 दिन | बिलेट ऑर्डरिंग, आगमन निरीक्षण, सामग्री प्रमाणन सत्यापन |

| फोर्जिंग ऑपरेशन | 2-4 दिन | बिलेट प्रीहीटिंग, फोर्जिंग प्रेस ऑपरेशन, ब्लैंक निरीक्षण |

| ताप उपचार | 3-5 दिन | घोल उपचार, शमन, कृत्रिम उम्रदराज़ी, कठोरता सत्यापन |

| सीएनसी मशीनिंग | 5-8 दिन | कच्ची टर्निंग, समाप्त मशीनिंग, स्पोक प्रोफाइलिंग, बोल्ट पैटर्न ड्रिलिंग |

| सतह की परिष्करण | 4-7 दिन | सतह तैयारी, कोटिंग आवेदन, उपचार, गुणवत्ता निरीक्षण |

| गुणवत्ता नियंत्रण और परीक्षण | 2-3 दिन | आयामी निरीक्षण, संतुलन परीक्षण, प्रमाणीकरण सत्यापन |

| पैकेजिंग और शिपिंग | 2-5 दिन | सुरक्षात्मक पैकेजिंग, दस्तावेज़ीकरण, फ्रेट समन्वय |

मानक कस्टम ऑर्डर के लिए कुल समय सीमा आमतौर पर 6 से 12 सप्ताह की होती है। हालाँकि, इस सीमा के भीतर आपकी परियोजना के समय पर कई कारक प्रभाव डालते हैं:

- डिज़ाइन जटिलता: विस्तृत पाँच-अक्षीय मशीनिंग की आवश्यकता वाले जटिल स्पोक पैटर्न सीएनसी चरण में कुछ दिन जोड़ देते हैं। मानक प्रोफाइल वाले सरल डिज़ाइन तेज़ी से प्रसंस्कृत होते हैं।

- परिष्करण का चयन: प्रति व्हील 8+ घंटे की आवश्यकता वाले हाथ से ब्रश किए गए परिष्करण, मानक पाउडर कोट विकल्पों की तुलना में परिष्करण समय सीमा को काफी बढ़ा देते हैं।

- प्रतिबंध राशि: बड़े उत्पादन चक्र में अधिक इकाइयों पर सेटअप समय कम हो जाता है, लेकिन मशीनिंग और परिष्करण संचालन की विशाल मात्रा कुल लीड समय को बढ़ा देती है।

- प्रमाणन आवश्यकताएं: विशिष्ट जेडबीएल या एसएई परीक्षण की आवश्यकता वाले ऑर्डर तीसरे पक्ष की प्रयोगशाला नियोजन और परीक्षण पूरा होने में समय जोड़ते हैं।

बाजार में आने के समय के लिए दबाव बढ़ने पर त्वरित प्रोटोटाइपिंग क्षमताएं विकास चक्र को नाटकीय ढंग से तेज कर सकती हैं। आंतरिक इंजीनियरिंग क्षमताओं और ऊर्ध्वाधर रूप से एकीकृत उत्पादन वाले निर्माता प्रारंभिक प्रोटोटाइप डिलीवरी को अद्भुत रूप से कम समयसीमा तक सीमित कर सकते हैं। उदाहरण के लिए, शाओयी (निंगबो) मेटल टेक्नोलॉजी गुणवत्ता को त्वरित समयसीमा के दौरान भी अप्रभावित रखने के लिए अपने IATF 16949 प्रमाणन का उपयोग करते हुए महज 10 दिनों में त्वरित प्रोटोटाइपिंग प्रदान करता है। यह क्षमता पूर्ण उत्पादन चक्र में जाने से पहले फिटमेंट, सौंदर्य या संरचनात्मक प्रदर्शन का आकलन करते समय अमूल्य साबित होती है।

कस्टम व्हील की कीमत को प्रभावित करने वाले लागत कारक

कस्टम फोर्ज्ड व्हील उच्च मूल्य क्यों लेते हैं? फोर्ज्ड व्हील मूल्य पर उद्योग विश्लेषण के अनुसार, फोर्ज्ड व्हील की कीमत केवल सामग्री और निर्माण प्रक्रिया को ही प्रतिबिंबित नहीं करती है, बल्कि उत्कृष्ट प्रदर्शन, सुरक्षा और अनुकूलन क्षमताओं के संयोजन को भी प्रतिबिंबित करती है जिन्हें निम्न मूल्य बिंदुओं पर नकल नहीं किया जा सकता है।

लागत संरचना कई प्रमुख श्रेणियों में विभाजित होती है:

- कच्चे माल की लागत (कुल का 15-20%): एयरोस्पेस-ग्रेड 6061-T6 एल्युमीनियम बिलेट्स की कीमत कास्टिंग मिश्र धातुओं की तुलना में काफी अधिक होती है। यह प्रीमियम प्रमाणित सामग्री के लिए दिया जाता है जिसकी संरचना और ट्रेसएबिलिटी की गारंटी दी गई होती है।

- फोर्जिंग परिचालन (कुल का 20-25%): उच्च-टन फोर्जिंग प्रेस में कई मिलियन डॉलर के पूंजीगत निवेश की आवश्यकता होती है। संचालन लागत में डाई रखरखाव, ऊर्जा खपत और कुशल ऑपरेटर श्रम शामिल है। एपेक्स व्हील निर्माण प्रलेखन के अनुसार, आंतरिक इंजीनियरों द्वारा डिज़ाइन किए गए विशेष मोटरस्पोर्ट्स डाई ब्रेक क्लीयरेंस और स्पोक डिज़ाइन में उत्कृष्टता प्रदान करते हैं—लेकिन ये कस्टम डाई उन सामान्य ब्लैंक्स की तुलना में उपकरण लागत बढ़ा देते हैं जो ऐसे डाई का उपयोग नहीं करते।

- ऊष्मा उपचार (कुल का 5-10%): सख्त तापमान नियंत्रण और प्रलेखन के साथ सटीक फर्नेस संचालन साधारण बैच प्रसंस्करण से परे लागत जोड़ते हैं।

- सीएनसी मशीनिंग (कुल का 25-35%): यह चरण अक्सर सबसे बड़े लागत घटक का प्रतिनिधित्व करता है। जटिल स्पोक डिज़ाइनों को पांच-अक्षीय सीएनसी केंद्रों पर प्रति व्हील 6 या उससे अधिक घंटे की मशीनिंग की आवश्यकता हो सकती है। विकसित बाजारों में सटीक उपकरणों के लिए मशीन समय दर आसानी से प्रति घंटे 150-200 डॉलर से अधिक हो जाती है।

- परिष्करण संचालन (कुल का 10-15%) बहु-चरणीय लेपन प्रक्रियाएं, हाथ से लगाए गए परिष्करण, और गुणवत्ता निरीक्षण महत्वपूर्ण श्रम लागत जमा करते हैं। हाथ से ब्रश किए गए उपचार जैसे प्रीमियम परिष्करण अपनी श्रम तीव्रता को दर्शाते हुए महत्वपूर्ण अतिरिक्त शुल्क लेते हैं।

- गुणवत्ता नियंत्रण और प्रमाणन (कुल का 5-10%) तीसरे पक्ष की जांच, दस्तावेजीकरण प्रणाली, और जांच में विफल होने वाले कभी-कभी खराब हो जाने वाले व्हील सभी अंतिम मूल्य निर्धारण में शामिल होते हैं।

अंतिम व्हील मूल्य निर्धारण को सबसे अधिक प्रभावित करने वाले निर्माण निर्णय कौन से हैं? कई कारक ऐसे उत्पादों के बीच महत्वपूर्ण लागत अंतर पैदा करते हैं जो समान दिखते हैं:

- ब्लैंक स्रोत सामान्य, तत्काल उपलब्ध फोर्जिंग ब्लैंक्स का उपयोग करने वाले निर्माता मोल्ड विकास लागत पर बचत करते हैं, लेकिन डिज़ाइन लचीलेपन और अनुकूलित प्रदर्शन विशेषताओं को नुकसान उठाते हैं।

- मशीनिंग गहराई: I-बीम स्पोक प्रोफ़ाइल बनाने के लिए व्यापक पार्श्व-मिलिंग प्रति व्हील मशीन समय के कई घंटे जोड़ती है, बिना ताकत को प्रभावित किए वजन कम कर देती है।

- परीक्षण कठोरता: के रूप में प्रीमियम निर्माता जोर देते हैं , अमेरिका में व्हील उद्योग पूरी तरह से नियंत्रणमुक्त है—ब्रांड बिना किसी सुरक्षा विनियमन को पूरा किए या बिना प्रदर्शन दावों के प्रमाण दिए व्हील बेच सकते हैं। वास्तविक तीसरे पक्ष के परीक्षण में निवेश करने वाले निर्माता ऐसी लागतों का भुगतान करते हैं जिनसे कटौती करने वाले प्रतिस्पर्धी बच जाते हैं।

- उत्पादन स्थान: श्रम दरें, सुविधा लागत और विनियामक अनुपालन आवश्यकताएं क्षेत्र के अनुसार भारी मात्रा में भिन्न होती हैं। प्रमुख शिपिंग बंदरगाहों के निकट स्थित निर्माता—जैसे निंगबो पोर्ट के पास रणनीतिक रूप से स्थित सुविधाएं—वैश्विक डिलीवरी के लिए लॉजिस्टिक्स लाभ प्रदान कर सकते हैं।

जब आप यह ध्यान में रखते हैं कि फोर्ज्ड व्हील्स क्या प्रदान करते हैं, तो मूल्य प्रस्ताव स्पष्ट हो जाता है: समकक्ष कास्ट व्हील्स की तुलना में लगभग 32% वजन में कमी, उत्कृष्ट प्रभाव प्रतिरोध, बढ़ी हुई थकान आयु, और अनुकूलन विकल्प जो बड़े पैमाने पर उत्पादित विकल्पों की प्रतिस्पर्धा नहीं कर सकते। प्रदर्शन अनुप्रयोगों, रेसिंग वातावरणों या भारी उपयोग वाले ट्रकों के लिए, ये लाभ अक्सर प्रीमियम निवेश को सही ठहराते हैं।

इन समयसीमा और लागत कारकों को समझने से आपको निर्माता के उद्धरणों का बुद्धिमतापूर्वक मूल्यांकन करने में सक्षम बनाया जाता है। संदिग्ध रूप से कम कीमतें आमतौर पर कहीं न कहीं समझौते को इंगित करती हैं—चाहे वह सामग्री की गुणवत्ता में हो, परीक्षण की कठोरता में हो या मशीनिंग की सटीकता में। इसके विपरीत, गुणवत्ता में संगत निवेश के बिना ऊंची कीमतें केवल मार्जिन निकालती हैं, बिना समानुपातिक मूल्य प्रदान किए।

अब जब निर्माण समयसीमा और लागत संरचना का रहस्योद्घाटन हो चुका है, अंतिम विचार उचित निर्माण भागीदार का चयन करने का बन जाता है—एक ऐसा भागीदार जिसकी क्षमताएँ, प्रमाणन और गुणवत्ता प्रणाली आपकी विशिष्ट आवश्यकताओं के अनुरूप हों।

उचित कस्टम फोर्ज्ड व्हील निर्माता का चयन करें

आप अब एल्युमीनियम बिलेट से लेकर तैयार फोर्ज्ड व्हील तक की पूरी यात्रा को समझते हैं—वे फोर्जिंग दबाव, ऊष्मा उपचार चक्र, सटीक मशीनिंग सहिष्णुता और कठोर परीक्षण प्रोटोकॉल जो असाधारण व्हील को मामूली वालों से अलग करते हैं। लेकिन यहाँ चुनौती यह है: इस निर्माण ज्ञान को उस भागीदार का चयन करने में कैसे बदलें जो वास्तव में इन गुणवत्ता अपेक्षाओं पर खरा उतरता हो?

कस्टम फोर्ज्ड व्हील बाजार उन निर्माताओं को शामिल करता है जो पूरी गुणवत्ता सीमा में फैले हुए हैं। कुछ उपकरण, प्रमाणन और परीक्षण में भारी निवेश करते हैं। दूसरे जहां मार्जिन अनुमति देता है, वहां कटौती करते हैं। इनके बीच अंतर करने की आपकी क्षमता यह निर्धारित करती है कि क्या आपको वर्षों तक बेदाग प्रदर्शन करने वाले व्हील मिलते हैं या ऐसे घटक जो आपकी अधिकतम आवश्यकता के समय विफल हो जाते हैं।

अपने व्हील निर्माता से पूछने के लिए मुख्य प्रश्न

निर्माण प्रक्रिया के ज्ञान से लैस होकर, अब आप ऐसे प्रश्न पूछ सकते हैं जो यह उजागर करें कि क्या आपूर्तिकर्ता वास्तव में गुणवत्ता पर नियंत्रण रखता है या केवल दावा करता है। अपने मूल्यांकन के दौरान इन महत्वपूर्ण प्रश्नों पर विचार करें:

- आप किस एल्यूमीनियम मिश्र धातु ग्रेड का उपयोग करते हैं, और क्या आप सामग्री प्रमाणपत्र प्रदान कर सकते हैं? गुणवत्ता वाले निर्माता प्रमाणित मिलों तक बिलेट्स के ट्रेस करने वाले प्रलेखन आसानी से प्रदान करते हैं। "एयरोस्पेस-ग्रेड एल्यूमीनियम" के बारे में बिना समर्थनकारी प्रलेखन के अस्पष्ट उत्तर अपर्याप्त सामग्री नियंत्रण का सुझाव देते हैं।

- आप कितने टन भार वाले फोर्जिंग प्रेस का उपयोग करते हैं? जैसा कि आपने सीखा, प्रेस क्षमता सीधे दानों के सुधार और संरचनात्मक अखंडता को प्रभावित करती है। निर्माता को अपने उपकरण क्षमताओं को निर्दिष्ट करना चाहिए—8,000 से 10,000+ टन की सीमा में प्रेस लगाने से फोर्जिंग बुनियादी ढांचे में गंभीर निवेश का संकेत मिलता है।

- क्या आप अपनी ऊष्मा उपचार प्रक्रिया और सत्यापन विधियों का वर्णन कर सकते हैं? घुलनशील उपचार तापमान, डुबोने की समयसीमा और एजिंग पैरामीटर के बारे में विशिष्ट उत्तर खोजें। कठोरता परीक्षण प्रलेखन वास्तविक सत्यापन का प्रदर्शन करता है न कि अनुमानित अनुपालन।

- आप मशीनिंग के लिए कौन-सा सीएनसी उपकरण उपयोग करते हैं? मान्यता प्राप्त निर्माताओं (DMG Mori, Mazak, Haas) के बहु-अक्ष मशीनिंग सेंटर जो कड़े सहिष्णुता को बनाए रखने में सक्षम हैं, वे सटीकता क्षमताओं का संकेत देते हैं। आयामी सटीकता को सत्यापित करने के लिए माप प्रणाली के बारे में पूछें।

- आपकी सुविधा के पास कौन से प्रमाणपत्र हैं? के अनुसार उद्योग प्रमाणन मानक , विश्वसनीय निर्माताओं के पास गुणवत्ता, सुरक्षा और उद्योग मानदंडों के प्रति प्रतिबद्धता का प्रदर्शन करने वाले कई प्रासंगिक प्रमाणपत्र होने चाहिए।

- तैयार पहियों पर कौन सी परीक्षण प्रक्रियाएं की जाती हैं? JWL डायनेमिक कॉर्नरिंग परीक्षणों, रेडियल थकान परीक्षणों और मात्रात्मक मापदंडों के साथ प्रभाव परीक्षणों के विशिष्ट संदर्भ व्यापक मान्यकरण का संकेत देते हैं। बिना विवरण के "कठोर परीक्षण" जैसे सामान्य दावों पर संदेह करना चाहिए।

- क्या आप कच्चे माल के बैच तक किसी भी व्हील की ट्रेसएबिलिटी प्रदान कर सकते हैं? पूर्ण ट्रेसएबिलिटी प्रणाली परिपक्व गुणवत्ता प्रबंधन का प्रदर्शन करती है। वारंटी से जुड़े मुद्दे उत्पन्न होने पर यह क्षमता अत्यंत महत्वपूर्ण साबित होती है।

उत्तरों की गहराई और विशिष्टता आपको उत्तरों के समान ही बहुत कुछ बताती है। जो निर्माता अपनी प्रक्रियाओं में आत्मविश्वास रखते हैं, वे विस्तृत प्रश्नों का स्वागत करते हैं। जो तकनीकी प्रश्नों से बचते हैं, उनके पास छिपाने के लिए कुछ होने की संभावना होती है।

संभावित साझेदारों में निर्माण उत्कृष्टता का मूल्यांकन

व्यक्तिगत प्रश्नों से परे, व्यवस्थागत मूल्यांकन मानदंड आपको संभावित आपूर्तिकर्ताओं की तुलना निष्पक्ष ढंग से करने में मदद करते हैं। निर्माता क्षमताओं का आकलन करते समय इन कारकों पर विचार करें:

- प्रमाणन पोर्टफोलियो: के अनुसार विश्वसनीय निर्माताओं के लिए प्रमाणन आवश्यकताएं प्रमुख प्रमाणनों में गुणवत्ता प्रबंधन प्रणालियों के लिए ISO 9001, ऑटोमोटिव उद्योग आपूर्तिकर्ताओं के लिए IATF 16949:2016, व्हील सुरक्षा मानकों के लिए JWL/JWL-T, स्वतंत्र तृतीय-पक्ष परीक्षण सत्यापन के लिए VIA, और यूरोपीय बाजार स्वीकृति के लिए TÜV शामिल हैं। IATF 16949 प्रमाणन विशेष रूप से मूल्यवान है क्योंकि यह पूरी उत्पादन प्रक्रिया को कवर करता है, निरंतर सुधार और दोष रोकथाम पर ध्यान केंद्रित करते हुए प्रत्येक चरण पर उच्च गुणवत्ता मानकों को सुनिश्चित करता है।

- उपकरण क्षमताएँ: ऊर्ध्वाधर एकीकरण—जिसमें फोर्जिंग प्रेस, ऊष्मा उपचार भट्ठियाँ, सीएनसी मशीनिंग केंद्र और फिनिशिंग लाइनों का स्वामित्व शामिल है—पूरी विनिर्माण श्रृंखला पर नियंत्रण को दर्शाता है। महत्वपूर्ण चरणों को बाहरी स्रोतों से प्राप्त करने से गुणवत्ता में अस्थिरता आ सकती है।

- गुणवत्ता नियंत्रण बुनियादी ढांचा: समन्वय मापन मशीनों, कठोरता परीक्षकों, गतिशील संतुलन उपकरणों और सतह विश्लेषण उपकरणों सहित समर्पित निरीक्षण उपकरणों में निवेश की जाँच के लिए धन लगाने के बजाय धारणा पर भरोसा करने के बजाय सत्यापन में निवेश को दर्शाता है।

- इंजीनियरिंग विशेषज्ञता: एफईए विश्लेषण, कस्टम डाई डिज़ाइन और एप्लीकेशन-विशिष्ट अनुकूलन करने में सक्षम आंतरिक इंजीनियरिंग टीमें सामान्य ब्लैंक्स को मशीन करने वाली साधारण जॉब शॉप्स से गंभीर निर्माताओं को अलग करती हैं।

- परीक्षण दस्तावेज़ीकरण: जैसा कि उद्योग विशेषज्ञ जोर देते हैं, प्रतिष्ठित निर्माता लोड सिमुलेशन, संकेंद्रता परीक्षण और परिमाणीय जाँच सहित कठोर परीक्षण करते हैं जो फाइनाइट एलिमेंट मेथड विश्लेषण का उपयोग करते हैं। वे जेडब्ल्यूएल वीआईए, टीयूवी, डीओटी, एसएई और अन्य प्रासंगिक निकायों से प्रमाणपत्र स्वेच्छा से प्रदान करने में सक्षम होने चाहिए।

- उत्पादन क्षमता और लीड टाइम: निर्माता जिनके पास गुणवत्ता को नुकसान पहुँचाए बिना आपकी समयसीमा आवश्यकताओं को पूरा करने के लिए पर्याप्त क्षमता है। कुछ सुविधाएँ महज 10 दिनों में प्रोटोटाइप प्रदान करती हैं—जो इंजीनियरिंग लचीलेपन का प्रदर्शन करती हैं।

- भौगोलिक प्रासंगिकता: प्रमुख शिपिंग बंदरगाहों के निकट होने से वैश्विक डिलीवरी में आसानी होती है। निंगबो बंदरगाह जैसे लॉजिस्टिक्स हब के निकट रणनीतिक स्थान अंतरराष्ट्रीय ऑर्डर के लिए पारगमन समय और शिपिंग लागत को कम करते हैं।

उन संगठनों के लिए जो इन क्षमताओं का प्रदर्शन करने वाले एक निर्माण साझेदार की तलाश में हैं, शाओयी (निंगबो) मेटल टेक्नोलॉजी इस मार्गदर्शिका में चर्चा किए गए योग्यता मानदंड को उदाहरणित करता है। उनका IATF 16949 प्रमाणन सुनिश्चित करता है कि प्रत्येक उत्पादन चरण को ऑटोमोटिव-ग्रेड गुणवत्ता प्रणाली द्वारा नियंत्रित किया जाता है। उनके परिशुद्ध गर्म आघात निर्माण समाधान केवल पहियों तक ही सीमित नहीं हैं, बल्कि निलंबन भुजाओं और ड्राइव शाफ्ट जैसे मांग वाले घटकों तक भी फैले हुए हैं—ऐसे अनुप्रयोग जिन्हें प्रीमियम आघातित पहियों के लिए आवश्यक धातुकर्म उत्कृष्टता और आयामी परिशुद्धता की आवश्यकता होती है। निंगबो बंदरगाह के निकट सामरिक स्थान वैश्विक डिलीवरी को सरल बनाता है, जबकि आंतरिक इंजीनियरिंग त्वरित प्रोटोटाइपिंग का समर्थन करती है जब त्वरित समयसीमा आवश्यक होती है।

पर्यावरणीय और उत्पादनशीलता पर विचार

आधुनिक निर्माण जिम्मेदारी उत्पाद गुणवत्ता से परे पर्यावरण संरक्षण तक जाती है। जब आघातित पहिया निर्माताओं का आकलन करें, तो उनके स्थिरता अभ्यासों पर विचार करें:

- सामग्री दक्षता: ढलाई की तुलना में फोर्जिंग स्वाभाविक रूप से कम अपशिष्ट उत्पन्न करती है, लेकिन प्रमुख निर्माता बिलेट आकार को अनुकूलित करते हैं और प्रमाणित एल्युमीनियम रीसाइकलर्स के माध्यम से मशीनिंग चिप्स को रीसाइकल करते हैं।

- ऊर्जा की खपत: पुनरुत्थान प्रणाली वाले आधुनिक फोर्जिंग प्रेस वापसी के दौरान ऊर्जा को पुनः प्राप्त करते हैं। कुशल इन्सुलेशन और ऊष्मा पुनर्प्राप्ति वाले ऊष्मा उपचार भट्ठियाँ प्रति चक्र ऊर्जा तीव्रता को कम करती हैं।

- कोटिंग प्रणाली: पारंपरिक तरल पेंट की तुलना में पाउडर कोटिंग लगभग शून्य वाष्पशील कार्बनिक यौगिक उत्पन्न करती है। जल-आधारित सफाई और प्रीट्रीटमेंट प्रणाली रासायनिक अपशिष्ट धाराओं को कम करती है।

- सुविधा प्रमाणन: ISO 14001 पर्यावरण प्रबंधन प्रमाणन संचालन के दौरान पर्यावरणीय प्रभाव को कम करने के लिए व्यवस्थित दृष्टिकोण को दर्शाता है।

इन विचारों का खरीद प्रक्रियाओं पर बढ़ता प्रभाव पड़ रहा है क्योंकि संगठनों को स्थिरता रिपोर्टिंग आवश्यकताओं और जिम्मेदार स्रोत के लिए ग्राहक अपेक्षाओं का सामना करना पड़ रहा है।

सब कुछ एक साथ लाकर

आपने जिस कस्टम फोर्ज्ड व्हील निर्माण यात्रा का अन्वेषण किया है—एयरोस्पेस-ग्रेड एल्युमीनियम के चयन से लेकर 10,000-टन फोर्जिंग संचालन, सटीक T6 ऊष्मा उपचार, माइक्रॉन-स्तरीय सीएनसी मशीनिंग, सुरक्षात्मक फिनिशिंग और व्यापक गुणवत्ता परीक्षण तक—वह धातु विज्ञान के विज्ञान और निर्माण में सटीकता के असाधारण संगम को दर्शाता है।

प्रत्येक चरण पिछले चरण पर आधारित होता है, और श्रृंखला में कहीं भी समझौता अंतिम उत्पाद को कमजोर कर देता है। यही कारण है कि निर्माता का चयन बहुत महत्वपूर्ण है। एक आपूर्तिकर्ता जो संदिग्ध बिलेट्स की आपूर्ति करता है, ऊष्मा उपचार सत्यापन को छोड़ देता है, या तृतीय-पक्ष परीक्षण से बचता है, आपके वाहन या आपके विश्वास के योग्य पहियों की आपूर्ति नहीं कर सकता—चाहे उसका विपणन कितना भी प्रभावशाली क्यों न दिखे।

आपके पास अब दावों के बजाय वास्तविकता के आधार पर निर्माताओं का आकलन करने का ज्ञान है। विस्तृत प्रश्न पूछें। प्रलेखन माँगें। प्रमाणीकरण की पुष्टि करें। जो निर्माता इस जाँच का स्वागत करते हैं, वेीं वास्तविक साझेदार हैं जो वर्ष दर वर्ष, मील दर मील वादे के अनुसार प्रदर्शन करने वाले पहिए प्रदान करते हैं।

चाहे आप ट्रैक-उन्मुख प्रदर्शन मशीन बना रहे हों, एक लक्ज़री वाहन का उन्नयन कर रहे हों, या माँग वाले वाणिज्यिक अनुप्रयोगों के लिए पहियों की विनिर्देश कर रहे हों, कस्टम फोर्ज्ड पहियों के पीछे निर्माण उत्कृष्टता निवेश को उचित ठहराती है। अपने निर्माण साझेदार का चयन उसी सटीकता से करें जिस सटीकता का उपयोग वे आपके पहिए बनाते समय करना चाहिए।

कस्टम फोर्ज्ड पहिया निर्माण के बारे में अक्सर पूछे जाने वाले प्रश्न

1. फोर्ज्ड पहिये कैसे बनाए जाते हैं?

मजबूत धातु के पहियों का निर्माण एक बहु-चरणीय प्रक्रिया के माध्यम से होता है, जिसकी शुरुआत एयरोस्पेस-ग्रेड 6061-T6 एल्युमीनियम बिलेट्स से 350-500°C तक गर्म करके की जाती है। गर्म किया गया बिलेट एक फोर्जिंग प्रेस में प्रवेश करता है जो अधिकतम 10,000 टन का दबाव उत्पन्न करने में सक्षम होता है, जो धातु को संपीड़ित और आकार देता है जबकि इसकी धात्विक संरचना को संरेखित करता है। फोर्जिंग के बाद, पहिया ब्लैंक को T6 ऊष्मा उपचार से गुजारा जाता है जिसमें 530°C पर घुलनशील उपचार, त्वरित शीतलन और लगभग 8 घंटे के लिए 175°C पर कृत्रिम उम्र बढ़ाना शामिल होता है। फिर सटीक CNC मशीनिंग अंतिम पहिया प्रोफ़ाइल, स्पोक पैटर्न, बोल्ट पैटर्न और हब बोर बनाती है। पाउडर कोटिंग या पॉलिशिंग के साथ सतह का निपटान सुरक्षा और सौंदर्य प्रदान करता है, जिसके बाद गतिशील थकान और प्रभाव परीक्षण जैसे कठोर गुणवत्ता परीक्षण किए जाते हैं।

2. ढलवाँ और मजबूत धातु के पहियों में क्या अंतर है?

ढलाई वाले पहिये मोल्ड में तरल एल्युमीनियम डालकर बनाए जाते हैं, जहाँ यह ठंडा होकर ठोस बन जाता है, जिससे अक्सर आंतरिक छिद्रता और कमजोर बिंदुओं के साथ अनियमित धान की संरचना बन जाती है। फोर्ज्ड पहिये ठोस एल्युमीनियम बिलेट से शुरू होते हैं जिन्हें अत्यधिक गर्मी और दबाव के अधीन किया जाता है, जिससे तनाव पथों के अनुदिश संरेखित घने, एकरूप धान की संरचना बनती है। इस मौलिक निर्माण अंतर के कारण फोर्ज्ड पहियों का ढलाई वाले पहियों की तुलना में लगभग 32% कम वजन होता है, जबकि समतुल्य मजबूती बनी रहती है, साथ ही उनमें उत्कृष्ट प्रभाव प्रतिरोध और काफी बेहतर थकान जीवन होता है। हालांकि ढलाई वाले पहिये अधिक किफायती होते हैं, फिर भी फोर्ज्ड पहिये रेसिंग और उच्च-प्रदर्शन ड्राइविंग जैसे मांग वाले अनुप्रयोगों के लिए अतुलनीय प्रदर्शन प्रदान करते हैं।

3. अन्य पहियों की तुलना में फोर्ज्ड पहिये महंगे क्यों होते हैं?

मजबूत धातु के पहियों की कीमत हर निर्माण चरण में भारी निवेश को दर्शाती है। कच्चे एयरोस्पेस-ग्रेड 6061-T6 एल्युमीनियम की लागत ढलाई मिश्र धातुओं की तुलना में काफी अधिक होती है। मजबूत धातु के पहियों के उत्पादन में कई मिलियन डॉलर की उच्च-टन भार वाली प्रेस और विशेष डाई की आवश्यकता होती है। सीएनसी मशीनिंग अक्सर कुल लागत का 25-35% हिस्सा होती है, जिसमें जटिल स्पोक डिज़ाइन को प्रति पहिया 6 घंटे या अधिक समय लग सकता है, जिसकी दर पाँच-अक्षीय केंद्रों पर प्रति घंटे 150-200 डॉलर होती है। हाथ से ब्रश किए गए उच्च-गुणवत्ता वाले फिनिश श्रम-गहन प्रक्रियाओं को जोड़ते हैं। तीसरे पक्ष के JWL और SAE प्रमाणन परीक्षण सहित गुणवत्ता नियंत्रण उन बजट निर्माताओं द्वारा टाले जाने वाले सत्यापन लागत जोड़ते हैं। परिणामस्वरूप पहिये उत्कृष्ट शक्ति-से-वजन अनुपात, अनुकूलन के विकल्प और दीर्घकालिक स्थायित्व के साथ आते हैं जो बड़े पैमाने पर उत्पादित विकल्पों के बराबर नहीं हो सकते।

4. एक मजबूत धातु के पहियों के निर्माता के पास कौन से प्रमाणपत्र होने चाहिए?

प्रतिष्ठित फोर्ज्ड व्हील निर्माताओं के पास गुणवत्ता के प्रति प्रतिबद्धता को दर्शाते हुए कई प्रमाणपत्र होने चाहिए। ऑटोमोटिव अनुप्रयोगों के लिए IATF 16949:2016 प्रमाणन विशेष रूप से मूल्यवान है, जो निरंतर सुधार और दोष रोकथाम पर ध्यान केंद्रित करते हुए पूरी उत्पादन प्रक्रिया को कवर करता है। ISO 9001 गुणवत्ता प्रबंधन प्रणाली की नींव स्थापित करता है। JWL और JWL-T प्रमाणन सत्यापित करते हैं कि व्हील जापानी मानकों के अनुसार गतिशील कोर्नरिंग थकान, अरीय थकान और प्रभाव परीक्षणों में उत्तीर्ण होते हैं। VIA प्रमाणन स्वतंत्र तृतीय-पक्ष परीक्षण सत्यापन की पुष्टि करता है। TÜV प्रमाणन यूरोपीय बाजार में स्वीकृति की अनुमति देता है। शाओयी (निंगबो) मेटल टेक्नोलॉजी जैसे निर्माता IATF 16949 प्रमाणन धारण करते हैं, जो यह सुनिश्चित करता है कि त्वरित प्रोटोटाइपिंग से लेकर बड़े पैमाने पर उत्पादन तक प्रत्येक उत्पादन चरण को ऑटोमोटिव-ग्रेड गुणवत्ता प्रणाली द्वारा नियंत्रित किया जाता है।

5. कस्टम फोर्ज्ड व्हील्स के निर्माण में कितना समय लगता है?

पूर्ण अनुकूलित फोर्ज्ड व्हील निर्माण में आमतौर पर जटिलता और विनिर्देशों के आधार पर 6 से 12 सप्ताह का समय लगता है। इस समयसीमा में डिज़ाइन और इंजीनियरिंग (3-7 दिन), सामग्री खरीद (5-10 दिन), फोर्जिंग संचालन (2-4 दिन), ऊष्मा उपचार (3-5 दिन), सीएनसी मशीनिंग (5-8 दिन), सतह परिष्करण (4-7 दिन), गुणवत्ता नियंत्रण परीक्षण (2-3 दिन) और शिपिंग के साथ पैकेजिंग (2-5 दिन) शामिल हैं। समयसीमा को बढ़ाने वाले कारकों में जटिल स्पोक पैटर्न, प्रति व्हील 8+ घंटे की आवश्यकता वाली हैंड-ब्रश की गई परिष्करण सतह, बड़ी ऑर्डर मात्रा और विशिष्ट प्रमाणन आवश्यकताएं शामिल हैं। कुछ निर्माता पूर्ण उत्पादन चक्र में जाने से पहले प्रारंभिक नमूनों के लिए मात्र 10 दिनों में त्वरित प्रोटोटाइपिंग की सुविधा प्रदान करते हैं।

छोटे पर्चे, उच्च मानदंड। हमारी तेजी से प्रोटोटाइपिंग सेवा मान्यता को तेजी से और आसानी से बनाती है —

छोटे पर्चे, उच्च मानदंड। हमारी तेजी से प्रोटोटाइपिंग सेवा मान्यता को तेजी से और आसानी से बनाती है —