Laser Cutting Sheet Steel: Fix Dross, Burrs, And Rough Edges Fast

What Is Laser Cutting Sheet Steel and Why It Matters

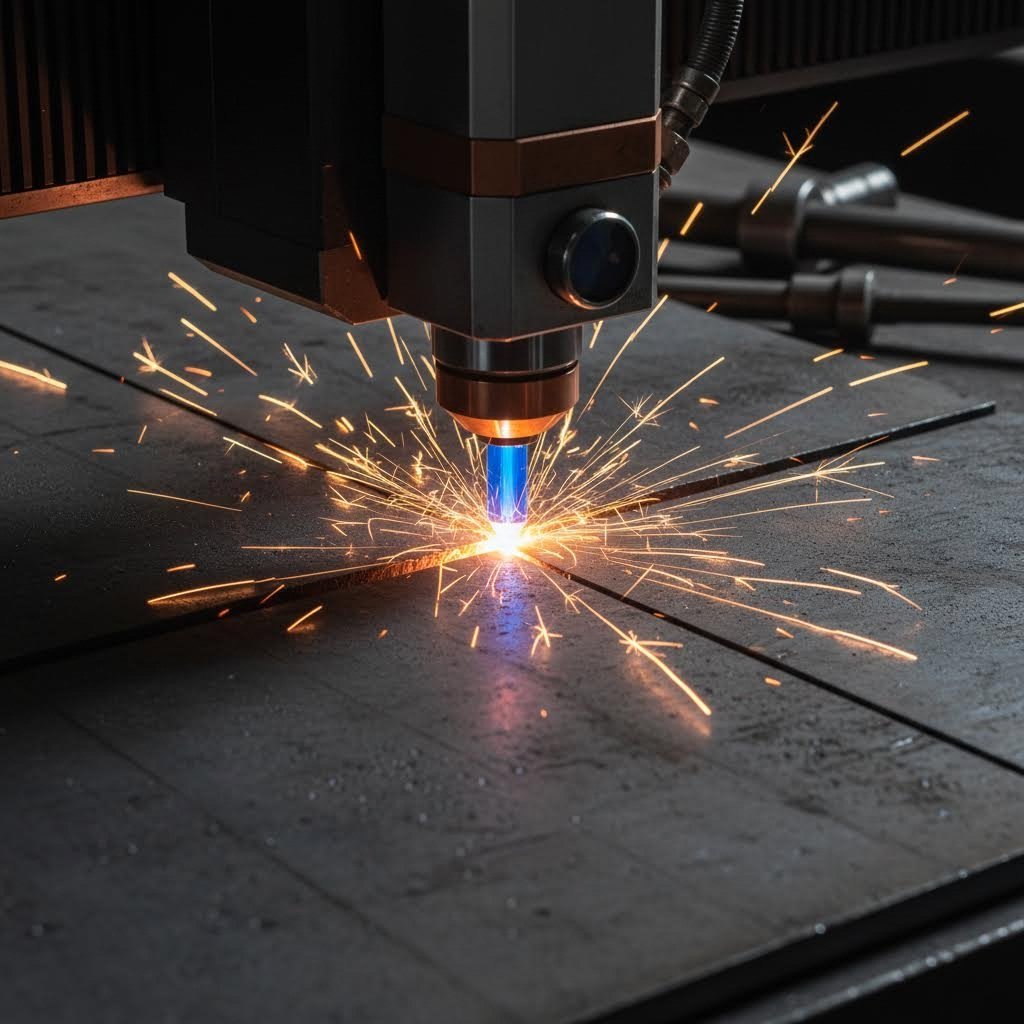

Imagine a beam of light so precisely focused that it can slice through metal sheets like a hot knife through butter. That's exactly what happens when you're working with laser cutting sheet steel. This process uses a concentrated, high-energy laser beam to melt, burn, or vaporize steel along a programmed cutting path. The result? Clean, precise cuts that traditional methods simply can't match.

A laser cutter generates temperatures reaching approximately 3,000°C at the focal point, according to Minifaber's technical documentation. This intense heat, concentrated on an incredibly small diameter, allows for exceptional geometric accuracy even on complex profiles. But here's what makes sheet steel particularly well-suited for this technology: thinner metal sheets absorb laser energy more efficiently and dissipate heat faster than thicker steel plate materials, resulting in cleaner edges and minimal distortion.

How Laser Energy Transforms Sheet Steel

When a laser beam strikes a steel surface, something fascinating happens at the molecular level. The concentrated photons transfer their energy directly to atoms within the steel's crystal lattice. According to research from the Czech Technical University in Prague, this energy transfer causes atoms to oscillate with increasing amplitude until they break free from their lattice bonds.

Here's the simplified breakdown:

- Energy absorption: Steel atoms absorb photon energy, causing rapid temperature increase

- Lattice disruption: Atomic bonds weaken as oscillation amplitude exceeds the lattice parameter

- Material removal: Steel either melts (for cutting) or vaporizes (for micromilling), depending on the energy intensity and cutting speed

Sheet steel's tensile strength actually works in your favor during this process. The material's structural integrity means the heat-affected zone remains localized, preventing warping that commonly plagues thicker materials.

The Science Behind Precision Steel Cutting

What sets laser cutting apart from traditional metal fabrication methods? The laser power density is extraordinarily high, and there's zero physical contact between the cutting head and your workpiece. This eliminates tool wear entirely and means the metal sheets experience no mechanical force during cutting.

The process relies on CNC systems that manage every parameter with precision: feed speed, laser power, beam focus, and assist gas flow. Modern equipment can achieve cutting accuracy that rivals the tightest tolerances in manufacturing, making it ideal for everything from intricate decorative panels to precision automotive components.

Throughout this article, you'll discover exactly how to optimize your laser cutting cutting operations. We'll cover fiber versus CO2 laser selection, steel grade compatibility, assist gas choices that most competitors overlook entirely, and practical troubleshooting for common defects like dross, burrs, and rough edges. Whether you're running a small fabrication shop or managing large-scale production, you'll find actionable guidance to improve your cut quality and efficiency.

Fiber Lasers vs CO2 Lasers for Steel Applications

So you've decided to invest in laser cutting steel for your fabrication needs. Here's the million-dollar question: should you go with a fiber laser cutting machine or stick with traditional CO2 technology? The answer depends entirely on what you're cutting, how thick it is, and what your long-term operational budget looks like.

The fundamental difference comes down to wavelength. A fiber laser cutter emits light at approximately 1.06 microns (1,064 nm), while CO2 lasers operate at 10.6 microns. That tenfold difference dramatically affects how steel absorbs the laser energy. According to Laser Photonics, metals absorb several times more light from a fiber laser than from a CO2 laser at equivalent power outputs. This means your fiber laser works harder with less electrical input.

Fiber Laser Advantages for Thin Gauge Steel

When you're working with thin to medium gauge steel, a metal laser cutter powered by fiber technology delivers clear advantages. The shorter wavelength creates a smaller, more precise focus spot that translates directly into tighter tolerances and narrower kerf widths. You'll notice cleaner edges on intricate cuts and reduced heat-affected zones that could otherwise warp delicate components.

Here's what makes fiber lasers stand out for sheet steel:

- Superior absorption rates: Steel readily absorbs the 1.06-micron wavelength, maximizing cutting efficiency

- Higher precision: The concentrated beam produces finely contoured components with tight tolerances

- Better reflective metal handling: Modern fiber systems include back-reflection protection for materials like stainless steel

- Lower operating costs: Efficiency rates often exceed 90%, compared to just 5-10% for CO2 systems

A metal laser cutting machine using fiber technology typically delivers 3 to 5 times the productivity of similarly capable CO2 equipment on appropriate jobs, according to Xometry's technical comparison. That productivity boost comes from faster cutting speeds on thin materials combined with reduced downtime.

When CO2 Lasers Make Sense for Steel Cutting

Does this mean CO2 lasers are obsolete? Not quite. When you're cutting thicker steel plates exceeding 10-20 mm, CO2 technology still holds its ground. Operators often add oxygen assist gas to speed up cuts on materials as thick as 100 mm. The longer wavelength also makes CO2 lasers the better choice if your shop handles mixed materials, including nonmetals like acrylic or wood alongside your steel work.

The upfront cost difference is substantial. A laser cutting machine for metal using fiber technology can run 5 to 10 times the price of equivalent CO2 equipment. However, fiber lasers typically offer up to 10 times the functional lifespan, often reported at 25,000+ working hours. That longevity, combined with dramatically lower power consumption, usually makes fiber the better long-term investment for dedicated steel cutting operations.

Consider this detailed comparison when selecting your laser for cutting machine:

| Parameter | Fiber Laser | CO2 Laser |

|---|---|---|

| Optimal Steel Thickness | Up to 20 mm (best under 12 mm) | 10-100+ mm with oxygen assist |

| Cutting Speed (Thin Steel) | 3-5x faster than CO2 | Slower on thin materials |

| Edge Quality | Superior precision, narrow kerf | Good quality, wider kerf |

| Power Efficiency | Above 90% | 5-10% |

| Operating Costs | Lower electricity, minimal consumables | High power draw, gas refills needed |

| Maintenance Requirements | Minimal, solid-state design | Regular mirror alignment, gas replenishment |

| Upfront Investment | 5-10x higher than CO2 | Lower initial cost |

| Expected Lifespan | 25,000+ working hours | ~2,500 working hours |

For shops focused primarily on sheet steel under 12 mm, a fiber laser cutter represents the clear winner. The combination of speed, precision, and operational efficiency justifies the higher upfront investment. However, if your work regularly involves thicker plates or diverse material types, a CO2 system or even a hybrid approach might serve you better.

Now that you understand the laser technology options, let's examine how different steel grades interact with these cutting systems and which parameters produce the best results for each material type.

Steel Grade Compatibility and Material Selection

Ever wondered why your laser cutting parameters work perfectly on one steel sheet but produce terrible results on another? The secret lies in understanding how different steel grades interact with laser energy. Each steel type has unique properties that directly influence cutting speed, edge quality, and parameter selection. Let's break down what you need to know for consistently clean cuts across carbon steel, stainless steel sheet, and galvanized sheet metal.

Material composition matters more than most operators realize. The alloying elements in steel affect thermal conductivity, reflectivity, and melting behavior. According to Longxin Laser's technical documentation, calibrating and saving parameter sets for each material and thickness combination is where shops quickly gain repeatability. Skip this step, and you'll spend far too much time troubleshooting defects that proper material selection would have prevented.

Carbon Steel Cutting Characteristics

Carbon steel is the workhorse of laser cutting operations. Its relatively straightforward composition makes it predictable and forgiving to cut. The iron-carbon structure absorbs laser energy efficiently, allowing for faster cutting speeds and lower power requirements compared to specialty alloys.

Here are the most common carbon steel grades you'll encounter:

- A36 Structural Steel: Excellent laser compatibility; ideal for general fabrication and structural components

- 1018 Low Carbon Steel: Cuts cleanly with minimal dross; preferred for precision parts requiring secondary machining

- 1045 Medium Carbon Steel: Requires slightly slower speeds due to higher carbon content; produces strong, wear-resistant parts

- 4140 Alloy Steel: Higher hardness demands careful heat management; excellent for high-stress applications

Fiber lasers handle carbon steel plates exceptionally well. The material's low reflectivity means maximum energy transfer to the cut zone. When cutting with oxygen assist gas, an exothermic reaction occurs that actually adds energy to the cutting process, enabling faster speeds on thicker materials. This makes carbon steel the most cost-effective option for high-volume production runs.

Stainless Steel and Specialty Alloy Considerations

Stainless steel sheet metal presents a different set of challenges. The chromium content that provides corrosion resistance also increases reflectivity and changes thermal behavior. You'll typically need to reduce cutting speeds by 20-30% compared to carbon steel of equivalent thickness.

Key stainless steel grades for laser cutting include:

- 304 Stainless Steel: Most common grade; excellent corrosion resistance; cuts well with nitrogen assist gas for oxide-free edges

- 316 Stainless Steel: Superior corrosion resistance for marine and chemical applications; slightly more challenging due to molybdenum content

- 430 Stainless Steel: Ferritic grade with good formability; lower cost alternative when extreme corrosion resistance isn't required

- 201 Stainless Steel: Budget-friendly option; higher manganese content may affect edge quality

Unlike carbon steel, stainless steel sheet requires nitrogen assist gas to achieve clean, oxide-free edges suitable for visible applications or welding. Oxygen cutting is possible but leaves a dark oxide layer that often requires secondary finishing.

Galvanized steel introduces unique complications. The zinc coating vaporizes at lower temperatures than steel, creating fumes and potentially interfering with the cut. According to Kirin Laser's safety documentation, modern fiber laser machines handle reflective materials and coatings well when configured correctly. A high-power fiber laser can cut galvanized steel up to 20mm thick, but optimal quality is typically seen at or below 12mm.

The reflectivity challenges with galvanized coatings require specific precautions. Always ensure proper ventilation since zinc fumes are hazardous if inhaled repeatedly. Modern fiber lasers include back-reflection protection that prevents damage from the highly reflective zinc surface. You may also notice slightly more dross formation compared to uncoated steel, requiring parameter adjustments to compensate.

When selecting materials for your project, consider how different grades compare to aluminum sheet in terms of laser compatibility. While aluminum sheet cuts cleanly with fiber lasers, it requires entirely different parameters due to its high thermal conductivity. Steel plates generally offer more predictable results across a wider range of power settings, making them preferable for shops without extensive parameter optimization experience.

Understanding these material differences sets the foundation for our next critical topic: how assist gas selection dramatically affects your cut quality and edge finish across all these steel variants.

Assist Gas Selection and Cut Quality Optimization

Here's a question that separates amateur laser cutting metal sheet operations from professional results: what gas are you blowing through that nozzle? Assist gas selection is arguably the most overlooked factor in sheet metal laser cutting, yet it directly determines whether you'll spend hours grinding off dross or deliver parts ready for assembly straight off the table.

Assist gases serve three critical functions during laser metal cutting. First, they physically expel molten material from the cut zone. Second, they control oxidation reactions at the cut edge. Third, they influence thermal dynamics throughout the cutting process. According to Pneumatech's technical documentation, the type of gas used can determine whether a cut is clean and oxidation-free or enhanced by an exothermic reaction for faster processing.

Nitrogen vs Oxygen Assist Gas Selection

Choosing between nitrogen and oxygen isn't about which gas is "better." It's about matching the gas to your material and quality requirements. Each option creates fundamentally different cutting conditions that affect everything from edge appearance to cutting speed.

Oxygen Cutting: Speed and Power for Carbon Steel

When oxygen hits molten carbon steel, something powerful happens. The oxygen reacts with iron in the steel, creating an exothermic reaction that adds significant heat energy to the cutting process. According to Bodor Laser's technical guide, oxygen does approximately 60 percent of the cutting work on carbon steel, supporting the laser beam with additional thermal energy.

This exothermic boost enables faster cutting speeds and the ability to cut thicker materials than laser power alone would allow. However, there's a tradeoff: the oxidation reaction leaves rougher, oxidized edges that may require post-processing for applications demanding clean finishes.

Nitrogen Cutting: Clean Edges for Stainless and Aluminum

Nitrogen takes an entirely different approach. As an inert gas, it creates a non-reactive atmosphere around the cut zone, preventing oxidation entirely. The result? Clean, oxide-free edges with superior visual quality that often require no secondary finishing.

For laser cutting of metal sheets made from stainless steel, aluminum, or other non-ferrous materials, nitrogen is the preferred choice. The absence of oxidation eliminates the need for grinding, cleaning, or other post-processing steps. This makes nitrogen ideal for visible components, parts destined for welding, and any application where aesthetic standards matter.

The tradeoff? Nitrogen cutting relies purely on thermal energy from the laser beam. Without the exothermic reaction that oxygen provides, cutting speeds are typically slower, and you may need higher laser power for equivalent thickness materials.

| Parameter | Nitrogen | Oxygen | Compressed Air |

|---|---|---|---|

| Best Steel Applications | Stainless steel, aluminum, galvanized steel | Carbon steel, mild steel | Thin carbon steel, thin stainless |

| Edge Characteristics | Clean, oxide-free, bright silver finish | Oxidized, darker edges, may need finishing | Partially oxidized, possible burrs |

| Cutting Speed Impact | Slower (thermal process only) | Faster (exothermic reaction adds energy) | Moderate speed |

| Optimal Thickness Range | All thicknesses (best for thin-medium) | 6mm and above for carbon steel | Up to ~6mm |

| Cost Considerations | Higher gas cost, lower post-processing | Lower gas cost, potential finishing costs | Lowest cost, on-site generation possible |

Gas Pressure Impact on Edge Quality

Selecting the right gas is only half the equation. Gas pressure dramatically affects cut quality, dross formation, and edge finish. Get this wrong, and even the correct gas choice won't save your parts from defects.

High-pressure nitrogen cutting presents a perfect example. Research from TWI (The Welding Institute) demonstrated that specially developed nozzles combined with high-pressure gas produce clean, dross-free cut edges in stainless steel. The key mechanism? High-velocity gas blasts molten metal away from the cut zone immediately after the laser melts it. This continuous, instant removal of molten material prevents dross adhesion and sideways heat transfer.

However, there's a catch: high gas consumption increases operating costs significantly. TWI's survey found that many shops avoided high-pressure cutting techniques because the gas costs outweighed the savings from eliminated post-processing. The solution lies in optimized nozzle designs that maintain cut quality while reducing gas waste.

Practical Pressure Guidelines:

- Low pressure oxygen (0.5-1 bar): Standard carbon steel cutting; faster speeds but potential for oxide buildup

- High pressure nitrogen (8-20 bar): Stainless steel and aluminum; delivers oxide-free edges when properly configured

- Medium pressure air (4-8 bar): Budget-friendly option for thin materials where edge quality is less critical

When cutting metal cutting laser operations produce unexpected dross or rough edges, gas pressure is often the culprit. Insufficient pressure fails to expel molten material quickly enough, allowing it to resolidify on the cut edge. Excessive pressure wastes gas without improving quality and can actually cause turbulence that disrupts the cut.

Troubleshooting Pressure-Related Issues:

- Slag at bottom of thick carbon steel: Lower cutting speed, lower focal point, and increase gas pressure to optimize the oxidation reaction

- Flying slag sticking to surface: Raise the focal point and lower gas pressure to reduce splatter

- Burrs on stainless steel: Lower focal point, increase nozzle diameter, and reduce duty cycle for cleaner edges

The interaction between laser parameters and assist gas creates a system where small adjustments cascade into significant quality differences. For laser cutting metal sheet applications requiring consistent results, document your optimal pressure settings for each material type and thickness combination. This reference library becomes invaluable when switching between jobs or training new operators.

With your assist gas strategy dialed in, the next step is understanding common cutting defects and how to eliminate them before they waste material and production time.

Common Cutting Defects and Troubleshooting Solutions

You've optimized your laser type, selected the right steel grade, and dialed in your assist gas settings. Yet your parts still come off the table with rough edges, stubborn dross clinging to the bottom, or unsightly striations running down the cut face. What's going wrong?

The truth is, even perfectly configured laser cut metal operations encounter defects. The difference between a frustrated operator and a skilled professional lies in understanding why these defects occur and how to eliminate them systematically. According to Halden's quality control documentation, common laser cutting defects like burrs, dross, and burn marks can compromise product quality, but identifying root causes and implementing proper solutions ensures smoother cuts and consistent results.

Let's define dross clearly before diving deeper: it's the resolidified molten metal that adheres to the bottom edge of your cut. Unlike burrs, which form on the top surface, dross accumulates where gravity pulls the melt downward. Both defects share similar causes but require different corrective approaches.

Identifying and Preventing Dross Formation

Dross is perhaps the most frustrating defect because it transforms a quick laser cutting operation into a labor-intensive cleanup job. When you see globules of hardened metal clinging to the underside of your parts, you're witnessing a failure of melt ejection efficiency. The laser melted the steel correctly, but the molten material wasn't expelled fast enough before it resolidified.

What causes dross formation? The answer lies in the delicate balance between energy input and material removal. According to ADHMT's troubleshooting guide, cut quality relies on equilibrium between energy coupling (how efficiently the laser energy is absorbed) and melt ejection efficiency (how effectively the assist gas clears molten material).

Primary Causes of Dross:

- Cutting speed too fast: The metal cutter moves before assist gas can fully expel molten material, leaving residue that hardens on the bottom edge

- Insufficient gas pressure: Low-velocity gas flow fails to blast away melt quickly enough, allowing adhesion before complete ejection

- Improper focus position: A focus point set too high or too low creates a wider melt pool that's harder to clear efficiently

- Excessive laser power: Too much energy creates more molten material than the gas stream can handle

- Contaminated optics: Dirty lenses scatter the beam, reducing energy density at the cut zone

Preventing dross requires systematic parameter adjustment. Start by verifying your focus position using a ramp test on scrap material. Then optimize the relationship between cutting speed and gas pressure. For thicker carbon steel, lowering your focal point and increasing gas pressure often eliminates stubborn slag. For stainless steel, try increasing the nozzle diameter and reducing the duty cycle.

Burr Formation and Solutions:

Burrs form when molten material doesn't detach cleanly from the top edge of the kerf. Unlike dross, burrs result primarily from an imbalance in cutting speed and laser power at the entry point of the cut. According to Halden's technical analysis, cutting too slowly causes excessive heating, while high power without corresponding speed adjustments produces rougher finishes.

Effective deburring techniques include mechanical grinding, tumbling, or vibratory finishing. However, prevention is always more cost-effective than remediation. Optimizing your cutting parameters, ensuring proper beam alignment, and maintaining clean optics will minimize burr formation from the start.

Managing Heat-Affected Zones in Sheet Steel

Every laser cut creates a heat-affected zone (HAZ) adjacent to the kerf. Within this zone, the steel's microstructure changes due to thermal exposure. On sheet steel, the HAZ is typically narrow, but improper parameters can expand it significantly, causing issues like discoloration, hardness changes, and susceptibility to cracking during subsequent bending operations.

The HAZ problem becomes particularly evident when parts require post-processing. Anodized surfaces near the cut edge may show discoloration if heat spreads too far. Parts destined for bending may crack along the cut line if the HAZ creates a brittle zone. Understanding these downstream effects helps you prioritize HAZ minimization for sensitive applications.

Factors that expand the HAZ:

- Excessive laser power: More energy means more heat spreading into adjacent material

- Slow cutting speeds: Extended exposure time allows heat to conduct further from the cut zone

- Incorrect focus position: A defocused beam spreads energy over a larger area, increasing thermal input

- Insufficient assist gas flow: Poor cooling allows heat to accumulate and spread

Striations and Surface Quality Issues:

Striations are the visible lines running vertically down the cut face. Some striation is normal and unavoidable, but excessive or irregular striations indicate process instability. Causes include fluctuating gas pressure, inconsistent laser power delivery, or mechanical vibration in the cutting head.

Burn marks present another common surface defect, particularly on reflective or coated materials. These result from excessive heat around the cutting area. Lowering laser power, increasing cutting speed, and using nitrogen assist gas all help reduce thermal effects that cause discoloration.

Troubleshooting Checklist: Defect Type, Causes, and Corrective Actions

- Dross on bottom edge: Likely caused by fast cutting speed, low gas pressure, or improper focus. Corrective actions: reduce speed, increase gas pressure, adjust focus position downward, clean optical components.

- Burrs on top edge: Likely caused by slow cutting speed, excessive laser power, or poor beam focus. Corrective actions: increase speed, reduce power, verify focus alignment, ensure material is properly clamped.

- Excessive striations: Likely caused by gas pressure fluctuations, laser power instability, or mechanical vibration. Corrective actions: check gas supply consistency, inspect laser source performance, tighten mechanical components.

- Wide heat-affected zone: Likely caused by high power, slow speed, or defocused beam. Corrective actions: reduce power, increase speed, optimize focus position, ensure adequate gas cooling.

- Burn marks or discoloration: Likely caused by excessive heat or oxygen reaction. Corrective actions: switch to nitrogen assist gas, reduce power, increase speed, verify proper gas flow.

- Incomplete cuts: Likely caused by insufficient power, excessive speed, or contaminated optics. Corrective actions: increase power, reduce speed, clean lenses and mirrors, verify material thickness.

Remember, troubleshooting is most effective when you change one parameter at a time. Adjusting multiple variables simultaneously makes it impossible to identify which change solved the problem. Document your successful parameter combinations for each material and thickness in a process matrix that your team can reference consistently.

With these defect prevention strategies in your toolkit, the next step is understanding how to optimize cutting parameters for different steel thicknesses and gauge specifications.

Cutting Parameters for Different Steel Thicknesses

You've identified your defects and understand what causes them. Now comes the practical question every operator faces: what power, speed, and focus settings should you actually use for your specific material? This is where many fabricators struggle because parameter guidance is surprisingly scarce across the industry.

The relationship between laser power, cutting speed, and material thickness follows predictable patterns once you understand the underlying principles. According to Raymond Laser's comprehensive speed charts, a direct relationship exists between power and thickness capability. As power increases, so does your maximum cutting thickness. However, the speed at which you can cut varies dramatically based on how you balance these variables.

Power and Speed Relationships for Clean Cuts

Think of laser cutting like cooking. Too much heat too fast burns your food. Too little heat means nothing cooks properly. The same principle applies when your laser metal cutting machine processes sheet steel. Finding that sweet spot where energy input perfectly matches material removal is the key to clean, dross-free edges.

Here's the fundamental rule: thinner materials require faster speeds and can use lower power, while thicker materials demand slower speeds and higher power. But the relationship isn't linear. According to GYC Laser's technical documentation, a 3000W fiber laser can cut 1mm carbon steel at 28-35 meters per minute, but that same machine processing 20mm carbon steel drops to just 0.5 meters per minute.

Key Speed-Power Relationships:

- Thin gauge steel (under 3mm): Maximum speed is achievable; reduce power to prevent burn-through and excessive HAZ

- Medium gauge steel (3-10mm): Balance speed and power; this range offers the most flexibility for parameter adjustment

- Thick gauge steel (over 10mm): Speed becomes the limiting factor; maximum power is typically required

What happens when you push speed too high? The laser doesn't have sufficient dwell time to fully melt through the material, resulting in incomplete cuts or excessive dross on the bottom edge. Push speed too low, and you create an oversized heat-affected zone, potential burn marks, and wasted production time.

For a cutter machine metal operators rely on daily, establishing baseline parameters for common gauge sizes eliminates guesswork. The table below provides starting points based on industry-standard fiber laser configurations:

| Gauge Number | Thickness (mm) | Thickness (inches) | Recommended Power | Typical Speed (m/min) |

|---|---|---|---|---|

| 22 gauge | 0.76 | 0.030 | 1000-1500W | 25-35 |

| 20 gauge | 0.91 | 0.036 | 1000-1500W | 20-30 |

| 18 gauge | 1.27 | 0.050 | 1500-2000W | 15-25 |

| 16 gauge | 1.52 | 0.060 | 1500-2000W | 12-20 |

| 14 gauge steel thickness | 1.98 | 0.078 | 2000-3000W | 8-15 |

| 12 gauge | 2.66 | 0.105 | 2000-3000W | 6-12 |

| 11 gauge steel thickness | 3.04 | 0.120 | 3000-4000W | 5-10 |

| 10 gauge | 3.43 | 0.135 | 3000-4000W | 4-8 |

| 7 gauge | 4.55 | 0.179 | 4000-6000W | 3-6 |

| 3 gauge | 6.07 | 0.239 | 6000-8000W | 2-4 |

This sheet metal gauge chart serves as a starting reference, but your specific machine, steel grade, and assist gas will require fine-tuning. Carbon steel with oxygen assist typically runs 20-30% faster than these values, while stainless steel with nitrogen may require speeds at the lower end of these ranges.

Focus Position Optimization Techniques

If power and speed are the engine of your cutting process, focus position is the steering wheel. Adjusting where the laser beam's focal point sits relative to your material surface dramatically changes cut characteristics. According to FINCM Future's focus guide, the focus position determines how laser energy distributes through the thickness of the plate, affecting cutting width, heat distribution, slag removal, and overall cut quality.

Understanding Focus Position Options:

- Zero focus (on surface): The focal point sits exactly at the material surface. Best for thin carbon steel sheets where a small laser spot provides high-precision cuts with smooth edges and fast cutting speeds.

- Positive focus (above surface): The focal point is positioned above the material. Widely used for medium-thickness carbon steel with oxygen cutting, concentrating energy near the surface for bright, clean cuts with excellent verticality.

- Negative focus (below surface): The focal point is positioned inside the material. Ideal for thick carbon steel plates, allowing deeper penetration and faster melting. This technique can boost cutting speeds by 40-100% compared to traditional positive focus methods.

Sounds complex? Here's the practical application: when cutting gauge sizes from your sheet metal gauge chart, start with zero focus for anything under 3mm. For 14 gauge steel thickness and similar mid-range materials, experiment with slight positive focus adjustments. Once you move into heavier plate beyond 11 gauge steel thickness, negative focus becomes increasingly valuable for maintaining production speed.

Focus Adjustment Best Practices:

Proper focus calibration requires systematic testing. Run a ramp test by cutting a diagonal line across a slightly angled workpiece. The point where the cut is narrowest and cleanest indicates your optimal focus position for that material and thickness combination.

For manufacturers seeking consistent results across different gauge sizes, document your focus settings alongside power and speed parameters. This creates a comprehensive reference that eliminates trial-and-error when switching between jobs. The combination of proper focus position, appropriate power levels, and optimized cutting speeds forms the foundation of reliable, high-quality laser cutting operations.

With your cutting parameters optimized for different steel thicknesses, it's worth understanding how laser cutting compares to alternative technologies when project requirements or budget constraints come into play.

Laser Cutting vs Alternative Steel Cutting Methods

You've mastered laser cutting parameters, but here's a question worth asking: is laser always the right choice for your project? The honest answer is no. While laser technology delivers unmatched precision for thin sheet steel, alternative metal cutting machine technologies sometimes offer better value depending on your material thickness, production volume, and quality requirements.

Understanding when to choose laser over plasma, waterjet, or mechanical shearing can save you thousands in operating costs and help you bid projects more competitively. According to Wurth Machinery's comprehensive testing, many successful shops eventually incorporate multiple cutting technologies to cover more ground. Let's examine where each method excels.

Laser vs Plasma for Sheet Steel Projects

The laser versus plasma debate often comes down to a simple question: how thick is your material? For sheet steel under 1/4 inch, laser cutting dominates. Once you cross into thicker plate territory, the equation shifts dramatically in plasma's favor.

Plasma cutting uses an electrical arc and compressed gas to melt and blast through conductive metals. The plasma arc reaches temperatures up to 45,000°F, instantly melting material along the programmed path. According to StarLab CNC's 2025 guide, a high-powered plasma system can cut 1/2" mild steel at speeds exceeding 100 inches per minute, making it the fastest option for medium to thick metal plates.

Where Laser Cutting Wins:

- Precision requirements: Laser achieves tolerances of ±0.002" compared to plasma's ±0.015-0.020"

- Edge quality: Near-polished finishes often require no secondary processing

- Complex geometries: Intricate patterns, small holes, and fine details that plasma simply cannot replicate

- Thin materials: Sheets under 1/4" cut faster and cleaner with laser technology

Where Plasma Cutting Wins:

- Thick materials: Steel plates from 1/2" to 2"+ cut significantly faster with plasma

- Initial investment: A complete industrial laser cutting machine costs significantly more than comparable plasma systems

- Operating costs: Lower consumable costs and simpler maintenance requirements

- Bevel cutting: Superior capability for weld preparation on structural steel

The cost difference deserves attention. According to StarLab CNC's cost analysis, a complete plasma system costs around $90,000 while a similar-sized waterjet system runs about $195,000. Laser systems with comparable cutting bed sizes can exceed both, though the gap is narrowing as fiber laser technology matures.

When Waterjet or Shearing Makes More Sense

Waterjet cutting uses high-pressure water mixed with abrasive particles to erode material along a programmed path. Operating at pressures up to 90,000 PSI, waterjet systems cut virtually any material without generating heat. This cold-cutting process means no warping, no hardening, and no heat-affected zones.

Why would you choose waterjet over laser for steel? The answer lies in thermal sensitivity. When you're cutting parts that will undergo critical post-processing, such as precision bending or joining operations similar to those compared in mig vs tig welding debates, eliminating heat distortion becomes paramount. Waterjet delivers this capability at the cost of slower cutting speeds.

Mechanical shearing offers yet another alternative for simple straight cuts. A die cut machine or hydraulic shear processes sheet steel faster than any thermal method when geometry permits. The tradeoff? You're limited to straight lines and basic shapes. For high-volume production of rectangular blanks or strips, shearing remains the most economical cutting metal machine option.

The waterjet market is growing quickly, projected to reach over $2.39 billion by 2034 according to Wurth Machinery's market analysis. This growth reflects increasing demand for heat-free cutting in aerospace, medical, and precision manufacturing applications.

| Technology Type | Precision Level | Thickness Range | Edge Quality | Operating Costs | Best Applications |

|---|---|---|---|---|---|

| Laser Cutting | ±0.002" (excellent) | Up to 1" (optimal under 1/4") | Near-polished, minimal finishing needed | Moderate (fiber) to High (CO2) | Thin sheets, intricate designs, precision parts |

| Plasma Cutting | ±0.015-0.020" | 0.018" to 2"+ (optimal 1/2"+) | Good with HD plasma, may need finishing | Low | Structural steel, heavy equipment, thick plates |

| Waterjet Cutting | ±0.003-0.005" | Up to 12" (any material) | Good, no heat distortion | High (abrasive consumption) | Heat-sensitive parts, mixed materials, aerospace |

| Mechanical Shearing | ±0.005-0.010" | Up to 1/2" (typical) | Clean on thin stock, may deform edges | Very Low | Straight cuts, rectangular blanks, high volume |

Making the Right Technology Decision:

When evaluating which technology fits your shop, consider these factors:

- Typical material thickness: If 80% of your work involves sheet steel under 1/4", laser provides the best value. Heavy plate fabricators benefit more from plasma.

- Precision requirements: Parts requiring tight tolerances or complex geometry demand laser or waterjet capabilities.

- Post-processing needs: When subsequent operations like tig vs mig welding require oxide-free edges, nitrogen-assisted laser or waterjet cutting eliminates grinding time.

- Production volume: High-volume simple shapes may justify dedicated shearing equipment alongside your laser.

- Material variety: Shops handling non-metals alongside steel benefit from waterjet's universal material compatibility.

The reality is that most growing fabrication shops eventually adopt multiple technologies. Plasma and laser often pair well, covering thin precision work through heavy structural steel. Adding waterjet extends your capabilities to virtually any material without thermal effects. Understanding these complementary relationships helps you plan equipment investments that grow with your business.

Now that you understand how laser cutting compares to alternative technologies, let's explore the design guidelines and material preparation requirements that ensure your laser cutting projects succeed from the start.

Design Guidelines and Material Preparation Requirements

You've selected your laser type, optimized your cutting parameters, and understand how different steel grades behave. But here's what separates amateur operations from professional sheet metal fabrication: getting the design and material preparation right before the laser ever fires. Poor design decisions or inadequate material prep will sabotage even the most perfectly tuned laser sheet metal cutter.

The reality? Most cutting defects and production delays trace back to upstream problems. According to Xometry's design guide, maintaining minimum feature-to-feature distances ensures the integrity of every cut. Skip these guidelines, and you'll spend hours reworking parts that should have been right the first time.

Design Rules for Laser-Cut Steel Parts

Imagine designing a beautiful part in CAD software, only to discover it's impossible to manufacture without distortion or excessive scrap. This happens constantly when designers ignore the physical realities of how a sheet metal cutting machine interacts with material. The laser beam has a finite width (kerf), heat spreads beyond the cut zone, and thin features can warp or tear during processing.

Minimum Feature Guidelines:

Every metal sheet has practical limits on how close features can be placed without compromising structural integrity. According to Xometry's technical specifications, these are the critical minimums for reliable laser cut sheet metal results:

- Minimum hole-to-edge distance: 2× material thickness (MT) or 0.125", whichever is smaller. Placing holes closer risks tearing or deformation, especially if the part later undergoes forming.

- Minimum hole-to-hole distance: 6× MT or 0.125", whichever is smaller. Tighter spacing creates weak bridges between features that may distort under thermal stress.

- Minimum relief cuts: 0.010" or 1× MT, whichever is greater. Relief cuts prevent material tearing at corners during subsequent bending operations.

- Minimum corner fillets: 0.5× MT or 0.125", whichever is smaller. Sharp internal corners concentrate stress and increase cracking risk.

- Minimum tab thickness: 0.063" or 1× MT, whichever is greater. Tabs hold nested parts in place during cutting; too thin and they'll break prematurely.

- Minimum slot thickness: 0.040" or 1× MT, whichever is greater. Narrow slots may close up due to thermal expansion during cutting.

Tab Placement for Nested Parts:

When you're cutting multiple parts from a single metal plate, tab placement becomes critical. Tabs are small bridges of material that hold parts in place until cutting completes. Poor tab placement causes parts to shift mid-cut, ruining both the moving piece and everything around it.

Think of nesting as the Tetris of fabrication, according to MakerVerse's DFM documentation. The goal is fitting disparate parts within a single sheet with maximum efficiency. Beyond saving material, optimal nesting reduces processing time and energy. When nesting, consider potential assembly and the sequence of operations to minimize movement and handling.

Place tabs strategically:

- Position tabs on straight edges rather than curves for easier removal

- Use at least two tabs per part to prevent rotation

- Space tabs evenly around the perimeter for balanced support

- Avoid placing tabs at locations that will require critical dimensions after removal

Text and Special Features:

Adding text to your design? Make sure to "explode" or convert text to outlines before sending files to the laser. According to Xometry's file preparation guide, active text may be visible on screen but not actually outlined for cutting. Additionally, closed-loop characters like D, O, P, and Q need stencil-style bridges to prevent the center sections from falling out.

For slots and notches, design features to their actual intended width, even if that matches the kerf thickness. Adding "lollipop" rounds on at least one end of slots helps compensate for the pierce hole, which is typically larger than the cutting kerf.

Material Preparation Best Practices

Your design is perfect. Now the question becomes: is your material ready for cutting? Surface condition, flatness, and cleanliness directly impact cut quality, edge finish, and even equipment longevity. Skipping preparation steps creates problems that no amount of parameter adjustment can solve.

Surface Preparation Checklist:

- Rust removal: Surface rust scatters the laser beam, reducing cutting efficiency and creating inconsistent edges. Wire brush, sandblast, or chemically treat rusted areas before loading material.

- Oil and contaminant removal: Cutting oils, fingerprints, and protective coatings can interfere with laser absorption or create hazardous fumes. Clean aluminum sheet metal and steel surfaces with appropriate solvents.

- Mill scale evaluation: Heavy mill scale on hot-rolled steel affects laser absorption. Light scale may be acceptable; heavy scale requires grinding or pickling for best results.

- Protective film handling: Some materials ship with protective plastic film. Decide whether to cut through it (adds processing complexity) or remove it (exposes surface to handling marks).

Flatness Requirements:

Laser cutting demands flat material. The focus distance between the cutting head and workpiece is typically measured in fractions of a millimeter. Warped, bowed, or wavy material throws off this critical dimension, causing inconsistent cuts, excessive dross, or even head crashes.

According to MakerVerse's best practices guide, spacing cutting geometry at least two times the sheet thickness helps avoid distortion during processing. But starting with flat material is equally important. Check incoming stock for warpage and either flatten mechanically or reject sheets that exceed acceptable tolerances.

For shops handling steel plates regularly, investing in a leveling machine pays dividends in reduced scrap and improved cut quality. Even minor waviness that seems acceptable to the eye can create significant focus variations across a large cutting bed.

Standard Gauge Selection:

Designing around standard material gauges prevents sourcing delays and reduces costs. According to Xometry's material guidelines, sheet cutting depends on stock material sizes to provide economical and quick-turn parts. If your design thickness falls within the tolerance range of a standard gauge, fabricators will source that standard gauge for the project.

Specifying non-standard thicknesses triggers material sourcing delays and premium pricing. Unless your application specifically requires a unique thickness, design around common gauge sizes documented in standard sheet metal gauge charts.

The DFM Advantage:

Proper Design for Manufacturing (DFM) support transforms good designs into great parts. When engineers consult with fabricators during the design phase, they catch manufacturability issues before they become expensive rework or scrap. This collaboration addresses everything from feature spacing to material selection to process sequencing.

For automotive applications where precision and consistency are non-negotiable, comprehensive DFM support becomes especially valuable. Working with manufacturers who offer rapid feedback on design feasibility, like Shaoyi (Ningbo) Metal Technology with their 12-hour quote turnaround, helps optimize laser cutting designs before committing to production. Their approach combines DFM expertise with IATF 16949-certified quality systems, ensuring that chassis, suspension, and structural components meet automotive industry standards from the first prototype through mass production.

The investment in upfront DFM review consistently pays for itself through reduced material waste, faster production cycles, and parts that fit correctly the first time. Whether you're cutting simple brackets or complex assemblies, following these design guidelines and preparation requirements sets the foundation for successful laser cutting operations.

With your designs optimized and materials properly prepared, let's explore how different industries leverage laser-cut sheet steel for their specific manufacturing applications.

Industrial Applications for Laser-Cut Sheet Steel

Now that you understand how to design and prepare materials for laser cutting, here's where the technology truly proves its value: real-world manufacturing applications across diverse industries. From the car you drive to the building you work in, laser-cut sheet steel components are everywhere. Each industry leverages this technology differently, adapting cutting parameters, material selections, and finishing processes to meet their unique requirements.

According to Accurl's comprehensive application guide, laser cutting technology has transformed various industries with its precision and versatility, from creating detailed jewelry to manufacturing critical components in aerospace and automotive sectors. The ability to work with stainless steel, carbon steel, and specialty alloys makes laser cutting indispensable for modern steel fabrication operations.

Automotive and Transportation Applications

The automotive industry represents one of the largest consumers of laser-cut sheet steel. Why? Because vehicles demand thousands of precision components that must fit together perfectly while meeting strict safety and performance standards. Traditional mechanical cutting methods result in rapid tool wear, and stamping gradually diminishes cutting quality when processing high-strength steel.

Laser cutting solves these challenges while enabling design flexibility that would be impossible with conventional methods. The technology operates continuously for extended durations and significantly reduces production setup times. By importing graphical patterns directly into CNC systems, steel components can be effortlessly cut without creating multiple diverse molds.

Common Automotive Steel Fabrication Applications:

- Body panels and frame components: Doors, roof panels, trunk lids, and structural elements made from quenched steel, high-strength steel, or galvanized steel

- Chassis structures: Numerous pipes and tubing used to support and connect various chassis components, customized to accommodate different vehicle models

- Suspension parts: Brackets, mounting plates, and control arm components requiring tight tolerances and consistent quality

- Exhaust system components: Exhaust pipes and connectors requiring precise cutting to ensure emissions performance and safety

- Fuel system parts: Pipes and connectors within fuel systems that require precise manufacturing for proper fuel supply

- Cooling system elements: Heat sinks and cooling pipes manufactured for effective heat dissipation

The integration of laser cutting with CNC systems substantially enhances equipment efficiency for steel fabricators serving automotive clients. This technology enables manufacturers to produce components that meet strict tolerance levels while maintaining the structural integrity essential for vehicle safety.

For automotive manufacturers requiring complete component solutions, IATF 16949-certified manufacturers like Shaoyi (Ningbo) Metal Technology combine laser cutting with metal stamping to deliver precision assemblies. Their approach covers everything from 5-day rapid prototyping to automated mass production, ensuring chassis, suspension, and structural components meet the demanding quality standards that automotive supply chains require.

Architectural and Decorative Steel Panels

Walk through any modern commercial building, and you'll encounter laser-cut steel panels in façades, interior partitions, staircase railings, and decorative screens. The construction industry has embraced laser cutting for its ability to produce both functional structural elements and visually striking architectural features.

The technology's ability to cut through thick steel plates while producing precise, clean edges makes it invaluable in construction, according to Accurl's industry overview. Whether it's stainless steel for structural support or decorative elements, laser cutting provides a combination of strength and aesthetic appeal highly sought after in modern architecture.

Architectural and Decorative Applications:

- Building façades: Perforated steel panels that control light, ventilation, and visual privacy while creating distinctive building identities

- Interior partitions: Decorative screens and room dividers with intricate geometric patterns impossible to produce economically with traditional methods

- Staircase components: Stringers, railings, and decorative balusters combining structural requirements with aesthetic considerations

- Custom metal signs: Business signage, wayfinding systems, and artistic installations with precise lettering and logos

- Furniture and fixtures: Tables, shelving, lighting fixtures, and retail displays featuring detailed designs and clean finishes

Many architectural projects require powder coating services after laser cutting to provide durability and color options. The clean edges produced by properly configured laser cutting ensure excellent paint adhesion and consistent finishing results across large panel runs.

Industrial Equipment and Precision Parts

Beyond automotive and architectural applications, laser-cut sheet steel serves countless industrial manufacturing needs. From food processing equipment to agricultural machinery, the precision and repeatability of laser cutting meets demanding specifications across sectors.

Industrial Manufacturing Applications:

- Machinery housings and enclosures: Control cabinets, machine guards, and protective covers requiring precise cutouts for components and ventilation

- Agricultural equipment: Tractor components, harvester parts, and implements subject to harsh working conditions demanding durability and reliability

- Food and beverage equipment: Stainless steel components for processing machinery and packaging systems meeting strict hygiene standards

- Medical device components: Surgical instruments, equipment housings, and implant components requiring exceptional accuracy and biocompatible materials

- Electronics enclosures: Chassis, brackets, and mounting plates for telecommunications, computing, and industrial control systems

- Energy sector components: Parts for wind turbines, solar panel mounting systems, and power generation equipment

The versatility of laser cutting in handling various material thicknesses and types ensures manufacturers can meet the specific requirements of diverse projects, whether involving heavy-duty steel or lighter gauge materials for precision applications.

When searching for metal fabricators near me or fabrication shops near me, look for operations that combine laser cutting capabilities with comprehensive finishing and assembly services. The best metal fabrication near me options offer integrated solutions from design through delivery, reducing supply chain complexity and ensuring consistent quality across all components.

The common thread across all these applications? Laser cutting's ability to deliver precision, repeatability, and design flexibility that traditional cutting methods simply cannot match. Whether you're producing automotive components, architectural panels, or industrial equipment, understanding how to optimize laser cutting sheet steel for your specific application transforms this technology from a manufacturing process into a competitive advantage.

Frequently Asked Questions About Laser Cutting Sheet Steel

1. Can you laser-cut a steel sheet?

Yes, laser cutting is highly effective for steel sheets. Fiber lasers excel at cutting thin to medium gauge steel (up to 20mm) with exceptional precision and speed. CO2 lasers handle thicker steel plates, especially when combined with oxygen assist gas. The process works on carbon steel, stainless steel, and galvanized steel, with each requiring specific parameter adjustments for optimal edge quality and minimal defects.

2. How much does it cost to get steel laser-cut?

Steel laser cutting costs vary based on material thickness, complexity, and volume. Setup fees typically range from $15-30 per job, with labor rates around $60 per hour for additional work beyond standard cutting. Fiber lasers offer lower operating costs than CO2 systems due to higher efficiency (90%+ vs 5-10%), though initial equipment investment is higher. Many fabricators provide instant online quotes based on DXF or STEP file uploads.

3. What grade of steel is used for laser cutting?

Multiple steel grades work well with laser cutting. Carbon steels like A36, 1018, and 1045 cut cleanly with minimal dross. Stainless steel grades including 304 and 316 require nitrogen assist gas for oxide-free edges. Mild steel grades S275, S355, and S355JR are popular choices for structural applications. Each grade requires calibrated parameter sets based on composition and thickness for consistent results.

4. Which material should you never cut in the laser cutter?

Avoid laser cutting materials that release toxic fumes or damage equipment. PVC and vinyl release chlorine gas when cut. Leather containing chromium (VI) produces hazardous compounds. Carbon fiber can ignite and damage optics. While galvanized steel is cuttable with proper ventilation, the zinc coating produces harmful fumes requiring adequate extraction systems and operator protection.

5. What is the difference between fiber and CO2 lasers for cutting steel?

Fiber lasers operate at 1.06 microns wavelength, which steel absorbs efficiently, making them 3-5x faster on thin materials with tighter tolerances. CO2 lasers at 10.6 microns suit thicker plates (10-100mm) and mixed material shops. Fiber lasers offer 90%+ energy efficiency, 25,000+ hour lifespan, and minimal maintenance compared to CO2's 5-10% efficiency and regular mirror alignment needs.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —