Чому виробники обирають важелі підвіски з штампованої сталі

Коротко

Виробники використовують штамповані стальні важелі підвіски, оскільки це найекономніший варіант для масового виробництва. Цей метод дозволяє швидко виготовляти велику кількість продукції з низькою собівартістю одиниці продукції, забезпечуючи достатню міцність і довговічність для більшості стандартних легкових автомобілів. Хоча альтернативи, такі як алюміній або трубчаста сталь, пропонують кращі експлуатаційні характеристики, штампована сталь є раціональним компромісом між вартістю, функціональністю та потребами середнього водія.

Головний чинник: економність та ефективність виробництва

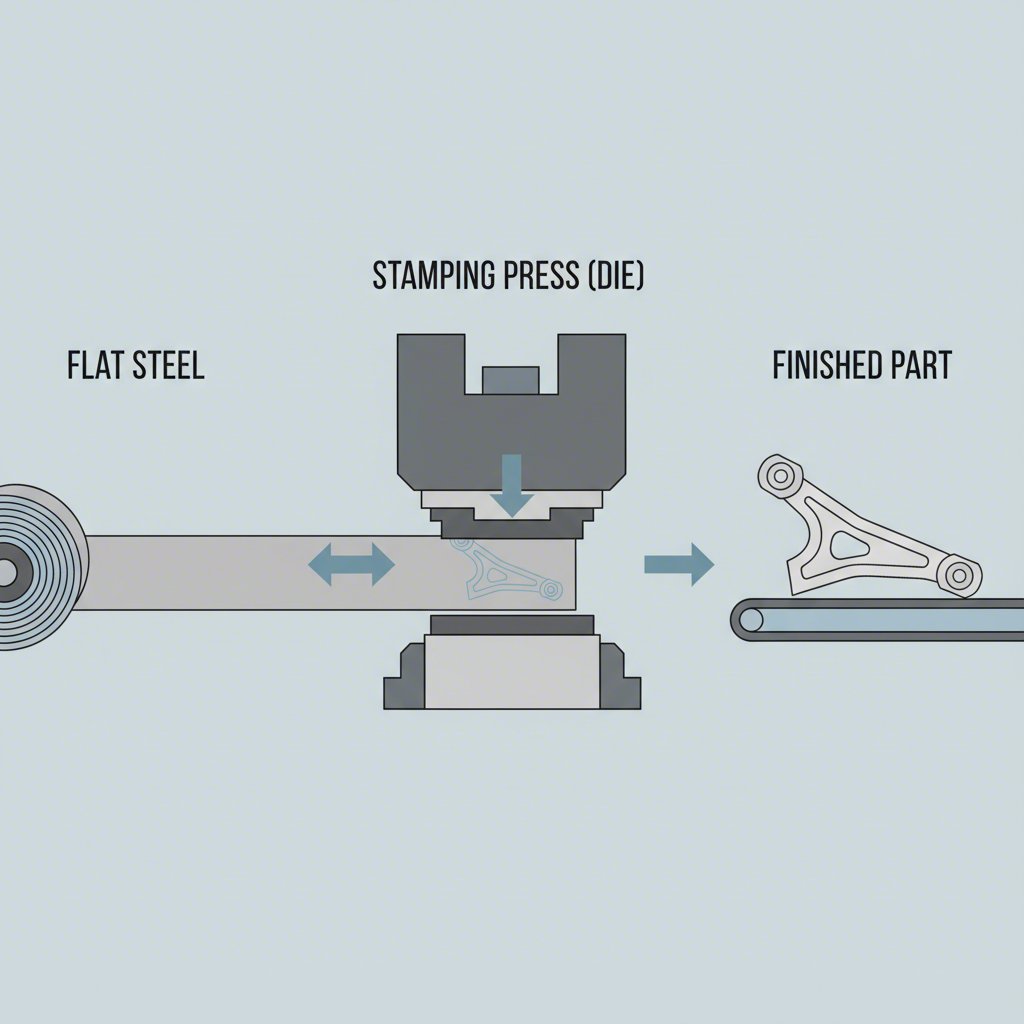

Рішення використовувати штамповану сталь для такого важливого компонента, як важіль підвіски, ґрунтується на економічних принципах сучасного автомобільного виробництва. Важіль підвіски — це життєво важливе з'єднання, що поєднує шасі автомобіля з колісним вузлом, і саме його конструкція безпосередньо впливає на керованість та стабільність. Штамповані стальні важелі виготовляють шляхом пресування сталевих листів у певну форму за допомогою високотискової матриці. Цей процес надзвичайно швидкий, високоточний і майже не утворює відходів, що робить його ідеальним для масштабів світового автомобілебудування.

Порівняно з іншими методами, такими як лиття або штампування алюмінію, штампування сталі є значно дешевшим. Сировина коштує менше, а енергія та час, необхідні для виробництва, — нижчі. Ця економія, помножена на мільйони автомобілів, випущених щороку, суттєво впливає на кінцеву ціну автомобіля. Також це робить запасні частини доступнішими для споживачів, зменшуючи витрати на тривале володіння. Акцент робиться на виготовленні деталей, які, як зазначають експерти підвісок, мають достатню міцність для більшості водіїв, які дотримуються асфальтованих доріг.

Цей виробничий вибір є обґрунтованим компромісом. Хоча штампова сталь і не є найлегшим або найпродуктивнішим варіантом, вона відповідає або перевершує структурні вимоги для повсякденного використання автомобіля. Цей процес забезпечує узгодженість мільйонів деталей, що критично важливо для безпеки транспортних засобів і ефективності конвеєра. Для автовиробників, які прагнуть точності та надійності в цій галузі, незамінними є спеціалізовані фірми. Наприклад, такі компанії, як Shaoyi (Ningbo) Metal Technology Co., Ltd. ілюструють необхідний високотехнологічний підхід, використовуючи сучасні автоматизовані потужності для виготовлення складних штампованих компонентів, які відповідають суворому автомобільному стандарту якості IATF 16949, забезпечуючи економічність і надійність на всіх етапах — від прототипування до масового виробництва.

Детальний аналіз продуктивності: компроміси між міцністю, вагою та довговічністю

Хоча вартість є головним чинником, продуктивність штампованих сталевих важелів підвіски — це історія добре відомих компромісів. Їхня основна перевага полягає у міцності та довговічності за типових навантажень. Сталь є принципово міцним матеріалом, здатним витримувати значні зусилля, що діють на підвіску автомобіля під час прискорення, гальмування та проходження поворотів. Для важких транспортних засобів, таких як вантажівки та позашляховики, або для застосувань, де важлива надійність, здатність сталі витримувати великі навантаження та удари робить її логічним вибором, як зазначено в порівнянні від Metrix Premium Parts .

Однак ця міцність має два істотних недоліки: вагу та схильність до корозії. Сталь значно важча за алюміній, що збільшує «непідтримувану масу» транспортного засобу — вагу всіх компонентів, які не підтримуються пружинами. Більша непідтримувана маса може зробити підвіску менш чутливою до нерівностей дороги, що потенційно призводить до жорсткішого ходу й менш точного керування. Для високопродуктивних транспортних засобів, де кожен фунт має значення, ця додаткова вага є серйозним недоліком.

Іншою критичною проблемою є корозія. Як пояснюється в посібнику від GMT Rubber , штамповані стальні важелі схильні до іржавіння, особливо у вологому кліматі або в районах, де взимку посипають дороги сіллю. Іржа з часом може порушити структурну цілісність важеля, що призведе до його можливого виходу з ладу. Хоча виробники наносять захисні покриття, вони можуть бути пошкоджені уламками на дорозі, внаслідок чого відкривається доступ до чистої сталі. Для власників транспортних засобів це означає, що регулярні перевірки на наявність іржі та тріщин є необхідними для довготривалої безпеки.

| Функція | Штамповані стальні поперечні важелі |

|---|---|

| Переваги |

|

| Недоліки |

|

Штампована сталь проти альтернатив: порівняльний аналіз

Щоб зрозуміти, чому штампова сталь є такою поширеною, потрібно порівняти її безпосередньо з популярними альтернативами: литим алюмінієм та трубчастою стальню. Кожен матеріал обирають для досягнення певних інженерних цілей, незалежно від того, чи йдеться про сімейний седан, розкішний позашляховик чи класичний масловий автомобіль. Вибір ніколи не є довільним і завжди передбачає балансування між вартістю, вагою та експлуатаційними характеристиками.

Ричаги з литого алюмінію є популярною модернізацією і часто стандартно встановлюються на розкішних і спортивних автомобілях. Основна перевага алюмінію — його низька вага, що значно зменшує непідвішenu масу. Це призводить до більш чутливої підвіски, покращеної якості їзди та кращої керованості. Алюміній також природно стійкий до корозії. Однак його виробництво коштує дорожче, і він може бути схильнішим до тріщин або поломок при надзвичайних раптових ударах у порівнянні зі схильністю сталі спочатку гнутися.

Трубчасті сталеві важелі є поширеним тюнінгом, особливо для класичних автомобілів і гоночних застосувань. Як зазначено виробником спортивних деталей QA1 , трубчасті важелі виготовлені з високоміцної сталевої труби, яка має значно краще співвідношення міцності до ваги, ніж штамповане металеве. Вони значно легші та жорсткіші, а їхня конструкція дозволяє оптимізувати геометрію підвіски, наприклад, збільшений кастер для покращеної стійкості на високих швидкостях. Хоча вони міцніші й легші, ніж штамповані сталеві, їх виготовлення набагато дорожче, через що вони непридатні для масового виробництва автомобілів.

| Функція | Штампованальна сталь | Литий алуміній | Трубчата сталь |

|---|---|---|---|

| Виробнича вартість | Низький | Середній-Високий | Високих |

| Поширене застосування в транспортних засобах | Стандартні легкові автомобілі, базові моделі вантажівок | Люксові автомобілі, спортивні автомобілі, позашляховики | Спортивні/гоночні автомобілі, оновлення для класичних автомобілів |

| Вага | Важке | Світло | Легкі-середні |

| Міцність | Добре | Дуже добре | Чудово |

| Стійкість до корозії | Погана (потребує покриття) | Чудово | Погана (потребує покриття) |

| Ідеальний випадок використання | Економічне щоденне використання | Покращений комфорт їзди та керування | Максимальна продуктивність і регульованість |

Поширені запитання щодо матеріалів важелів підвіски

1. Який найкращий матеріал для важелів підвіски?

Немає єдиного «найкращого» матеріалу для всіх важелів підвіски; ідеальний вибір повністю залежить від призначення транспортного засобу та пріоритетів водія. Для більшості автомобілів, що використовуються у повсякденній експлуатації, штампова сталь є найкращим варіантом, оскільки забезпечує необхідну міцність за найнижчою вартістю. Для автомобілів класу люкс або спортивних моделей, де пріоритетними є комфорт ходи та керованість, часто кращим є легкий литий алюміній. Для спеціалізованих автомобілів для треку або реставрації класичних авто з метою досягнення максимальної продуктивності, трубчаста сталь пропонує найкраще поєднання міцності, малої ваги та геометричної точності.

Малі партії, високі стандарти. Наша послуга швидкого прототипування робить перевірку швидшою та простішою —

Малі партії, високі стандарти. Наша послуга швидкого прототипування робить перевірку швидшою та простішою —