Контрольний список постачальника для швидкого прототипування в автосфері

Контрольний список постачальника для швидкого прототипування в автосфері

Коротко

Вичерпний контрольний список постачальника для швидкого прототипування в автомобільній галузі має ретельно оцінювати чотири ключові аспекти: технічні можливості, експертні знання в галузі матеріалів, системи контролю якості та аналіз проектування з урахуванням технологічності (DFM). Вибір партнера з перевіреним досвідом роботи в автомобільній галузі є критично важливим для забезпечення відповідності галузевим стандартам, управління складними геометріями та успішного масштабування від окремого прототипу до якості, придатної для виробництва.

Базові критерії перевірки: технічні можливості та матеріали

Перший крок у оцінці потенційного постачальника швидкого прототипування — це ретельна оцінка їхніх базових можливостей. Це більше, ніж просто перелік обладнання; тут важливо зрозуміти, чи можуть їхні технології та наявні матеріали відповідати суворим вимогам автомобільної промисловості. Технічна кваліфікація постачальника безпосередньо впливає на точність, міцність і функціональну продуктивність ваших прототипів, що є важливим для ефективного підтвердження та тестування.

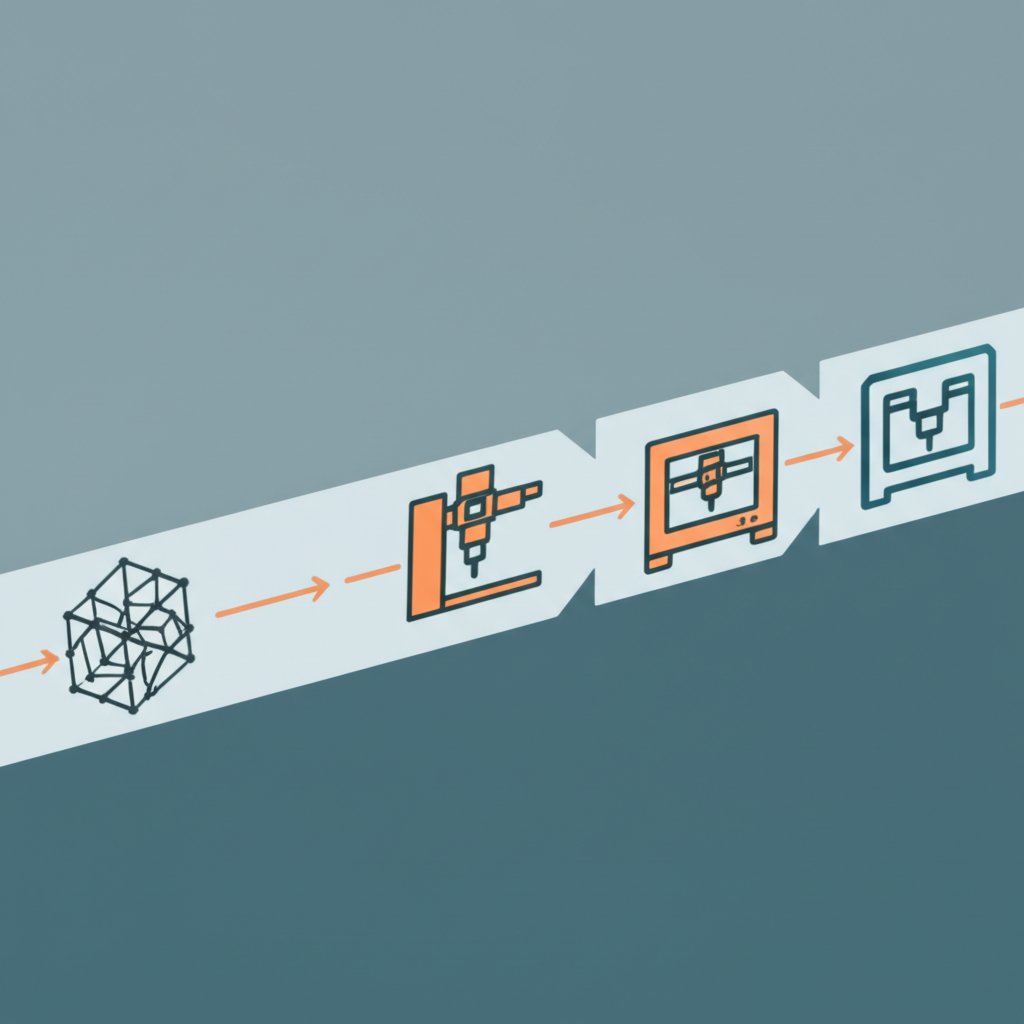

Кваліфікований партнер має пропонувати різноманітний спектр технологій прототипування. Це гарантує, що вони зможуть порекомендувати найоптимальніший процес саме для ваших потреб, а не притягувати ваш проект до меж своїх обмежених можливостей. Згідно з посібником від Uidearp , ключовими технологіями, на які варто звернути увагу, є CNC-обробка для виготовлення високоточних деталей із металу та пластику та різні методи 3D-друку, такі як стереолітографія (SLA) для дрібних деталей, селективне лазерне спікання (SLS) для міцних функціональних деталей та послідовне осадження матеріалу (FDM) для концептів на ранніх етапах. Кожна технологія має свої переваги щодо швидкості, вартості, властивостей матеріалів і точності, тому постачальник із кількома варіантами може запропонувати більш індивідуальне рішення.

Не менш важливим є вибір матеріалів та експертність постачальника. У сфері автомобілебудування використовується широкий спектр матеріалів — від пластмас промислового призначення до спеціальних металевих сплавів. У вашого обраного постачальника мають бути доступні ці матеріали, а також необхідна експертність, щоб порадити найкращий варіант для вашого застосування, враховуючи такі фактори, як міцність на розрив, стійкість до високих температур та вага. Для проектів, спрямованих на зменшення ваги та забезпечення структурної цілісності, співпраця зі спеціалістом може бути надзвичайно цінною. Наприклад, коли ваш проект вимагає прецизійних інженерних компонентів, варто розглянути індивідуальні алюмінієві профілі від перевіреного партнера, такого як Shaoyi Metal Technology , який пропонує комплексний сервіс — від створення прототипів до виробництва — в межах суворої системи якості, сертифікованої за IATF 16949.

Забезпечення якості та можливості виробництва: етапи DFM та контролю якості

Поза фізичним створенням деталі, постачальник високого рівня додає цінність, забезпечуючи оптимізацію конструкції для виробництва та відповідність жорстким стандартам якості. Саме тут критерії проектування з урахуванням технологічності (DFM) та надійний процес контролю якості (QC) стають обов’язковими. Недбалість до цих аспектів може призвести до прототипів, які неможливо економічно серійно виробляти, або до деталей, що виходять з ладу під час реальних випробувань, що спричиняє значні затримки та перевитрати.

Проектування з урахуванням технологічності (DFM) — це критичний аналіз на ранній стадії, під час якого постачальник перевіряє ваш дизайн на наявність потенційних виробничих труднощів. Як зазначено в контрольному списку прототипування від HLH Sheet Metal , впровадження рекомендацій DFM з самого початку може запобігти виникненню проблем, таких як тріщини, зміщення розмірів або надмірна складність, що збільшує витрати. Проактивний постачальник надасть звіт DFM, у якому запропонує зміни для поліпшення технологічності, наприклад, коригування товщини стінок, оптимізацію кутів випуску або спрощення геометрії без погіршення функціональності. Такий цикл співпраці є ознакою справжнього виробничого партнера, а не просто сервісного підрозділу.

Структурований процес контролю якості (КЯ) забезпечує необхідну перевірку того, що деталі відповідають вашим точним специфікаціям. Ця система повинна включати кілька контрольних точок або етапів на протязі всього виробничого процесу. Основні елементи контролю якості включають сертифікацію вхідних матеріалів для підтвердження марок сплавів або полімерів, перевірки в процесі для своєчасного виявлення відхилень та остаточну розмірну та функціональну перевірку перед відправленням. Для автомобільних застосувань цей процес має бути докладно задокументованим, щоб забезпечити відстежуваність та відповідність галузевим стандартам.

Відповідність вимогам автомобільної галузі та готовність до виробництва

Автомобільна промисловість працює в умовах одних із найсуворіших стандартів якості та відповідності в галузі виробництва. Звичайний цех для створення прототипів може не мати достатнього досвіду або сертифікацій, необхідних для виконання таких вимог. Тому надзвичайно важливо оцінити конкретний досвід постачальника в автомобільній галузі та його готовність перейти від окремого прототипу до процесу, придатного для виробництва, наприклад, до Процесу затвердження деталей виробництва (PPAP).

Знайомство постачальника з вимогами автомобільної галузі є значною перевагою. Досвідчені партнери розуміють необхідність точних допусків, відстежуваності матеріалів та обсяжної документації, яку вимагають автовиробники (OEM). Згідно з оглядом контрольних списків виробництва від Фалконі , контрольний список аудиту постачальника є ключовою процедурою для мінімізації ризиків у ланці постачання та підтримання стандартів якості. Дізнайтеся про їхній досвід роботи з автотранспортними клієнтами та розуміння стандартів, таких як IATF 16949, який регулює системи управління якістю для постачальників автомобільної галузі. Такий досвід гарантує, що вони говорять однією мовою з вами та передбачають сувору валідацію, необхідну для компонентів, що використовуються у транспортних засобах.

Крім того, враховуйте здатність постачальника підтримувати весь життєвий цикл вашого проекту. Хоча поточна потреба — це прототип, кінцевою метою часто є виробництво невеликими партіями або масове виробництво. Постачальник, який може подолати цей розрив, пропонує величезну цінність. Вони можуть використовувати етап прототипування для удосконалення оснащення, оптимізації виробничих процесів і підготовки необхідної документації для безперебійного переходу. Це передбачення запобігає дорогому та трудомісткому процесу пошуку нового партнера з виробництва та повторної валідації, коли настає час масштабування.

Повний контрольний список постачальників автомобільних прототипів

Щоб систематично оцінити та вибрати правильного партнера, скористайтеся цим комплексним контрольним списком. Він уніфікує ключові критерії у вигляді практичних запитань, що допомагає провести ретельну та послідовну оцінку кожного потенційного постачальника.

| Критерій оцінки | Ключові запитання до постачальника | Важливість у автомобільній галузі |

|---|---|---|

| Технічні можливості |

|

Забезпечує, що постачальник зможе виготовити деталі з необхідною точністю, якістю поверхні та механічними властивостями для функціонального тестування. |

| Експертиза з матеріалами |

|

Критично важливо для перевірки продуктивності в реальних умовах, таких як висока температура, вібрація та хімічний вплив. |

| Проектування для виробництва (DFM) |

|

Зменшує витрати на виробництво, скорочує терміни виконання замовлення та запобігає дорогим помилкам у конструкції до виготовлення інструменту. |

| Контроль якості та інспекція |

|

Гарантує, що деталі відповідають суворим розмірним і функціональним вимогам, забезпечуючи безпеку та надійність. |

| Досвід у автомобільній галузі |

|

Вказує на розуміння галузевих високих стандартів щодо документування, відстежуваності та якості. |

| Управління проектами та підтримка |

|

Забезпечує чітку комунікацію, оперативність та гнучкість, що є життєво важливим для швидкісних циклів розробки. |

| Масштабування для виробництва |

|

Партнер, який може масштабувати, економить час і ресурси, усуваючи необхідність пошуку та атестації нового постачальника для виробництва. |

Прийняття остаточного рішення щодо постачальника

Вибір постачальника швидкого прототипування для автомобільного проекту — це стратегічне рішення, яке впливає на весь життєвий цикл вашого продукту. Хоча технічні специфікації є основою, правильний партнер також надає цінний досвід у забезпеченні можливості виробництва, контролю якості та відповідності галузевим вимогам. Використовуючи структурований контрольний список для оцінки, ви зможете вийти за межі простого порівняння пропозицій і натомість оцінити здатність постачальника діяти як справжнє продовження вашої інженерної команди. Такий методичний підхід гарантує вибір партнера, який не лише швидко постачає деталі високої якості, але й сприяє більш плавному та економічно ефективному шляху до виробництва.

Поширені запитання

1. Який прийнятний час виготовлення автомобільного прототипу?

Час виконання може значно варіюватися залежно від складності деталі, обраної технології та наявності матеріалів. Для багатьох процесів 3D-друку постачальники часто можуть доставити деталі протягом 2–7 днів. Однак для складніших деталей, виготовлених методом фрезерування з ЧПУ, або тих, що потребують певної додаткової обробки, термін виготовлення може бути довшим. Завжди уточнюйте строки в постачальника заздалегідь.

2. Як можна перевірити досвід постачальника в галузі?

Найефективнішим способом перевірки досвіду є запит конкретних кейсів або прикладів попередніх проектів у сфері автомобілебудування. Ви також можете поцікавитися їхніми сертифікатами, наприклад IATF 16949, який стосується системи управління якістю в автомобільній галузі. Нарешті, запит відгуків клієнтів або контактів для звернення надасть пряме уявлення про їхню репутацію та надійність.

3. У чому різниця між прототипом і деталлю, готовою до виробництва?

Прототип використовується переважно для перевірки форми, посадки та функціональності, і він може бути виготовлений за допомогою процесів або матеріалів, відмінних від тих, що використовуватимуться у кінцевому продукті. Деталь, готова до виробництва, як визначено в процесі запровадження нового продукту (NPI), виготовляється з використанням точних матеріалів, інструментів та контролю якості, які будуть застосовуватися під час масового виробництва. Мета етапу створення прототипу — вдосконалення конструкції до її готовності до цього переходу.

Малі партії, високі стандарти. Наша послуга швидкого прототипування робить перевірку швидшою та простішою —

Малі партії, високі стандарти. Наша послуга швидкого прототипування робить перевірку швидшою та простішою —