Досягнення ідеального покриття: дробоструйне очищення виливків

Коротко

Дробоструменна обробка — це механічна обробка поверхні, необхідна для остаточної обробки виливків, отриманих литтям під тиском. Вона полягає у метанні абразивного матеріалу на високій швидкості для ретельного очищення забруднень, видалення заусенців та литникових систем і створення дрібнотекстурованої поверхні. Цей процес має важливе значення для покращення адгезії подальших покриттів, таких як фарба чи порошкове покриття, а також для підготовки компонентів до прецизійної механообробки.

Що таке дробоструменна обробка і навіщо її використовують для деталей, виготовлених литтям під тиском?

Дробоструменева обробка — це контрольований механічний процес, який використовується для очищення, зміцнення та підготовки поверхонь металевих компонентів. У контексті лиття під тиском це передбачає обстріл деталі потоком дрібних абразивних частинок, відомих як дроб або оброблювальний матеріал. Ці частинки рухаються з високою швидкістю та вдаряються об поверхню, усуваючи дефекти й утворюючи рівномірну структуру. На відміну від хімічних методів очищення, дробоструменева обробка фізично очищає поверхню, що робить її надзвичайно ефективною для видалення стійких забруднень, які залишаються після процесу лиття.

Основна мета дробострумення литих під тиском деталей — підготовка поверхні. Процес лиття під тиском, хоча й є точним, може залишати небажані елементи, такі як заусенці (тонкий надлишковий матеріал на лінії роз'єднання форми), задири та оксидні шари. Дробострумення ефективно усуває ці дефекти, забезпечуючи відповідність деталі заданим розмірам і естетичним вимогам. Ця очищувальна дія є важливим підготовчим етапом перед подальшою обробкою.

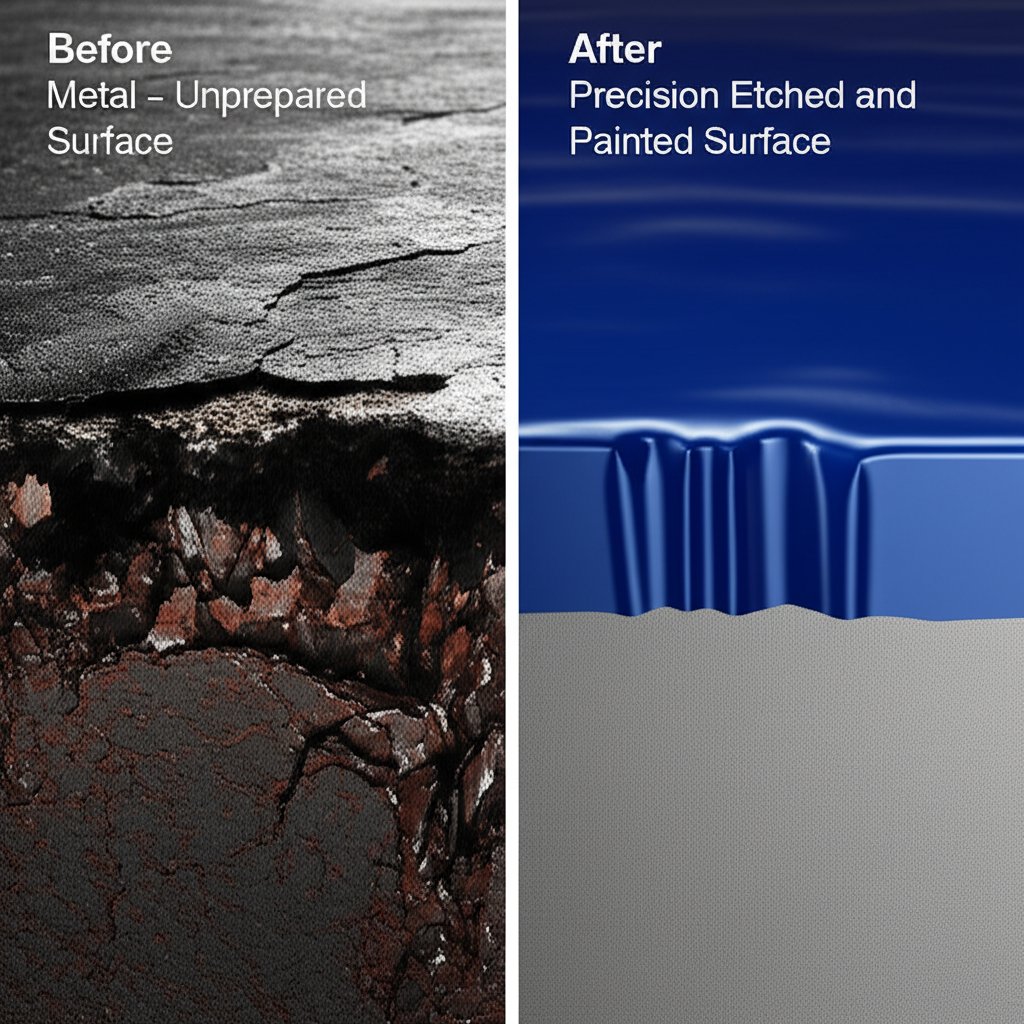

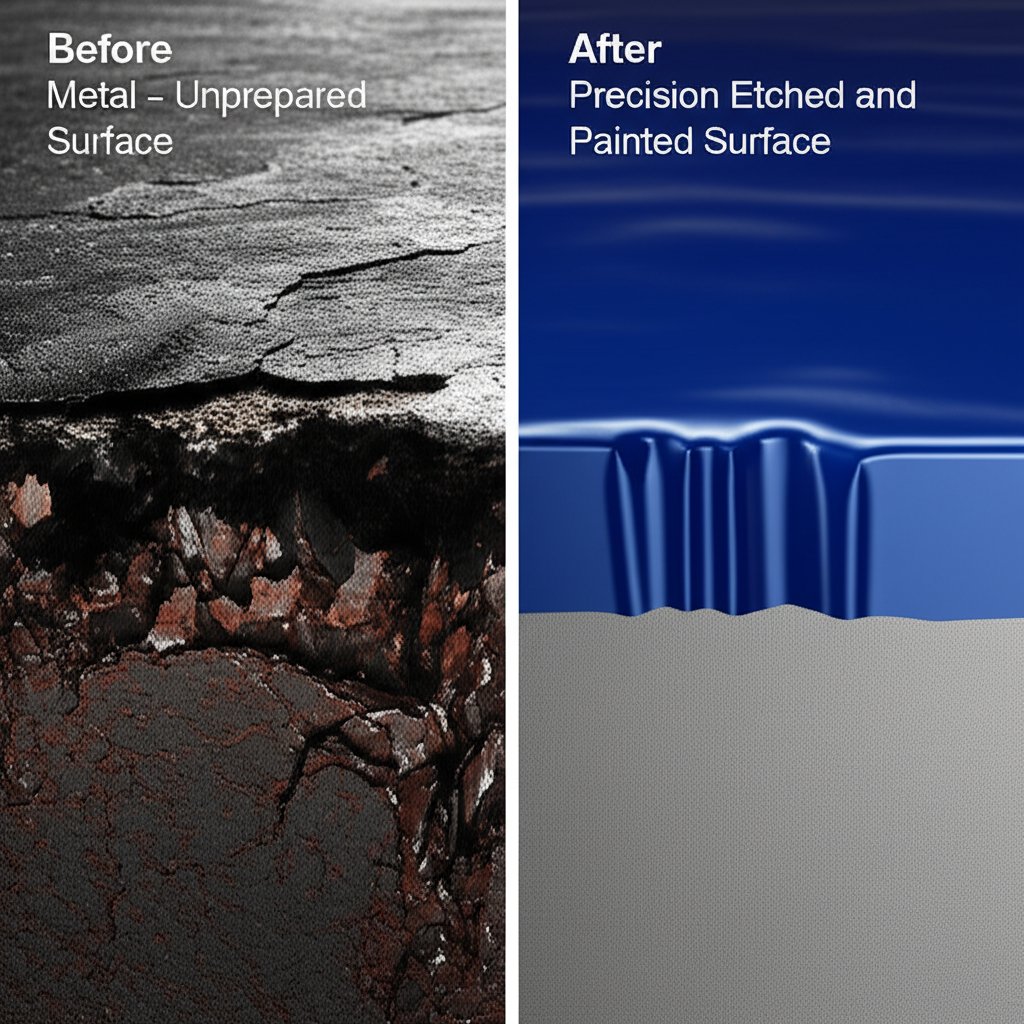

Крім того, процес кардинально змінює топографію поверхні компонента. Вплив абразивного матеріалу створює мікропрофіль — сукупність мікроскопічних піків і западин — на металевій поверхні. Ця текстурована, або «травлена», поверхня забезпечує відмінне зчеплення для фарб, порошкових покриттів та інших гальванопокриттів, значно покращуючи адгезію та запобігаючи відшаруванню чи відлущуванню. Чиста, належним чином текстурована поверхня також ідеально підходить для подальшої механічної обробки, оскільки може допомогти зменшити знос інструменту та покращити загальну ефективність і точність циклу обробки.

Основні переваги дробоструменної обробки в операціях гарячого пресування

Впровадження дробоструменної обробки в процес гарячого пресування забезпечує кілька суттєвих експлуатаційних і якісних переваг. Ці переваги призводять до вищої якості кінцевого продукту з покращеною довговічністю та експлуатаційними характеристиками. До основних переваг належать:

- Покращене зчеплення для покриттів: Найважливішою перевагою є створення ідеальної поверхні для нанесення покриття. Отримана рівномірна шорсткість, зазвичай у діапазоні Ra1,6–6,3 мкм, забезпечує міцне прилягання фарби, порошкових покриттів та інших видів обробки, що призводить до довшого терміну служби та більш міцного захисного шару.

- Високоефективне очищення та видалення заусенців: Процес дуже ефективно видаляє забруднення з поверхні, включаючи литникові роз'єми, заусенці та оксидні шари. Це часто усуває необхідність у трудомісткому ручному видаленні заусенців, спрощує виробничий процес і забезпечує однаковість обробки великих партій деталей.

- Покращення механічних властивостей: Дробоструменева обробка може створювати шар стискальних залишкових напружень на поверхні деталі. Цей ефект, відомий як дробоструменеве зміцнення (якщо виконується з цією метою), допомагає усунути концентрації напружень, що виникають під час лиття, і значно підвищує опірність деталі до втоми та твердість.

- Естетична та рівномірна поверхнева обробка: Цей процес надає чистого, рівномірного та структурованого матового або напівглянсового покриття литим під тиском деталям. Це забезпечує постійний і професійний вигляд, який часто є остаточною вимогою для багатьох компонентів.

- Економічна ефективність: Для виробництва великих обсягів дробоструменева обробка є високоефективним і економічно вигідним методом оздоблення. Автоматизовані машини можуть обробляти велику кількість деталей із мінімальним наглядом, знижуючи витрати на робочу силу та збільшуючи продуктивність.

Ця увага до цілісності поверхні має вирішальне значення для високопродуктивних компонентів, особливо в таких вимогливих галузях, як автомобілебудування. Хоча лиття під тиском ґрунтується на дробоструменевій обробці для підготовки поверхні, інші методи виробництва, такі як штампування, також потребують ретельної обробки поверхні, щоб забезпечити надійність. Наприклад, фахівці з штампування для автомобільної промисловості, такі як Shaoyi (Ningbo) Metal Technology , використовують сучасні процеси гарячого штампування та суворий контроль якості для виробництва компонентів, які відповідають найвищим стандартам довговічності.

Процес дробоструменевої обробки: типи абразивного матеріалу та обладнання

Процес дробострумення полягає в розміщенні виливків у спеціальній камері, де турбіни направляють абразивний матеріал на їхні поверхні. Вибір машини та абразиву є критичним і залежить від розміру, геометрії, матеріалу деталі та бажаного типу обробки. Сучасні системи часто мають спеціальні сітки для розділення видалених заусенців від повторно використовуваного дробострумного матеріалу, забезпечуючи ефективність процесу.

Різні машини розроблено для різних виробничих потреб. Для невеликих, міцних деталей, які можна обробляти партіями, дробострумні установки з стрічковим барабаном є поширеними. Ці машини обережно перекочують деталі по неперервній стрічці, забезпечуючи обробку всіх поверхонь струменем дробу. Для більших, складніших або делікатних компонентів, таких як корпуси трансмісій або конструкційні деталі, дробострумні установки з підвісними гвинтами використовуються. У цих системах деталі підвішуються на пристроях, які обертаються під час проходження через дробострумну камеру, захищаючи їх від контакту одна з одною.

Вибір абразивного матеріалу є не менш важливим, оскільки він безпосередньо впливає на остаточну обробку поверхні та інтенсивність очищення. Ідеальний матеріал забезпечує баланс між ефективністю очищення та необхідністю уникнути пошкодження поверхні деталі.

| Тип середовища | Характеристики | Основне застосування для деталей з литих сплавів |

|---|---|---|

| Сталевий гарт | Гострокутний, твердий і агресивний. Забезпечує швидке очищення та глибоке травлення. | Використовується для важких алюмінієвих сплавів з метою агресивного очищення, видалення заусенців і створення грубого профілю для товстих покриттів. |

| Сталевий дріб | Круглий, менш агресивний, ніж гарт. Забезпечує більш гладку поверхню з ефектом дроблення. | Універсальне очищення та обробка поверхні багатьох алюмінієвих деталей, де потрібен менш агресивний профіль. |

| Алюмінієвий дріб | Круглий і відносно м'який. Запобігає потраплянню залізистих домішок. | Засіб, який використовується для остаточної обробки цинкових виливків, ефективно очищає, не пошкоджуючи м’якшу поверхню. |

| Кульки з нержавіючої сталі | Міцні, стійкі до корозії та забезпечують яскраву, чисту поверхню без ферозного забруднення. | Ідеальний варіант для алюмінієвих і цинкових деталей, які потребують високоякісного естетичного покриття. Більш дорогий варіант. |

| Скляні бусини | Дуже дрібний і щадний абразив. Забезпечує м’яку сатинову або матову поверхню. | Використовується для делікатних деталей або як остаточний етап обробки з естетичних міркувань, особливо перед такими процесами, як анодування. |

Рекомендації щодо конкретних матеріалів лиття під тиском: алюміній проти цинку

Оптимальні параметри дробоструменевої обробки мають бути адаптовані до конкретного матеріалу виливка. Алюміній і цинк — два найпоширеніші матеріали у литті під тиском — мають різну твердість і характеристики поверхні, що вимагає різних підходів для досягнення бажаного результату без пошкодження.

Обробка алюмінієвих виливків

Сплави алюмінію є відносно твердими та міцними, що робить їх придатними для ширшого діапазону абразивних матеріалів, включаючи сталевий гарт, сталеві дробинки та кульки з нержавіючої сталі. Основні цілі дробоструменевого оброблення алюмінію — зазвичай видалення литникових систем та заусенців, очищення поверхні та створення рівномірної текстури для фарбування чи порошкового покриття. Вибір абразиву залежить від бажаної шорсткості: гострокутний сталевий гарт створює більш агресивний профіль, придатний для міцного зчеплення покриття, тоді як круглий дроб створює гладшу, більш дроблену поверхню.

Остаточна обробка деталей із цинкових сплавів, виготовлених під тиском

Сплави цинку є м'якшими та щільнішими, ніж алюміній, через що вони більше схильні до пошкодження поверхні при надто інтенсивному дробоструменевому обробленні. Щоб уникнути забруднення поверхні залізовмісними частинками (що може призвести до корозії) і запобігти пошкодженню поверхні, потрібно використовувати менш агресивний абразив. Згідно з Вебсайтом із інформацією про лиття під тиском із цинкових сплавів , найпошильнішим матеріалом для обробки цинкових виливків під тиском є круглий алюмінієвий дроб, зазвичай діаметром від 0,6 до 0,8 мм. Цей матеріал ефективний для «зачистки» — процесу очищення та видалення литникових приливів — з одночасним збереженням цілісності поверхні деталі та підготовкою її до наступних операцій, таких як покриття чи фарбування.

Оптимізація процесу оздоблення виливків під тиском

Отже, дробострумене очищення — це набагато більше, ніж простий метод очищення; це важливий додатковий процес у сучасному литті під тиском. Шляхом ретельного підбору відповідного обладнання та абразивного матеріалу виробники можуть значно покращити якість, довговічність і експлуатаційні характеристики своїх компонентів. Така стратегічна підготовка поверхні забезпечує відмінне зчеплення покриттів, покращує механічні властивості та гарантує стабільний високоякісний естетичний вигляд. У підсумку, впровадження добре контрольованого процесу дробоструменого очищення є обов’язковим для виробництва виливків під тиском, які відповідають суворим вимогам сучасних галузей високотехнологічного виробництва.

Поширені запитання

1. Чи може дробострумене очищення пошкодити виливки під тиском?

Так, якщо процес не контролюється належним чином. Використання надто твердого або агресивного середовища або надмірного тиску обробки може пошкодити поверхню литого під тиском виробу, особливо виробів із м'яких сплавів, таких як цинк. Важливо правильно підібрати тип і розмір середовища для конкретного матеріалу, щоб уникнути небажаних пошкоджень поверхні або змін у розмірах.

2. У чому різниця між дробоструменною та піскоструменною обробкою?

Основна відмінність полягає у типі абразивного матеріалу. Дробоструменна обробка зазвичай використовує сферичний металевий абразив (дріб), який можна багаторазово відновлювати, що робить його поширеним у промислових умовах. Піскоструменна обробка використовує пісок або силіцій, які швидко руйнуються та можуть становити небезпеку для здоров'я (силікоз), якщо не дотримуватися відповідних заходів безпеки. Для виробів лиття під тиском дробоструменна обробка є кращим варіантом завдяки кращому контролю, стабільності та можливості повторного використання абразиву.

3. Чи призводить дробоструменна обробка до суттєвої зміни розмірів виробу?

Хоча вплив на розміри часто є незначним, дробоструменне очищення може спричиняти відхилення, критичні для деталей із жорсткими допусками. Цей процес вважається способом обробки поверхні, а не видалення матеріалу, як при обробці різанням. Хоча видаляється дуже мала кількість матеріалу, зокрема заусенці та литникові відходи, зміна основних розмірів компонента зазвичай незначна і вкладається в межі виробничих допусків.

Досягнення ідеального покриття: дробоструйне очищення виливків

Коротко

Дробоструменна обробка — це механічна обробка поверхні, необхідна для остаточної обробки виливків, отриманих литтям під тиском. Вона полягає у метанні абразивного матеріалу на високій швидкості для ретельного очищення забруднень, видалення заусенців та литникових систем і створення дрібнотекстурованої поверхні. Цей процес має важливе значення для покращення адгезії подальших покриттів, таких як фарба чи порошкове покриття, а також для підготовки компонентів до прецизійної механообробки.

Що таке дробоструменна обробка і навіщо її використовують для деталей, виготовлених литтям під тиском?

Дробоструменева обробка — це контрольований механічний процес, який використовується для очищення, зміцнення та підготовки поверхонь металевих компонентів. У контексті лиття під тиском це передбачає обстріл деталі потоком дрібних абразивних частинок, відомих як дроб або оброблювальний матеріал. Ці частинки рухаються з високою швидкістю та вдаряються об поверхню, усуваючи дефекти й утворюючи рівномірну структуру. На відміну від хімічних методів очищення, дробоструменева обробка фізично очищає поверхню, що робить її надзвичайно ефективною для видалення стійких забруднень, які залишаються після процесу лиття.

Основна мета дробострумення литих під тиском деталей — підготовка поверхні. Процес лиття під тиском, хоча й є точним, може залишати небажані елементи, такі як заусенці (тонкий надлишковий матеріал на лінії роз'єднання форми), задири та оксидні шари. Дробострумення ефективно усуває ці дефекти, забезпечуючи відповідність деталі заданим розмірам і естетичним вимогам. Ця очищувальна дія є важливим підготовчим етапом перед подальшою обробкою.

Крім того, процес кардинально змінює топографію поверхні компонента. Вплив абразивного матеріалу створює мікропрофіль — сукупність мікроскопічних піків і западин — на металевій поверхні. Ця текстурована, або «травлена», поверхня забезпечує відмінне зчеплення для фарб, порошкових покриттів та інших гальванопокриттів, значно покращуючи адгезію та запобігаючи відшаруванню чи відлущуванню. Чиста, належним чином текстурована поверхня також ідеально підходить для подальшої механічної обробки, оскільки може допомогти зменшити знос інструменту та покращити загальну ефективність і точність циклу обробки.

Основні переваги дробоструменної обробки в операціях гарячого пресування

Впровадження дробоструменної обробки в процес гарячого пресування забезпечує кілька суттєвих експлуатаційних і якісних переваг. Ці переваги призводять до вищої якості кінцевого продукту з покращеною довговічністю та експлуатаційними характеристиками. До основних переваг належать:

- Покращене зчеплення для покриттів: Найважливішою перевагою є створення ідеальної поверхні для нанесення покриття. Отримана рівномірна шорсткість, зазвичай у діапазоні Ra1,6–6,3 мкм, забезпечує міцне прилягання фарби, порошкових покриттів та інших видів обробки, що призводить до довшого терміну служби та більш міцного захисного шару.

- Високоефективне очищення та видалення заусенців: Процес дуже ефективно видаляє забруднення з поверхні, включаючи литникові роз'єми, заусенці та оксидні шари. Це часто усуває необхідність у трудомісткому ручному видаленні заусенців, спрощує виробничий процес і забезпечує однаковість обробки великих партій деталей.

- Покращення механічних властивостей: Дробоструменева обробка може створювати шар стискальних залишкових напружень на поверхні деталі. Цей ефект, відомий як дробоструменеве зміцнення (якщо виконується з цією метою), допомагає усунути концентрації напружень, що виникають під час лиття, і значно підвищує опірність деталі до втоми та твердість.

- Естетична та рівномірна поверхнева обробка: Цей процес надає чистого, рівномірного та структурованого матового або напівглянсового покриття литим під тиском деталям. Це забезпечує постійний і професійний вигляд, який часто є остаточною вимогою для багатьох компонентів.

- Економічна ефективність: Для виробництва великих обсягів дробоструменева обробка є високоефективним і економічно вигідним методом оздоблення. Автоматизовані машини можуть обробляти велику кількість деталей із мінімальним наглядом, знижуючи витрати на робочу силу та збільшуючи продуктивність.

Ця увага до цілісності поверхні має вирішальне значення для високопродуктивних компонентів, особливо в таких вимогливих галузях, як автомобілебудування. Хоча лиття під тиском ґрунтується на дробоструменевій обробці для підготовки поверхні, інші методи виробництва, такі як штампування, також потребують ретельної обробки поверхні, щоб забезпечити надійність. Наприклад, фахівці з штампування для автомобільної промисловості, такі як Shaoyi (Ningbo) Metal Technology , використовують сучасні процеси гарячого штампування та суворий контроль якості для виробництва компонентів, які відповідають найвищим стандартам довговічності.

Процес дробоструменевої обробки: типи абразивного матеріалу та обладнання

Процес дробострумення полягає в розміщенні виливків у спеціальній камері, де турбіни направляють абразивний матеріал на їхні поверхні. Вибір машини та абразиву є критичним і залежить від розміру, геометрії, матеріалу деталі та бажаного типу обробки. Сучасні системи часто мають спеціальні сітки для розділення видалених заусенців від повторно використовуваного дробострумного матеріалу, забезпечуючи ефективність процесу.

Різні машини розроблено для різних виробничих потреб. Для невеликих, міцних деталей, які можна обробляти партіями, дробострумні установки з стрічковим барабаном є поширеними. Ці машини обережно перекочують деталі по неперервній стрічці, забезпечуючи обробку всіх поверхонь струменем дробу. Для більших, складніших або делікатних компонентів, таких як корпуси трансмісій або конструкційні деталі, дробострумні установки з підвісними гвинтами використовуються. У цих системах деталі підвішуються на пристроях, які обертаються під час проходження через дробострумну камеру, захищаючи їх від контакту одна з одною.

Вибір абразивного матеріалу є не менш важливим, оскільки він безпосередньо впливає на остаточну обробку поверхні та інтенсивність очищення. Ідеальний матеріал забезпечує баланс між ефективністю очищення та необхідністю уникнути пошкодження поверхні деталі.

| Тип середовища | Характеристики | Основне застосування для деталей з литих сплавів |

|---|---|---|

| Сталевий гарт | Гострокутний, твердий і агресивний. Забезпечує швидке очищення та глибоке травлення. | Використовується для важких алюмінієвих сплавів з метою агресивного очищення, видалення заусенців і створення грубого профілю для товстих покриттів. |

| Сталевий дріб | Круглий, менш агресивний, ніж гарт. Забезпечує більш гладку поверхню з ефектом дроблення. | Універсальне очищення та обробка поверхні багатьох алюмінієвих деталей, де потрібен менш агресивний профіль. |

| Алюмінієвий дріб | Круглий і відносно м'який. Запобігає потраплянню залізистих домішок. | Засіб, який використовується для остаточної обробки цинкових виливків, ефективно очищає, не пошкоджуючи м’якшу поверхню. |

| Кульки з нержавіючої сталі | Міцні, стійкі до корозії та забезпечують яскраву, чисту поверхню без ферозного забруднення. | Ідеальний варіант для алюмінієвих і цинкових деталей, які потребують високоякісного естетичного покриття. Більш дорогий варіант. |

| Скляні бусини | Дуже дрібний і щадний абразив. Забезпечує м’яку сатинову або матову поверхню. | Використовується для делікатних деталей або як остаточний етап обробки з естетичних міркувань, особливо перед такими процесами, як анодування. |

Рекомендації щодо конкретних матеріалів лиття під тиском: алюміній проти цинку

Оптимальні параметри дробоструменевої обробки мають бути адаптовані до конкретного матеріалу виливка. Алюміній і цинк — два найпоширеніші матеріали у литті під тиском — мають різну твердість і характеристики поверхні, що вимагає різних підходів для досягнення бажаного результату без пошкодження.

Обробка алюмінієвих виливків

Сплави алюмінію є відносно твердими та міцними, що робить їх придатними для ширшого діапазону абразивних матеріалів, включаючи сталевий гарт, сталеві дробинки та кульки з нержавіючої сталі. Основні цілі дробоструменевого оброблення алюмінію — зазвичай видалення литникових систем та заусенців, очищення поверхні та створення рівномірної текстури для фарбування чи порошкового покриття. Вибір абразиву залежить від бажаної шорсткості: гострокутний сталевий гарт створює більш агресивний профіль, придатний для міцного зчеплення покриття, тоді як круглий дроб створює гладшу, більш дроблену поверхню.

Остаточна обробка деталей із цинкових сплавів, виготовлених під тиском

Сплави цинку є м'якшими та щільнішими, ніж алюміній, через що вони більше схильні до пошкодження поверхні при надто інтенсивному дробоструменевому обробленні. Щоб уникнути забруднення поверхні залізовмісними частинками (що може призвести до корозії) і запобігти пошкодженню поверхні, потрібно використовувати менш агресивний абразив. Згідно з Вебсайтом із інформацією про лиття під тиском із цинкових сплавів , найпошильнішим матеріалом для обробки цинкових виливків під тиском є круглий алюмінієвий дроб, зазвичай діаметром від 0,6 до 0,8 мм. Цей матеріал ефективний для «зачистки» — процесу очищення та видалення литникових приливів — з одночасним збереженням цілісності поверхні деталі та підготовкою її до наступних операцій, таких як покриття чи фарбування.

Оптимізація процесу оздоблення виливків під тиском

Отже, дробострумене очищення — це набагато більше, ніж простий метод очищення; це важливий додатковий процес у сучасному литті під тиском. Шляхом ретельного підбору відповідного обладнання та абразивного матеріалу виробники можуть значно покращити якість, довговічність і експлуатаційні характеристики своїх компонентів. Така стратегічна підготовка поверхні забезпечує відмінне зчеплення покриттів, покращує механічні властивості та гарантує стабільний високоякісний естетичний вигляд. У підсумку, впровадження добре контрольованого процесу дробоструменого очищення є обов’язковим для виробництва виливків під тиском, які відповідають суворим вимогам сучасних галузей високотехнологічного виробництва.

Поширені запитання

1. Чи може дробострумене очищення пошкодити виливки під тиском?

Так, якщо процес не контролюється належним чином. Використання надто твердого або агресивного середовища або надмірного тиску обробки може пошкодити поверхню литого під тиском виробу, особливо виробів із м'яких сплавів, таких як цинк. Важливо правильно підібрати тип і розмір середовища для конкретного матеріалу, щоб уникнути небажаних пошкоджень поверхні або змін у розмірах.

2. У чому різниця між дробоструменною та піскоструменною обробкою?

Основна відмінність полягає у типі абразивного матеріалу. Дробоструменна обробка зазвичай використовує сферичний металевий абразив (дріб), який можна багаторазово відновлювати, що робить його поширеним у промислових умовах. Піскоструменна обробка використовує пісок або силіцій, які швидко руйнуються та можуть становити небезпеку для здоров'я (силікоз), якщо не дотримуватися відповідних заходів безпеки. Для виробів лиття під тиском дробоструменна обробка є кращим варіантом завдяки кращому контролю, стабільності та можливості повторного використання абразиву.

3. Чи призводить дробоструменна обробка до суттєвої зміни розмірів виробу?

Хоча вплив на розміри часто є незначним, дробоструменне очищення може спричиняти відхилення, критичні для деталей із жорсткими допусками. Цей процес вважається способом обробки поверхні, а не видалення матеріалу, як при обробці різанням. Хоча видаляється дуже мала кількість матеріалу, зокрема заусенці та литникові відходи, зміна основних розмірів компонента зазвичай незначна і вкладається в межі виробничих допусків.

Малі партії, високі стандарти. Наша послуга швидкого прототипування робить перевірку швидшою та простішою —

Малі партії, високі стандарти. Наша послуга швидкого прототипування робить перевірку швидшою та простішою —