Sheet Metal Forming Dies: From Design Flaws To Flawless Parts

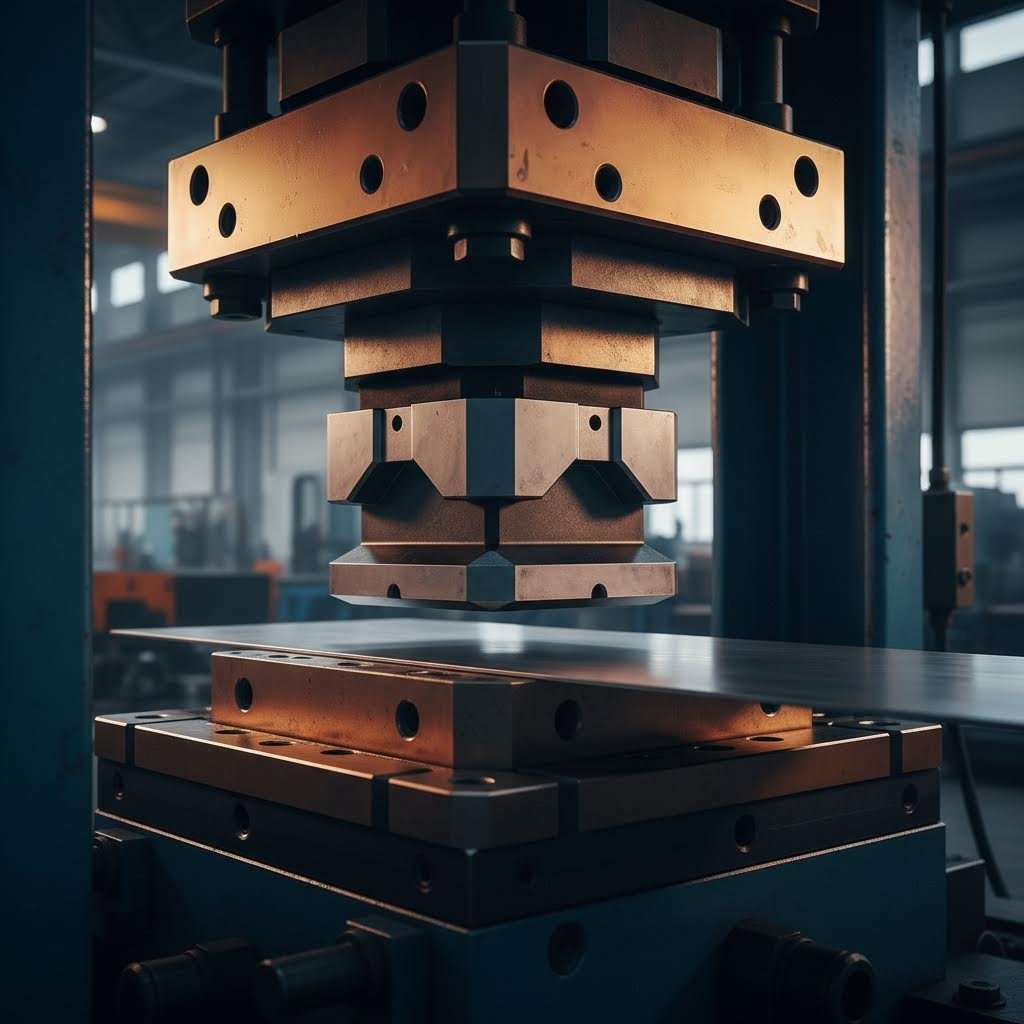

Understanding Sheet Metal Forming Dies and Their Manufacturing Role

Ever wondered how a flat piece of metal becomes a car door panel, an aircraft component, or the sleek casing of your smartphone? The answer lies in precision tooling that most people never see—sheet metal forming dies. These specialized tools sit at the heart of modern manufacturing, quietly transforming raw materials into the complex shapes that define our everyday world.

The Foundation of Modern Metal Manufacturing

At its core, a die is used to shape, cut, and form metal through controlled force application. But what is die making in the context of sheet metal forming? It's the art and science of creating precision tools that can repeatedly produce identical parts with exacting tolerances.

A forming die specifically refers to tooling that reshapes material through deformation—using compression, tension, or both—rather than removing material through cutting alone. Unlike cutting dies that simply shear metal, forming dies rely on the material's mechanical properties to bend, stretch, and draw flat stock into three-dimensional shapes.

Sheet metal forming represents one of the most efficient manufacturing methods available. A single die tool can produce thousands—even millions—of identical parts with remarkable consistency. This repeatability makes these precision instruments indispensable across industries ranging from automotive and aerospace to consumer electronics and medical devices.

How Dies Transform Flat Stock Into Precision Parts

The transformation process involves two primary components working in harmony: the punch (male component) and the die block (female component). When mounted inside a press capable of generating tremendous force, these elements work together to reshape metal in ways that would be impossible through manual methods.

The mechanics are elegantly simple yet remarkably precise. As the press cycles downward, the punch forces the sheet metal into or around the die cavity. The metal forming process depends on carefully calculated factors including:

- Material thickness and mechanical properties

- Clearances between punch and die surfaces

- Applied force and press speed

- Lubrication and surface conditions

- Temperature considerations for certain alloys

What makes forming dies particularly fascinating is how they exploit the material's natural behavior. When you bend a piece of metal, it wants to spring back toward its original shape. Skilled die designers account for this spring-back phenomenon, engineering their tools to over-bend or over-form slightly so the finished part relaxes into the correct final geometry.

The choice of die type directly impacts everything from part quality to production economics. A mismatched die selection can result in defective parts, excessive scrap rates, and production delays that ripple through entire supply chains. Conversely, the right die solution—properly designed and manufactured—delivers consistent quality at optimal cost-per-part economics.

Throughout this guide, you'll discover how different forming dies serve distinct manufacturing needs, what materials and methods go into their creation, and how to select the right approach for your specific application. Whether you're exploring metal forming for the first time or looking to optimize existing processes, understanding these foundational concepts sets the stage for smarter tooling decisions.

Complete Guide to Forming Die Types and Classifications

Now that you understand how these precision tools work, the next logical question is: which type of die fits your manufacturing needs? The variety die and stamping options available can seem overwhelming at first glance. However, each category serves specific production scenarios, and understanding their distinctions will help you make informed tooling decisions that balance quality, speed, and cost.

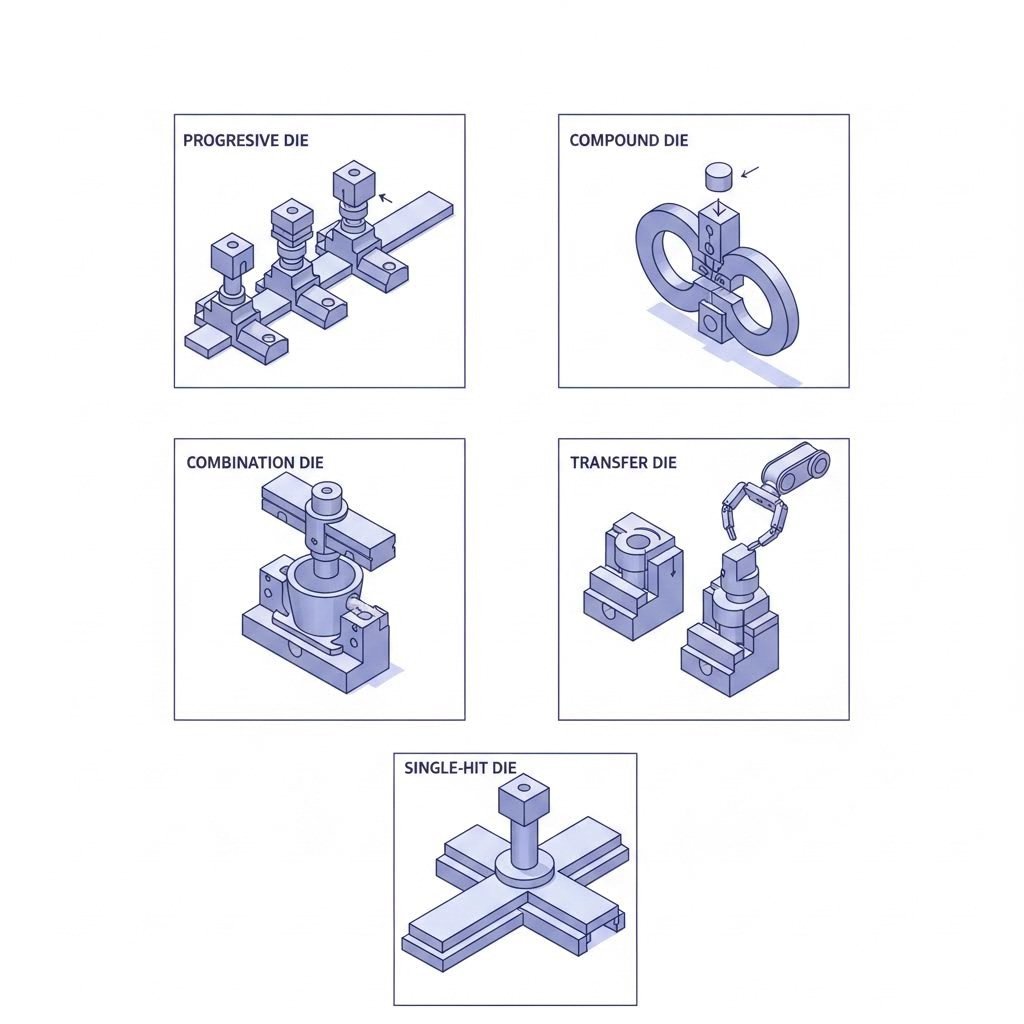

Dies and stamping operations fall into five primary classifications, each engineered for particular volume requirements, part complexities, and production environments. Let's break down what makes each type unique.

Progressive Dies for High-Volume Efficiency

Imagine a manufacturing line where raw coil stock enters one end and finished parts emerge from the other—with minimal human intervention in between. That's the power of progressive dies. These sophisticated tools perform sequential operations across multiple stations as material advances through the press with each stroke.

Here's how the process unfolds:

- Metal strip feeds into the die from a coil, guided by precision alignment systems

- Each press cycle advances the material one "progression" (typically right to left)

- Early stations punch pilot holes that ensure accurate positioning for subsequent operations

- Sequential stations perform cutting, punching, bending, or forming operations

- The finished part separates from the carrier strip at the final station

Progressive stamping dies excel in high-volume applications where speed and consistency matter most. Once set up, these systems can run continuously with feeders managing material flow automatically. The trade-off? Higher upfront design and tooling costs. However, the cost-per-part drops dramatically over long production runs, making progressive dies the go-to choice for automotive components, electronic connectors, and consumer product housings.

Compound and Combination Dies Explained

What if you need multiple operations completed in a single press stroke rather than across sequential stations? Compound dies deliver exactly that capability. These metal stamping dies perform multiple operations—typically blanking and piercing—simultaneously at the same station.

Picture this workflow: the punch descends, and in one unified motion, holes are punched downward while the outer profile blanks upward. Slugs fall through the die, and the finished part remains in the cavity for ejection. This simultaneous action produces parts with excellent flatness and tight tolerances between features.

The advantages of compound die stamping include:

- Superior dimensional accuracy between punched features and outer edges

- Excellent part flatness compared to sequential operations

- Reduced tooling costs versus progressive dies for simpler geometries

- Shorter lead times from concept to production

However, compound dies have limitations. Part removal requires additional mechanisms, and they're generally classified as single-hit dies—though they can run continuously with proper ejection systems. They work best for medium-volume production of relatively flat parts where feature-to-feature accuracy is critical.

Combination dies take a hybrid approach, merging cutting and forming operations within a single tool. Unlike pure compound dies that focus on cutting operations, combination dies might blank a part's perimeter while simultaneously creating a formed feature like a bend or emboss. This versatility makes them valuable for parts requiring both cutting precision and shaped geometry.

Transfer Dies for Complex Multi-Station Work

Some parts are simply too large or complex for progressive die stamping. When the workpiece must be physically separated from the strip and moved independently between stations, transfer dies become the solution of choice.

Transfer die stamping uses mechanical systems—fingers, grippers, or rails—to transport individual parts from station to station. Each station contains separate tooling that performs specific operations on the freed workpiece. This independence allows for:

- Deep draws and complex three-dimensional forming

- Operations requiring part rotation or repositioning

- Large parts that cannot maintain strip connectivity

- Multi-axis forming that would be impossible in progressive systems

The sophistication of transfer systems means higher tooling and setup costs compared to other types of stamping dies. Maintenance requirements are also more demanding since both the dies and transfer mechanisms need regular attention. Still, for medium to high-volume production of intricate components—think automotive structural parts or appliance housings—transfer dies offer capabilities that no other approach can match.

Single-Hit Dies for Simpler Applications

Not every manufacturing challenge requires complex multi-station tooling. Single-hit dies (also called single-station dies) complete one forming or cutting operation per press stroke. Their simplicity offers distinct advantages for specific production scenarios.

Single punch dies shine when:

- Production volumes are low to medium

- Punch positions or shapes change frequently

- Quick tooling adjustments are necessary

- Budget constraints limit initial tooling investment

- Part designs are still evolving during development phases

The trade-off is reduced automation and lower throughput. Each part typically requires manual loading and positioning between operations. However, the flexibility and lower manufacturing costs make single-hit tooling ideal for prototyping, short-run production, and applications where design changes are anticipated.

Die Type Comparison at a Glance

Choosing between die types requires balancing multiple factors. This comparison table summarizes key characteristics across all five categories:

| Die Type | Best Application | Production Volume Range | Complexity Level | Typical Industries |

|---|---|---|---|---|

| Progressive Die | Complex parts requiring multiple sequential operations | High volume (100,000+ parts) | High | Automotive, electronics, appliances |

| Compound Die | Flat parts needing simultaneous blanking and piercing | Medium volume (10,000-100,000 parts) | Moderate | Electronics, hardware, precision components |

| Combination Die | Parts requiring both cutting and forming in one stroke | Medium volume (10,000-100,000 parts) | Moderate to High | Automotive, consumer products, industrial equipment |

| Transfer Die | Large or complex parts needing independent station operations | Medium to High volume (50,000+ parts) | High | Automotive structural, appliances, heavy equipment |

| Single-Hit Die | Simple operations with frequent design changes | Low to Medium volume (under 50,000 parts) | Low | Prototyping, job shops, custom fabrication |

Understanding these classifications provides the foundation for intelligent tooling decisions. But the die type is only part of the equation. The specific forming operations these tools perform—and how material properties influence those operations—determine whether your parts meet specifications or end up in the scrap bin.

Forming Operations and Their Mechanical Principles

You've seen how different die types serve distinct production needs. But here's where things get really interesting: the specific metal forming operations these tools perform determine whether your finished parts meet exacting specifications or fall short. Each forming process exploits unique mechanical principles, and understanding them helps you anticipate challenges before they become costly problems.

The forming manufacturing process involves permanently reshaping metal without adding or removing material. Unlike cutting operations that shear through stock, metal forming operations rely on controlled plastic deformation—pushing material past its yield point so it retains the new shape. Let's explore the most critical techniques and the parameters that influence their success.

Bending Operations and Spring-Back Control

Bending is perhaps the most common forming operation in sheet metal work. Sounds simple, right? Fold the metal at an angle and you're done. In reality, achieving precise bend angles consistently requires understanding three distinct bending methods—each with unique characteristics.

Air bending offers the greatest flexibility. The punch presses the material into a V-shaped die opening without bottoming out. The final angle depends entirely on punch depth, meaning one die can produce multiple angles simply by adjusting stroke depth. However, air bending produces the highest spring-back since the metal isn't fully constrained during forming.

Bottoming (sometimes called bottom bending) forces the material completely into the die cavity. The punch and die surfaces fully contact the workpiece at the bend zone, producing more consistent angles with reduced spring-back. The trade-off? You need dedicated tooling for each specific angle.

Coining bending takes things further. This metal forming and coining technique applies extreme pressure—typically five to eight times more than bottoming—to plastically deform the material at the bend. The result? Virtually zero spring-back and razor-sharp bend radii. Coining is essential when tight angle tolerances are non-negotiable.

Spring-back remains the critical engineering consideration across all bending operations. When pressure releases, the metal attempts to return toward its original flat state. Key parameters affecting spring-back include:

- Material yield strength: Higher-strength materials spring back more aggressively

- Bend radius to thickness ratio: Tighter radii reduce spring-back but risk cracking

- Bend angle: Larger angles generally produce more spring-back

- Grain direction: Bending across the grain versus with it affects results significantly

- Material thickness: Thicker stock typically exhibits less proportional spring-back

Experienced die designers compensate by over-bending—engineering the tooling to produce angles beyond the target so the part relaxes into correct geometry. Getting this compensation right often requires trial runs and iterative adjustments, especially when working with high-strength steels or exotic alloys.

Drawing, Flanging, and Embossing Mechanics

While bending creates angular features, drawing operations produce depth. Imagine transforming a flat disc into a seamless cup—that's the essence of the metal forming process called drawing. According to The Fabricator, drawing can be defined as displacing pre-existing surface area into an alternate-shaped vessel containing nearly the same total surface area.

Here's what makes drawing unique: it requires controlled metal flow rather than pure stretching. The blank holder (also called a draw pad or binder) applies pressure to control how material feeds into the die cavity. Too little pressure causes wrinkling; too much restricts flow and causes tearing. Finding the sweet spot is critical.

Key parameters affecting drawing operations include:

- Draw ratio: The relationship between blank diameter and finished part diameter

- Blank holder pressure: Must balance wrinkle prevention against material flow restriction

- Die radius: Larger radii ease material flow but may compromise feature definition

- Lubrication: Reduces friction to enable smooth metal movement into the cavity

- Punch speed: Faster speeds can generate heat affecting material behavior

- Air venting: Trapped air must escape to prevent defects and stripping difficulties

Flanging creates bent edges—either inward or outward—along a part's perimeter or around holes. This forming operation strengthens edges, creates attachment points, or prepares surfaces for joining operations. The mechanics combine bending principles with material flow considerations, especially when flanging curved edges where metal must stretch or compress.

Embossing produces raised or recessed features without breaking through the material. Think of logos pressed into appliance panels or stiffening ribs formed into structural components. The forming process uses matched male and female die surfaces to create shallow, localized deformation while maintaining overall part flatness.

Parameters influencing embossing quality include:

- Feature depth: Deeper embosses require more force and risk tearing

- Wall draft angles: Slight tapers ease material flow and tool release

- Corner radii: Sharp internal corners concentrate stress and may cause failure

- Material ductility: More formable alloys accept deeper, more complex embossed features

Material thickness and type fundamentally influence operation selection across all these processes. Thinner stock bends and draws more easily but offers less structural rigidity. Thicker materials require greater force and wider radii to avoid cracking. Similarly, material composition matters—aluminum's higher spring-back demands different compensation strategies than mild steel, while stainless steel's work-hardening characteristics create unique challenges during deep drawing.

Understanding these mechanical principles gives you the foundation to evaluate whether a proposed die design will actually deliver the results you need. But material selection adds another layer of complexity—different metals behave differently under forming forces, and matching your tooling to your specific material is essential for consistent quality.

Material-Specific Requirements for Different Sheet Metals

So you've selected your die type and understand the forming mechanics—but here's a question that can make or break your production: how does your specific material change everything? The truth is, sheet metal for stamping isn't a one-size-fits-all category. Each alloy family brings unique behaviors that directly influence die design, clearance calculations, and process parameters.

Think of it this way: forming aluminum feels completely different from working with stainless steel. The forces involved, how the material springs back, and how quickly your tooling wears all vary dramatically. Getting these material-specific details right separates successful production runs from frustrating scrap piles.

Aluminum and Lightweight Alloy Considerations

Aluminum's popularity in sheet metal stamping continues growing—especially in automotive and aerospace applications where weight reduction matters. But don't let aluminum's reputation for being "easy to form" fool you. This lightweight metal presents its own set of challenges.

The good news? Aluminum requires significantly lower forming forces compared to steel. According to tooling specifications from industry manufacturers, calculating punching force for aluminum uses a shear strength factor of only 20-25 kg/mm², compared to 40-50 kg/mm² for mild steel. This means your press capacity goes further when working with aluminum alloys.

The challenging part? Spring-back. Aluminum's lower elastic modulus means parts want to return toward their original shape more aggressively after forming. Coining sheet metal—applying extreme pressure to virtually eliminate spring-back—becomes essential for achieving tight angular tolerances in aluminum components.

Die clearance requirements for aluminum also differ substantially. The recommended clearance percentage for aluminum ranges from 12-16% of material thickness—tighter than steel but looser than copper. This translates to specific clearance values:

- 1.0mm aluminum: 0.12-0.16mm total clearance

- 2.0mm aluminum: 0.24-0.30mm total clearance

- 3.0mm aluminum: 0.35-0.45mm total clearance

Galling presents another aluminum-specific concern. The metal's tendency to adhere to tool surfaces requires careful attention to die coatings, lubrication, and surface finishes. Without proper precautions, aluminum can weld itself to punch surfaces, causing surface defects and accelerated tool wear.

Steel and Stainless Steel Forming Requirements

Steel remains the workhorse material for stamped sheet metal components, but the category spans an enormous range—from soft low-carbon grades to high-strength structural alloys. Each subset demands tailored die specifications.

Mild steel offers the most forgiving forming characteristics. With moderate strength and good ductility, it accepts aggressive forming operations without excessive spring-back or cracking. Steel stamping dies designed for mild steel typically use clearances of 16-20% of material thickness, translating to:

- 1.0mm mild steel: 0.16-0.20mm total clearance

- 2.0mm mild steel: 0.34-0.40mm total clearance

- 3.0mm mild steel: 0.50-0.60mm total clearance

Stainless steel changes the equation dramatically. Its higher tensile strength—requiring 60-70 kg/mm² shear strength in punching force calculations—demands more robust press capacity and tooling. But the bigger challenge? Work hardening. Stainless steel gets progressively harder as it's formed, which means:

- Progressive operations must account for increasing hardness at each station

- Deep draws may require intermediate annealing to restore ductility

- Sharper punch edges and tighter clearances help minimize work-hardening effects

Clearance requirements for stainless run higher than mild steel at 18-24% of thickness. According to metal stamping design guidelines, when creating holes in stainless steel alloys, the minimum diameter should be at least two times wider than the material's thickness—compared to just 1.2 times for lower-strength materials.

High-strength low-alloy (HSLA) steels and advanced high-strength steels (AHSS) push these considerations further. Their exceptional strength-to-weight ratios come with reduced formability, higher spring-back, and accelerated die wear. Sheet metal stamping dies for these materials often require premium tool steels or carbide inserts at high-wear locations.

Copper and Brass Forming Characteristics

Copper and its alloys—including brass and bronze—offer excellent formability coupled with unique challenges. These materials are favorites for electrical components, decorative hardware, and precision instruments where their conductivity or appearance matters.

Copper requires the tightest die clearances of common sheet metals, typically 10-14% of thickness. This translates to clearance values of:

- 1.0mm copper: 0.10-0.14mm total clearance

- 2.0mm copper: 0.20-0.25mm total clearance

- 3.0mm copper: 0.30-0.40mm total clearance

Why tighter clearances? Copper's exceptional ductility allows it to flow into gaps between punch and die, creating excessive burrs if clearances run too loose. The flip side is that copper's softness produces minimal die wear—tools forming copper typically last longer than those working harder materials.

Brass—typically a copper-zinc alloy—behaves similarly but with slightly higher strength. It machines beautifully after forming, making it popular for parts requiring secondary operations. Both materials share copper's tendency toward galling, requiring attention to lubrication and tool surface conditions.

Material Properties Comparison for Die Design

When specifying sheet metal stamping dies, understanding how material properties interact with die parameters is essential. This comparison table summarizes the critical differences:

| Material Type | Typical Thickness Range | Relative Forming Force | Spring-Back Tendency | Die Wear Considerations |

|---|---|---|---|---|

| Aluminum Alloys | 0.5mm - 4.0mm | Low (20-25 kg/mm² shear) | High - requires over-bending compensation | Moderate - galling risk requires coatings/lubrication |

| Mild Steel | 0.5mm - 6.0mm | Medium (40-50 kg/mm² shear) | Moderate - predictable compensation | Moderate to High - standard tool steels adequate |

| Stainless Steel | 0.5mm - 4.0mm | High (60-70 kg/mm² shear) | Moderate to High - work hardening compounds issues | High - premium tool steels recommended |

| Copper | 0.3mm - 3.0mm | Low (15-20 kg/mm² shear) | Low - forms easily to final shape | Low - soft material minimizes wear |

| Brass | 0.3mm - 3.0mm | Low to Medium | Low to Moderate | Low to Moderate - similar to copper |

Thickness ranges deserve special attention. Thinner materials may require tighter percentage clearances to maintain edge quality, while thicker stock needs proportionally larger absolute clearances. When thickness approaches the upper limits for a material category, forming radii must increase to prevent cracking—especially critical for stainless steel and high-strength alloys.

Material selection doesn't happen in isolation. Your choice directly influences die component specifications, from the tool steels used in punch and die construction to the clearances engineered into the design. Understanding these relationships helps ensure your stamped sheet metal parts emerge from the press meeting specifications—not ending up as expensive scrap.

Die Design Engineering and Component Fundamentals

You understand the forming operations and material requirements—but here's where theory meets reality: die design engineering. This is where precision calculations, component selection, and validation methods determine whether your tooling produces flawless parts or frustrating rejects. Surprisingly, many resources skip over these critical details. Let's change that.

Successful die making requires mastering three interconnected elements: clearance specifications that match your material and operation, components engineered to withstand production demands, and validation methods that catch problems before they become expensive. Understanding these fundamentals transforms you from someone who uses dies into someone who specifies them intelligently.

Critical Clearances and Tolerance Specifications

Remember those clearance percentages from the material section? Now it's time to put them into practice. According to MISUMI's engineering guidelines, clearance represents the optimal space between punch and die cutting edges required to puncture material in shear and produce clean holes.

Here's the key formula for calculating actual clearance values:

Clearance (per side) = Material Thickness × Recommended Clearance Percentage

The "per side" distinction matters enormously. When specifications call for 10% clearance, that 10% must exist on each side of the punch—meaning the die opening is actually 20% larger than the punch diameter in total. Misunderstanding this relationship is one of the most common die tooling errors.

What determines the right clearance percentage? Several factors interact:

- Material hardness and tensile strength: Harder, stronger materials require increased clearance—typically 15-25% for high-strength steel versus 10-12% for soft aluminum

- Workpiece thickness: Thicker stock needs proportionally larger absolute clearances while maintaining percentage relationships

- Edge quality requirements: Tighter clearances produce cleaner cut edges but accelerate tool wear

- Tooling life expectations: Running slightly larger clearances (11-20%) can considerably reduce tooling strain and extend operational life

Proper clearance achieves something elegant: it aligns grain boundary fracture planes at the top and bottom of the workpiece, creating clean cleavage at cut edges. When clearance runs too tight, the punch works harder—generating excess heat and accelerating wear. Too loose, and burrs form as material flows into the gap, requiring costly secondary finishing.

Radius specifications add another dimension to metal stamping die design. Bend radii must balance formability against spring-back control. The general rule? Inside bend radius should equal at least the material thickness for ductile materials like mild steel, and 1.5-2 times thickness for less formable alloys. Violate these minimums and you risk cracking at bend lines.

Tolerance stacking presents perhaps the trickiest engineering challenge. Each die component carries its own tolerance—punch dimensions, die cavity dimensions, guide pin positioning, plate flatness. These individual tolerances compound. A die set for press applications demanding ±0.05mm part accuracy needs individual component tolerances significantly tighter than that final specification.

Essential Die Components and Their Functions

Die sets for press operations consist of specialized components working in harmony. Understanding what each element does—and why it matters—helps you evaluate tooling quality and troubleshoot problems when they arise. According to Moeller Precision Tool's engineering resources, these are the fundamental die components you'll encounter:

- Die Shoe (Die Plates): The foundation upon which all other components mount. These steel or aluminum plates provide rigid support and maintain alignment between upper and lower die halves. Quality die shoe construction determines overall tooling accuracy and longevity.

- Guide Pins and Bushings: These precision elements align upper and lower die plates with accuracy to within 0.0001" (one ten-thousandth of an inch). Ball-bearing guide pins have become industry standard for their ease of separation, while friction pins offer accurate guidance in specific applications.

- Punches: The male tools that actually press into and transform the metal sheet. Available in round, oblong, square, rectangular, and custom shapes, punches are fixed within retainers and can either pierce holes or create formed features depending on nose geometry.

- Die Buttons: The female counterparts to punches, providing the cutting edge against which punches work. Die buttons offset larger than punch dimensions by 5-10% of material thickness—this "die break" creates the clearance space where cutting occurs.

- Strippers: Components that hold the workpiece flat and strip it from the punch after forming. Without effective stripping, parts can stick to punches and cause jams or damage. Mechanical and urethane strippers each offer distinct advantages.

- Pressure Pads (Blank Holders): Used in drawing operations to control material flow into die cavities. These spring-loaded or nitrogen-actuated elements prevent wrinkling while allowing controlled metal movement during forming.

- Die Springs: Helical, high-force compression springs that provide the force needed to hold sheets in place during transformation. Mechanical wire coil springs and nitrogen gas springs serve different force and space requirements.

- Die Retainers: Holders mounted on die plates that secure punches, buttons, and other cutting components in position. Ball-lock, shoulder, and retractable styles accommodate different tooling configurations and maintenance needs.

Each component category offers customization options for specific applications. The interplay between these elements—their materials, tolerances, and configurations—ultimately determines whether your die tooling delivers consistent quality or constant headaches.

How CAE Simulation Has Transformed Die Design Validation

Here's a question that used to haunt die designers: will this tooling actually work? Traditionally, the answer only came after machining expensive dies and running trial parts. Problems meant rework, delays, and cost overruns.

Computer-aided engineering (CAE) has fundamentally changed this equation. According to Engineering.com's coverage of simulation technology, engineers can now validate tooling designs through virtual simulation before machining any physical dies—saving significant development time while improving accuracy.

Modern sheet forming simulation software like PAM-STAMP provides end-to-end validation capabilities for progressive, transfer, and line sheet metal dies. The technology allows engineers to:

- Predict whether parts will split, stretch, or wrinkle during forming

- Identify areas of excessive thinning before creating physical tooling

- Optimize blank holder pressures and draw bead configurations virtually

- Validate spring-back compensation strategies through digital iterations

- Confirm material flow patterns match design intent

The correlation between simulation results and actual manufactured parts has reached impressive accuracy levels. Engineers can now run detailed models of tools and dies for fast, accurate final validation—catching issues that would have required expensive physical prototyping in the past.

What does this mean practically? Faster development cycles, reduced tooling revisions, and higher first-pass success rates. For complex parts where traditional experience-based design might require multiple tryout iterations, simulation can compress development timelines dramatically while improving final part quality.

Die design engineering represents the bridge between forming theory and production reality. Getting clearances, components, and validation right determines whether your sheet metal forming dies deliver consistent quality or become sources of ongoing frustration. But even the best-designed dies require proper manufacturing—and the methods used to create them significantly impact both performance and longevity.

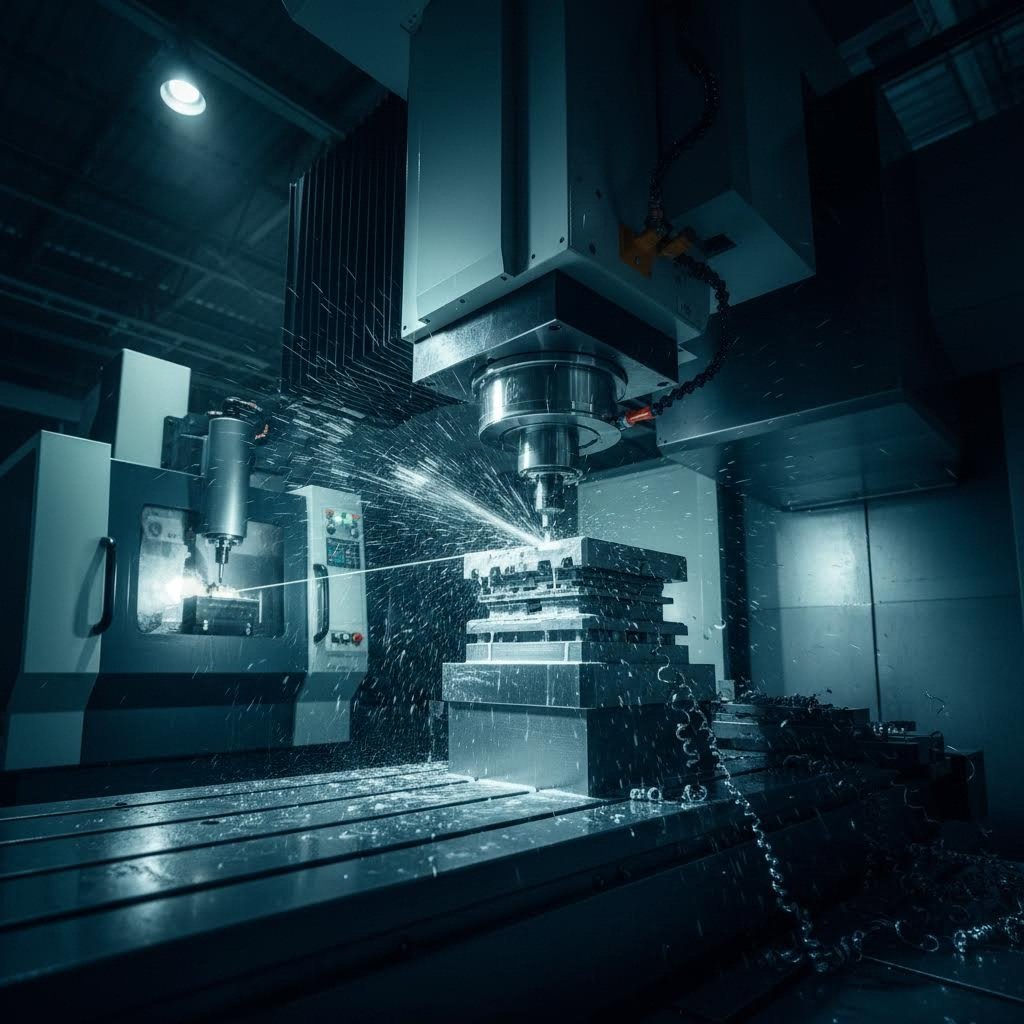

Die Manufacturing Methods and Material Selection

You've specified the perfect die design with optimal clearances and validated it through simulation—but here's the reality check: how that tooling gets manufactured determines whether your precision calculations translate into production success. The gap between design intent and physical reality depends entirely on manufacturing methods and material choices. Surprisingly, this critical topic often gets overlooked in tooling discussions.

Dies in manufacturing require specialized fabrication techniques that match the complexity, precision, and durability demands of each application. Three primary methods dominate the landscape: CNC machining for general die making, conventional EDM for complex internal features, and wire EDM for precision cutting applications. Understanding when each approach makes sense—and which tool steel grades deliver the performance you need—separates successful tooling programs from costly disappointments.

CNC Machining Versus EDM Technologies

When it comes to machining die components, CNC (Computer Numerical Control) machining represents the workhorse method. Mills, lathes, and grinding centers remove material through mechanical cutting action—tools spinning against workpieces to create desired geometries. For straightforward die components with accessible features, CNC machining offers excellent speed and cost-effectiveness.

CNC machining excels when:

- Features are accessible from multiple angles without interference

- Internal corner radii can accommodate standard tool diameters

- Material hardness remains below approximately 45 HRC (before heat treatment)

- Production timelines demand faster turnaround

- Cost optimization is a primary concern

But what happens when part geometries demand features that cutting tools simply cannot reach? That's where Electrical Discharge Machining enters the picture. According to industry manufacturing resources, EDM uses precision machining techniques to carve out intricate features that conventional methods cannot achieve.

Conventional EDM (also called sinker EDM or ram EDM) uses a shaped electrode that "sinks" into the workpiece. Electrical discharges between the electrode and workpiece erode material in the electrode's mirror image. This process creates complex internal cavities—think injection mold cores or deep die pockets with irregular geometries—that would be impossible to machine conventionally.

The advantages of conventional EDM include:

- Complex three-dimensional cavity creation in hardened materials

- No mechanical cutting forces that could distort delicate features

- Ability to work on pre-hardened tool steels (60+ HRC)

- Fine surface finishes achievable without secondary operations

Wire EDM takes a different approach. Instead of a shaped electrode, a thin brass or copper wire (typically 0.004" to 0.012" diameter) passes through the workpiece like an electrically charged bandsaw. The process cuts intricate profiles with exceptional precision—and here's what makes it particularly valuable for metal forming dies.

According to specialized machining experts, wire EDM delivers several distinct advantages over conventional CNC machining:

- Unique shapes: The ultra-thin wire cuts complex profiles with precision that other methods cannot achieve

- Material hardness immunity: Hard materials like Inconel, titanium, and even carbide—the material CNC tools themselves are made from—cut with ease since the process runs on electricity rather than mechanical force

- Tight tolerances: Precision within ±0.0002" is achievable for parts requiring exceptionally tight specifications

- Square corners: Wire sizes as small as 0.004" cut extremely tight corner radii that end mills cannot match—critical for tooling dies where small gaps affect part quality

- Consistency: Wire EDM runs multiple parts simultaneously, even unmanned, with high repeatability

The primary trade-off? Speed and cost. Wire EDM cuts more slowly than CNC machining, and machine time rates tend to run higher. However, for precision die tools requiring tight tolerances in hardened materials, the technology often proves more economical overall by eliminating rework and achieving first-pass accuracy.

Tool Steel Selection for Die Longevity

Manufacturing method selection goes hand-in-hand with material choice. The tool steel grades specified for your tooling dies directly impact wear resistance, toughness, and ultimately how many parts you can produce before maintenance becomes necessary.

According to die manufacturing specialists, common materials for dies include tool steels offering excellent hardness and wear resistance, and carbide for superior durability in high-stress applications. Here's how the primary options compare:

D2 Tool Steel represents the industry standard for many stamping applications. This high-carbon, high-chromium steel offers:

- Excellent wear resistance for extended production runs

- Good dimensional stability during heat treatment

- Hardness capability to 60-62 HRC

- Cost-effective balance of performance and machinability

D2 works well for blanking punches, forming dies, and general-purpose applications where abrasive wear is the primary concern. However, its toughness—resistance to chipping under impact—falls short of some alternatives.

A2 Tool Steel trades some wear resistance for improved toughness. This air-hardening steel offers:

- Better resistance to chipping and fracture under impact

- Good machinability before heat treatment

- Lower distortion during hardening than oil-quenched grades

- Hardness capability to 57-62 HRC

A2 becomes the preferred choice when dies experience shock loading or when cutting thicker materials that transmit impact forces through the tooling.

Carbide Inserts address the most demanding wear situations. Tungsten carbide offers exceptional hardness (significantly harder than any tool steel) and maintains sharp edges even under extreme abrasion. Die manufacturers commonly use carbide for:

- Punch tips in high-volume production exceeding millions of cycles

- Die buttons cutting abrasive materials like stainless steel

- Applications where replacement frequency needs minimizing

The trade-off with carbide? Brittleness. While carbide resists wear beautifully, it can crack under impact loading. Modern carbide composites have improved this characteristic, but applications still require careful evaluation of the forces involved.

Manufacturing Method Selection Guide

Choosing between manufacturing methods requires balancing multiple factors. This comparison summarizes when each approach makes the most sense for manufacturing die components:

| Manufacturing Method | Best Applications | Precision Level | Cost Considerations |

|---|---|---|---|

| CNC Machining | Accessible features, pre-hardened materials under 45 HRC, die shoes, retainers, general components | ±0.001" to ±0.0005" typical | Lower hourly rates, faster cycle times, most economical for standard geometries |

| Conventional EDM | Complex 3D cavities, blind pockets, hardened die inserts, injection mold features | ±0.0005" to ±0.0002" achievable | Higher hourly rates, electrode costs add expense, justified for complex internal features |

| Wire EDM | Precision punch and die profiles, tight-tolerance clearances, hardened tool steels and carbide, intricate perimeter cuts | ±0.0002" achievable | Moderate to high hourly rates, excellent for precision die tools, eliminates multiple setups |

Most metal forming dies utilize combinations of these methods. Die shoes might be CNC machined from pre-hardened plate. Punch profiles could be wire EDM cut after heat treatment to maintain precision. Complex forming cavities might require conventional EDM for internal features followed by grinding for final surface finish.

The key insight? Match manufacturing method to feature requirements. Overspending on wire EDM for features that CNC machining handles perfectly wastes budget. Underspending by forcing CNC methods on geometries requiring EDM precision creates quality problems that cost far more than the initial savings.

Material and manufacturing method decisions establish the foundation for die performance. But even perfectly manufactured tooling requires intelligent application—knowing which die type fits your production volume and part complexity determines whether your investment delivers optimal returns.

Choosing the Right Die Type for Your Application

You understand die types, forming operations, materials, and manufacturing methods—but here's the question that brings it all together: which stamping die actually makes sense for your specific situation? The answer isn't just about technical capability. It's about economics, timeline, and how your production needs will evolve over time.

Choosing between different types of forming tooling requires balancing upfront investment against long-term cost-per-part, matching complexity to capability, and anticipating how requirements might shift as products mature. Let's build a practical decision framework you can actually use.

Volume-Based Die Selection Criteria

Production volume serves as the primary driver for die type selection—and the thresholds might surprise you. A custom metal stamping die representing a significant investment makes perfect sense at high volumes but becomes economically irrational for short runs.

Here's how volume typically influences tooling decisions:

Under 500 parts: Single-hit dies or even manual forming operations often prove most economical. The tooling investment stays minimal, and flexibility remains high for design iterations. Yes, labor costs run higher per part, but they're offset by dramatically lower upfront tooling expenditure.

500 to 10,000 parts: This middle ground gets interesting. Compound dies or simple combination tooling begin making economic sense. You're producing enough parts that modest tooling investment pays back through reduced labor and improved consistency—but not enough to justify complex progressive systems.

10,000 to 50,000 parts: Combination dies and simpler progressive dies enter the picture. The forming manufacturing process becomes more automated, cycle times drop, and your cost-per-part decreases meaningfully. Tooling investment increases, but payback periods shorten considerably.

50,000+ parts: Progressive dies become the clear winner for most applications. According to industry experience, the crossover point where progressive die economics beat simpler alternatives typically falls somewhere in this range—though exact thresholds depend heavily on part complexity and material costs.

500,000+ parts: At these volumes, every fraction of a second in cycle time matters. Highly optimized progressive dies with integrated sensors, automatic scrap removal, and in-die quality monitoring deliver maximum efficiency. The substantial tooling investment amortizes across enough parts that cost-per-piece approaches material cost alone.

Part Complexity Considerations

Volume tells only half the story. Part geometry and tolerance requirements significantly influence which types of forming approaches remain viable—regardless of production quantity.

Consider these complexity factors:

- Number of features: Parts requiring multiple punched holes, bends, and formed features favor progressive or transfer dies that complete operations sequentially

- Dimensional relationships: When tight tolerances between features matter most, compound dies performing simultaneous operations often deliver superior accuracy

- Three-dimensional depth: Deep-drawn or heavily formed parts may require transfer dies where workpieces move independently between stations

- Part size: Large components that cannot maintain strip connectivity during progressive operations necessitate transfer or single-station approaches

- Material flow requirements: Complex draw operations with controlled metal flow demand blank holder systems that simpler dies cannot accommodate

A seemingly simple bracket with three bends and two holes might run efficiently on a five-station progressive die. But a deep-drawn cup with embossed features and flanged edges could require a transfer system even at similar volumes—the geometry simply demands it.

From Prototype to High-Volume Production

Here's what many engineers overlook: die requirements evolve as products move from concept through production maturity. The tooling that makes sense during development rarely matches what you'll need at full production scale.

A smart approach follows this pathway:

- Concept validation (1-50 parts): Start with rapid prototyping methods—laser cutting, brake forming, or soft tooling. The goal is proving the design works, not optimizing production efficiency. Invest minimally until the design stabilizes.

- Design refinement (50-500 parts): Transition to simple hard tooling—single-hit dies or basic compound dies. This validates that the part can be stamped while maintaining flexibility for design tweaks. Custom metal stamping dies at this stage balance capability against revision risk.

- Pre-production (500-5,000 parts): Invest in production-representative tooling. This might mean a simplified progressive die or well-designed combination tooling. Parts from this stage support final testing, qualification, and initial customer shipments.

- Production ramp (5,000-50,000 parts): Optimize tooling based on lessons learned. Address wear patterns observed during pre-production, refine clearances based on actual material behavior, and add automation features that reduce operator intervention.

- Mature production (50,000+ parts): Deploy fully optimized production tooling. Progressive dies with maximum station efficiency, integrated quality monitoring, and robust maintenance provisions deliver lowest total cost of ownership at scale.

This staged approach manages risk intelligently. You're not investing in complex progressive tooling while designs remain fluid, but you're also not handicapping production efficiency once volumes justify sophisticated forming manufacturing solutions.

Practical Decision Framework

When evaluating die type options, work through this systematic process:

- Define your volume trajectory: Consider not just current needs but realistic projections for 12-24 months. Will volumes grow, remain stable, or decline as the product matures?

- Map part complexity: List every operation required—punching, blanking, forming, drawing. Identify critical tolerances and surface finish requirements.

- Assess design stability: How confident are you that the current design is final? Pending revisions argue for simpler, more flexible tooling.

- Calculate crossover economics: Get quotes for multiple die types serving your volume. Where does the cost-per-part crossover occur between simpler and more complex tooling?

- Factor maintenance and changeover: Complex dies require more sophisticated maintenance. If your shop lacks experience with progressive tooling, factor in the learning curve.

- Consider lead time requirements: Progressive dies take longer to design and build. If speed-to-market matters, simpler tooling gets you producing sooner.

- Plan for the future: Will this product family expand? Tooling that accommodates future variants may justify higher initial investment.

No single die type wins universally. The right choice emerges from honestly evaluating your specific situation against these criteria—balancing immediate needs against long-term efficiency.

Smart die selection sets the stage for successful production. But even perfectly chosen tooling requires ongoing attention to maintain performance. Understanding common wear patterns, failure modes, and maintenance practices keeps your investment delivering quality parts throughout its service life.

Die Maintenance and Troubleshooting Essentials

You've invested in quality tooling, selected the right die type, and optimized your forming process—but here's a reality that catches many manufacturers off guard: even the best steel dies degrade over time. Every press stroke chips away at performance, and without proper maintenance, your precision tooling gradually becomes a source of quality problems rather than quality assurance.

Think of die maintenance like preventive healthcare. Catching problems early costs far less than emergency repairs—and keeps your production line running smoothly. According to industry specialists at The Phoenix Group, poor die maintenance causes quality defects during production, driving up sorting costs, increasing the likelihood of shipping defective parts, and risking expensive forced containments.

Recognizing Common Die Wear Patterns

Before you can fix problems, you need to read them. Every scratch, burr, or dimensional drift in your die formed parts tells a story about what's happening inside your tooling. Learning to interpret these signals separates reactive firefighting from proactive management.

Abrasive wear appears as gradual material loss from die surfaces—visible as polished areas, shallow grooves, or dimensional growth in die openings. This wear pattern develops when hard particles (scale, debris, or work-hardened material fragments) slide across tool surfaces. You'll notice it first on die plate edges and punch faces where material contact is most intense.

Adhesive wear (galling) looks completely different. Instead of smooth erosion, you'll see torn, rough surfaces where workpiece material has welded to the die and then ripped away. Galling accelerates rapidly once it starts—each successive cycle tears more material, creating increasingly severe surface damage. Stainless steel and aluminum are particularly prone to this failure mode.

Fatigue wear manifests as fine surface cracks that eventually connect and cause material flaking or spalling. This pattern typically appears in high-stress areas subjected to repeated loading cycles. The die plate surface may look fine initially, but microscopic examination reveals networks of stress fractures waiting to propagate.

Impact damage shows as chipping, cracking, or localized deformation—usually traceable to specific events like misfeeds, double-hits, or foreign material in the press. Unlike gradual wear patterns, impact damage appears suddenly and often requires immediate attention.

According to Jeelix's technical resources, properly distinguishing between these wear types is the first step in prescribing the right remedy. Treating abrasive wear with lubrication changes won't help—you need harder tool materials or coatings. Conversely, addressing galling by increasing die hardness misses the root cause entirely.

Warning Signs That Demand Attention

Don't wait for catastrophic failure. These indicators signal that your machine dies need inspection or service:

- Increasing burr height: Burrs growing beyond acceptable limits indicate punch-to-die clearance has opened up through wear

- Dimensional drift: Parts gradually moving out of tolerance suggest die surfaces are eroding or components shifting

- Surface scratches on parts: Linear marks on formed surfaces reveal damage or debris accumulation on die surfaces

- Inconsistent forming depth: Variable draw depths or bend angles point to worn pressure pads or inconsistent die stamp alignment

- Increased forming force: Rising tonnage requirements often indicate lubrication breakdown or surface condition deterioration

- Unusual noise or vibration: Changes in press sound or feel frequently precede visible problems

- Stripped or stuck parts: Difficulty removing formed parts suggests surface galling or inadequate stripper function

Preventive Maintenance Best Practices

Reactive maintenance—fixing problems after they cause defects—costs significantly more than prevention. A systematic approach keeps your forging dies and forming tooling performing at peak capability while extending service life.

Recommended maintenance intervals:

- Every shift: Visual inspection for obvious damage, lubrication verification, scrap and debris removal from die surfaces

- Every 10,000-25,000 strokes: Detailed inspection of cutting edges, formed surfaces, and guide components; measurement of critical clearances

- Every 50,000-100,000 strokes: Complete die disassembly, thorough cleaning, dimensional verification of all wear surfaces, spring replacement evaluation

- Every 250,000-500,000 strokes: Comprehensive rebuild assessment, surface reconditioning or coating renewal, guide component replacement

These intervals vary based on material hardness, lubrication effectiveness, and part complexity. High-strength steel applications may require inspection at half these intervals, while soft aluminum forming might extend them.

Documentation matters enormously. According to The Phoenix Group's die maintenance guidelines, the work order system allows an organization to document, track, prioritize, and schedule all die repair or maintenance activities. Completed work orders should detail what was accomplished and provide means to track issue recurrence.

Regrinding Versus Replacement Decisions

When wear accumulates beyond acceptable limits, you face a critical decision: restore the existing tool or invest in replacement components? The answer depends on several factors.

Regrinding makes sense when:

- Wear is uniform and within the material's regrind allowance (typically 0.5-2mm total)

- No cracks, chips, or structural damage exist

- The die geometry allows material removal without compromising function

- Cost of regrinding runs significantly below replacement component cost

- Lead time for replacement exceeds production schedule tolerance

Replacement becomes necessary when:

- Wear exceeds maximum regrind limits established during die design

- Fatigue cracks have propagated beyond surface-level damage

- Dimensional accuracy cannot be restored through grinding alone

- The component has been reground multiple times and material is depleted

- Heat damage has altered the tool steel's hardness or microstructure

Smart die design anticipates this decision by specifying replaceable inserts at high-wear locations. Rather than regrinding or replacing entire die plates, you swap inserts at a fraction of the cost and downtime.

The goal isn't eliminating maintenance—that's impossible. The goal is transforming maintenance from an unpredictable crisis into a managed process that maximizes tooling value while minimizing production disruption. With proper attention, quality steel dies deliver years of reliable service, producing millions of precision parts before requiring significant intervention.

Automotive Industry Applications and Quality Standards

You've mastered die selection, maintenance, and troubleshooting—but here's where everything we've discussed gets tested at the highest level: automotive manufacturing. This industry doesn't just use sheet metal dies; it demands perfection from them. When a single defective stamping can trigger million-dollar recalls, the stakes couldn't be higher.

The automotive sector represents the ultimate proving ground for metal stamping die technology. According to industry quality specialists, a well-built tool and die is the foundation of successful stamping operations—when built precisely, it produces consistent and repeatable parts essential for meeting stringent quality standards.

Meeting OEM Quality Standards

Ever wonder why automotive stamping dies cost more and take longer to develop than tooling for other industries? The answer lies in certification requirements that leave zero room for error.

IATF 16949 certification has become the global quality management standard for automotive supply chains. Established by the International Automotive Task Force, this certification ensures consistent quality across every tier of suppliers. For stamping die manufacturers, meeting IATF standards means:

- Documented processes for every aspect of die design and fabrication

- Statistical process control throughout production

- Traceability from raw material through finished tooling

- Continuous improvement systems that identify and eliminate defects

- Customer-specific requirements integration into quality systems

What does this mean practically? Your forming die supplier must demonstrate not just capability, but systematic excellence. Shaoyi exemplifies this approach with their IATF 16949-certified operations, combining rigorous quality management with advanced engineering capabilities that meet the most demanding OEM specifications.

First-pass approval rates serve as the critical metric separating adequate tooling suppliers from exceptional ones. When a new sheet metal die enters production, how often do the first parts meet specifications without rework or adjustment? Industry leaders achieve rates exceeding 90%—Shaoyi reports a 93% first-pass approval rate, representing the benchmark for quality tooling development.

Why does this matter so much? Consider the alternative. Every failed tryout means:

- Additional engineering hours diagnosing problems

- Material waste from rejected trial parts

- Press time consumed by non-production activities

- Project delays that ripple through vehicle launch schedules

- Potential design compromises to accommodate tooling limitations

The difference between 70% and 93% first-pass success translates directly into development timeline and budget—often meaning weeks of schedule compression and significant cost savings.

How CAE Simulation Drives Defect-Free Results

Achieving those impressive first-pass rates doesn't happen by accident. Modern automotive tooling development relies heavily on Computer-Aided Engineering simulation to validate metal die designs before any steel gets cut.

According to automotive prototyping specialists, CAD models serve as the starting point for modern development—these digital blueprints guide production processes, ensuring precision and accuracy while enabling modifications before committing to physical tooling.

Advanced CAE simulation capabilities allow engineers to:

- Predict material flow, thinning, and potential failure points virtually

- Optimize blank holder pressures and draw bead configurations before tryout

- Validate spring-back compensation strategies through digital iterations

- Identify forming issues that would have required expensive physical prototyping

- Reduce development cycles from months to weeks

This simulation-driven approach fundamentally changes the economics of sheet metal dies development. Problems that once required multiple physical tryout iterations—each consuming press time, material, and engineering resources—now get resolved in virtual environments where changes cost nothing but computing time.

Accelerating Development with Rapid Prototyping

Speed matters in automotive development. Vehicle programs operate on aggressive timelines, and delays in tooling development cascade into launch schedule problems that can cost manufacturers millions in delayed revenue.

Rapid prototyping technologies have revolutionized how automotive components move from concept to production. According to Hidaka USA's automotive research, rapid prototyping eliminates the need for expensive tooling during early development phases by using technologies like 3D printing and CNC machining to produce prototypes in days rather than weeks.

The benefits extend beyond simple speed:

- Design validation: Physical models can be tested for form, fit, and function before committing to production tooling

- Cost-effectiveness: Early-stage prototypes avoid the expense of hard tooling for designs that may still change

- Parallel development: Multiple design variants can be prototyped simultaneously, accelerating decision-making

- Customer approval: Physical samples enable earlier customer review and feedback integration

Imagine reducing prototype lead times from weeks to just 5 days. That's exactly what leading suppliers like Shaoyi deliver through their integrated rapid prototyping and production tooling capabilities. This compressed timeline allows engineering teams to iterate designs faster, validate concepts earlier, and transition to production tooling with greater confidence.

From Prototype to High-Volume Production

The transition from prototype parts to production-ready sheet metal stamping dies requires careful planning. Automotive components must meet identical specifications whether produced during prototype validation or high-volume manufacturing—and the tooling must deliver that consistency across millions of cycles.

Key technologies enabling rapid tooling development include:

- 3D printing for complex prototype geometries and fixture development

- CNC machining for precision components requiring tight tolerances

- Wire EDM for hardened die components with complex profiles

- Rapid tooling that bridges the gap between prototyping and mass production

According to industry resources, rapid tooling is essential for creating prototypes that need to match the final product closely—allowing quick iterations and adjustments before full-scale production begins.

The automotive industry's demanding requirements have driven sheet metal forming dies technology to its highest levels of precision, reliability, and efficiency. The lessons learned here—rigorous quality systems, simulation-validated designs, and rapid development capabilities—apply across every industry where stamped components matter.

Whether you're launching a new vehicle platform or simply seeking to improve your existing stamping operations, the principles remain consistent: invest in quality tooling, validate designs thoroughly before cutting steel, and partner with suppliers whose capabilities match your quality expectations. That's how design flaws become flawless parts.

Frequently Asked Questions About Sheet Metal Forming Dies

1. What are the different types of stamping dies used in sheet metal forming?

The five primary types of stamping dies are progressive dies for high-volume continuous operations, compound dies for simultaneous blanking and piercing, combination dies that merge cutting and forming in one stroke, transfer dies for complex multi-station work on large parts, and single-hit dies for simpler low-volume applications. Progressive dies excel at 100,000+ part runs, while compound dies suit medium volumes requiring tight feature-to-feature accuracy. Transfer dies handle parts too large for progressive strip feeding, and single-hit dies offer flexibility for prototyping and frequent design changes.

2. What is the difference between forming operations like bending, drawing, and embossing?

Bending creates angular features through air bending, bottoming, or coining methods—each offering different levels of spring-back control. Drawing transforms flat blanks into cup-shaped or three-dimensional parts by controlling metal flow into die cavities using blank holders. Embossing produces raised or recessed surface features without breaking through the material, commonly used for logos or stiffening ribs. Each operation exploits different mechanical principles: bending relies on controlled plastic deformation at specific bend lines, drawing requires balanced material flow to prevent wrinkling or tearing, and embossing creates localized shallow deformation.

3. How do you calculate proper punch and die clearance for different materials?

Die clearance is calculated by multiplying material thickness by the recommended clearance percentage for that specific metal. Aluminum requires 12-16% clearance per side, mild steel needs 16-20%, stainless steel demands 18-24%, and copper uses the tightest at 10-14%. For example, 2.0mm mild steel requires 0.34-0.40mm total clearance. Proper clearance ensures clean shearing by aligning grain boundary fracture planes—too tight accelerates tool wear and generates excess heat, while too loose creates burrs requiring secondary finishing.

4. What tool steels are best for manufacturing durable sheet metal forming dies?

D2 tool steel serves as the industry standard, offering excellent wear resistance with hardness up to 62 HRC—ideal for blanking punches and general forming applications. A2 tool steel trades some wear resistance for improved toughness, making it preferable when dies experience shock loading or cut thicker materials. Carbide inserts address the most demanding wear situations, maintaining sharp edges even after millions of cycles. The choice depends on balancing wear resistance against impact toughness based on your specific application forces and production volume requirements.

5. How can automotive manufacturers ensure high-quality stamped parts with first-pass approval?

Achieving high first-pass approval rates requires IATF 16949-certified quality systems, advanced CAE simulation for virtual die validation, and rapid prototyping capabilities. Leading suppliers like Shaoyi achieve 93% first-pass approval rates by combining rigorous quality management with simulation-driven design that predicts material flow, thinning, and spring-back before cutting any steel. Their rapid prototyping in as little as 5 days allows design validation earlier in development, while comprehensive mold design capabilities ensure production tooling meets demanding OEM specifications from the start.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —