வாகன அலுமினியம் எக்ஸ்ட்ரூஷனுக்கான மேற்பரப்பு சிகிச்சை விருப்பங்கள்: சிறந்த பொருத்தம்

தானியங்கி எக்ஸ்ட்ரூஷன் முடிப்பு தெரிவுகளுக்கான அறிமுகம்

நீங்கள் தானியங்கி அலுமினியம் எக்ஸ்ட்ரூஷன்களை வாங்கும் போதோ அல்லது பொறியியல் செய்யும் போதோ, நீங்கள் தேர்வு செய்யும் முடிப்பு என்பது வெறும் அழகியல் முடிவு மட்டுமல்ல. உங்கள் பாகம் எவ்வாறு செயல்படும், எவ்வளவு காலம் நீடிக்கும், மற்றும் நவீன வாகன உற்பத்தி வரிசைகளில் எவ்வாறு ஒருங்கிணைக்கப்படும் என்பதை நிர்ணயிக்கும் முக்கியமான காரணியாகும். சிக்கலானதாக தெரிகிறதா? 2025 மற்றும் அதற்குப் பிறகு நிலைப்பாடு, தோற்றம் மற்றும் உற்பத்தி செயல்திறனை சமன் செய்யும் போது அது சிக்கலாக இருக்கலாம்.

- கடுமையான சூழல்கள் மற்றும் நீண்ட சேவை வாழ்விற்கு எதிராக சிதைவு எதிர்ப்பு

- இயங்கும் அல்லது வெளிப்படையான பாகங்களுக்கு உராய்வு மற்றும் அரிப்பு பாதுகாப்பு

- தெரிந்து கொள்ளக்கூடிய அலங்காரம் மற்றும் பிராண்டிங் தேவைகளை பூர்த்தி செய்ய தோற்ற வகுப்புகள்

- இணைப்பு ஒப்புதல் - வெல்டிங், ஒட்டும் பொருள் அல்லது இயந்திர ஃபாஸ்டனர்

- சூழலியல் சீரான தொடர்ந்து மாறிவரும் ஒழுங்குமுறைகளுடன்

- உயர் தொகுதி உற்பத்திக்கான வாகனத்திற்கான செலவு மற்றும் உற்பத்தி வெளியீடு

தானியங்கி அலுமினியம் எக்ஸ்ட்ரூஷன்களில் (automotive aluminum extrusions) முடிக்கும் தரம் ஏன் முக்கியம்

ஒரு கூரை ரெயில், பேட்டரி என்க்ளோசர் அல்லது உள்துறை ட்ரிம் பீஸை கற்பனை செய்து பாருங்கள் - இவை தங்கள் சொந்த சுற்றுச்சூழல் மற்றும் இயந்திர சவால்களை எதிர்கொள்கின்றன. சரியான அலுமினியம் பரப்பு முடிக்கும் தரம் என்பது பல ஆண்டுகளாக குறிப்பிடத்தக்க தோற்றத்தை வழங்கி காரோசியை எதிர்க்கும் பாகத்திற்கும், மற்றொரு பாகத்திற்கும் இடையே வேறுபாடு ஏற்படுத்துகிறது, இது பிட்டிங், பீலிங் அல்லது நிறம் மாற்றத்தின் காரணமாக முன்கூட்டியே தோல்வியடைகிறது. ஆட்டோமோட்டிவ் பொறியாளர்களுக்கு, இது தோற்றத்தை மட்டும் குறிக்கவில்லை - நம்பகமான செயல்திறனை உறுதி செய்ப்பதற்கும், உத்தரவாத இடர்களை குறைப்பதற்கும் இது முக்கியமானது.

பரப்பு சிகிச்சை என்றால் என்ன மற்றும் எங்கு ஒவ்வொன்றும் சிறப்பாக செயல்படுகிறது

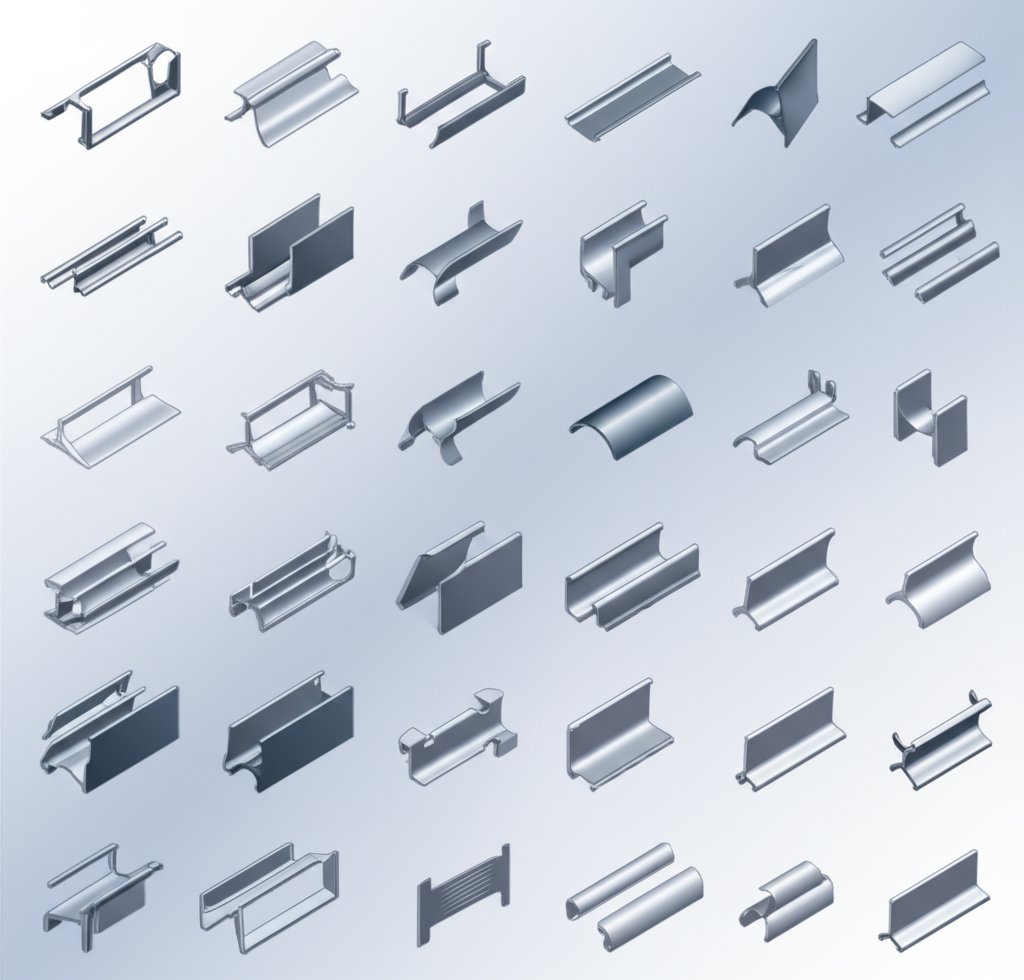

அலுமினியம் எக்ஸ்ட்ரூஷன்களின் உலகில், பரப்பு சிகிச்சை என்பது குறிப்பிட்ட செயல்பாட்டு அல்லது அழகியல் இலக்குகளை அடைய பரப்பை மாற்றும் எந்த செயல்முறையையும் குறிக்கிறது. இவை பின்வருவனவற்றை உள்ளடக்கியது:

- முன் சிகிச்சைகள்: மேலதிக முடிக்கும் நிலைகளுக்கு தயார்செய்யுதல், டீ-ஆக்சிடைசிங், மாற்று பூச்சுகளை பயன்படுத்துதல்

- ஆனோடைசிங் (Anodizing): காரோசியை எதிர்க்கும் மற்றும் அழிவு எதிர்ப்பு தன்மைக்கான மின்கேமிக்கல் அடர்த்தியான ஆக்சைடு அடுக்குகள், அலங்கார அல்லது கடினமான (வகை III) பதிப்புகளில் கிடைக்கின்றன

- பொடி பூச்சு மற்றும் ஈ-கோட் அமைப்புகள்: வண்ணம், வேதியியல் எதிர்ப்பு மற்றும் சீரான மூடிய பரப்புக்கு பயன்படுத்தப்படும் கரிம பூச்சுகள்

- மில் முடிப்பு மற்றும் பெயின்ட் பணிப்பாய்வுகள்: எக்ஸ்ட்ரூடெட் பரப்பை பிரைமர் மற்றும் பெயின்ட்டிற்கான அடிப்படையாகவும், செலவு மற்றும் நெகிழ்வுத்தன்மைக்கு இடையே சமநிலை கொண்டதாகவும் பயன்படுத்துதல்

இந்த அலுமினியம் பரப்பு முடிப்புகளில் ஒவ்வொன்றும் தனித்துவமான வலிமைகள் மற்றும் சமரசங்களைக் கொண்டுள்ளன. உதாரணமாக, ஆனோடைசிங் சிறந்த கார்ரோசன் பாதுகாப்பு மற்றும் வண்ணங்களின் வரிசையை வழங்குகிறது, பொடி கோட்டிங் வண்ணம் மற்றும் உருவமைப்பு விருப்பங்களின் பரந்த அளவில் நேர்த்தியான, விசித்திரமான அடுக்கை வழங்குகிறது. பீட் பிளாஸ்டிங் அல்லது பிரைட் டிப்பிங் போன்ற இயந்திர மற்றும் வேதியியல் முடிப்புகள் தோற்றத்தை மேலும் மெருகூட்டலாம் அல்லது பின்னர் வரும் பூச்சுகளுக்கு பரப்பை தயார் செய்யலாம். தேர்வு உங்கள் பயன்பாட்டின் குறிப்பிட்ட தேவைகளைப் பொறுத்தது - வெளிப்புற ட்ரிம்மிற்கு யுவி எதிர்ப்பு அல்லது மறைக்கப்பட்ட அமைப்பு பாகங்களுக்கு செலவு குறைந்த முடிப்பு போன்றவை.

இந்த தரவரிசைப்படுத்தப்பட்ட பட்டியலை தரப்படுத்தவும் மூலம் கொள்ளவும் எவ்வாறு பயன்படுத்துவது

இந்த வழிகாட்டி உங்கள் தேவைகளுக்கு ஏற்ப தரை சிகிச்சை விருப்பங்களை ஒப்பிடவும், தேர்வு செய்யவும் உதவும். அடுத்து வரும் பிரிவுகளில், ஒவ்வொரு முடிவும் பின்வருமவற்றுடன் மதிப்பீடு செய்யப்படும்:

- வேகமாக ஸ்கேன் செய்ய H3 தலைப்புகள் தெளிவாக உள்ளன

- புள்ளிகளில் நன்மைகள் மற்றும் தீமைகள்

- உலகளாவிய பயன்பாடுகள் மற்றும் தர விவரக்குறிப்புகள்

சம்பந்தப்பட்ட இடங்களில் நாங்கள் முக்கியமான தரநிலைகளையும் (ASTM, SAE, ISO, MIL-A-8625 போன்றவை) குறிப்பிடுவோம், இதன் மூலம் உங்கள் தேவைகளை தொழில் சிறப்பு நடைமுறைகளுடன் ஒருங்கிணைக்கலாம்.

சரியான உலோகக்கலவை, வசதி மற்றும் பாகத்தின் வடிவத்தை சரியான அலுமினியம் பரப்பு முடிப்புடன் இணைப்பது மிகவும் முக்கியமானது. தவறான கலவை நூல் வடிவ அரிப்பு, ஓரத்தின் மெலிதாக்கல் அல்லது மோசமான ஒட்டுதல் போன்ற பிரச்சினைகளுக்கு வழிவகுக்கலாம் - எதிர்காலத்தில் விலை உயர்ந்த தோல்விகளுக்கு காரணமாகலாம்.

தொடங்க தயாரா? பின்வரும் பிரிவுகள் ஒவ்வொரு முடிவு வகையையும் விரிவாக விளக்கும், உங்கள் செயல்திறன், தோற்றம் மற்றும் செலவு இலக்குகளை உங்கள் அடுத்த ஆட்டோமொபைல் திட்டத்திற்கு சரியான தீர்வுடன் பொருத்த உதவும்.

முறை மற்றும் மதிப்பீடு முறைகள் பரப்பு சிகிச்சைகளை தரவரிசைப்பதற்கான நிலைகள்

தானியங்கி பயன்பாடுகளுக்காக அலுமினியம் எக்ஸ்ட்ரூசன்களை முடிக்கும் டஜன் கணக்கான வழிகளை நீங்கள் எதிர்கொள்ளும் போது, எந்த செயல்முறை சிறந்த முடிவுகளை வழங்கும் என்று உங்களுக்கு எப்படி தெரியும்? விடை ஒரு தெளிவான, தடம் பிடிக்கக்கூடிய மதிப்பீட்டு செயல்முறையில் உள்ளது. இந்த பிரிவு, பொறியாளர்கள், வாங்குபவர்கள் மற்றும் தர மேலாளர்கள் அலுமினியம் பரப்பு சிகிச்சை குறித்து தகவல் அடிப்படையிலான முடிவுகளை எடுக்க உதவும் நிபந்தனைகள், படிகள் மற்றும் சோதனை புள்ளிகளை விரிவாக விளக்குகிறது - கடினமான தானியங்கி திட்டங்களில் செயல்பாடு மற்றும் ஒத்துழைப்பை உறுதி செய்வதற்காக.

தானியங்கி தரநிலைகளுக்கு ஏற்ப மதிப்பீட்டு நிபந்தனைகள்

ஓஇஎம் துருப்பிடித்தல் அல்லது ஒடுங்கும் தன்மை தேவைகளை பூர்த்தி செய்யாததை மட்டும் கண்டறிய, ஒரு பரப்பு சிகிச்சையை தேர்வு செய்வதை கற்பனை செய்யுங்கள். இதைத் தவிர்க்க, ஒவ்வொரு முடிவும் தொழில் தரநிலைகள் மற்றும் உண்மையான உற்பத்தி உலக உண்மைகளுக்கு எதிராக மதிப்பீடு செய்யப்படுகிறது. முக்கிய நிபந்தனைகள் பின்வருமவை:

- துருப்பிடித்தல் எதிர்ப்பு: உப்புத்தெளிப்பு மற்றும் சுழற்சி துருத்தடுப்பு சோதனைகளில் (ASTM, ISO, SAE நெறிமுறைகள்) செயல்திறன்

- ஒடுங்கும் தன்மை மற்றும் நிலைத்தன்மை: குறுக்கு வெட்டு, சீல் மற்றும் தாக்கம் சோதனைகளை உறுதி செய்யப்பட்டது

- வெடிக்கை: மின்தடை, நிறம் மற்றும் உருவமைப்பில் தொடர்ந்து செயல்படுதல், நிறமானியியல் மற்றும் தெரிவு நிலைகளின் மூலம் அளவிடப்படுகிறது

- பெயிண்ட்-பேக் ஒத்துழைப்புத்தன்மை: முழுமைத்தன்மையில் இழப்பின்றி கீழ்த்தரப்பு சிகிச்சை சுழற்சிகளை தாங்கும் திறன்

- சுற்றுச்சூழல் ஒத்துழைப்புத்தன்மை: இயலவிருக்கும் இடங்களில் குரோமேட்-இலவச மாற்ற பூச்சுகள் மற்றும் VOC-இலவச முடிவுகளை பயன்படுத்துதல்

- தயாரிப்பு வெளியீடு: சுழற்சி நேரம், மறுசெய்கை விகிதங்கள் மற்றும் தானியங்கு தயார்நிலை

- செலவு மற்றும் வழங்குதலில் தொடர்ச்சித்தன்மை: வாகனத்திற்கான செலவினத்தில் செல்வினை மற்றும் உயர்-தொகுதி வாகன அட்டவணைகளை ஆதரிக்கும் திறன்

இந்த நிலைகள் துவரொளியின் மேற்பரப்பு முடிவு முறைகள் தொழில்நுட்ப ரீதியாக சரியானதாக இருப்பதுடன், வாகன உற்பத்தி வரிசைகளுக்கு பொருத்தமானதாகவும் இருப்பதை உறுதிப்படுத்துகின்றது.

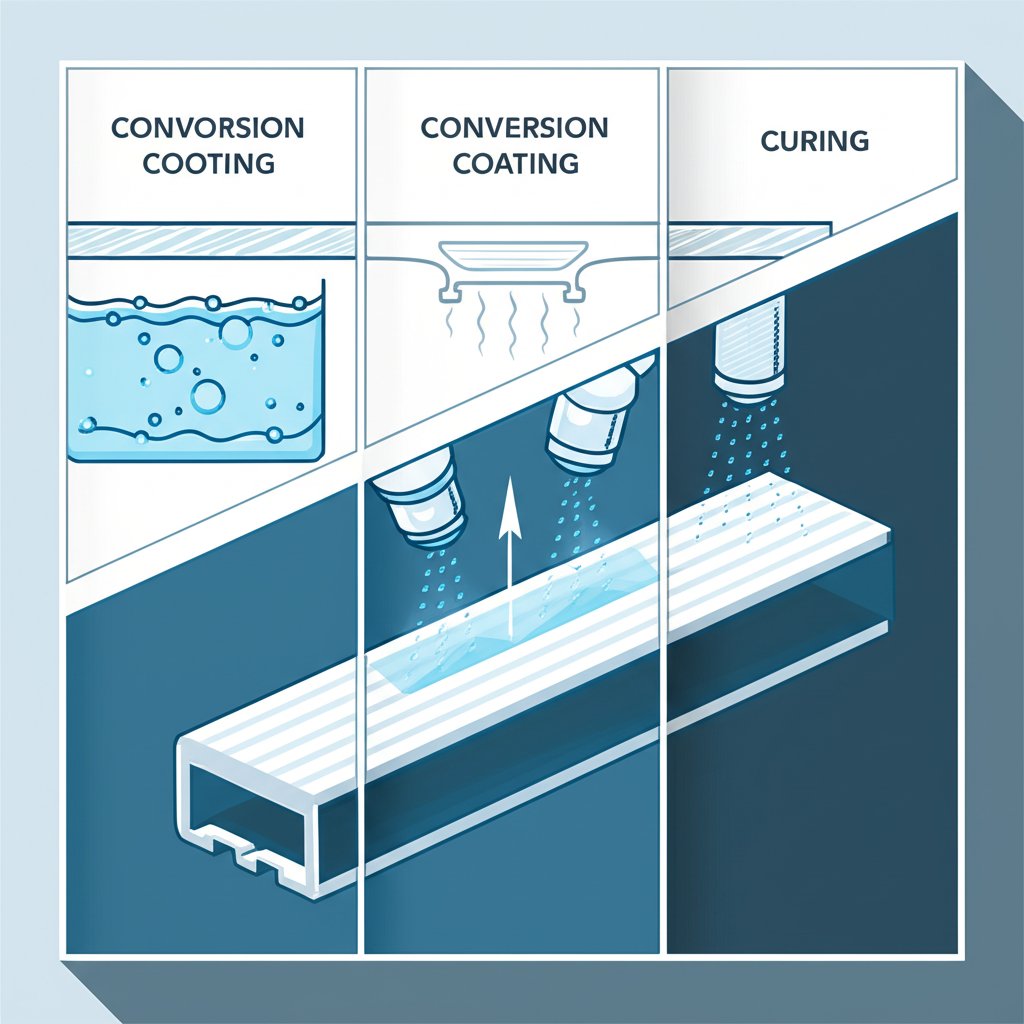

செயல்முறை பாதை: முன் சிகிச்சை முதல் டோப்கோட் வரை

உயர்தர முடிக்கப்பட்ட அலுமினியம் பாகத்திற்கான பயணம் ஒரு கட்டுப்பாடான செயல்முறையை பின்பற்றுகிறது. பிழை முறைகளுக்கான சாத்தியக்கூறுகளை கண்டறிய பின்வரும் வரிசைமுறை பார்க்கவும்:

-

சுத்தம் செய்தல் மற்றும் ஆக்சைடு நீக்கம் செய்தல்

- பிழை முறைகள்: எஞ்சியுள்ள எண்ணெய்கள் அல்லது ஆக்சைடுகள் காரணமாக ஒட்டுதல் இழப்பு; சீரற்ற சுத்தம் செய்தல் காரணமாக பட்டைகள் தோன்றும் முடிக்கப்பட்ட பரப்புகள்

-

மாற்று பூச்சு (குரோமேட்-இலவசம் விருப்பமானது)

- பிழை முறைகள்: மோசமான பயன்பாடு காரணமாக போதுமான எரிஷன் எதிர்ப்பு இல்லாமல் போதல்; தவறான நீரால் துவைக்கும் போது குமிழ்கள் உருவாதல்

-

தேர்ந்தெடுக்கப்பட்ட முடிக்கும் (அனோடைஸ், பொடி, ஈ-கோட், திரவ பெயின்ட்)

- பிழை முறைகள்: சிக்கலான வடிவங்களில் ஃபாரடே நிழல்; சீரற்ற படத்தின் உருவாக்கம்; காட்சிக்கூடிய பகுதிகளில் நிறம் பொருந்தாமை

-

குணப்படுத்துதல்/சீல் செய்தல்

- பிழை முறைகள்: அனோடைஸில் போதுமான சீல் இல்லாமை; கரிம பூச்சுகளில் மிகைப்பான சூடுபடுத்தல் அல்லது போதுமான குணப்படுத்தல் இல்லாமை; மினுமினுப்பு அல்லது ஒட்டுதல் இழப்பு

-

சரணிபாடு

- தோல்வி முறைகள்: விளிம்பு-மெல்லியதாகுதலை தவறவிடுதல், கண்டறியப்படாத பரப்பு குறைபாடுகள், அல்லது பள்ளங்களில் மோசமான மூடிய தன்மை

செங்குத்துதல், பூச்சு தடிமன், மற்றும் சுழற்சி நீராவியாகும் பொருட்டு ASTM மற்றும் ISO தரநிலைகளில் குறிப்பிடப்பட்டுள்ள சோதனை முறைகளைப் பயன்படுத்தி ஒவ்வொரு படிநிலையும் செல்லுபடியாகிறது. ஆனோடைசிங்கிற்கு, MIL-A-8625 ஒரு பொதுவான தரநிலையாகும், அதே நேரத்தில் பெயிண்ட்-பேக் மற்றும் பொருத்தம் தொடர்பான தரநிலைகள் OEM நெறிமுறைகளுக்கு எதிராக சோதிக்கப்படுகின்றன ( source ).

ஆய்வு மற்றும் ஏற்பு சோதனை நிலைகள்

தர உத்தரவாதம் வரிசையில் முடிவடைவதில்லை. மாறாக, பார்வை ஆய்வு, பரப்பு மேடுமூடும் அளவீடு, மற்றும் அழிவின்றி சோதனை (NDT) ஆகியவை முடிக்கப்பட்ட அலுமினியம் பாகம் தரநிலைகளுக்கு ஏற்ப உள்ளதை உறுதிப்படுத்த உதவுகின்றன. பொதுவான சோதனை நிலைகள் பின்வருமாறு:

- விரிசல்கள், பள்ளங்கள் அல்லது நிறம் மாற்றம் போன்றவற்றிற்கான பார்வை ஆய்வு

- பூச்சு தடிமன் அளவீடு (புரோஃபைலோமீட்டர் அல்லது மீயொலி முறைகள்)

- செங்குத்து சோதனை (குறுக்கு வரிசை, டேப் புல்)

- முக்கியமான பரப்புகளின் பரப்பு மேடுமூடும் சோதனைகள்

- தோற்றத்திற்கான பாகங்களுக்கு குறிப்பாக நிறம் மற்றும் மினுமினுப்பு மதிப்பீடு

அலுமினியம் எக்ஸ்ட்ரூஷன்களில் உள்ள பூச்சுகள் செயல்பாடு மற்றும் தோற்றத்தை வழங்குவதை உறுதிசெய்ய இந்த படிகள் முக்கியமானவை.

சப்ளை செய்வதை எளிதாக்கும் வகையில் வார்த்தைகளுக்கான வடிவமைப்புகள்

[சம்பந்தப்பட்ட தரநிலை] இன் தரத்திற்கு முடிவு சம்மதமாக இருக்க வேண்டும், மேலும் OEM நெறிமுறையின் படி பிடிப்புத்தன்மை மற்றும் சுழற்சி சேதத்தை தாங்க வேண்டும். வேறு விதமாக குறிப்பிடப்படாவிட்டால், மாற்று பூச்சு குரோமேட்-இலவசமாக இருக்க வேண்டும். முக்கியமான அளவுகள் மற்றும் திரெட் செய்யப்பட்ட அம்சங்களை மறைக்கவும். பூச்சு தடிமன் வரைபடத்தின் திட்டத்தை சேர்க்கவும்.

உங்கள் சப்ளை ஆவணங்களில் தெளிவான, தரநிலை அடிப்படையிலான மொழி வழங்குநர்கள் சரியான அலுமினியம் மேற்பரப்பு சிகிச்சையை வழங்க உதவுகிறது.

தயாரிப்பு மற்றும் முடிப்பதற்கான வடிவமைப்பு (DFM/DFA) கருத்தில் கொள்ள வேண்டியவை

உங்கள் வரைபடங்களை இறுதி செய்யும் முன், பின்னர் ஏற்படும் ஆச்சரியங்களைத் தவிர்க்க இந்த நடைமுறை குறிப்புகளைக் கருத்தில் கொள்ளவும்:

- மறைக்கப்பட வேண்டிய அல்லது செலுத்த வேண்டிய பகுதிகளை அடையாளம் காணவும் (திரெட்கள், துளைகள், மின்னணு தொடர்புகள்)

- மெல்லிய அல்லது கூர்மையான விளிம்புகள் பூச்சு சீராக இல்லாமல் இருப்பதைத் தடுக்க விளிம்பு ஆரத்தை வடிவமைக்கவும்

- ஹோலோ எக்ஸ்ட்ரூஷன்களுக்கு சரியான ஒழுக்கு மற்றும் வென்டிங் உறுதி செய்யவும், சிக்கியுள்ள திரவங்கள் அல்லது முழுமையற்ற மூடிய தடுக்க

- திரைடிவிங் காரணமாக அளவுரு மாற்றங்களைக் கணக்கில் எடுத்துக்கொள்ளவும் - இறுக்கமான பொறுப்புகளுக்கு முக்கியம்

இந்த வழிகாட்டுதல்களைப் பின்பற்றுவதன் மூலம், நீங்கள் தொழில்நுட்ப மற்றும் உற்பத்தி இலக்குகளை பூர்த்தி செய்யும் அலுமினியம் எக்ஸ்ட்ரூஷன்களை குறிப்பிடவும், முடிக்கவும் முடியும். அடுத்து, ஒருங்கிணைந்த மேற்பரப்பு சிகிச்சை வழங்கல் பற்றிய விமர்சனத்துடன் தொடங்கி, உண்மையான உலக முடிக்கும் தீர்வுகளில் இந்த விமர்சனங்கள் எவ்வாறு செயல்படுகின்றன என்பதை நாம் பார்ப்போம்.

சாயி ஆட்டோமொபைல் எக்ஸ்ட்ரூஷன்களுக்கான மேற்பரப்பு சிகிச்சை தீர்வுகள்

உங்கள் வாங்குதல் அலுமினியம் எக்ஸ்ட்ரூஷன் பாகங்கள் ஆட்டோமொபைல் திட்டங்களுக்கு, நம்பகமான, ஒருங்கிணைந்த முடிக்கும் பங்காளியின் தேவை தெளிவாகிறது. அனைத்து முக்கிய முடிக்கும் செயல்முறைகளையும் - அனோடைசிங் (அலங்காரம் மற்றும் கடினமானது), பவுடர் கோட்டிங், ஈ-கோட், மற்றும் மேம்பட்ட பெயின்ட் சிஸ்டம்கள் - ஒரே இடத்தில் கிடைப்பதை கற்பனை செய்து பாருங்கள், மேலும் உறுதியான தர உத்தரவாதம் மற்றும் முழு டேட்டா கண்காணிப்பு ஆதரவு கிடைக்கிறது. அதுதான் ஆட்டோமொபைல் அலுமினியம் எக்ஸ்ட்ரூஷன்களுக்கு சாயி, ஒரு முன்னணி அலுமினியம் முடிக்கும் நிறுவனம் வழங்குவது.

ஆட்டோமொபைல் எக்ஸ்ட்ரூஷன்களுக்கு சாயி வழங்குவது என்ன

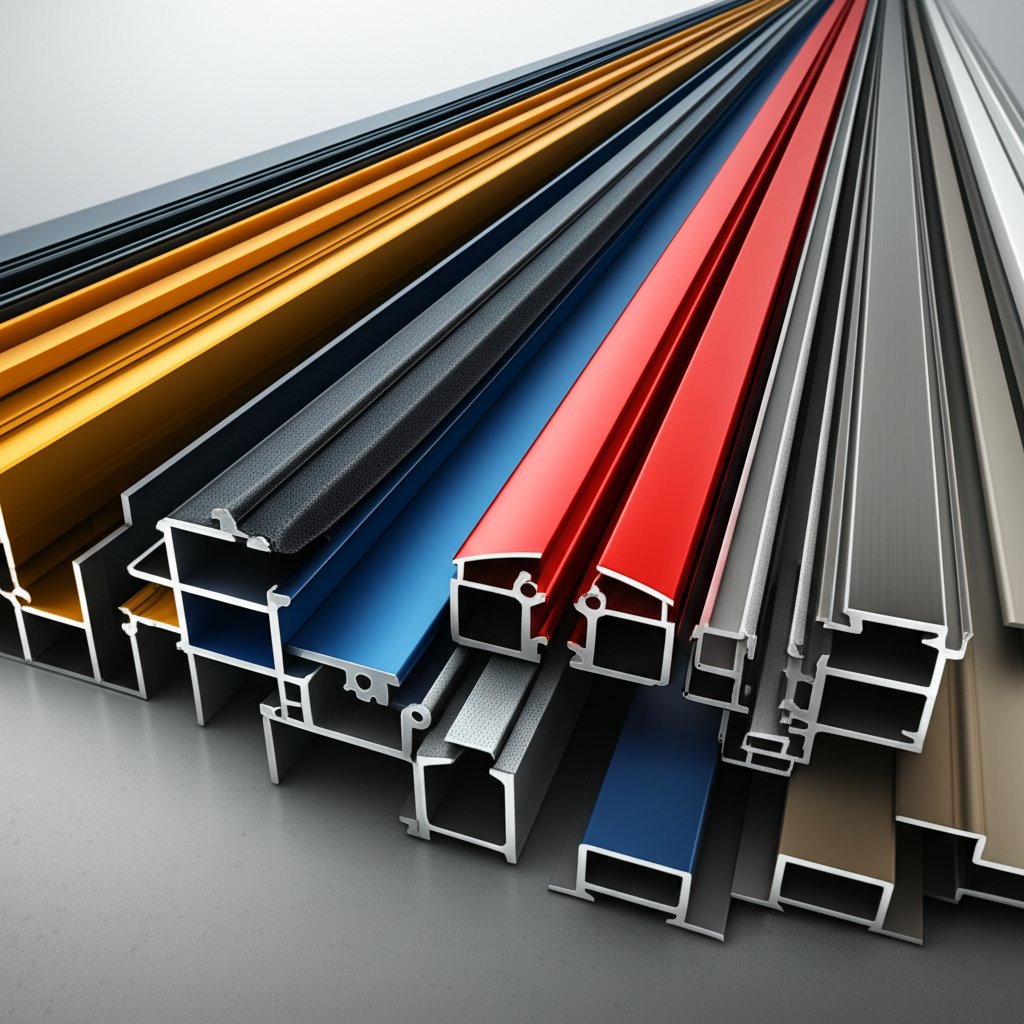

ஷாயி ஆட்டோமோட்டிவ் அலுமினியம் எக்ஸ்ட்ரூஷன்களுக்கான முழுமையான பரப்பு சிகிச்சை விருப்பங்களை வழங்குவதன் மூலம் தனித்து நிற்கிறது. அவற்றின் திறன்கள் பின்வருமவற்றை உள்ளடக்கியது:

- ஆனோடைசிங் (Anodizing): காட்சிப்படுத்தப்பட்ட ட்ரிம் அல்லது அதிக அணிகலன்களுக்கான ஹார்ட் ஆனோடைஸ் ஆகியவற்றிற்கான அலங்கார முடிவுகள்

- பவுடர் கோட்டிங்: வெளிப்புறம் அல்லது ஹூட் கீழ் கூறுகளுக்கு ஏற்றது, நிறம் மற்றும் உருவமைப்பில் பரந்த தெரிவு

- இ-கோட் (எலெக்ட்ரோபோரெட்டிக் பெயிண்டிங்): சிக்கலான அல்லது மூடிய பிரோஃபைல்களில் மிக சீரான பிரைமர் மூட்டுதல்

- பெயிண்ட் சிஸ்டம்ஸ்: மில் முடிப்பு மற்றும் செலவு உணர்வுடன் கூடிய பயன்பாடுகளுக்கு பெயிண்ட் சேர்க்கையுடன் கூடிய வெட் பெயிண்ட் மற்றும் பிரைமர் பணிமுறைகள்

- முன் சிகிச்சை மற்றும் மாஸ்கிங்: துல்லியமான சுத்திகரிப்பு, கன்வெர்ஷன் பூச்சுகள் (குரோமேட்-இலவசம் உட்பட) மற்றும் நூல்கள், போர்கள் மற்றும் முக்கியமான அம்சங்களுக்கான தனிபயன் மாஸ்கிங்/பிளக்கிங்

ASTM, SAE, ISO, மற்றும் MIL-A-8625 ஆகியவற்றிற்கு ஆவணங்கள் மற்றும் தர நிர்ணயத்தின் படி அனைத்து செயல்முறைகளும் ஆதரவு பெறுகின்றன, வாங்குபவரின் தரவரைவுகள் மற்றும் உலகளாவிய OEM தேவைகளுடன் தொடர்ச்சியான ஒத்திசைவை உறுதி செய்கின்றன source ).

இது சிறப்பாகச் செயல்படும் இடம் மற்றும் இதைத் தேர்வு செய்ய வேண்டிய நேரம்

உங்கள் அனைத்து எக்ஸ்ட்ரூஷன் தேவைகளுக்கும் ஒரே ஒரு அலுமினியம் முடிக்கும் நிறுவனத்தை நம்புவதற்கு என்ன காரணம்? இங்கே ஷாயியின் அணுகுமுறை சிறப்பாக இருக்கிறது:

- ஒருங்கிணைந்த செயல்முறை ஓட்டம்: முன் சிகிச்சை முதல் இறுதி ஆய்வு வரை ஒவ்வொரு படியும் ஒரே கூரையின் கீழ் மேலாண்மை செய்யப்படுகிறது, தலைமை நேரத்தைக் குறைத்தல் மற்றும் கைமாற்ற பிழைகளைக் குறைத்தல்

- தர மேலாண்மை மோட்டார் வகை: APQP/PPAP ஆதரவு, மேம்பட்ட செயல்முறை கட்டுப்பாடு மற்றும் IATF 16949 சான்றிதழ்

- ஓடும் தடிமன் வரைபடம்: சிக்கலான வடிவங்கள் மற்றும் முக்கியமான பரப்புகளுக்கான விரிவான ஆவணம்

- உலோகக்கலவை மற்றும் வெப்ப வழிகாட்டுதல்: பெயின்ட்-பேக் சைக்கிள்கள் அல்லது டௌன்ஸ்ட்ரீம் அசெம்பிளுடன் ஒத்துழைப்பதை உறுதிசெய்ய நிபுணர்களின் ஆலோசனை

- தொடர்ந்து வழங்கும் தொடர்புத்தன்மை: அதிக அளவிலான OEM உற்பத்தி திட்டங்களை ஆதரிக்கும் நிரூபிக்கப்பட்ட பதிவு

தோற்றம், துருப்பிடிக்காமை மற்றும் உற்பத்தி அளவு ஆகியவை முக்கியமான திட்டத்தை நிர்வகிக்கின்றீர்கள் என்றால், ஷாயியின் முழுமையான சேவை மாடல் உங்கள் பணிச்செயல்முறையை எளிதாக்குகிறது மற்றும் ஆபத்தைக் குறைக்கிறது.

பாரம்பரியங்கள் மற்றும் தவறுகள்

பார்வைகள்

- முதன்மை அலுமினியம் பூச்சுகள் மற்றும் பரப்பு சிகிச்சைகளுக்கான ஒரே இடத்தில் கிடைக்கும் சேவை

- ஒருங்கிணைந்த QA மற்றும் தரநிலை ஒத்துழைப்பு (ASTM, SAE, ISO, MIL-A-8625)

- பூசப்பட்ட அலுமினியம் பாகங்களுக்கான அலங்கார மற்றும் செயல்பாடுகளுக்கான நிபுணத்துவம்

- தொடர்பு செயலிழப்புகளின் ஆபத்தைக் குறைக்கும் வகையில் வழங்குநர் கைமாற்றங்களைக் குறைத்தல்

- சிக்கலான முகமூடி/சீல் மற்றும் பல செயல்முறைகளுக்கான ஆதரவு

தவறுகள்

- குறிப்பிட்ட முடிவுகளுக்கு குறைந்தபட்ச ஆர்டர் அளவுகள் (MOQகள்) தேவைப்படலாம்

- உற்பத்தி அட்டவணை சிறப்பாக சிறிய அளவிலான இயந்திர பேட்ச் ஜன்னல்களுடன் ஒத்திசைக்கப்படலாம், இதனால் மிகச் சிறிய இயந்திர இயக்கங்களுக்கு நெகிழ்வுத்தன்மை பாதிக்கப்படலாம்

பயன்பாட்டு சூழல்கள் மற்றும் ஒத்துழைக்கக்கூடிய உலோகக் கலவைகள்

- தோற்றத்திற்கான தரங்களை தேவைப்படும் வெளிப்புற அலங்கார பாகங்கள்: தெரிந்தும் பயன்படுத்தப்படும் பரப்புகளில் நிலையான நிறம் மற்றும் பளபளப்பை வழங்குவதற்கு அழகியல் ஆனோடைசிங் அல்லது பவுடர் கோட்டிங் பயன்படுத்தவும்

- பெயிண்ட்-பேக் ஒத்துழைப்பினை தேவைப்படும் அமைப்பு பாகங்கள்: தொழில்நுட்ப செயலாக்கங்களை தாங்கும் வகையில் உங்களுக்கு தேவையான உலோகக் கலவை/தன்மை மற்றும் கோட்டிங் முறைமையை தேர்வு செய்யவும்

- மேல்பூச்சிற்கு கீழ் ஈ-கோட் தேவைப்படும் பேட்டரி என்கிளோசர் பாகங்கள்: சிக்கலான, மூடிய வடிவங்களில் கூட உறுதியான துருப்பிடிக்காத எதிர்ப்பை வழங்கவும்

தரக்கட்டுப்பாடு மற்றும் தரநிலை ஆதரவு

ஷாயியின் மேற்பரப்பு சிகிச்சை தீர்வுகள் கடுமையான தரக்கட்டுப்பாட்டின் அடிப்படையில் உருவாக்கப்பட்டுள்ளது. கோட்டிங் அலுமினியம் அல்லது முடிக்கப்பட்ட எக்ஸ்ட்ரூசனின் ஒவ்வொரு பேட்ச்சும் பின்வருவனவற்றிற்காக ஆய்வு செய்யப்படுகிறது:

- சேதமின்றி முறைகளைப் பயன்படுத்தி பூச்சு தடிமன் மற்றும் சீரமைப்பு

- சம்பந்தப்பாடு மற்றும் துருப்பிடிப்பு எதிர்ப்பு (சம்பந்தப்பட்ட ASTM/ISO/MIL தரநிலைகளுக்கு ஏற்ப)

- அலங்கார முடிவுகளுக்கான தோற்றம் மற்றும் பளபளப்பு

- முக்கியமான அம்சங்களின் சரியான மறைப்பு மற்றும் பாதுகாப்பு

தொழில்நுட்ப ஆதரவானது விரிவான வரைபடத் திட்டங்கள், தொடர்ந்து ஆவணம் செய்யக்கூடிய ஆவணங்கள் மற்றும் உங்கள் தேர்ந்தெடுத்த உலோகக்கலவை மற்றும் பாக வடிவவியலுக்கு சரியான முடிவை குறிப்பிடுவதற்கான வழிகாட்டுதல் ஆகியவற்றை உள்ளடக்கியது

உங்கள் எக்ஸ்ட்ரூசன்கள் பல பூச்சு தொழில்நுட்பங்களிலிருந்து ஒற்றை மூல முடிவு மற்றும் QA தொடர்புடைமையிலிருந்து பயனடைகின்றன - பல வழங்குநர் ஒருங்கிணைப்பின் சிக்கல்களைத் தவிர்க்கவும், ஒவ்வொரு பாகமும் செயல்பாட்டு தரநிலைகளை பூர்த்தி செய்வதை உறுதிசெய்யவும்

ஷாயி போன்ற நம்பகமான அலுமினியம் முடிப்பு நிறுவனத்தைத் தேர்வுசெய்வதன் மூலம், ஒருங்கிணைந்த தரக் கட்டமைப்பின் கீழ் பூச்சு அலுமினியம் மற்றும் முழுமையான முடிக்கப்பட்ட பொருத்தங்களை வழங்கக்கூடிய பங்காளியை நீங்கள் பெறுகிறீர்கள். அடுத்து, தனிப்பட்ட முடிவு வகைகள் - டைப் II ஆனோடைசிங் உட்பட - செயல்பாட்டு நிலப்பரப்பில் எவ்வாறு பொருந்துகின்றன என்பதைப் பார்ப்போம்.

வகை II ஆனோடைசிங்

வகை II ஆனோடைசிங் குறிப்பு மற்றும் தோற்ற விருப்பங்கள்

பிரீமியம் ஆட்டோமோட்டிவ் ட்ரிம்மின் சீரான, தொடர்ந்து கிடைக்கும் தோற்றத்தை நீங்கள் பார்க்கும்போது, நீங்கள் Type II ஆனோடைசிங்கின் விளைவைத்தான் பார்த்துக் கொண்டிருக்கிறீர்கள். ஆனால் இந்த செயல்முறை செயல்திறன் மற்றும் தோற்றத்திற்கு ஏன் மிகவும் பயனுள்ளதாக இருக்கிறது? Type II ஆனோடைசிங், அடிக்கடி சல்பூரிக் ஆசிட் ஆனோடைசிங் என அழைக்கப்படுவது, அலுமினியத்தில் ஒரு கட்டுப்பாட்டு ஆக்சைடு அடுக்கை உருவாக்குகிறது, இது எரிமான பாதுகாப்பையும், தோற்றத்தையும் மேம்படுத்துகிறது.

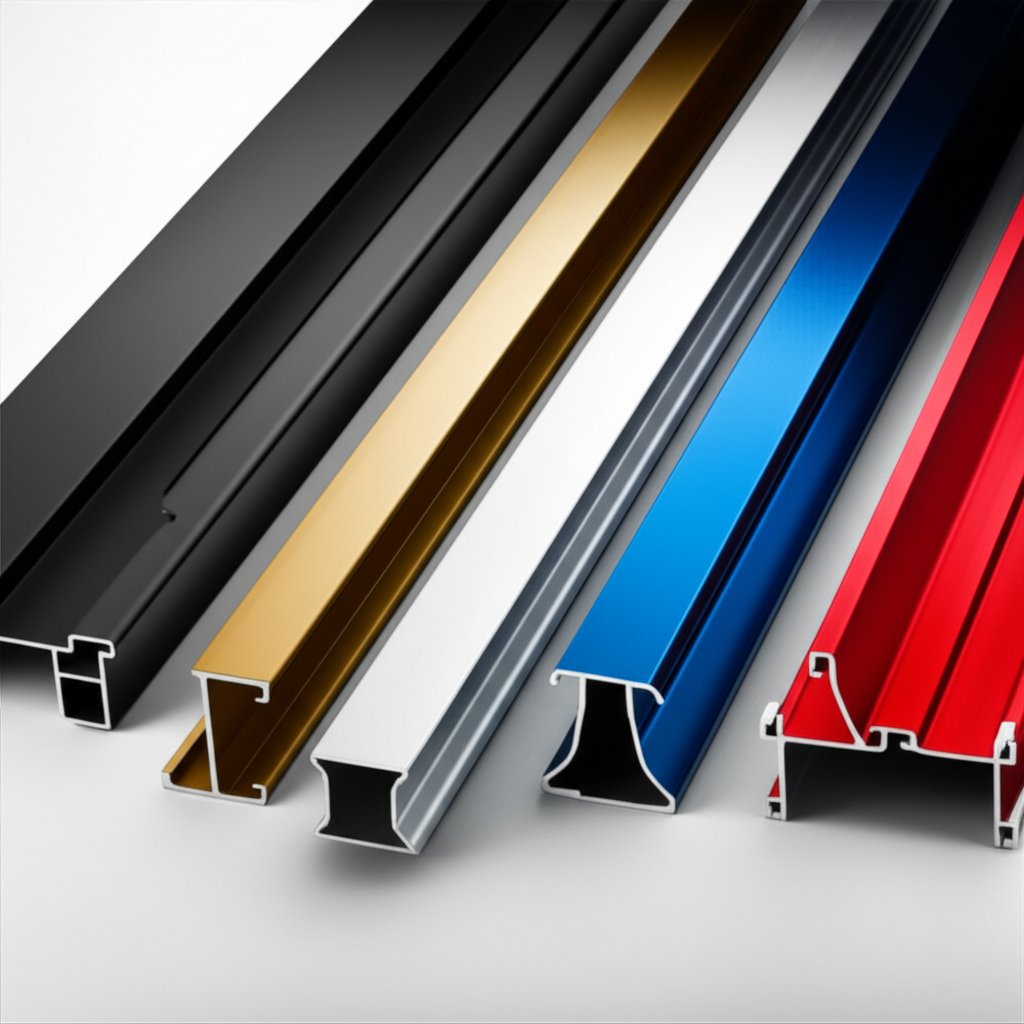

இந்த முடிவு தோற்றத்தின் பல்வேறு வகைகளை வழங்கும் திறனுக்கு மிகவும் மதிப்புமிக்கதாக கருதப்படுகிறது. கீழ்க்கண்ட விருப்பங்களை நீங்கள் காணலாம்:

- மட்டான ஆனோடைசிங் செய்யப்பட்ட அலுமினியம்: விரல்தட பொறுப்புத்தன்மை கொண்ட மெல்லிய, குறைந்த பளபளப்புடன் கூடிய தோற்றம், மற்ற பொருட்களுடன் நன்றாக பொருந்தும்

- மேட்டே அலுமினியம் முடிவு: ஆனோடைசிங்கிற்கு முன் பீட் பிளாஸ்டிங் அல்லது எட்சிங் மூலம் உருவாக்கப்பட்டது, மென்மையான, பிரதிபலிக்காத தோற்றத்தை வழங்குகிறது

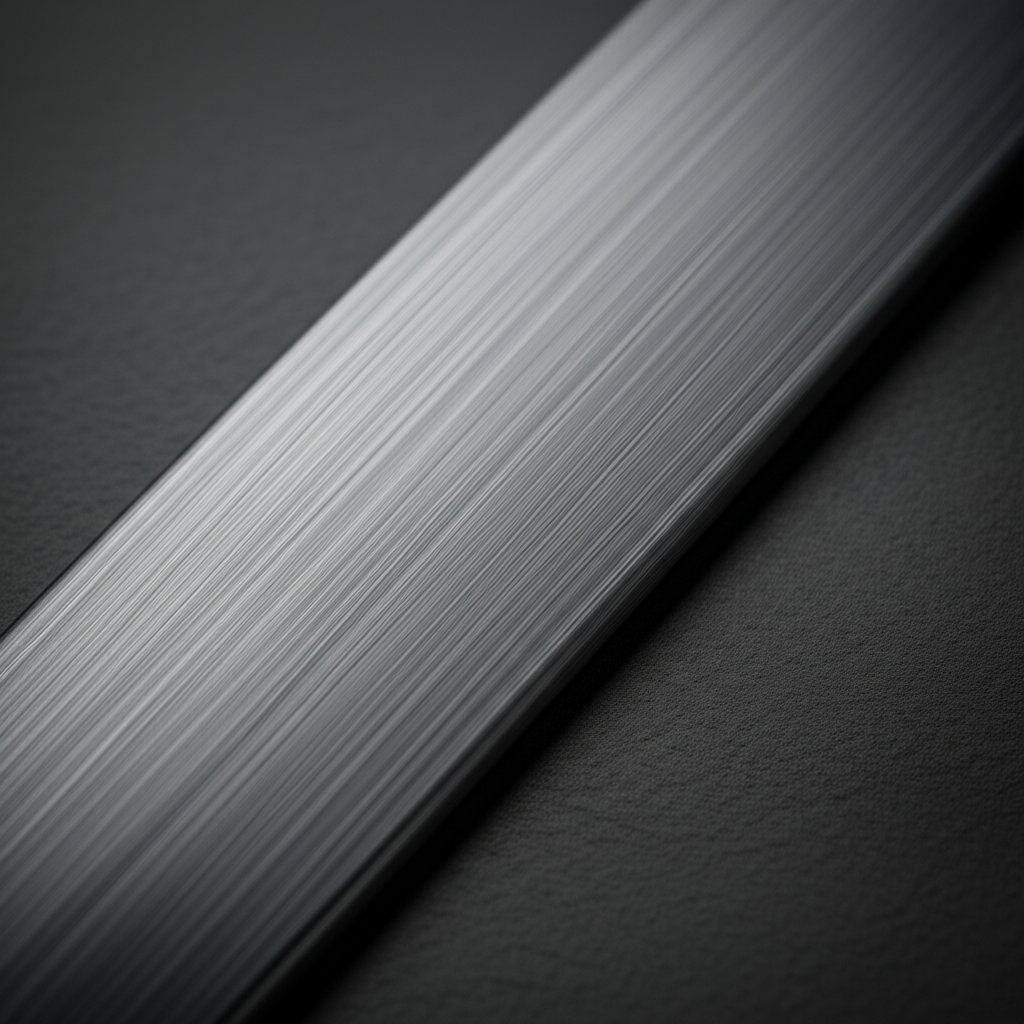

- அலுமினியம் பிரஷ் செய்யப்பட்ட முடிவு: ஆனோடைசிங்கிற்கு முன் இயந்திர பிரஷ்சிங் மூலம் உருவாக்கப்பட்டது, நேர்கோட்டு மற்றும் உருவாக்கப்பட்ட தோற்றத்தை வழங்குகிறது

- நிற டையிங்: ஆக்சைடு அடுக்கு டைகளை ஏற்றுக் கொள்ள தயாராக இருப்பதால், இயற்கை வெள்ளியிலிருந்து ஆழமான கருப்பு, வெங்காலம் அல்லது தனிபயன் நிறங்கள் வரை பல்வேறு வண்ண தெரிவுகளை வழங்குகிறது

வகை II ஆனோடைசிங்கின் முக்கியமான நன்மை என்னவென்றால், நேர்த்தியான மாடிசாய்ஸ் அலுமினியம் முடிக்கும் திறனை வழங்குவது, இது நேரம் கழித்து சிப்பில், பீல் அல்லது மங்கலாக மாறாது. முடிக்கும் பகுதி தனி அடுக்கு அல்ல, மாறாக மேற்பரப்பின் ஒரு பகுதியாகும், எனவே அது தொடர்ந்து கையாளும் போதும் அதன் முழுமைத்தன்மையை பாதுகாத்துக் கொள்கிறது.

Automotive Performance Fit

வகை II ஆனோடைசிங் என்னவென்றால் அலுமினியம் எக்ஸ்ட்ரூசன்களுக்கு பிரபலமான தேர்வாக இருப்பதற்கு காரணம் என்ன? இது நீடித்த தன்மை, தோற்றம் மற்றும் செயல்முறை நம்பகத்தன்மையை சமன் செய்வது பற்றியது. ஆனோடைசிங் செயல்முறையின் போது உருவாகும் ஆக்சைடு அடுக்கு என்பது குறிப்பாக வெளிப்புறம் மற்றும் உட்புற ட்ரிம், கூரை ரெயில்கள், மற்றும் வெவ்வேறு சூழல்களுக்கு உள்ளாகும் அலங்கார விருப்பங்களுக்கு எதிராக காரோசனுக்கு எதிராக ஒரு வலுவான தடையாக செயல்படுகிறது.

மேலும், அலுமினியம் மாட்டு (satin) முடிவுற்ற பகுதி இரண்டாம் நிலை செயல்முறைகள் மற்றும் கீழ்நோக்கு சேர்க்கைக்கு மிகவும் ஒத்துழைக்கக்கூடியது. ஆனோடைசேஷன் செய்யப்பட்ட பரப்பு பிரீமியம் உலோகத் தோற்றத்திற்கு அப்படியே விட்டுவிடலாம், அல்லது பிராண்டிங் அல்லது பாகங்களை அடையாளம் காணும் தேவை இருக்கும் போது பெயிண்ட்டுகள், மைகள் அல்லது லேசர் குறிப்புகளுடன் மேல்பூச்சு செய்யலாம். ஆனோடைசேஷன் அடுக்கை சீல் செய்வது நிலையான நடைமுறையாகும், நிறத்தை நிலைநிறுத்துவதற்கும், பசை அல்லது சுற்றுச்சூழல் தாக்கங்களுக்கு எதிரான எதிர்ப்பை அதிகரிப்பதற்கும் இது உதவும். இதனால் தான் Type II ஆனோடைசிங் சிறப்பான தோற்றத்துடன் நீடித்துழைக்கும் பாகங்களுக்கு சிறந்ததாக கருதப்படுகிறது - பொடி போடுதல், நிறம் மங்குதல் அல்லது கருப்பேறுதல் போன்ற அபாயங்கள் இல்லாமல் இருக்க இது உதவும்.

பாரம்பரியங்கள் மற்றும் தவறுகள்

பார்வைகள்

- பெரும்பாலான ஆட்டோமோட்டிவ் சூழல்களுக்கு சிறந்த துருப்பிடிக்காத எதிர்ப்பு

- சீரான, மீண்டும் மீண்டும் தோற்றம் - காட்சிக்கு தெரியும் ட்ரிம்மிற்கு மிகவும் முக்கியம்

- முடிவுற்ற பல்வேறு வகைகள்: மாட்டு (satin), மாட்டு (matte), மற்றும் பிரஷ் செய்யப்பட்ட, நிறத்துடன் அல்லது நிறமின்றி

- இணைக்கப்பட்ட, பிரியாத பரப்பு - பெயிண்ட் போல பொருந்துவதற்கான வாய்ப்பு இல்லை

- சுற்றுச்சூழலுக்கு நட்பானது; VOC இல்லை மற்றும் குறைந்த பராமரிப்பு தேவை

- சிறிய கீறல்களுக்கு சீரமைப்பது சாத்தியம், பழுதுபார்க்கும் கிட்டுகளுடன்

தவறுகள்

- அதிக உராவல் பாகங்களுக்கு Type III ஆனோடைசிங் ஐ விட குறைவான அணிவிக்கும் எதிர்ப்பு

- நிறம் மற்றும் பளபளப்பு ஆகியவற்றை தொகுதிகளுக்கு இடையில் பராமரிக்க சரியான செயல்முறை கட்டுப்பாடு தேவை

- சேர்ப்பு போது உள்ள வெப்ப விளைவுகள் (எ.கா., வெல்டிங்) முடிக்கும் நிறத்தை மாற்றலாம்

- கனமான உராய்வு அல்லது சுமை சுமக்கும் பரப்புகளுக்கு ஏற்றதல்ல

பயன்பாடுகள் மற்றும் QA சரிபார்ப்பு புள்ளிகள்

- வெளிப்புற ட்ரிம்: சாடின் அலுமினியம் முடிக்கும் தேவையான இடங்களில் கதவு கைப்பிடிகள், சன்னல் சுற்றுப்புறங்கள் மற்றும் கிரில் அலங்காரங்கள்

- உள் அலங்கார பாகங்கள்: டாஷ்போர்டு செருகுதல்கள், கட்டுப்பாடு பெசல்கள் மற்றும் இருக்கை ட்ரிம், அலுமினியம் சாடின் முடிக்கும் தொடர்பு உணர்வு மற்றும் தொழில்முறை ஒருமைத்தன்மை நன்மை பயக்கும்

- கூரை தாங்குதல் மூடிகள்: நிறம் பொருத்தம் மற்றும் UV நிலைத்தன்மை நீண்ட கால தோற்றத்திற்கு முக்கியமான இடங்களில்

வகை II ஆனோடைசிங்கிற்கான தர உத்தரவாதம் பொதுவாக பின்வருவனவற்றை உள்ளடக்கியது:

- அதிகபட்ச துருப்பிடிப்பு எதிர்ப்பை உறுதிசெய்ய சீல் தரம் சோதனைகள்

- நிறம் மற்றும் பளபளப்பு ஒருமைத்தன்மைக்கான தோற்ற வகை மாதிரி எடுத்தல்

- இரண்டாம் நிலை பெயிண்ட்கள் அல்லது மைகள் பயன்படுத்தப்பட்டால் ஒட்டுதல் சோதனை

- சரிபார்ப்பிற்காக MIL-A-8625 வகை II மற்றும் OEM-குறிப்பிட்ட தரநிலைகளை குறிப்பிடுதல்

குறிப்பு: ஆனோடைசிங்கிற்கு முன்பு தேவையான மேற்பரப்பு தயாரிப்பை - உங்கள் திட்டத்தில் உள்ள அனைத்து பாகங்களிலும் ஒரு தொடர்ச்சியான சாடின் ஆனோடைசட் அலுமினியம் அல்லது அலுமினியம் சாடின் முடிக்கப்பட்ட தோற்றத்தை உறுதிசெய்ய துலங்குதல், மெருகூட்டுதல் அல்லது பீட் பிளாஸ்ட்டிங் போன்றவற்றை குறிப்பிடவும்.

தரைப்பரப்பு பொருட்கள், நெகிழ்வுத்தன்மை மற்றும் மெருகூட்டப்பட்ட தோற்றத்தின் கலவையுடன், வகை II ஆனோடைசிங் தொடர்ந்து கார்களில் தெரியும் மற்றும் அலங்கார அலுமினியம் எக்ஸ்ட்ரூசன்களுக்கான தரநிலையை நிர்ணயிக்கிறது. அடுத்ததாக, வகை III ஹார்ட் ஆனோடைசிங் எவ்வாறு அதிக தேவைகள் கொண்ட பயன்பாடுகளில் உராய்வு மற்றும் அரிப்பு எதிர்ப்பிற்கான தரநிலையை உயர்த்துகிறது என்பதை ஆராய்வோம்.

ஹார்ட் ஆனோடைச் வகை III

நீடித்துழைத்தலுக்கான ஹார்ட் ஆனோடைசிங் அடிப்படைகள்

மிகவும் கடினமான உராய்வு மற்றும் வெப்பத்தை எதிர்கொள்ளக்கூடிய முடிவுறுதி தேவைப்படும் போது, கடின ஆனோடைஸ் (Hard Anodize) — மற்றும் டைப் III ஆனோடைசிங் என அழைக்கப்படுகிறது — தரமான தீர்வாக உள்ளது. அலங்கார ஆனோடைசிங்கை போலல்லாமல், கடின ஆனோடைசிங் மிகவும் தடிமனான மற்றும் அடர்த்தியான அலுமினியம் ஆக்சைடு அடுக்கை உருவாக்குகிறது, இது குறைந்த வெப்பநிலைகளிலும் அதிக மின்னோட்ட அடர்த்தியிலும் ஆனோடைசிங் செயல்முறையை இயங்கச் செய்வதன் மூலம் உருவாகின்றது. இதன் விளைவாக, நழுவும் இணைப்புகளுக்கு, அதிக உராய்வு அடைஞ்ச பாகங்கள் மற்றும் உராய்வு அல்லது தேய்மானத்திற்கு ஆளாகும் பாகங்களுக்கு ஏற்றது போன்றவைகளுக்கு ஏற்ற ஒரு உறுதியான பாதுகாப்பு பூச்சு அமைகிறது குறிப்பு ).

கடின அனோடைஸ் பூச்சுகள் பொதுவாக 0.0005 முதல் 0.0030 அங்குலம் வரை தடிமனாக இருக்கும், இதில் பாதி தடிமன் பாதனையில் ஊடுருவி மற்றும் மேற்பரப்பில் பாதி உருவாகின்றது. அடர்த்தியான ஆக்சைடு உராய்வு மற்றும் மிதமான வெப்பத்திற்கு சிறந்த எதிர்ப்பை வழங்குகிறது, இதனால் இது நகரும் பாகங்கள் மற்றும் இயந்திரங்களுக்கு முன்னணி தேர்வாக உள்ளது. எனினும், கடின அனோடைஸ் அடுக்குகள் இருண்ட நிறத்தில்—அடர் சாம்பல், வெண்கலம் அல்லது கருப்பு நிறத்தில் காணப்படும், இது உலோகக்கலவை மற்றும் தடிமனை பொறுத்தது, மேலும் இவை வகை II முடிச்சுகளை விட குறைவாக அலங்காரமானவை என்பதை கவனத்தில் கொள்ள வேண்டும். நிறம் தேவைப்பட்டால், ஆக்சைடு படலத்தின் தன்மையால் கருப்பு மிகவும் நம்பகமான தேர்வாக உள்ளது.

தானியங்கி பொருத்தம் மற்றும் வடிவமைப்பு கட்டுப்பாடுகள்

ஹார்டு அனோடைஸ் என்பது ஆட்டோமோட்டிவ் அலுமினியம் பரப்பு பொறியியலில் எவ்வாறு பொருந்தும்? நீங்கள் நிலைத்தன்மை மற்றும் குறைந்த உராய்வு முக்கியமான இடங்களில் இதைக் காணலாம் - இருக்கை ட்ராக்குகள், சூரியன் மேற்கூரை ரெயில்கள், ஹின்ஜ் ஆர்ம்கள் அல்லது வழிநடத்தும் ரெயில்கள். ஹார்டு அனோடைஸ் செய்யப்பட்ட அடுக்கின் நுண்ணிய நெடுவரிசை நுண்கட்டமைப்பை உராய்வைக் குறைக்கவும், சவாரி பயன்பாடுகளில் சேவை ஆயுளை நீட்டிக்கவும் அலுமினியம் மேட் முடிச்சில் பாலிஷ் செய்யலாம் குறிப்பு ).

இருப்பினும், இந்த வகை அலுமினியம் ஆக்சைடு பூச்சு சில வடிவமைப்பு கருத்துகளுடன் வருகிறது. அதிகரிக்கப்பட்ட திரை தடிமன் குறுகிய பொறுப்புகளை பாதிக்கலாம் மற்றும் CAD மாதிரிகள் மற்றும் வரைபடங்களில் கணக்கில் எடுத்துக்கொள்ளப்பட வேண்டும். முக்கியமான பொருத்தங்களுக்கு, துளைகள், நூல்கள் அல்லது நில மேற்பரப்புகளுக்கு முகமூடி தரைவை தருமாறு கூறுவது அவசியம். மேலும், ஹார்ட் அனோடைஸ் சிறந்த உடைக்கும் எதிரான தடையை வழங்கினாலும், கனமான சுமைகள் அல்லது அதிக அழுத்தத்தின் கீழ் தடிமன் மைக்ரோகிராக்குகளை உருவாக்கலாம், இது தொடர்ச்சியான பயன்பாடுகளில் களைப்பு வலிமையை குறைக்கலாம். இந்த காரணத்திற்காகத்தான் சிறந்த பயன்பாடுகளில் உலோகக்கலவை, வடிவவியல் மற்றும் முடிக்கும் செயல்முறையின் கவனமான தேர்வு அலுமினியம் மேற்பரப்பு பொறியியலின் சிறப்பியல்பாக உள்ளது.

பாரம்பரியங்கள் மற்றும் தவறுகள்

பார்வைகள்

- அதிக உராய்வு பாகங்களுக்கு சிறந்த உடைக்கும் மற்றும் தேய்மான எதிர்ப்பு

- மிதமான வெப்பம் மற்றும் நழுவும் நிலைமைகளின் கீழ் நல்ல செயல்திறன்

- மின்சார காப்பு பண்புகள் - பாகங்களை பிரிக்க பயனுள்ளது

- உராய்வை குறைக்க பாலிஷ் செய்யலாம் (அலுமினியம் மேட் முடிக்கும்)

- MIL-A-8625 வகை III மற்றும் வாகன QA தரநிலைகளை பூர்த்தி செய்கிறது

தவறுகள்

- இருண்ட, குறைவான அலங்கார தோற்றம் - நிற விருப்பங்கள் குறைவு

- டைட் டாலரன்சுகளை மாற்றக்கூடிய படியான பில்ம் பில்ட்; வடிவமைப்பு இடைக்கால சரிசெய்தல் தேவை

- உயர் களைப்பு சுமைகளுக்கு உட்பட்ட போது பூச்சில் நுண்ணிய பிளவுகள் ஏற்படும் வாய்ப்பு

- களைப்பு வலிமை முக்கியமான போது கனமான சுமை தாங்கும் பாகங்களுக்கு ஏற்றதல்ல

- சிக்கலான வடிவங்களுக்கு துல்லியமான செயல்முறை கட்டுப்பாடு மற்றும் மாஸ்கிங் தேவை

பயன்பாடுகள் மற்றும் QA சரிபார்ப்பு புள்ளிகள்

- இருக்கை டிராக் பாகங்கள்: சவாரி அணிவிப்பு மற்றும் மீண்டும் மீண்டும் நகர்வு கடினமான, குறைந்த உராய்வு மேற்பரப்பை கோரும் இடங்களில்

- சன்ரூஃப் இயந்திரங்கள்: சுற்றுச்சூழல் மாசுபாடுகள் மற்றும் இயந்திர உராய்வு இரண்டிற்கும் வெளிப்படும்

- இணைப்பு அமைப்புகள் மற்றும் வழிநடத்தும் பாதைகள்: மிதமான சுமைகளுக்கு கீழ் நகர்வு மற்றும் சீரமைப்பை ஆதரிக்கின்றன

- பேட்டரி என்கிளோசர் ஹார்டுவேர்: மின்தடை மற்றும் அழிவு எதிர்ப்பு தேவைப்படுகிறது

ஹார்டு அனோடைஸிற்கான தர உத்தரவாதம் பின்வருவனவற்றை உள்ளடக்கியது:

- தடையில்லா முறைகளைப் பயன்படுத்தி (மின்னோட்டம், மீயொலி) தடிமன் வரைபடம் தயாரித்தல்

- அழிவு மற்றும் உராய்வு சோதனைகள் மூலம் அழிவு எதிர்ப்பை சரிபார்த்தல்

- விளிம்புகள், துளைகள் மற்றும் மறைக்கப்பட்ட பகுதிகளின் மூடிய நிலை மற்றும் அளவுரு துல்லியத்தை ஆய்வு செய்தல்

- சரிபார்ப்பிற்காக MIL-A-8625 வகை III மற்றும் OEM-குறிப்பிட்ட நெறிமுறைகளை குறிப்பிடுதல்

குறிப்பு: ஹார்டு அனோடைஸை தருவிக்கும் போது எப்போதும் திரை உருவாக்கத்தை முக்கிய அளவுருக்களுடன் சமன் செய்யவும். துளைகள், நூல் முறைகள் அல்லது மின்னிணைப்புகளுக்கான மறைப்பு தேவைகளை குறிப்பிடவும் - இது வாகனத் துண்டுகளுக்கான நம்பகமான அலுமினியம் பரப்பு பொறியியலில் ஒரு முக்கியமான படியாகும்.

ஹார்டு அனோடைஸ் ஒரு அலுமினியம் பாதுகாப்பு பூச்சு என வலிமைகள் மற்றும் குறைபாடுகளை புரிந்து கொள்வதன் மூலம், நீங்கள் அதிக அழிவுக்குள்ளாகும் வாகன பயன்பாடுகளுக்கு தகுந்த முடிவுகளை எடுக்க முடியும். அடுத்ததாக, பொடி பூச்சு வாகனத்தின் வெளிப்புறம் மற்றும் எஞ்சின் கீழ் அலுமினியம் துண்டுகளுக்கான நிலைத்தன்மை மற்றும் நிற நெகிழ்வுத்தன்மையை எவ்வாறு நீட்டிக்கிறது என்பதை பார்ப்போம்.

தூள் பூச்சு

பொடி ரெசின் தெரிவுகள் மற்றும் முன் சிகிச்சை

சாலையின் கடினமான சூழ்நிலைகளை தாங்கக்கூடியதும், விசித்திரமான நிறத்தை வழங்கக்கூடியதுமான முடிப்பு தேவைப்படும் போது, ஆட்டோமோட்டிவ் அலுமினியம் எக்ஸ்ட்ரூஷன்களுக்கு பவுடர் கோட்டிங் முக்கியமான தெரிவாக உள்ளது. ஆனால் அதை மிகவும் பயனுள்ளதாக்குவது என்ன? அது பவுடர் ரெசினில் இருந்து தொடங்குகிறது - பொதுவாக பாலியெஸ்டர், ஈப்பாக்ஸி அல்லது ஹைப்ரிட் கலவைகள். இவற்றில், பாலியெஸ்டர் பவுடர்கள் சிறப்பான வானிலை மற்றும் நிறம் தக்கவைப்பு பண்புகளை கொண்டிருப்பதால், வெளிப்புறம் மற்றும் புலனாகும் பயன்பாடுகளுக்கு முன்னுரிமை பெற்றவை. ஈப்பாக்ஸி பவுடர்கள் சிறந்த வேதியியல் எதிர்ப்பை வழங்குகின்றன, ஆனால் அவை பொதுவாக உட்புறம் அல்லது எஞ்சின் போர்டு பாகங்களுக்கு மட்டுமே பயன்படுத்தப்படுகின்றன, ஏனெனில் அவற்றின் குறைந்த UV நிலைத்தன்மை காரணமாக. ஹைப்ரிட் பவுடர்கள் இரண்டின் பண்புகளையும் கலக்கி குறிப்பிட்ட செயல்திறன் தேவைகளுக்கு ஏற்ப வழங்குகின்றன.

உறுதியான அலுமினியம் கோட்டிங்கிற்கான பாதை கவனமான முன் சிகிச்சையுடன் தொடங்குகிறது. ஒரு பாகத்தை பெயிண்ட் பணிக்கு தயார் செய்வதை கற்பனை செய்யுங்கள்: எந்த ஒரு எண்ணெய், தூசி அல்லது ஆக்சைடு தவறவிடப்பட்டாலும் முடிப்பு பாதிக்கப்படலாம். இந்த செயல்முறை விரிவான சுத்திகரிப்புடன் தொடங்குகிறது - காரத்தன்மை கொண்ட கழுவுதல், கரைப்பான் குளங்கள் அல்லது சிக்கலான வடிவங்களுக்கு மிக்ரோ அலை சுத்திகரிப்பு போன்ற முறைகளை பயன்படுத்தி source மேலும், பொடிக்கோட்டிங் ஒட்டிக்கொள்ளவும், அதன் செயல்பாடுகளை முறையாக நிறைவேற்றவும் உதவும் வகையில், ஒரு மாற்று பூச்சு (அடிக்கடி சுற்றுச்சூழல் தகுதிக்கு ஏற்ப குரோமேட்-இல்லா பூச்சு) பயன்படுத்தப்படுகிறது. இது ஒட்டுதல் தன்மையையும், துருப்பிடிக்காமல் பாதுகாக்கும் தன்மையையும் மேம்படுத்துகிறது. மேலும், இது ஒரு சீரான, நடுநிலையான பரப்பை உருவாக்குகிறது. இறுதியாக, கழுவும் செயல்முறைகள் மிகவும் முக்கியமானவை – எஞ்சியிருக்கும் எந்த மீதிப்பொருளும் பொங்கி எழுதல் (blistering) அல்லது ஆரம்பகால தோல்விக்கு வழிவகுக்கலாம்.

தானியங்கி செயல்திறன் மற்றும் பொருத்தமைப்புத்தன்மை

பொடிக்கோட்டிங் அதன் நிலைத்தன்மை, சிப்பிங் எதிர்ப்பு மற்றும் தடிமனான, பாதுகாப்பு அடுக்கை வழங்கும் தன்மைக்கு பாராட்டப்படுகிறது, இது அலுமினியத்தை துருப்பிடிக்காமலும், தாக்கங்களிலிருந்தும் பாதுகாக்கிறது. வாகனப் பயன்பாடுகளுக்கு, இதன் பொருள் வெளிப்புற டிரிம், கூரை பட்டைகள், மற்றும் பேட்டரி பேக் கம்பி அமைப்புகள் சூரியன், உப்பு, மற்றும் வேதிப்பொருள்களுக்கு ஆண்டுகளாக வெளிப்படுத்தப்பட்ட பின்னரும் அவற்றின் தோற்றத்தையும், முழுமைத்தன்மையையும் பாதுகாத்துக்கொள்ள முடியும்.

எனினும், சிக்கலான குறுக்கு வெட்டு வடிவங்களுடன் கூடிய அலுமினியம் எக்ஸ்ட்ரூஷன்களை கோட் செய்யும் போது சில தனித்துவமான சவால்களை நீங்கள் காண்பீர்கள். ஃபாரடே கேஜ் விளைவின் காரணமாக ஆழமான பகுதிகளிலும் இறுக்கமான மூலைகளிலும் மெல்லிய அல்லது சீரற்ற மூடிய பகுதிகளை உருவாக்கலாம். அதனால்தான் சரியான ராக்கிங், கிரௌண்டிங் மற்றும் ஸ்ப்ரே நுட்பம் முக்கியமானது - பொடியானது ஒவ்வொரு மேற்பரப்பையும் அடைவதை உறுதி செய்ய. பெயின்ட்-பேக் சைக்கிள்களுக்கு உட்படும் பாகங்களுக்கு, உங்கள் தேவைகளில் ஓவர்-பேக் பொறுப்புத்தன்மையை குறிப்பிடுவது முக்கியமானது, அதிகப்படியான வெப்பம் மினுமினுப்பு, நிறம் அல்லது ஒட்டுதல் இழப்பை கூட மாற்றக்கூடும்.

பாரம்பரியங்கள் மற்றும் தவறுகள்

பார்வைகள்

- சிறந்த நிற வரம்பு மற்றும் முடிக்கும் விருப்பங்கள் (மேட், மினுமினுப்பான, உருவாக்கப்பட்டது)

- நீடித்த, சிப்- மற்றும் கீறல் எதிர்ப்பு மேற்பரப்பு

- தடிமனான, சீரான கோட் சிதைவு மற்றும் தாக்கத்திற்கு எதிராக பாதுகாக்கிறது

- VOCகள் இல்லை - சுற்றுச்சூழலுக்கு நட்பான பயன்பாடு

- மீதமுள்ள பொடி மீட்கப்படலாம், கழிவைக் குறைக்கிறது

- விரைவான குணப்படுத்தும் நேரங்கள் அதிக உற்பத்தி திறனை ஆதரிக்கின்றன

தவறுகள்

- சிக்கலான அல்லது உள்நோக்கி வளைந்த வடிவங்களில் மூடிய சவால்கள் (ஃபாரடே விளைவு)

- திரை உருவாக்கம் குறைந்த பொறுப்புத்தன்மையை பாதிக்கலாம் - வடிவமைப்பு சரிசெய்தல் தேவைப்படலாம்)

- மீண்டும் பணியாற்ற முடியும், ஆனால் பழுதுபார்த்து மீண்டும் பூச்சு தேவை

- திரவ பெயிண்டை விட சிறிய பழுதுகளை சரி செய்யும் வாய்ப்புகள் குறைவு

- அதிகபட்ச ஒடுங்கி தங்கும் தன்மை மற்றும் நீடித்த தன்மைக்கு உறுதியான முன் சிகிச்சை தேவை

பயன்பாடுகள் மற்றும் QC சரிபார்ப்பு புள்ளிகள்

- வெளிப்புற ட்ரிம்: கதவு பிடிப்புகள், ஜன்னல் சுற்றுப்புறங்கள் மற்றும் கிரில் அலங்காரங்களுக்கு நீடித்த நிறம் மற்றும் கழிவு பாதுகாப்பை பவுடர் பூச்சு வழங்குகிறது

- கூரை ரெயில்கள் மற்றும் குறுக்கு பட்டைகள்: அதிக UV மற்றும் வானிலை வெளிப்படையாக்கம் நிலையான மின்னல் மற்றும் நிறத்துடன் கூடிய உறுதியான அலுமினியம் பூச்சு தேவை

- பேட்டரி-பேக் சட்டங்கள்: திரவங்கள் மற்றும் வெப்பநிலை ஆட்டங்களுக்கு வெளிப்படும் இன்ஜின் கீழ் அல்லது பேட்டரி கூண்டு பாகங்களுக்கு வேதியியல் எதிர்ப்பு முக்கியமானது

- சேவை மூடிகள் மற்றும் தாங்கிகள்: தாக்கம் மற்றும் உராய்வு எதிர்ப்பு அதே அளவு முக்கியத்துவம் வாய்ந்ததாக இருக்கும் இடங்களில் தோற்றமும் முக்கியமானது.

பூச்சுகளுக்கான தரக்கட்டுப்பாடு அலுமினியம் பாகங்களுக்கு பின்வருவனவற்றை உள்ளடக்கியது:

- ஒட்டுதல் சோதனைகள் (குறுக்கு வரிசை அல்லது டேப் சோதனை)

- சிகிச்சை உறுதிப்பாடு (கரைப்பான் துடைப்பு, பென்சில் கடினத்தன்மை)

- மின்னல் மற்றும் நிற ஒருமைப்பாட்டு சோதனைகள்

- பூச்சு தடிமன் அளவீடு (காந்த அல்லது மின்னோட்ட முறைகள்)

குறிப்பு: இறுதி மெருகூட்டும் செயல்முறையின் போது மேலதிக பெயிண்ட்-பேக் சுழற்சிகளுக்கு உட்படும் பவுடர் பூசிய பாகங்களுக்கு மேலதிக சூடேற்ற பொறுப்பை தரவு செய்யவும். இந்த நடவடிக்கை உற்பத்தி செயல்முறை முழுவதும் நிறம், மின்னல் மற்றும் ஒட்டுதல் நிலைமைக்கு உதவும்.

பவுடர் பூச்சு ஆட்டோமொபைல் பயன்பாட்டிற்கான அலுமினியம் எக்ஸ்ட்ரூஷன்களை பூசுவதற்கான பல்துறைசார், நிலையான மற்றும் நிலையான முறையாக தெரிவு செய்யப்படுகிறது. நீங்கள் தோற்றம், பாதுகாப்பு மற்றும் உற்பத்தி செயல்திறனை சமன் செய்யும் முடிவை விரும்பும்போது, நன்கு தரவு செய்யப்பட்ட அலுமினியம் பூச்சு பெரும்பாலும் சிறந்த பொருத்தமாக இருக்கும். அடுத்து, சிக்கலான சுட்டிகளில் மிக சீரான மூடிய மூடுதலை அடைவதற்கும் மேல் பூச்சுகளுக்கு கீழ் துரு எதிர்ப்பு பிரைமராகவும் ஏற்ற e-கோட் அமைப்புகளுக்குள் நாம் நுழைவோம்.

இ-கோட்

இ-கோட் அமைப்பு குறிப்பு மற்றும் பதிப்புகள்

சிக்கலான வடிவங்கள் அல்லது ஆழமான பகுதிகள் கொண்ட அலுமினியம் எக்ஸ்ட்ரூஷன்களுக்கு பாதுகாப்பு பூச்சுக்கான தீர்வைத் தேடும் போது, e-கோட் (மின்காந்த பெயிண்டிங்) முன்னணி தேர்வாக உள்ளது. ஆனால் அது எவ்வாறு செயல்படுகிறது? உங்கள் அலுமினியம் பாகத்தை ஒரு குளத்தில் மூழ்கடிக்கின்றீர்கள் என்று கற்பனை செய்யுங்கள், அங்கு மின்னால் சார்ஜ் செய்யப்பட்ட பெயிண்ட் துகள்கள் தெரிந்த அனைத்து பரப்புகளிலும் இழுக்கப்படுகின்றன—மூலைகள் மற்றும் இறுக்கமான குழிகளின் உள்ளேயும் கூட. இந்த செயல்முறை, மின் பூச்சு என்றும் அழைக்கப்படுகிறது, இது கேட்டோனிக் ஈப்பாக்ஸி அல்லது அக்ரிலிக் ரெசின்களைப் பயன்படுத்தி மெல்லிய, ஒரே மாதிரியான அடுக்கை உருவாக்குகிறது, இது நீடித்ததும் தொடர்ந்து செயல்பாடுமாக இருக்கும்.

கேட்டோனிக் ஈப்பாக்ஸி e-கோட்கள் அவற்றின் உறுதியான காரோசன் எதிர்ப்பு திறனுக்காக மதிப்புமிக்கவை, மற்றும் ஆட்டோமொபைல் பயன்பாடுகளில் பிரைமர்களாக பரவலாக பயன்படுத்தப்படுகின்றன. அக்ரிலிக் கலவையிலான e-கோட்கள், இடையில், மேம்பட்ட UV நிலைத்தன்மையை வழங்குகின்றன மற்றும் சில சமயங்களில் காட்சிக்கு உட்படும் பாகங்களுக்கு தேர்வு செய்யப்படுகின்றன. ரெசின் வகை எதுவாக இருந்தாலும், e-கோட்டின் முத்திரை முழு பாகத்திலும் 15 முதல் 25 மைக்ரான்கள் வரை சீரான படலத்தை வழங்கும் திறன் ஆகும்—சிக்கலான வடிவங்களில் பல பாரம்பரிய பூச்சுகளை விட சிறப்பாக செயல்படுகிறது.

இயந்திர செயல்திறன் மற்றும் மேல்பூச்சு ஒத்துழைப்பு

அலுமினியம் பரப்பு சிகிச்சைகளுக்கான அடிப்படையாக e-கோட் ஐ வரையறுக்க வேண்டும் என்று இயந்திரவியல் பொறியாளர்கள் ஏன் குறிப்பிடுகிறார்கள்? அதன் மிகச்சிறந்த துருப்பிடிப்பு பாதுகாப்பு மற்றும் அதிக உற்பத்தி செயலாக்கத்தின் கலவையில் விடை அமைந்துள்ளது. E-கோட் ஈரப்பதம், உப்பு மற்றும் பிற துருப்பிடிக்கும் பொருட்களிலிருந்து அலுமினியத்தை பாதுகாக்கும் தொடர்ச்சியான தடையை உருவாக்குகிறது, இது மேல்பூச்சுகளுக்கு மேல் அல்லது மறைக்கப்பட்ட அல்லது பாதிப்பாக தெரியும் பாகங்களுக்கு தனித்து நிற்கும் முடிவுற்ற முடிவுக்கு ஏற்றதாக இருக்கிறது. பவுடர் அல்லது திரவ மேல்பூச்சுகளுக்கு கீழ் பிரைமராக e-கோட் பயன்படுத்தப்படுவதை நீங்கள் அடிக்கடி பார்ப்பீர்கள், வெளிப்புறம் மற்றும் உட்கட்டமைப்பு பாகங்களுக்கு வலுவான ஒட்டுதல் மற்றும் நீண்டகால நிலைத்தன்மையை உறுதிப்படுத்துகிறது.

மற்றொரு நன்மை: இ-கோட் (e-coat) இன் ஒருமைத்தன்மை காரணமாக துருப்பிடித்தல் தொடங்கும் இடங்களில் உள்ள பலவீனமான புள்ளிகள் அல்லது மெல்லிய விளிம்புகள் குறைவாக இருக்கும். இது குறிப்பாக காலியாக உள்ள பிரிவுகளைக் கொண்ட ஆட்டோமோட்டிவ் அலுமினியம் எக்ஸ்ட்ரூஷன்கள் (automotive aluminum extrusions), சிக்கலான வெட்டுதல்களுடன் கூடிய பிராக்கெட்டுகள் (brackets) அல்லது ஒன்றின் மேல் ஒன்று பொருந்திய ஜோடிப்புகள் கொண்ட பொருட்களுக்கு மிகவும் மதிப்புமிக்கதாக இருக்கிறது. மேலும், இந்த செயல்முறை மிகவும் அளவில் விரிவாக்கக்கூடியது - நவீன ஆட்டோமோட்டிவ் தொழிற்சாலைகளில் அதிக அளவு உற்பத்தி முடிக்க சிறந்தது.

பாரம்பரியங்கள் மற்றும் தவறுகள்

பார்வைகள்

- சிறந்த துருப்பிடிக்காத எதிர்ப்பு - உறுதியான பாதுகாப்பு அடிப்படையை உருவாக்குகிறது

- மிக ஒருமைத்துவமான படத்தின் உருவாக்கம், சிக்கலான அல்லது உள்நோக்கி வளைந்த சுருக்கங்களில் கூட

- அதிக உற்பத்தி திறன் கொண்ட தொழில்நுட்பத்தை ஆதரிக்கிறது

- தெளிப்பு பூச்சுகளை விட குறைவான பொருள் கழிவுகள்

- மேலதிக பாதுகாப்பு அல்லது நிறத்திற்கு பவுடர் அல்லது திரவ மேல் பூச்சுகளுடன் ஒத்துழைக்கக்கூடியது

தவறுகள்

- சிறப்பான பிடிப்பிற்கு துல்லியமான மற்றும் முழுமையான முன் சிகிச்சை தேவை

- உபகரணங்கள் மற்றும் செயல்முறை அமைப்பிற்கு அதிக மூலதன முதலீடு

- தனித்தன்மை வாய்ந்த முடிவுற்ற தோற்றத்திற்கு குறைவான நிறம் மற்றும் தோற்ற விருப்பங்கள்

- கடத்தா அடிப்படைகளுக்கு ஏற்றதல்ல (அலுமினியம் சுத்தமாகவும் கடத்தக்கூடியதாகவும் இருக்க வேண்டும்)

பயன்பாடுகள் மற்றும் QC சரிபார்ப்பு புள்ளிகள்

- பாடி-இன்-வைட் அட்ஜசண்ட் அலுமினியம் பொருத்தமைப்புகள்: இ-கோட் எஃகு கட்டமைப்புகளுடன் ஒருங்கிணைக்கப்பட்ட பாகங்களுக்கு துருப்பிடிப்பு எதிர்ப்பு பிரைமரை வழங்குகிறது.

- பேட்டரி என்க்ளோசர் உட்பாகங்கள்: சிக்கலான ஹௌசிங்குகளுக்குள் சீரான மூடிய பரப்பளவு நீடித்துழைத்தல் மற்றும் பாதுகாப்பை உறுதி செய்கிறது.

- பிராக்கெட்டுகள் மற்றும் மவுண்டிங் ஹார்ட்வேர்: இ-கோட் குறிப்பாக அதிக வெளிப்படையான பகுதிகளில் நிறம் மேல் கோட்டிற்கு கீழ் பாதுகாப்பான அடிப்படையாக செயல்படுகிறது.

இ-கோட்டிற்கு அலுமினியம் மேற்பரப்பு சிகிச்சைக்கான தரக்கட்டுப்பாடு பொதுவாக பின்வருவனவற்றை உள்ளடக்கும்:

- பெயின்ட் வேதியியல் மற்றும் கடத்தும் தன்மையை கண்காணிக்கும் குளம் கட்டுப்பாடுகள்

- செரிக்கப்பட்ட சோதனை (குறுக்கு வரிசை அல்லது டேப் புல்)

- துல்லியமான படல கடினமாதலை உறுதிப்படுத்தும் சிகிச்சை சோதனை

- சீரான மூடுதலை உறுதிப்படுத்த தடிமன் அளவீடு

எப்போதும் இ-கோட் வேதியியலுக்கும் தொடர்ந்து வரும் சீலெண்டுகள் அல்லது ஒட்டும் பொருட்களுக்கும் இடையே ஒத்துழைப்பை குறிப்பிடவும். ஒத்துப்போகாத பொருட்கள் கண்டமினேற்றம் அல்லது ஒட்டுதல் தோல்விக்கு வழிவகுக்கலாம், இது அலுமினியம் பரப்பு சிகிச்சைகளின் பயனுறுத்தன்மையை குறைக்கும்.

அலுமினியம் எக்ஸ்ட்ரூஷன்களுக்கு உயர்தர, மிகவும் சீரான கோட்டிங்குகளை வழங்கும் தனித்துவமான திறன் காரணமாக, இ-கோட் நவீன ஆட்டோமொபைல் தயாரிப்பு முடிக்கும் போது முக்கியமானதாக உள்ளது. அடுத்து, மில் முடிப்புடன் பிரைமர் மற்றும் பெயிண்ட் குறிப்பிட்ட பயன்பாடுகளுக்கு ஒரு நெகிழ்வான, பொருளாதார மாற்று தீர்வை வழங்குவதை ஆராய்வோம்.

பிரைமர் மற்றும் பெயிண்டுடன் கூடிய மில் முடிப்பு

மில் முடிப்பு வரைவிலக்கணம் மற்றும் அது பொருந்தும் நேரம்

அலுமினியம் எக்ஸ்ட்ரூஷன்களில் மில் முடிப்பு (மேற்பரப்பு) என்றால் என்னவென்று நீங்கள் யோசித்தது உண்டா? எளிமையாகச் சொன்னால், மில் முடிப்பு என்பது அலுமினியத்தின் அப்படியே எக்ஸ்ட்ரூடெட் (திடீரென வெளிவந்த) சிகிச்சை செய்யப்படாத மேற்பரப்பைக் குறிக்கிறது – அழுத்தி வெளியேற்றப்பட்ட நிலையில், கூடுதல் பாலிஷ், வேதியியல் சிகிச்சை அல்லது பூச்சு ஏதும் இல்லாமல். இந்த ஆரம்ப நிலை ஒரு மங்கிய, மேட் தோற்றம், தெரிந்துகொண்ட டை கோடுகள், சில சமயங்களில் தயாரிப்பு செயல்முறையிலிருந்து வரும் குறிகள் அல்லது சிறிய கீறல்கள் ஆகியவற்றைக் கொண்டுள்ளது. மில் முடிப்பு அலுமினியம் அதன் குறைந்த விலையால் மதிப்புமிக்கது மற்றும் பெரும்பாலும் மேற்பரப்பு சிகிச்சைகள் அல்லது பூச்சுகளுக்கான ஆரம்ப புள்ளியாக உள்ளது.

பெயிண்ட் அல்லது தெரியாத, பாதுகாக்கப்பட்ட இடங்களில் பயன்படுத்தப்போகும் பாகங்களுக்கு மில் முடிப்புடன் கூடிய அலுமினியம் ஒரு நடைமுறை தெரிவாக இருக்கலாம். இது வண்ணத்தில் செலவு சிக்கனம் மற்றும் நெகிழ்வுத்தன்மை முக்கியமானதாக இருக்கும் உள் டிரிம் ரெயில்கள், மறைக்கப்பட்ட அமைப்பு உறுப்புகள் அல்லது சேவை பாகங்களுக்கு குறிப்பாக பொருந்தும், அழகியல் உலோக பளபளப்பை விட.

எக்ஸ்ட்ரூஷன்களுக்கான பிரைமர் மற்றும் பெயிண்ட் பணிப்பாய்வு

மில் முடிப்பு அலுமினியத்தை பெயின்ட் செய்ய நினைத்துக் கொண்டிருக்கிறீர்களா? நீடித்த முடிவுகளுக்கு முக்கியமானது சரியான பரப்பு தயாரிப்புதான். ஏனெனில் எக்ஸ்ட்ரூடெட் பரப்பில் எண்ணெய், ஆக்சைடுகள் அல்லது சிறிய குறைபாடுகள் இருக்கலாம், பெயின்டிங்கிற்கு முன்பு மில் முடிப்பு அலுமினியத்தை தயார் செய்வது ஒட்டுதல் மற்றும் துருப்பிடிப்பு எதிர்ப்புக்கு மிகவும் முக்கியம். இதுதான் சாதாரண பணிவரிசை:

- பரப்பு சுத்தம் செய்தல்: எண்ணெய், தூசி மற்றும் குப்பைகளை கரைப்பான்கள் அல்லது கார கிரீட்டர்களை பயன்படுத்தி நீக்கவும்.

- இயந்திர சமன் செய்தல்: மென்மையான துலைக்கும் அல்லது மண் தேய்க்கும் மூலம் மேற்பரப்பை சமன் செய்யவும், குறிப்பாக காணப்படும் டை வரிகளை குறைக்கவும் - இந்த படியானது பெயின்ட்டின் கீழ் மில் முடிப்பு குறைபாடுகள் தெரியாமல் போக உதவும்.

- வேதியியல் முன் சிகிச்சை: பிரைமர் ஒட்டுதலை ஊக்குவிக்கவும், துருப்பிடிப்பு எதிர்ப்பை மேம்படுத்தவும் எட்சிங் கரைசல் அல்லது வேதியியல் பிணைப்பு முகவரை பயன்படுத்தவும்.

- அலுமினியம் பிரைமர் பயன்பாடு: அலுமினியத்திற்காக உருவாக்கப்பட்ட உயர்தர பிரைமரை உபயோகித்து மேல் பெயின்ட்டிற்கு வலுவான அடித்தளத்தை உருவாக்கவும்.

- பெயின்ட் மேல் பூச்சு: விரும்பிய நிறம் மற்றும் முடிக்கும் விருப்பத்தை பயன்படுத்தவும், இது உள்துறை அல்லது வெளித்துறை தேவைகளுக்கு ஏற்ப தனிபயனாக மாற்றலாம்.

இந்த ஒவ்வொரு படிநிலையும் அலுமினியம் பிரைமர் மற்றும் பெயின்ட் சிஸ்டங்களின் ஆயுளையும் தோற்றத்தையும் அதிகபட்சமாக்குவதற்காக வடிவமைக்கப்பட்டுள்ளது, மேலும் முடிக்கும் வாகன சேவை நிலைமைகளின் கீழ் கூட நிலைத்தன்மை கொண்டதாக இருப்பதை உறுதிசெய்கிறது.

பாரம்பரியங்கள் மற்றும் தவறுகள்

பார்வைகள்

- முதலீட்டு முடிக்கும் செலவு குறைவு - மில் முடிக்கப்பட்ட அலுமினியம் மலிவானது மற்றும் எளிதாக கிடைக்கக்கூடியது

- பெயின்ட் தேர்வு மூலம் நிறம் மற்றும் பளபளப்பு தன்மையில் அதிகபட்ச நெகிழ்வுத்தன்மை

- புலத்தில் பெயின்ட் செய்யப்பட்ட பரப்புகளைத் தொட்டுச் சரிசெய்யவோ அல்லது பழுதுபார்க்கவோ எளிதானது

- தோற்றம் முக்கியமில்லாத அல்லது காட்சியிலிருந்து மறைக்கப்பட்ட பாகங்களுக்கு நன்றாக வேலை செய்கிறது

- பாகத்தின் வடிவமைப்பில் எந்த கட்டுப்பாடும் இல்லை - சிக்கலான எக்ஸ்ட்ரூஷன்களுக்கு பெயின்ட் பயன்படுத்த முடியும்

தவறுகள்

- கவனமான முன் சிகிச்சை தேவை - மோசமான தயாரிப்பு பெயின்ட் துவளைகள், பிசுபிசுப்பு அல்லது துருப்பிடித்தலுக்கு வழிவகுக்கலாம்

- மில் முடிக்கும் பரப்பு மோசமானதாகவோ அல்லது சீரற்றதாகவோ இருந்தால் பெயின்ட் வழியாக குறைபாடுகள் தெரிவதற்கான அதிக வாய்ப்பு

- வெளிப்புறம், அதிக அளவிலான அழிவு அல்லது துருப்பிடிக்கும் சூழல்களுக்கு அனோடைசிங் அல்லது பவுடர் கோட்டிங் முடிக்கும் விருப்பங்களை விட குறைவான நிலைத்தன்மை

- பெயின்ட் செய்த முடிவுகள் தொடர்ந்து பராமரிப்பு அல்லது தொடுதல் தேவைப்படலாம்

பயன்பாடுகள் மற்றும் QC சரிபார்ப்பு புள்ளிகள்

- உள்துறை டிரிம் ரெயில்கள் பெயின்ட் செய்யப்பட்டது: மில் முடிவு அலுமினியம் உள்துறை நிற அமைப்புகளுக்கு பொருத்தமாக பிரைம் செய்யப்பட்டு பெயின்ட் செய்யப்பட்டது, நீடித்த தன்மை மற்றும் தொடுதல் சாத்தியக்கூறுகள் மதிப்பு வைக்கப்படும் இடங்களில்

- மறைக்கப்பட்ட கட்டமைப்பு உறுப்புகள்: சேர்ப்பதற்கு பிறகு தெரியாத பாகங்கள் ஆனால் காரோசன் பாதுகாப்பு மற்றும் செலவு குறைந்த முடிவுகள் தேவைப்படுகின்றன

- புனரமைப்பு தேவைப்படும் சேவை பாகங்கள்: பெயின்ட் செய்யப்பட்ட மில் முடிவு அலுமினியம் பாகங்களை பராமரிப்பின் போது சேதமடைந்தால் எளிதாக மணல் தட்டு மற்றும் மீண்டும் பெயின்ட் செய்யலாம்

இந்த முறைமைக்கான தரக் கட்டுப்பாடு செயல்பாடு மற்றும் தோற்றத்தை உறுதிசெய்ய மிகவும் முக்கியமானது. பொதுவான QC சோதனை புள்ளிகள் பின்வருமாறு:

- பிரைமர் மற்றும் பெயின்ட் பயன்பாட்டிற்கு பிறகு ஒட்டுதல் சோதனை (குறுக்கு வரிசை அல்லது டேப் இழுப்பு)

- ஓடு தடிமன் அளவீடு மூலம் மூடுதல் மற்றும் நீடித்த தன்மையை உறுதிப்படுத்தவும்

- விரிவான மாதிரி நிறம் மற்றும் பளபளப்பு சரிபார்ப்பு

- கடுமையான சூழல்களுக்கு உள்ளாகும் பாகங்களுக்கான சுழற்சி அரிப்பு சோதனை

குறிப்பு: மில் முடிக்கப்பட்ட அலுமினியத்தை பிரைமர் செய்வதற்கு முன்பு, லேசான துலைத்தல் அல்லது மணல் தடவுதல் போன்ற மேற்பரப்பு சமனாக்கும் படிகளை எப்போதும் குறிப்பிடவும். இந்த நடைமுறை இறுதி பெயிண்ட்டிற்கு மில் முடிப்பு குறைபாடு தெரியும் ஆபத்தை குறைக்கிறது, இதனால் சிக்கனமான மற்றும் தொழில்முறை தோற்றத்தை பெறலாம்.

மில் முடிப்புடன் பிரைமர் மற்றும் பெயிண்ட் ஆனது அனோடைசிங் அல்லது பவுடர் கோட்டிங் விருப்பங்களின் பிரீமியம் நிலைத்தன்மை அல்லது அழகியலை வழங்காவிட்டாலும், பல ஆட்டோமொபைல் அலுமினியம் எக்ஸ்ட்ரூஷன் தேவைகளுக்கு இது ஒரு பொருளாதார மற்றும் தகவமைக்கக்கூடிய தீர்வாக உள்ளது. அடுத்ததாக, உங்கள் திட்டத்தின் தேவைகளுக்கு சிறந்த தேர்வை மேற்கொள்ள உதவும் வகையில் அனைத்து முடிப்பு வகைகளையும் பக்கவாட்டு ஒப்பீட்டில் கொண்டு வருவோம்.

ஆட்டோமொபைல் அலுமினியம் எக்ஸ்ட்ரூஷன் முடிப்புகளுக்கான பக்கவாட்டு ஒப்பீடு மற்றும் முடிவு மெட்ரிக்ஸ்

தாங்கள் தானியக் கூடுதல் பயன்பாடுகளுக்கான பரப்பு சிகிச்சை விருப்பங்களை தேர்வு செய்யும் போது, அதில் உள்ள பல மாறிகள் தலைவலியை உண்டு செய்யலாம். எந்த முடிவு உங்கள் பயன்பாட்டிற்கு தேவையான பாதுகாப்பு, தோற்றம், உற்பத்தி விகிதம் மற்றும் செலவு ஆகியவற்றின் சமநிலையை வழங்கும்? தீர்மானிக்க சுலபமாக்கும் பொருட்டு, முன்னணி முடிவுகளின் விரிவான ஒப்பீட்டை தொகுத்துள்ளோம். இந்த அட்டவணை மற்றும் விரைவான முடிவெடுக்கும் விரிவானை உங்கள் திட்டத்தின் தேவைகளுக்கு சிறந்த அலுமினியம் பரப்பு முடிவை பொருத்த உதவும்.

வாகன தருந்தொழில் நிபந்தனைகளின் படி பக்கவாட்டு ஒப்பீடு

| முடிவு விருப்பம் | வாகன பயன்பாட்டிற்கு பொருத்தம் | உறிஞ்சியல் தோல்விக்கு எதிர்த்து | Wear Resistance | தோற்ற வரம்பு | பெயின்ட்-பேக் ஒத்துழைப்பு | ஒப்பீட்டு செலவு | நேர தாக்கத்தின் | மறுசுழற்சி செய்யக்கூடியது | மேற்கோள் தரநிலைகள் |

|---|---|---|---|---|---|---|---|---|---|

| சாவோயி பரப்பு சிகிச்சை தீர்வுகள் | வெளிப்புற, அமைப்பு மற்றும் சிறப்பு பாகங்களுக்கான ஒரே தீர்வு | உயர் | உயர் | அகலமான (அலங்கார, செயல்பாடு, தனிபயன் நிறங்கள்/உருவாக்கங்கள்) | உயர் | சராசரி | சராசரி | உயர் | ASTM, SAE, ISO, MIL-A-8625 |

| இரண்டாம் வகை ஆனோடைஸ் | காட்சி ட்ரிம், உட்புற/வெளிப்புற அலங்காரம் | மிதமான-உயர் | சராசரி | மேட், சாட்டின், நிறம் தீட்டப்பட்டவை | சராசரி | சராசரி | சராசரி | உயர் | MIL-A-8625 வகை II, OEM |

| கடின ஆனோடைஸ் (வகை III) | அதிக அணிவிக்கப்படும், நழுவும், கட்டமைப்பு | உயர் | மிக அதிகம் | இருண்ட, குறைந்த நிறங்கள் | சராசரி | மிதமான-உயர் | சராசரி | உயர் | MIL-A-8625 வகை III, OEM |

| தூள் பூச்சு | வெளிப்புற ட்ரிம், எஞ்சின் பகுதி, பேட்டரி சட்டங்கள் | உயர் | உயர் | மிகவும் (மேட், கிளாஸ், உருவாக்கப்பட்ட, தனிபயன்) | உயர் | சராசரி | குறைவு-மிதமான | உயர் | ASTM, ISO, OEM |

| இ-கோட் | சிக்கலான சுருக்கங்கள், பாகங்களுக்கு பிரைமர் | மிக அதிகம் | சராசரி | குறைந்த (முக்கியமாக கருப்பு/சிவப்பு, அரை-மின்) | உயர் | சராசரி | மிதமான-உயர் | உயர் | ASTM, ISO, OEM |

| பிரைமர் மற்றும் பெயிண்டுடன் கூடிய மில் முடிப்பு | மறைக்கப்பட்ட, சேவை, அல்லது பெயிண்ட் செய்யப்பட்ட உட்புற பாகங்கள் | சராசரி | குறைவு-மிதமான | கட்டுப்பாடற்ற (பெயிண்ட் சிஸ்டம் அடிப்படையில்) | சராசரி | குறைவு | குறைவு | உயர் | ASTM, ISO, OEM |

இந்த பக்கவாட்டு காட்சி உங்கள் ஆட்டோமொபைல் திட்டத்திற்காக பரிசீலிக்க வேண்டிய மேற்பரப்பு முடிக்கும் பாகங்களை ஒப்பிடுவதை எளிதாக்குகிறது, எங்கெல்லாம் ஒவ்வொன்றும் சிறப்பாக செயலாற்றுகிறதோ அவற்றை வெளிப்படுத்துகிறது

செலவு மற்றும் தொடக்க நேர கருத்துகள்

- ஒருங்கிணைந்த தீர்வுகள் (சாயி போன்றவை) உங்கள் விநியோக சங்கிலியை செயல்பாடு மிக்கதாக மாற்றலாம் மற்றும் மொத்த தலைமை நேரத்தை குறைக்கலாம், குறிப்பாக பல முடிவுகள் அல்லது சிக்கலான QA தேவைப்படும் போது.

- இரண்டாம் வகை ஆனோடைஸ் மற்றும் தூள் பூச்சு பெரும்பாலான ட்ரிம் மற்றும் தெரிந்து கொள்ளக்கூடிய பாகங்களுக்கு செலவு, செயலாக்க வேகம் மற்றும் தோற்றத்திற்கு இடையிலான நடுநிலை சமநிலையை வழங்குகின்றன.

- ஹார்டு ஆனோடைஸ் மற்றும் இ-கோட் செயல்முறை கட்டுப்பாடு மற்றும் QA செலவுகள் அதிகமாக இருப்பதை பொதுவாக ஈடுபடுத்துகின்றன, ஆனால் அழிவு அல்லது கருப்பு பாதிக்கப்பட்ட பாகங்களுக்கு சிறப்பான செயல்திறனை வழங்குகின்றன.

- மில் முடிக்கும் பிரைமர்/பெயிண்ட் பெரும்பாலும் மிக குறைந்த தலைமை நேரத்துடன் மிகவும் பொருத்தமான பாதையாகும் - ஆனால் கவனமான தயாரிப்பு தேவைப்படுகிறது மற்றும் தெரியாத அல்லது எளிதாக சேவை செய்யக்கூடிய பாகங்களுக்கு சிறந்தது.

பல முடிவுகளை தேவைப்படும் அல்லது சிக்கலான உற்பத்தி கால அளவுகளை கொண்ட திட்டங்களுக்கு, ஷாய் மெட்டல் பார்ட்ஸ் சப்ளையர் -சீனாவில் ஒருங்கிணைந்த துல்லியமான ஆட்டோ உலோக பாகங்களுக்கான முன்னணி தீர்வுகளை வழங்குபவர்-உங்கள் அலுமினியம் எக்ஸ்ட்ரூஷன் பாகங்கள் ஒரே PPAP மற்றும் விநியோக திட்டத்தின் கீழ் முடிக்கப்பட்டு தகுதி பெற வழிவகுக்கிறது, இதன் மூலம் அபாயத்தை குறைக்கலாம் மற்றும் தொடர்பினை எளிமைப்படுத்தலாம்.

முடிவு மெட்ரிக்ஸ் மற்றும் குவிக் பிக்ஸ்

- வெளிப்புறம் A வகுப்பு தோற்றம்: பரந்த நிற விருப்பங்கள் மற்றும் காட்சி ஒருமைப்பாட்டிற்கு பவுடர் கோட்டிங் அல்லது Type II ஆனோடைஸை தேர்வுசெய்யவும்.

- அடிப்பகுதி துருப்பிடித்தல் அடிப்படை: சிக்கலான சுருக்கங்களில் குறிப்பாக உறுதியான, ஒருபடித்தான பாதுகாப்பிற்கு E-கோட் அல்லது ஒருங்கிணைந்த Shaoyi தீர்வுகள்.

- அதிக அணிவிக்கப்பட்ட இயந்திரம் அல்லது நழுவும் பயன்பாடுகள்: ஹார்ட் ஆனோடைஸ் (Type III) அல்லது Shaoyi-ன் அணிவிப்பு குவிந்த சிகிச்சைகள்.

- செலவு உணர்திறன் கொண்ட, தெரியாத பாகங்கள்: முடிவுற்ற முடிச்சுடன் பிரைமர் மற்றும் பெயிண்டை வளைப்பதற்கு தேர்வுசெய்யவும், நெகிழ்வுத்தன்மை மற்றும் எளிய புல சரிசெய்தலுக்கு.

- பல-செயல்முறை அல்லது தனிபயன் தேவைகள்: உலோகத்திற்கான Shaoyi மேற்பரப்பு முடிவுகள், ஒற்றை-மூல QA மற்றும் ஆவணப்படுத்துதலுடன்.

முக்கியமான விழிப்புணர்வு: உங்கள் வரைபடக் குறிப்புகளில் முன் சிகிச்சை மற்றும் மறைப்பதற்கான தேவைகளை எப்போதும் குறிப்பிடுங்கள். உங்கள் அலுமினியம் பரப்பு முடிக்கும் தேர்வு எதுவாக இருந்தாலும், கீழ்நோக்கு திசையில் ஏற்படும் தோல்விகள், மீண்டும் செய்ய வேண்டியதல் அல்லது உத்தரவாத கோரிக்கைகளைத் தவிர்க்க இந்த படி மிகவும் முக்கியமானது.

உங்கள் தரநிலையை இறுதி செய்யும் போது, சிறந்த பொருத்தம் என்பது முடிக்கும் மட்டுமல்ல, உங்கள் உற்பத்தி, செலவு மற்றும் தரக் குறிக்கோள்களுடன் அது எவ்வளவு நன்றாக ஒத்துப்போகிறது என்பதையும் கருத்தில் கொள்ள வேண்டும். அடுத்து, தரநிலை எழுதுவதற்கான செயல்பாடு தொடர்பான குறிப்புகள் மற்றும் வழங்குநருக்கு கையளிப்பது குறித்து நாம் முடிப்போம் - உங்கள் தேர்ந்தெடுத்த பரப்பு சிகிச்சை அலுமினியம் துறையில் நீடித்த மதிப்பை வழங்குவதை உறுதி செய்ய.

இறுதி பரிந்துரை மற்றும் தரநிலை எழுதுவதற்கான குறிப்புகள்: ஆட்டோமோட்டிவ் அலுமினியம் எக்ஸ்ட்ரூஷன்கள்

உங்கள் திட்டத்திற்கு எந்த முடிக்கும் தேர்வு செய்வது

இறுதி முடிவு புள்ளியை அடையும் போது, கிடைக்கும் அலுமினியம் பரப்பு சிகிச்சைகளின் வரிசையால் மன எழுச்சி மிகுந்த உணர்வை ஏற்படுத்தலாம். எனவே, உங்கள் திட்டத்திற்கு சிறந்த பொருத்தத்தை எவ்வாறு கண்டறிவது? ஒரு புதிய EV பேட்டரி என்கிளோசரை நீங்கள் வடிவமைக்கின்றீர்கள் அல்லது அடுத்த தலைமுறை எஸ்யூவியின் வெளிப்புற ட்ரிம்மை புதுப்பிக்கின்றீர்கள் என்று கற்பனை செய்யுங்கள் - பரப்பு சிகிச்சை அலுமினியத்தின் தேர்வு நீடித்ததன்மையிலிருந்து செலவு வரை மற்றும் பிராண்ட் பார்வை வரை அனைத்தையும் நேரடியாக பாதிக்கும். உங்கள் தேவைகளை சரியான முடிவுடன் பொருத்த உதவும் குறிப்பு விரைவான குறிப்பு வழிகாட்டி இதோ:

- அனோடைச் செய்யவும்: அலங்கார துருப்பிடிக்காத எதிர்ப்பு மற்றும் பிரீமியம், நீடிக்கும் உலோகத்தன்மை தோற்றத்திற்கு தேர்வு செய்யவும்.

- ஹார்ட் அனோடைஸ்: உயர் அணிகலன் பகுதிகள் அல்லது நழுவும் பாகங்களுக்கு தேர்வு செய்யவும் - இருக்கை தடங்கள் அல்லது சூரிய பொறிமுறை ரெயில்கள் போன்றவை.

- பவுடர் கோட்டிங்: வெளிப்புற ட்ரிம்மில் அல்லது ஹூட் கீழ் பாகங்களில் நிறத்திற்கு சிறந்தது, வேதியியல் எதிர்ப்பு மற்றும் தோற்ற விருப்பங்களின் பரந்த அளவு.

- இ-கோட்: சிகிச்சைக்கு பின் துருப்பிடிக்காத பிரைமராக தேர்வு செய்யவும், குறிப்பாக சிக்கலான சுட்டிகள் அல்லது கூடுதல் கோடிங்குகளுக்கு கீழ் உறுதியான அடிப்படை தேவைப்படும் பாகங்களுக்கு.

- மில் முடிக்கவும் பிரைமர்/பெயிண்ட்: இந்த விருப்பத்தை உங்கள் பார்வைக்கு தெரியாத அல்லது மறைக்கப்பட்ட அமைப்பு உறுப்புகளுக்கு செலவு சார்ந்த, பெயிண்ட் செய்யப்பட்ட பாகங்களுக்கு அல்லது நெகிழ்வுத்தன்மை மற்றும் எளிய பழுது நீக்கம் முக்கியமானவையாக இருக்கும் போது தேர்வு செய்யவும்.

இந்த பரப்பு சிகிச்சை அலுமினியம் விருப்பங்களில் ஒவ்வொன்றும் தனித்துவமான பங்கை வகிக்கின்றன, எனவே உங்கள் பயன்பாட்டின் வெளிப்பாடு, அழிவு, தோற்றம் மற்றும் பட்ஜெட் தேவைகளை கணக்கில் எடுத்துக்கொண்டு உங்கள் தரவரிசையை உறுதி செய்யவும்.

தரவரிசை மொழி மற்றும் படம் குறிப்புகள்

தெளிவான, தரநிலை அடிப்படையிலான தரவரிசைகள் குழப்பத்தை தவிர்க்கவும் மறுசெய்கைக்கு எதிராகவும் உங்கள் சிறந்த பாதுகாப்பாக இருக்கும். பெரும்பாலான அலுமினியம் எக்ஸ்ட்ரூஷன் திட்டங்களுக்கு பயன்படுத்தக்கூடிய ஒரு வடிவமைப்பை இங்கே காணலாம்:

முடிப்பு: [செயல்முறை]. முன் சிகிச்சை: [மாற்றம், குரோமேட்-இல்லா விருப்பம்]. தரநிலைகள்: [ASTM/ISO/MIL பொருத்தமானவை]. சோதனைகள்: ஒட்டுதல், தடிமன், தோற்ற வகுப்பு, OEM நெறிமுறைப்படி சுழற்சி துர்நாற்றம். முகமூடி: [அம்சங்கள்]. பெயிண்ட்-பேக் ஒப்புதல்: [ஆம்/இல்லை].

அலுமினியத்தை பெயிண்ட் அல்லது வேறு எந்த பூச்சுக்கும் முன் சிகிச்சை செய்யும் போது, மாற்றங்கள், சுத்தம் செய்தல் மற்றும் மாஸ்கிங் போன்ற நிலைகளை உங்கள் படங்களில் குறிப்பிடுங்கள். இதன் மூலம் வடிவமைப்பு முதல் உற்பத்தி வரை அனைவரும் அலுமினியம் பரப்பு சிகிச்சைக்கான எதிர்பார்ப்புகளை புரிந்து கொள்வார்கள்.

வழங்குநர் கைமாற்ற பட்டியல்

உங்கள் திட்டம் கைமாற்றத்திற்கு தயாராக இருப்பதை கற்பனை செய்யுங்கள். உங்கள் வழங்குநர் ஈடுபாட்டை சுழல் முறையிலும், உங்கள் தர திட்டத்தை சரியான பாதையிலும் வைத்திருக்க இந்த பட்டியலை பயன்படுத்தவும்:

- ஒவ்வொரு எக்ஸ்ட்ரூசனுக்கும் உலோகக்கலவை மற்றும் வகையை குறிப்பிடவும்

- விரிவான வடிவமைப்பு மற்றும் மாஸ்கிங் வரைபடங்களை சேர்க்கவும் (நூல்கள், துளைகள், மின்னணு தொடர்புகள்)

- சிறப்பான பூச்சு மூடுதலுக்கான ராக்கிங் புள்ளிகளை அடையாளம் காணவும்

- முக்கியமான அளவுகளையும் அனுமதிக்கப்பட்ட தரநிலைகளையும் (படல உருவாக்கத்தை கணக்கில் கொண்டு) குறிப்பிடவும்

- தர கட்டுப்பாட்டிற்கான ஏற்பு நிலைமைகளையும் சான்று தரநிலைகளையும் வரையறுக்கவும்

- முதல் கட்டுரை, தொகுப்பு அல்லது தொடர்ந்து சோதனைகளை மேற்கொள்ள ஒரு மாதிரி மற்றும் ஆய்வு திட்டத்தை பகிரவும்

- மீண்டும் செய்யும் மற்றும் துறை சீரமைப்பு கொள்கையை முன்கூட்டியே தெளிவுபடுத்தவும்

இந்த நடவடிக்கைகளை பின்பற்றுவதன் மூலம், உங்கள் தேர்ந்தெடுத்த பரப்பு சிகிச்சை அலுமினியம் தொடர்ந்து உயர்தர முடிவுகளை வழங்கும் என்பதை உறுதி செய்யவும், ஆச்சரியங்களை குறைக்கவும்.

உங்கள் முடிப்பு மற்றும் தரக்கட்டுப்பாட்டை ஒரே இடத்தில் ஒருங்கிணைக்க தயாரா? ஷாய் மெட்டல் பார்ட்ஸ் சப்ளையர் —சீனாவில் முன்னணி ஒருங்கிணைந்த துல்லியமான ஆட்டோ உலோக பாகங்களுக்கான தீர்வுகளை வழங்குபவர்— அலுமினியம் எக்ஸ்ட்ரூஷன் பாகங்களுக்கான பரப்பு சிகிச்சை விருப்பங்களில் அவர்களது நிபுணத்துவம் உங்களுக்கு ஒவ்வொரு முறையும் சரியான முடிப்பை வழங்குவதை உறுதி செய்து கொண்டு, வடிவமைப்பிலிருந்து தொடங்கி தொடர் உற்பத்தி வரை ஒவ்வொரு படிநிலையையும் எளிமைப்படுத்த உங்களுக்கு உதவலாம்.

அடிக்கடி கேட்கப்படும் கேள்விகள்

1. ஆட்டோமொபைல் அலுமினியம் எக்ஸ்ட்ரூஷன்களுக்கான பொதுவான பரப்பு சிகிச்சைகள் எவை?

துவக்க நோக்கங்களுக்காக (தோற்றத்திற்கும் துருப்பிடிக்காத தன்மைக்காக வகை II, அரிப்பு எதிர்ப்பிற்காக வகை III), நீடித்த நிறம் மற்றும் வேதியியல் பாதுகாப்பிற்காக பவுடர் கோட்டிங், சிக்கலான வடிவங்களுக்கு ஒரே மாதிரியான துருப்பிடிக்காத பாதுகாப்பிற்காக e-கோட் மற்றும் பொருளாதார நெகிழ்வுத்தன்மைக்காக மில் முடிக்கும் பிரைமர் மற்றும் பெயின்ட் ஆகியவை தான் தானியங்கி வாகன அலுமினியம் எக்ஸ்ட்ரூஷன்களுக்கான மிகவும் பரவலாக பயன்படுத்தப்படும் மேற்பரப்பு சிகிச்சைகள் ஆகும். நீடித்த தன்மை, தோற்றம் மற்றும் தானியங்கி வாகன உற்பத்தி தரநிலைகளுடன் ஒத்துப்போகும் தன்மை போன்ற அம்சங்களில் ஒவ்வொரு சிகிச்சையும் குறிப்பிட்ட நன்மைகளை வழங்குகின்றது.

2. எனது தானியங்கி வாகன அலுமினியம் எக்ஸ்ட்ரூஷன் திட்டத்திற்கான சரியான முடிக்கும் முறையை நான் எவ்வாறு தேர்வு செய்வது?

உங்கள் திட்டத்தின் தேவைகளைப் பொறுத்து, சிறந்த முடிக்கும் வகையைத் தேர்வு செய்யலாம். அதாவது, துருப்பிடிக்காத எதிர்ப்பு, தோற்றம், உடைகள் செய்திடும் தன்மை மற்றும் பட்ஜெட் ஆகியவற்றைக் கொண்டு தேர்வு செய்யவும். காட்சிப்படுத்தக்கூடிய ட்ரிம்களுக்கு அழகியல் ஆனோடைசிங் (Decorative anodizing) ஏற்றது, அதிக உடைவு ஏற்படும் பாகங்களுக்கு கடின ஆனோடைசிங் (Hard anodizing) ஏற்றது, வண்ணமயமான, நீடித்த நிறத்தை பவுடர் கோட்டிங் (powder coating) வழங்கும், சிக்கலான வடிவங்களுக்கு சீரான பாதுகாப்பு தேவைப்பட்டால் ஈ-கோட் (e-coat) சிறந்தது, மறைக்கப்பட்ட அல்லது பழுதுபார்க்கக்கூடிய பாகங்களுக்கு மில் ஃபினிஷ் (mill finish) மற்றும் பெயின்ட் செலவு குறைந்தது. உங்கள் பாகத்தின் வெளிப்பாடு, பொருத்தும் தேவைகள் மற்றும் தரக் கோட்பாடுகளைக் கருத்தில் கொண்டு சரியான தேர்வை மேற்கொள்ளவும்.

3. அலுமினியம் எக்ஸ்ட்ரூஷன்களில் (aluminum extrusions) ஆனோடைசிங் மற்றும் பவுடர் கோட்டிங் ஆகியவற்றிற்கு உள்ள வேறுபாடு என்ன?

ஆனோடைசிங் அலுமினியம் பரப்பில் ஒரு ஆக்சைடு அடுக்கை உருவாக்குகிறது, இது துருப்பிடிப்பதை எதிர்க்கும் தன்மையை அதிகரிக்கிறது மற்றும் பல்வேறு உலோகத் தீட்டுகளை வழங்குகிறது. வகை II ஆனோடைசிங் அதன் அலங்கார தோற்றத்திற்காக மதிப்புமிக்கது, அதே நேரத்தில் வகை III (ஹார்ட் ஆனோடைசிங்) அதிக அளவு உழைக்கும் எதிர்ப்பை வழங்குகிறது. மாறாக, பவுடர் கோட்டிங் என்பது ஒரு பொடியாக பயன்படுத்தப்படும் கரிம பூச்சு ஆகும், பின்னர் பாதுகாப்பான, வண்ணமயமான மற்றும் நீடித்த அடுக்கை உருவாக்க சிகிச்சை அளிக்கப்படுகிறது. பவுடர் கோட்டிங் வண்ணம் மற்றும் மேற்பரப்பு விருப்பங்களை மேலும் வழங்குகிறது, ஆனால் சிறப்பான பிடிப்பிற்கு முன் சிகிச்சை அவசியம்.

4. ஏன் அலுமினியம் எக்ஸ்ட்ரூஷன்களில் எந்த மேற்பரப்பு முடிக்கும் முன்னரும் முன் சிகிச்சை முக்கியம்?

முன் சிகிச்சை முக்கியமானது, ஏனெனில் இது மாசுபாடுகளை நீக்குகிறது, ஒட்டுதலை மேம்படுத்துகிறது மற்றும் துருப்பிடிப்பை எதிர்க்கும் தன்மையை அதிகரிக்கிறது. சரியான சுத்திகரிப்பு மற்றும் மாற்ற பூச்சு (அடிக்கடி குரோமேட்-இலவசம்) ஆனோடைசிங், பவுடர், இ-கோட் அல்லது பெயிண்ட் போன்ற தேர்ந்தெடுக்கப்பட்ட முடிக்கும் செயல்முறை உறுதியாக இணைக்கப்படுவதையும், நோக்கம்போல் செயல்படுவதையும் உறுதி செய்கிறது. முன் சிகிச்சையை தவிர்ப்பது அல்லது போதுமான முறையில் செய்யாமல் இருப்பது பீலிங், குமிழிகள் அல்லது துருப்பிடிப்பு போன்ற முன்கூட்டியே தோல்விகளுக்கு வழிவகுக்கலாம்.

5. அலுமினியம் எக்ஸ்ட்ரூஷன் மேற்பரப்பு சிகிச்சைக்கு ஷாயி போன்ற ஒரு ஒருங்கிணைந்த வழங்குநரைப் பயன்படுத்துவதற்கான நன்மைகள் எவை?

ஷாயி போன்ற ஒரு ஒருங்கிணைந்த வழங்குநருடன் இணைந்து பணியாற்றுவதன் மூலம் முக்கிய மேற்பரப்பு சிகிச்சைகள், தரக் கட்டுப்பாடு மற்றும் விநியோகத் தொடர் மேலாண்மை ஆகியவற்றை ஒரே இடத்தில் வழங்குவதன் மூலம் முடிக்கும் செயல்முறையை எளிதாக்குகிறது. இந்த அணுகுமுறை தலைமை நேரத்தைக் குறைக்கிறது, பல வழங்குநர்களிடமிருந்து பிழைகள் ஏற்படும் ஆபத்தைக் குறைக்கிறது, செயல்முறை தரநிலைகளுக்கு இணங்குமாறு உறுதி செய்கிறது மற்றும் உங்கள் பயன்பாட்டிற்கு சரியான உலோகக்கலவை, வடிவவியல் மற்றும் முடிக்கும் செயல்முறையை தேர்வு செய்வதற்கு நிபுணர் வழிகாட்டுதலை வழங்குகிறது.

சிறு கலைகள், உயர் தரம் தரவுகள். எங்கள் வேகமான மாதிரி செயற்படுத்தும் சேவை சரிபார்ப்பை வேகமாக்கும் மற்றும் எளிதாக்கும் —

சிறு கலைகள், உயர் தரம் தரவுகள். எங்கள் வேகமான மாதிரி செயற்படுத்தும் சேவை சரிபார்ப்பை வேகமாக்கும் மற்றும் எளிதாக்கும் —