Custom Sheet Metal Cutting Costs Decoded: What Actually Drives Your Quote

Understanding Custom Sheet Metal Cutting Fundamentals

Ever wondered what separates a perfectly fitted metal component from one that just doesn't work? The answer lies in custom sheet metal cutting—the precise process of transforming flat metal sheets into components tailored to your exact specifications. Unlike off-the-shelf parts, this approach delivers pieces designed specifically for your application, whether you're building automotive brackets, electronic enclosures, or architectural panels.

What Makes Sheet Metal Cutting Custom

When you cut sheet metal to custom specifications, you're not simply trimming material to size. You're creating components engineered for a specific purpose. This process involves selecting the right cutting technology, matching it to your material type and thickness (measured in gauge), and achieving the precise dimensions your project demands.

The "custom" aspect means every decision—from the cutting method to the edge finish—is based on your unique requirements. A metal laser cutter might be perfect for intricate designs requiring tight tolerances, while plasma cutting excels at processing thicker materials quickly. Some projects even benefit from traditional machine die cutting when simpler shapes and high-volume production are the priority.

Custom sheet metal manufacturing serves industries ranging from aerospace and automotive to medical devices and consumer electronics. The versatility of this fabrication process allows manufacturers to create brackets, covers, frames, enclosures, and countless other components with remarkable accuracy.

Why Precision Matters in Metal Fabrication

Imagine assembling a product only to discover that a single component is off by a fraction of an inch. That tiny error can cascade into major problems—parts that don't fit, systems that malfunction, or costly rework that delays your entire project.

Precision in sheet metal cutting ensures that every piece performs exactly as intended. A perfectly crafted part doesn't just fit—it enhances the overall efficiency and reliability of whatever system it supports. This is why understanding the fundamentals before requesting quotes helps you communicate your needs clearly and evaluate suppliers effectively.

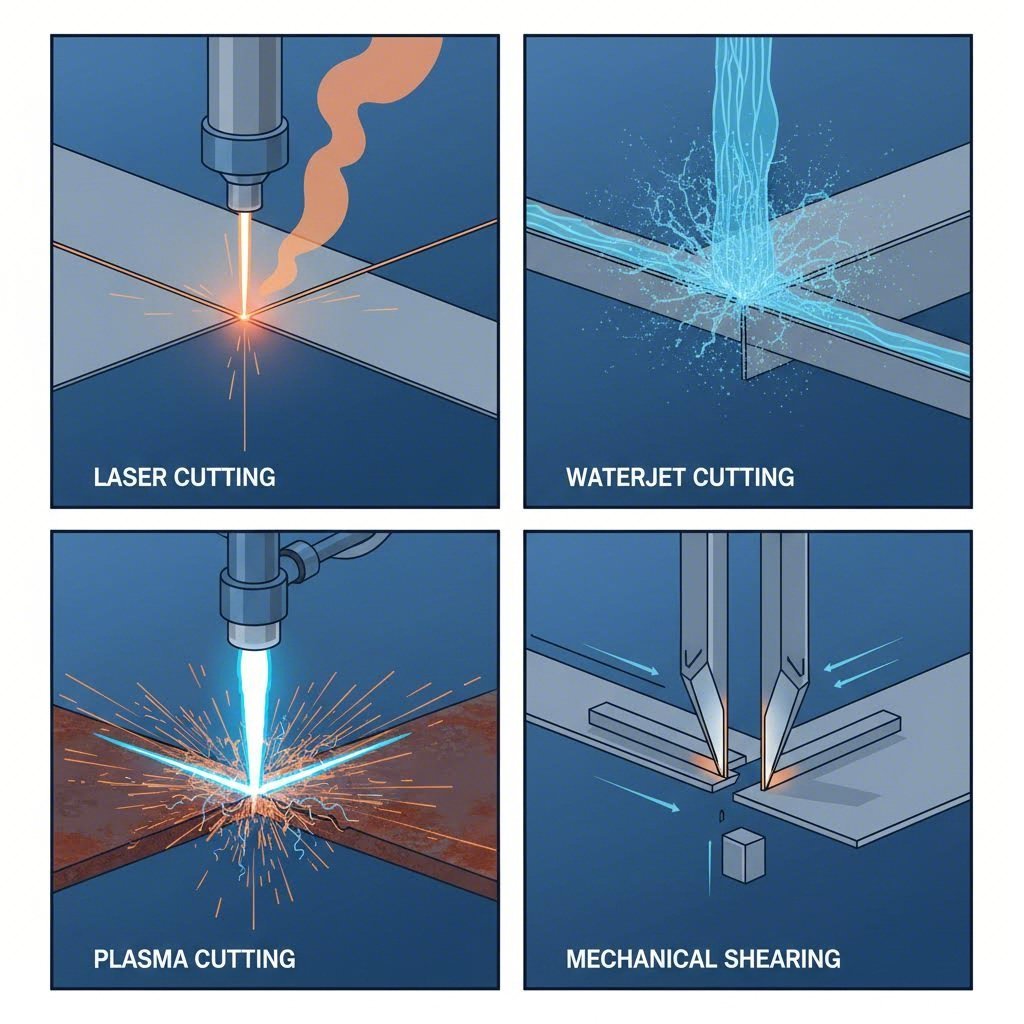

Throughout this guide, you'll explore the primary cutting technologies available for your projects:

- Laser cutting – Uses focused light beams for extremely precise cuts and intricate designs

- Waterjet cutting – Employs high-pressure water mixed with abrasives for heat-free cutting

- Plasma cutting – Utilizes ionized gas to cut through thicker conductive metals rapidly

- Mechanical shearing – Delivers fast, straight cuts for basic shapes and high-volume work

Each method has distinct advantages depending on your material, design complexity, and budget. By understanding these options, you'll be equipped to make informed decisions—and understand exactly what's driving your quote when you request one.

Four Primary Cutting Methods and How They Work

Now that you understand what makes sheet metal cutting custom, let's dive into the technologies that make it all possible. Each cutting method operates on fundamentally different principles—and understanding these differences is key to knowing why one approach costs more or works better for your specific project.

Laser Cutting Technology Explained

Think of a laser metal cutter as an incredibly precise, concentrated beam of light powerful enough to melt through metal. A laser cutting machine for metal employs either CO2 or fiber laser sources to focus energy onto an extremely small point, vaporizing or melting material along a programmed path.

What makes laser cutting stand out? The focused beam creates a remarkably narrow kerf—the width of material removed during cutting. A narrower kerf means less wasted material and the ability to cut intricate patterns with exceptional detail. According to fabrication experts, laser cutting produces an even smaller heat-affected zone (HAZ) compared to other thermal methods because heat is applied to such a concentrated area.

Fiber lasers dominate when processing thin materials under 1/4" thick, achieving exceptional cutting speeds. However, as material thickness increases, laser cutting slows significantly—making it less cost-effective for plates over 1" thick.

Waterjet and Plasma Cutting Differences

When heat distortion isn't an option, water cutting provides the solution. Waterjet systems force water through a tiny nozzle at pressures reaching 90,000 PSI—often mixed with abrasive particles like garnet—to erode material along the cutting path. Because there's no heat involved, this cold-cutting process preserves the metal's structural integrity completely.

Sounds ideal, right? The tradeoff is speed. Waterjet systems typically cut at just 5-20 inches per minute, making them the slowest option among these technologies. However, for applications where material properties cannot be compromised, this method is irreplaceable.

Cut plasma technology takes the opposite approach. Plasma cutting uses an accelerated jet of ionized gas reaching temperatures up to 45,000°F (25,000°C) to melt and blow away material. This extreme heat enables remarkable speed—cutting aluminum with plasma cutter equipment can exceed 100 inches per minute on 1/2" material.

The HAZ in plasma cutting is relatively thin because cutting speeds can be manipulated to minimize heat exposure. Modern high-definition plasma systems have evolved dramatically, now rivaling laser quality on many applications while maintaining superior throughput.

Mechanical Shearing: The Straight-Cut Specialist

For simple, straight cuts, mechanical shearing remains a practical choice. This process uses opposing blades—similar to giant scissors—to separate sheet metal along a linear path. Because shearing relies on mechanical force rather than heat, it produces no HAZ whatsoever.

The limitation? Shearing only creates straight cuts. Complex geometries, curves, or interior cutouts require other methods. However, for high-volume production of basic shapes, shearing delivers fast results at lower operating costs.

Key Terminology You Need to Know

Before comparing these methods, let's clarify three terms that directly impact your project quality and cost:

- Kerf – The width of material removed during cutting. Narrower kerfs mean less waste and tighter nesting of parts.

- Heat-Affected Zone (HAZ) – The area where metal microstructure changes due to heat exposure, potentially reducing strength. The weakest sections of a structure exist in the HAZ, making this a critical consideration for structural applications.

- Burr Formation – Small raised edges or rough spots created during cutting that may require secondary finishing.

Understanding these terms helps you evaluate quotes accurately—a supplier mentioning "minimal HAZ" or "burr-free edges" is describing tangible quality characteristics that affect your finished parts.

Comparing All Four Methods

How do these technologies stack up against each other? This comparison covers the factors that most directly influence your project decisions:

| Factor | Laser Cutting | Waterjet Cutting | Plasma Cutting | Mechanical Shearing |

|---|---|---|---|---|

| Precision Level | Highest (±0.001" - 0.005") | High (±0.003" - 0.010") | Good (±0.010" - 0.030") | Moderate (±0.010" - 0.060") |

| Material Thickness Range | Up to 1" (optimal under 1/4") | Up to 12"+ (any thickness) | 0.018" to 2" (optimal range) | Typically up to 1/4" |

| Edge Quality | Excellent, minimal burr | Good, slightly textured | Good to excellent with HD plasma | Clean but may have slight distortion |

| Heat Generation | Moderate (small HAZ) | None (cold process) | High (manageable HAZ) | None (mechanical process) |

| Best Applications | Intricate designs, thin materials, precision parts | Heat-sensitive materials, thick materials, composites | Thick steel, high-volume production, structural work | Straight cuts, high-volume basic shapes |

Notice how each method excels in different scenarios. A metal cutting laser machine delivers unmatched precision for detailed work, while plasma dominates when processing thick steel quickly. Waterjet stands alone for applications where any heat exposure is unacceptable, and shearing remains the economical choice for straightforward cuts.

With these cutting methods understood, the next question becomes: which materials work best with each technology? The answer depends on factors like reflectivity, thickness, and the specific properties you need to preserve.

Choosing the Right Material for Your Cutting Project

You've learned how each cutting technology works—but here's the catch: not every metal plays nicely with every method. The material you select directly influences which cutting approach delivers the best results, the fastest turnaround, and the most cost-effective quote. Let's break down which metals pair best with each technology and why thickness matters more than you might expect.

Matching Metals to Cutting Technologies

Different metals have unique properties—reflectivity, thermal conductivity, hardness—that determine how they respond to cutting. Choosing the wrong pairing can mean poor edge quality, slower processing, or even damaged equipment.

Aluminum is lightweight, corrosion-resistant, and excellent for laser cutting when you're working with thinner gauges. Fiber lasers handle aluminum exceptionally well, producing clean edges with minimal burr. However, aluminum's high thermal conductivity means heat dissipates quickly, so laser cut aluminum projects benefit from optimized power settings to maintain edge quality.

Steel and Stainless Steel are the workhorses of metal fabrication—versatile across virtually all cutting methods. Carbon steel responds beautifully to plasma cutting, which was originally developed specifically for metals that traditional flame cutting couldn't handle efficiently. Stainless steel works well with laser, plasma, and waterjet, though its corrosion-resistant properties make it popular in applications where edge quality and material integrity are paramount.

Copper and Brass present a unique challenge. These reflective metals can bounce laser energy back toward the cutting head, potentially damaging CO2 laser systems. Plasma cutting machines are ideal for cutting through shiny or reflective metals like copper, making them the preferred choice when lasers aren't practical. Alternatively, fiber lasers with specific wavelengths can handle copper more safely than traditional CO2 systems.

Here's a quick reference for matching materials to cutting methods:

- Aluminum – Best with fiber laser (thin gauges) or waterjet (thicker materials); plasma works for structural applications

- Mild Steel – Excellent across all methods; plasma offers the lowest operating cost for thicker plates

- Stainless Steel – Laser for precision, waterjet for heat-sensitive applications, plasma for speed on thicker sections

- Copper – Plasma cutting preferred; fiber laser with proper settings; waterjet for zero heat distortion

- Brass – Similar to copper; avoid CO2 lasers; plasma or waterjet recommended

- Titanium – Waterjet ideal to prevent oxidation; laser possible with inert gas shielding

If you're exploring options beyond metal—like custom cut acrylic or acrylic sheets for laser cutting—know that laser technology excels at these materials too. Acrylic glass custom cut with CO2 lasers produces polished, flame-finished edges that often require no secondary processing. However, the focus here remains on metals, where material selection directly impacts your fabrication costs.

Material Thickness and Gauge Considerations

Here's something that surprises many first-time buyers: sheet metal thickness isn't measured in inches or millimeters alone. The industry uses a gauge system where higher numbers indicate thinner material. Sounds counterintuitive? It is—but understanding this system helps you communicate specifications clearly and interpret quotes accurately.

Common gauge measurements include:

- 10 Gauge – Approximately 0.135" (3.4 mm); used for heavy-duty structural components

- 14 Gauge – Approximately 0.075" (1.9 mm); suitable for automotive parts and commercial equipment

- 16 Gauge – Approximately 0.060" (1.5 mm); common for appliances and cabinetry

- 20 Gauge – Approximately 0.032" (0.81 mm); frequently used in HVAC and decorative applications

Why does thickness matter so much for your quote? Thinner gauges allow faster cutting speeds, which translates directly to lower processing costs. A 20-gauge steel panel might cut three to four times faster than a 10-gauge plate using the same laser system. That speed difference shows up in your bottom line.

Conversely, thicker materials often require different technologies entirely. Oxy-fuel cutting excels at carbon steel greater than 2 inches thick, while plasma efficiently handles materials up to 1.25 inches. Laser cutting typically becomes less economical beyond 1 inch. For plates exceeding 2 inches, waterjet cutting often becomes the only precision option—though at higher cost.

When planning your project, consider how thickness influences method selection:

- Under 1/4" – Laser cutting typically offers the best combination of speed, precision, and cost

- 1/4" to 1" – Laser, plasma, or waterjet all viable; choice depends on edge quality needs and budget

- Over 1" – Plasma or waterjet preferred; oxy-fuel for carbon steel structural work

- Over 2" – Waterjet or oxy-fuel; laser rarely cost-effective at this thickness

Beyond cutting, some projects require custom engraving or decorative details. If you're searching for metal engraving near me alongside cutting services, many fabrication shops offer both capabilities—consolidating your supply chain and potentially reducing overall costs.

With material and thickness considerations clarified, the next critical factor is understanding how precision tolerances and edge quality requirements shape both your method selection and final quote.

Precision Tolerances and Edge Quality Explained

You've selected your material and identified a cutting method that suits your project. But here's where things get technical—and where many buyers get surprised by their quotes. The precision you require, measured in tolerances, directly affects which cutting technology makes sense and how much you'll pay. Let's translate these specifications into practical terms you can actually use.

What Tolerances Mean for Your Parts

Tolerance refers to the acceptable variation from your specified dimensions. When a fabricator says they achieve ±0.005" tolerance, they're telling you that a feature designed at exactly 2.000" might actually measure anywhere from 1.995" to 2.005". Sounds tiny? For some applications, that range is perfectly acceptable. For others—like parts that must interlock precisely or fit into existing assemblies—even smaller variations matter.

Different cutting methods deliver different tolerance capabilities. Here's what you can realistically expect:

- Laser cutting – Standard tolerance of ±0.005" (0.13mm) for position, inside dimensions, and outside dimensions. This applies to the distance between any cut edges in a profile.

- Waterjet cutting – Typically achieves ±0.003" to ±0.010" depending on material thickness and cutting speed. Slower speeds improve precision.

- Plasma cutting – Generally delivers ±0.010" to ±0.030" with modern high-definition systems approaching the tighter end of this range.

- Mechanical shearing – Usually ±0.010" to ±0.060" depending on blade condition and material thickness.

What do these numbers mean practically? Imagine you're fabricating brackets that bolt together. If the hole positions vary by more than your tolerance allows, the bolts won't align—and you're looking at rework or scrap. Parts destined for laser engraved identification or metal laser engraving detail work require even tighter base tolerances since any variation compounds when adding secondary operations.

Your tolerance requirements should drive your method selection—not the other way around. Choosing a cutting technology that barely meets your needs invites quality issues, while specifying tighter tolerances than necessary inflates your costs.

Edge Quality Across Cutting Methods

Beyond dimensional accuracy, edge quality affects both appearance and function. Each cutting method produces distinct edge characteristics that may—or may not—require secondary finishing.

Laser cutting produces exceptionally clean edges with minimal burr formation. Sheet metal laser cutting creates a slight taper on thicker materials, but the surface finish typically requires no additional processing for most applications. The small heat-affected zone means edges maintain their hardness and corrosion resistance. For precision parts, laser etching services often complement laser cutting, adding identification marks without additional handling.

Waterjet cutting creates slightly textured edges—think fine sandpaper rather than polished metal. The cold-cutting process means absolutely zero heat distortion, making it ideal when material properties cannot be compromised. However, the texture may require smoothing for cosmetic applications or precision fits.

Plasma cutting produces edges that vary based on system quality and settings. Modern high-definition plasma systems achieve near-laser quality on many applications, but standard plasma may leave rougher edges requiring grinding or machining for precision fits. The heat-affected zone is manageable but present, which matters for applications involving subsequent welding or heat treatment.

Mechanical shearing creates clean edges but may produce slight distortion or rollover along the cut line. For structural applications where appearance isn't critical, this rarely matters. For visible components or precision assemblies, secondary deburring may be necessary.

Why Certifications Actually Matter

You've probably seen fabricators tout ISO 9001 or IATF 16949 certifications. But what do these designations actually mean for your parts?

ISO 9001 establishes a quality management system (QMS) that documents responsibilities, processes, and procedures required to meet quality objectives. Quality management systems help organizations meet customer and regulatory requirements consistently—meaning the parts you receive today should match the quality of parts ordered months from now.

IATF 16949 takes this further for automotive applications. This certification builds on ISO 9001 but adds automotive-specific requirements for safety, consistency, and traceability. When IATF 16949 certification is awarded, it signifies that the organization has met requirements proving their ability and commitment to limit defects—reducing waste and ensuring parts perform as intended in demanding automotive environments.

For buyers, these certifications provide assurance that:

- Documented processes ensure repeatable quality across production runs

- Equipment calibration and maintenance follow established schedules

- Inspection procedures verify parts meet specified tolerances

- Traceability systems track materials and processes for each order

When your application demands consistent metal laser cutting quality—especially for automotive, aerospace, or medical components—working with certified fabricators reduces risk significantly. The certification isn't just a logo; it represents systems designed to catch problems before they reach you.

Understanding tolerances and edge quality helps you specify exactly what you need—but how does a cutting project actually flow from your design file to finished parts? The next section walks through that complete process, helping you prepare files that translate smoothly into accurate quotes and quality components.

The Complete Cutting Process From Design to Delivery

You've selected your cutting method, chosen your material, and defined your tolerance requirements. Now what? Understanding the journey from your CAD file to finished parts helps you prepare properly, avoid delays, and understand exactly what you're paying for. Let's walk through the complete workflow that transforms your digital design into precision metal components.

From CAD File to Cut Parts

The path from concept to finished component follows a predictable sequence—but each step offers opportunities to optimize for speed, cost, or quality. Here's what happens when you submit a project to a metal laser cutting services provider or waterjet cutting services shop:

- Design Submission – You upload your CAD files through the fabricator's portal or email. Most shops accept multiple formats, though some work better than others for cutting operations.

- Design for Manufacturability (DFM) Review – Engineers analyze your design for potential issues before cutting begins. This critical step catches problems early.

- Quoting and Confirmation – You receive pricing based on material, complexity, quantity, and timeline. Once approved, material selection is confirmed.

- Production Programming – Your design is converted into machine instructions (G-code), with nesting optimization to minimize material waste.

- Cutting Operation – Your parts are cut using the specified technology—laser, waterjet, plasma, or shearing.

- Quality Inspection – Finished parts are measured against specifications to verify dimensional accuracy and edge quality.

- Secondary Operations – If required, parts undergo deburring, bending, welding, or finishing processes.

- Packaging and Shipping – Components are carefully packaged to prevent damage during transit and shipped to your facility.

This entire sequence can happen remarkably fast. According to industry analysis, digital manufacturing platforms now enable turnaround times measured in days rather than weeks—with some providers delivering from CAD to cut parts in as little as 48 hours for straightforward projects.

Preparing Your Design Files for Cutting

The file format you submit directly impacts how smoothly your project moves through production. Different formats carry different information, and choosing wisely prevents translation errors that delay your timeline.

Preferred file formats for laser cut services include:

- DXF (Drawing Exchange Format) – Industry standard for 2D cutting; widely compatible and retains accurate geometry

- DWG (AutoCAD Drawing) – Similar to DXF with additional CAD-specific data; excellent for complex designs

- STEP/STP (Standard for Exchange of Product Data) – Ideal for 3D models that require flat pattern development

- PDF (Portable Document Format) – Acceptable for simple designs but may require conversion; dimensions should be clearly noted

- AI (Adobe Illustrator) – Common for decorative or artistic applications; ensure paths are properly closed

Beyond format selection, several design considerations affect cutting success:

- Line weight consistency – All cut lines should be the same weight; varying thicknesses confuse programming software

- Closed contours – Every shape that needs cutting must form a completely closed path with no gaps

- Layer organization – Separate cut lines from engrave lines, bend lines, and reference geometry using distinct layers

- Scale verification – Confirm your drawing is at 1:1 scale; scaled drawings create costly errors

- Dimension inclusion – Add key dimensions for verification, even when submitting CAD files

If your project includes decorative details, a laser engraving service can often be combined with cutting operations. Similarly, if you're searching for laser engravers near me, many tube laser cutting services providers offer integrated engraving capabilities—handling both operations in a single setup and reducing handling time.

What Happens During DFM Review

Design for Manufacturability review is where experienced engineers examine your design through a manufacturing lens. This step catches issues that look fine on screen but create problems during production—and addressing them early saves significant time and money.

According to manufacturing experts, effective DFM implementation can reduce manufacturing costs by 15-40% and cut lead times by 25-60% compared to non-optimized designs. The review typically examines:

- Feature proximity – Are cut lines too close together? Thin sections between cuts may warp or tear during processing.

- Minimum feature size – Small details that look crisp in CAD may not translate to physical parts; laser kerf width limits minimum slot and hole sizes.

- Sharp internal corners – Sharp corners require specialized tooling and can increase programming time by 50-100%. Adding small radii simplifies production.

- Material considerations – Does your chosen material suit the required cutting method? Will heat-affected zones impact functionality?

- Bend allowances – If parts require bending after cutting, has the flat pattern accounted for material stretch and the K-factor?

The DFM process isn't about criticizing your design—it's about collaboration. A good fabricator will suggest alternatives that maintain your functional requirements while simplifying production. These suggestions might include adding corner radii, adjusting feature spacing, or recommending a different material thickness that cuts more efficiently.

The choices made during the design phase ripple through every subsequent manufacturing step. A seemingly minor design decision can transform a straightforward cutting operation into a complex, time-intensive process that delays product launch by weeks.

Rapid Prototyping: Testing Before Committing

What if you're not certain your design will work as intended? Rapid prototyping bridges the gap between digital design and full production, allowing you to validate form, fit, and function before committing to larger quantities.

Modern laser cutting service near me providers often specialize in quick-turn prototypes, delivering sample parts in days rather than weeks. This speed enables an iterative approach:

- Submit initial design – Upload your first concept for quick fabrication

- Evaluate physical samples – Test fit, function, and appearance with actual parts

- Refine and resubmit – Make adjustments based on testing; repeat as needed

- Approve for production – Once validated, proceed to full-volume manufacturing

This approach costs more per piece initially but often saves money overall by catching design issues before they're replicated across hundreds or thousands of parts. Industry research indicates that the global CNC machine market is projected to grow at a CAGR of 10.3% from 2023 to 2030, driven largely by demand for automation and rapid prototyping capabilities.

For projects requiring multiple iterations, look for fabricators who offer design support alongside cutting services. Their experience identifying manufacturability issues early—combined with fast turnaround on prototype orders—accelerates your development timeline significantly.

With the complete process understood, the natural question becomes: what factors in this workflow actually drive your costs? The next section breaks down the specific variables that determine your custom sheet metal cutting quote—and how you might optimize each one.

What Affects Custom Sheet Metal Cutting Costs

You've walked through the complete cutting process—from design submission to delivery. Now comes the question that matters most for your budget: what actually determines how much you'll pay? Understanding these cost drivers doesn't just help you interpret quotes more accurately; it empowers you to make strategic decisions that optimize your spending without sacrificing quality.

Cost Variables in Metal Cutting Projects

Every quote you receive reflects a combination of interconnected factors. Some you can influence through design decisions; others depend on market conditions or your project requirements. Let's break down each variable so you know exactly what's driving your numbers.

Material Type and Market Pricing

The raw material often represents a primary cost driver. Common materials like carbon steel are generally less expensive than stainless steel or aluminum alloys, while copper, brass, and titanium command premium prices. Beyond base costs, material prices fluctuate based on global market dynamics—steel prices in particular can swing significantly quarter to quarter.

Here's what you might expect for laser cutting of metal sheets across different materials, according to industry pricing data:

- Iron – $0.30–$0.80/kg for 2.0 mm thickness

- Mild Steel – $0.50–$1.00/kg for 1.0 mm thickness

- Stainless Steel – $1.50–$3.00/kg for 1.5 mm thickness

- Aluminum – $2.00–$4.00/kg for 2.0 mm thickness

Material Thickness and Cutting Time

Thickness affects cost in two ways: thicker sheets cost more per square foot, and they require significantly more cutting time. A machine cutter metal system processing 2 mm mild steel moves much faster than one cutting through 10 mm plate—and that time difference translates directly to your invoice.

The cost of laser or plasma cutting on common material thicknesses ranges from $1.50 to $6.00 per linear foot depending on the material and complexity. For context, cutting a 1-meter straight line on 2 mm thick mild steel typically costs approximately $0.75 to $1.25 when factoring in machine time and operating expenses.

Design Complexity and Cut Count

Simple rectangles cut faster than intricate patterns with dozens of curves and internal features. Every piercing point (where the laser cutter for metal starts a new cut), every curve, and every small detail adds time to your job.

Design preparation costs vary significantly based on complexity. According to fabrication industry data, designers typically charge $20–$100 per hour, with project costs breaking down as:

- Simple shapes – 1 hour, $20–$100 total

- Complex geometries – 2–4 hours, $40–$400 total

- Custom prototypes – 5+ hours, $100–$500+ total

Quantity and Setup Costs

Every cutting job requires setup: loading material, calibrating equipment, and running test cuts. Setup time typically takes 20–30 minutes with labor rates ranging from $20–$50 per hour, adding $6.67–$29.17 to each job regardless of quantity.

This fixed cost gets divided across all pieces in your order. Order 10 parts? That's potentially $3 per piece just for setup. Order 1,000 parts? Setup becomes negligible at fractions of a cent per piece.

Cutting Method Selection

Your choice of technology—laser, plasma, waterjet, or shearing—directly impacts hourly rates and cutting speeds. A lazer cutter running fiber laser technology may cost $100–$150 per hour but cuts thin materials extremely fast. Waterjet systems might charge $75–$125 per hour but cut much slower, potentially making total costs higher despite lower hourly rates.

Secondary Finishing Requirements

Post-cutting operations add layers of cost. Deburring typically costs $0.50–$2.00 per part, while painting or powder coating adds $5–$20 per square foot. A 1 m² laser-cut part requiring deburring and painting might add $30–$50 to your total.

Cost Factor Comparison Table

How do these variables stack up in terms of overall impact? This breakdown helps you prioritize where to focus your optimization efforts:

| Cost Factor | Impact Level | Optimization Tips |

|---|---|---|

| Material Type | High | Use carbon steel instead of stainless when corrosion resistance isn't critical; verify functional requirements before specifying premium alloys |

| Material Thickness | High | Design to the thinnest gauge that meets structural requirements; thicker doesn't always mean stronger for your application |

| Design Complexity | Medium-High | Simplify geometries where possible; reduce pierce points; add corner radii to speed programming and cutting |

| Order Quantity | High | Consolidate orders to spread setup costs; consider ordering prototype and production quantities together |

| Cutting Method | Medium | Match method to your actual tolerance needs—don't pay for laser precision when plasma meets requirements |

| Lead Time | Medium | Plan ahead; rush orders typically incur 15–30% premium charges |

| Secondary Operations | Medium | Specify only necessary finishing; laser-cut edges often need no deburring for non-critical applications |

| Sheet Nesting Efficiency | Low-Medium | Adjust part dimensions slightly if it improves material yield; consult with fabricator on standard sheet sizes |

How to Optimize Your Budget

Now that you understand what drives costs, how do you actually reduce them without compromising your project? These strategies address the highest-impact factors first.

Leverage Economies of Scale

The volume of parts being cut directly affects per-unit pricing. Small batches of 1–10 pieces may cost $10–$50 per piece, while orders of 100+ pieces can drop to $1–$5 per piece—and high-volume orders often qualify for material discounts or batch processing that further reduces costs.

Think strategically about timing. If you know you'll need additional quantities later, ordering everything upfront often costs less than splitting into multiple orders—even accounting for inventory holding costs.

Optimize Your Design for Manufacturing

The more complex your design, the higher the cost. Consider whether every feature truly serves your functional requirements. Sometimes a decorative curve or tight corner radius adds visual appeal but doubles cutting time.

Material utilization matters too. Can your part dimensions be slightly adjusted to fit better onto standard sheet sizes? Reducing scrap directly reduces material costs—and good fabricators will suggest nesting optimizations if you ask.

Choose Materials Strategically

A prototype doesn't always need to be created with an expensive material, especially if you're only validating a design. Mild steel often substitutes for stainless during development phases, with final production switching to specified materials once designs are locked.

Plan Your Timeline

If a provider must prioritize your project or work overtime, surcharges can range from 15–30% or higher. Standard lead times allow fabricators to schedule production optimally, and that efficiency gets passed along in your pricing.

Consolidate Secondary Operations

Every handoff between processes adds cost. If your parts need cutting, bending, and finishing, working with a single provider who handles all operations typically costs less than coordinating between specialists—and reduces the risk of parts getting damaged in transit between facilities.

Understanding cost drivers transforms you from a passive quote recipient into an active project optimizer. The same part can vary 50% or more in price depending on how you specify materials, quantities, and tolerances.

Armed with this cost knowledge, you're ready to think about how these factors apply to your specific application. Different industries and project types have distinct priorities—and matching your approach to your actual needs is where real savings emerge.

Matching Cutting Methods to Your Application

You now understand the cost variables and how to optimize them—but here's the practical question: which approach actually makes sense for your specific project? The "best" cutting method isn't universal; it shifts dramatically based on whether you're fabricating automotive brackets, decorative architectural panels, or one-off prototype parts. Let's match cutting technologies to real-world applications so you can request quotes with confidence.

Industrial and Automotive Applications

When parts must perform under stress, vibration, and demanding conditions, cutting method selection becomes a safety consideration—not just a cost decision. Industrial and automotive components typically demand:

- Tight dimensional tolerances – Parts must fit precisely within assemblies without modification

- Consistent repeatability – Every piece in a production run must match specifications identically

- Certified quality assurance – Traceability and documentation requirements often mandate IATF 16949 or similar certifications

- Material integrity – Heat-affected zones must be minimized to preserve structural properties

For automotive chassis components, suspension brackets, and structural assemblies, laser cutting typically delivers the best balance of precision and throughput. The tight tolerances achievable—often ±0.005" or better—ensure proper fit during assembly, while modern fiber lasers maintain production speeds that keep per-piece costs manageable at volume.

Plasma cutting becomes the practical choice when processing thicker structural steel. Automotive frames and heavy equipment brackets often use 1/4" to 1/2" plate where high-definition plasma delivers adequate precision at significantly lower cost per inch than laser cutting. For critical holes requiring ±0.1mm tolerance, such as M4 bolt holes, fiber laser often handles the precision work while plasma manages larger structural cuts.

When searching for laser cutting near me or metal cutting near me for industrial applications, prioritize shops demonstrating documented quality systems. The certification isn't just paperwork—it indicates calibrated equipment, trained operators, and inspection processes that catch dimensional drift before parts ship.

Architectural and Decorative Projects

Architectural metalwork flips the priority hierarchy. Edge appearance often matters more than achieving the tightest possible tolerances, and the visual impact of finished installations drives method selection.

For decorative panels, signage, and facade elements:

- Laser cutting excels at intricate patterns, logos, and detailed designs where clean edges define visual quality

- Waterjet cutting serves heat-sensitive materials or when absolutely zero discoloration is acceptable—particularly important for visible stainless steel or copper installations

- Acrylic laser cutting creates stunning backlit panels, illuminated signage, and decorative screens with polished, flame-finished edges

Architectural applications often combine cutting with decorative finishing. If your project requires both fabrication and personalization, many shops offering laser cutting and engraving can handle pattern cutting and surface detailing in coordinated operations. Similarly, projects needing engraving metal near me services often benefit from consolidating with your cutting provider—reducing handling and ensuring consistent quality across processes.

Laser cutting excels in creating intricate designs and producing smooth edges, often eliminating the need for additional finishing—a significant advantage when edge visibility defines project success. For larger architectural panels where some edge texture is acceptable, waterjet cutting near me providers can process thick aluminum or stainless without any heat-related discoloration.

Prototyping and Development Projects

Prototype work prioritizes different metrics entirely: speed and flexibility outweigh per-piece cost optimization, and the ability to iterate quickly often matters more than achieving production-level efficiency.

For rapid prototyping applications:

- Laser cutting – Fastest turnaround for thin materials; minimal setup allows quick transitions between design iterations

- Waterjet cutting – No tooling changes needed between materials; cut steel in the morning, aluminum in the afternoon, composites before closing

- Plasma cutting – Economical for structural prototypes where edge finish refinement happens during later production optimization

When you're testing form, fit, and function, material substitution often makes sense. A prototype doesn't always need to be created with expensive material—mild steel can validate geometry before committing to stainless, reducing iteration costs substantially.

Look for providers offering design feedback alongside cutting services. The combination of fast turnaround and manufacturing expertise accelerates development cycles more effectively than pure speed alone.

Hobbyist and Maker Projects

Working on smaller-scale personal projects? Your priorities likely differ from industrial buyers, but the same principles apply—just scaled appropriately.

For hobbyists, artists, and makers:

- Online laser cutting services – Upload DXF files, receive cut parts by mail; ideal for one-off projects without minimum order requirements

- Local metal fabrication shop – Personal service, quick questions answered, sometimes willing to run small jobs between production orders

- Makerspaces with cutting equipment – Access to laser cutters or plasma tables at hourly rates; requires learning equipment operation

Small-quantity orders face the setup cost challenge discussed earlier. When ordering just a few pieces, consider whether your design can share a sheet with another maker's project (some services offer this), or whether ordering slightly larger quantities reduces per-piece costs enough to justify the extra material.

For projects requiring personalized details, metal engravers near me or a local metal fabrication shop often accommodate smaller runs that high-volume operations might decline. The personal relationship can also prove valuable when you need guidance on material selection or design optimization for first-time projects.

Application-Based Method Selection Summary

Matching your specific application to the right cutting technology simplifies decision-making. Here's a consolidated reference:

- Automotive structural components – Laser cutting for precision; plasma for thick structural steel; always verify quality certifications

- Industrial machinery parts – Balance precision requirements against budget; plasma often sufficient for non-critical brackets

- Architectural panels and facades – Laser for intricate designs; waterjet when heat effects on visible edges aren't acceptable

- Decorative signage and art – Laser cutting delivers cleanest edges; consider combined cutting and engraving services

- Prototypes and development parts – Prioritize turnaround speed; accept higher per-piece costs for faster iteration

- Hobbyist and maker projects – Online services for convenience; local shops for personalized guidance and small quantities

With your application requirements clarified, the final step is selecting a fabrication partner who can deliver on your specific needs. The next section walks through exactly what to evaluate—and what questions to ask—before committing to a provider.

How to Choose a Reliable Cutting Service Partner

You've identified your application, understood cost drivers, and clarified your precision requirements. Now comes the decision that ties everything together: selecting the fabrication partner who'll actually produce your parts. The right provider doesn't just cut metal—they become an extension of your engineering team, catching problems before they become expensive and suggesting optimizations you hadn't considered.

How do you separate capable partners from those who'll deliver headaches? Let's walk through the evaluation criteria that matter most—and the questions you should ask before committing to any quote.

Evaluating Metal Cutting Service Providers

Not all fabrication shops are created equal. Some specialize in high-volume production runs; others excel at rapid prototyping and design iteration. Some maintain aerospace-grade quality systems; others serve general industrial needs adequately but can't meet stringent documentation requirements. Matching provider capabilities to your specific needs prevents costly misalignments.

Equipment Capabilities and Technology Range

Not all fabrication shops offer the same level of capability. Some only cut metal, while others outsource machining, finishing, or assembly—which can lead to delays, communication gaps, and inconsistencies in quality. Before requesting quotes, understand what technologies a provider operates in-house:

- Laser cutting systems – Fiber or CO2? What maximum thickness can they handle?

- Plasma cutting – Standard or high-definition? Thickness capacity?

- Waterjet capabilities – Available for heat-sensitive materials?

- Secondary operations – Bending, welding, finishing under one roof?

- CNC machining – Can they handle precision features beyond cutting?

Full-service, integrated facilities streamline the entire process under one roof. This provides tighter control over production, faster turnaround times, and consistent quality standards across all operations.

Certifications and Quality Systems

Quality certifications signal more than marketing polish—they represent documented systems designed to deliver consistent results. The best custom metal fabricators follow strict quality processes and use advanced inspection tools to verify accuracy throughout production.

For general manufacturing, ISO 9001 certification demonstrates commitment to documented quality management systems. For automotive applications, IATF 16949 certification becomes essential—indicating the provider meets stringent automotive-specific requirements for safety, consistency, and traceability.

A strong quality framework typically includes first-article inspection, in-process dimensional checks, weld integrity testing, and final inspection validation. Before partnering, confirm the company's quality standards, inspection procedures, and certifications align with your industry requirements.

Turnaround Time and Rapid Prototyping

Understanding typical delivery timelines is necessary for planning your project schedule. Ask about standard lead times as well as any expedited options they may offer.

For development projects, rapid prototyping capabilities can dramatically accelerate your timeline. Some providers deliver prototype parts in as little as 5 days, enabling multiple design iterations before committing to production tooling. This speed particularly matters when you're validating new designs or responding to tight product launch schedules.

For example, Shaoyi (Ningbo) Metal Technology offers 5-day rapid prototyping alongside automated mass production—demonstrating how leading providers bridge the gap between development speed and volume manufacturing capability.

Design for Manufacturability Support

Successful fabrication doesn't begin at the machine—it begins with engineering. A reliable fabricator will collaborate with you early in the process, reviewing drawings, CAD files, tolerances, and functional requirements.

Many projects benefit from comprehensive DFM guidance, helping refine designs for cost-effective production without compromising performance. When evaluating a partner, ask whether they provide:

- CAD/CAM support and file format flexibility

- Engineering consultation on material and method selection

- Proactive design feedback before production begins

- Prototype testing and validation support

This level of support reduces risk, shortens lead times, and ensures smooth production—especially for complex assemblies. Providers like Shaoyi demonstrate this approach with comprehensive DFM support that catches manufacturability issues before they impact your timeline or budget.

Communication and Responsiveness

Transparent communication is equally critical. A reliable fabricator provides clear timelines, project updates, and realistic expectations. Strong communication prevents costly surprises and keeps projects aligned from start to finish.

Quote turnaround time offers a useful proxy for overall responsiveness. If a provider takes weeks to return a simple quote, imagine the delays you'll face when questions arise during production. Leading suppliers—including Shaoyi with their 12-hour quote turnaround—demonstrate that responsive communication is operationally achievable.

Key Questions Before Requesting Quotes

Walking into the quoting process prepared saves time and surfaces potential issues early. Here's a checklist of questions that reveal provider capabilities and alignment with your needs:

Capability and Experience Questions

- How long have you been fabricating parts similar to mine?

- Do you have experience serving my specific industry?

- Can you share case studies or references from comparable projects?

- What cutting technologies do you operate in-house?

- What secondary operations (bending, welding, finishing) can you handle internally?

Quality and Certification Questions

- What quality certifications do you maintain (ISO 9001, IATF 16949)?

- What inspection equipment and processes do you use?

- How do you document and track quality throughout production?

- Can you provide material certifications and test reports?

Timeline and Capacity Questions

- What are your standard lead times for my order size?

- Do you offer expedited or rush delivery options?

- How quickly can you turn around prototypes?

- What's your current capacity, and how do you handle demand spikes?

Support and Communication Questions

- Do you provide DFM review and design feedback?

- What file formats do you accept?

- Who will be my primary contact throughout the project?

- How quickly do you typically respond to questions or change requests?

If your project involves decorative elements alongside functional cutting, ask about combined capabilities. Providers offering custom laser engraving alongside cutting can consolidate operations—reducing handoffs and ensuring consistent quality across processes. Similarly, if you need laser etching near me or specialized surface treatments, understanding a provider's full capability range upfront prevents scrambling for additional vendors later.

The right fabrication partner doesn't just execute your specifications—they improve your outcomes through proactive engineering support, consistent quality systems, and communication that keeps your project on track.

Provider Evaluation Checklist

Use this consolidated checklist when comparing potential cutting service partners:

- Equipment range – Multiple cutting technologies available (laser, plasma, waterjet)

- In-house capabilities – Secondary operations handled internally, not outsourced

- Relevant certifications – ISO 9001 minimum; IATF 16949 for automotive applications

- Documented quality processes – Inspection procedures, calibration schedules, traceability systems

- Rapid prototyping options – Fast-turn capability for design validation (5-day or faster ideal)

- DFM support availability – Engineering review included before production

- Quote responsiveness – Same-day or next-day quote turnaround demonstrates operational efficiency

- Communication clarity – Dedicated contacts, clear project updates, realistic timelines

- Industry experience – Demonstrated track record with similar applications

- Scalability – Capacity to support both prototypes and full production volumes

For automotive, chassis, suspension, or structural component projects requiring IATF 16949-certified quality alongside rapid prototyping speed, providers like Shaoyi (Ningbo) Metal Technology exemplify the combination of capabilities that reduce supply chain complexity. Their integrated approach—from 5-day prototyping through automated mass production with comprehensive DFM support—demonstrates what to look for when selecting partners for demanding applications.

Beyond metal cutting, some projects require complementary services like wood engraving near me for mixed-material assemblies or packaging components. Understanding a provider's network and willingness to coordinate related services can simplify project management significantly.

The fabrication partner you choose becomes a long-term investment in your manufacturing success. A trusted fabrication partner doesn't just build parts—they support your goals, improve your product, and help position your project for long-term success. Take the time to evaluate thoroughly, ask the right questions, and select a partner whose capabilities, quality systems, and communication style align with your specific needs.

Frequently Asked Questions About Custom Sheet Metal Cutting

1. What is the best cutting method for custom sheet metal parts?

The best method depends on your material, thickness, and precision needs. Laser cutting offers the highest precision (±0.001" to ±0.005") and cleanest edges for thin materials under 1/4". Plasma cutting excels at processing thicker steel quickly and cost-effectively. Waterjet cutting is ideal when heat distortion cannot be tolerated, preserving material integrity completely. For simple straight cuts in high volumes, mechanical shearing remains the most economical option.

2. How much does custom sheet metal cutting cost?

Costs vary based on material type, thickness, design complexity, quantity, and cutting method. Laser cutting of metal sheets typically ranges from $1.50 to $6.00 per linear foot. Material costs differ significantly—mild steel runs $0.50 to $1.00 per kg while stainless steel costs $1.50 to $3.00 per kg. Setup charges add $6.67 to $29.17 per job, making larger orders more cost-effective per piece. Small batches of 1-10 pieces may cost $10-$50 each, while orders of 100+ pieces can drop to $1-$5 per piece.

3. Where can I get custom metal cut near me?

You have several options for custom metal cutting services. Online fabrication platforms like SendCutSend, OSH Cut, and Xometry accept DXF or STEP files and deliver parts within days. Local metal fabrication shops offer personalized service and are often willing to handle smaller jobs. For automotive or industrial applications requiring IATF 16949 certification, specialized manufacturers like Shaoyi (Ningbo) Metal Technology provide rapid prototyping within 5 days and comprehensive DFM support alongside production capabilities.

4. What file formats are needed for custom sheet metal cutting?

DXF (Drawing Exchange Format) is the industry standard for 2D cutting operations due to its wide compatibility and accurate geometry retention. DWG files from AutoCAD work similarly well for complex designs. STEP or STP files are ideal for 3D models requiring flat pattern development. PDFs are acceptable for simple designs but may require conversion. Ensure all cut lines have consistent weight, contours are completely closed, and drawings are at 1:1 scale to avoid costly errors.

5. What tolerances can I expect from different metal cutting methods?

Tolerance capabilities vary significantly by cutting technology. Laser cutting achieves the tightest tolerances at ±0.001" to ±0.005" for position and dimensions. Waterjet cutting delivers ±0.003" to ±0.010" depending on cutting speed and material thickness. Plasma cutting typically achieves ±0.010" to ±0.030", with high-definition systems approaching the tighter end. Mechanical shearing offers ±0.010" to ±0.060". Your tolerance requirements should drive method selection—specifying tighter tolerances than necessary inflates costs.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —