Stamping Die Set Selection: Match Your Press, Material, And Production Goals

What Is a Stamping Die Set and How Does It Work

Ever wondered what makes high-speed metal forming possible? At the heart of every stamping operation sits a stamping die set—the foundational assembly that transforms flat metal sheets into precisely shaped components. Understanding what a die set is and how it functions gives engineers, buyers, and manufacturing professionals the knowledge needed to make smarter tooling decisions.

So, what is a die in manufacturing? Simply put, a die set is a precision-engineered assembly consisting of upper and lower die shoes held in exact alignment by guide posts and bushings. When mounted in a press, this assembly provides the rigid, repeatable framework that supports all cutting, forming, and shaping operations. Think of it as the skeleton of your stamping tool—everything else builds upon this critical foundation.

Core Components That Make Die Sets Work

When you examine a die set closely, you'll notice several interconnected components working together. Each plays a specific role in ensuring accurate, consistent metal forming. Here's a breakdown of the primary die components and their functions:

- Upper Die Shoe (Top Plate): The mounting surface for punches and upper die tooling. It attaches to the press ram and moves vertically during operation.

- Lower Die Shoe (Bottom Plate): Also called the die plate, this stationary component mounts to the press bed and holds die buttons, springs, and lower forming tools in position.

- Guide Posts: Precision-ground cylindrical pins that maintain exact alignment between upper and lower shoes. Manufactured to tolerances within .0001" according to industry standards, they ensure repeatable positioning throughout millions of cycles.

- Guide Bushings: Hardened sleeves that receive the guide posts, available in friction or ball-bearing styles. Ball-bearing bushings have become industry standard due to their ease of separation and smooth operation.

These components form the essential die tool framework. What are dies without proper alignment? Essentially, they're liability-prone equipment that produces inconsistent parts and accelerates wear on expensive tooling.

Why Precision Alignment Matters in Metal Forming

Imagine pressing a punch through metal when the upper and lower shoes are even slightly misaligned. You'll experience uneven cutting, premature tool wear, and parts that fail quality inspection. That's why precision alignment isn't optional—it's fundamental to successful stamping operations.

The relationship between guide posts and bushings creates what engineers call "guided motion." This ensures the upper shoe travels in a perfectly vertical path relative to the lower shoe, maintaining consistent clearances between punches and die buttons. Modern stamping die sets achieve alignment accuracy measured in tenths of a thousandth of an inch, enabling the tight tolerances demanded by automotive, aerospace, and electronics applications.

Whether you're evaluating your first die set or upgrading existing equipment, understanding these fundamentals positions you to make informed decisions about configuration, materials, and supplier selection—topics we'll explore in detail throughout this guide.

Types of Die Set Configurations and When to Use Each

Now that you understand the fundamental components, you're probably wondering—how do these elements come together in different arrangements? The answer lies in die set configurations. Choosing the right die style directly impacts accessibility during setup, alignment precision during operation, and overall production efficiency. Let's break down the four main configurations and help you determine which press die set arrangement fits your specific needs.

Back Post vs Four-Post Configurations Explained

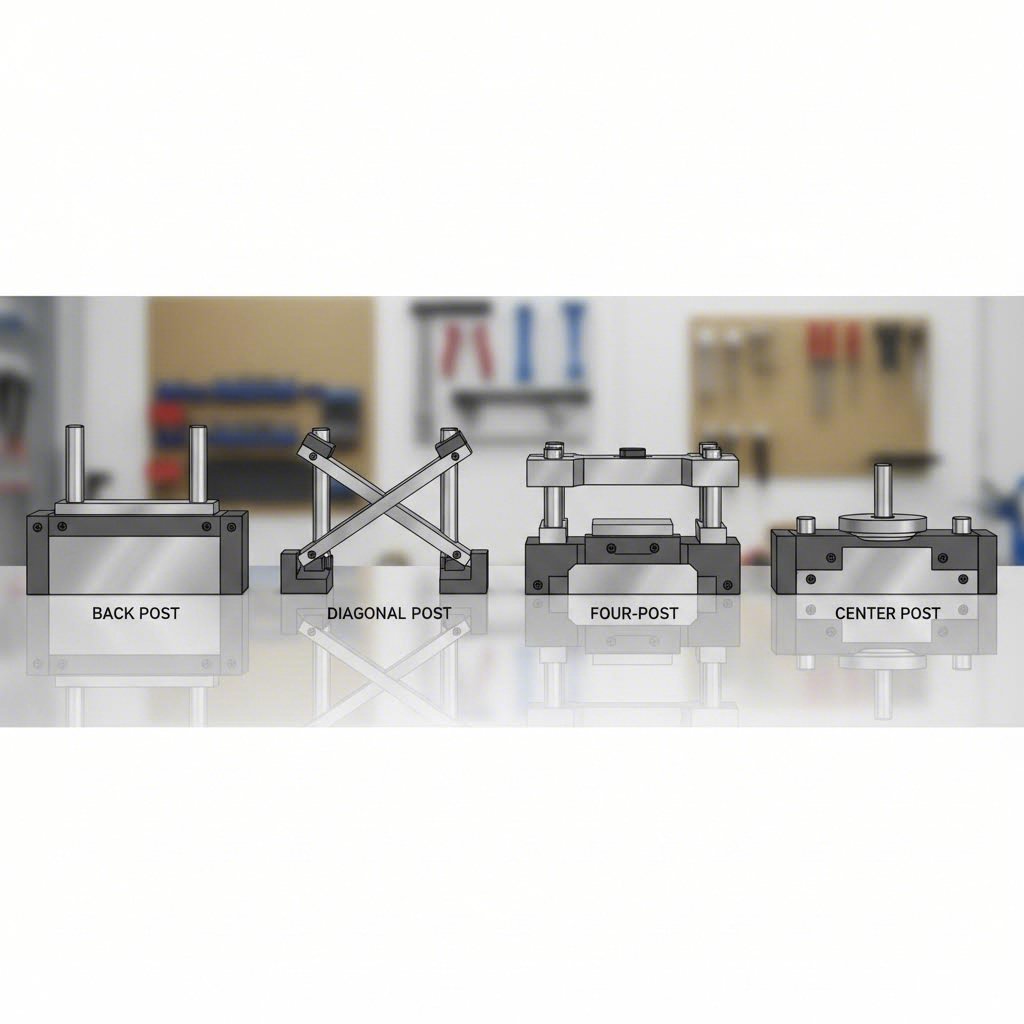

When you examine commercially available die sets, you'll encounter four primary configurations based on guide post placement. Each arrangement offers distinct advantages depending on your application requirements.

Back Post Configuration: This popular design positions two guide posts along the rear edge of the die shoes. Why does this matter? It provides maximum front and side accessibility for feeding strip material, removing finished parts, and performing maintenance. Die tooling specialists often recommend back post arrangements for progressive dies where strip material feeds continuously from one side.

Diagonal Post Configuration: Here, two posts sit at opposite corners—typically front-left and rear-right positions. This arrangement balances accessibility with improved stability compared to back post designs. You'll find diagonal configurations particularly useful when operators need access from multiple directions without sacrificing alignment quality.

Four-Post Configuration: With a guide post in each corner, this design delivers maximum rigidity and alignment precision. The additional posts distribute load forces evenly across the die shoes, making four-post die sets ideal for heavy-duty blanking operations, thick materials, and applications demanding the tightest tolerances. The trade-off? Reduced accessibility for feeding and part ejection.

Center Post Configuration: Less common but valuable for specific applications, center post designs position guides near the middle of the die area. This configuration suits operations requiring equal access from all sides or specialized tooling arrangements where corner posts would interfere with die components.

Matching Die Set Style to Your Production Needs

Selecting the appropriate configuration isn't about finding the "best" option—it's about matching capabilities to your specific production requirements. Consider these factors when reviewing a die chart or evaluating suppliers:

- Material feed direction: Back post designs excel when strip feeds front-to-back; diagonal posts work better for angled feeding arrangements.

- Part ejection requirements: Complex parts requiring manual removal benefit from open-front configurations.

- Tonnage and material thickness: Higher forces and thicker materials demand the enhanced rigidity of four-post designs.

- Tolerance requirements: Precision applications justify the investment in four-post configurations with their superior alignment stability.

The following comparison table provides a comprehensive overview to guide your decision:

| Configuration | Accessibility | Rigidity | Alignment Precision | Typical Applications | Recommended Press Types |

|---|---|---|---|---|---|

| Back Post | Excellent (3 sides open) | Moderate | Good | Progressive dies, strip feeding operations | OBI presses, high-speed stamping |

| Diagonal Post | Very Good (2 corners open) | Good | Good to Very Good | Transfer dies, multi-directional access needs | Gap frame presses, straight-side presses |

| Four-Post | Limited (all corners occupied) | Excellent | Excellent | Heavy blanking, precision forming, thick materials | Straight-side presses, hydraulic presses |

| Center Post | Good (all sides partially open) | Moderate to Good | Good | Specialized tooling, symmetrical access requirements | Various press types depending on application |

Keep in mind that die shoes must match your selected configuration—the post arrangement determines hole patterns in both upper and lower shoes. When ordering from catalogs or suppliers, verify that configuration specifications align with your press bed dimensions and clamping requirements.

Understanding these configurations prepares you for the next critical decision: selecting the right material for your die sets based on production volume and performance requirements.

Material Selection Guide for Steel and Aluminum Die Sets

You've selected your configuration—now comes another decision that directly impacts tooling longevity, production costs, and operational efficiency. What material should your stamping die set be made from? This choice affects everything from how long your metal die lasts to how easily operators handle it during setup. Let's explore the practical differences between steel dies and aluminum alternatives so you can match material properties to your specific production demands.

Tool Steel Grades for High-Volume Production

When production volumes climb into the hundreds of thousands or millions of cycles, tool steel becomes the obvious choice for metal stamping dies. Why? Steel delivers unmatched durability, wear resistance, and dimensional stability under repeated high-tonnage impacts.

Most manufacturers specify their metal die set components from these common tool steel categories:

- A2 Tool Steel: An air-hardening steel offering excellent wear resistance and good toughness. Popular for die shoes that experience moderate impact forces.

- D2 Tool Steel: High-carbon, high-chromium steel providing superior wear resistance. Ideal for high-volume metal forming dies where abrasion is a primary concern.

- O1 Tool Steel: Oil-hardening steel that's easier to machine than D2. Often selected when complex geometries require extensive machining before heat treatment.

- S7 Tool Steel: Shock-resistant steel designed for high-impact applications. Consider this grade when your stamping operations involve heavy blanking or thick materials.

Steel die tools typically undergo heat treatment to achieve hardness levels between 58-62 HRC for working surfaces. This hardening process ensures the material withstands millions of press cycles without significant dimensional change or surface degradation.

The trade-offs? Steel adds significant weight to your die assembly. A large four-post steel die set can weigh several hundred pounds, requiring overhead cranes or forklifts for die changes. This weight also increases shipping costs and demands more robust press mounting considerations.

When Aluminum Die Sets Make Economic Sense

Sounds like steel is always the answer? Not quite. Aluminum die sets have carved out a valuable niche in modern stamping operations, particularly for specific production scenarios where their unique properties provide genuine advantages.

Consider aluminum for your metal die set when:

- Prototyping and short runs: When you need fewer than 50,000 parts, aluminum's lower material and machining costs often outweigh its reduced lifespan.

- Frequent die changes: Aluminum weighs roughly one-third of steel. For operations requiring multiple die changes per shift, the reduced weight translates to faster setups and less operator fatigue.

- Heat-sensitive applications: Aluminum's superior thermal conductivity dissipates heat more effectively during high-speed operations, potentially reducing lubricant requirements.

- Low-tonnage forming: Light-gauge materials and modest forming forces don't demand steel's extreme durability.

Modern aircraft-grade aluminum alloys (6061-T6 and 7075-T6) provide surprisingly good wear characteristics when properly specified. Some manufacturers apply hard anodizing or nickel plating to aluminum die shoes, extending service life while maintaining weight advantages.

Steel vs Aluminum: A Direct Comparison

The following table summarizes key differences to help you evaluate which material aligns with your production requirements:

| Factor | Tool Steel Die Sets | Aluminum Die Sets |

|---|---|---|

| Weight | Heavy (approximately 0.283 lb/in³) | Light (approximately 0.098 lb/in³—about 1/3 of steel) |

| Durability | Excellent; handles millions of cycles | Moderate; best for under 100,000 cycles without surface treatments |

| Initial Cost | Higher material and machining costs | Lower material cost; faster machining reduces labor expense |

| Thermal Conductivity | Lower; retains heat during high-speed operations | Higher; dissipates heat approximately 4x faster than steel |

| Ideal Use Cases | High-volume production, heavy blanking, thick materials, tight tolerances | Prototyping, short runs, frequent changeovers, light-gauge forming |

| Maintenance | Requires rust prevention; periodic regrinding of worn surfaces | Corrosion-resistant; may need surface replacement if galling occurs |

One practical consideration often overlooked: your die tools don't need to be entirely one material. Some manufacturers specify steel guide posts with aluminum die shoes, combining the alignment precision of hardened steel with the weight savings of aluminum plates. This hybrid approach works particularly well for medium-volume applications where neither extreme fully applies.

Whatever material you select, ensure compatibility with your press requirements and production volumes. The right choice balances upfront investment against long-term operational costs—a calculation that leads naturally into understanding how to properly size and specify your die set for specific press equipment.

How to Select the Right Die Set for Your Press Requirements

You've determined your configuration and material preferences—but here's where many buyers stumble. How do you ensure that your stamping die set actually fits and performs optimally within your specific press? Selecting the wrong size die creates alignment problems, limits production capacity, and can even damage expensive equipment. Let's walk through a practical decision framework that matches die press specifications to your machine capabilities.

Calculating Die Set Size Requirements

Before ordering any press dies, you need to establish the dimensional envelope available in your stamping equipment. Think of this as measuring a room before buying furniture—except the consequences of getting it wrong are far more costly.

Start by gathering these critical measurements from your press specifications:

- Bed dimensions: The length and width of your press bed determine the maximum footprint your die sets for press operations can occupy. Always leave clearance margins for clamping hardware and safety considerations.

- Shut height: This measurement represents the distance from the press bed to the bottom of the ram when fully down. Your combined die shoe thickness plus tooling height must fall within this envelope.

- Stroke length: The vertical travel distance of the ram affects how much clearance exists for part ejection and material feeding between cycles.

- Daylight opening: The maximum distance between bed and ram when the press is fully open. This dimension matters for die loading and unloading procedures.

When you size die shoes, a general principle applies: the die set should provide adequate working area for your tooling while leaving sufficient margin for mounting and adjustment. Experienced tooling engineers typically recommend that die shoe dimensions exceed your actual tooling footprint by enough margin to accommodate clamps, pilot holes, and any future modifications.

Consider this practical scenario: imagine your part requires a 12" x 18" working area. You'll need die shoes sized larger—perhaps 16" x 22"—to accommodate mounting hardware, stripper bolts, and proper edge clearance. Jumping straight to the minimum possible size die creates headaches during assembly and limits your flexibility for tooling adjustments.

Press Compatibility Factors You Cannot Ignore

Sizing isn't just about fitting through the door—your machine die must work harmoniously with press mechanics throughout millions of cycles. Here's what to verify before finalizing your die set selection:

- Tonnage capacity: Your press's rated tonnage must exceed the forces required for your stamping operation. Under-capacity creates dangerous overload conditions; excessive over-capacity wastes energy and accelerates wear.

- Ram parallelism: The precision of your press ram alignment affects how your die set performs. High-precision dies demand equally precise press equipment to maintain consistent part quality.

- Mounting hole patterns: Verify that die shoe bolt patterns align with your press bed T-slots or clamping provisions. Standard patterns vary between press manufacturers.

- Shank diameter (if applicable): For dies using upper shanks for ram attachment, confirm the shank size matches your press ram bore dimensions exactly.

- Feed line height: Where does your strip material enter the press? The die set must position your tooling at the correct height relative to feed equipment.

Production volume also influences sizing decisions. Higher volumes justify investing in larger, more robust die sets that handle stress accumulation over extended runs. Short-run applications may tolerate lighter-duty assemblies, though never compromise alignment precision regardless of production quantity.

Matching die set specifications to press capabilities isn't optional—it's the foundation of safe, efficient stamping operations. Taking shortcuts here creates problems that compound throughout the entire production lifecycle.

A Practical Selection Checklist

Before committing to any hydraulic press die set or mechanical press tooling, work through these compatibility checkpoints:

- Confirm bed dimensions accommodate die shoe footprint plus clamping clearance

- Verify shut height allows for total die assembly thickness with adjustment margin

- Check that stroke length provides adequate clearance for part ejection

- Ensure press tonnage exceeds calculated stamping force requirements

- Match mounting provisions between die shoes and press bed

- Validate guide post length against available daylight opening

- Consider feed equipment integration and material flow paths

When in doubt, consult your press manufacturer's specifications and discuss requirements with your die set supplier. Reputable suppliers maintain expertise in matching their products to various press platforms and can identify compatibility issues before they become expensive problems.

With your die set properly sized and matched to your press, the next priority becomes keeping everything running smoothly over time—which brings us to maintenance and inspection practices that extend die life and preserve production quality.

Die Set Maintenance and Inspection Best Practices

Your stamping die set is properly sized, correctly configured, and running production—but here's the reality many manufacturers overlook. Even the most precisely engineered die assembly degrades over time. Guide posts wear, bushings develop play, and alignment drifts cycle after cycle. Without systematic maintenance protocols, these subtle changes eventually surface as quality defects, unplanned downtime, and costly emergency repairs.

According to manufacturing specialists at The Phoenix Group, poor die maintenance causes quality defects during production, driving up sorting costs and increasing the likelihood of shipping defective parts. The hidden costs extend beyond scrap—assembly lines must alter fixtures and clamping to compensate for part variation introduced by worn tooling. Let's establish the inspection procedures and preventive practices that keep your precision dies performing at peak levels.

Inspection Checkpoints for Extended Die Set Life

Think of die set inspection as preventive medicine for your stamping operation. Catching problems early—before they cause defects—costs far less than reactive repairs during production emergencies. A structured inspection routine addresses three critical timeframes:

Before Each Production Run:

- Visually inspect guide posts for scoring, galling, or surface damage that indicates alignment problems

- Check bushing fit by feeling for excessive play when manually cycling the die assembly

- Verify die shoes seat flat on the press bed without rocking or gaps

- Confirm all mounting bolts are present and properly torqued

- Inspect working surfaces for debris, rust, or residual lubricant buildup

During Production Monitoring:

- Listen for unusual sounds—clicking, grinding, or intermittent contact noises signal developing problems

- Monitor part dimensions at regular intervals to detect progressive drift

- Watch for increased force requirements that suggest binding or misalignment

- Check operating temperature of guide posts and bushings for abnormal heat buildup

Post-Run Inspection:

- Clean all surfaces thoroughly before storage or the next die setter begins setup

- Document any issues discovered during the run in your work order system

- Measure guide post diameter at wear points and compare to baseline specifications

- Inspect bushing bores for galling, scoring, or out-of-round conditions

When setting die assemblies back into storage, apply rust preventive to exposed steel surfaces. This simple step prevents corrosion that accelerates wear during the next production cycle.

Recognizing Wear Patterns Before They Cause Defects

Experienced die makers develop an eye for wear patterns that predict future problems. Here's what to look for on your die equipment during routine inspections:

Guide Post Wear: Check for polished or burnished areas that indicate metal-to-metal contact. Healthy guide posts show uniform surface finish along their entire length. Localized wear patterns—especially diagonal scoring—suggest misalignment between upper and lower die shoes that needs immediate correction.

Bushing Degradation: Ball-bearing bushings should cycle smoothly with minimal resistance. If you feel roughness, binding, or hear grinding during manual operation, the bearings are failing. Friction bushings develop measurable bore enlargement over time—track these dimensions and replace when clearance exceeds manufacturer specifications.

Alignment Drift: Perhaps the most insidious issue, alignment drift happens so gradually that operators adapt without realizing quality is degrading. Watch for these warning signs:

- Parts requiring progressively more trimming or secondary operations

- Burr height increasing on blanked edges

- Punch wear concentrated on one side rather than evenly distributed

- Stripper marks appearing in new locations on the strip

The frequency of die maintenance directly determines production quality consistency. Manufacturers who inspect systematically experience fewer emergency repairs, lower scrap rates, and more predictable output—the correlation is undeniable.

Preventive Maintenance Protocols That Work

Moving from reactive to preventive maintenance transforms your die shop from a firefighting operation into a strategic asset. Here's a practical framework based on production cycles rather than arbitrary calendar schedules:

- Every production run: Clean, inspect, and document condition before storage

- Every 50,000-100,000 cycles: Measure guide post diameters and bushing clearances against baseline specifications

- Every 250,000 cycles: Perform detailed alignment verification using precision measuring equipment

- Annually or per manufacturer recommendation: Complete disassembly, inspection, and replacement of wear components as needed

Documenting maintenance activities creates valuable historical data. When quality issues arise, you can trace back to determine if die condition correlates with defect patterns. This data-driven approach also helps predict when components will need replacement, enabling proactive scheduling rather than reactive scrambling.

A well-maintained die assembly doesn't just last longer—it produces more consistent parts throughout its service life. However, even with excellent maintenance practices, problems occasionally develop. Understanding how to diagnose and correct common die set failures prevents minor issues from becoming major production disruptions.

Troubleshooting Common Die Set Problems and Solutions

Even with diligent maintenance, problems eventually surface in any stamping die set. When parts suddenly fail inspection or your press starts making unfamiliar sounds, how do you pinpoint the root cause quickly? The difference between a minor adjustment and extended downtime often comes down to diagnostic speed and accuracy. Let's walk through the most common die set failures, their telltale symptoms, and the corrective actions that get you back to production.

Diagnosing Alignment Problems in Production

Alignment issues rank among the most frustrating problems because they develop gradually. One day everything runs perfectly; weeks later, you're chasing quality defects that seem to appear randomly. Understanding how misalignment manifests helps you catch problems before they cascade into expensive repairs.

Watch for these warning signs during production:

- Uneven burr patterns: When burrs appear heavier on one side of blanked parts, your punch and die aren't meeting concentrically. This indicates lateral shift between upper and lower shoes.

- Progressive punch wear: According to troubleshooting specialists at DGMF Mold Clamps, inconsistent wear across punch surfaces—where some areas show larger scratches and wear faster—signals alignment problems between upper and lower turntable mounting seats.

- Dimensional drift: Parts that measured correctly last week now fall outside tolerance, particularly on features formed by punch-to-die interaction.

- Unusual noise patterns: Clicking, grinding, or intermittent contact sounds during cycling often precede visible quality problems.

When you suspect alignment issues, start your diagnosis at the source. Use an alignment mandrel to check the relationship between your press turret and mounting base. Often, the problem isn't your die and tooling at all—it's the press itself that has drifted out of specification.

Forming die operations are particularly sensitive to alignment because material flow depends on consistent contact between punch and die surfaces. Even small deviations create uneven stress distribution, leading to wrinkling on one side while tearing occurs on another.

Corrective Actions for Common Die Set Failures

Once you've identified the problem, what's the fix? The following table organizes common die set issues into a diagnostic framework that manufacturing professionals can apply immediately:

| Problem | Symptoms | Root Causes | Corrective Actions |

|---|---|---|---|

| Misalignment | Uneven burrs, one-sided punch wear, dimensional variation | Worn guide bushings, damaged guide posts, press turret misalignment, improper die setting | Check and adjust turret alignment using mandrel; replace worn bushings; verify die shoes seat flat on press bed; consider full-guide die machining for critical applications |

| Precision Loss | Parts drifting out of tolerance, inconsistent hole positions, shape deviation | Guide post wear, thermal expansion during extended runs, loose mounting hardware, material springback | Measure guide post diameters against baseline; allow thermal stabilization before critical measurements; verify all mounting bolts torqued to specification; implement springback compensation in die design |

| Premature Wear | Scoring on guide posts, rapid bushing degradation, surface damage on working areas | Inadequate lubrication, contamination in lubricant, mismatched clearances, excessive press speed | Review and upgrade lubrication protocol; filter or replace contaminated lubricant; verify punch-to-die clearance matches material thickness (typically 8-12% of thickness); reduce pressing die cycle speed if needed |

| Galling | Metal transfer between surfaces, seized components, rough operation | Incompatible materials in contact, insufficient lubrication, excessive pressure at contact points | Apply anti-galling coatings (TiN, TiAlN); switch to EP (extreme pressure) lubricants; reduce blank holder force if applicable; consider surface treatments like nitriding for blanking die applications |

| Guide Post Binding | Resistance during cycling, jerky motion, heat buildup | Debris accumulation, bushing bore damage, bent or scored posts, thermal expansion mismatch | Thoroughly clean all guide surfaces; inspect bushings for out-of-round conditions; replace damaged posts immediately; verify adequate clearance for thermal expansion during high-speed runs |

Notice how many problems trace back to the same fundamental causes? Lubrication failures, clearance issues, and alignment drift account for the vast majority of die set troubles. Address these systematically, and you'll prevent most failures before they occur.

For persistent issues that resist standard corrections, consider these advanced diagnostic approaches:

- Dial indicator testing: Mount indicators on your upper shoe and sweep against the lower die surface to quantify misalignment in thousandths of an inch.

- Blue dye contact checks: Apply machinist's dye to mating surfaces, cycle the die once, and examine contact patterns for uneven engagement.

- Thermal imaging: During extended runs, thermal cameras reveal hot spots that indicate binding, excessive friction, or inadequate lubrication.

When corrective actions require shimming or clearance adjustments, work incrementally. Industry experience suggests limiting adjustments to no more than 0.15mm per iteration to avoid overcorrection. Document every change—what seemed like a quick fix today becomes valuable diagnostic data when similar problems resurface months later.

Sometimes the real issue isn't the die set itself but how it integrates into your broader production system. Understanding where stamping die sets fit within the complete metal forming ecosystem helps you identify problems that originate upstream or downstream from the tooling.

Where Stamping Die Sets Fit in Metal Forming Operations

Understanding how to troubleshoot your tooling is essential—but have you considered how your stamping die set connects to the bigger manufacturing picture? These precision assemblies don't operate in isolation. They serve as the foundation for various die types and production methods across virtually every industry that transforms sheet metal into finished components. Let's explore this broader ecosystem and see where your tooling decisions fit within it.

Die Sets in Progressive and Transfer Stamping Operations

Think of a stamping die set as the stage upon which different performance styles can unfold. The same precision-aligned foundation supports dramatically different manufacturing approaches depending on your production requirements.

Progressive Dies: In a progressive stamping operation, a continuous metal coil feeds automatically through multiple stations embedded in a single die set. Each station performs a specific operation—blanking, piercing, bending, or forming—in sequence until the finished part emerges. According to industry specialists, progressive die solutions excel in high-volume metal stamping thanks to full automation, with some operations achieving daily outputs exceeding 11,000 pieces after proper optimization.

Transfer Dies: Similar to progressive tooling but more flexible, transfer dies pick up individual workpieces and move them between stations rather than relying on continuous strip material. Your die set provides the rigid framework for each station while automated transfer mechanisms handle material movement. This approach reduces material waste since there's no carrier strip connecting parts.

Compound Dies: Sometimes called combination dies, these advanced stamping dies execute multiple operations—such as blanking, piercing, embossing, and bending—in a single press stroke at one station. The die set must provide exceptional alignment because all cutting and forming die operations happen simultaneously, demanding precise relationships between upper and lower tooling components.

The die industry continues evolving these configurations. Modern manufacturers often employ hybrid approaches, combining the flexibility of single-stage operations with progressive die speed through automated transfer systems. Workpieces move seamlessly between stations, maximizing throughput while maintaining the tight tolerances that precision stamping demands.

Industry Applications From Automotive to Aerospace

Where do all these metal stamping die configurations actually find application? The answer spans virtually every sector that relies on precision-formed metal components. According to industry research, the metal stamping market is expected to grow from $205 billion in 2021 to more than $283 billion by 2030—driven by expanding applications across multiple industries.

Here's where stamping dies and their supporting die sets create value:

- Automotive: From structural body panels to intricate sensor housings, automotive manufacturing depends heavily on forming dies. The shift toward electric vehicles is creating new opportunities, particularly for battery enclosure applications and upper body components that accommodate sensors and cameras.

- Consumer Electronics: The consumer electronics sector drives significant demand for metal stamping, with applications in mobile phone frames, headphone components, speaker housings, and gaming controller elements requiring exceptional precision.

- Appliance Manufacturing: Washing machine drums, refrigerator panels, and HVAC components all originate from stamping operations. High-volume production demands justify investment in robust tool and die manufacturing for these applications.

- Aerospace: Where tolerances are measured in thousandths and material specifications are exacting, aerospace die manufacturing represents the pinnacle of precision. Components must meet stringent quality standards while maintaining structural integrity under extreme conditions.

- Telecommunications: Enclosures, heat sinks, and structural brackets for network equipment rely on precision stamping. The rapid expansion of 5G infrastructure continues driving demand in this sector.

- Medical Devices: Surgical instruments, implant components, and diagnostic equipment housings require contamination-free forming operations with exceptional dimensional control.

Die manufacturing for these diverse applications shares common requirements: precision alignment, appropriate material selection, and configurations matched to production volumes. Whether you're producing automotive brackets or aerospace fasteners, the fundamental principles of die set selection remain consistent—only the specific parameters change.

With this understanding of where stamping die sets fit within the broader manufacturing landscape, you're better positioned to evaluate potential suppliers who can support your specific industry requirements and production goals.

Choosing a Quality Die Set Supplier for Your Production Needs

You've mastered the fundamentals of stamping die set selection—configurations, materials, sizing, and maintenance. But here's where theory meets reality: finding a supplier who can actually deliver what you need, when you need it, at the quality level your production demands. The die making partner you choose affects everything from initial tooling costs to long-term production consistency. So what separates exceptional suppliers from those who merely take orders?

Whether you're sourcing a custom die for prototype validation or establishing a relationship for high-volume production tooling, the evaluation criteria remain remarkably consistent. Let's break down the factors that matter most when selecting your precision die and stamping partner.

Quality Certifications That Matter for OEM Standards

When you're supplying components to automotive, aerospace, or other demanding industries, your die supplies must come from certified sources. Certifications aren't just wall decorations—they represent verified systems for quality management, process control, and continuous improvement.

IATF 16949 Certification: If you're serving the automotive supply chain, this certification is non-negotiable. According to the NSF certification authority, IATF 16949 provides a standardized Quality Management System that focuses on driving continuous improvement, with emphasis on defect prevention and reduction of variation and waste. Most major automotive OEMs mandate this certification for their supply chain partners.

Why does this matter for die for manufacturing applications? Certified suppliers maintain documented procedures for every aspect of tooling production—from initial design through final inspection. When problems arise, traceable quality systems enable rapid root cause identification and corrective action. Organizations certified to IATF 16949 demonstrate improved customer satisfaction, increased efficiency, and better risk management across their operations.

Beyond IATF 16949, look for suppliers holding ISO 9001 as a baseline quality standard, plus industry-specific certifications relevant to your application. Aerospace applications may require AS9100 compliance, while medical device tooling demands ISO 13485 adherence.

Engineering Support and Prototyping Capabilities

Here's a reality many buyers overlook: the lowest-priced tooling quote often becomes the most expensive choice. Why? Because suppliers who lack engineering depth deliver dies that require extensive modifications, produce inconsistent parts, or fail prematurely. The real value lies in stamping tool and die partners who prevent problems before production begins.

CAE Simulation for Defect Prevention: Modern die engineering leverages Computer-Aided Engineering to visualize forming processes before cutting steel. As explained by metal forming simulation specialists, CAE analysis allows visualization of load progression, deformation, and temperature changes during forming—plus prediction of potential defects like cracks that may occur during production. By optimizing tooling designs based on simulation results, defects can be prevented in advance, ensuring smoother production and significantly reducing component costs.

This simulation capability matters tremendously for precision die and stamping applications. Rather than discovering forming problems during tryout—when changes are expensive and time-consuming—CAE-equipped suppliers identify issues during the design phase when modifications cost virtually nothing.

Rapid Prototyping Timelines: Production schedules rarely accommodate extended tooling development cycles. When your product launch depends on validated stamping dies, supplier lead times become critical constraints. Look for partners offering rapid prototyping capabilities that can deliver functional tooling for validation testing in compressed timeframes.

Shaoyi exemplifies this combination of capabilities, offering IATF 16949 certification alongside advanced CAE simulation for defect-free results. Their engineering team delivers rapid prototyping in as little as 5 days, supporting the accelerated development timelines that modern automotive production demands. With a 93% first-pass approval rate on tooling, they demonstrate the quality outcomes that proper engineering support enables. You can explore their comprehensive mold design and fabrication capabilities to see how these elements come together.

Key Supplier Evaluation Criteria

When comparing potential stamping tool and die suppliers, work through these critical checkpoints:

- Quality certifications: IATF 16949 for automotive applications; verify current certification status and audit history

- Engineering capabilities: CAE simulation, DFM (Design for Manufacturability) analysis, and experienced tooling engineers who understand your industry

- Prototyping speed: Can they deliver functional tooling within your development timeline? Ask for specific lead time commitments

- First-pass approval rates: What percentage of their tooling meets specifications on initial submission? Industry leaders achieve 90%+ approval rates

- Production volume capacity: Can they scale from prototype quantities to high-volume manufacturing without quality degradation?

- Material expertise: Do they understand the specific alloys and gauges you're forming? Material knowledge prevents costly design errors

- Communication and support: How responsive are they during development? Will they provide ongoing technical support after delivery?

- Geographic considerations: Proximity affects lead times, shipping costs, and the feasibility of on-site collaboration during tryout

Beyond these tangible factors, assess cultural fit. The best supplier relationships function as partnerships where both parties invest in mutual success. Suppliers who ask detailed questions about your application, challenge assumptions constructively, and proactively suggest improvements typically deliver better outcomes than those who simply quote to print.

Production timeline considerations deserve special attention. Custom die development involves multiple phases—design, engineering review, fabrication, heat treatment, assembly, and tryout. Each phase presents opportunities for delays if suppliers lack capacity, expertise, or effective project management. Request detailed project timelines with milestone commitments, and verify suppliers have adequate capacity for your project alongside their existing workload.

With clear criteria for evaluating die set suppliers established, you're prepared to make informed sourcing decisions. But how do you synthesize everything we've covered into a practical action plan? Let's consolidate the key considerations into a decision-making framework you can apply immediately.

Making Your Stamping Die Set Decision With Confidence

You've covered substantial ground—from understanding core components to evaluating supplier capabilities. Now comes the critical moment: translating knowledge into action. Whether you're specifying your first stamping die set or refining your sourcing strategy for high-volume production, having a structured approach prevents costly oversights and accelerates your path to quality parts.

Think of this final section as your decision-making compass. The considerations we've explored throughout this guide distill into specific action steps you can implement immediately—regardless of whether you're working with a danly die set standard catalog or developing fully custom tooling for specialized applications.

Your Die Set Selection Checklist

Before committing to any press and die configuration, work systematically through these foundational decisions. Rushing past any step creates problems that compound throughout your production lifecycle:

- Define your production requirements: Establish annual volumes, part complexity, material specifications, and tolerance requirements. These parameters drive every subsequent decision about configuration, material, and supplier selection.

- Match configuration to application: Select back post for progressive operations requiring maximum accessibility, diagonal for balanced access and stability, or four-post when rigidity and precision outweigh accessibility concerns.

- Choose appropriate materials: Steel for high-volume durability exceeding 100,000 cycles; aluminum when weight reduction, rapid prototyping, or frequent changeovers justify the trade-offs.

- Verify press compatibility: Confirm bed dimensions, shut height, stroke length, and tonnage capacity before finalizing any set of die specifications. Mismatches here create safety risks and quality problems.

- Establish maintenance protocols: Plan inspection frequencies, lubrication schedules, and wear measurement baselines before production begins—not after problems surface.

- Qualify potential suppliers: Verify certifications (IATF 16949 for automotive), engineering capabilities, prototyping timelines, and first-pass approval rates through documented evidence.

- Request detailed project timelines: Obtain milestone commitments for design, fabrication, and tryout phases. Ambiguous schedules typically indicate capacity or capability constraints.

This systematic approach applies whether you're sourcing standard punch press dies or investing in complex progressive tooling. The fundamentals remain consistent—only the specific parameters change based on your application.

Taking the Next Step in Your Tooling Project

Ready to move from planning to execution? Your next actions depend on where you stand in the development cycle:

If you're in early design phases: Engage potential suppliers now—before designs are finalized. Die stamp tooling partners with strong engineering capabilities can identify manufacturability issues while changes remain inexpensive. This collaborative approach typically reduces overall development time and prevents costly redesigns during tryout.

If you're sourcing for existing designs: Focus your evaluation on suppliers demonstrating proven quality systems and rapid response capabilities. For automotive applications, Shaoyi offers an excellent example of what to look for—IATF 16949 certification, advanced CAE simulation for defect prevention, and rapid prototyping capabilities delivering functional tooling in as little as 5 days. Their 93% first-pass approval rate demonstrates the quality outcomes that proper engineering support enables. Explore their comprehensive stamping die solutions to see how these capabilities align with your requirements.

If you're troubleshooting existing tooling: Review the diagnostic frameworks covered earlier, focusing on alignment verification and wear pattern analysis. Sometimes the most cost-effective path forward involves refurbishing existing die sets rather than replacing them entirely.

Whatever stage you're at, remember this fundamental truth: the quality of your stamping die set directly determines the quality of every part it produces. Investing in proper selection, certified suppliers, and systematic maintenance pays dividends across millions of production cycles. Your tooling decisions today shape your manufacturing outcomes for years to come.

Frequently Asked Questions About Stamping Die Sets

1. What is a stamping die set and what does it do?

A stamping die set is a precision-engineered assembly consisting of upper and lower die shoes held in exact alignment by guide posts and bushings. It serves as the foundational framework for metal stamping operations, supporting all cutting, forming, and shaping processes. The upper die shoe attaches to the press ram while the lower die shoe mounts to the press bed, with guide posts maintaining alignment accuracy within .0001 inches throughout millions of production cycles.

2. What are the different types of die set configurations?

There are four main die set configurations: back post (two posts along the rear edge for maximum accessibility), diagonal post (posts at opposite corners for balanced access and stability), four-post (one post in each corner for maximum rigidity and precision), and center post (guides near the middle for specialized applications). Back post designs excel for progressive dies with strip feeding, while four-post configurations are ideal for heavy blanking and tight tolerance requirements.

3. Should I choose steel or aluminum for my die set?

Choose tool steel for high-volume production exceeding 100,000 cycles where durability and dimensional stability are critical. Aluminum die sets make economic sense for prototyping, short runs under 50,000 parts, frequent die changes (aluminum weighs about one-third of steel), and heat-sensitive applications. Some manufacturers use hybrid approaches with steel guide posts and aluminum die shoes to combine precision with weight savings.

4. How do I select the right die set size for my press?

Start by measuring your press bed dimensions, shut height, stroke length, and daylight opening. Die shoes should exceed your tooling footprint by enough margin for mounting hardware, clamps, and adjustments. Verify tonnage capacity exceeds your stamping force requirements, confirm mounting hole patterns align with press T-slots, and ensure guide post length works within available daylight opening. Always leave clearance margins for clamping and safety considerations.

5. What certifications should I look for in a die set supplier?

For automotive applications, IATF 16949 certification is essential as it demonstrates verified quality management systems with emphasis on defect prevention and continuous improvement. ISO 9001 serves as a baseline quality standard, while aerospace applications may require AS9100 compliance. Suppliers like Shaoyi offer IATF 16949 certification combined with advanced CAE simulation capabilities and rapid prototyping in as little as 5 days, achieving 93% first-pass approval rates on tooling.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —