Manufacturing Process Stamping Decoded: From Raw Sheet To Finished Part

What Metal Stamping Really Means in Modern Manufacturing

Ever wondered how your car's body panels or the tiny connectors inside your smartphone are made with such remarkable precision? The answer lies in one of manufacturing's most powerful techniques: metal stamping. This manufacturing process transforms flat sheet metal into precisely shaped components through controlled force and specialized tooling—producing everything from simple brackets to complex automotive parts at incredible speeds.

From Flat Sheet to Finished Part

So, what is metal stamping exactly? At its core, this process uses a stamping press to drive a hardened die into sheet metal, cutting, bending, or shaping the material into specific forms. Imagine a cookie cutter—but engineered to withstand thousands of pounds of pressure and capable of producing identical parts thousands of times per hour.

The stamping meaning in manufacturing differs significantly from decorative or craft stamping. Here, we're talking about industrial-scale production where flat metal coils enter one end of the process and finished components emerge from the other. According to Wikipedia's documentation on metalworking, stamped parts revolutionized manufacturing as early as the 1880s when they replaced die forging and machining for bicycle components, dramatically reducing production costs while maintaining acceptable quality.

The Physics Behind Metal Forming

What makes the metal stamping process so effective? It's all about controlled deformation. When the press applies force through the die, the sheet metal undergoes plastic deformation—permanently changing shape without breaking. The die acts as both a mold and a cutting tool, depending on the specific operation being performed.

Modern stamping relies on precise calculations of material properties, force requirements, and tooling geometry. Lubricants protect both the tooling and the stamped metal from surface damage while allowing the material to flow smoothly into complex shapes. This careful orchestration of force, tooling, and material science is what separates successful stamping operations from failed attempts.

Why Stamping Dominates Mass Production

What is a stamping operation's greatest advantage? Speed and consistency. While machining might produce one complex part in several minutes, stamping can create dozens per minute—each virtually identical to the last. This efficiency explains why automotive manufacturers, electronics companies, and appliance makers rely so heavily on this technology.

As noted by Die-Matic's industry analysis, stamping excels in high-volume production where thousands or millions of identical parts are required with minimal variation. The process delivers tight tolerances and consistent durability—critical requirements for industries like automotive and aerospace where part reliability directly impacts safety.

What is stamped metal used for today? You'll find it everywhere: body panels and brackets in vehicles, circuit board components in electronics, structural elements in aircraft, and countless household appliance parts. This versatility, combined with cost efficiency at scale, ensures that stamping remains the backbone of modern manufacturing.

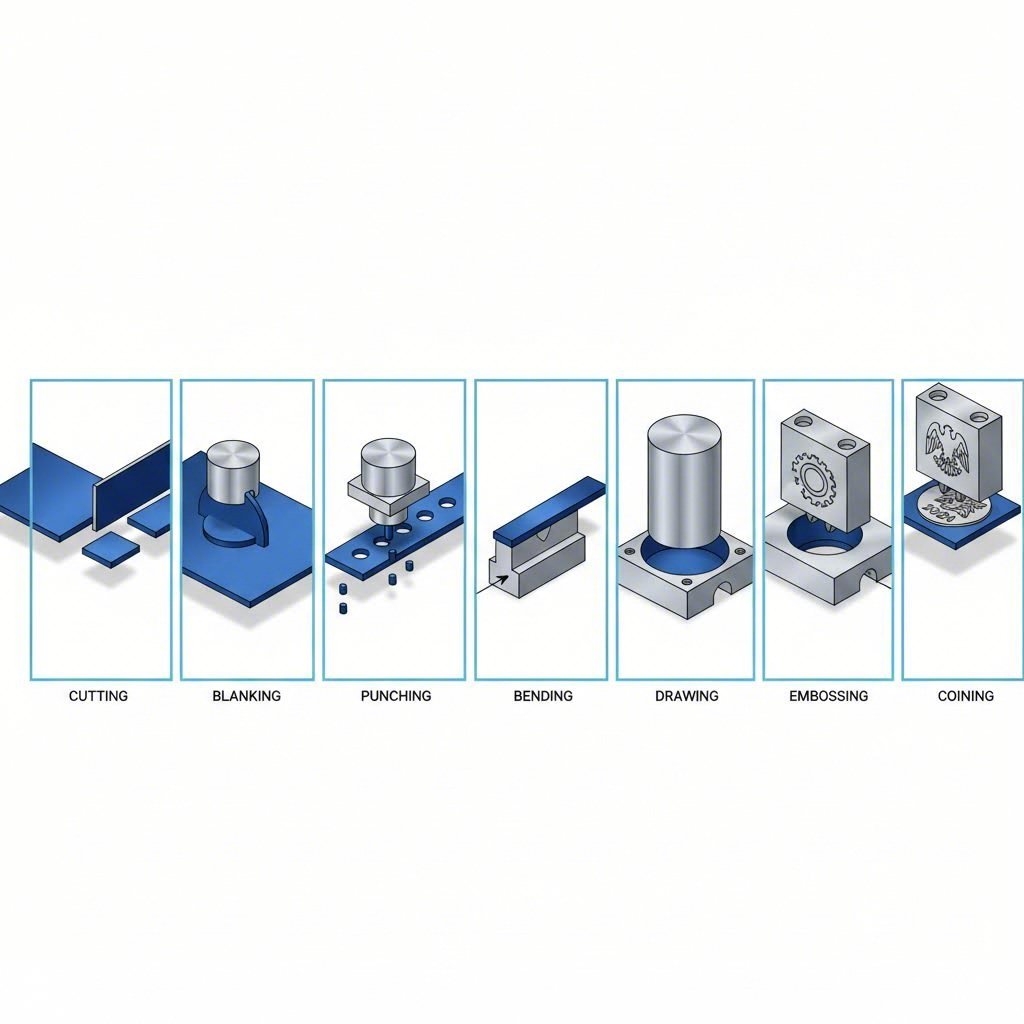

Seven Core Stamping Operations Every Engineer Should Understand

Now that you understand what stamping means in the manufacturing context, let's explore the specific operations that make this process so versatile. Think of these operations as individual tools in a craftsman's workshop—each designed for a particular purpose, yet often combined to create complex finished parts. Whether you're designing components or evaluating manufacturing options, understanding these seven core operations will help you make smarter decisions.

Cutting Operations Explained

Cutting operations form the foundation of most stamping processes. They separate material, create openings, and establish the basic shape of your component. Two primary cutting operations dominate the industry:

- Blanking – This operation cuts flat shapes from sheet metal to form the basic workpiece. During blank stamping metal operations, a punch forces through the material, and the cut-out piece becomes your product while the remaining sheet becomes scrap. Think of it like using a cookie cutter where you keep the cookie. According to Master Products, blanking is optimized for producing large quantities of similar-shaped components efficiently.

- Punching (Piercing) – While mechanically similar to blanking, punching creates holes or openings within the workpiece. Here, the punched-out material is scrap, and the sheet with the holes is your product. This die stamping operation is essential for creating positioning holes, connection points, and ventilation openings in finished parts.

What distinguishes these operations? Simply put: which piece you keep. Blank stamping retains the cut shape; punching retains the surrounding material.

Forming and Shaping Techniques

Once you've established your basic shape through cutting, forming operations transform flat blanks into three-dimensional components. These techniques manipulate the metal without removing material:

- Bending – A press brake applies extreme force to bend metal at precise angles about a specific axis. This stamping and pressing operation creates V-shaped, U-shaped, or custom angular components. You'll find bent parts everywhere—from electrical enclosures to automotive brackets.

- Drawing – This precision stamping technique forms cup-shaped or box-shaped parts by forcing sheet metal down onto a die. The metal stretches and flows around the die geometry, creating complex cross-sectional shapes. Deep drawing extends this process for parts requiring significant depth, like beverage cans or automotive fuel tanks.

- Embossing – Need raised or recessed designs on your parts? Embossing stamps one side of the workpiece to create decorative patterns, lettering, logos, or functional textures. As noted by HLC Metal Parts, this process enhances product decoration while maintaining structural integrity.

- Flanging – This operation bends edges around punched holes or along workpiece perimeters at 90-degree angles. Flanging creates smooth rims instead of sharp edges, enhances structural strength, and prepares surfaces for joining operations. You'll commonly see flanged components in containers, pipes, and automotive body panels.

Precision Operations for Critical Tolerances

When your application demands exceptional accuracy, these specialized operations deliver results that standard techniques cannot match:

- Coining – The most precise stamping process available, coining steel and other metals involves stamping both sides of the workpiece simultaneously under extremely high pressure. This compresses the material into every detail of the die cavity, achieving tolerances as tight as ±0.001 inches. The name comes from currency manufacturing—those crisp details on quarters and commemorative medallions result from coining operations.

Each operation in the stamping process serves distinct purposes, but their real power emerges when combined. A single progressive die might blank, punch, bend, and flange a component in sequential stations—transforming flat coil stock into finished parts in seconds. Understanding when to apply each technique helps you design manufacturable parts and select the right production approach for your specific requirements.

| Operation | Primary Function | Typical Applications | Key Advantage |

|---|---|---|---|

| Blanking | Cutting flat shapes from sheet | Base components, washers, brackets | High-volume shape production |

| Punching | Creating holes and openings | Mounting holes, ventilation, connections | Precise hole positioning |

| Bending | Forming angles and curves | Enclosures, frames, brackets | Creates 3D geometry from flat stock |

| Drawing | Forming cup/box shapes | Containers, housings, covers | Complex depth without seams |

| Embossing | Creating surface features | Logos, decorative panels, grip textures | Visual and functional enhancement |

| Flanging | Bending edges at 90° | Tanks, pipes, body panels | Improved strength and smooth edges |

| Coining | High-pressure precision forming | Coins, jewelry, tight-tolerance parts | Exceptional dimensional accuracy |

With these seven operations in your manufacturing vocabulary, you're ready to explore how they combine into complete production workflows—from initial design through finished part delivery.

The Complete Metal Stamping Workflow from Design to Delivery

Understanding individual stamping operations is essential—but how do these techniques come together in actual production? The sheet metal stamping process follows a carefully orchestrated sequence where each step builds upon the previous one. Miss a critical parameter at any stage, and you'll face quality issues, production delays, or costly scrap. Let's walk through the complete stamping manufacturing process from initial concept to finished component.

Pre-Production Engineering Phase

Before any metal touches a die, significant engineering work must happen. This phase determines whether your production stamping operation will succeed or struggle.

Step 1: Material Selection and Preparation

Your material choice affects everything downstream. Engineers evaluate mechanical properties like tensile strength, ductility, and work hardening rate alongside practical considerations such as cost and availability. According to National Material Company, considerations include mechanical properties such as strength and ductility, as well as factors like corrosion resistance, conductivity, and cost.

Once selected, raw coils or sheets undergo preparation processes including:

- Cutting and slitting to proper widths

- Leveling to ensure flatness

- Surface cleaning to remove oils and contaminants

- Edge conditioning to prevent feeding issues

Common errors here? Selecting materials that look good on paper but behave poorly during forming, or skipping proper leveling—which causes inconsistent part geometry throughout your run.

Step 2: Die Design and Engineering

The die is essentially the DNA of your stamping manufacturing process. As noted by Jeelix's comprehensive die design guide, this step offers the greatest leverage in the entire process—every hour of focused thinking invested here can save scores of hours in revisions and tens of thousands in costs later.

Die engineering involves:

- Creating strip layouts that optimize material utilization

- Calculating cutting, forming, and stripping forces

- Determining the pressure center to prevent uneven die wear

- Selecting appropriate die materials based on production volume and part material

- Running CAE simulations to identify potential forming issues before physical tryouts

A well-designed die anticipates problems before they occur. Where will springback affect final dimensions? Which areas risk wrinkling or cracking? Experienced die designers address these questions during engineering—not after production begins.

Step 3: Press Setup and Calibration

Matching your die to the right press is critical for the metal stamping manufacturing process. Engineers calculate total tonnage requirements by summing all forces across stations, then select a press with adequate capacity—typically 20-30% above calculated requirements for safety margin.

Setup involves:

- Installing and aligning the die within the press

- Setting proper shut height (distance between ram and bed at bottom of stroke)

- Programming stroke length, speed, and dwell times

- Calibrating hydraulic pressures for cushions and pad systems

- Testing safety interlocks and sensors

The Stamping Cycle in Action

With engineering complete and equipment ready, production metal stamping begins. This is where flat stock transforms into finished components.

Step 4: Feeding and Positioning

Automated feeding systems deliver material into the die with remarkable precision. Coil stock unwinds through straighteners and into servo-driven roll feeders that advance material exactly the required distance—often within ±0.001 inches—before each stroke.

Proper feeding requires:

- Correct feed length matching your strip layout progression

- Adequate pilot pins that locate material precisely within the die

- Loop controls that prevent material tension variations

- Misfeed sensors that halt the press if positioning errors occur

At high speeds—sometimes exceeding 1,000 strokes per minute—even minor feeding inconsistencies multiply into major quality problems. Modern manufacturing stamping process controls monitor every cycle.

Step 5: The Stamping Stroke

Here's where the magic happens. According to RCO Engineering, a typical stamping cycle involves the press lowering toward the die, the dies closing together and shaping the metal through high force and pressure, and the press releasing and retracting.

During this fraction-of-a-second event:

- The ram descends, bringing the upper die toward the lower die

- Pilot pins engage to ensure precise material positioning

- Cutting, forming, or drawing operations occur as designed

- Material flows and deforms according to die geometry

- The ram retracts, allowing material advancement

Engineers use lubricants strategically during this phase to reduce friction, prevent galling, and control material flow. Cooling systems dissipate heat generated during high-speed or high-pressure operations.

Step 6: Part Ejection and Handling

Finished parts must exit the die reliably—every single cycle. Stripper plates prevent parts from sticking to punches, while spring-loaded ejectors push completed components clear of the die cavity. Air jets and mechanical fingers may assist with part removal and orientation.

Scrap also requires management. Slug removal systems clear punched material from die cavities, and scrap cutters reduce carrier strip waste for efficient disposal. A single stuck slug can cause catastrophic die damage within milliseconds.

Post-Stamping Quality Verification

Step 7: Quality Inspection

The metal stamping manufacturing process doesn't end when parts exit the die. Quality control measures ensure every component meets specifications before reaching customers.

Inspection methods include:

- Visual assessment for surface defects, burrs, and cosmetic issues

- Dimensional measurement using gauges, calipers, or coordinate measuring machines

- Functional testing to verify fit and performance requirements

- Statistical process control to identify trends before they become problems

Many production stamping operations also include secondary processes like deburring, heat treatment, plating, or painting before final assembly and shipping.

| Step | Purpose | Key Equipment | Critical Parameters | Common Error Points |

|---|---|---|---|---|

| 1. Material Selection & Prep | Ensure proper formability and quality | Slitting lines, levelers, cleaners | Thickness tolerance, surface finish, flatness | Wrong material grade, inadequate leveling |

| 2. Die Design & Engineering | Create tooling that produces accurate parts | CAD/CAM software, CAE simulation, CNC machining | Clearances, strip layout, force calculations | Insufficient springback compensation, poor material flow |

| 3. Press Setup & Calibration | Configure equipment for optimal operation | Stamping press, die carts, alignment tools | Shut height, tonnage, stroke speed | Misalignment, incorrect tonnage setting |

| 4. Feeding & Positioning | Deliver material precisely to die stations | Coil cradles, straighteners, servo feeders | Feed length, pilot engagement, loop tension | Misfeed, pilot damage, material buckling |

| 5. Stamping Stroke | Form material into desired shape | Press ram, dies, lubrication systems | Force distribution, dwell time, lubrication | Cracking, wrinkling, inconsistent forming |

| 6. Part Ejection & Handling | Remove parts and scrap reliably | Stripper plates, ejectors, conveyors | Ejection timing, scrap removal, part orientation | Stuck parts, slug pulling, die crashes |

| 7. Quality Inspection | Verify parts meet specifications | CMMs, optical comparators, go/no-go gauges | Dimensional tolerances, surface quality, SPC limits | Missed defects, inadequate sampling |

Notice how each step connects to the next? Material preparation quality affects die wear and part consistency. Die design determines what your press must deliver. Feeding precision impacts every forming operation. This interconnected nature explains why successful stamping manufacturing requires attention across the entire workflow—not just individual operations.

With the complete workflow understood, you're ready to explore the different die methods that organize these steps into efficient production systems—from progressive dies that perform multiple operations in sequence to transfer systems designed for larger, more complex components.

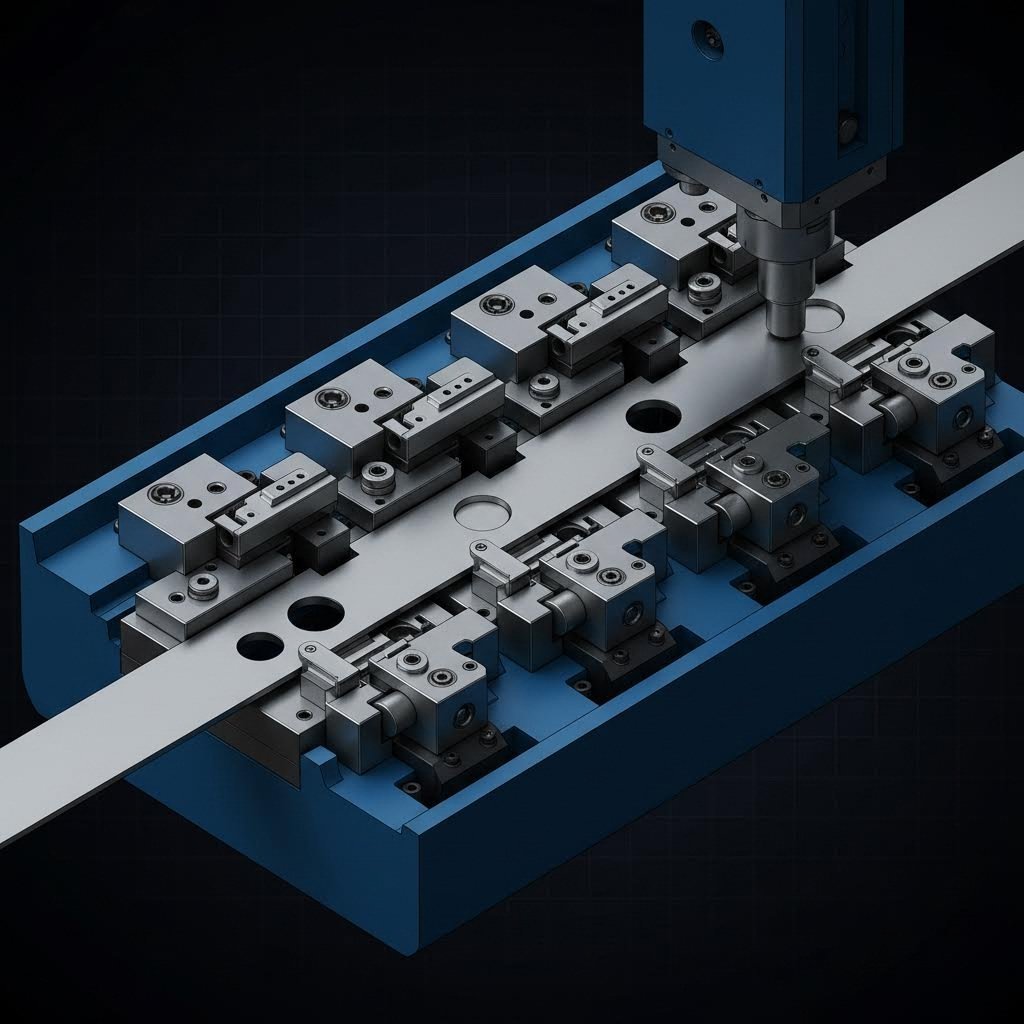

Progressive Transfer and Compound Die Methods Compared

You've seen how individual stamping operations work and how they flow through a complete production cycle. But here's where things get interesting: how do manufacturers organize these operations into efficient production systems? The answer lies in choosing the right die method—and this decision can make or break your project's economics.

Think of it this way: you wouldn't use a sledgehammer to hang a picture frame, right? Similarly, selecting between progressive, transfer, and compound die stamping depends entirely on what you're making, how many you need, and how complex your stamped parts are. Let's break down each approach so you can make informed decisions for your stamping design requirements.

Progressive Die for Maximum Efficiency

Imagine an assembly line compressed into a single tool. That's progressive die and stamping in action. A continuous metal strip feeds through multiple stations within one die, with each station performing a different operation—blanking, punching, bending, forming—in precise sequence. The part remains attached to the carrier strip throughout, only separating at the final station.

According to Die-Matic's process comparison, progressive die stamping moves a metal strip through multiple stations that perform different operations such as cutting, bending, piercing, or punching—making it perfect for high-speed production of complex parts at medium to high volumes.

Why does this matter for your production? Speed. A single press stroke advances the strip and performs operations at every station simultaneously. While one section gets blanked, another gets punched, and a third gets formed—all in the same fraction of a second. This parallel processing delivers remarkable throughput for precision stamping parts.

Progressive die stamping excels when:

- You need high-volume production (thousands to millions of parts)

- Parts are small to medium-sized

- Your design requires multiple operations but not deep draws

- Consistency and speed outweigh tooling investment concerns

The tradeoff? Initial tooling costs run higher than simpler alternatives. As noted by Keats Manufacturing, progressive die stamping requires costly steel stamping dies—but saves time and money by performing multiple operations simultaneously, reducing waste, and enabling long production runs with lower labor costs.

Transfer Stamping for Large Components

What happens when your parts are too large for progressive dies, or when deep drawing is required? Transfer die stamping steps in. Unlike progressive stamping where parts stay connected to the strip, transfer stamping separates the workpiece early—either starting with a pre-cut blank or detaching it at the first station.

Here's where it gets clever: mechanical fingers or automated transfer systems physically move each part between stations. This "free" part handling enables operations that would be impossible with a connected strip—deeper draws, more complex orientations, and access to areas blocked by carrier material in progressive setups.

According to Worthy Hardware's detailed comparison, transfer die stamping allows more flexibility in part handling and orientation, making it suitable for intricate designs and shapes. It can incorporate various operations such as punching, bending, drawing, and trimming in a single production cycle.

Transfer die stamping shines when:

- Parts are medium to large in size

- Deep drawing operations are required

- Complex geometries demand multiple orientations during forming

- Your design includes features like threading, ribs, or knurls

The flexibility comes with considerations. Setup times can run longer, operational costs increase due to more complex handling mechanisms, and you'll need skilled technicians for maintenance. Still, for stamped sheet metal components like automotive body panels, structural brackets, and appliance housings, transfer stamping often represents the only practical solution.

Compound Die: Single-Stroke Simplicity

Sometimes the most elegant solution is the simplest one. Compound die stamping performs multiple cutting operations in a single stroke—typically combining blanking and piercing to produce complete flat parts without progressive stations or transfer mechanisms.

Picture a washer: you need to cut the outer diameter (blanking) and the center hole (piercing) simultaneously. A compound die accomplishes both in one press cycle. This approach delivers exceptional flatness since the part isn't subjected to multiple handling or feeding stresses.

According to Keats Manufacturing, compound die stamping delivers less costly tooling than progressive die tooling, efficient and fast production of simplistic and small parts, and one stroke that produces flatter parts with high repeatability.

Compound die stamping works best for:

- Flat parts requiring only cutting operations (no forming)

- Medium to high production volumes

- Components where flatness is critical

- Simple geometries like washers, gaskets, and wheel blanks

The limitation? Compound dies handle cutting operations only. Need bending, drawing, or forming? You'll need progressive or transfer methods—or secondary operations that add cost and handling.

Specialized Techniques for Unique Requirements

Beyond the three primary methods, specialized stamping techniques address specific manufacturing challenges that standard approaches can't efficiently solve.

Deep Draw Stamping

When your sheet metal stamping design calls for cup-shaped, cylindrical, or box-shaped parts with significant depth, deep drawing becomes essential. This process pulls flat blanks into dies, stretching and flowing metal into three-dimensional forms without seams or welds.

Think beverage cans, automotive fuel tanks, or kitchen sinks. Deep drawing typically requires transfer die setups that allow the separated blank maximum freedom during forming. Multiple draw reductions may be needed for extreme depths, with annealing operations between stages to restore ductility.

Fine Blanking

Standard blanking leaves edges with some rollover and break—acceptable for many applications but problematic when precision matters. Fine blanking applies extreme pressure through specialized triple-action tooling to produce parts with smooth, sheared edges and exceptional dimensional accuracy.

As noted by Die-Matic, fine blanking eliminates the need for extensive post-processing such as deburring or grinding, saving both time and production costs while delivering consistent part repeatability across large production runs.

Fine blanking suits applications where edge quality directly impacts function: gears, sprockets, seatbelt components, and brake system parts that can't tolerate rough edges or dimensional variation.

Choosing Your Stamping Method: A Practical Comparison

How do you decide which method fits your project? Consider these factors across each approach:

| Factor | Progressive Die | Transfer Die | Compound Die |

|---|---|---|---|

| Part Complexity | Simple to moderately complex | Complex, intricate designs | Simple flat parts only |

| Part Size | Small to medium | Medium to large | Small to medium |

| Production Volume | High volume (optimal) | Medium to high volume | Medium to high volume |

| Tooling Cost | Higher initial investment | Higher (complex handling) | Lower than progressive |

| Per-Part Cost at Volume | Lowest | Moderate | Low for simple parts |

| Production Speed | Fastest | Moderate | Fast for single operations |

| Deep Drawing Capability | Limited | Excellent | Not applicable |

| Typical Applications | Connectors, brackets, clips, terminals | Body panels, housings, structural parts | Washers, blanks, gaskets |

Notice how each method occupies a distinct niche? Progressive dies dominate high-volume production of smaller stamped parts. Transfer systems handle larger, more complex components. Compound dies offer economical solutions for simpler geometries. Your specific requirements—part size, complexity, volume, and budget—guide the selection.

With the right die method selected, your next consideration becomes equally critical: which materials will perform best during stamping and meet your application requirements? Material selection directly impacts formability, tooling wear, and final part performance.

Material Selection Guide for Optimal Stamping Results

You've selected your die method—but what about the metal feeding into it? Here's a truth many engineers learn the hard way: choosing the wrong material can undermine even the most sophisticated tooling. A part that forms beautifully in aluminum might crack in stainless steel. A design that works with brass could wrinkle badly with galvanized steel. Understanding how different metal stamping materials behave during forming is essential for achieving consistent, high-quality results.

Material selection isn't about finding the "best" metal—it's about matching material properties to your specific application requirements. Let's explore the characteristics, advantages, and limitations of the most common metals for stamping.

Steel Grades and Their Stamping Characteristics

Steel remains the workhorse of the stamping industry, offering combinations of strength, formability, and cost-effectiveness that few materials can match. But "steel" encompasses dozens of grades, each behaving differently under the press.

Carbon Steel and Galvanized Steel

For structural parts where cost matters most, carbon steel delivers. According to Tenral's material selection guide, galvanized steel features a zinc coating thickness of ≥8μm over a carbon steel base, providing both low cost and basic rust prevention—making it ideal for cost-sensitive applications like chassis brackets and appliance control panels.

Stamped steel components dominate automotive frames, household appliance housings, and industrial equipment brackets. The material forms predictably, tolerates aggressive die operations, and delivers tensile strengths of ≥375 MPa. The tradeoff? Limited corrosion resistance without coatings or plating.

Stainless Steel Metal Stamping

When your application demands corrosion resistance alongside strength, stainless steel stamping becomes the go-to choice. But not all stainless grades behave equally:

- 304 Stainless Steel – The most common austenitic grade, containing approximately 18% chromium and 8% nickel. According to Larson Tool & Stamping, Grade 304 offers excellent corrosion resistance and formability with outstanding mechanical properties—making it ideal for medical equipment shells, food processing components, and new energy vehicle charging terminals.

- 409 Stainless Steel – A ferritic grade with approximately 11% chromium, offering good heat resistance and weldability at lower cost than 304. Commonly used for automotive exhaust systems and heat exchangers.

- 430 Stainless Steel – As noted by Tenral, this grade offers lower cost than 304 and suits structural parts without demanding rust prevention requirements.

The key consideration with stainless? Work hardening. These alloys strengthen significantly during forming, which can cause cracking if your die design doesn't account for this behavior. Proper lubrication and controlled forming sequences become critical for successful stainless steel stamping operations.

Aluminum Challenges and Solutions

Sounds attractive, right? Aluminum offers roughly one-third the density of steel while maintaining good strength-to-weight ratios. For weight-sensitive applications—think 5G base station heat sinks, automotive body panels, and electronic enclosures—aluminum stamping often proves essential.

But here's what catches many engineers off guard: stamped aluminum behaves differently than steel in several critical ways.

Springback Issues

Aluminum exhibits more elastic recovery than steel after forming. When you bend aluminum to 90 degrees, it might spring back to 87 or 88 degrees once pressure releases. Your die design must compensate by overbending—anticipating how much the material will recover.

Surface Sensitivity

Aluminium stamping parts scratch and gall more readily than steel. This demands careful attention to lubrication, die surface finishes, and material handling throughout the process. Protective films may be applied to critical surfaces before stamping.

Material Grade Selection

Not all aluminum alloys stamp equally well. The 1000 and 3000 series offer excellent formability for deep draws and complex shapes. The 5000 series provides better strength with good corrosion resistance. The 6000 series (particularly 6061-T6) balances strength and formability for structural applications.

According to Tenral's case study, a communications company achieved 25% improved heat dissipation efficiency and 18% production cost reduction by selecting 6061-T6 aluminum for precision-stamped 5G base station heat sinks—demonstrating how proper material selection directly impacts both performance and economics.

Selecting Materials for Your Application

Beyond steel and aluminum, several specialty materials address specific application needs:

- Copper – With conductivity reaching 98%, copper excels in electrical applications. Tenral notes its suitability for SIM card springs and industrial sensor wiring terminals. The material forms easily but costs significantly more than steel alternatives.

- Brass (H62) – Offering hardness of HB≥80 with excellent machinability, brass requires no secondary processing after stamping. Common applications include smart door lock components and automotive HVAC connectors. It provides a cost-effective alternative to pure copper when maximum conductivity isn't essential.

- Specialty Alloys – Beryllium copper for springs requiring both conductivity and fatigue resistance. Phosphor bronze for demanding electrical contacts. Nickel alloys for extreme temperature applications. These materials command premium prices but solve problems that common metals cannot.

Key Material Properties Affecting Stampability

When evaluating any metal for stamping, four properties matter most:

- Ductility – How much can the material stretch before cracking? Higher ductility enables deeper draws and more complex forms.

- Yield Strength – The stress at which permanent deformation begins. Lower yield strength ratios typically improve formability for drawing operations.

- Work Hardening Rate – How quickly does the material strengthen during deformation? High work hardening complicates multi-stage forming but can improve final part strength.

- Surface Finish Requirements – Will your application tolerate tool marks? Cosmetic parts demand materials that resist galling and special die finishes.

| Material Type | Tensile Strength (MPa) | Density (g/cm³) | Primary Advantages | Typical Applications |

|---|---|---|---|---|

| Aluminum Alloys | 110-500 | 2.7 | Lightweight, good conductivity, excellent ductility | Heat sinks, device frames, automotive panels |

| Stainless Steel (304) | ≥515 | 7.9 | Corrosion resistance, high strength, ≥48h salt spray | Medical equipment, food processing, charging terminals |

| Copper | 200-450 | 8.9 | 98% conductivity, excellent thermal properties | Electrical contacts, connectors, terminals |

| Brass (H62) | 300-600 | 8.5 | Easy machining, moderate cost, no secondary processing | Lock components, HVAC fittings, decorative parts |

| Galvanized Steel | ≥375 | 7.8 | Low cost, basic rust prevention, predictable forming | Chassis brackets, appliance panels, structural parts |

Remember: material selection involves balancing multiple factors simultaneously. The "right" choice depends on your specific combination of performance requirements, production volumes, and budget constraints. A part that justifies stainless steel in a medical device might work perfectly well in galvanized steel for an appliance application.

With your material selected, the next critical consideration becomes the equipment that will transform it—the stamping presses and tooling that must match both your material properties and production requirements.

Stamping Presses and Tooling Equipment Essentials

So you've selected your material and die method—but what about the machine doing the actual work? Here's the reality: even the best die design paired with optimal material won't deliver quality parts if your metal stamping press doesn't match the job. Understanding stamping machines and their capabilities is essential for anyone involved in production decisions.

What is a stamping press, exactly? Think of it as the powerhouse that converts energy into precisely controlled force, driving your tooling through sheet metal to create finished components. But not all presses work the same way—and selecting the wrong type can mean wasted energy, poor part quality, or expensive equipment damage.

Mechanical vs Hydraulic Press Selection

The two dominant press technologies each bring distinct advantages to your stamping operation. Your choice between them depends largely on what you're making and how fast you need to make it.

Mechanical Stamping Presses

These workhorses dominate high-volume production floors. According to JVM Manufacturing, mechanical stamping presses use flywheels to store and transfer energy, achieving high strokes per minute—making them ideal for large-scale production runs where time is money.

Why does speed matter so much? A mechanical press might run 200-1,500 strokes per minute depending on size and application. At those rates, you're producing parts in fractions of a second. For automotive brackets, electrical terminals, or any component needed in massive quantities, this throughput translates directly to lower per-part costs.

The tradeoff? Mechanical presses deliver fixed stroke lengths and force profiles. The ram moves through the same motion cycle after cycle—great for consistency, but limiting when you need to adjust forming parameters on the fly. Their simplicity means less maintenance and easier operation, which explains their continued popularity despite newer technologies.

Two primary configurations exist within mechanical stamping presses:

- C-Frame (Gap Frame) Presses – Feature an open structure allowing operators easy access from three sides. Well-suited for small-part assembly, light stamping tasks, and applications requiring quick die changes.

- H-Frame (Straight-Side) Presses – Offer enhanced rigidity and strength through their four-column design. Better suited for high-tonnage operations and tasks demanding precise, repetitive forming.

Hydraulic Stamping Presses

When precision and flexibility outweigh raw speed, hydraulic metal stamping presses step in. These machines use hydraulic cylinders to generate force, allowing operators to control pressure throughout the entire stroke—not just at bottom dead center.

Imagine forming a deep-drawn cup shape. The material needs consistent pressure as it flows into the die cavity, not a single punch of force. According to JVM Manufacturing, hydraulic presses maintain consistent force throughout the stroke, making them ideal for high-precision tasks such as forming intricate shapes or working with delicate materials.

The adjustability extends beyond force control. Stroke length, dwell time (how long the ram holds at bottom), and approach speed can all be modified without mechanical changes. This adaptability proves particularly valuable for operations producing varied parts or working with challenging materials that require careful forming sequences.

The limitation? Speed. Hydraulic presses typically run slower than mechanical equivalents—sometimes significantly slower. For applications where precision trumps throughput, this tradeoff makes sense. For high-volume commodity parts, it rarely does.

Understanding Tonnage Requirements

Every stamping operation requires a specific amount of force—measured in tons—to complete successfully. Underestimate your tonnage needs, and you'll damage equipment or produce defective parts. Overestimate dramatically, and you're wasting capital on capacity you'll never use.

According to Production Resources, tonnage is the force that the press is designed to exert against the workpiece in the die, specified at a distance above the bottom of the stroke. For most mechanical presses under 45 tons, this rating applies at 1/32" to 1/16" from bottom dead center.

How do you calculate required tonnage? For simple blanking operations, multiply the cut perimeter by material thickness by material shear strength. A 6-inch diameter blank in 0.125" mild steel, for example, requires approximately 59 tons according to the formula: diameter × π × thickness × 25 (for mild steel).

But here's what catches engineers off guard: progressive dies require summing forces across all stations, plus additional capacity for variables like material hardness fluctuations and die wear. Most operations specify presses with 20-30% capacity above calculated requirements—a safety margin that prevents overloading during normal production variations.

A steel stamping press rated at 200 tons might seem adequate for a job calculated at 150 tons. But if that calculation didn't account for all simultaneous operations, or if material runs slightly harder than specification, you're suddenly operating at or beyond capacity—accelerating wear and risking catastrophic failure.

Modern Servo Press Advantages

What if you could combine the speed of mechanical presses with the flexibility of hydraulics? Servo-driven stamping presses represent the cutting edge of stamping technology, using programmable servo motors to control ram motion with exceptional precision.

According to JVM Manufacturing, servo-driven presses allow manufacturers to precisely control every aspect of the press's movement, from speed to position—enabling complex operations that were previously difficult or impossible with traditional presses.

Consider the possibilities: you can program the ram to slow during critical forming stages, dwell momentarily to allow material flow, then accelerate through less demanding portions of the stroke. This programmable motion profile optimizes each operation individually rather than forcing all operations to conform to a single mechanical cycle.

The energy efficiency advantage often surprises newcomers. Unlike mechanical presses that run flywheels continuously, servo motors operate only when needed. This reduces energy consumption significantly—benefiting both operating costs and environmental impact.

The investment barrier? Higher upfront costs and the need for more sophisticated setup and programming expertise. But for manufacturers seeking competitive advantages in precision, flexibility, and efficiency, servo technology increasingly represents the path forward.

Critical Die Components

While the press provides power, the die determines what that power produces. According to U-Need's comprehensive die components guide, the stamping die is the lifeblood of high-volume manufacturing, with the design, material, and integrity of individual components determining overall performance and operational lifespan.

Understanding these working components helps you appreciate how equipment specifications connect to part quality:

- Punch – The male component that performs piercing, blanking, or forming work. Made from hardened tool steel or carbide, punches must withstand repeated impact while maintaining precise dimensions.

- Die Block (Die Button) – The female counterpart to the punch in cutting operations. A precision-ground component with a hole profile matching the punch, plus carefully calculated clearance for clean shearing.

- Stripper Plate – Removes material from the punch as it retracts. Without proper stripping force, parts stick to punches and cause misfeed, damage, or production stoppage.

- Guide Pins and Bushings – The precision alignment system ensuring upper and lower die halves meet exactly as designed. Made from hardened, precision-ground materials, these components prevent the misalignment that destroys tooling and produces scrap.

As noted by U-Need, small errors of a few micrometers in one component may cause a chain reaction of failures: wrong part dimensions, early tool wear, expensive unscheduled downtime, and high scrap rates. This interconnection between equipment precision and production outcomes explains why successful stamping operations invest heavily in quality tooling and proper maintenance.

| Press Type | Speed Capability | Force Control | Best Applications | Key Limitation |

|---|---|---|---|---|

| Mechanical | High (200-1,500+ SPM) | Fixed stroke profile | High-volume, repetitive parts | Limited flexibility for complex forming |

| Hydraulic | Moderate to Low | Variable throughout stroke | Deep drawing, precision forming, varied production | Slower cycle times |

| Servo-Driven | Programmable | Fully programmable motion | Complex operations, mixed production, precision work | Higher initial investment |

The connection between equipment and quality runs both directions. Proper press selection and maintenance enable consistent production. Inadequate capacity or worn tooling creates defects that cascade through your entire operation. Understanding this relationship—and investing appropriately in both stamping presses and tooling systems—separates world-class stamping operations from struggling ones.

Even with optimal equipment selection, problems inevitably arise during production. Knowing how to identify, diagnose, and correct common defects becomes essential knowledge for anyone managing stamping operations.

Troubleshooting Common Defects and Quality Control Strategies

Your press is running, parts are flowing—and then you spot it. A crack forming at the corner radius. Burrs catching on your inspection gloves. Dimensions drifting out of tolerance. Sound familiar? Every metal stamping operation encounters defects, but what separates successful manufacturers from struggling ones is the ability to diagnose problems quickly and implement effective corrective actions.

Here's the reality: defects in stamped metal parts don't appear randomly. They follow patterns rooted in material behavior, tooling conditions, and process parameters. Understanding these patterns transforms troubleshooting from guesswork into systematic problem-solving. Let's build a comprehensive resource for identifying, correcting, and preventing the most common stamping defects.

Diagnosing Surface Defects

Surface quality issues often signal deeper problems within your metal stamping process. Catching these early prevents larger quality failures downstream.

Wrinkling

When excess material has nowhere to go during forming, it buckles and folds—creating wrinkles that compromise both appearance and function. According to DR Solenoid's comprehensive defect guide, wrinkling typically appears at flange edges during drawing operations, indicating insufficient blank holder force or excessive drawing ratios.

What causes wrinkling in your metal stamped parts? Consider these factors:

- Blank holder force too low—material flows too freely

- Drawing ratio exceeds material capability (depth/diameter ratio > 2.5)

- Improper lubrication distribution allowing uneven material flow

- Die radius too large, providing insufficient material control

The fix? Increase blank holder force gradually until wrinkling disappears without inducing cracking. For severe cases, consider step-by-step drawing with intermediate annealing operations to restore material ductility between stages.

Cracking

Nothing ruins a production run faster than parts splitting during forming. Cracks typically appear at corners, edges, or areas of maximum stretch—telling you exactly where material limits have been exceeded.

DR Solenoid notes that cracking may be caused by insufficient toughness of the material itself, improper stamping process parameters such as excessive stamping speed, or too small a radius at mold corners. When material stress exceeds its strength limit during stamping, cracks occur.

Root causes for cracking in stamped metal components include:

- Die corner radii too tight (recommendation: R ≥ 4 times material thickness)

- Material ductility insufficient for the required deformation

- Work hardening from previous operations reducing remaining formability

- Blank holder force excessive, restricting needed material flow

- Stamping speed too fast for material response characteristics

Solutions involve increasing die radii where possible, selecting more ductile material grades, or adding intermediate annealing to relieve work hardening. For high-strength steels, hot forming at 200-400°C may be necessary to achieve required shapes without fracture.

Scratches and Surface Damage

Cosmetic defects might seem minor compared to dimensional failures, but they often indicate tooling problems that will escalate. According to DR Solenoid, scratches appear when foreign matter contaminates the die surface, when surface roughness fails to meet requirements, or when friction occurs during relative sliding between material and die.

Prevention strategies include:

- Polishing die surfaces to Ra 0.2μm or better

- Using volatile stamping oils that leave no residue

- Pre-cleaning material to remove oils, dust, and contaminants

- Replacing steel pressure plates with nylon alternatives for aluminum parts

Dimensional Accuracy Troubleshooting

When your stamped steel parts measure outside tolerance, the cause rarely lies in a single factor. Dimensional variation typically results from interactions between tooling wear, material properties, and process parameters.

Springback

Every formed metal part wants to spring back toward its original flat state. Controlling this elastic recovery determines whether your quality metal stamping operation hits tolerances or generates scrap.

According to DR Solenoid, uneven stress release in the material, unreasonable distribution of clamping force, and improper process arrangement leading to accumulated stress all contribute to springback issues.

Compensation strategies that work:

- Overbending beyond target angles to account for elastic recovery

- Using CAE simulation to predict springback and adjust die profiles accordingly

- Adding shaping processes with 0.05-0.1mm strong pressure after initial forming

- Optimizing layout direction—aligning bends with material rolling direction reduces springback

- Adjusting blank holder force distribution across multiple zones

For warping issues, DR Solenoid recommends adding a negative angle pre-bending structure to the mold—counteracting the material's natural tendency to spring back.

Burrs

Sharp edges and material protrusions along cut lines indicate problems with your cutting operations. Beyond cosmetic concerns, excessive burrs (height > 0.1mm) create handling hazards, assembly interference, and potential field failures.

According to Metal Infinity's quality inspection guide, excessive burrs can cut hands, scratch surface appearance, and indicate die wear conditions that will worsen without intervention.

What drives burr formation in metal stamping components?

- Punch-to-die clearance outside optimal range (should be 8-12% of material thickness for mild steel)

- Cutting edge wear or chipping

- Material properties varying from specification

Corrective actions include:

- Grinding dies regularly—DR Solenoid recommends inspection every 50,000 strokes

- Adjusting clearances based on material type (smaller clearance values for softer materials)

- Considering fine blanking technology with V-shaped blank holders for burr-free edges

- For copper terminals, implementing zero-gap blanking eliminates burr formation entirely

Dimensional Drift

Gradual dimension changes during a production run signal progressive tooling wear or process instability. According to Metal Infinity's inspection guide, one manufacturer discovered hole dimensions gradually increasing during patrol inspection—later confirming this resulted from wear on the die's guide posts. Without in-process monitoring, the entire batch of 20,000 products might have been scrapped.

Process control measures for dimensional stability include:

- Regular patrol inspection (checking 5 pieces every 30 minutes during production)

- First article inspection before each production run

- Adding guide posts or precision positioning pins to molds

- Tracking dimensional trends through statistical process control charts

| Defect Type | Common Causes | Corrective Actions | Prevention Measures |

|---|---|---|---|

| Wrinkling | Insufficient blank holder force; excessive draw ratio; uneven lubrication | Increase blank holder force; use step-by-step drawing; optimize lubrication | CAE simulation during die design; multi-point blank holder force control |

| Cracking | Die radius too small; material ductility inadequate; excessive work hardening | Increase die radius (R ≥ 4t); add intermediate annealing; use hot forming for high-strength steel | Material testing before production; proper forming sequence design |

| Springback | Uneven stress release; inappropriate clamping force; accumulated stress | Overbending compensation; add shaping process; adjust layout direction | CAE springback simulation; negative angle pre-bending structures |

| Burrs | Improper punch-die clearance; cutting edge wear; material variation | Adjust clearance to 8-12% of thickness; grind dies; consider fine blanking | Regular die inspection every 50,000 strokes; coating technology (TiAlN) |

| Scratches | Contaminated die surface; rough surface finish; inadequate lubrication | Polish die to Ra 0.2μm; use volatile stamping oil; pre-clean material | Chrome plating or TD treatment on dies; material surface inspection |

| Dimensional Variation | Die wear; guide post wear; material thickness deviation; press misalignment | Replace worn components; recalibrate press parallelism; tighten material specs | SPC monitoring; patrol inspection; mold life record tracking |

| Uneven Thickness | Material flow blocked; excessive friction; die radius too small | Optimize draw bead layout; apply high-viscosity lubricant locally; use more ductile material | Balanced material flow design; proper lubrication strategy |

Preventive Maintenance for Consistent Quality

Reactive troubleshooting solves immediate problems—but preventive approaches stop defects before they occur. Building systematic quality control into your stamped metal parts production pays dividends in reduced scrap, fewer customer complaints, and more predictable delivery schedules.

Dimensional Inspection Methods

According to Metal Infinity, the dimensional tolerance for stamped parts often hovers around ±0.05mm—equivalent to the thickness of two sheets of A4 paper. Detecting variations this small requires appropriate measurement tools and systematic approaches:

- Vernier calipers and micrometers – Quick checks for accessible dimensions during patrol inspection

- 2.5D measuring machines – Video-based systems for precise planar dimensions and hole diameters

- Coordinate measuring machines (CMM) – Full 3D verification for critical dimensions and complex geometries

- Go/no-go gauges – Rapid functional checks during high-volume production

Surface Quality Assessment

Visual inspection remains fundamental, but standardizing the process improves consistency:

- Inspect under controlled lighting—Metal Infinity recommends a 45-degree viewing angle light box

- Use OK/NG standard samples for burr, crack, and scratch comparison

- Employ microscopes for examining surface defects invisible to the naked eye

- Document defects with photographs for root cause analysis

Statistical Process Control

The real power of quality metal stamping lies in using data to predict and prevent problems. According to Metal Infinity, through long-term data statistics, a part's Process Capability Index (CPK) can be established—if CPK falls below 1.33, it indicates unstable yield requiring process adjustments.

Effective SPC implementation includes:

- Recording dimensional data continuously during production

- Plotting control charts (X-bar/R charts) to identify trends before they exceed tolerances

- Setting action limits that trigger investigation before rejection limits are reached

- Feeding inspection data back to engineering for die design and process improvement

DR Solenoid emphasizes the importance of this feedback loop: when metal stamping parts encounter quality problems, conduct in-depth analysis of the causes, formulate practical solutions, and keep good process records. Feedback key issues to prevent the same problems from happening again.

Die Maintenance Protocols

Your tooling is a wasting asset—every stroke brings it closer to failure. Systematic maintenance extends die life while maintaining part quality:

- Establish mold life records tracking strokes and maintenance history

- Schedule regular inspection of wear parts (punches, guide sleeves, cutting edges)

- Apply coating technology such as TiAlN to improve wear resistance

- Store different material batches separately to prevent mixing

- Document all maintenance actions for trend analysis

The true value of inspection is not eliminating defective products, but improving processes and building trust through data.

Quality control in metal stamping isn't a single checkpoint—it's an integrated system spanning incoming material verification, in-process monitoring, finished part inspection, and continuous improvement feedback. Manufacturers who master this system transform quality from a cost center into a competitive advantage.

With defect troubleshooting and quality control strategies established, you might be wondering how stamping compares to alternative manufacturing methods—and when each approach makes the most sense for your specific requirements.

Metal Stamping Versus Alternative Manufacturing Methods

So you've mastered the stamping workflow, selected your materials, and understand quality control—but here's a question that deserves honest consideration: is stamping actually the right choice for your project? Sometimes the answer is yes. Sometimes it's not. Knowing when to use sheet metal stamping versus alternative processes can save you thousands of dollars and months of development time.

Think of manufacturing methods like tools in a workshop. A hammer excels at driving nails but fails miserably at cutting wood. Similarly, each metal forming process has ideal applications—and forcing the wrong method onto a project creates unnecessary cost, quality issues, or both. Let's compare stamping against the major alternatives so you can make informed decisions.

Stamping vs Machining Economics

CNC machining and stamping represent fundamentally different approaches to creating metal parts. Machining removes material from solid blocks; the metal pressing process reshapes sheet material without significant removal. This distinction drives major differences in cost structure and application suitability.

When does CNC machining make more sense?

- Low production volumes – According to Gizmospring's manufacturing guide, CNC machining is ideal for precision and smaller production runs where tooling investment cannot be justified.

- Complex 3D geometries – Parts requiring undercuts, internal features, or shapes impossible to form from flat sheet

- Tight tolerances on thick materials – Machining maintains accuracy across substantial material cross-sections

- Prototype development – No tooling lead time means parts within days, not weeks

When does stamping win?

- High-volume production – Once tooling costs are amortized, per-part costs drop dramatically

- Parts derived from sheet geometry – Brackets, enclosures, panels, and similar components

- Speed requirements – Hundreds or thousands of parts per hour versus minutes per part

- Material efficiency – Sheet metal stamping typically generates less waste than machining solid blocks

The crossover point varies by part complexity, but generally falls between 1,000 and 5,000 units. Below this range, machining's flexibility often outweighs stamping's tooling investment. Above it, stamping's per-part economics become compelling.

Laser Cutting: Flexibility Without Tooling

What if you could start production immediately without waiting weeks for tooling? Laser cutting delivers exactly that—digital files become cut parts within hours, with no dies to design, fabricate, or maintain.

According to Hotean's detailed comparison, laser cutting delivers 40% cost reduction versus stamping for batches under 3,000 units by eliminating $15,000+ tooling costs and achieving ±0.1mm precision compared to stamping's ±0.3mm tolerance.

Laser cutting advantages:

- Zero tooling investment – Start cutting immediately from CAD files

- Design flexibility – Changes cost nothing; just update the digital program

- Superior precision – ±0.1mm tolerance versus ±0.3mm typical for stamping

- Complex contours – Intricate shapes that would require expensive progressive dies

Hotean notes that a 500-unit HVAC bracket production run demonstrated remarkable results: laser-cut brackets achieved 100% assembly fitment without adjustment, while stamped brackets required manual modification on 65 units (13% failure rate).

When stamping still wins:

- Volume exceeding 3,000-5,000 units – Per-part processing costs favor stamping

- 3D forming requirements – Laser cutting produces flat parts only; a sheet metal press creates bends, draws, and forms

- Material thickness constraints – Laser cutting becomes slow and expensive above 6-10mm thickness

- Cycle time requirements – Stamping produces parts in fractions of seconds; laser cutting takes minutes per part

The key insight? Laser cutting and stamping aren't always competitors—they're often complementary. Many manufacturers use laser cutting for prototypes and low-volume runs, then transition to stamping tooling once designs are validated and volumes justify the investment.

When Alternative Processes Make Sense

Casting: Complex Shapes, Different Properties

Metal pressings and castings solve different problems. Casting pours molten metal into molds, creating parts with complex internal geometries, varying wall thicknesses, and shapes impossible to form from flat sheet.

Choose casting when:

- Parts require internal cavities or complex 3D shapes

- Wall thickness varies significantly across the component

- Material properties like damping or heat resistance matter more than strength-to-weight ratio

- Production volumes justify mold investment but don't require stamping speeds

However, casting typically delivers lower strength-to-weight ratios than stamped parts, requires more secondary finishing operations, and produces parts with less consistent dimensional accuracy. For structural sheet metal components, stamping generally delivers superior performance.

Forging: Superior Strength, Different Applications

When absolute strength matters most, forging creates parts with superior mechanical properties. The process compresses metal under extreme pressure, aligning grain structure and eliminating internal voids—producing components that outperform both stamped and machined alternatives in demanding applications.

According to Gizmospring, casting and forging provide durable solutions for heavy industries like automotive—but each serves distinct purposes. Forging excels for:

- Safety-critical components requiring maximum strength (crankshafts, connecting rods)

- Parts subjected to high cyclic stresses

- Applications where failure consequences are severe

The tradeoff? Forging costs more than stamping, requires different equipment and expertise, and produces parts with less precise dimensions that typically need secondary machining. For most sheet metal applications, stamping delivers adequate strength at lower cost.

Hybrid Manufacturing Approaches

Here's what experienced manufacturers understand: choosing between processes isn't always an either/or decision. Hybrid approaches often deliver the best results by combining process strengths.

Common hybrid strategies:

- Laser cutting + stamping – Laser-cut blanks fed into forming dies for bending and drawing operations

- Stamping + machining – Stamped base components with machined features where tolerances demand it

- Stamping + welding – Multiple stamped parts joined into assemblies larger or more complex than single-piece stamping allows

The sheet metal process you select should match your specific combination of volume, geometry, tolerance, and budget requirements—not force your design into a predetermined manufacturing approach.

Process Comparison: Making the Right Choice

| Factor | Stamping | CNC Machining | Laser Cutting | Casting | Forging |

|---|---|---|---|---|---|

| Ideal Volume | 5,000+ units | 1-500 units | 1-3,000 units | 500-50,000 units | 100-10,000 units |

| Tooling Investment | $10,000-$50,000+ | Minimal (fixtures) | None | $5,000-$30,000 | $10,000-$100,000+ |

| Lead Time (First Part) | 4-8 weeks | Days | Hours to days | 4-12 weeks | 6-16 weeks |

| Typical Tolerance | ±0.1-0.3mm | ±0.01-0.05mm | ±0.1mm | ±0.5-1.0mm | ±0.5-2.0mm |

| Per-Part Cost at Volume | Lowest | Highest | Moderate | Moderate | High |

| Part Geometry | Sheet-derived forms | Any 3D shape | Flat profiles only | Complex 3D shapes | Simple to moderate 3D |

| Design Changes | Expensive (new tooling) | Easy (reprogram) | Free (update file) | Expensive (new mold) | Very expensive |

| Best Applications | Brackets, panels, enclosures, terminals | Prototypes, complex parts, low volume | Prototypes, flat parts, varied designs | Housings, engine blocks, complex internals | Crankshafts, gears, high-stress components |

Key decision factors to consider:

- Production volume – Below 1,000 units, avoid stamping tooling investment. Above 10,000 units, stamping economics become compelling.

- Part geometry – If your design starts as sheet metal and requires bending, drawing, or forming, stamping is purpose-built for the task.

- Timeline urgency – Need parts in days? Laser cutting or machining. Can wait 4-8 weeks? Stamping tooling delivers long-term value.

- Design stability – Frequent changes favor flexible processes; stable designs justify tooling investment.

- Tolerance requirements – Critical dimensions below ±0.1mm may require machining or fine blanking rather than standard stamping.

The metal pressing process excels at what it's designed for: high-volume production of sheet-derived parts with consistent quality and cost efficiency at scale. But forcing stamping onto applications better suited for other methods wastes money and creates unnecessary quality challenges.

Understanding these tradeoffs positions you to make informed manufacturing decisions—and to work effectively with suppliers who can guide you toward the optimal approach for your specific requirements.

Selecting the Right Stamping Partner for Your Project

You've mastered the technical fundamentals—operations, materials, equipment, and quality control. But here's a truth that catches many engineers off guard: your stamping project's success depends as much on your manufacturing partner as it does on your design. Choosing the wrong supplier leads to missed deadlines, quality escapes, and costly redesigns. Choosing the right one? That transforms your project from stressful to seamless.

Whether you need custom metal stamping services for a new product launch or precision metal stamping for critical automotive components, the evaluation process follows predictable patterns. Let's walk through the criteria that separate exceptional metal stamping services from those that will leave you scrambling.

Evaluating Supplier Capabilities

Not all stamping partners are created equal. Before requesting quotes, you need to understand what capabilities actually matter for your specific requirements.

Certifications That Signal Quality Commitment

Industry certifications serve as shorthand for quality systems and process maturity. According to Die-Matic's manufacturer selection guide, ensuring suppliers have relevant certifications—ISO 9001 and IATF 16949 are good ones to start with—provides foundational assurance of quality control processes.

What do these certifications actually mean?

- ISO 9001 – Baseline quality management system requirements applicable across industries

- IATF 16949 – Automotive-specific quality standards required by major OEMs worldwide. If you're in automotive stamping, this certification isn't optional—it's essential.

- AS9100 – Aerospace quality management system requirements for suppliers serving aviation and defense markets

- ISO 14001 – Environmental management system certification, increasingly important for sustainability-conscious programs

Beyond certifications, Die-Matic emphasizes evaluating solid solutions for inspection and testing, consistency across large runs, and strong traceability systems. A metal stamping service without robust quality infrastructure will eventually deliver problems to your production line.

Engineering and Technical Capabilities

The best suppliers don't just run presses—they solve problems before production begins. Look for partners offering:

- CAE simulation – Computer-aided engineering that predicts forming issues, springback, and material flow before cutting steel. This capability prevents costly tooling revisions.

- Rapid prototyping – According to StampingSimulation, simulation at the prototype stage can be pushed forward to the mass manufacturing process, saving even more time further down the project timeline.

- Design for manufacturability (DFM) review – Experienced engineers who can optimize your design for stamping efficiency

- In-house tooling capabilities – Control over die design, fabrication, and maintenance

For automotive metal stamping projects requiring both speed and precision, suppliers like Shaoyi demonstrate how these capabilities combine—offering IATF 16949 certification alongside advanced CAE simulation, rapid prototyping in as little as 5 days, and high volume metal stamping with a 93% first-pass approval rate.

Production Flexibility and Capacity

Your volume requirements today may differ dramatically from tomorrow's needs. Die-Matic's guide emphasizes that if you plan on needing fewer or more parts at any point in the future, you'll want a metal stamping partner who is flexible enough to adapt accordingly.

Evaluate potential suppliers on:

- Range of press tonnages available (small precision work through heavy forming)

- Ability to scale from prototype quantities to high-volume production

- Secondary operation capabilities (welding, plating, assembly) that reduce supply chain complexity

- Geographic footprint—local manufacturers or those with strategically placed facilities provide quicker turnaround and reduced shipping costs

Design Optimization for Stamping Success

Even the best supplier can't overcome fundamentally problematic designs. Applying design for manufacturability (DFM) principles early saves money, improves quality, and accelerates your timeline.

According to Die-Matic's DFM guide, 70 percent of product cost is determined during the development phase—but engineering changes during manufacturing can inflate costs and severely impact profitability. It's far more cost-effective to design holistically from the start.

Critical DFM Guidelines for Stamped Parts

| Feature | DFM Recommendation | Why It Matters |

|---|---|---|

| Hole diameter | ≥ material thickness | Prevents punch breakage and ensures clean cuts |

| Hole-to-hole spacing | ≥ 2× material thickness | Prevents material bulging between features |

| Hole-to-edge distance | ≥ 2× material thickness | Maintains structural integrity |

| Hole near bend | ≥ 1.5× thickness + bend radius | Prevents distortion during forming |

| Minimum flange width | ≥ 2.5× material thickness | Ensures proper forming without cracking |

| Inside bend radius | ≥ material thickness | Prevents cracking at bend lines |

| Bend height | ≥ 2.5× thickness + bend radius | Allows tooling engagement for accurate forming |

| Corner radius (blanks) | ≥ 0.5× material thickness | Reduces stress concentration and die wear |

| Emboss depth | ≤ 3× material thickness | Prevents thinning and fracturing |

Die-Matic notes that engineers will look at part complexity and tolerances to ensure their equipment can stamp the part efficiently and remove secondary operations when possible. Working closely with your custom metal stamping partner during the design phase ensures you receive finished parts that cost-effectively meet expectations.

From Prototype to Production Scale

The journey from concept to high-volume manufacturing involves critical handoffs where problems often emerge. Structuring this progression deliberately prevents costly surprises.

Prototyping Phase

According to StampingSimulation, sheet metal prototyping remains necessary for every manufacturing project because the formed sheet metal product must come from actual sheet material—it can't be 3D printed. All the same challenges of metal forming are present at the proto part stage.

This is precisely why simulation matters so much. StampingSimulation emphasizes that simulation is far more efficient—both in cost and time—than trial and error methods. Simulating the forming process prior to proto part making prevents splits, wrinkles, and severe springback from derailing your timeline.

Look for suppliers offering:

- Rapid prototype turnaround (days, not weeks)

- Simulation-validated designs before physical tryouts

- Collaborative feedback on design optimization

Supplier Qualification Checklist

Before committing to a custom metal stamping services partner, verify these critical factors:

- Quality history – Request measurables and defect rates from current customers

- Financial stability – How many years in business? What's management tenure and turnover?

- Customer relationships – How long have existing customers partnered with them?

- Communication responsiveness – Die-Matic emphasizes that ease of communication is essential—you want a partner who is responsive, accessible, and easy to collaborate with

- Engineering support depth – Can they optimize designs, resolve issues quickly, and keep projects on schedule?

Red Flags to Avoid

Die-Matic's manufacturer selection guide identifies warning signs including:

- Inconsistent quality or lack of documented quality systems

- Poor communication or unresponsive contacts

- Inability to provide customer references or quality metrics

- Lack of relevant industry certifications

- No engineering support or DFM capabilities

Selecting the right manufacturing partner isn't just about price or capability—it's about long-term partnership and strategic alignment. A bad fit leads to delays, costly rework, and product failures. The right partner ensures quality, innovative solutions, and dependable service every time.

The precision metal stamping industry offers countless supplier options—but the evaluation process outlined here helps you identify partners capable of supporting both immediate project goals and long-term manufacturing success. Take time to assess capabilities thoroughly, optimize designs for manufacturability, and build relationships with suppliers who demonstrate technical excellence and responsive collaboration. Your stamping projects will run smoother, cost less, and deliver the quality your customers expect.

Frequently Asked Questions About Manufacturing Process Stamping

1. What is the process of stamping in manufacturing?

Metal stamping is a manufacturing process that converts flat sheet metal into precisely shaped components using controlled force and specialized tooling. A stamping press drives a hardened die into sheet metal to perform operations like blanking, punching, bending, drawing, embossing, flanging, and coining. The process involves seven key steps: material selection and preparation, die design and engineering, press setup and calibration, feeding and positioning, the stamping stroke, part ejection and handling, and quality inspection. This method dominates high-volume production across automotive, aerospace, electronics, and appliance industries due to its speed, consistency, and cost efficiency at scale.

2. What are the 7 steps in the stamping method?

The seven steps in the metal stamping method include: (1) Material Selection and Preparation - evaluating mechanical properties and preparing coils through cutting, leveling, and cleaning; (2) Die Design and Engineering - creating strip layouts, calculating forces, and running CAE simulations; (3) Press Setup and Calibration - matching die to press, setting shut height, and programming stroke parameters; (4) Feeding and Positioning - automated delivery of material with precision alignment using servo feeders and pilot pins; (5) The Stamping Stroke - the press cycle where cutting, forming, or drawing operations occur; (6) Part Ejection and Handling - removal of finished parts using stripper plates and ejectors; (7) Quality Inspection - dimensional measurement, surface assessment, and statistical process control verification.

3. What process does stamping fall under?

Stamping falls under sheet-metal forming manufacturing processes. Also known as pressing, it involves placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into new shapes. The process encompasses multiple metal forming techniques including blanking, punching, bending, piercing, embossing, coining, and drawing. Stamping is classified as a cold forming process since it typically occurs at room temperature, distinguishing it from hot forming methods like forging. It belongs to the broader category of metal fabrication alongside processes like machining, casting, and welding.

4. What is the difference between progressive, transfer, and compound die stamping?

Progressive die stamping uses a continuous metal strip that moves through multiple stations within one die, with each station performing different operations simultaneously - ideal for high-volume production of small to medium-sized complex parts. Transfer die stamping separates the workpiece early and uses mechanical fingers to move individual parts between stations, making it suitable for larger components and deep drawing operations. Compound die stamping performs multiple cutting operations in a single stroke, producing flat parts like washers with exceptional flatness at lower tooling costs than progressive dies. The choice depends on part size, complexity, production volume, and whether forming operations beyond cutting are required.

5. How do you select the right material for metal stamping?

Material selection for metal stamping depends on balancing formability, strength, corrosion resistance, and cost. Carbon and galvanized steel offer cost-effective solutions for structural parts with tensile strengths exceeding 375 MPa. Stainless steel (304, 409, 430 grades) provides corrosion resistance but requires careful attention to work hardening during forming. Aluminum delivers lightweight benefits but exhibits more springback and surface sensitivity. Copper and brass excel in electrical applications due to high conductivity. Key properties to evaluate include ductility (stretch before cracking), yield strength, work hardening rate, and surface finish requirements. Your application requirements - whether weight-critical, corrosion-resistant, or cost-sensitive - ultimately guide the optimal choice.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —