Een technische gids voor heatsinkontwerp voor spuitgieten

TL;DR

Spuitgieten is een productieproces dat warmteafvoeren creëert door gesmolten metaal, meestal aluminium- of zinklegeringen, onder hoge druk in een herbruikbare stalen mal te persen. Deze methode is uitstekend geschikt voor het vervaardigen van complexe, driedimensionale warmteafvoeren met geïntegreerde lamellen, waardoor het oppervlak wordt gemaximaliseerd voor efficiënte warmteafvoer. Het proces is zeer kosteneffectief voor massaproductie, wat het tot een populaire keuze maakt voor elektronica-, automotive- en industriële toepassingen waar betrouwbare thermische beheersing cruciaal is.

Inzicht in het spuitgietproces voor warmteafvoeren

In wezen houdt het spuitgietproces voor koellichamen het injecteren van gesmolten metaal in een gehard stalen matrijs, of vorm, onder hoge druk in. Deze techniek maakt het mogelijk om snel onderdelen te produceren met ingewikkelde details en nauwkeurige afmetingen. Zodra het metaal is geïnjecteerd, koelt het snel af en verhardt, waarna de matrijs wordt geopend en het gevormde onderdeel wordt uitgeworpen. Deze cyclus kan zeer snel worden herhaald, waardoor spuitgieten een ideale oplossing is voor massaproductie.

Een belangrijk voordeel van deze methode is dat er massieve koellichamen in één geheel worden gemaakt. In tegenstelling tot andere productietechnieken, waarbij vinnen mogelijk aan een basisplaat worden gelijmd of bevestigd, worden bij spuitgieten de vinnen als een integraal onderdeel van het component gevormd. Zoals beschreven in een technisch rapport van Advanced Thermal Solutions, Inc. , hierdoor wordt de thermische weerstand geëlimineerd die optreedt aan de interface tussen een basis en zijn vinnen, wat leidt tot efficiëntere warmteoverdracht van het elektronische component naar de omringende lucht. Het proces is in staat complexe vormen te produceren die moeilijk of onmogelijk te realiseren zijn via extrusie of machinale bewerking.

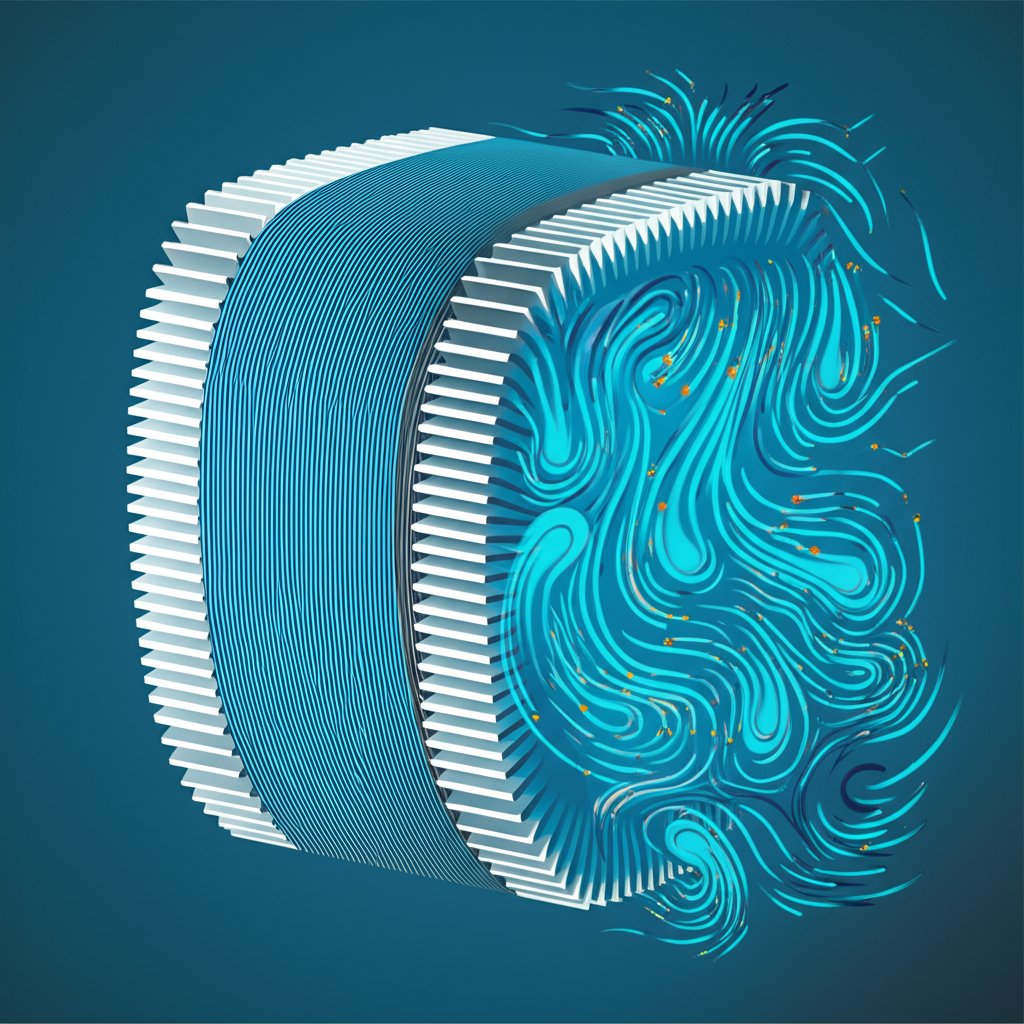

Deze mogelijkheid is cruciaal om aan de primaire eis van elke heat sink te voldoen: het maximaliseren van het oppervlak om warmte effectief af te voeren. Hoe groter het oppervlak van een heat sink, hoe efficiënter deze thermische energie kan overdragen naar de koelere omgeving. Spuitgieten stelt ingenieurs in staat om vinnen en pennen te ontwerpen in complexe rijen en vormen die de luchtvloei en thermische prestaties optimaliseren voor specifieke toepassingen.

De veelzijdigheid van spuitgieten maakt het geschikt voor een breed scala aan toepassingen. Het wordt bijvoorbeeld vaak gebruikt om kooplossingen te creëren voor LED-verlichting, waarbij heatsinks vaak direct in de behuizing van de armatuur worden geïntegreerd. Het komt ook veel voor in auto-elektronica, communicatieapparatuur en industriële voedingen, waar betrouwbaarheid en prestaties van groot belang zijn. De mogelijkheid om dimensionaal stabiele en corrosiebestendige onderdelen te produceren, draagt bij aan de aantrekkelijkheid ervan binnen deze sectoren.

Kernmaterialen vergeleken: Aluminium, Zink, Koper en Magnesium

De keuze van materiaal is een cruciale factor bij het ontwerp van een spuitgiet-heatpipe, omdat dit direct invloed heeft op thermische prestaties, gewicht en kosten. De meest gebruikte materialen zijn legeringen van aluminium, zink, magnesium en koper, waarbij elk materiaal een unieke set eigenschappen biedt die geschikt is voor verschillende toepassingen.

Aluminiumlegeringen, zoals A380 en ADC12, zijn de meest populaire keuze vanwege hun uitstekende balans tussen warmtegeleidingsvermogen, lage dichtheid en corrosieweerstand. Ze zijn lichtgewichtig en kosteneffectief, waardoor ze ideaal zijn voor de meeste toepassingen, van consumentenelektronica tot industriële apparatuur. Zink is een andere veelgebruikte optie, die gemakkelijker te gieten is en lagere gereedschapskosten heeft dan aluminium. Echter, zoals MyHeatSinks uitlegt, is zink aanzienlijk zwaarder dan aluminium, wat in gewichtsgevoelige toepassingen zoals draagbare apparaten een uitsluitende factor kan zijn.

Voor toepassingen waarbij gewicht de belangrijkste overweging is, biedt magnesium een overtuigend alternatief. Een technisch document van Chicago White Metal Casting benadrukt dat magnesium 35% lichter is dan aluminium. Hoewel de warmtegeleidingscoëfficiënt lager is, stelt de lage dichtheid ontwerpers in staat om constructies met langere vinnen te maken die vergelijkbare of zelfs betere thermische prestaties kunnen behalen, terwijl het gewichtsvoordeel behouden blijft. Dit maakt het bijzonder aantrekkelijk voor de lucht- en ruimtevaart en high-performance draagbare elektronica. Koper biedt de hoogste warmtegeleidingscoëfficiënt, maar is zwaarder en duurder, en wordt meestal voorbehouden voor toepassingen waarbij maximale warmteafvoer in een beperkte ruimte vereist is.

Om de afwegingen beter te illustreren, vergelijkt de volgende tabel belangrijke eigenschappen van gangbare spuitgietlegeringen:

| Materiaal | Thermische geleidbaarheid (BTU/ft hr °F) | Dichtheid (lb/in³) |

|---|---|---|

| Aluminium 380 | 55.6 | 0.099 |

| Aluminium 360 | 65.3 | 0.095 |

| Magnesium AZ91D | 41.8 | 0.066 |

| Zink nr. 3 | 65.3 | 0.24 |

Gegevens afkomstig van Chicago White Metal Casting.

Voordelen en nadelen van elk materiaal

- Aluminium: Biedt een uitstekend algemeen evenwicht tussen prestaties, gewicht en kosten. Het is de standaardkeuze voor de meeste algemene koellichamen.

- Zink: Het beste voor toepassingen met groot volume en lage kosten waar gewicht geen probleem is. Het geeft een hoogwaardig gevoel en is gemakkelijk te plateren of afwerken.

- Magnesium: De onbetwiste keuze voor lichtgewichttoepassingen. Hiermee kunnen ontwerpen worden gerealiseerd die beter presteren dan aluminium in situaties waar het gewicht kritiek is.

- Koper: Biedt de beste thermische prestaties, maar tegen hogere kosten en meer gewicht. Het wordt gebruikt wanneer andere materialen niet voldoen aan de koelvereisten.

Belangrijke ontwerpprincipes voor gegoten heatsinks

Een effectief heatsinkontwerp voor spuitgieten draait om één hoofddoel: het maximaliseren van warmteafvoer op een kostenefficiënte manier. Dit wordt bereikt door zorgvuldig rekening te houden met verschillende kernprincipes, waaronder vin geometrie, oppervlakte, luchtvloeibesturing en de integratie van bevestigingsmogelijkheden. De flexibiliteit van spuitgieten stelt ingenieurs in staat om zeer geoptimaliseerde en complexe geometrieën te creëren die met andere methoden, zoals extrusie, niet haalbaar zijn.

De belangrijkste drijfveer achter prestaties is het oppervlak. Zo wordt opgemerkt door experts uit de industrie bij Zetwerk , is de vormgeving van lamellen — hun vorm, hoogte, dikte en onderlinge afstand — cruciaal om het effectieve oppervlak voor warmteoverdracht te vergroten. Hogere, dunnere lamellen leveren over het algemeen meer oppervlak, maar daar staat een afweging tegenover. Lamellen die te dicht op elkaar staan, kunnen de luchtstroom belemmeren, met name bij natuurlijke convectie, waardoor de algehele efficiëntie afneemt. De optimale vormgeving brengt een balans tussen oppervlak en voldoende afstand tussen de lamellen om vrije luchtcirculatie mogelijk te maken.

Luchtstroom is een andere cruciale overweging. De oriëntatie van de koellichaam en zijn lamellen moet afgestemd zijn op het pad van natuurlijke of geforceerde luchtstroom binnen het apparaat. Spuitgieten maakt het mogelijk unieke vormen van lamellen te creëren, zoals speldragers met vleugelprofiel, die de luchtweerstand kunnen verlagen en turbulentie kunnen verhogen, waardoor de thermische prestaties verder worden verbeterd. De mogelijkheid om het koellichaam direct in de behuizing of kast van een product te integreren, vereenvoudigt ook het thermische pad en kan de noodzaak van extra componenten en assemblagestappen elimineren.

Hoewel spuitgieten uitstekend is voor het creëren van complexe componenten voor thermische beheersing, zijn er vaak andere productieprocessen nodig voor verschillende onderdelen binnen dezelfde assemblage, met name in veeleisende industrieën zoals de automobielindustrie. Bijvoorbeeld, structurele componenten die cruciaal zijn en extreme duurzaamheid en sterkte vereisen, zijn vaak afhankelijk van processen zoals smeden. Specialisten in autodelen voor smeden gebruiken geavanceerde warmtesmeettechnieken om robuuste componenten te produceren waar de materiaaleigenschappen van spuitgietlegeringen niet geschikt zouden zijn, wat aantoont hoe verschillende productiemethoden elkaar aanvullen in complexe technische systemen.

Ontwerpkavelijst voor optimale prestaties

- Maximaliseer oppervlakte: Gebruik complexe vin- en pinstructuren om het beschikbare oppervlak voor warmteafvoer te vergroten.

- Optimaliseer vinafstand: Zorg voor voldoende ruimte tussen de vinnen om een adequate luchtstroom toe te staan, zowel bij natuurlijke als geforceerde convectie.

- Houd rekening met de luchtstroomroute: Richt de lamellen in de richting van de luchtstroom om de weerstand te minimaliseren en de koelingsprestaties te maximaliseren.

- Integreer montagevoorzieningen: Gebruik het spuitgietproces om montagepunten, gaten en andere kenmerken direct in de koellichaam te integreren om montagesnelheid te verlagen en het thermische contact te verbeteren.

- Kies de juiste materiaaldikte: De dikte van de basis en lamellen van het koellichaam beïnvloedt de capaciteit om warmte te verdelen en af te voeren. Weeg de thermische behoeften af tegen gewichts- en kostenbeperkingen.

Voordelen en geavanceerde spuitgiettechnieken

Spuitgieten biedt tal van voordelen waardoor het een aantrekkelijke keuze is voor de productie van koellichamen, met name voor middelgrote tot grote oplagen. Een van de belangrijkste voordelen is de mogelijkheid om complexe 3D-vormen te produceren die met andere methoden prohibitief duur of onmogelijk zouden zijn. Dit maakt het mogelijk om meerdere functies in één onderdeel te integreren; bijvoorbeeld kan een koellichaam worden gecombineerd met de behuizing, het frame of het omhulsel van een apparaat. Deze integratie vermindert niet alleen het aantal onderdelen en de assemblagekosten, maar verbetert ook de thermische prestaties door een directe warmteoverdrachtspad te creëren.

De voordelen van spuitgegoten koellichamen gaan verder dan geometrische complexiteit. Het proces levert onderdelen op met nauwe toleranties, uitstekende dimensionale stabiliteit en gladde oppervlakken die vaak geen nabewerking vereisen. Deze "near-net-shape"-productie minimaliseert materiaalverspilling en productietijd. Aanvullende voordelen zijn:

- Kosteneffectiviteit bij grootschalige productie: Hoewel de initiële gereedschapskosten hoog kunnen zijn, is de lage stukprijs economisch aantrekkelijk voor grote productiehoeveelheden.

- Geïntegreerde functies: Gaten, schroefdraden en bevestigingselementen kunnen rechtstreeks in het onderdeel worden gevormd of gegoten.

- Corrosiebestendigheid: Aluminium- en zinklegeringen bieden een goede tot hoge weerstand tegen corrosie.

- EMI/RFI-scherming: De metalen aard van de onderdelen zorgt voor inherente afscherming tegen elektromagnetische en radiofrequentie-interferentie.

Naast standaard spuitgieten zetten geavanceerde technieken de grenzen van thermische prestaties verder. Een van de meest opvallende is High Density Die Casting (HDDC) . Zoals beschreven in onderzoek dat werd benadrukt door Advanced Thermal Solutions, Inc., omvat het HDDC-proces een extra stap met druktoename terwijl het metaal zich in vloeibare toestand bevindt. Dit maakt het mogelijk om legeringen met hogere thermische geleidbaarheid te gebruiken, zoals walsaluminium (bijvoorbeeld AL 6063).

HDDC produceert koellichamen die aanzienlijk minder poreus zijn en een hogere mechanische weerstand hebben. Dit geavanceerde proces maakt het mogelijk om dunner vinnen te gieten met een hogere aspectverhouding en kleinere tussentruimtes, wat de warmteafvoer verder verbetert. De poreloze structuur maakt ook afwerkingsprocessen zoals anodiseren mogelijk, wat niet altijd haalbaar is bij standaard spuitgietonderdelen. Voor toepassingen die de allerbeste prestaties vereisen, vormt HDDC een belangrijke stap voorwaarts in thermische beheerstechnologie.

Thermisch beheer optimaliseren met spuitgieten

Kortom, spuitgieten onderscheidt zich als een zeer effectief en veelzijdig productieproces voor het vervaardigen van koellichamen. De mogelijkheid om complexe, integrale ontwerpen te creëren, stelt ingenieurs in staat de thermische prestaties te optimaliseren door het oppervlak te maximaliseren, terwijl tegelijkertijd rekening wordt gehouden met factoren zoals luchtdoorstroming en gewicht. De keuze van het materiaal—van goed uitgebalanceerd aluminium tot lichtgewicht magnesium of hooggeleidend koper—biedt verdere flexibiliteit om specifieke toepassingsvereisten te kunnen vervullen.

De belangrijkste voordelen, waaronder kosten-effectiviteit bij grootschalige productie, integratie van functies en uitstekende dimensionele nauwkeurigheid, maken het tot een superieure keuze voor productie in grote oplagen in sectoren variërend van LED-verlichting tot automotive-elektronica. Bovendien zorgt de opkomst van geavanceerde technieken zoals High Density Die Casting (HDDC) ervoor dat de mogelijkheden van deze technologie voortdurend worden uitgebreid, waardoor nog efficiëntere en robuustere thermische oplossingen kunnen worden gerealiseerd. Door de basisprincipes van ontwerp en materiaalkeuze te begrijpen, kunnen ingenieurs gebruikmaken van spuitgieten om zeer effectieve koelsystemen te ontwikkelen die de betrouwbaarheid en levensduur van producten waarborgen.

Veelgestelde Vragen

1. Wat is het beste ontwerp voor een heatsink?

Het meest effectieve koellichaamontwerp is een ontwerp dat het oppervlak maximaliseert om warmteoverdracht naar de omgeving te vergemakkelijken. Dit wordt doorgaans bereikt door gebruik van lamellen of pinnen. De ideale geometrie hangt af van de toepassing, inclusief de hoeveelheid warmte die moet worden afgevoerd en de aard van de luchtstroom (natuurlijke of gedwongen convectie). De keuze van materiaal is eveneens kritiek; materialen met hoge thermische geleidbaarheid, zoals koper of aluminium, zijn essentieel voor een efficiënte warmteoverdracht van de warmtebron naar de lamellen.

2. Hoe berekent u de vereiste koellichaamgrootte?

Het berekenen van de benodigde koellichaam komt neer op het bepalen van de thermische weerstand die nodig is om een component onder zijn maximale bedrijfstemperatuur te houden. De berekening begint met het maximale door het apparaat gedissipeerde vermogen, de maximale omgevingstemperatuur en de maximale junctietemperatuur van de component. Vanuit deze waarden kunt u de maximaal toegestane thermische weerstand voor het gehele systeem berekenen (junction-naar-omgeving). Door de bekende thermische weerstanden van de component en het thermische interfacemateriaal af te trekken, kunt u de vereiste thermische weerstand van het koellichaam zelf bepalen.

3. Wat zijn de eisen voor een koellichaam?

De primaire eis voor een koellichaam is om warmte effectief af te voeren vanaf een elektronisch component. Om dit te bereiken, moet het zijn vervaardigd uit een materiaal met hoge thermische geleidbaarheid om warmte efficiënt van de bron af te voeren. Het moet ook een groot oppervlak hebben, gecreëerd door lamellen of andere structuren, om die warmte over te dragen aan de omringende lucht. Ten slotte moet het ontwerp geschikt zijn voor de beschikbare luchtstroom, of dit nu natuurlijke convectie is of gedwongen luchtstroom van een ventilator, om ervoor te zorgen dat de warmte wordt afgevoerd van het apparaat.

Kleine series, hoge eisen. Onze snelprototyperingservice maakt validatie sneller en eenvoudiger —

Kleine series, hoge eisen. Onze snelprototyperingservice maakt validatie sneller en eenvoudiger —