Die Stamped Products Decoded: From Raw Metal To Precision Parts

What Are Die Stamped Products and How Are They Made

Ever wondered how manufacturers produce thousands of identical metal parts with remarkable precision? The answer lies in die stamping—a cold forming technique that transforms flat metal sheets into complex, functional components you encounter daily. Die stamped products range from the tiny connectors inside your smartphone to the large body panels on your car, all created through the same fundamental process.

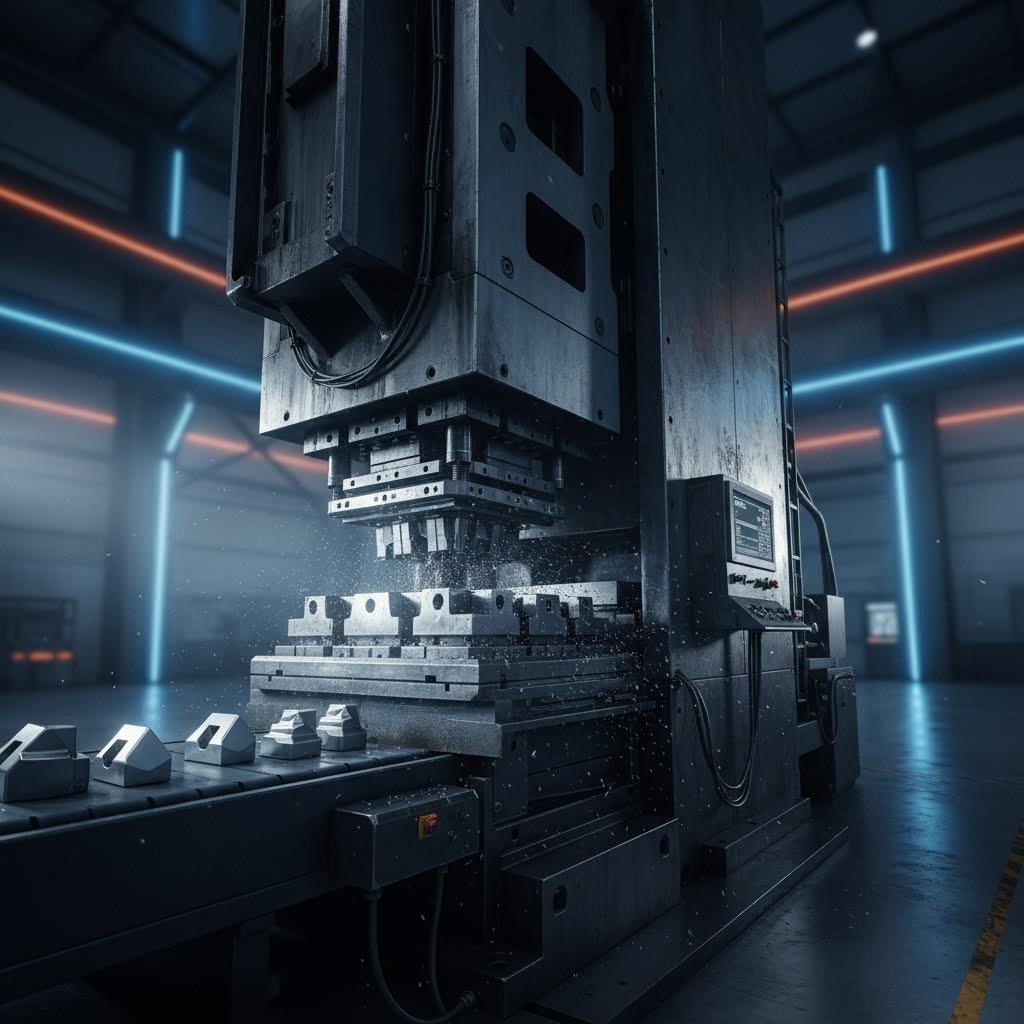

At its core, die stamping involves placing a metal sheet (often called a blank) between specialized tools known as dies. When a press applies force, these dies cut, bend, or shape the metal into a specific design or profile. The beauty of this process? It can produce parts of virtually any size—from components measuring fractions of a millimeter to industrial-scale pieces—all with exceptional consistency.

The Basic Mechanics of Die Stamping

Imagine a cookie cutter pressing through dough. Die stamping works on a similar principle, but with metal and significantly more force. The process uses a stamping press equipped with two essential components: a punch (the upper tool) and a die (the lower tool). When the press activates, the punch descends and forces the metal sheet against or through the die, permanently altering its shape.

What makes this technique particularly valuable is its reliance on plastic deformation. Unlike cutting with a saw or drilling holes individually, die stamping applies controlled force that causes the metal to flow and reshape without fracturing. This cold forming approach—performed at room temperature—preserves the metal's structural integrity while creating precise geometries impossible to achieve through other methods.

The dies themselves are specialized tools crafted from hardened steel, engineered to create everything from simple, everyday items to intricate electronic components. Some dies perform a single operation, while others execute multiple functions in sequence, dramatically increasing production efficiency.

How Dies Transform Raw Metal Into Precision Parts

The transformation from flat metal sheet to finished component happens through several distinct operations. Each operation applies force in specific ways to achieve different results. Understanding these core processes helps you appreciate how manufacturers select the right approach for each application:

- Blanking: Cuts out a flat shape from the metal sheet, creating a discrete part (the blank) that becomes the finished product or undergoes further processing.

- Piercing: Punches holes or specific internal features into the workpiece—the opposite of blanking, where the punched-out section becomes scrap while the parent material is retained.

- Bending: Deforms the metal along a straight axis to create L, U, or V profiles, forming brackets, enclosures, and structural components without cutting the material.

- Forming: Reshapes sheet metal into three-dimensional features without cutting, adding decorative trim, stiffened panels, or reinforced areas to parts.

- Drawing: Pulls metal into deeper, three-dimensional shapes—think kitchen sinks, automotive body panels, or electronic housings—while maintaining nearly the same surface area.

These operations can be performed individually or combined in sophisticated sequences. For instance, a single progressive die might blank a shape, pierce mounting holes, bend flanges, and form stiffening ribs—all in rapid succession as the metal strip advances through the press. This capability to integrate multiple operations explains why die stamping products dominate industries requiring high-volume, precision metal components.

Materials Used in Die Stamped Products

Now that you understand how dies transform flat sheets into precision components, a critical question emerges: which metal should you choose? Material selection isn't simply about picking what's available—it directly impacts your part's durability, manufacturability, and total project cost. The wrong choice can lead to cracked components, production delays, or budget overruns. The right choice? A stamped part that performs flawlessly for years.

Sheet metal stamping works with an impressive range of metals and alloys, each offering unique properties suited to specific applications. Whether you're designing electrical connectors requiring excellent conductivity or automotive brackets demanding high strength, understanding material characteristics helps you make informed decisions before tooling ever begins.

Common Metals for Die Stamped Components

The metals used in stamping dies products fall into several major categories, each serving distinct industrial needs. Here's what you'll encounter most frequently:

Carbon Steel remains the workhorse of metal stamping. It's strong, affordable, and easy to form—making it ideal for structural components, machinery parts, and high-volume applications where cost-effectiveness matters. Mild carbon steel offers excellent formability and weldability, while high-carbon grades (spring steels) deliver the resilience needed for clips, fasteners, and stress-bearing components. For corrosion protection, galvanized versions provide zinc coatings that extend service life in construction and automotive applications.

Stainless Steel steps in when durability and corrosion resistance become priorities. According to Verdugo Tool & Engineering, common grades include 304L for food processing and medical devices, 316 with molybdenum for marine or chemical environments, and 301 for springs and clips requiring high strength with good ductility. The chromium content creates a self-healing protective layer that outperforms carbon steels in harsh conditions.

Aluminum delivers lightweight strength—perfect when weight reduction matters without sacrificing structural integrity. Grade 6061 offers excellent corrosion resistance and weldability for structural applications. Grade 2024 provides superior strength-to-weight ratios favored in aerospace components. And 5052-H32 combines formability with corrosion resistance for marine and automotive manufacturing. However, aluminum can resist forming and drawing, requiring careful engineering for manufacturability.

Copper and Copper Alloys excel wherever electrical or thermal conductivity takes priority. Pure copper, brass (copper-zinc), and bronze (copper-tin) each serve specific roles in electronics, electrical connectors, and HVAC systems. Beryllium copper combines high conductivity with exceptional strength, making it ideal for precision instruments and connectors that must endure heavy loads. Phosphor bronze offers outstanding fatigue and wear resistance for demanding applications.

Specialty Alloys handle the most extreme environments. Inconel withstands incredibly high temperatures in aerospace and chemical processing. Titanium offers strength at 55% of steel's density for aerospace and marine applications. Hastelloy resists corrosion in aggressive chemical environments. These materials cost more and can be challenging to stamp, but they're irreplaceable when standard metals simply won't survive.

Matching Material Properties to Application Requirements

Choosing the best stamping die products starts with understanding how specific material properties translate into real-world performance. Consider these critical factors:

Tensile Strength and Hardness determine whether your part can withstand applied forces without breaking. Structural brackets need high-strength steel. Flexible electrical contacts might require softer copper alloys. Match the material's strength rating to your application's mechanical stresses.

Ductility and Formability affect how easily metal can be shaped without cracking. Highly ductile materials like copper and aluminum bend and stretch into intricate forms. Less ductile metals may limit design complexity or require specialized tooling approaches.

Thickness Tolerance becomes crucial in precision applications. Consistent material thickness ensures dimensional accuracy across thousands of stamped parts. Inconsistent stock creates quality control nightmares.

Conductivity matters for electrical and thermal applications. Copper and aluminum conduct electricity and heat efficiently. When you need insulation or heat resistance, lower-conductivity options become preferable.

Corrosion Resistance extends part life in harsh environments. Stainless steel, aluminum, and certain copper alloys naturally resist degradation. Carbon steel typically requires protective coatings for outdoor or chemical exposure.

| Material | Key Properties | Best Applications | Relative Cost Range |

|---|---|---|---|

| Carbon Steel | High strength, excellent formability, magnetic | Structural components, machinery parts, brackets | Low |

| Stainless Steel | Corrosion resistant, durable, attractive finish | Medical devices, food processing, marine applications | Medium-High |

| Aluminum | Lightweight, corrosion resistant, high strength-to-weight | Aerospace, automotive, electronics housings | Medium |

| Copper/Brass | Excellent conductivity, antimicrobial, decorative appeal | Electrical connectors, HVAC, decorative hardware | Medium-High |

| Beryllium Copper | High conductivity with strength, fatigue resistant | Precision instruments, springs, aircraft parts | High |

| Titanium | Extremely strong, lightweight, corrosion proof | Aerospace, marine, chemical processing | Very High |

When evaluating customized stamping die products for your project, remember that material cost represents just one piece of the puzzle. A cheaper metal requiring extensive post-processing or one that fails prematurely in service ultimately costs more than selecting the right material from the start. The best approach involves balancing performance requirements, manufacturing compatibility, and total lifecycle cost to identify your optimal choice.

With material selection clarified, the next logical question becomes: what type of die stamping process best suits your production needs? The answer depends largely on volume requirements, part complexity, and how you've chosen to balance upfront tooling investment against per-piece costs.

Types of Die Stamping Processes Explained

You've selected your material. Now comes another pivotal decision: which stamping process will bring your design to life most effectively? The answer isn't one-size-fits-all. Production run requirements, part complexity, and budget constraints all influence whether you should invest in progressive, compound, or transfer die stamping. Each method offers distinct advantages—and understanding these differences can save you thousands in tooling costs while optimizing your manufacturing timeline.

Think of it this way: choosing the wrong die type is like using a sledgehammer to hang a picture frame. It might work, but you'll waste resources and potentially damage your results. Let's break down each approach so you can match the right process to your specific production needs.

Progressive Die Stamping for High-Volume Efficiency

When your project demands thousands—or millions—of identical parts, progressive die and stamping production becomes your most powerful ally. This method operates through a series of sequential stations, each performing a specific operation as a continuous metal strip advances through the press. The workpiece stays attached to the strip from start to finish, only separating as a completed part in the final step.

Imagine an assembly line compressed into a single die. With each press stroke, multiple operations happen simultaneously across different sections of the strip: blanking here, piercing there, bending at the next station. This parallel processing dramatically increases output speed while maintaining tight tolerances throughout the run.

According to Keats Manufacturing, progressive die stamping can produce parts with exacting tolerances in large volumes while performing multiple operations simultaneously. The efficiency gains are substantial—reduced labor costs, minimal setup time, and less material waste compared to single-operation approaches.

- Key Advantages: High-speed production, simultaneous multi-operation capability, reduced per-part labor costs, excellent repeatability, minimal material waste through optimized strip layouts

- Ideal Use Cases: Small to medium-sized components requiring multiple operations, electronic connectors, automotive brackets, appliance hardware, high-volume production runs exceeding 10,000 parts

- Considerations: Higher upfront tooling investment, not suitable for deep-drawn parts, requires precision strip feeding equipment

The trade-off? Progressive dies demand significant upfront investment in design and tooling. Complex multi-station dies require meticulous engineering and hardened tool components to withstand high-volume runs. However, as Stamping Simulation notes, tooling costs per part decrease significantly with larger production volumes—making progressive stamping increasingly cost-effective as quantities rise.

Choosing the Right Die Type for Your Production Needs

Not every project justifies progressive die tooling. Sometimes simpler solutions deliver better value. Let's examine two alternatives that excel in different scenarios:

Compound Die Stamping performs multiple operations—cutting, punching, forming—in a single press stroke. Unlike progressive dies, compound dies complete all operations simultaneously rather than sequentially. This approach works beautifully for flat parts like washers, gaskets, and simple brackets where you need high repeatability without complex geometries.

- Key Advantages: Lower tooling costs than progressive dies, efficient production of flat and simple parts, produces exceptionally flat components, high repeatability for single-die applications

- Ideal Use Cases: Washers, blanks, simple shaped flat parts, medium to high volume runs of uncomplicated designs, wheel blanks

- Considerations: Limited to relatively simple part geometries, larger components may slow production speed, not suitable for parts requiring sequential forming operations

Transfer Die Stamping takes a fundamentally different approach. Instead of keeping the workpiece attached to a strip, transfer dies separate the blank immediately and use automated mechanical fingers to move individual parts between stations. This freedom allows manufacturers to handle larger components and more intricate geometries—including deep-drawn features, threading, ribs, and knurls that progressive dies simply cannot achieve.

- Key Advantages: Handles large or intricate parts, accommodates deep drawing operations, versatile for complex geometries, reduces need for secondary operations on specialized components

- Ideal Use Cases: Large structural components, deep-drawn housings and enclosures, parts requiring operations from multiple directions, medium to high volume production of complex designs

- Considerations: Higher tooling and setup costs than compound dies, requires sophisticated transfer mechanisms, demands regular maintenance of both die and transfer systems

So how do you decide? Production volume serves as your primary guide. For runs under a few thousand parts, compound dies often deliver the best value with their lower tooling investment. As volumes climb into tens of thousands, progressive dies typically become more economical despite higher upfront costs—the reduced per-part expense quickly offsets initial tooling expenditure. Transfer dies occupy a middle ground: justified when part complexity or size prevents progressive die use, yet volumes remain high enough to amortize the sophisticated tooling investment.

The relationship between die complexity and economics follows a clear pattern. Simple compound dies might cost a fraction of progressive tooling, but they produce parts more slowly and cannot handle complex operations. Progressive dies demand greater investment but slash per-unit costs at volume. Transfer dies cost more than compound alternatives but enable designs impossible to achieve otherwise. Your optimal choice balances these factors against your specific production requirements.

With process selection clarified, you might wonder: where exactly do all these stamped components end up? The answer spans virtually every industry you can imagine—from the vehicle in your driveway to the phone in your pocket.

Industries and Applications for Die Stamped Components

Look around you right now. That light fixture overhead? Stamped metal housing. The laptop on your desk? Stamped connectors and shielding inside. Your car keys in your pocket? Stamped components throughout. Die stamped products touch virtually every aspect of modern life—often invisibly, always reliably. Understanding where these components appear reveals why stamping die products manufacturers remain essential partners across diverse industries.

What makes stamped components so universally adopted? Three words: precision, repeatability, and economics. When you need identical parts by the thousands—or millions—with tolerances measured in fractions of a millimeter, die stamping delivers. Let's explore how different sectors leverage this manufacturing method to solve their unique challenges.

Automotive and Transportation Applications

The automotive industry represents the largest consumer of die stamped products globally. According to LMC Industries, the metal stamping market is expected to grow from $205 billion in 2021 to more than $283 billion by 2030—driven significantly by automotive demand. Every vehicle rolling off assembly lines contains hundreds of stamped components, from visible body panels to hidden structural reinforcements.

Why does automotive manufacturing depend so heavily on stamping? Vehicles demand consistent, crash-worthy components produced at volumes reaching hundreds of thousands annually. Progressive die stamping excels precisely at this challenge—delivering structural brackets, chassis reinforcements, and body panels with the repeatability that safety regulations demand.

- Body Panels and Exterior Components: Door panels, fenders, hoods, trunk lids, and roof sections—all formed through large-scale stamping operations that shape complex curves while maintaining dimensional accuracy across production runs

- Structural and Safety Components: Seat frames, bumper reinforcements, pillar brackets, and crash absorption structures requiring high-strength steel stamping for occupant protection

- Powertrain and Drivetrain Parts: Engine brackets, transmission housings, exhaust heat shields, and motor mounts designed to withstand vibration and thermal cycling

- Electrical and Sensor Applications: Battery terminals, connector housings, ground straps, and sensor mounting brackets—increasingly important as electric vehicle adoption accelerates

- Interior Hardware: Seat adjustment mechanisms, dashboard brackets, door hinge components, and window regulators combining strength with smooth operation

The electric vehicle revolution is reshaping automotive stamping requirements. As industry reports indicate, electric vehicles create new opportunities for stamping die products company partners—particularly in battery enclosure applications and upper body modifications accommodating sensors, cameras, and autonomous driving technologies.

Electronics, Medical, and Consumer Product Uses

Beyond automotive, stamped components prove equally indispensable across electronics, medical devices, and consumer goods. Each sector values stamping for different reasons—yet all benefit from the same core advantages of precision and scalability.

Electronics and Telecommunications

Modern electronics would be impossible without precision stamped components. The consumer electronics market continues driving metal stamping growth, with applications spanning metal frames for headphones, mobile phones, speakers, and controllers. Inside every device, you'll find:

- Connectors and Terminals: USB ports, battery contacts, SIM card holders, and charging interfaces requiring precise dimensional control for reliable electrical connections

- EMI/RFI Shielding: Metal shields protecting sensitive circuits from electromagnetic interference—essential for device certification and reliable operation

- Heat Sinks and Thermal Management: Stamped aluminum and copper components dissipating heat from processors, power supplies, and LED systems

- Chassis and Housing Components: Structural frames, mounting brackets, and decorative bezels combining aesthetics with durability

Medical Devices and Healthcare

Medical applications demand the highest precision and quality standards. According to Wiegel Manufacturing, stamping die products manufacturers serve leading medical OEMs and Tier 1 suppliers, producing miniature and complex components with exceptional consistency, quality, and compliance.

Medical stamping applications include:

- Surgical Instruments: Scalpel handles, forceps components, retractor mechanisms, and scissor blades requiring surgical precision and biocompatible materials

- Implantable Device Components: Pacemaker housings, cochlear implant parts, and defibrillator stampings manufactured from titanium, stainless steel, and specialty alloys

- Medical Staplers and Closure Devices: Stapling mechanisms for endoscopic, laparoscopic, and skin closure tools demanding high-performance alloys for surgical reliability

- Drug Delivery Systems: Injection device components, pump mechanisms, and dispensing system parts requiring repeatable tolerances for accurate dosing

- Diagnostic Equipment: Electronic monitor stampings, medical enclosures, and power supply components supporting imaging and testing devices

Aerospace and Defense

Weight savings translate directly into fuel efficiency and performance in aerospace applications. Stamped aluminum, titanium, and specialty alloy components provide the strength-to-weight ratios that aircraft designers require:

- Structural Brackets and Fittings: Lightweight mounting systems, airframe reinforcements, and attachment points engineered for extreme stress and temperature variations

- Avionics Housings: EMI-shielded enclosures protecting sensitive navigation, communication, and flight control electronics

- Fasteners and Hardware: High-strength clips, clamps, and retention systems certified for aerospace applications

Consumer Goods and Appliances

Everyday products rely on stamped components for both function and aesthetics. Die stamped products inc companies serve manufacturers producing:

- Major Appliances: Refrigerator door panels, washing machine drums, oven housings, and HVAC system components requiring corrosion resistance and dimensional stability

- Small Appliances: Toaster housings, coffee maker brackets, and kitchen tool components balancing cost-effectiveness with durability

- Hardware and Fasteners: Cabinet hinges, drawer slides, shelf brackets, and decorative hardware combining strength with attractive finishes

- Furniture Components: Metal frames, adjustment mechanisms, and structural reinforcements supporting modern furniture designs

Construction and Infrastructure

Building and infrastructure projects consume millions of stamped components annually:

- Structural Fasteners: Joist hangers, beam connectors, and framing hardware engineered for load-bearing applications

- Electrical Fittings: Junction box covers, conduit brackets, and cable management systems meeting building codes

- Plumbing Hardware: Pipe clamps, mounting brackets, and valve components resisting corrosion in wet environments

- HVAC Components: Ductwork fittings, damper mechanisms, and sensor mounting systems maintaining dimensional accuracy through temperature cycles

Across all these industries, the preference for die stamping comes down to economics at scale. When production volumes justify tooling investment, stamped components consistently outperform alternatives in per-unit cost while maintaining the precision that modern products demand. The question then becomes: how do you design parts that maximize these manufacturing advantages? That requires understanding the critical tolerances and design principles that separate successful stamped components from costly failures.

Design Considerations for Die Stamped Parts

Here's a sobering reality: even the most capable stamping die products suppliers can't rescue a poorly designed part. The decisions you make during design directly determine whether your component runs smoothly through production—or becomes a costly headache requiring endless tooling adjustments. Understanding critical design parameters before you buy stamping die products separates successful projects from expensive failures.

Think of it this way: designing for die stamping isn't just about creating a shape that looks good on screen. It's about respecting the physics of metal deformation, the limitations of tooling, and the realities of high-volume production. When you design with manufacturability in mind, you'll reduce tooling costs, accelerate lead times, and produce higher-quality parts from day one.

Critical Tolerances and Precision Standards

Every dimension you specify affects tooling complexity and production cost. Overly tight tolerances might seem like insurance against quality problems, but they often create the opposite effect—driving up costs while introducing unnecessary production challenges.

Standard stamping operations can achieve impressive precision when properly designed. According to Alekvs Metal Stamping Design Guide, dimensional tolerances for holes and edges can often be held to ±0.002" in high-precision applications. However, achievable tolerances depend heavily on material type, thickness, and the specific operations involved.

Hole Sizing and Placement deserves particular attention. The minimum hole diameter should equal or exceed 1.2 times the material thickness. For high-tensile materials like stainless steel, increase this to at least twice the material thickness to prevent punch breakage. Maintain a minimum distance of two stock thicknesses between any hole and the nearest edge to avoid distortion and bulging.

Bend-to-Hole Relationships cause frequent problems when ignored. Forming a bend too close to a hole causes deformation that ruins dimensional accuracy. The safe spacing equals the bend radius plus 2.5 times the material thickness. For holes smaller than 2.5mm in diameter, increase this minimum to twice the material thickness plus the bend radius.

Feature Spacing Requirements prevent the distortion that occurs when operations interfere with each other. Holes should be spaced at least 1.5 times the material thickness apart. For slots near bends, increase spacing to the bend radius plus four times the material thickness.

Holes should be spaced at least 1.5× material thickness apart, and holes near bends should maintain a distance of 2× material thickness plus the bend radius to prevent deformation.

Flatness Specifications often get over-constrained. According to Aranda Tooling, components requiring flatness under 0.003 inches may need costly secondary operations. Specify flatness tolerances only as tight as your application genuinely requires.

Design-for-Manufacturability Principles

The most successful stamped components emerge from early collaboration between designers and die manufacturers. As The Fabricator emphasizes, subtle differences in how a part is dimensioned can make significant differences in tooling and production cost.

Bend Radii and Material Limits determine whether your design will form cleanly or crack during production. The minimum inside bend radius typically equals the material thickness for soft materials, increasing to 1.5 times thickness or more for harder alloys. Grain direction matters too—bending perpendicular to the grain direction reduces cracking risk on harder stocks.

Corner and Radius Design affects both formability and tool life. Be generous with corner radii—the punch and die radius should be at least four times the material thickness for reliable forming. Sharp corners become possible only with materials 1.5mm or thinner.

Burr Management requires realistic expectations. Burrs are a natural byproduct of stamping operations, typically reaching heights up to 10% of material thickness. Design your part with burr direction in mind, specifying which surfaces are critical. Avoid complex cutouts and unnecessarily sharp internal corners that intensify burr formation.

Feature Function Communication saves money and headaches. Tooling manufacturers rarely know what each feature actually does. A hole specified with tight tolerances might simply hang parts on a paint line—information that could have relaxed tolerances and reduced costs. Share functional requirements with your stamping die products for sale near me partners early in the process.

The payoff for design-for-manufacturability? One lighting industry example from The Fabricator documented 20% tooling cost savings after eliminating non-essential dimensions and consolidating a three-piece assembly into one stamped part. That collaboration also reduced assembly time and shipping costs—proving that manufacturability discussions deliver benefits far beyond the stamping press.

With solid design principles in place, you're positioned to evaluate stamping objectively against alternative manufacturing methods—understanding exactly where die stamping excels and where its limitations might steer you toward different solutions.

Benefits and Trade-Offs of Die Stamped Manufacturing

You've designed your part with manufacturability in mind. Now comes the critical question every procurement manager and engineer faces: is die stamping actually the right choice for your project? The answer isn't always yes—and understanding exactly when stamping excels versus when alternatives make more sense can save your organization significant time and money.

Die stamping offers remarkable advantages, but these benefits come with trade-offs that deserve honest evaluation. Let's examine both sides objectively so you can make truly informed manufacturing decisions based on your specific production requirements.

Advantages of Die Stamping Over Alternative Methods

When conditions align with its strengths, die stamping delivers manufacturing performance that's genuinely difficult to match. Here's what makes this process so valuable for the right applications:

Exceptional Repeatability and Consistency stands as perhaps the most compelling advantage. According to Jeelix, a die acts as a meticulously crafted template forged in hardened steel, physically encoding design specifications so each part produced is virtually identical—even across millions of units. Modern automated assembly lines demand flawlessly interchangeable components, and die stamping delivers exactly that with tolerances measured in microns.

Unmatched Production Speed becomes apparent once tooling is operational. Where CNC machining might produce parts in minutes, stamping dies churn out components in seconds—sometimes fractions of seconds. This speed advantage compounds across high-volume runs, dramatically reducing per-unit labor costs and accelerating delivery schedules.

Superior Material Utilization results from optimized strip layouts and nesting strategies. Smart die design minimizes scrap by strategically positioning parts on metal sheets or coils. Over large production runs, these material savings translate into substantial cost reductions that alternative processes simply cannot match.

Consistent Quality Without Operator Dependency emerges from the process itself. Unlike manual operations where quality varies with operator skill and attention, stamping dies produce identical results stroke after stroke. This consistency reduces inspection burdens and virtually eliminates the quality variation that plagues more labor-intensive methods.

In-Die Operations Eliminate Secondary Processing in many applications. Progressive dies can pierce, bend, form, coin, and even tap threads—all within a single production sequence. Each operation eliminated from your downstream workflow saves handling time, reduces work-in-process inventory, and minimizes opportunities for damage or dimensional variation.

Understanding Tooling Investment and Break-Even Points

Now for the honest trade-offs. Die stamping's advantages come with entry costs and constraints that make it unsuitable for certain projects:

Significant Upfront Tooling Investment represents the most immediate barrier. As industry experts note, designing and producing a complex die can require investment ranging from tens of thousands to several hundred thousand dollars. This capital commitment happens before producing a single viable part—creating substantial financial risk if production volumes don't materialize as projected.

Extended Lead Times for Die Development challenge fast-moving markets. Moving from design freeze to first article inspection often stretches over several weeks to many months. For sectors where product lifecycles are measured in months rather than years, this development timeline can mean missing market windows entirely.

Design Rigidity After Tooling Completion locks you into your original specifications. Once hardened steel is cut and heat-treated, modifications become extraordinarily expensive. Discovering a design flaw or needing to pivot based on market feedback after die completion can multiply costs exponentially—a harsh penalty that enforces rigid, linear development processes.

Maintenance Requirements and Skilled Labor Dependency create ongoing operational considerations. Dies require meticulous care including cleaning, lubrication, inspection, and eventual refurbishment. This work depends on experienced tool and die makers—professionals whose ranks are shrinking as retirements outpace new training.

Comparing Die Stamping Economics with Alternatives

The decision between stamping and alternatives ultimately comes down to break-even analysis. According to TheSupplier, the fundamental equation is straightforward: when tooling cost divided by the per-part cost difference between alternatives equals your production volume, you've reached break-even. Beyond that point, stamping's lower per-unit costs generate increasing savings.

| Factor | Die Stamping | Laser Cutting | CNC Machining |

|---|---|---|---|

| Setup/Tooling Cost | High ($10K-$300K+ for dies) | Low (programming only) | Low to Medium (fixtures, programming) |

| Per-Unit Cost at Volume | Very Low (seconds per part) | Stable (doesn't drop sharply) | Higher (minutes per part) |

| Design Change Cost | High (die rework or replacement) | Low (reprogram and re-nest) | Low (modify program) |

| Lead Time to First Parts | Weeks to months | Hours to days | Days to weeks |

| Precision/Repeatability | Excellent after die tuning | Good (±0.1-0.2mm typical) | Excellent |

| Best Production Volume | High (10,000+ parts) | Low to Medium (1-3,000 parts) | Low to Medium (prototypes, small batches) |

Laser cutting wins when you need speed and design flexibility—ideal for prototypes, pilot runs, or products with frequent engineering changes. Per-part costs remain stable regardless of volume, making it economical for quantities under a few thousand units.

CNC machining excels for complex three-dimensional parts, prototyping, and applications requiring material removal rather than forming. It offers design flexibility similar to laser cutting but handles thicker materials and more intricate geometries.

Die stamping dominates once volumes climb high enough to amortize tooling investment. The crossover point varies by part complexity, but as procurement experts advise: start with laser to validate your design, then transition to stamping when annual quantities justify the investment and your design is truly frozen.

The strategic approach? Recognize that these methods aren't competitors—they're complementary tools for different stages of your product lifecycle. Many successful manufacturers use laser cutting or machining for development and initial production, then invest in stamping dies only after designs stabilize and volume projections prove reliable.

With economics clarified, your next concern likely centers on quality assurance: how do you verify that stamped components meet specifications consistently, and what certifications should you expect from manufacturing partners?

Quality Standards and Certifications in Die Stamping

A stamped component might look perfect coming off the press—but how do you verify it actually meets specifications? More importantly, how do you ensure the thousandth part maintains the same quality as the first? These questions drive quality assurance systems that separate reliable manufacturing partners from risky suppliers. Understanding the certifications, inspection methods, and predictive technologies behind quality stamping helps you evaluate potential partners and set appropriate expectations for your projects.

Quality in die stamping isn't just about catching defects—it's about preventing them from occurring in the first place. The most capable manufacturers build quality into every stage of production, from initial die design through final inspection. Let's examine the systems and standards that make this possible.

Industry Certifications That Matter

Certifications serve as third-party verification that a manufacturer has implemented robust quality management systems. While certificates alone don't guarantee perfect parts, they do indicate organizational commitment to consistent processes and continuous improvement. Here's what to look for:

- ISO 9001: The foundational quality management standard applicable across industries. Demonstrates documented processes, management commitment, and systematic approaches to quality improvement. Consider this baseline certification for any serious supplier.

- IATF 16949: The automotive industry's demanding quality standard, building on ISO 9001 with additional requirements specific to automotive supply chains. Mandates defect prevention approaches, waste reduction, and continuous improvement focused on customer satisfaction. Required for most OEM automotive programs.

- AS9100: Aerospace industry quality management certification incorporating ISO 9001 requirements plus aerospace-specific provisions for safety, reliability, and traceability. Essential for suppliers serving aircraft manufacturers and defense contractors.

- ISO 13485: Medical device quality management standard emphasizing risk management, design controls, and regulatory compliance. Necessary for manufacturers producing stamped components for medical applications.

- NADCAP: Aerospace special process accreditation covering specific operations like heat treating, non-destructive testing, and surface treatments. Provides additional assurance for critical manufacturing processes beyond basic quality system certifications.

Certified manufacturers like Shaoyi demonstrate quality commitment through IATF 16949 certification, indicating their systems meet the rigorous requirements that automotive OEMs demand. This certification requires extensive documentation, regular audits, and demonstrated performance against measurable quality objectives—providing meaningful assurance beyond marketing claims.

Quality Control and Inspection Methods

Certifications establish systems; inspection methods verify results. Effective quality programs combine multiple verification approaches to catch different types of defects at appropriate production stages.

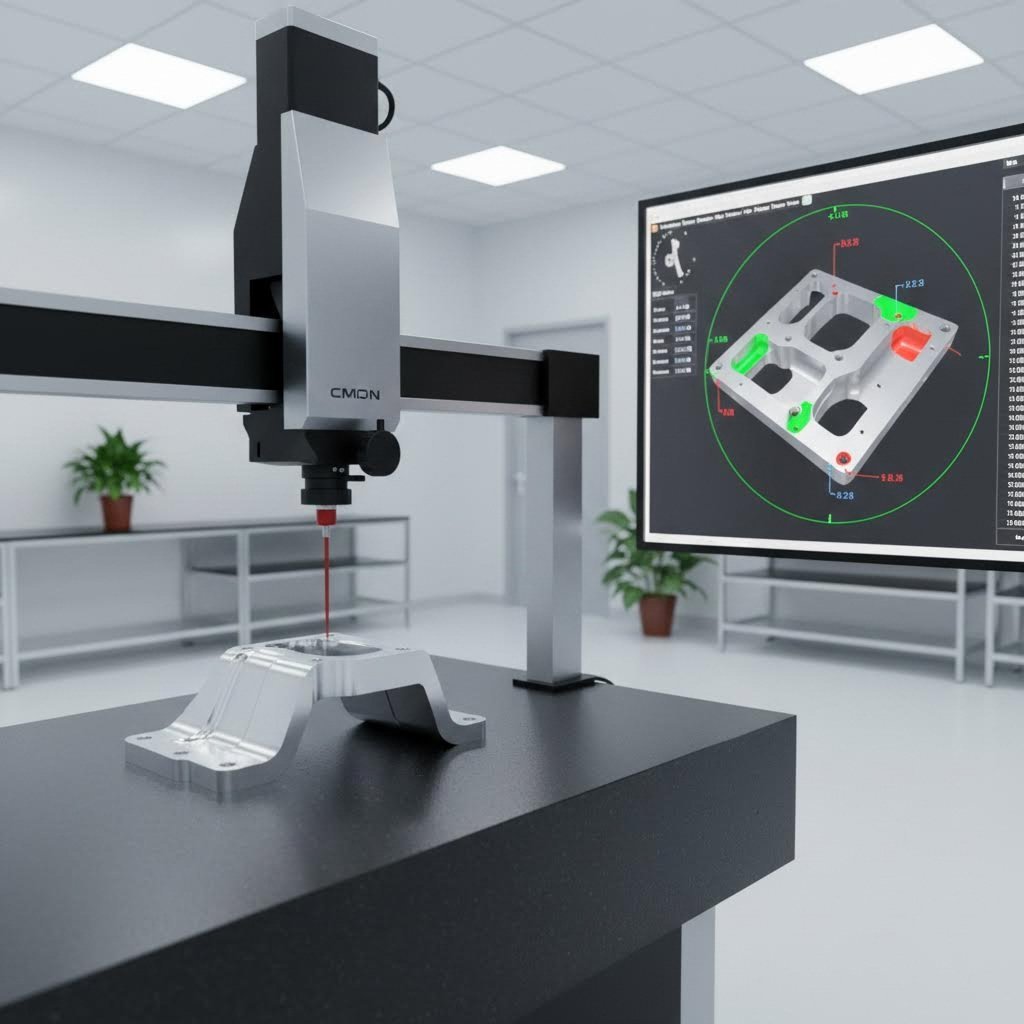

Dimensional Verification confirms that stamped parts meet specified tolerances. Methods range from simple go/no-go gauges for high-speed production checks to coordinate measuring machines (CMMs) for comprehensive dimensional analysis. First article inspection thoroughly measures initial production samples against engineering drawings, while statistical process control (SPC) monitors ongoing production through measured samples at defined intervals.

Surface Quality Assessment identifies visual defects that dimensional measurements miss. Trained inspectors examine parts for scratches, dents, burrs, and surface imperfections against defined acceptance criteria. Automated vision systems increasingly supplement human inspection, providing consistent evaluation at production speeds while flagging questionable parts for closer examination.

Material Testing verifies that incoming materials meet specifications before stamping begins. Hardness testing, tensile testing, and chemical analysis confirm material properties match purchase orders. This incoming verification prevents defects caused by out-of-spec materials—problems that become expensive to discover after stamping operations complete.

Destructive Testing evaluates part performance under actual use conditions. Cross-sectional analysis examines material flow and grain structure. Fatigue testing subjects samples to repeated stress cycles. Salt spray testing accelerates corrosion evaluation. These methods sacrifice sample parts to gain confidence that production components will perform reliably in service.

CAE Simulation: Preventing Defects Before Production

The most cost-effective approach to quality? Preventing defects before cutting the first die. Computer-aided engineering (CAE) simulation has transformed die development by predicting forming problems during virtual try-outs rather than expensive physical trials.

According to Keysight's research on sheet metal forming simulation, the stamping industry faces significant challenges with advanced high-strength steels and aluminum alloys that exhibit high springback magnitudes—making dimensional accuracy a constant challenge. Defects often emerge only during first physical trials, when corrections become both time-consuming and costly.

Sheet metal forming simulation addresses these challenges by:

- Predicting Springback: Modeling how parts will deform after forming pressure releases, allowing die compensation before physical tooling is cut

- Identifying Thinning and Splits: Highlighting areas where material will stretch excessively, enabling design modifications or process adjustments before production

- Optimizing Process Parameters: Testing different blank holder forces, press speeds, and lubrication conditions virtually rather than through expensive physical trials

- Evaluating Material Variations: Simulating how property variations within material specifications affect final part quality

Manufacturers with advanced CAE simulation capabilities—such as Shaoyi's engineering team—can predict and prevent defects before production begins, achieving higher first-pass approval rates and reducing the costly iterations that plague traditional die development. Their 93% first-pass approval rate demonstrates how simulation-driven engineering translates into practical production efficiency.

The investment in simulation capabilities pays dividends throughout production. Problems identified during virtual try-outs cost a fraction of those discovered during physical trials. And with vehicle designs growing more intricate and material requirements becoming more demanding, simulation has shifted from competitive advantage to competitive necessity for quality-focused stamping operations.

Quality systems provide assurance; certifications demonstrate commitment; and simulation prevents problems before they occur. But these elements only deliver value when your manufacturing partner actually implements them effectively. That raises the final critical question: how do you evaluate potential stamping partners to find those who truly deliver on quality promises?

Selecting the Right Die Stamping Partner

You've validated your design, confirmed die stamping makes economic sense, and understand the quality standards your application demands. Now comes perhaps the most consequential decision of all: choosing who will actually manufacture your components. The wrong partner can transform a well-designed project into a nightmare of missed deadlines, quality failures, and budget overruns. The right partner becomes an extension of your engineering team—solving problems you didn't anticipate and delivering results that exceed specifications.

What separates exceptional stamping partners from adequate suppliers? It's rarely just equipment or price. According to Penn United Technologies, making a purchasing decision based only on quoted cost may result in overall dissatisfaction with a supplier's performance—or even in a disastrous situation. The evaluation criteria below help you identify partners positioned for long-term success rather than just the lowest bid.

Key Criteria for Evaluating Die Stamping Partners

Technical Capabilities and Equipment form the foundation of any evaluation. A supplier's press tonnage range, bed sizes, and feeding equipment determine what parts they can physically produce. But look deeper than equipment lists. Can they design precision dies in-house? As industry experts note, a supplier who designs and builds precision metal stamping dies will inevitably be much more qualified to succeed than one without these capabilities. In-house toolmaking means faster troubleshooting when issues arise and deeper understanding of what makes dies perform reliably.

Industry Experience and Track Record reveal whether a supplier truly understands your application's demands. A company serving automotive OEMs understands PPAP requirements and the documentation burden that entails. Medical device specialists know cleanliness protocols and traceability expectations. Ask for case studies, references from similar projects, and evidence of success with comparable part complexity and materials. According to KY Hardware, their longevity in business often speaks to stability and ability to deliver on promises.

Quality Certifications and Systems provide third-party verification of process discipline. ISO 9001 establishes baseline quality management. IATF 16949 demonstrates automotive-grade rigor. But certifications alone don't guarantee quality—ask how they implement these systems day-to-day. Visit their facility. Observe their quality technicians in action. Evaluate their investment in inspection equipment. According to Penn United, seeing their quality system in operation is probably the best way to evaluate a supplier's attention to process control.

Prototyping Speed and Engineering Support dramatically impact your development timeline. How quickly can a potential partner deliver sample parts for validation? Capable suppliers like Shaoyi offer rapid prototyping in as little as 5 days—a capability that accelerates development cycles and enables faster design iteration. Equally important: does their engineering team engage proactively with design-for-manufacturability feedback, or simply quote what you submit? According to Rotation Engineering, optimized engineering and design support helps businesses develop custom products for optimum cost-effective manufacturability.

Production Capacity and Scalability determine whether a partner can grow with your needs. Assess their current utilization and how they manage production scheduling. Can they ramp from prototype quantities to high-volume production without quality degradation? Do they offer inventory management programs like Kanban or Just-in-Time delivery that reduce your warehousing burden? A supplier constrained at current volumes becomes a bottleneck as your product succeeds.

From Prototype to Production Partnership

The best supplier relationships extend far beyond transactional purchasing. True partners collaborate throughout tooling development, share expertise that improves your designs, and communicate proactively when challenges arise.

Communication and Collaboration quality often predicts project outcomes more reliably than technical specifications. Notice supplier behavior during the quoting process. As Penn United observes, a supplier who asks detailed questions about part quality, key features, and tolerances typically over-delivers in attention to detail. Suppliers who simply quote without questions may lack the engagement needed for complex projects.

Geographic and Supply Chain Considerations affect logistics, communication, and risk management. Domestic suppliers often provide faster response times, easier collaboration, and reduced shipping complexity. International partners may offer cost advantages but introduce longer lead times, communication challenges, and supply chain vulnerabilities. Evaluate total cost of ownership—including freight, inventory carrying costs, and risk of disruption—rather than piece price alone.

Secondary Operations Capability simplifies your supply chain when partners handle operations beyond stamping. Cleaning, plating, heat treating, assembly, and custom packaging performed by your stamping partner eliminate logistics between suppliers and reduce handling damage risks. According to Penn United, a supplier with these capabilities typically results in significant savings for overall supply chain logistics.

Questions to Ask Potential Die Stamping Suppliers

Before committing to a partnership, use this checklist to ensure you've gathered the information needed for a confident decision:

- How many years have you been producing precision stamped components, and what industries do you primarily serve?

- Do you design and build dies in-house, or outsource tooling to third parties?

- What quality certifications do you hold, and when were you last audited?

- What is your typical lead time from design approval to first article inspection?

- Can you provide references from customers with similar part complexity and volume requirements?

- How do you handle engineering changes after tooling is complete?

- What inspection equipment do you use, and how do you document quality data?

- Do you offer die maintenance programs, and what do they include?

- What secondary operations can you perform in-house or through managed partners?

- How do you track and report on-time delivery performance?

- What is your process for addressing quality issues or non-conformances?

- Can you support inventory management programs like Kanban or JIT delivery?

The answers to these questions—combined with facility visits, reference checks, and sample evaluation—provide the complete picture needed to select a partner rather than just a vendor. Take time for thorough evaluation upfront. The investment in due diligence pays dividends across years of production, preventing the costly disruptions that inevitably follow poor supplier selection.

Frequently Asked Questions About Die Stamped Products

1. What are die stamped products and how are they manufactured?

Die stamped products are metal components created through cold forming, where flat metal sheets are placed between specialized dies and pressed to create precise shapes. The process uses operations like blanking, piercing, bending, forming, and drawing to transform raw metal into finished parts. A stamping press applies controlled force through a punch and die system, causing permanent plastic deformation without fracturing the material. This technique produces everything from tiny electronic connectors to large automotive body panels with exceptional consistency and repeatability across high-volume production runs.

2. What materials are commonly used for die stamped components?

The most common materials include carbon steel for structural components due to its strength and affordability, stainless steel (grades 304L, 316, 301) for corrosion-resistant applications in medical and food processing, and aluminum alloys (6061, 2024, 5052) for lightweight aerospace and automotive parts. Copper and brass excel in electrical applications requiring high conductivity, while specialty alloys like Inconel, titanium, and Hastelloy handle extreme temperatures and corrosive environments. Material selection depends on factors including tensile strength, ductility, corrosion resistance, conductivity requirements, and cost considerations.

3. What is the difference between progressive, compound, and transfer die stamping?

Progressive die stamping performs multiple sequential operations as a continuous metal strip advances through stations, ideal for high-volume production of small to medium parts. Compound die stamping executes multiple operations in a single press stroke simultaneously, best suited for flat, simpler parts like washers and gaskets at lower tooling costs. Transfer die stamping separates blanks immediately and uses mechanical fingers to move individual parts between stations, enabling larger components and complex geometries including deep-drawn features that progressive dies cannot achieve. Production volume, part complexity, and budget determine the optimal choice.

4. What industries use die stamped products most frequently?

Automotive manufacturing represents the largest consumer, using stamped components for body panels, structural brackets, and powertrain parts. Electronics relies on stamped connectors, EMI shielding, and heat sinks. Medical devices incorporate stamped surgical instruments, implant components, and drug delivery systems. Aerospace uses stamped aluminum and titanium for lightweight structural parts and avionics housings. Consumer goods manufacturers produce appliance housings, hardware, and furniture components through stamping. Construction applications include structural fasteners, electrical fittings, and HVAC components. The process dominates wherever precision, repeatability, and cost-effectiveness at scale are required.

5. How do I choose the right die stamping partner for my project?

Evaluate technical capabilities including in-house die design and toolmaking, which indicates deeper problem-solving ability. Verify relevant industry experience and request references from similar projects. Confirm quality certifications like ISO 9001 or IATF 16949 for automotive applications, and observe their quality systems in operation during facility visits. Assess prototyping speed—capable partners like Shaoyi offer rapid prototyping in as little as 5 days. Consider production capacity for scalability, secondary operations capabilities to simplify your supply chain, and communication quality during the quoting process. Prioritize partners who ask detailed questions about your requirements rather than simply quoting submitted drawings.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —