Die For Stamping Decoded: From Raw Steel To Precision Parts

What Is a Die for Stamping and Why It Matters

Ever wondered how manufacturers produce thousands of identical metal parts with perfect precision? The answer lies in a specialized die tool that transforms raw sheet metal into everything from smartphone casings to automotive body panels. So, what is a die in manufacturing? Simply put, a die for stamping is a precision-engineered tool installed in a press machine that cuts, bends, or shapes metal sheets into specific forms with remarkable accuracy.

A stamping die is a precision tool that cuts and forms metals into functional shapes. The two die halves are placed inside a press that can generate enough force to perform the necessary die functions, including cutting, bending, piercing, embossing, forming, drawing, stretching, coining, and extruding.

The Manufacturing Foundation Behind Every Metal Part

Understanding what is stamping starts with recognizing how these dies function as the backbone of modern mass production. A stamping die consists of two primary halves—an upper and lower section—that work together like a highly sophisticated cookie cutter for metal. When the press closes, these halves apply tremendous force to transform flat sheet material into three-dimensional components.

What is metal stamping without proper tooling? Essentially impossible at scale. Industries like automotive, aerospace, and electronics rely heavily on these tools because they deliver unmatched consistency. Once you've created a stamping die, it can produce hundreds of thousands of identical parts, ensuring every component meets exact specifications.

From Raw Sheet to Precision Component

The magic happens when metal enters the die. During each press cycle, the die performs four essential functions: locating the material, clamping it securely, working the metal through various operations, and releasing the finished piece. While die cutting and forming might seem straightforward, the engineering behind these processes requires meticulous attention to detail.

Why does this matter to you? Whether you're sourcing parts for a new product or exploring manufacturing options, understanding what is dies in manufacturing helps you make informed decisions. This guide will walk you through everything from die anatomy and types to material selection and troubleshooting—giving you the knowledge to confidently navigate your next stamping project.

Essential Components of a Stamping Die Explained

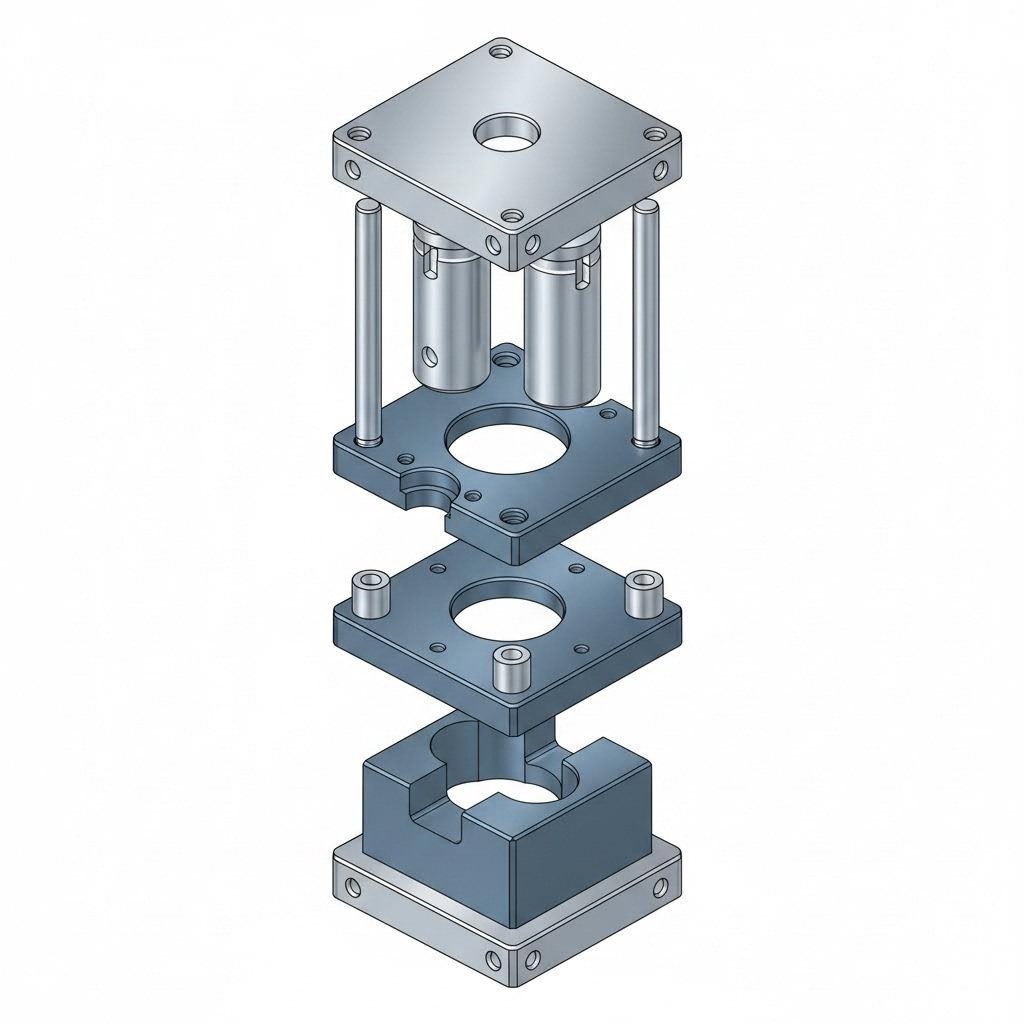

Picture a stamping die as a finely tuned orchestra—each component plays a distinct role, yet they must work together in perfect harmony to produce flawless metal parts. Understanding how these elements interact helps you appreciate why precision tooling matters and how each piece contributes to dimensional accuracy. Let's break down the anatomy of a metal punch and die system component by component.

A complete die assembly contains several critical elements, each engineered for specific functions within the stamping cycle:

- Punch: The male component that enters the die cavity, applying direct force to cut or form the material into shape

- Die Block: The female component containing the cavity or opening that receives the punch and determines the final part geometry

- Stripper Plate: Holds the workpiece flat during operations and removes material from the punch after forming or cutting

- Guide Pins and Bushings: Precision alignment components ensuring the upper and lower die halves meet perfectly every cycle

- Backing Plates: Support structures that prevent the die block and punch from deforming under extreme pressure

- Die Set (Upper and Lower Shoe): The framework holding all components in proper alignment throughout operation

Inside the Die Block and Punch Assembly

The punch and die relationship forms the heart of every stamping operation. Imagine the punch as a precisely shaped hammer and the die block as its matching anvil. When the press closes, the punch descends into the die block's cavity, and together they transform flat sheet metal into your desired component.

The die block contains carefully machined cavities that mirror the exact shape you need. According to manufacturing specifications, this component must withstand repeated high-pressure impacts while maintaining dimensional stability. That's where the press plate and backing plates come into play—they distribute forces evenly and prevent the die block from warping over time.

What makes this relationship special? The clearance between punch and die—typically measured in thousandths of an inch—determines edge quality, burr formation, and overall part precision. Too tight, and you'll experience excessive wear. Too loose, and your parts develop unacceptable burrs. This critical tolerance is why punch drawing specifications require such meticulous engineering during the design phase.

The stripper plate serves a dual purpose in this assembly. First, it holds your material flat against the die block during operations, preventing movement that could cause dimensional errors. Second, after the press tool completes its stroke, the stripper removes the workpiece from the punch, ensuring clean separation and preparing for the next cycle.

Guide Systems That Ensure Precision

Ever wonder how tooling dies maintain accuracy after millions of cycles? The answer lies in the guide system. Guide pins and bushings form a precision alignment mechanism that keeps the upper and lower die halves perfectly synchronized throughout every stroke.

Here's how it works: guide pins—typically hardened steel cylinders—are mounted on one half of the die set. Matching bushings on the opposite half receive these pins as the press closes. This arrangement eliminates lateral movement, ensuring the die punch enters the die block cavity at exactly the same position every time.

The die set itself—consisting of upper and lower shoes connected by this guide system—provides the structural foundation for all other components. Think of it as the chassis that keeps everything properly positioned. Without a rigid, well-aligned die set, even the most precisely machined punch and die would produce inconsistent results.

Additional components round out the system's functionality:

- Pilots: Small pins that locate and align the material within the die, ensuring consistent positioning for each operation

- Springs: Provide return motion for moving components and controlled pressure during forming operations

- Knockouts and Ejectors: Remove finished parts from the die cavity, preventing sticking and enabling continuous production

When all these components work together—from the press tool framework to the smallest pilot pin—you achieve the repeatability that makes high-volume stamping economically viable. Understanding this interrelationship helps you recognize quality tooling and communicate effectively with die manufacturers about your production requirements.

Types of Stamping Dies and Their Applications

Now that you understand how die components work together, you're probably wondering: which type of stamping die is right for your project? Choosing among the different types of stamping dies isn't just about technical specifications—it's about matching your production goals with the right tooling strategy. Let's explore the four major categories of metal stamping dies and discover when each one delivers optimal results.

Think of selecting stamping dies like choosing the right vehicle for a road trip. A compact car works great for city driving, but you'd want a truck for hauling heavy loads. Similarly, each die type excels in specific scenarios based on part complexity, production volume, and cost considerations.

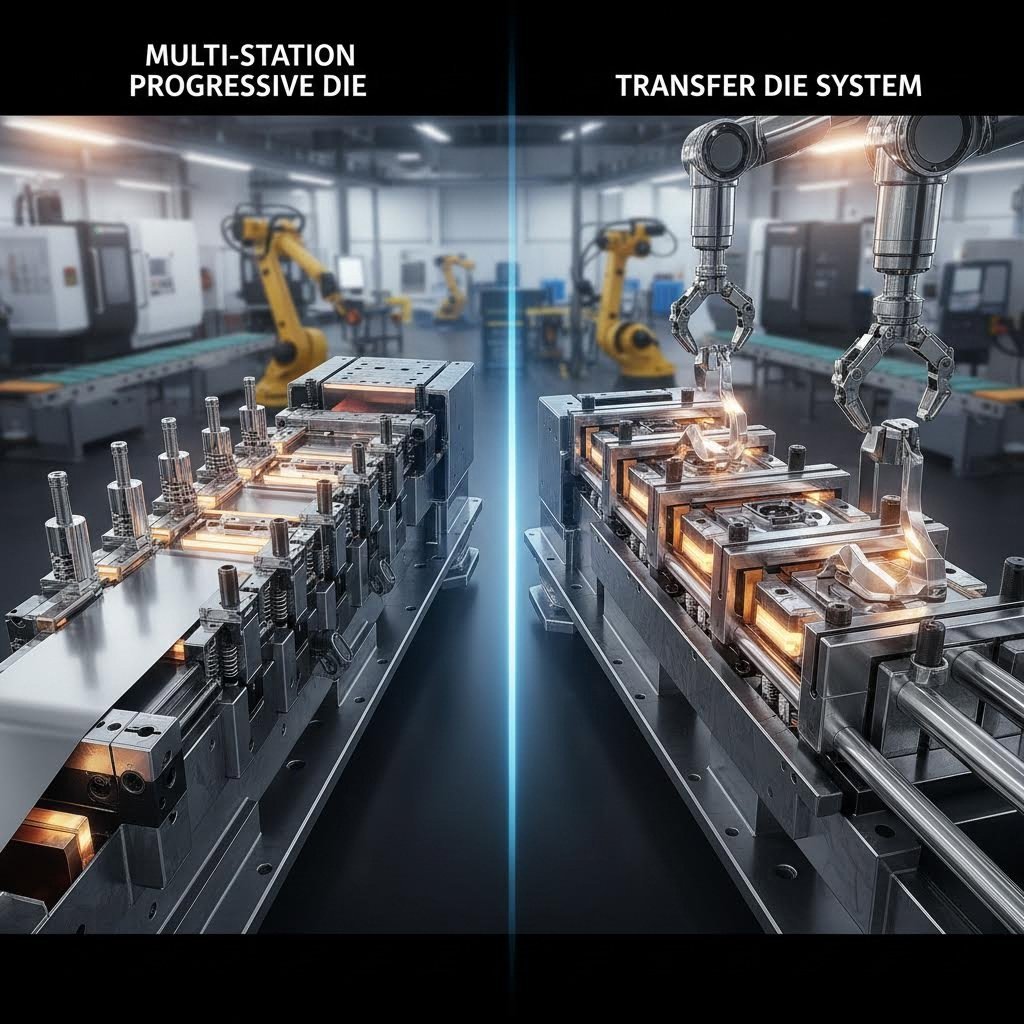

Progressive Dies for High-Volume Efficiency

Imagine an assembly line where each station handles one specific task—that's essentially how progressive dies operate. These sheet metal stamping dies consist of multiple stations arranged in sequence, with each station performing a distinct operation as the metal strip advances through the press. The material feeds continuously from a coil, moving from station to station until a finished part emerges at the end.

What makes progressive dies so popular for die stamping operations? According to Durex Inc., progressive dies deliver high efficiency and are capable of producing large volumes of parts quickly while ensuring uniformity across all produced components. They're commonly used in automotive manufacturing for brackets and clips, and in electronics for intricate parts requiring consistent precision.

Here's why manufacturers love them:

- Speed: Parts are produced with each press stroke, maximizing output

- Consistency: Every component meets identical specifications

- Automation-friendly: Minimal manual handling reduces labor costs

- Material efficiency: Strip feeding minimizes waste when properly designed

However, progressive dies aren't ideal for every situation. The initial tooling investment runs higher than simpler options, and they work best with smaller to medium-sized parts that can be formed from continuous strip material. Complex three-dimensional shapes may require alternative approaches.

When Transfer Dies Outperform Progressive Systems

What happens when your parts are too large or complex for progressive tooling? That's where transfer dies shine. Unlike progressive systems where material remains connected throughout the process, transfer dies move individual blanks between separate stations using mechanical or automated transfer mechanisms.

Picture a skilled craftsman passing a workpiece from one specialized workstation to another—each station adds its contribution until the final product takes shape. As noted by Worthy Hardware, transfer die stamping allows more flexibility in part handling and orientation, making it suitable for intricate designs and shapes that progressive dies simply cannot accommodate.

Transfer dies excel when you need:

- Large parts that exceed progressive die size limitations

- Complex three-dimensional geometries requiring multiple orientations

- Deep draws or significant forming operations

- Flexibility to incorporate various operations like punching, bending, drawing, and trimming in a single production cycle

The trade-off? Higher operational costs and longer setup times compared to progressive dies. You'll also need skilled operators for maintenance and die adjustment. But for complex assemblies in aerospace, heavy machinery, or large automotive components, transfer dies often prove indispensable.

Compound Dies: Multiple Operations in a Single Stroke

Sometimes simplicity wins. Compound dies perform multiple cutting operations simultaneously in one press stroke—think of a cutting die that blanks your part's outer profile while simultaneously piercing interior holes. This approach eliminates the need for material transfer between stations.

According to industry sources, compound dies integrate tasks such as cutting, bending, and embossing within one die set, significantly reducing production time and enhancing productivity. They're particularly effective when you need:

- Flat parts with tight tolerances between features

- Medium production volumes where tooling cost matters

- Components requiring precise alignment between multiple cut features

Because all operations occur simultaneously, compound dies eliminate potential misalignment issues that can occur when parts move between stations. However, they're limited to relatively simple geometries—primarily flat parts without complex forming requirements.

Combination Dies: The Best of Both Worlds

When you need both cutting and forming operations but want to minimize tooling complexity, combination dies offer an attractive solution. These versatile tools function like a hybrid die cutter for metal, performing both cutting and non-cutting operations (like bending or drawing) in a single stroke.

Combination dies bridge the gap between pure cutting tools and complex forming systems. They're ideal for parts requiring a cut profile plus simple forming features—saving you from investing in multiple separate dies while maintaining good production efficiency.

Comparing Die Types: Which One Fits Your Project?

Selecting the right stamping die type requires weighing multiple factors against your specific requirements. The following comparison breaks down key decision criteria:

| Factor | Progressive Dies | Transfer Dies | Compound Dies | Combination Dies |

|---|---|---|---|---|

| Operation Complexity | Multiple sequential operations | Multiple operations with part transfer | Multiple simultaneous cutting operations | Cutting plus forming in one stroke |

| Production Volume | High volume (100,000+ parts) | Medium to high volume | Low to medium volume | Low to medium volume |

| Part Size Range | Small to medium parts | Medium to large parts | Small to medium flat parts | Small to medium parts |

| Setup Time | Moderate (coil threading required) | Longer (transfer system calibration) | Quick (single-station operation) | Quick to moderate |

| Typical Applications | Automotive brackets, electronic components, fasteners | Aerospace assemblies, large automotive panels, appliance parts | Washers, gaskets, precision flat components | Parts requiring cut profiles with simple bends |

| Initial Tooling Cost | Higher | Highest | Lower | Moderate |

| Per-Part Cost at Volume | Lowest | Moderate | Moderate | Moderate |

Sounds complex? Here's a quick decision framework: Start with your annual volume requirements. If you're producing hundreds of thousands of smaller parts, progressive dies typically deliver the best economics. For larger, complex parts or lower volumes, transfer or compound dies may prove more cost-effective despite higher per-piece costs.

Material type and thickness also influence your choice. Thicker materials or harder alloys may require the controlled forming capabilities of transfer systems, while thinner gauge materials work beautifully in high-speed progressive operations.

Understanding these distinctions positions you to have productive conversations with die manufacturers about your specific needs. But the die type is only part of the equation—the materials used to construct your tooling significantly impact performance, longevity, and ultimately, your production costs.

Die Materials and Selection Criteria

You've chosen your die type—but what should it be made from? The material inside your steel stamping dies directly determines how long your tooling lasts, how precise your parts remain, and ultimately, how much each component costs to produce. Think of it this way: selecting die materials is like choosing the right ingredients for a recipe. Even with perfect technique, inferior ingredients yield disappointing results.

So, what is tool & die material selection really about? It's balancing four critical factors: hardness for wear resistance, toughness to prevent cracking, heat resistance for high-speed operations, and cost-effectiveness for your production volume. Let's explore how different materials deliver on these requirements.

Tool Steel Grades and Their Performance Characteristics

Tool steel forms the foundation of most metal die applications. According to Ryerson's comprehensive guide, tool steel contains between 0.5% and 1.5% carbon along with carbide-forming elements like tungsten, chromium, vanadium, and molybdenum. These alloys deliver the hardness, abrasion resistance, and dimensional stability that die manufacturing demands.

Here are the most common grades you'll encounter in tool die making:

- D2 Tool Steel: A high-carbon, high-chromium steel offering exceptional wear resistance. Reaching 62-64 HRC after hardening, D2 excels in long-run tooling applications like blanking and punching dies requiring close tolerances. Its hard carbide particles provide outstanding abrasion resistance for high-volume production.

- A2 Tool Steel: An air-hardening steel known for balancing toughness with wear resistance. With 5% chromium content delivering 63-65 HRC hardness, A2 provides excellent dimensional stability—making it ideal for blanking punches, forming dies, and injection molding applications where precision matters.

- S7 Tool Steel: The shock-resistant champion. When your manufacturing tooling undergoes significant mechanical impact, S7's exceptional toughness prevents cracking and chipping. Achieving 60-62 HRC, this air-hardening steel works beautifully in chisels, punches, and rivet sets where impact resistance trumps maximum hardness.

- M2 Tool Steel: A high-speed steel that maintains sharpness at elevated temperatures. At approximately 62-64 HRC, M2 delivers excellent toughness and wear resistance for cutting tools like drills and taps—and for stamping dies running at higher speeds where heat buildup becomes a concern.

Notice how each grade offers distinct advantages? D2 prioritizes wear resistance for long production runs, while S7 sacrifices some hardness for superior impact resistance. Understanding these trade-offs helps you match steel stamping tools to your specific application demands.

Carbide Inserts for Extended Die Life

When tool steel isn't tough enough—or when you're stamping abrasive materials at extreme volumes—carbide inserts become your secret weapon. These tungsten-carbon composites deliver remarkable hardness and wear resistance that far exceed conventional steel tooling.

Why consider carbide for your metal die applications?

- Exceptional durability: Carbide maintains its cutting edge significantly longer than tool steel, reducing replacement frequency and minimizing production downtime

- Heat resistance: Carbide withstands elevated temperatures without losing hardness—critical for high-speed stamping operations

- Abrasive material capability: When stamping stainless steel, hardened alloys, or other wear-intensive materials, carbide inserts outlast steel alternatives by substantial margins

- Precision maintenance: The material's dimensional stability ensures consistent part quality throughout extended production runs

Carbide inserts are commonly applied in tool and die making for moulds and dies that must withstand extensive wear and tear. The trade-off? Higher initial cost compared to tool steel. However, for high-volume applications where durability drives overall economics, carbide often delivers superior total cost of ownership.

Selecting Materials Based on Your Production Requirements

Choosing between these options requires evaluating your specific situation. As noted by CMD PPL, proper material selection significantly impacts die performance, production efficiency, and finished part quality. Consider these factors:

- Production volume: High-volume runs justify carbide or premium tool steels like D2, while lower volumes may perform adequately with more economical options

- Workpiece material hardness: Stamping hardened or abrasive materials demands harder die materials—carbide or high-chromium steels resist wear from aggressive workpieces

- Tolerance requirements: Tighter tolerances require materials with superior dimensional stability, such as A2 or D2, that maintain precision over millions of cycles

- Budget constraints: Balance initial tooling investment against long-term costs including replacement dies, production downtime, and part rejection rates

- Operating temperatures: High-speed operations generate significant heat—select materials like M2 or carbide that retain hardness at elevated temperatures

Remember: dies constructed from robust materials with superior wear resistance require less maintenance and replacement over time. This reduces associated costs and downtime while maintaining steady production schedules. The right material choice isn't just about upfront cost—it's about total production economics.

With die types and materials now clear, how do you actually select the right combination for your specific project? The decision-making process involves weighing multiple factors against your unique requirements.

How to Choose the Right Die for Your Application

You've explored die types, materials, and components—but how do you actually make the right choice for your specific project? Selecting a die for press operations isn't about picking the most advanced or expensive option. It's about matching your production requirements with the tooling that delivers optimal results at the best total cost. Let's walk through a practical decision-making framework that turns complex variables into clear choices.

Think of this process like assembling a puzzle. Each factor—part geometry, volume, material, tolerance, and budget—represents a piece that fits together to reveal your ideal solution. When you understand how these pieces interact, the metal stamping process becomes far less mysterious.

- Define your part geometry and complexity: Start by examining what you're making. Is it a simple flat washer or a complex three-dimensional bracket? Does it require multiple bends, draws, or forming operations? Complex geometries typically push you toward progressive or transfer dies, while simpler shapes may work perfectly with compound tooling.

- Calculate your annual production volume: How many parts do you need per year? Volume dramatically influences your die press selection because higher quantities justify greater tooling investments that lower per-piece costs over time.

- Identify your material type and thickness: What metal are you stamping? Aluminum behaves differently than stainless steel, and material thickness affects forming forces, die wear, and tooling requirements.

- Establish tolerance requirements: How precise must your finished parts be? Tighter tolerances demand more sophisticated tooling and materials—driving both initial costs and ongoing maintenance requirements.

- Set realistic budget parameters: Balance your upfront tooling investment against long-term production economics. Sometimes spending more initially saves significantly over a die's lifetime.

Matching Die Type to Production Volume

Production volume serves as perhaps the most influential factor in die selection. Here's why: the stamping manufacturing economics shift dramatically based on how many parts you're producing.

For low-volume runs—say under 10,000 parts annually—the math often favors simpler tooling. Compound dies or even manual operations may prove more cost-effective because you're not producing enough parts to amortize expensive progressive tooling. According to Zintilon's die selection guide, estimating your annual production volume is crucial for justifying investment in different die types.

Medium-volume production (10,000 to 100,000 parts) opens more options. Combination dies or simpler progressive systems start making economic sense as the per-piece tooling cost spreads across more units. You'll want to analyze the break-even point where higher initial investment delivers lower total costs.

High-volume operations—hundreds of thousands or millions of parts—almost always point toward progressive dies for sheet metal stamping applications. The initial tooling investment, though substantial, becomes negligible when divided across massive production runs. Plus, progressive systems maximize press utilization and minimize labor costs per part.

Consider potential volume changes too. If you anticipate growth, investing in more capable tooling now may prevent costly retooling later. Conversely, uncertain demand might suggest starting with simpler dies until the market proves itself.

Tolerance Requirements That Drive Die Selection

How tight are your dimensional requirements? Tolerance specifications fundamentally shape your metal stamping choices—from die type to material selection to maintenance schedules.

According to Interstate Specialty Products' tolerance guide, die cutting tolerances vary significantly based on tooling type. Matched metal (male/female) dies achieve the tightest tolerances of .001" to .005", while steel rule dies typically deliver .010" to .015". Solid milled dies fall between at .005" to .010".

Here's how tolerance requirements interact with other factors:

- Tight tolerances + high volume: Invest in precision progressive tooling with hardened components and robust guide systems. The consistency pays dividends across millions of cycles.

- Tight tolerances + low volume: Matched metal compound dies may deliver required precision without progressive die investment.

- Moderate tolerances + high volume: Standard progressive dies work beautifully—no need for premium precision tooling.

- Loose tolerances + any volume: Focus on speed and cost rather than premium tooling. Simple dies often suffice.

Remember that tolerance capabilities depend on more than just die type. Material properties, press condition, and maintenance practices all influence dimensional consistency. Harder materials may exhibit spring-back that requires compensation in die design, while softer metals can deform during handling.

Understanding the Press and Die Relationship

Your die press capabilities directly constrain your tooling options. Before finalizing die selection, evaluate these press characteristics:

- Tonnage capacity: Does your press generate sufficient force for the planned operations? Material thickness, hardness, and part complexity all affect required tonnage.

- Bed size: Will your die fit within the press's working envelope? Consider not just the die dimensions but also feed mechanisms and part ejection requirements.

- Stroke length: Is the ram travel adequate for your forming operations? Deep draws require longer strokes than simple blanking.

- Speed capabilities: Does the press support your production rate requirements? Progressive dies demand presses capable of higher stroke rates.

The metal stamping process works best when die and press are properly matched. An undersized press strains components and shortens die life, while an oversized press wastes energy and capital. Work with your die manufacturer to ensure compatibility before committing to tooling investment.

Balancing Budget Against Production Economics

Metal parts stamping decisions ultimately come down to economics. Initial die cost represents just one piece of the financial puzzle—consider the complete picture:

- Tooling investment: What's the upfront cost for die design and fabrication?

- Per-piece production cost: How does tooling choice affect labor, material waste, and cycle time?

- Maintenance expenses: What ongoing costs will you incur for die maintenance and repair?

- Replacement frequency: How often will you need new tooling based on production volume and die material selection?

- Quality costs: What are the rejection rates and rework expenses associated with different tooling options?

As Zintilon notes, die selection significantly influences operational costs through reduced material waste, minimized downtime, and extended tool life. The right die reduces maintenance requirements and lowers replacement frequency—savings that compound over production lifecycles.

Don't let initial sticker shock drive you toward inadequate tooling. A $50,000 progressive die producing parts at $0.03 each may deliver far better economics than a $15,000 compound die producing the same parts at $0.08 each—depending on your volume. Run the numbers for your specific situation.

With your decision framework established, you're ready to explore how modern technology transforms die design and development—reducing risk and accelerating time-to-production.

Modern Die Design Technology and CAE Integration

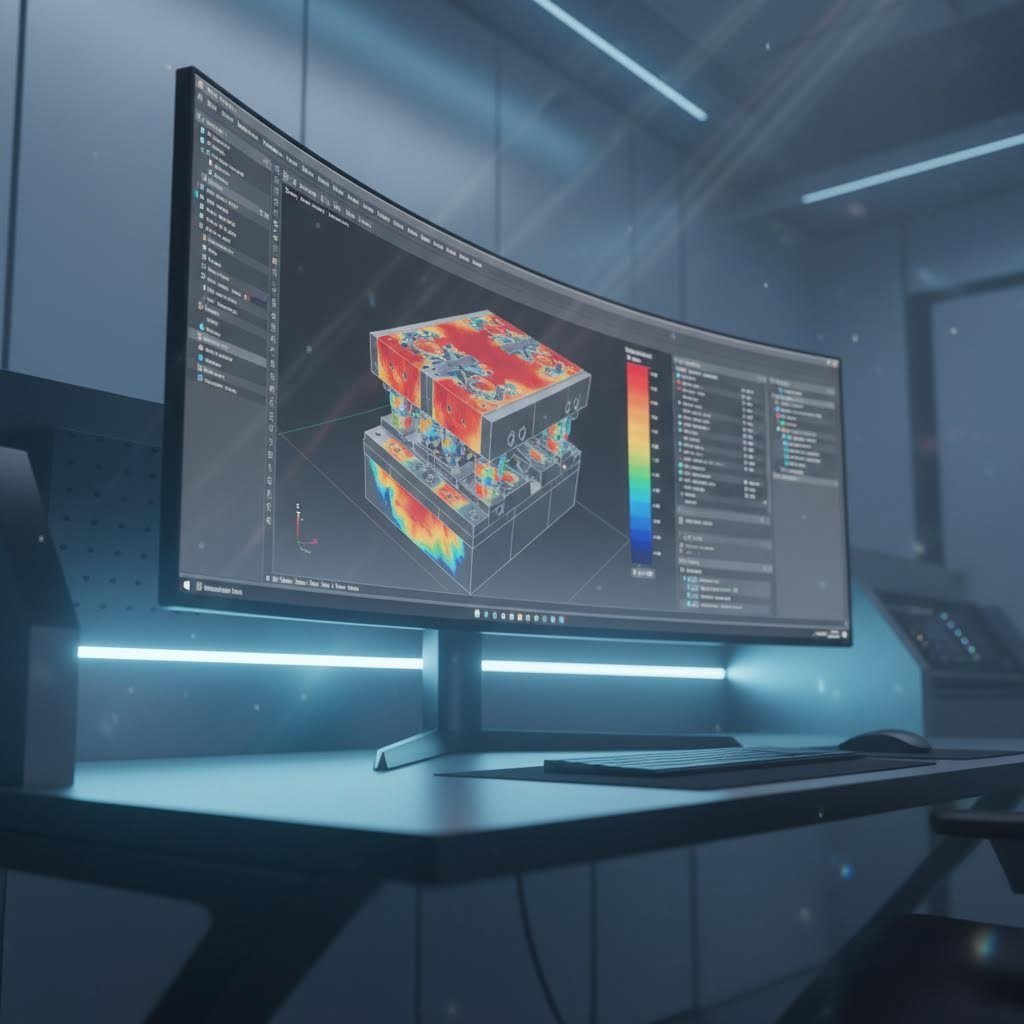

Imagine discovering a critical flaw in your stamping die—not during expensive physical trials, but on a computer screen weeks before cutting any steel. That's the power modern stamping die design technology brings to manufacturing. Today's die machine development has evolved far beyond traditional drafting boards, embracing sophisticated digital tools that predict problems, optimize performance, and slash development timelines.

How does metal stamping die design actually work in modern facilities? The answer involves a powerful combination of CAD/CAM software, simulation tools, and computer-aided engineering analysis that transforms concepts into production-ready tooling with remarkable precision. Let's explore how these technologies revolutionize the die process from initial concept through final production.

CAD/CAM Software Applications in Die Design

Every precision die in manufacturing starts as a digital model. Computer-Aided Design (CAD) software enables engineers to create detailed three-dimensional representations of every die component—from punch profiles to guide pin placements. But modern systems go far beyond simple geometry creation.

According to VISI Die Tool Design documentation, today's integrated CAD/CAE/CAM platforms automate every stage of sheet metal die development—from blank creation and unfolding to tool assembly, force calculation, and manufacturing. These systems offer capabilities that dramatically accelerate the design process:

- Variable neutral fiber calculation: Precisely determines the neutral axis for enhanced blank prediction and unfolding accuracy

- Part analysis and bend study: Thoroughly assesses manufacturability, providing insights into potential forming or stretching issues

- Automatic blank development: Effortlessly unfolds both surface and solid models to generate optimal developed blanks

- Step-by-step unfolding: Simulates and plans every forming stage, incorporating features at exactly the right process step

- 3D strip design: Quickly builds strip layouts, rotates and aligns blanks, and dynamically manages stages

The integration between design and manufacturing proves particularly valuable. Modern platforms automatically generate drill cycles, milling routines, and 3D toolpaths for every plate and component—eliminating manual programming errors and ensuring the physical die processing matches design intent perfectly.

CAE Simulation in Modern Die Development

Here's where things get truly powerful. Computer-Aided Engineering (CAE) simulation allows engineers to virtually test die performance before committing to expensive tooling fabrication. Think of it as a crystal ball that reveals how your die will behave under real production conditions.

As detailed by ETA's sheet metal forming simulation guide, these simulations enable engineers to predict and optimize metal sheet behavior during shaping operations. The technology guides design decisions, reduces trial-and-error iterations, and enhances product quality across automotive panels, aerospace components, and consumer appliances.

What makes CAE simulation so valuable for automotive stamping die development? The ability to identify critical defects before they occur:

- Springback prediction: Materials rebound elastically after forming forces are removed, causing deviations from intended shapes. Advanced simulation accounts for material anisotropy, the Bauschinger effect, and residual stresses to predict this behavior accurately

- Wrinkling detection: Simulation reveals where material compression may cause surface defects, allowing engineers to adjust blank holder forces or die geometry

- Thinning analysis: Identifies areas where material stretches excessively, risking tears or structural weakness in finished parts

- Material flow optimization: Visualizes how metal moves through the die, enabling adjustments to draw beads, blank holders, and die radii

According to Keysight's analysis, part and process design defects often emerge only during first trials in the try-out stage—when corrections are both time-consuming and costly. Virtual simulation eliminates this costly discovery phase by revealing problems during the digital design stage.

Digital Prototyping That Prevents Costly Errors

Traditional die development followed a frustrating pattern: design, build, test, discover problems, modify, and repeat. Each iteration consumed weeks and substantial costs. Digital prototyping breaks this cycle by compressing multiple physical iterations into virtual refinements.

The die process benefits enormously from iterative simulations. Engineers run multiple cycles adjusting tooling and process parameters, gradually achieving closer alignment with desired part geometry. Compensation strategies—like over-bending or modifying tool geometry—can be tested virtually before implementation.

Consider the critical process parameters that simulation helps optimize:

- Blank holder force: Controls pressure on sheet metal to prevent wrinkling while avoiding tearing or excessive thinning

- Punch speed: Influences strain rates and material temperature during deformation

- Lubrication conditions: Reduces friction between tool and material, ensuring smooth material flow

- Temperature parameters: Critical for hot forming processes where material response changes significantly

The result? Leading manufacturers leveraging these technologies achieve remarkably high first-pass approval rates. For example, Shaoyi's engineering team reports a 93% first-pass approval rate on their automotive stamping die projects—a testament to the power of advanced CAE integration combined with IATF 16949 certified quality management systems.

Quality Management Through Certification Standards

Technology alone doesn't guarantee results—systematic quality management ensures consistent outcomes. IATF 16949 certification has become the benchmark for automotive die production, establishing rigorous requirements for design validation, process control, and continuous improvement.

This certification matters because it ensures simulation results translate into physical reality. When manufacturers combine advanced CAE capabilities with certified quality systems, they deliver tooling that performs as predicted—reducing costly surprises during production ramp-up.

The integration of digital prototyping with robust quality management also accelerates time-to-production dramatically. Rather than months of physical trials, manufacturers can move from concept to production-ready tooling in weeks. Some providers offer rapid prototyping capabilities delivering initial samples in as little as five days—impossible without the predictive power of modern simulation technology.

With die design technology optimizing your tooling before production begins, you'll still encounter challenges once stamping operations commence. Understanding common problems and their solutions ensures your investment delivers maximum returns.

Troubleshooting Common Stamping Die Problems

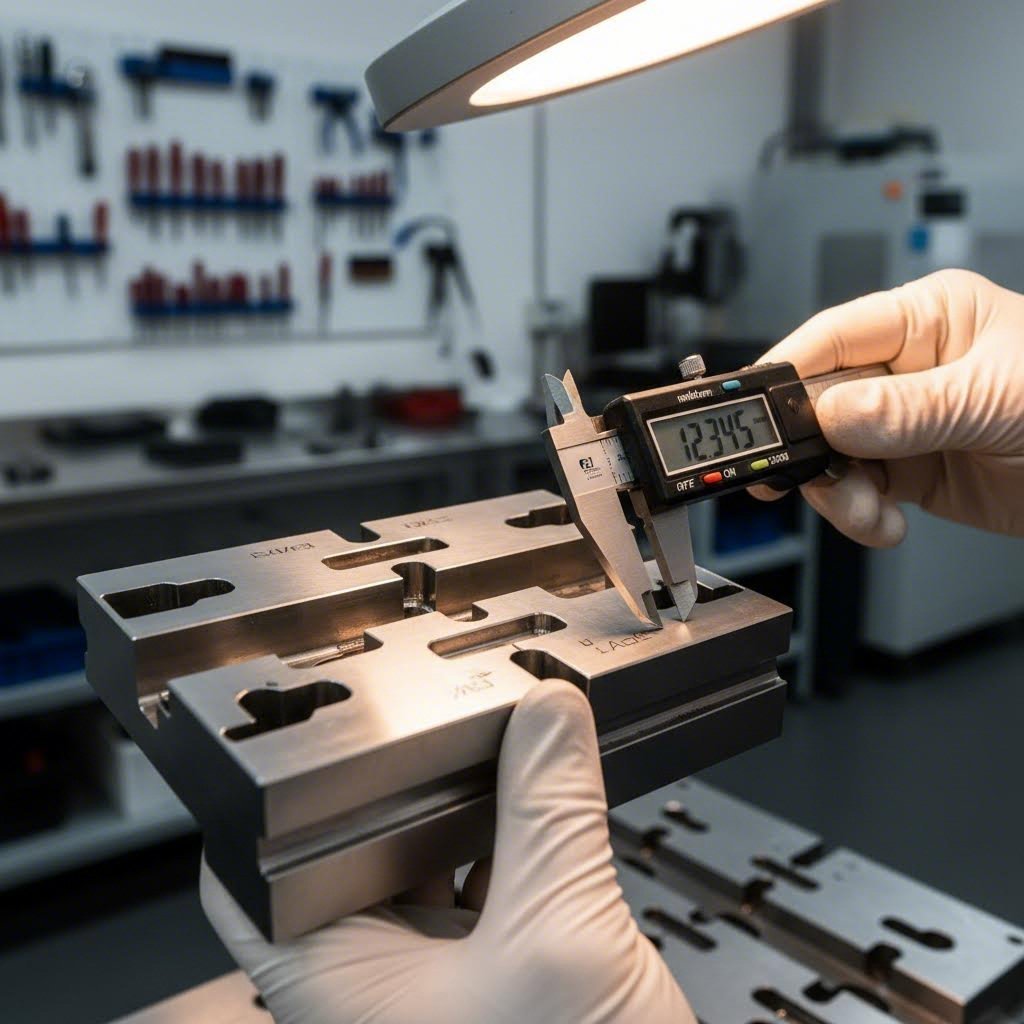

Even the best-designed stamping dies encounter problems during production. The difference between a minor hiccup and a costly production shutdown often comes down to how quickly you diagnose and resolve issues. When stamped parts start showing defects—burrs, dimensional drift, or surface imperfections—knowing the root cause saves you hours of frustrating trial-and-error.

Ready to become a die troubleshooting expert? Let's walk through the most common problems you'll encounter with stamped sheet metal and the proven solutions that get production back on track.

Diagnosing Burr and Edge Quality Issues

Burrs are those annoying raised edges or rough protrusions that form along cut lines—and they're among the most frequent complaints in stamping operations. According to Leelinepack's defect analysis, burrs typically result from excessive tool wear or misalignment during the stamping process.

What causes burrs to form on your stamped parts?

- Excessive punch-to-die clearance: When the gap between punch and die grows too large—often from wear—metal tears rather than shears cleanly

- Dull cutting edges: Worn punch or die surfaces can't produce the clean fracture needed for smooth edges

- Misalignment: When upper and lower die halves don't meet precisely, uneven cutting forces create irregular edges

- Improper material selection: Some materials are more prone to burr formation based on their hardness and ductility

How do you eliminate burrs? Start with regular tool inspection and sharpening schedules. According to DGMF's troubleshooting guide, regularly using an alignment mandrel to check and adjust machine tool turret alignment prevents the uneven wear that leads to burr formation. Also, ensure you're selecting convex and concave mold combinations with appropriate clearance for your material type and thickness.

Solving Dimensional Variation Problems

When your stamped parts suddenly fall out of tolerance, production grinds to a halt. Dimensional inconsistency frustrates quality teams and delays shipments—but the causes are usually traceable with systematic investigation.

Springback ranks among the most challenging dimensional issues. As Leelinepack explains, springback occurs when material partially restores its original shape after forming forces are removed. This problem intensifies with high-strength materials where the difference between yield strength and tensile strength is relatively small.

Factors influencing dimensional variation include:

- Material property inconsistency: Batch-to-batch variations in hardness, thickness, or grain structure affect forming behavior

- Die wear patterns: Uneven wear across die surfaces causes progressive dimensional drift

- Temperature fluctuations: Thermal expansion of dies and materials during extended runs shifts dimensions

- Press tonnage variations: Inconsistent force application produces variable forming results

Solutions focus on compensation and control. Use CAE simulation to predict springback and design dies with appropriate overbend angles. Implement strict incoming material inspection to catch property variations before they reach production. Monitor die temperatures during extended runs and consider cooling systems for high-speed operations.

Comprehensive Troubleshooting Matrix

When problems arise, quick diagnosis matters. Use this reference matrix to identify likely causes and implement proven solutions for common metal stamping techniques issues:

| Problem | Likely Cause | Solution |

|---|---|---|

| Burr formation | Excessive clearance, dull edges, or misalignment | Sharpen cutting edges, verify clearances, realign die components using alignment mandrel |

| Dimensional inconsistency | Springback, material variation, or die wear | Compensate die geometry, implement material inspection, replace worn components |

| Premature die wear | Insufficient lubrication, improper material selection, or excessive tonnage | Optimize lubrication, upgrade to harder die materials, verify press settings |

| Galling (material transfer) | Inadequate lubrication, excessive pressure, or incompatible materials | Apply appropriate lubricants, reduce forming forces, consider surface treatments |

| Part distortion/warping | Uneven force distribution, residual stresses, or improper blank holding | Adjust binder force, optimize blank shape, position forming operations away from edges |

| Wrinkling | Insufficient blank holder force or excessive material flow | Increase binder pressure, add draw beads, optimize blank dimensions |

| Splitting/tearing | Excessive stretching, sharp die radii, or insufficient material ductility | Increase fillet radii, select materials with better elongation, adjust lubrication |

| Inconsistent feeding | Edge camber in coil material, worn feed mechanisms, or missing pitch notches | Add pitch notches, replace worn feeders, verify coil quality |

Understanding Bypass Notches in Sheet Metal Stamping Dies

Ever wondered about the purpose of bypass notches in stamping dies? These small but critical features—sometimes called pitch notches or French notches—serve essential functions in progressive die operations that prevent catastrophic failures.

According to The Fabricator's technical analysis, bypass notches in sheet metal stamping dies serve several vital purposes:

- Overfeed prevention: Pitch notches provide a solid stop that prevents operators from overfeeding material into the die—a condition that causes severe damage and creates safety hazards

- Edge camber removal: By cutting a straight line on the strip edge, notches eliminate the severe edge camber that can result from coil slitting, allowing smooth material feeding

- First-hit positioning: Properly placed notches provide a starting location for the leading edge when material first enters the die

- Part registration: For large progressive dies using wide or thick coil material, pitch notches help locate and register each part in its proper station

The bypass notches sheet metal forming purpose extends beyond simple feeding control. As The Fabricator notes, one severe die crash from overfeeding can cost 100 times more than the additional material consumed by a pitch notch. Even sophisticated electronic die protection cannot prevent feeding problems caused by edge camber—only physical notches provide that capability.

An innovative alternative to conventional slug-producing pitch notches is the lance and flange design. This approach lances a small area in the strip and bends it down to create a straight flange. The flange provides a solid stop while also stiffening the carrier and aiding feeding—without the slug shedding problems associated with traditional notches.

Preventing Recurring Problems

Troubleshooting reactive problems is essential, but preventing issues before they occur delivers better results. According to DGMF's guidelines, implementing these practices significantly reduces stamped parts defects:

- Direction verification: Always check mold direction during installation to ensure punch and die are aligned correctly

- Incremental adjustments: Limit stamping depth adjustments to no more than 0.15mm per change to avoid overcorrection

- Speed management: Use lower punching speeds when introducing new tooling or materials

- Material preparation: Ensure plates are flat without deformation or warping before processing

- Process sequencing: Position forming operations away from clamps and use common dies first, saving forming dies for final operations

Systematic troubleshooting transforms random problem-solving into predictable quality management. Document your findings, track recurring issues, and use that data to drive preventive improvements. The patterns you discover often reveal opportunities for die design refinements or process parameter adjustments that eliminate problems at their source.

With troubleshooting skills in your toolkit, the next priority becomes extending die life through proper maintenance—maximizing your tooling investment and minimizing production interruptions.

Die Maintenance and Lifecycle Management

Your stamping die just produced its millionth part—but how many more cycles can it deliver before quality suffers? Understanding die maintenance isn't just about fixing problems when they occur. It's about maximizing your tooling investment through systematic care that extends die life, reduces unplanned downtime, and keeps your die stamped parts consistently within specification.

According to The Phoenix Group's maintenance analysis, a poorly defined die shop management system—including die maintenance and repair processes—can dramatically decrease press line productivity and increase costs. The solution? Implementing proactive lifecycle management that addresses potential issues before they disrupt production.

Preventive Maintenance That Extends Die Life

Think of preventive maintenance like regular health checkups—catching small issues before they become expensive emergencies. A well-structured maintenance program keeps every die maker and steel stamper operating at peak efficiency while preventing the quality defects that drive up sorting costs and risk shipping defective parts.

What should your preventive maintenance checklist include?

- Visual inspection after each run: Check for obvious surface damage, cracks, pitting, or discoloration on cutting edges and forming surfaces

- Cutting edge sharpness verification: Measure edge condition and schedule sharpening before burr formation begins affecting part quality

- Clearance measurements: Verify punch-to-die clearances remain within specification—wear increases clearances over time

- Guide system inspection: Check guide pins and bushings for wear that causes alignment drift

- Spring condition assessment: Verify springs maintain proper tension for stripping and pressure pad functions

- Lubrication system review: Ensure lubrication points receive adequate coverage and lubricant quality remains acceptable

- Fastener torque verification: Confirm all bolts and set screws maintain proper tension

- Pilot and locator inspection: Check positioning components for wear that affects material registration

According to Keneng Hardware's wear analysis, routine maintenance and inspection are critical for identifying potential issues before they result in die failure. Regularly scheduled maintenance allows manufacturers to address wear early and replace or repair components before they cause significant problems.

Wear Indicators That Signal Service Needs

How do you know when your standard die requires attention? Experienced stamping die manufacturing professionals watch for specific warning signs that indicate developing problems:

- Burr formation on stamped parts: Increasing burr size signals cutting edge wear or clearance issues

- Dimensional drift: Parts gradually moving out of tolerance indicate wear in forming surfaces or guides

- Surface finish degradation: Scratches or marks appearing on parts suggest die surface damage or lubrication failure

- Increased stripping force: Parts sticking to punches indicate wear on strippers or galling conditions

- Unusual noise or vibration: Changes in sound during operation often precede visible failures

- Visible wear marks: Polished areas, grooves, or material buildup on die surfaces require immediate attention

Tracking these indicators through production records helps establish patterns. When you notice burrs appearing after 50,000 hits, you can schedule sharpening at 45,000 hits—preventing quality issues rather than reacting to them.

Factors Affecting Die Lifespan

Why do some die stamps last millions of cycles while others wear out in thousands? Several interacting factors determine how long your tooling remains productive:

- Die material quality: Premium tool steels and carbide components outlast economy alternatives significantly—sometimes by ten times or more

- Production volume and intensity: Higher stroke rates and continuous operation accelerate wear compared to intermittent production

- Workpiece material characteristics: Stamping abrasive materials like stainless steel or high-strength alloys wears dies faster than mild steel or aluminum

- Maintenance consistency: Regular preventive care extends life dramatically—neglected dies fail prematurely

- Lubrication effectiveness: Proper lubrication reduces friction and heat, slowing wear progression

- Press condition and alignment: Well-maintained presses with proper alignment distribute forces evenly, preventing localized wear

- Operator practices: Proper setup, material handling, and operating procedures protect tooling from avoidable damage

Understanding these factors helps you predict maintenance needs and budget for tooling costs accurately. A stamp die running high-strength steel at maximum speed requires more frequent attention than one processing aluminum at moderate rates.

The Refurbish vs Replace Decision

Eventually, every die reaches a crossroads: invest in refurbishment or purchase new tooling? Making this decision wisely requires honest cost-benefit analysis rather than emotional attachment to existing equipment.

Consider refurbishment when:

- Wear is limited to replaceable components like punches, buttons, or springs

- The die block and shoe remain dimensionally stable and undamaged

- Refurbishment costs fall below 40-50% of replacement cost

- The original design still meets current part requirements

- Lead time for new tooling would cause unacceptable production gaps

Consider replacement when:

- Core components like die blocks show fatigue cracks or dimensional instability

- Cumulative repairs approach or exceed replacement cost

- Design changes require modifications beyond practical refurbishment scope

- The original design incorporates outdated technology that limits performance

- Quality requirements have tightened beyond the existing die's capability

As The Phoenix Group emphasizes, decisions should be based on production needs, customer satisfaction, and return on investment. A die with frequent quality issues may cost more in sorting, scrap, and customer complaints than replacement tooling would—even if individual repairs seem economical.

Document your maintenance history thoroughly. Tracking repair frequency, costs, and quality trends provides the data needed for confident refurbish-or-replace decisions. When a die requires quarterly repairs while similar tooling runs trouble-free, the pattern speaks clearly.

With proper lifecycle management maximizing your existing tooling investment, you're positioned to evaluate manufacturing partners who can deliver quality dies when new tooling becomes necessary.

Selecting a Stamping Die Manufacturing Partner

You've mastered die types, materials, troubleshooting, and maintenance—but none of that knowledge matters without the right manufacturing partner bringing your tooling to life. Choosing a tool and die supplier isn't simply about finding the lowest quote. It's about identifying a partner whose capabilities, quality systems, and engineering expertise align with your production goals and quality requirements.

Think about it this way: your stamping tool and die represents a significant investment that will produce parts for years. The manufacturer you select determines whether that investment delivers reliable production or endless headaches. So what separates exceptional die and tool partners from mediocre ones? Let's explore the criteria that matter most.

Evaluating Die Manufacturing Partners

According to Penn United's supplier evaluation guide, selecting a precision metal stamping supplier requires considering multiple factors beyond unit cost. Making purchasing decisions based solely on quoted price may result in overall dissatisfaction with supplier performance—or even disastrous outcomes.

What should you prioritize when evaluating tool and die manufacturing partners?

- Shaoyi Precision Stamping: Exemplifies comprehensive capabilities with IATF 16949 certification, advanced CAE simulation delivering 93% first-pass approval rates, and rapid prototyping in as little as 5 days—backed by engineering expertise tailored to OEM standards

- Years of experience: Understand how long suppliers have operated and their familiarity with components similar to yours—whether flat parts, formed parts, or complex geometries

- Die design capability: Suppliers who design precision metal stamping dies understand which features and stations deliver maximum efficiency and quality during production

- Die building and troubleshooting expertise: Partners who build dies in-house can troubleshoot unplanned stamping issues quickly, minimizing production interruptions

- Process control systems: ISO or IATF certification provides assurance that control processes are properly implemented and maintained

- Die maintenance programs: Comprehensive maintenance offerings maximize die life and optimize total lifecycle costs

- Delivery track record: Suppliers actively tracking on-time delivery performance demonstrate the systems needed to meet commitments consistently

- Running speed capability: Experienced metal stamping tool suppliers achieve faster speeds while maintaining quality, providing optimized pricing

- Spare tooling provisions: Proactive discussion of spare tooling requirements maximizes success likelihood for stamping campaigns

- Secondary operation capabilities: Partners offering cleaning, plating, assembly, or custom automation provide significant supply chain logistics savings

Notice how these criteria extend far beyond initial pricing? As Penn United emphasizes, a supplier who asks detailed questions about part quality, key features, and tolerances early in the quoting process typically over-delivers on attention to detail throughout the project.

From Prototype to Production Excellence

What is die manufacturing success really about? It's the seamless journey from initial concept through validated production. According to Transmatic's prototyping analysis, custom prototyping is essential for industries like automotive, HVAC, and aerospace where components must meet strict tolerances and performance standards.

Why does prototyping capability matter so much in metal stamping manufacturing? Prototypes allow engineers to validate designs before committing to full-scale production. By producing sample parts, manufacturers identify potential issues—stress points, material deformation, or fitment problems—early in the process when corrections cost far less.

Quality partners leverage prototyping to deliver multiple benefits:

- Design validation: Physical samples reveal issues that even sophisticated simulation might miss, particularly in progressive die stamping where complex dies create intricate parts

- Material optimization: Testing various materials during prototyping identifies the best fit for performance requirements before committing to production tooling

- Cost reduction: Catching design flaws and manufacturing inefficiencies early avoids costly revisions once production tooling is complete

- Quality assurance: Testing parts under simulated conditions ensures components meet the highest standards before mass production begins

Metal stamping and forming success depends on this validation phase. Soft tooling approaches—using temporary dies made from aluminum or urethane—provide cost-effective prototype parts quickly, testing designs before investing in hardened steel production tooling.

Quality Certifications That Matter

How do you verify a supplier's quality claims? Certifications provide independent validation that manufacturers maintain rigorous quality systems. For stamping tool and die suppliers serving automotive applications, IATF 16949 certification represents the gold standard.

This certification ensures suppliers maintain:

- Documented design validation processes

- Statistical process control throughout production

- Continuous improvement systems

- Traceability for materials and processes

- Customer-specific requirement management

Visiting suppliers and observing their quality systems in operation remains the best way to evaluate attention to process control. Determine the role of quality technicians, evaluate investment in inspection equipment, and understand how control plans guide production operations.

Making Your Final Selection

Ready to move forward with your metal stamping tool project? Summarize your requirements—part geometry, annual volume, material specifications, tolerance requirements, and budget parameters—before engaging potential suppliers. This preparation enables focused conversations and comparable quotations.

Remember: the right partner combines technical capability with responsive communication and proven quality systems. They'll ask probing questions about your application, offer design-for-manufacturability suggestions, and demonstrate relevant experience with similar components.

Your stamping die investment deserves a partner who treats your success as their own. Whether you need rapid prototyping to validate designs or high-volume production tooling built to OEM specifications, selecting the right tool and die manufacturer transforms your metal stamping vision into production reality.

Explore comprehensive mold design and fabrication capabilities at Shaoyi's automotive stamping dies resource center to see how advanced engineering and certified quality systems deliver precision tooling that performs.

Frequently Asked Questions About Dies for Stamping

1. How much does a metal stamping die cost?

Metal stamping die costs range from $500 to $15,000 or more depending on complexity, die type, and production requirements. Progressive dies for high-volume production typically cost more upfront but significantly reduce per-part costs. Factors influencing price include part geometry, tolerance requirements, die materials like D2 or carbide, and whether CAE simulation is used during design. Working with IATF 16949 certified manufacturers like Shaoyi can optimize costs through advanced simulation achieving 93% first-pass approval rates.

2. What is the difference between die cut and stamping?

Die cutting and metal stamping are distinct processes. Die cutting typically refers to cutting materials using a shaped blade or rule die, often for softer materials like paper or leather. Metal stamping uses matched punch and die sets in a press to cut, bend, form, or shape sheet metal through high-pressure operations. Stamping is almost always a cold working process using sheet metal blanks or coils, while die casting melts metal. Stamping dies perform multiple operations including piercing, embossing, drawing, and coining.

3. What is the difference between a progressive die and a stamping die?

A stamping die is the general term for any precision tool used to cut or form sheet metal in a press. A progressive die is a specific type of stamping die containing multiple stations that perform sequential operations as material advances through the tool. While compound dies complete multiple operations simultaneously at one station, progressive dies produce finished parts with each press stroke by feeding strip material through several stations. Transfer dies differ by moving individual blanks between separate stations.

4. What are the main components of a stamping die?

Essential stamping die components include the punch (male component applying force), die block (female component with cavity), stripper plate (holds material and removes it from punch), guide pins and bushings (ensure alignment), backing plates (prevent deformation), and die set (upper and lower shoes providing framework). Additional components like pilots for material positioning, springs for return motion, and knockouts for part ejection work together to achieve consistent dimensional accuracy across millions of cycles.

5. How do I choose the right stamping die for my application?

Selecting the right stamping die requires evaluating five key factors: part geometry complexity, annual production volume, material type and thickness, tolerance requirements, and budget constraints. High-volume runs over 100,000 parts favor progressive dies for lowest per-piece costs. Complex three-dimensional parts may require transfer dies. Compound dies suit medium volumes with tight tolerances between features. Consider press compatibility including tonnage, bed size, and stroke length. Partnering with experienced manufacturers offering CAE simulation helps optimize selection.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —