Өнеркәсіпте қолданылатын алюминий: салмақ пен құнды азайтатын қолданыстары

Неліктен өндірісте барлық жерде алюминий қолданылады

Алюминий дегеніміз не және өндірісте неліктен оған сүйенеді

Сіз газдалған су банкасын алып, биік ғимараттың терезесінен қарап немесе заманауи көлік немесе ұшақпен саяхат жасап жатқан кезде, әсіресе алюминийдің жұмысын көріп тұрсыз. Бірақ дәл не алюминий және ол неліктен өндірістің көптеген салаларында қолданылады? Жауап оның өзіне тән қасиеттерінде, соның арқасында материал көптеген өндірістік қолданыстар үшін таңдалады. өндірісте алюминийдің қолданысы транспорттан бастап құрылысқа, электр жүйелеріне, ыдыстауға және одан әрі қарай таралған, оңай әрі берік материалдардың қажеттілігіне негізделген.

Алюминий мен алюминум: екі жазылу, бір металл

Сіз «алюминий» және «алюминий» сөздерінің әртүрлі мәтіндерде кездесетінін байқаған болуыңыз мүмкін. Екі атау да дұрыс: «алюминий» Америка Құрама Штаттары мен Канадада қолданылады, ал «алюминий» Британия мен әлемнің басқа бөліктерінде қолданылады. Бұл айырмашылық 19 ғасырдың басына жатады, осы кезде ғалымдар мен сөздіктер стандартты атаудың жалғыз нұсқасына келісе алмады. Қазіргі таңда Таза және Қолданбалы Химиялық Қоғамдар Одағы екі түрін де мойындайды, сондықтан сіз көрермендердің немесе аймақтың талаптарына сәйкес бір немесе екінші нұсқаны қолдана аласыз. Атауы қандай болса да, металдың қасиеттері мен көпқырлылығы өзгермейді.

Қабылдауды қозғалысқа келтіретін негізгі қасиеттер

Неліктен алюминий салмақты өте жеңіл, бірақ салмағына қарай мықты? Бұның себебі оның тығыздық — шамамен 2,7 г/см³, болаттың үштен бір бөлігін құрайды. Бұл инженерлерге компоненттерді жеңілдетіп, отын шығынын және материалдық шығындарды азайтуға мүмкіндік береді. Бірақ алюминий басқа металдармен салыстырғанда ауыр ма? Ешқандай, керісінше, оның төмен тығыздығы — ең үлкен артықшылықтарының бірі.

Сондықтан, алюминий берік пе ? Таза алюминий болаттан жұмсақ болса да, басқа элементтермен қосылған кезде салмағына қатысты беріктігі едәуір артады. Бұл әрі берік, әрі жеңіл болуы қажеттігін қанағаттандыратын қолданыстар үшін идеалды, мысалы, ұшақ шассиі, көлік кузовы және конструкциялық панельдер.

- Жеңіл : Көліктер мен ғимараттарда отын шығынын және конструкциялық жүктемені азайтады.

- Коррозияға тұрақтылық : Табиғи түрде қорғаныш оксидті қабат түзеді, бұл оны теңіз, ашық ауа және ыдыстау үшін қолайлы етеді.

- Тепловоділік және электр ластаныс : Жылу шығарғыштар, электр желілері және электроника үшін өте жақсы.

- Қоспалануы : Магний, кремний және мыс сияқты элементтермен біріктіріп, беріктігін, пластикалылығын және өңдеуге қабілеттілігін реттеуге болады.

- Тікелей қайта өңдеуге мүмкіндік : Алюминий сапасын жоғалтпай қайта переработка жасауға болады, энергия шығынын азайтып, тұрақты дамуды қолдайды.

| Қасиет | Пайда | Өнеркәсіптік әсер |

|---|---|---|

| Төмен тығыздық (2,7 г/см³) | Жеңіл | Отын үнемдейтін көліктер, ыңғайлы пайдалану және конструкциялық жүктемені азайтуды іске асырады |

| Коррозияға тұрақтылық | Ұзақ қызмет мерзімі | Теңіз, құрылыс және ыдыстау салаларында пайдалануға ыңғайлы |

| Жоғары проводимдік | Жылу/электр беру тиімділігі | Электр сымдарында, электроника және жылу алмастырғыштарда пайдаланылады |

| Қоспалануы | Қасиеттерін баптау мүмкіндігі | Нақты пайдалану жағдайларына сәйкес беріктік пен пішінделуін реттеу |

| Тікелей қайта өңдеуге мүмкіндік | Энергияны аз пайдалану | Шеңберлік экономиканы қолдайды және қоршаған ортаға әсерін азайтады |

Таза металға дейінгі шолу: Қысқаша шолу

Алюминий негізінен бокситтен алынады. Оны өңдеу процесі бокситті алюминий тотығына (Al₂O₃) дейін тазарту мен кейіннен электролиз арқылы таза алюминий металына дейін қысқарту қамтиді. Осы таза металға дейінгі өнім өндіру энергия көп қажет ететін процесс болса да, оны шексіз рет қайта өңдеуге болатындықтан, өнеркәсіп үшін тұрақты таңдау болып табылады (бұлақ) .

Мәнді максималдай үшін алюминий қасиеттерін орта, жүктеме және өмір сүру цикліне сәйкестендіріңіз.

Жалпы алғанда, алюминийдің салмақтың аздығы, беріктігі, коррозияға тұрақтылығы және қайта өңдеуге болатындығы оның өнеркәсіпте қолданысының кеңейіп келе жатқанының негізгі себептері болып табылады. Көлік құралын жобдасаңыз, биік ғимарат салсаңыз немесе азық-түлікті қаптап жатсаңыз, осы қасиеттерді түсіну сізге өнімділік пен құндылық тұрғысынан тиімді материалды таңдауға көмектеседі.

Өнеркәсіпте алюминий қай жерде көп қолданылады

Алюминийге деген сұраныс қай жерде шоғырланған

Рафинадан шыққан соң сол алюминийдің бәрі қай жерге баратынын еш ойладыңыз бе? Жауабы: барлық жерге. өнеркәсіптегі алюминийдің қолданылуы ұшақ рамаларынан бастап мұздатқыш фольгасына дейінгі аралықты қамтиды. Бірақ кейбір салалар бұл металға басқаларға қарағанда көбірек тәуелді – әрқайсысы алюминийдің жеңіл салмақтылығы, коррозияға тұрақтылығы мен пішінделуіне байланысты нақты себептерге байланысты. Негізгі өнеркәсіп салаларын талқылап шығайық және экструзиялар, алюминий жапсырлары мен құймалар сияқты әртүрлі пішіндер шынайы қолданыстарға қалай сәйкес келетінін көрейік.

| Сектор | Басым өнім пішіндері | Негізгі таңдау ынталандырғыштары | Типтік өнім мысалдары |

|---|---|---|---|

| Транспорт (Автомобиль, Әуе шаруашылығы, Темір жол) | Профильді шығару, алюминий жапсырмалары, парақтар, құймалар | Салмақтың азаюы, отын тиімділігі, беріктік | Автокөлік шассиі, корпус панельдері, ұшақ фюзеляжі, пойыздардың корпусы |

| Ғимарат және құрылыс | Профильді шығару, парақ, пластина, алюминий құбыры, арқалықтар | Қорға тұрақтылық, дизайның икемділігі, жасалуының жеңілдігі | Терезе аяқтары, перде қабырғалары, шатырлар, құрылымдық тіреулер |

| Электр және электроника | Сым (мысалы, 4/0 алюминий сымы), фольга, профильді шығару | Өткізгіштік, жеңіл салмақ, пластикалық қасиет | Электр желілері, жылу шығыны, қосқыштар |

| Қаптама | Фольга, жапырақ, сақтау үшін ыдыстар | Кедергі қасиеттері, пішінделуі, қайта өңделуі | Ішімдіктер банкасы, тағам ыдыстары, иілгіш орау |

| Өнеркәсіптік жабдықтар мен машиналар | Пластина, экструзия, құймалар, таяқша | Салмаққа қатысты беріктік, өңделгіштік, коррозияға тұрақтылық | Машина рамалары, корпус, тасымалдау жүйелері |

| Деніздік | Жапырақ, пластина, экструзия | Коррозияға тұрақтылық, аз салмақ | Қайықтардың корпусы, надстройки, жалғау өзектері |

- Сыртын азайту көлік және құрылыс салаларындағы негізгі тенденция болып табылады және экструдерленген және қаңылтыр алюминий өнімдеріне деген сұранысты арттырады.

- Электрлендіру көліктерде және инфрақұрылымдарда ток өткізгіш пішіндердің қажеттілігін арттырады, мысалы, 4/0 алюминий сымы.

- Циклділік және тұрақтылық жәшіктер мен ғимараттар материалына қайта өңделген қоспалардың көбейіп кетуіне ықпал етеді.

Көлік, Жәшіктер және Құрылыс Қолданулары

Көлік секторында алюминийдің төмен тығыздығы әсерінен көліктер, пойыздар және ұшақтар жеңіл болып, отынды аз пайдаланып, жүк көтергіштігі артады. Мысалы, автомобиль инженерлері автомобиль корпусының панельдері мен шасси бөлшектері үшін алюминий қаңылтыры мен экструзияларды пайдаланады, ал әуе қауіпсіздігі мен қатаң стандарттарға сәйкес келетін алюминий плиталар мен арнайы қорытпаларға сүйенеді. Темір жол жүйелері жоғары жылдамдықты пойыздар үшін үйкелісті азайтып, жөндеу қажеттілігін төмендететін алюминийді таңдайды.

Құрылыс саласында да алюминийдің өнеркәсіптік қолданулары жарқылдатады. Терезе аяқтарынан бастап перде қабырғасы жүйелеріне дейін, экструзиялық профильдер мен қаңыл металдар сәулетшілерге жеңіл, коррозияға тұрақты құрылыстар жобалау еркіндігін береді. Құрылыстардың беріктігі мен көркемдігін арттыру үшін алюминий тақтасы мен құбырлар да құрылыс тіреулері мен шатырлар үшін қолданылады.

Электр және электроника салалары

Алюминийдің өткізгіштігі электр энергетикасында үлкен айырмашылық жасайды. Электр желілерінде әдетте 4/0 алюминий сым ұзын аралықтарға беру үшін қолданылады, себебі ол мыстан жеңілірек және арзанырақ. Құрылғылардың ішінде экструзиялық радиаторлар мен қосқыштар жылуды шашыратып, тұрақты жұмыс істеуін қамтамасыз етеді. Электроникада алюминийдің жұқа парақтары мен фольгалары кең таралған: олардан смартфон корпустарынан бастап LED корпустарына дейінгі құрылғыларда пайдаланылады.

Тауарларды орау, өнеркәсіптік жабдықтар және теңіз қолданысы

Мұртасыңызға шолу жасаңыз, сіз алюминийдің ең кең таралған қолданыстарының бірнешеуін байқай аласыз: ішімдік банкалары, тағам ыдыстары және иілгіш фольга орау. Пішінделуі, улы еместігі мен қайта өңдеуге болатындығы алюминийді орау үшін ең жақсы таңдау етеді. Өнеркәсіптік жабдықтарда құрылымдар, қораптар және тасымалдау жүйелері үшін өңделетін алюминий тақтасы мен таяқшалары қолданылады, салмақсыз күш береді. Теңіз қолданысында алюминийдің коррозияға тұрақтылығы пайдаланылады, яғни қайықтардың корпусы мен үстіңгі құрылымдары үшін парақ пен тақта қолданылады.

Әрбір секторға қарай отырып, сіз өнімнің пішінін таңдау – алюминий парақ, тақта, экструзия немесе сым – тікелей қолдану бағытының өнімділік талаптары мен орта жағдайларына сәйкес келетінін байқай аласыз. Келесі кезекте бұл пішіндердің қалай жасалатынын, қаншалықты күшке, сыртқы түрге және өлшемдерге сай әзірленетінін қарастырамыз.

Алюминий бөлшектері қалай жасалады

Экструзия, қайырғыштық, құйма: сіздің сұранысыңызға сәйкес келетін қай процес?

Сіз алюминийдің кең қолданыс аясына қарасаңыз—автокөлік рамалары, терезе профилдері, ішімдік банкалары немесе машиналық қораптар туралы ойлаңыз—онда шикі құйманың дайын бөлшекке айналу процесінің күрделілігі туралы ұмытып кету оңай. Сіз таңдайтын өндіріс процесі тек қана соңғы өнімнің пішінін ғана емес, сонымен қатар құнын, бетінің сапасын және өнімнің жұмыс істеу сипаттамаларын анықтайды. Сонымен қатар, өнеркәсіпте қалай алюминийдің әйгілі икемділігі мен көпшілдігі пайдаланылады?

Өнеркәсіптегі алюминий бөлшектері үшін ең кең тараған өңдеу процесстерін қарастырайық:

| Процесс | Типтік пішіндер | Өлшемдік терпімділік | Тауып отыру | Құрал-жабдық бағасы | Масштабталу |

|---|---|---|---|---|---|

| Экструзия | Тұрақты көлденең қима профилдері (қатты, қуыс, жартылай қуыс) | ±0,1–0,4 мм (профильге тәуелді) | Өте жақсы (экструзиядан кейінгі күйінде); анодтау арқылы одан әрі жақсартуға болады | Орташа (400–5 000+ доллар) | Прототиптен бастап жоғары көлемге дейін |

| Домалау | Парақ, плита, фольга | Жоғары (әсіресе қалыңдық үшін) | Өте жақсы (айналық өңдеуге болады) | Жоғары (роликті түтік өндіру станоктары, матрицалар) | Үлкен көлем үшін ең жақсысы |

| ҚҰЙМА | Күрделі 3D пішіндер | Орташа (кейінгі өңдеу қажет болуы мүмкін) | Әртүрлі (өңдеу немесе жалпылау қажет болуы мүмкін) | Жоғары (әсіресе HPDC формалары үшін) | Үлкен көлем үшін ең жақсысы |

| Соғу | Қатты жүктеме, компактты бөлшектер | Жоғары (жалпылау өңдеуінен кейін) | Жақсы (өңдеуден кейін) | Жоғары (тұйық матрицалық құрал-жабдықтар) | Орташа және жоғары көлемде |

| CNC Машиналық өңдеу | Нақты детальдар, прототиптер | Өте жоғары (микрон деңгейі мүмкін) | Керемет | Төмен (аз құрал-жабдық) | Төмен және орташа көлемде |

Сіздің алюминий қолданысыңыз үшін тиісті өндіріс процесін таңдау геометрияға, дәлдікке, көлемге және өнімнің қажеттілігіне байланысты. Мысалы, экструзиялық профильдер архитектуралық рамалар үшін өте қолайлы, ал алюминий жапырақтары мен фольганы өндіру үшін қатты қысу қажет. Ең жоғары усталуға төзімді бөлшектер үшін құйма қолданылады, ал күрделі, интегралданған 3D пішіндерді жасау үшін құйма литей әдісі қолданылады.

Қадам-қадам: Алюминий профильдеу процесі

Жұқа, түз сызықты алюминий профильдер қалай жасалатыны қызықты ма? Бұл жайтты түсіну үшін біз қарапайым экструзия процесінің кезеңдерін ұсынамыз: қалай қысқыштардан өндірістік бөлшектерге дейінгі процес жүзеге асады.

- Сыртқы дайындық алюминий қысқышты 400–500°C дейін қыздыру үшін кесіп алып, алдын ала қыздыру.

- Экструзия қыздырылған қысқышты құрылғының қалыбы арқылы үлкен қысыммен өткізіп, үздіксіз профиль жасау.

- Жылы туғызушы : Механикалық қасиеттерді сақтау үшін профильді ауамен немесе сумен тез суытыңыз.

- Ұшыру : Бұрмалануды түзету және техникалық шарттарға сәйкес келтіру үшін профильді механикалық тәсілмен созыңыз.

- Жетілу/Жылумен өңдеу : Беріктік пен қаттылықтың мақсатты деңгейіне жету үшін экструзияны жылумен өңдеңіз (T5/T6).

- Беткі өңдеу : Ұзындығы бойынша кесіңіз, түзетіңіз және коррозиядан және эстетикалық үшін анодтау немесе ұнтақтық қаптау сияқты беткі өңдеу түрлерін қолданыңыз.

Бұл процесс алюминийдің өнеркәсіптегі әртүрлі қолданыстары үшін танымал таңдау болып табылатын, біркелкі қималары бар, қайталануы жоғары және қасиеттерін түрлендіруге болатын профильдерді шығарады.

Пішіндеу шектеулері мен кездесетін ақаулар: неге назар аудару керек

Ешбір өндірістік процесс жетілмеген, сонымен қатар сапаны бақылау бойынша сападағы алюминий қолдану үшін потенциалды ақауларды түсіну маңызды. Ақаулардың кейбір түрлері мен оларды қалай анықтау керектігінің қысқаша тізімі төменде берілген:

- Экструзиялық матрица сызықтары – Профиль бойында көрінетін сызықтар; визуалды стандарттарға сәйкес тексеріңіз.

- Жыртылуы немесе жарықшақтар – Әдетте сүйір бұрыштарда; пішіндеу кезінде және одан кейін тексеріңіз.

- Құймадағы қуыстар – Құйма бөлшектердің ішіндегі қуыстар немесе тесіктер; бояғыш пенетранты немесе рентгеннің көмегімен анықтау.

- Апельсин терісі (артық пішіндеуден) – Тең емес, дәнді бет; пішіндеу қысымы мен температураны бақылаңыз.

- Жылумен өңдеуден кейінгі өлшемдердің ығысуы – Спецификациядан тыс бөлшектер; CMM (координатты өлшеу машинасы) тексерулері арқылы растау.

Қосымша прокат ақауларына беткей сызықтары, толқындылық немесе жиектік жарықшақтар жатады, әдетте жабдықтардың ақаулары немесе дұрыс емес прокат параметрлерінен туындайды. Толық тізім мен шешімдер үшін ақауларды талдау және алдын алу бойынша дереккөздерге қарасыз.

Қорытындылау және алдын-ала дайындау негіздері

Жоғары сапалы алюминий бөлшектерін шығарудың соңғы кезеңі — бетін жөндеу. Анодтау мен ұнтақты безіту үшін жақсы жабысу үшін және ұзақ мерзімді қорғау үшін дұрыс алдын ала дайындау маңызды. Негізгі алдын ала дайындау кезеңдеріне кіреді:

- Тазалау: Май, майлылықтар мен ластануларды алып тастау.

- Этчинг: Жақсы жабысу үшін бетін біркелкі түрде тозу.

- Де-смуттинг: Еттік қалдықтарды, әсіресе кремнийлі қорытпалардағы қалдықтарды жою.

Дайындағаннан кейін анодтау тұрақты тотығу қабатын (әдетте 10–25 мкм қалың) құрайды, ал ұнтақты безіту түрлі-түсті палитра мен атмосфераға төзімділік ұсынады. Екі таңдау да алюминий жапқыштардың, экструзиялардың және құймалардың өнімділігі мен сырт пішінін арттырады — сонымен қатар соңғы өнімнің өндірістік ортаға төтеп бере алатынын қамтамасыз етеді.

«Алюминийді қолдану үшін дұрыс процессті таңдау — геометрияны, өнімділікті, бетін жөндеуді және өндіріс көлемін теңестіру мәселесі.»

Бұл өндіріс әдістерін білу алюминий қолданысыңыз үшін ең тиімді процессті анықтауға көмектеседі - күрделі құйма, дәл өңделген бөлшек немесе ылғи сән әуездегі сәулеттік профиль болсын. Келесі кезекте, қорытпа мен қатайтуды таңдау сіздің жобаңыздың қажеттіліктеріне сәйкес өнімділікті қалай бейімдеуге болатынын қарастырамыз.

Таңдау әдісі қалай жұмыс істейтіні туралы

Өнеркәсіптік қажеттіліктерге сәйкес қорытпаның дұрыс тобын таңдау

Неліктен бір алюминий бөлшек оңай иіліп, екіншісі ауыр жүктеме кезінде қатты ұсталып тұрады? Сиқыр қорытпа мен қатайтуды дұрыс таңдауда. Қазіргі кезде өте көп алюминий түрлері таралған болғандықтан, ең тиімді нұсқаны таңдау қиын болып көрінуі мүмкін. Бірақ өндірістік талаптарды дұрыс материалға сәйкестендіру мен қымбатқа түсетін қайта жасалымдар мен істен шығуларды болдырмау үшін аздап білім жеткілікті.

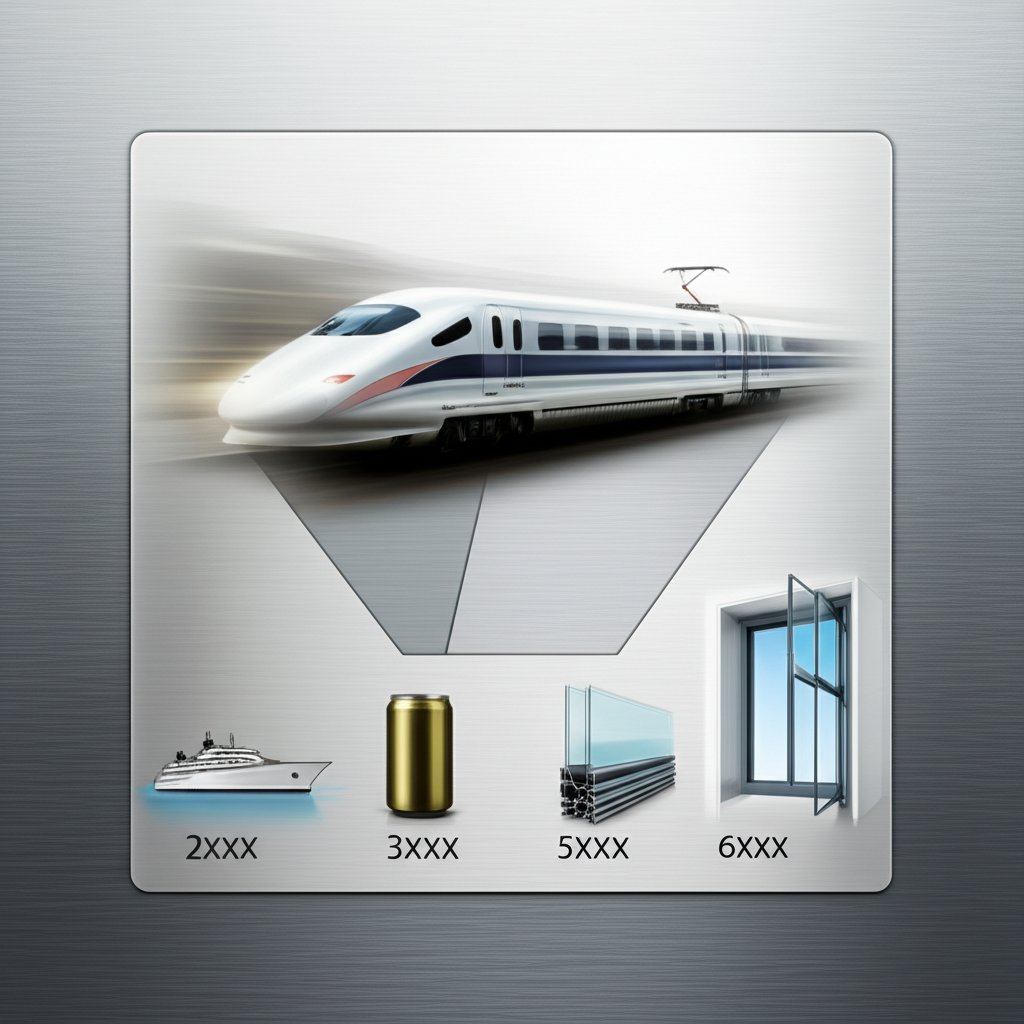

Алюминий қорытпалары негізгі қоспалық элементіне қарай топтарға бөлінеді, олардың әрқайсысы әртүрлі өндірісте алюминийдің қолданысы сипаттамаларын ашады. Мұнда жеті негізгі серия мен олардың ең таралған қолданыстары туралы қысқаша нұсқаулық:

| Қорытпа сериясы | Негізгі қосымша элемент | Негізгі қасиеттер | Типілік қолданулар |

|---|---|---|---|

| 1xxx | Жоқ (99%+ таза) | Өте жақсы өткізгіштік, коррозияға тұрақтылық, жоғары пластикалық қасиет, өте жұмсақ | Электр өткізгіштер, химиялық ыдыстар, жылу алмастырғыштар |

| 2xxx | Күміс | Жоғары беріктік, жақсы қаттылық, төмен коррозияға тұрақтылық | Әуе-космостық конструкциялар, жоғары өнімділікті автобөлшектер |

| 3xxx | Манган | Орташа беріктік, жақсы коррозияға тұрақтылық, өте жақсы өңделгіштік | Сусындар банкалары, жылу алмастырғыштар, шатырлар |

| 4xxx | Силікон | Төменгі балқу температурасы, жақсы ағу, орташа беріктік | Сымды дәнекерлеу, қосымша дәнекерлеу, автомобиль бөлшектері |

| 5xxx | Магний | Жоғары беріктік, теңіз коррозиясына тұрақтылық, жақсы дәнекерлеу қабілеті | Кеме жасау, қысым ыдыстары, теңіз жапсырмалары (мысалы, қорытпа 5005 ) |

| 6xxx | Магний және Кремний | Жақсы беріктік, жоғары коррозияға тұрақтылық, өте жақсы экструзиялық қасиет, дәнекерленетін | Архитектуралық профильдер, автомобиль рамалары, құрылыс компоненттері (ең ең танымал алюминий қорытпасы мұнда 6061) |

| 7xxx | Қырылға | Өте жоғары беріктік, төменгі пішінделуі, орташа коррозияға тұрақтылық | Әуе қатынасы, спорт құралдары, қиын қорытпалы алюминий жоғары температура жағдайында қолдану үшін |

Мысалы, көлік саласында қолданылатын алюминий қорытпалары көбінесе 6xxx және 7xxx серияларынан алынады, көлік рамалары мен ұшақтар үшін салмақ, беріктік пен дәнекерлеуге ыңғайлылықты тепе-теңдікте ұстайды. Ал кеме инженерлері әдетте тұзды суға тұрақтылығы мен пішінделуі үшін 5xxx сериясын таңдайды.

Температура өңдеуі және оның мағынасы

Күрделі болып көрінеді? Негізгілерін білген сайын оңай болады. Температура белгілеуі (мысалы, O, H немесе T сияқты) қорытпаның нөмірінен кейін келеді және металды өңдеу тәсілін көрсетеді – оның қаттылығына, беріктігіне және пішінделуіне тікелей әсер ететін. Мына жерде қысқаша түсіндірме:

| Температура | Өңдеу | Типтік әсері | Пішіндеу салдары |

|---|---|---|---|

| O | Тұрақтандырылған (жұмсартылған) | Ең төменгі беріктік, ең жоғары пластикалық қасиет | Пішіндеуге жеңіл, терең тарту үшін ең жақсы |

| H | Деформациялық қаттылау (суық тәндеу) | Беріктіктің артуы, пластикалық қасиеттің төмендеуі | Орташа пішіндеуге жарамды, шектеулі бүгуге |

| T | Жылумен өңделген (ерітіндімен өңделіп, кейін жастандырылған) | Жоғары беріктік, орташа пластикалық қасиет | Жоғары беріктікті, пішіндеудің төменгі деңгейіне арналған қолданулар үшін ең жақсы |

Мысалы, 6061-T6 конструкциялық бөлшектер үшін негізгі қорытпа болып табылады, өйткені ол беріктік пен өңдеуге жеңілдіктің жақсы тепе-теңдігін ұсынады, ал 5052-H32 – теңіз бетінің қаңқасы үшін таңдалады, онда пішіндеу мен коррозияға тұрақтылық басым маңызға ие.

Кең таралған жағдайлар үшін шешім матрицасы

Жоғары жылдамдықты пойыз, ішімділік құтысы немесе теңіз қабығы үшін бөлшекті көрсетіп беріп жатырсыз деп елестетіңіз. Қалай шешім қабылдау керек? Осындай тәсіл бар:

- Ортадан бастаңыз : Тұзды суға, жылуға немесе ауыр жүкке ұшырай ма?

- Қорытпаның дұрыс түрін таңдаңыз : Теңіз құрылысы үшін 5xxx, жалпы құрылымдар үшін 6xxx, әуе қозғалтқыштары/жоғары беріктік үшін 7xxx қолданыңыз.

- Беріктік пен пішінделуге сәйкес температураны таңдаңыз : Терең пішіндеу үшін O, беріктік үшін T, тепе-теңдік үшін H.

- Түсінікті құжаттаңыз : Сызбаларда және сатып алу тапсырыстарында қорытпаның да, температураның да екеуін (мысалы, 6061-T6) көрсетіңіз, өйткені бұл қымбатқа түсетін алмастыруларды немесе өнімнің өнімділігіне әсер ететін мәселелерді болдырмау үшін қажет.

Қиын орталар үшін, артықшылықтары 7xxx сериясындағы қорытпалар — жоғары беріктігі және жақсы әлсіреу төзімділігін қоса алғанда — арнайы өңдеуді және дәл пісіру мүмкіндігіне назар аударуды талап етуі мүмкін. Егер сізге жоғары өткізгіштік пен ыңғайлы пішіндеу қажет болса, онда 1xxx немесе 3xxx сериясын таңдаңыз.

Орта мен өңдеу әдісінен бастаңыз, ол қорытпаның түрі мен қаттылығын анықтайды.

Түсіну арқылы алюминийдің кең тараған қорытпалары және қаттылық әсерінен орындалу сапасы қалай тәуелді екенін біле отырып, сіз келесі құрылысыңыз — көпір, ішімдік банкасы немесе келесі ұрпақтың көлігі болсын — тиімді және шығын жағынан тиімді шешім қабылдауға дайын боласыз. Келесі кезекте біз алюминийдің басқа материалдармен салыстырғандағы артықшылықтары мен кемшіліктерін салыстырамыз және келесі жобаңыз үшін дұрыс шешім қабылдауға көмектесеміз.

Шынайы әлемде алюминий мен басқа материалдар

Алюминий болат пен пластмассаларды жеңген кезде

Өндірістік жоба үшін материалдарды таңдағанда шешім әдетте бірнеше бәсекеге қабілетті материалдар: алюминий, болат, пластмасса, композиттер және кейде титан арасында болады. Бірақ қолдануыңыз үшін салмақ, беріктік, коррозияға тұрақтылық пен құнның ең жақсы тепе-теңдігін қайсысы ұсынады? Келіңіздер, алюминийдің артықшылықтары мен кемшіліктерін негізгі бәсекелестерімен салыстырып талқылайық, сонда сіз өзіңіздің өнімділік пен бюджет мақсаттарыңызға сәйкес дұрыс таңдау жасай аласыз.

| Материал | Тығыздық | Тегістік-сапа | Коррозияға тұрақтылық | Пластичность/Пішінделуі | Өңдеу жеңілдігі | Жабын нұсқалары | Баға | Тікелей қайта өңдеуге мүмкіндік |

|---|---|---|---|---|---|---|---|---|

| Алюминий | Төмен (~2,7 г/см³) |

Жогары | Керемет (оксидті қабат түзеді, таттанбайды) |

Жогары | Оңай (экструзия, темірету, өңдеу) | Көп (анодтау, ұнтақ бояу, бояу) | Орташа (нержавайқа қарағанда аз, көміртекті болатқа қарағанда көп) |

Керемет (100% қайта переработка жасалынады) |

| Болат | Жогары (~7,8 г/см³) |

Өте жоғары | Айнымалы (көміртекті болат пайда болады, нержавайтын болат жақсырақ) |

Төмен орташа | Қиын (пішіндеу, дәнекерлеу қиын) | Көп (цинктелу, бояу, лактау) | Төмен (көміртекті болат); Жоғары (нержавайтын болат) |

Керемет |

| Пластмассадан жасалған | Өте төмен (~0,9–1,5 г/см³) |

Төмен | Жақсы (түріне байланысты) | Өте жоғары | Өте жеңіл (құю, пішіндеу) | Көп (түс, дәм, мөлдірлік) | Төмен | Орташа (түріне қарай өзгереді) |

| Қоспалар | Төмен | Өте жоғары | Керемет | Айнымалы | Күрделі (мамандандырылған процесстер) | Кейбір (гелькоат, бояу) | Жогары | Төмен (қайта өңдеу қиын) |

| Титан | Төменгі-Орташа (~4,5 г/см³) |

Өте жоғары | Керемет | Орташа | Қиын (өңдеу/пішіндеу қымбат) | Кейбір (анодтау, парлы қабат жабу) | Өте жоғары | Жақсы |

Қоспалар мен Титанмен салыстырмалы түрде артықшылықтар мен кемшіліктер

Алюминийдің құнды қасиеті – оның аз тығыздығы, үлкен беріктік-салмақ қатынасы және жоғары коррозияға тұрақтылығының ұштастығында. Ал ортаңғы болаттан айырмашылығы, ол таттанбайды – алюминий таттанады ма? Кәдімгі ұғымда емес. Оның орнына металл бетін қорғайтын тұрақты оксидті қабат түзіледі. Бұл алюминийді ұзақ тұқымтау қажеттілігі бар ашық аумақтарда, теңіз жағдайында және тамақ өнеркәсібінде пайдалануға ыңғайлы етеді.

Пластмассамен салыстырғанда алюминий әлдеқайда берік және қатты болып келеді, сондықтан құрылыс бөлшектері мен салмақ түсетін элементтер үшін тиімді. Алайда пластикалық материалдарды күрделі пішіндерге құю жеңілірек және құнызбекті шығын көлемінде құрылымдық емес қосалқы бөлшектер үшін тиімді. Композиттер мен титан өте жоғары беріктік-салмақ қатынасы мен коррозияға тұрақтылық деңгейін ұсынады, бірақ олардың қымбат тұруы мен күрделі өңдеу процесстері әдетте ғарыш-әуе немесе арнайы өнеркәсіптік салаларда қолданылуын шектейді.

Өнеркәсіптегі алюминийдің артықшылықтары мен кемшіліктері

Алюминийдің артықшылықтары

-

Күштілік:

- Жеңіл – жеткізу мен орнату құнын төмендетеді

- Жоғары беріктік-салмақ қатынасы — тасымалдау, әуе және ғарыш индустриясы, сондай-ақ рамалар үшін идеалды

- Тот басуға тұрақтылығы жоғары — қалың қаптаманы пайдалану қажет емес

- Жылу мен электр өткізгіштігі жоғары — жылу алмастырғыштар мен электр желілері үшін өте тиімді

-

Жасау:

- Пішіндеуге, прокаттауға және өңдеуге оңай — күрделі конструкцияларды қолдау мүмкіндігін береді

- Аяқтау түрлерінің кең ассортименті — анодтау, ұнтақты эмальмен бояу, бояу

-

Өмірлік цикл:

- сапасын аз шығынмен 100% қайта өңдеуге болады

- Тұрақты даму мен шеңберлік экономика мақсаттарын қолдайды

Алюминийдің кемшіліктері

-

Күштілік:

- Болатқа қарағандағы абсолютті беріктігі мен қаттылығы төмен

- Жұмсақтық абразивті ортада тозуға қарсы тұру қабілетін шектеуі мүмкін

- Балқу температурасы төмен — жоғары температурада пайдалануға тиесіз

-

Жасау:

- Қосу кезінде ұқыптылық қажет (арнайы дәнекерлеу немесе бекітпе құралдары)

- Қатты металдарға қарағанда бетінен сызықтар мен шошқырлар оңай пайда болады

-

Өмірлік цикл:

- Шикізаттың құны жай болатқа қарағанда жоғары

- Кейбір қорытпалар ауыр жүктемелі немесе жоғары жүктемелі қолдануларға сәйкес келмейді

Қолдану негізінде таңдау: Қашан алюминий таңдау керек

- Алюминий: Жеңіл салмақты, коррозияға тұрақты конструкциялар, жылу алмастырғыштар және дәл құйылған профильдер үшін ең жақсы таңдау — әсіресе ондағы алюминийдің артықшылықтары қайта өңдеуге болатындығы мен пішінделуге болатындығы сияқты қасиеттер маңызды болған жағдайда

- Болат: Ауыр жүктемелі инфрақұрылым немесе құралдардағы үлкен беріктік, ең төмен бастапқы құн мен жоғары тозуға тұрақтылық үшін таңдаңыз.

- Пластика: Құрылымдық жүктемелер аз болған жағдайда арзан, көп көлемді, күрделі пішіндерді таңдаңыз.

- Композиттер: Ең жоғары қаттылық-салмақ қатынасы қажет болып, құн соншалықты маңызды емес болған жағдайда қолданыңыз (мысалы, әуе-кеңістік, жоғары өнімді спорт).

- Титан: Жоғары беріктік пен коррозияға тұрақтылықтың маңызды болған және бюджет мүмкіндіктері болған ең қиын орталар үшін қолданыңыз.

Ең жақсы материал – бұл сіздің қолданысыңыздың салмағы, беріктігі, коррозияға тұрақтылығы және өмірлік цикл құнының қажеттілігіне сәйкес келетін материал – тек әр фунт құнның ең төменгісі ғана емес.

Түсіну алюминийдің артықшылықтары мен кемшіліктері келесі өнеркәсіптік бөлшекке тапсырыс берер алдында – тығыздық, коррозия, өңдеу және қайта өңдеуге болатындығын барлық факторларды ескере отырып бағалауға мүмкіндік береді. Келесі кезекте, алюминий бөлшектерінің уақыт пен пайдалануға төтеп беруіне қосу, біріктіру және тексеру тәсілдерін қарастырамыз.

Қосу, біріктіру және тексеру – ақауларды болдырмау үшін

Ұзақ мерзімді аяқтау: алюминийді қорғау және әсемдеу

Сіз өнеркәсіптік пайдалану үшін алюминий бөлшектеріне инвестиция жасаған кезде, олардың сыртқы түрі мен өнімділігі де ұзақ уақыт бойы сақталуын қалайсыз. Бірақ алюминий уақыт өте келе тат бере ала ма немесе бұзыла ала ма? Алюминий табиғи оксидті қабат түзіп, коррозиядан қорғаса да, шынайы әлемдегі жағдайлар жиі күшейтілген беткей аяқтауларды талап етеді. Қажетті аяқтау алюминийдің сапасын сақтап қана қоймай, сонымен қатар оның сыртқы түрі мен қызметін жақсартады.

| Бітім түрі | Қорытынды қорғау | Көрінісі | Жөндеу және техникалық қызмет көрсету |

|---|---|---|---|

| Андодилеу | Өте жақсы (қалың оксидті қабат) | Маталы немесе жартылай жылтыр, түстердің шектеулі диапазоны | Кішігірім сызықтар көрінетін болуы мүмкін; сыртта түс уақыт өте келе бәсеңдеуі мүмкін |

| Порошковый қатынасы | Өте жақсы (егер қаптама бүтін болып қалса) | Түстердің кең таңдауы, жоғары жылтырлық мүмкіндігі | Шағын сындырулар қайта қаптауды талап етеді; ультракүлгін тұрақты нұсқалары бар |

| Конверсиялық қаптама (Алодин/Химиялық пленка) | Жақсы (жұқа пассивтену қабаты) | Қойма, түрлі-түсті, өткізгіштігін сақтайды | Үйлесімді химиялық пленкамен жөндеу; анодтауға қарағанда тұрақсыз |

| Механикалық өңдеу (әлпеттеу, ұрттау) | Аз (кедергі қабаты жоқ) | Айнымалы - айна-жарық немесе маталы болуы мүмкін | Тұрақтылық үшін герметиктеу немесе қосымша өңдеу қажет |

Әдетте алюминийдің көптеген өнеркәсіптік пайдалану жолдарында жоғары тозуға және коррозияға тұрақты болу үшін анодтау әдісі қолданылады, ал порошоктық бояу кең түрлі-түсті палитра мен УК тұрақтылығын ұсынады. Электрондық корпус сияқты өткізгіштікті қажет ететін жағдайларда Alodine сияқты түрлендіру покрытиялары таңдалады. Механикалық өңдеу - әлпеттеу немесе ұрттау сияқты әдетте эстетикалық мақсаттар үшін немесе қосымша көркемдеу алдында дайындау ретінде қолданылады.

Дәнекерлеу, бұрандалы қосу және желімдеу таңдаулары

Алюминийді қосу темірді қосуға қарағанда қаншалықты қарапайым емес. Оның жоғары жылу өткізгіштігі, тотығу қабаты және алюминийдің ұнғыштығы дәнекерлеуді және байланыстыруды әрі өнер, әрі ғылымға айналдырады. Сонымен, қай жалғау әдісі сіздің жобаңызға сәйкес келеді?

- Дәнекерлеу (GTAW/TIG, GMAW/MIG): Берік, тұрақты қосылыстар береді — құрылымдық рамаларға немесе қысымды ыдыстарға ыңғайлы. Бетін дайындау маңызды: оксидті арнайы болат щеткамен тазалаңыз, толтырғыш сымды қорытпаларға сәйкестендіріңіз және бұрмалануды немесе қуыстарды болдырмау үшін жылу кірісін бақылаңыз. Магний мен мырыш көп қорытпалар (5xxx, 7xxx) жарылмаларды болдырмау және беріктігін жоғалтпау үшін арнайы қамтамасыз етуді талап етеді.

- Күміс дәнекерлеу: Жұқа бөліктер мен жылу алмастырғыштар үшін қолданылады. Төменгі температура бұрмалануды азайтады, бірақ қосылыс беріктігі дәнекерлеуге қарағанда төмен болады.

- Жабыстыру ("металл үшін желім"): Әртүрлі материалдарды немесе жұқа парақтарды жылу қолданбай қосу үшін ыңғайлы. Ең жақсы жабысу үшін беті таза және жеңіл қабырғалау болуы керек. Қату уақыты мен температура шектеулері қолданылатын желімнің түріне байланысты әртүрлі болады — қолдануыңызға сәйкес өндірушінің техникалық сипаттамаларын әрқашан тексеріңіз.

- Аралас қосылыстар: Динамикалық немесе қауіпсіздікке әуесті жинақтарда қосымша қауіпсіздік үшін механикалық бекітпелер мен желімді бірге қолдану.

Артықшылықтары мен кемшіліктері: Дәнекерлеу мен жабыстыру

-

Дәнекерлеу

- Артықшылықтары: Жоғары беріктік, біртекті көрініс, тұрақтылық

- Кемшіліктері: Білікті еңбекке, жылу деформациясының қаупіне, барлығына да ыңғайсыз емес қорытпалар

-

Жабыстыру (металл желімдеу)

- Артықшылықтары: Жұқа немесе әртүрлі материалдарды қосу, жылуды тарату, кернеуді тарату

- Кемшіліктері: Бетін дайындау маңызды, температура мен химиялық әсерге шектеу қойылған, күту уақыты қажет

Әдістердің бірі үшін алюминийдің пластикалық қасиеті бөлшектерді қосар алдында пішіндеу немесе майыстыруға мүмкіндік беріп, жобалау икемділігін ұсынады. Алайда әрқашан таңдалған процесстің алюминийдің қажетті сапасы мен пайдалану шарттарына сәйкес келетінін қамтамасыз етіңіз.

Тексеру және техникалық қызмет көрсету тізімдері

Ең жақсы аяқталған және қосылған алюминий бөлшектері де алюминий сапасын сақтап, қымбатқа түсетін істен шығуды болдырмау үшін кезең-кезеңге тексерілуі қажет. Сіздің мүлкіңізді жақсы жағдайда ұстап тұру үшін практикалық тізім осындай:

- Тексеру талшық тәрізді коррозия әсіресе соққы немесе үйкелістен кейінгі бояу жабындарының жанында

- Тексеріңіз гальваникалық коррозия әртүрлі металдардан жасалған бекітпелер мен қосылыстарда.

- Дәнекер жіктерін тексеріңіз газ қуыстары, сызаттар немесе қорғаныс қабатының жоғалуы – қажет болса, визуалды стандарттар немесе КТҚ қолданыңыз.

- Іздеу бос болттар мен гайкалар немесе қосылыстың беріктігін бұзуы мүмкін бекітпелер.

- Механикалық өңдеу аяқталған аймақтарда сызықтар немесе қорғаныш қабатының жоғалуын тексеріңіз.

Қаншалықты жиі тексеру керек? Ашық аумақта немесе теңіз ортасында болса, тоқсандық сайын немесе үлкен апаттық ауа райынан кейін тексеріңіз. Жабық кеңістікте немесе төменгі қауіп аймағында болса, жыл сайын тексеру жеткілікті болуы мүмкін. Егер ақаулар байқалса, уақытылы шешім қабылдаңыз – қаптаманы жаңартыңыз, болттар мен гайкаларды қайта бұраңыз немесе дәнекер жіктерін қайта жөндеңіз. Бұл шаралар алюминийден жасалған заттардың сыртқы түрі мен өнімділігін сақтап қалуға, пайдалану мерзімін ұзартуға және инвестициялардың тиімділігін арттыруға көмектеседі.

"Кез келген өнеркәсіптік ортада сенімді, ұзақ мерзімді пайдаланылатын алюминий бөлшектерді шығару үшін өңдеу мен қосылыстарды орындау және тексеру бойынша үйлесімді тәжірибелер негіз болып табылады."

Осы аяқтау, қосылу және тексеру туралы түсініктер арқылы сіз өндірістік қолданбаларыңыздағы алюминийдің беріктігі мен сапасын қамтамасыз етуге дайын боласыз. Келесі кезекте тұрақтылық пен өмірлік циклді қарастыру сіздің жобаңыздың құндылығы мен қоршаған ортаға әсерін қалай арттыра алатынын қарастырамыз.

Тұрақтылық және өмірлік цикл дизайны

Негізгі және қайта өңделген алюминий: шын мәнінде әсері қандай?

Сіз өндірісте алюминийдің қолданылуы туралы ойланғанда, оны тұрақтылық чемпионы ететін нәрсе не екенін еш ойладыңыз ба? Жауап оның ерекше өмірлік циклында. Көптеген металдардан айырмашылығы алюминий негізгі қасиеттерін жоғалтпай қайта қайта өңдеуге болады. Бірақ жаңа (негізгі) алюминий мен ескіні қайта өңдеу арасында қандай айырмашылық бар?

| Қасиет | Негізгі алюминий | Қайта өңделген алюминий |

|---|---|---|

| Энергия күштілігі | Өте жоғары (базалық энергияның 100% пайдаланады) | Өте төмен (тек негізгі энергияның шамамен 5% ғана) |

| Жабайылар | Жоғары CO 2және өнеркәсіптің шығарындыларының 90%-нан астам күшейтілген қысқыш әсер туғызатын газдар | Аз шығарындылар; декарбонизацияға негізгі ықпал ететін фактор |

| Ресурстарды пайдалану | Боксит өндіру қажет, суға деген сұраныс жоғары | Табиғи ресурстарды үнемдейді, суға деген сұраныс аз |

| Қоспаларға төзімділік | Жоғары тазалық, барлық қолданыстарға сәйкес келеді | Қоспалар жоғары болуы мүмкін; дамып жатқан сұрыптау/өңдеу технологиялары қолдану аясын кеңейтуде |

| Типілік қолданулар | Барлық өнеркәсіп салалары, әсіресе тазалық маңызды болған жағдайда | Автокөлік, құрылыс, ыдыстау, электроника (технологиялардың жетілуіне байланысты қолдану аясы кеңейіп келеді) |

Қайта өңделген алюминийді өндіру үшін бастапқы өндіруге қарағанда энергияның тек 5%-ы ғана жұмсалады және қажетті шығындар мен шығарындыларды үнемдейді. Сол себепті алюминий қалдық бағасы және қалдық алюминий бағасы олардың тұрақтылығы мен тиімділігіне қатысты негізгі көрсеткіштер болып табылады.

Циклдық өмір сүру мерзімін жобалау: Циклды тұйықтау

Егер әрбір алюминий өнімін қайта переработка жасау үшін қайта қолданылатындай етіп жобаласақ қандай болар еді. Бұл циклдық жобалаудың мақсаты осы. Бірақ кедергі болып не табылады? Жиі жағдайда, бұл қайта переработка процесстерін күрделендіретін қаптамалар, таңбалау және қоспалар болып табылады. Мысалы, пластик таңбалауы немесе қақпақтары бар сусын банкалары қайта өңделген материалдың құнын төмендетіп, өңдеу шығындарын арттыруы мүмкін (бұлақ) .

- Қайта переработка жасау жеңіл болатын таза алюминий немесе үйлесімді қоспаларды таңдаңыз.

- Пластик таңбалау немесе қақпақ тәрізді алюминий емес компоненттерді азайтыңыз және оларды алу жеңіл болсын.

- Қайта переработка процесстеріне ыңғайлы немесе тиімді құрып алынатын қаптамалар мен бояуларды қолданыңыз.

- Мүмкіндігінше, қоспалардың қайта қолданылатын материалдарының пайдалану деңгейін арттыратын жоғары қоспалы ластану деңгейіне төзімді қоспаларды көрсетіңіз.

Лазерлік индуцирленген спектроскопия сияқты түрлерді сорттау мен өңдеу бойынша жетістіктер енді қайта өңделетін алюминийдің кеңейтілген өнеркәсіптік қолданысын және қауіпсіз қалдықтардың кеңейтілген түрлерін өңдеуге мүмкіндік беруде (бұлақ) .

Қайта өңделген материалдардың құрамына берілген талаптарды түсіну: сатып алу кезінде білу керек

Күрделі дыбыс шығады? Қайта өңделген алюминий тізбектің негізгі бөлігі болып табылатынын есте сақтау көмектеседі. Мысалы, АҚШ-та орташа ыдыста қайта өңделген материалдардың 73% құрайды. Бірақ барлық қайта өңделген алюминий бірдей емес - кейбір қолданулар жоғары тазалықты талап етеді, ал басқалары қоспалардың кеңейтілген қоспасын пайдалана алады.

Механикалық талаптар мүмкіндік беретін жерде қайта өңделген материалдардың құрамын көрсетіңіз және құжаттамада қалай тексерілетінін анықтаңыз.

- Стабильдік фунтқа алюминий бағасы немесе әр фунттық бағасы ұзақ мерзімді баға жоспарлау үшін маңызды қалдық нарығының денсаулығын білдіреді.

- Ауыстырулар фунтқа алюминий қаншалықты жобалық бюджеттер мен қайта өңдеу бағдарламаларының экономикасына әсер етуі мүмкін.

- Тұйықталған қалдық стратегиялары – өндірістік қалдықтарды қайта өңдеу тізбегіне қайтару – тұрақтылық пен құндылықты ұстауды жақсартады.

Тұрақты материалдарға деген сұраныс артқан сайын сатып алу және тұрақтылық бөлімдерінің шеңберлік мақсаттармен үйлесімді техникалық сипаттамалар жасауға одан әрі себеп болып отыр. Қайта өңделген материалдарды пайдалануды, жеңіл қалпына келтіруге арналған жобалауды және қалдықтар нарығының тенденцияларын бақылауды ұстана отырып, сіз алюминийдің өнеркәсіпте қаншалықты құнды екенін сақтай отырып, қоршаған орта мен экономикалық тиімділікті арттыра аласыз. Келесі кезекте келесі жобыңыз үшін айқын техникалық сипаттамаларды қалай жазу керектігі мен алюминийді қайдан сатып алу туралы айтылады.

Практикалық нұсқаулар мен көзделімдер

Көшіріп алуға болатын техникалық сипаттамалар шаблоны

Сіз бірдеңе алюминий бөлшектер үшін анық, қатты техникалық сипаттама қалай жазу керектігін ойланып қалдыңыз ба? Сіз бірденсіз. Құрылыс алюминий профилін, қаңылды немесе дайын бөлшектерді сатып алу болсын, алдын-ала нақты ақпарат беру өнімнің сапасы мен құнын бақылау үшін маңызды. Біздің практикалық әдісіміз амбигулықты азайтып, қандай да болмасын жобаны сәтті іске асыруға көмектеседі.

- Материал: Қорытпаны және қаттылығын көрсету керек – мысалы, «ASTM B209 бойынша 6061-T6».

- Температураны растау: «Әрбір партияға қаттылық сертификатын өндіруші ұсынуы тиіс».

- Толеранс: «Өлшемдік дәлдік сызба бойынша; басқаша көрсетілмеген жағдайда EN 755-9 (экструзия) немесе EN 485-3 (қаңыл/пластинка) бойынша болуы тиіс».

- Аяқтау: «II дәрежелі таза анодтау, қалыңдығы ең аз 15 мкм, техникалық шарт бойынша».

- Тестілеу: «Механикалық қасиеттерді ASTM E8 бойынша сынау керек; бетінің өңделуі визуалды стандарт бойынша».

- Сертификаттар: «Әрбір жіберілімге миллик сынақ куәландыруы (MTC) және сәйкестік куәлігі (CoC) қосылуы тиіс».

- Қаптама: «Сыну мен ылғалдың енуін болдырмау үшін бөлшектерді қаптау қажет; қорғаныш пленкасы мен тартқыш кептіргішті қажет болған жағдайда пайдалану керек.»

Нақты үшін түрлендіру қажет алюминий қолдану аясы ? Қажет болса, тұзды бұзылу сынағы (теңіз), өткізгіштік (электрлік) немесе түс сәйкестендіру (архитектуралық) бойынша тармақтарды қосыңыз. Тілді қаншалықты дәл қарастырсаңыз, соғұрлым қымбат түзету немесе кешігу ықтималдығы аз болады.

Сапаны қамтамасыз ету және құжаттама: Қандай құжаттарды сұрау керек

Сіз өз сұранысыңызды алды деп елестетіңіз – оның барлық талаптарға сәйкес келетінін қалай білуге болады? Осы жерде сенімді құжаттама мен СҚ орын алады. Көпшілік үшін алюминиевық сплав өнімдері алюминий материалдарының өндірушілерінен келесі құжаттарды сұраңыз:

- Зауыт сынақ куәліктері (MTC): Қорытпаның, қаттылығының және химиялық құрамының сәйкестігін растайды.

- Бірінші үлгі тексеру (FAI) есептері: Бастапқы үлгілердің өлшемдерін, дәлдік классын және бетінің жағдайын тексеру.

- PPAP/APQP Пакеттері: Автокөлік немесе маңызды өнеркәсіптік қорытпалар үшін өндірістік бөлшекке қабылдау процесі (PPAP) немесе өнім сапасын алдын ала жоспарлау (APQP) файлын талап етіңіз – әсіресе жаппай өндіріс немесе қауіпсіздікке маңызы бар бөлшектер үшін.

- Жабынды растау: Тасымалдау кезінде зақымдануды болдырмау үшін транзиттік сынақтардың құжатталғанын қамтамасыз етіңіз.

Тұрақты тапсырыстар үшін өзгерістерді басқару мен редакциялау бойынша айқын күтімдерді белгілеңіз. Қабылдаушыларды процессте немесе материалдарда өзгерістер болған жағдайда хабарлауға міндетті етіп, өзгерістер журналын жүргізіп отырыңыз.

Жабдықтау нұсқалары мен қабылдаушыларды салыстыру

Келесі өндірістік алюминий жобасыңыз үшін дұрыс серіктесті таңдау қиын болуы мүмкін. Глобалдық маман, жергілікті шебер немесе онлайн-науқарлықтың қайсысын таңдау керек? Шешім қабылдауға көмектесетін құрылымды салыстыру:

| Жеткізуші | КЕНАРЛЫҚТAR | Терпіліс | СЕРТИФИКАТТАР | Жетекшілік уақыты | Ең тиімдісі |

|---|---|---|---|---|---|

|

Shaoyi Metal Parts Supplier (Қытай) |

Дәл өнеркәсіптік алюминий экструзиясы, CNC өңдеу, толық DFM/QA қолдау, автомобиль саласындағы сараптама | Жоғары дәлдік; 2000 ДППМ мақсатынан төмен | IATF 16949, ISO9001; толық PPAP/APQP | Тез прототиптеу; сериялық өндіріске дейін кеңейту мүмкіндігі | Автомобиль, EV, конструкциялық, жоғары құнды алюминий экструзия бөлшектері |

| Аймақтық шаруашылық | Стандартты пішіндер, кесу, негізгі өңдеу | Стандартты (EN/ASTM бойынша) | ISO9001, жергілікті сапа бақылауы | Қоймадағы тауарлар үшін қысқа; дайындау үшін ұзақ | Төменнен орта деңгейге дейінгі көлем, жергілікті қолдау |

| Онлайн базарлық алаң | Қорытпалар/өнімдердің кең ассортименті, жылдам бағалар | Әртүрлі тауар ұсынушылар бойынша әртүрлі | Тауар ұсынушыға тәуелді | Дайын өнімдер үшін жылдам; ерекше тапсырыстар үшін әртүрлі | Прототиптер, жалғыз даналық, стандартты бөлшектер |

Талапқа сай өнеркәсіптік қорытпаларды қолдану саласы —әсіресе автомобиль және дәл құрастыруларда—Shaoyi Metal Parts Supplier интеграцияланған инженериялық қолдау, қатаң сапа бақылауы мен тексерілген тәжірибесімен ерекшеленеді. Олардың бастапқыдан соңына дейінгі қолдауы сіздің алюминий қолдану аясы дизайннен өндіріске дейінгі процеске тегіс өтеді. Құрылымдық алюминий экструзия бөлшектері маңызды болып табылады, Shaoyi-дің сараптамасын пайдалану жобаның қауіп-қатерін азайтып, өнімнің нарыққа шығу уақытын қысқартады.

Дұрыс бағалау: жобаны қорғау үшін қажетті қадамдар

Сіз қандай өндірушіні таңдасаңыз да, дұрыс бағалау – бұл сіздің қауіпсіздік желіңіз. Сатып алу процесіңіздің бағыттауын сақтау үшін төмендегі тізімді пайдаланыңыз:

- Сенімді емес жобалау шартын (NDA) қол қою керек және құпиялы дизайндарды бөлісуден бұрын келісім шарт жасасу керек.

- Өндірісті кеңейтуден бұрын бірінші үлгілерді тексеру (FAI) үлгілерін сұраңыз және қарастырыңыз.

- Автокөлік немесе реттелетін секторлар үшін PPAP/APQP құжаттамасын талап етіңіз.

- Өндірушінің сапа жүйесін аудит жасаңыз – қашықтықтан немесе жерде қажетіне қарай.

- Сіздің RFQ-ңызда жеткізуге дайындау, таңбалау және жеткізу талаптарын анықтап көрсетіңіз.

- Әр кезең бойынша қабылдау/бас тарту критерийлерін нақты орнатыңыз.

Бұл жол картасын басынан өткізу — техникалық сипаттама, сапа құжаттамасы, әріптестерді салыстыру және тиісті талаптарды орындау — келесі өндірістік алюминий әкелу жобыңыздың тиімділігін, сенімділігін және өнімділігін қамтамасыз етеді. Келесі кезекте біз барлығын біріктіріп, іс-қимыл жасайтын қадамдар мен сенімді ресурстарды ұсынамыз, олар сізге сеніммен техникалық сипаттамадан өндіріске өтуге көмектеседі.

Іс-қимылға жарамды қорытындылар және сенімді ресурстар

Көлік пен ырғақтылық үшін жеңілдету нәтижелері

Қазіргі заманғы пойызға мініп немесе отын үнемдейтін көлік жүргізіп көріңіз — сізді қоршаған орта алюминийден жасалған заттарды — конструкциялық арқалықтардан соққыны жұтатын профильдерге дейін. Неліктен? Өйткені өнеркәсіптегі алюминий қолданулары салмақты азайту мен дәлдікті қамтамасыз ету міндетті болған жерде ең жақсы нәтиже көрсетеді. Көлік саласында әрбір үнемделген фунт салмақтың төмендеуіне, отын тиімділігінің артуына немесе электр көліктердің жүру ауқымының ұзаруына әкеледі. Сонымен қатар, алюминий профильдері инженерлерге бірнеше қызметтерді бір жеңіл бөлшекке біріктіріп, жинақтау процесін жеңілдетіп және соқтығысу қауіпсіздігін арттыруға мүмкіндік береді — бұл сұраққа нақты жауап болып табылады: алюминийдің қолданылуы қандай жылжымдылықта?

Келесі қадамдар: Техникалық талаптардан өндіріске дейін

Сіздің идеяларыңызды алюминийден жасалған заттарға жұмыс өнімділігі мен құнды қанағаттандыратындай етіп айналдыруға дайын болдыңыз ба? Төменде сізге өнімнің соңғы нұсқасына дейін сенімді түрде жетуіңіз үшін қадамдап әрекет ету жоспары берілген:

- Жұмыс циклі мен ортаны анықтаңыз : Бөлшектің қай жерде және қалай пайдаланылатынын талдаңыз — жүктеме, температура, әсер ету ортасы мен қызмет ету мерзімін ескеріңіз.

- Қорытпа мен қаттылықты таңдаңыз : Қолданыңызға сәйкес қорытпаның дұрыс түрі мен қаттылығын таңдаңыз, беріктік, пішінделу және коррозияға тұрақтылық арасында теңдік сақтаңыз.

- Дұрыс өндіріс процесін таңдаңыз : Геометрия, дәлдік және көлемге қарай экструзия, қысқыш, құю немесе соғу процесінен бірін таңдаңыз.

- Сыртқы пішіні мен сапаны растауды көрсетіңіз : Беткей өңдеу мен тексеру критерийлерін ұзақ мерзімділігі мен сырт келбеті сіздің стандарттарыңызға сәйкес келетін етіп жасаңыз.

- Сенімді әрістен әкеліңіз : Бірнеше әрістерді салыстырыңыз, үлгілерді сұраңыз және өндірісті кеңейту алдында сертификаттарды қарастырыңыз.

-

Қателіктерден сақтану:

- Айқын емес немесе жоқ қаттылық сипаттамалары

- Тексерілмеген дәлдік немесе тексеру деректерінің жоқтығы

- Басқа металдармен гальваникалық үйлесімділікті ескермеу

- Бір ғана бағалауға сүйену және салыстыру жасамау

- Қайта өңделген материал немесе тұрақтылық бойынша құжаттандыруды ескермеу

Алюминий әкелу мен жобалау бойынша сенімді дереккөздер

Келесі жобаңызды сәтті іске асыру үшін дәлелденген серіктестер мен сарапшылардың кеңесінен бастаңыз. Сізге жоғары сапалы алюминий экструзия бөлшектері көлік және басқа да салалар үшін:

- Shaoyi Metal Parts Supplier – Қызмет көрсету транспорттық және өнеркәсіптік қолданбалар үшін дәл алюминий экструзиясы бөлшектеріне маманданған Қытайдың алдыңғы қатарлы интеграцияланған дәл метал бөлшектер шешімдерінің қамтамасыз етушісі.

- Өнеркәсіптік стандарттар ұйымдары (ASTM, EN, ISO) – материалдар мен процестердің жаңартылған техникалық сипаттамалары үшін.

- Техникалық консультанттар мен жобалаушы инженерлер – құйма таңдау, жобалау оптимизациясы және сапаны басқару жоспары бойынша қолдануға арналған нақты кеңес алу үшін.

- Интернеттегі аукциондар мен аймақтық өндірушілер – тәжірибелік үлгілер немесе стандартты пішіндер үшін, бірақ әрқашан мүмкіндіктер мен құжаттандыруды растаңыз.

Қашан болса алюминий қайда қолданылады және алюминийдің қолданылуы , жауап айқын: көлік рамаларынан бастап электронды қораптарға дейін, алюминийдің көпшілдігі бәсекеге қабілетті. Бірақ нәтиженіз жоспарлаудың ұқыптылығына және дұрыс тауар әріпкерлерімен серіктестікке тәуелді. Әсіресе, маңыздылығы жоғары құрылғылар үшін мүмкіндіктерді салыстырып, бірнеше ұсыныстарды бағалап, қабілеттілік пен сапаны растау үшін үлгілер сұраңыз алюминийден жасалған заттарды көлік және қозғалыс салаларында (бұлақ) .

«Техникалық сипаттамадан өндіріске дейінгі жол эксперт әріпкерлерді пайдалану, дәл құжаттама және өнеркәсіпте алюминийдің ерекше артықшылықтарын түсіну арқылы жеңілдетіледі."

Бұл нақты әрекет жоспарын және сенімді ресурстарды пайдалана отырып, сіз келесі дизайныңызды жоғары өнімділікке, құндылыққа тиімділікке айналдыруға дайын боласыз алюминийден жасалған заттарға — өнеркәсіптік жобаның әрбір кезеңінде құндылықты жеткізу.

Өнеркәсіпте алюминийдің қолданылуы бойынша жиі қойылатын сұрақтар

1. Өнеркәсіпте алюминийдің негізгі қолданылуы қандай?

Қазіргі уақытта қоңыртас қозғалыс саласында (машиналар, пойыздар, ұшақтар), құрылыста (терезе ашылмалары, шатырлар), электр жабдықтарында (сымдар, жылу шығарғыштар), ыдыстау ыдыстарда (банкалар, фольга) және теңіз саласында (кеме корпусы) кеңінен қолданылуда. Оның жеңілдігі, коррозияға тұрақтылығы және қайта өңделуі оны салмақты азайту мен әсер ету дәлдігін арттыру үшін қолданылатын басты материалға айналдырады.

2. Неліктен қоңыртас көптеген өнеркәсіптік қолдануларда болатқа қарағанда үстемдік етеді?

Қоңыртас болатқа қарағанда оның төмен тығыздығы арқасында жеңіл бөлшектерді және көлік құралдары мен құрылыстардың отын тиімділігін арттыруға мүмкіндік береді. Сонымен қатар, ол өзінің коррозияға тұрақтылығымен, пішіндеу мен экструзияны жеңілдетуімен және әртүрлі аяқтау нұсқаларын қолдауымен ерекшеленеді. Болат қаттырақ болғанымен, қоңыртас өз салмағына қатысты қаттылығы мен қайта өңделуі арқасында көптеген өнеркәсіптік қолданулар үшін тиімді болып табылады.

3. Қоңыртас қалай өндіріледі және өнеркәсіптік өнімдерге айналдырылады?

Алюминий боксит рудасынан алынады және ыдыстарға немесе құймаларға айналдырылады. Содан кейін олар экструзия, темірдеу, құйма, соғу және CNC өңдеу сияқты әдістер көмегімен өндірістік бөлшектерге айналады. Қажетті пішін, дәлдік және қолдануға байланысты процесстер таңдалады және әрбір процесстің өзіндік өнеркәсіптік қажеттерге сәйкес ерекшеліктері болады.

4. Өнеркәсіп үшін алюминий бөлшектерін сатып алу кезінде нені ескеру керек?

Алюминий компоненттерді сатып алу кезінде қоспаның және қаттылығының дұрыс таңдалуы, дәлдіктің шектеуін анықтау, бетінің қабықшасын таңдау және өндірушінің сапа куәлігі сияқты құжаттарды талап ету маңызды. Shaoyi Metal Parts Supplier сияқты тауар өндірушісімен жұмыс істеу автомобиль және өнеркәсіптік қолданулар үшін дайындалған экструзияларға, қатаң сапа бақылауына және бүкіл процеске қолдау көрсетуге мүмкіндік береді.

5. Алюминий өнеркәсіпте тұрақтылыққа қалай үлес қосады?

Қайта өңдеуден өткізгеннен сапасы төмендемейтіндіктен, алюминий өте тұрақты материал болып табылады. Алюминийді қайта өңдеу үшін бастапқы өндіруге қажетті энергияның шамамен 5% ғана пайдаланылады, бұл шығарындылар мен ресурстарды пайдалануды біршама азайтады. Қайта өңдеуге ыңғайлы етіп жобалау және тұйық циклдік практикаларға басымдық беретін жеткізушілерді таңдау алюминийдің қоршаған ортаға пайдасын тағы да арттырады.

Кіші көліктер, жоғары стандарттар. Біздің шуақты проTOTYPE қызметі табиғатты тексеру процессін жылдамдаған және оңайластырады —

Кіші көліктер, жоғары стандарттар. Біздің шуақты проTOTYPE қызметі табиғатты тексеру процессін жылдамдаған және оңайластырады —