Laser Cut Metal Design Secrets: 8 Costly Mistakes Fabricators Won't Tell You

Understanding Laser Cut Metal Design Fundamentals

Imagine transforming a flat sheet of steel into an intricate decorative panel with patterns so precise they seem impossible to achieve by hand. That's the power of laser cut metal design—a technology that has revolutionized how manufacturers, architects, and artists create everything from automotive components to stunning architectural facades.

But here's what most fabricators won't tell you: the difference between a flawless project and a costly disaster often comes down to understanding a few critical design principles before your file ever reaches the cutting machine.

How Laser Technology Revolutionizes Metal Fabrication

So, what is laser cutting exactly? At its core, metal laser cutting uses a high-powered, focused beam of light to melt, vaporize, or burn through material along a computer-programmed path. The laser for cutting machine generates this beam by exciting a gain medium—typically optical fibers doped with rare-earth elements in modern fiber laser systems—to produce photons with remarkable properties.

Two characteristics make this technology extraordinarily powerful: monochromaticity and coherence. According to Virmer's technical documentation, these properties allow the beam to focus to a point as small as 0.01mm in diameter—roughly eight times smaller than a human hair—with power densities exceeding 10¹³W.

A laser cutter can focus energy to a spot smaller than a human hair, heating metal to its melting point in a fraction of a second—precision that traditional cutting methods simply cannot match.

This extreme precision enables laser CNC systems to execute complex designs with tolerances that mechanical cutting tools struggle to achieve. An assist gas—oxygen for faster cutting of ferrous metals or nitrogen for cleaner edges on stainless steel—blows away molten material and helps control the heat-affected zone surrounding each cut.

From Industrial Roots to Creative Applications

Laser metal cutting originated in heavy manufacturing, where speed and accuracy justified the technology's initial cost. Today, its applications span virtually every industry:

- Architecture and construction: Privacy screens, decorative facade panels, and interior partitions with intricate geometric patterns

- Automotive manufacturing: Body panels, brackets, and mechanical components requiring exact specifications

- Signage and branding: Custom metal letters, logos, and decorative displays with polished, burr-free edges

- Art and design: Sculptures, wall art, and laser cutting and engraving projects that push creative boundaries

The technology handles sheet metal up to 80mm thick and can cut pipes of various cross-sections, making it suitable for both delicate artistic work and robust industrial applications. Whether you're creating a single prototype or running production batches, designs can be repeated with identical accuracy every time.

In the sections ahead, you'll discover the material selection strategies that prevent costly mistakes, design principles that ensure clean cuts, and the insider knowledge fabricators rarely share upfront. Understanding these fundamentals before you submit your first file can save you significant time, money, and frustration—turning laser cut metal from a complex process into a powerful creative tool.

Choosing the Right Metal for Your Laser Cut Project

Ever wondered why two seemingly identical laser cut designs can produce dramatically different results? The secret often lies in the metal itself. Selecting the wrong material doesn't just affect appearance—it can lead to warped edges, excessive costs, and parts that fail in their intended application.

Understanding how each metal behaves under intense laser energy is crucial for achieving professional results. Let's break down what you need to know before committing to any material.

Steel, Aluminum, and Stainless Steel Compared

When it comes to laser cutting steel sheet, you'll encounter three primary categories: mild steel, stainless steel, and aluminum. Each responds differently to the cutting process based on its physical properties.

Mild steel (also called low carbon steel) remains the most cost-effective option for structural applications. According to Fabworks, this iron-carbon alloy offers excellent strength and hardness while being easy to machine and weld. The trade-off? Lower corrosion resistance means it's best suited for indoor applications or projects where protective finishing is planned.

Stainless steel laser cutting produces exceptionally clean edges that often require no additional finishing. The chromium content that gives stainless steel its corrosion resistance also creates smooth, oxide-free cuts under the right conditions. This makes it ideal for outdoor installations, food service equipment, and medical applications where hygiene matters.

Laser cut aluminum presents unique challenges due to its high thermal conductivity and reflectivity. Heat dissipates quickly through the material, requiring careful power management to prevent warping. However, modern fiber lasers handle aluminum laser cutting far better than older CO₂ systems. The result is a lightweight, corrosion-resistant material that works beautifully for architectural panels and aerospace components.

| Metal Type | Typical Thickness Range | Minimum Feature Size | Best Applications | Relative Cost | Finishing Compatibility |

|---|---|---|---|---|---|

| Mild Steel | 0.5mm - 25mm | 1x material thickness | Structural brackets, frames, industrial equipment | Low ($) | Powder coating, painting, galvanizing |

| Stainless Steel | 0.5mm - 20mm | 1x material thickness | Outdoor signage, kitchen equipment, medical devices | Medium-High ($$$) | Brushing, polishing, passivation |

| Aluminum | 0.5mm - 12mm | 1.5x material thickness | Lightweight panels, aerospace parts, decorative items | Medium ($$) | Anodizing, powder coating, brushing |

| Brass | 0.5mm - 6mm | 1.5x material thickness | Decorative hardware, musical instruments, ornaments | High ($$$$) | Lacquering, patina treatments |

| Copper | 0.5mm - 6mm | 2x material thickness | Electrical components, architectural accents, art | High ($$$$) | Patina, clear coating, lacquering |

Matching Metal Properties to Project Requirements

Sounds complex? Let's simplify the decision-making process by focusing on your project's specific demands.

Thermal conductivity is perhaps the most overlooked factor in material selection. Metals like copper and aluminum conduct heat rapidly, which affects both cutting quality and design possibilities. As noted by Universal Tool, high thermal conductivity requires greater energy input to compensate for heat dissipation—but excessive power can cause warping and discoloration.

This property directly impacts your design parameters:

- Minimum feature size: Highly conductive materials require larger minimum features (typically 1.5-2x material thickness versus 1x for steel)

- Spacing between cuts: Plan for at least two times the sheet thickness between cutting lines to prevent distortion

- Edge quality: Nitrogen assist gas produces cleaner edges on conductive materials but increases processing costs

For outdoor installations, prioritize corrosion resistance. Stainless steel and properly anodized aluminum excel in weather-exposed applications. Laser cut steel works outdoors only with protective coatings like hot-dip galvanizing or marine-grade powder coating.

For structural applications, steel laser cutting typically delivers the best strength-to-cost ratio. When you need both strength and corrosion resistance without the weight penalty, consider stainless steel or aluminum alloys like 6061-T6.

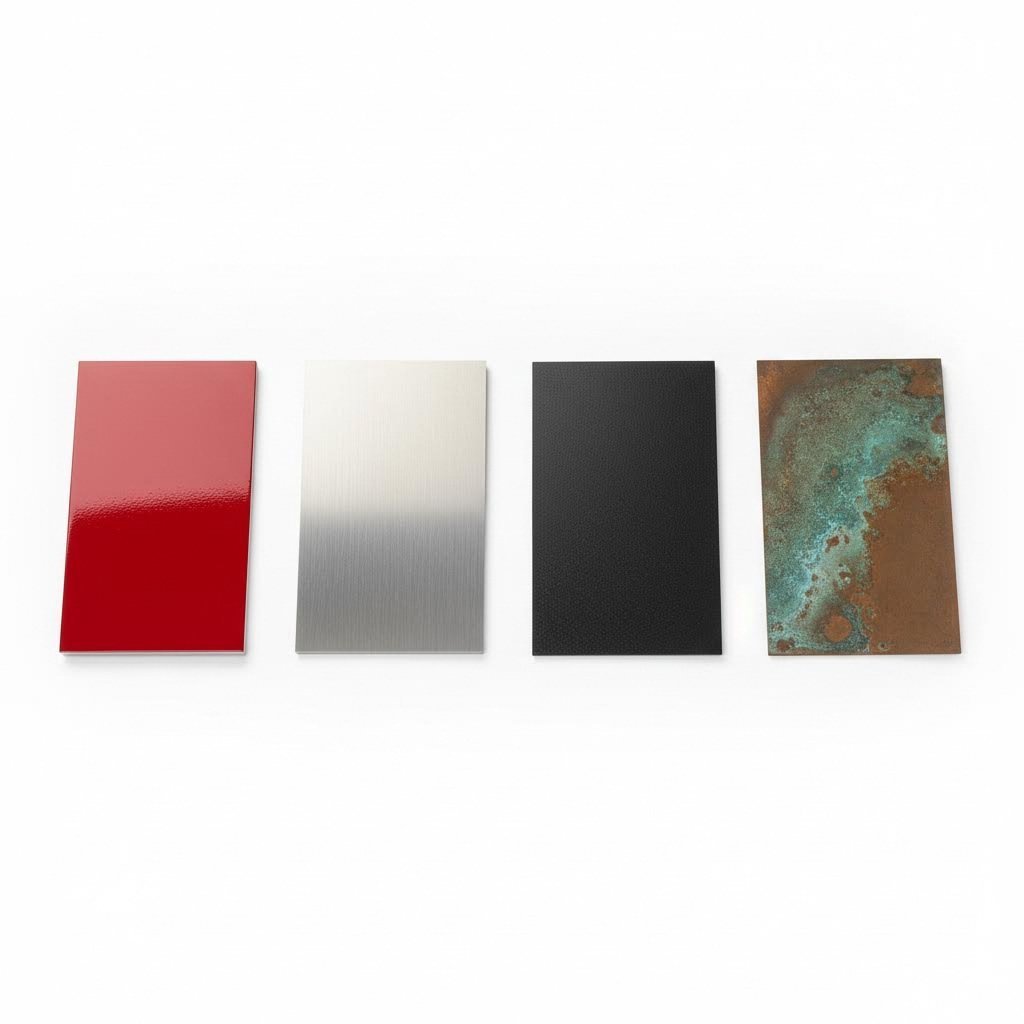

For decorative projects, brass and copper offer aesthetic warmth that steel can't match. Their natural patina development creates evolving visual interest over time—though this means planning for either controlled oxidation or protective clear coats.

A sheet metal laser cutter handles all these materials effectively, but aluminium laser cutting and copper processing demand operators with experience managing reflective, thermally challenging metals. When evaluating fabrication partners, ask specifically about their experience with your chosen material at your required thickness.

Now that you understand which metals suit different applications, the next critical step is mastering the design principles that ensure your chosen material cuts cleanly—starting with tolerances, kerf width, and minimum feature sizing.

Design Principles for Precision Laser Cutting

You've selected the perfect metal for your project. Now comes the moment that separates successful laser cut designs from expensive failures—translating your creative vision into a file that actually cuts cleanly.

Here's what most designers learn the hard way: even flawless artwork can produce disappointing results if you ignore the physical realities of how lasers interact with metal. The good news? Once you understand a few key principles, you'll avoid the costly mistakes that plague first-time projects.

Critical Tolerances and Kerf Width Considerations

When you design laser cut metal sheets, what you see on screen isn't exactly what you'll hold in your hand. The culprit? Kerf width—the tiny amount of material the laser beam vaporizes as it cuts.

According to Stanford's Making Lab documentation, kerf refers to the width of material removed during cutting, resulting from the laser beam melting or vaporizing a small portion along its path. While this might seem like a minor detail, it directly affects your final dimensions and how parts fit together.

For most metals, kerf width ranges from 0.1mm to 0.3mm depending on material thickness and laser settings. This means:

- External dimensions: Your finished part will be slightly smaller than designed

- Internal features: Holes and cutouts will be slightly larger than drawn

- Interlocking parts: Tabs and slots require offset adjustments for proper fit

When does kerf matter most? If you're creating laser cut parts that need to interlock—like box joints or snap-fit assemblies—ignoring kerf leads to loose, wobbly connections. However, for standalone decorative pieces or signage where tight mechanical fits aren't required, kerf compensation may not be critical.

Always consult your fabricator's specific kerf values before finalizing designs with tight tolerances—equipment and material combinations produce varying results.

Designing Features That Cut Cleanly

Beyond kerf, laser cutting precision depends on respecting the relationship between material thickness and feature size. Pushing these limits doesn't just compromise quality—it can increase laser cutting charges when operators must slow down or make multiple passes.

Here are the essential design rules every laser cut metal signage project and industrial application should follow:

- Minimum hole diameter: Design holes at least 1x the material thickness (1.5x for aluminum and copper). A 3mm steel sheet needs holes no smaller than 3mm diameter.

- Hole-to-edge distance: Maintain at least 1.5x material thickness between any hole and the nearest edge to prevent deformation.

- Recommended corner radii: Internal corners should have a radius of at least 0.5x material thickness. Sharp internal corners concentrate stress and can crack during handling.

- Bridge width requirements: Thin sections connecting parts of your design need minimum widths of 1.5-2x material thickness to maintain structural integrity.

- Spacing between cuts: Leave at least 2x material thickness between parallel cut lines to prevent thermal distortion.

- Text sizing: For legible text, stroke width should be minimum 1.5x material thickness. Fine serif fonts rarely cut cleanly—use bold, sans-serif typefaces.

For large panels, thermal distortion becomes a serious concern. As the laser sheet metal cutter works across the surface, localized heating causes expansion and contraction. Minimize this by designing symmetrical cut patterns and avoiding clusters of dense cuts in one area.

File Preparation for Flawless Results

Even perfectly designed features fail if your file isn't properly prepared. As noted by American Laser Cutter, laser cutters require precision-ready vector files—not raster or photo-based images.

Submit your designs in these accepted formats:

- AI (Adobe Illustrator) — preferred for complex designs

- DXF (AutoCAD) — universal compatibility across CAD systems

- PDF (vector-exported only) — ensure no embedded raster images

Before exporting, verify these critical file requirements:

- Convert text to outlines: Fonts must become shapes, not editable text characters

- Ensure closed paths: Open vector paths cause incomplete cuts—every shape needs a closed loop

- Remove duplicate lines: Overlapping geometry causes double cuts, damaging material and wasting time

- Design at 1:1 scale: Always work in actual size with consistent units (preferably millimeters)

- Simplify complex curves: Too many nodes slow processing and can overheat thin sections

Working with a laser cutter sheet metal specialist who offers Design for Manufacturability (DFM) review can catch problems before they become expensive mistakes. Many fabricators will flag issues like undersized features or problematic geometries and suggest modifications that maintain your design intent while ensuring clean cuts.

With your design optimized for the cutting process, you're ready to explore the exciting range of applications where laser cut metal truly shines—from architectural statement pieces to precision industrial components.

Popular Applications for Laser Cut Metal Designs

Now that you understand design principles and material selection, you're probably wondering: what can I actually create with this technology? The answer spans far beyond simple cut shapes—laser cut metal designs have transformed industries from architecture to aerospace, enabling projects that were once impossible or prohibitively expensive.

Let's explore where this precision technology makes the biggest impact and what design considerations matter most for each application.

Architectural and Decorative Panel Applications

Walk through any modern commercial building or upscale residential development, and you'll likely encounter laser cut metal panels serving both aesthetic and functional purposes. According to VIVA Railings, these panels have become a sought-after solution for their ability to enhance visual appeal while addressing practical needs like privacy and sun control.

The versatility of decorative metal signs and architectural panels is remarkable. Consider these common applications:

- Privacy screens and partitions: Intricate geometric or organic patterns allow light and air to pass while obscuring direct sightlines—perfect for outdoor patios, office dividers, and residential balconies

- Facade cladding: Building exteriors featuring laser cut panels create dynamic shadow patterns throughout the day, transforming static structures into living artwork

- Interior wall systems: From lobby feature walls to restaurant design elements, decorative panels add sophistication to commercial and hospitality spaces

- Ceiling systems: Beyond aesthetics, laser cut ceiling panels provide acoustic control while maintaining visual interest overhead

- Sun control structures: Precisely calculated perforations manage natural light and reduce heat gain, contributing to energy-efficient building design

What makes architectural applications unique? Weather resistance becomes paramount for exterior installations. Laser cut metal panels destined for facades require careful material selection—typically powder-coated aluminum or stainless steel—along with appropriate mounting systems that accommodate thermal expansion.

Pattern possibilities extend from traditional motifs to abstract designs and even photographic imagery. Technologies like perforated metal panels can integrate photographs or graphics within the metal itself, adding depth and visual interest that flat surfaces simply cannot achieve.

Signage and Branding Solutions

When businesses need to make a lasting impression, laser cut metal signs deliver impact that plastic or painted alternatives cannot match. The dimensional quality of cut metal—with its visible depth and professional edges—communicates permanence and quality.

Custom laser cut metal signs serve diverse purposes:

- Business identification: Storefront logos, building addresses, and corporate reception signage with precise brand representation

- Wayfinding and directional signs: Interior and exterior navigation elements that guide visitors while reinforcing design aesthetics

- Metal outdoor signs: Property markers, garden art, and residential address plaques built to withstand years of exposure

- Commemorative and memorial installations: Donor recognition walls, historical markers, and tribute pieces requiring lasting durability

- Promotional displays: Trade show elements, retail fixtures, and point-of-purchase displays that demand attention

According to Sign Customiser, durability is paramount for outdoor metal signage. Factors like weather resistance, rust-proofing, and maintenance requirements directly influence how well a sign withstands the elements over time.

For laser cut signs installed outdoors, consider these design factors:

- Material choice: Aluminum naturally resists corrosion, while steel requires protective coatings like powder coating or galvanizing

- UV protection: Protective UV-resistant coatings prevent fading and maintain color vibrancy under prolonged sunlight exposure

- Mounting method: Drilled holes at corners provide secure anchor points, but standoff mounts create dramatic shadow effects

- Finish selection: Brushed silver offers professional subtlety, while brushed gold adds warmth and mirror finishes catch attention dynamically

Custom metal signs outdoor installations require periodic inspection for wear or damage. Proactive cleaning and occasional sealant application extend lifespan significantly—transforming a one-time investment into decades of reliable branding.

Industrial and Structural Applications

Beyond decorative uses, laser cutting technology plays a critical role in manufacturing precision components across demanding industries. As noted by Accurl, this process has become indispensable in sectors where tolerance levels are strict and component reliability is non-negotiable.

Key industrial applications include:

- Automotive manufacturing: Body panels, brackets, structural reinforcements, and custom parts requiring exact specifications for proper fit and function

- Aerospace components: Lightweight, high-strength parts where precision meets strict safety standards—every millimeter matters at altitude

- Medical device production: Surgical instruments and implants demanding exceptional accuracy and biocompatible materials

- Electronics enclosures: Ventilated housings, mounting brackets, and EMI shielding with precise cutout patterns

- Agricultural equipment: Durable machinery components subjected to harsh working conditions requiring reliability

Structural applications demand different design considerations than decorative work. Load distribution becomes critical—thin sections that look beautiful in a decorative panel may fail under mechanical stress. Engineers must account for:

- Stress concentration: Sharp internal corners can become failure points under load—generous radii distribute forces more safely

- Material grain direction: Steel strength varies based on rolling direction, affecting component performance

- Weld preparation: Edge quality from laser cutting often provides excellent surfaces for subsequent welding operations

- Dimensional consistency: Production runs require parts that interchange perfectly—laser cutting delivers repeatable accuracy batch after batch

The precision of laser cutting ensures that each component meets exact specifications, which proves essential in industries where safety and performance depend on manufacturing quality.

With this understanding of what laser cut metal can accomplish across industries, you're better equipped to envision your own project possibilities. However, even the most creative vision can stumble if common design pitfalls aren't avoided—mistakes that fabricators frequently see but rarely discuss upfront with new customers.

Common Laser Cut Design Mistakes and How to Avoid Them

Here's the uncomfortable truth fabricators rarely share upfront: most laser cutting failures aren't equipment problems—they're design problems. After reviewing thousands of projects, experienced fabricators report that the same preventable mistakes appear again and again, costing customers time, materials, and budget.

The good news? Once you know what to watch for, avoiding these errors becomes straightforward. Let's examine the most costly design mistakes in laser cutting of metal sheets and exactly how to fix them before your file ever reaches the cutting bed.

Avoiding Costly Design Errors

When designing custom cut metal projects, small oversights create big consequences. According to CIMtech Green Energy's analysis of over 1,000 projects, design files may look perfect on screen, but if they're not optimized for laser cutting, they lead to distorted features, scrap material, and failed parts.

Here are the most frequent mistakes that plague laser cutting metal sheet projects:

- Insufficient bridge connections causing parts to fall: Thin tabs or bridges connecting internal pieces to the main sheet can burn away during cutting. When this happens, loose pieces drop through the cutting bed, potentially damaging equipment or becoming irretrievable. The solution? Keep bridge widths at least 1.5-2x the material thickness, and place them strategically where post-cutting removal is manageable.

- Text too small to cut cleanly: Fine fonts and thin strokes simply cannot survive the laser's heat. Letters with stroke widths smaller than the material thickness will either close up entirely or produce illegible results. Always use bold, sans-serif typefaces with stroke widths at minimum 1.5x material thickness—and test questionable text sizes with a prototype.

- Sharp internal corners that concentrate stress: Perfectly square internal corners look clean in CAD software but create problems in reality. During cutting, the laser must pause and change direction, creating heat buildup that weakens the material. Under load or during handling, these stress concentration points can crack. As noted by Cyclotron Industries, use a corner radius of about 0.5x the sheet thickness for internal corners to maintain consistent kerf and reduce cracking during forming.

- Inadequate spacing between cuts: When features sit too close together, heat accumulates faster than the material can dissipate it. The result? Warped edges, discoloration, and dimensional inaccuracy. Maintain edge-to-edge spacing of at least 1x material thickness for thin sheets, increasing for thicker materials or heat-sensitive alloys like aluminum.

- Ignoring material grain direction: Steel and aluminum have a grain direction from the rolling process that affects both strength and appearance. Bends made against the grain are more likely to crack, and decorative finishes may show inconsistent patterns. Specify grain orientation requirements for structural parts and coordinate with your fabricator on sheet layout.

- Designing impossibly small internal features: Laser cutter sheet metal systems have physical limits. According to fabrication guidelines, holes significantly smaller than the sheet thickness will distort or melt closed. A 0.5mm hole in 3mm steel? Simply impossible—the hole closes up during cutting.

- Forgetting bend reliefs on formed parts: If your custom cut sheet metal will be bent after cutting, stress concentrates at corners during forming. Without small relief cuts or notches, the material tears rather than folding cleanly. Add bend reliefs at all internal corners where bends will occur.

- Placing critical holes too close to bend lines: Holes near bend areas distort when the sheet is formed, making them useless for fasteners or alignment. Position holes at least 2-3x material thickness away from any bend centerline.

Troubleshooting Common Cutting Problems

Even well-designed files can encounter issues during production. Understanding what causes common cutting problems helps you diagnose issues and communicate effectively with your fabrication partner.

Burrs and rough edges typically indicate incorrect cutting parameters rather than design flaws. However, overly complex geometries force the laser to slow down repeatedly, generating excess heat that creates burrs. If your design requires numerous tight turns, discuss parameter adjustments with your fabricator or simplify curves where possible.

Thermal distortion on large panels often stems from unbalanced cut patterns. When all dense cutting occurs on one side of a sheet, uneven heat distribution warps the entire piece. Design symmetrically when possible, or specify sequential cutting strategies that distribute heat evenly across the workpiece.

Parts falling through the cutting bed means bridges or tabs failed. Review your file for any connections thinner than 1.5x material thickness, and verify that lead-in/lead-out placements don't compromise structural connections.

Identifying and Fixing File Issues Before Fabrication

Catching problems early saves significant expense. Before submitting your laser cut sheet metal design, run through this pre-flight checklist:

- Zoom to 100% and inspect every feature: What looks fine at overview scale may reveal problems up close—overlapping lines, unclosed paths, or features below minimum size

- Verify all paths are closed: Open vectors cause incomplete cuts. Most CAD software can highlight open paths automatically

- Check for duplicate geometry: Overlapping lines cause double cuts, wasting time and damaging material with excessive heat

- Measure critical dimensions: Confirm that holes, slots, and spacing meet minimum requirements for your material thickness

- Confirm text is outlined: Editable text causes font substitution issues—convert all type to vector paths

- Review bridge and tab placement: Ensure connections are adequately sized and positioned for easy removal after cutting

The Case for Prototyping Complex Designs

When does prototyping become essential rather than optional? Any time your design pushes boundaries—intricate patterns, tight tolerances, unfamiliar materials, or parts that must interlock precisely.

Custom laser cutting prototypes reveal problems that even careful file review can miss. Thermal behavior, actual kerf width, and edge quality become tangible rather than theoretical. For production runs, a single prototype investment prevents scrapping entire batches.

Discuss prototyping options with your fabricator before committing to full production. Many shops offer expedited single-part runs specifically for validation purposes—a small upfront cost that can prevent much larger losses downstream.

Working with Fabrication Partners to Optimize Designs

The most successful laser cut metal projects treat fabricators as collaborators rather than vendors. As CIMtech emphasizes, treating your laser cutting partner like part of your design team—not just a vendor—leads to dramatically better outcomes.

What should you expect from a quality fabrication partner?

- Design for Manufacturability (DFM) review: Experienced shops flag problematic features before cutting begins, suggesting modifications that maintain design intent while ensuring clean production

- Material-specific guidance: Your fabricator should advise on minimum feature sizes, spacing requirements, and finish compatibility for your chosen metal

- Kerf compensation assistance: For parts requiring precise fits, your partner should provide their actual kerf measurements and help adjust files accordingly

- Honest communication about limitations: Good fabricators tell you what won't work rather than attempting impossible cuts that waste your material

Provide your fabricator with complete information: intended application, tolerance requirements, which dimensions are critical versus cosmetic, and any post-processing plans. This context helps them optimize cutting parameters and flag potential issues you might not anticipate.

Understanding these common mistakes positions you to submit designs that cut cleanly on the first attempt. But getting a perfect cut is only part of the equation—the finish you apply afterward determines how your laser cut metal looks and performs over time.

Surface Finishing Options for Laser Cut Metal

Your laser cut metal design just came off the cutting bed with perfect edges and precise dimensions. Now what? Without the right surface finish, that flawless cut won't stay flawless for long—especially if it's heading outdoors or into a demanding environment.

Here's what many designers overlook: finish selection isn't just about appearance. It affects everything from corrosion resistance to how your custom metal sign ages over decades. Choosing the wrong finish for your application can undo all the precision work that went into cutting.

Protective Coatings for Durability

When durability matters more than decorative flair, protective coatings become essential. According to SendCutSend's finishing guide, metal finishes can increase abrasion resistance, change surface hardness, prevent corrosion, inhibit conductivity, and much more.

Powder coating stands as one of the most popular protective options for metal signs custom applications and industrial parts alike. Unlike wet paint, powder coating starts as a dry powder applied electrostatically, then cures in an oven to form an uninterrupted protective skin. The results speak for themselves—powder coating can last up to 10x longer than paint while containing none of the volatile organic compounds that make traditional paints environmentally problematic.

What makes powder coating particularly valuable for laser cut designs? Testing by SendCutSend's durability comparison found that powder coated steel dramatically outperformed other finishes in abrasion resistance—with the shortest time to expose bare metal being significantly longer than the runner-ups' longest time.

Hot dip galvanizing takes a different approach to protection. This process dips steel fabrications into molten zinc, creating a metallurgically bonded layer that protects through sacrificial corrosion. According to Wiley Metal's comparative analysis, galvanizing can extend the life of a metal structure as much as five times that of powder coating—making it the superior choice for infrastructure and outdoor industrial applications where longevity trumps aesthetics.

However, galvanizing has limitations. The process only produces one finish: a shiny, spangled silver that fades to dull gray over time. It's also more expensive due to surface preparation complexity, energy requirements, and zinc costs. For aluminum metal signs or decorative projects requiring color, galvanizing simply isn't an option.

Anodizing offers a third path—specifically for aluminum. This electrochemical process thickens aluminum's natural oxide layer, creating exceptional scratch and corrosion resistance. Type 2 anodizing adds minimal thickness while providing decent durability, whereas Type 3 (hardcoat) anodizing delivers superior wear resistance for demanding applications.

Decorative Finishes That Enhance Design

Sometimes protection alone isn't enough—your personalized metal signs or architectural panels need to look as good as they perform. Decorative finishes bridge the gap between durability and aesthetics.

Brushed finishes create a distinctive linear texture that reduces fingerprint visibility while adding visual depth. For stainless steel signs, brushing is often the go-to choice. The process involves using abrasive materials to create consistent directional lines across the surface. You can achieve this effect at home using lubricant, 120-180 grit sandpaper, and a sanding belt moved consistently in one direction.

Patina treatments offer controlled oxidation for copper and brass, creating the verdigris green or warm brown tones associated with aged architectural metalwork. Rather than fighting natural oxidation, patina treatments accelerate and control it—resulting in a stable, protective layer that continues to evolve subtly over time.

Zinc and nickel plating serve both protective and decorative purposes. While zinc plating primarily protects steel through sacrificial corrosion, nickel plating adds a bright, lustrous finish suitable for decorative hardware and ornamental applications. However, testing shows zinc plating offers minimal abrasion resistance compared to powder coating or anodizing.

| Finish Type | Durability | Relative Cost | Best Applications | Aesthetic Effect |

|---|---|---|---|---|

| Powder Coating | Excellent abrasion/corrosion resistance; 10x paint lifespan | Low-Medium ($) | Signs metal, outdoor furniture, automotive parts, industrial equipment | Wide color range; matte, gloss, or textured finishes available |

| Anodizing (Type 2) | Good scratch/corrosion resistance; thin coating | Medium ($$) | Aluminum architectural panels, decorative items, electronics | Clear or dyed colors; metallic appearance preserved |

| Anodizing (Type 3) | Superior wear resistance; consistent thickness | High ($$$) | High-wear aluminum components, aerospace, industrial parts | Darker, more muted colors; industrial appearance |

| Hot Dip Galvanizing | Exceptional; 5x powder coating lifespan | Medium-High ($$$) | Structural steel, outdoor infrastructure, marine applications | Silver spangled finish fading to gray; no color options |

| Brushed Finish | Moderate; requires clear coat for protection | Low ($) | Stainless steel signs, appliances, architectural accents | Linear texture; reduces fingerprints; professional appearance |

| Patina Treatment | Good; continues evolving over time | Low-Medium ($) | Copper/brass architectural elements, decorative art, signage | Verdigris green, brown, or custom aged appearances |

How Finish Selection Impacts Design Decisions

Here's what catches many designers off guard: the finish you choose affects decisions you made much earlier in the design process.

Dimensional considerations: Every coating adds thickness. According to durability testing data, powder coating increases part thickness by approximately 4.7 thousandths of an inch, while Type 2 anodizing adds the least dimensional change. For parts with tight tolerances—interlocking components or precision assemblies—you must account for finish thickness in your original design or risk parts that no longer fit together.

Hole sizing adjustments: Small holes can become significantly smaller after powder coating. If you're designing mounting holes or fastener clearances, add extra diameter to compensate. Anodizing presents a unique situation: half the coating thickness grows inward while half grows outward, requiring different compensation calculations than powder coating.

Edge treatment requirements: Some finishes require specific edge preparation. Powder coating adheres best to slightly rounded or deburred edges—sharp laser-cut edges can cause coating to chip at corners. Galvanizing, by contrast, flows around edges but may accumulate unevenly, creating drips or thick spots on complex geometries.

Tab and microJoint visibility: If your design uses tabs for holding parts during cutting, be aware that these connection points may remain visible through certain finishes, especially on thicker metals with powder coating.

Maintenance Requirements and Longevity

Your finish choice determines ongoing maintenance obligations. Understanding these requirements helps you advise clients and set appropriate expectations.

Powder coated surfaces require periodic cleaning with mild soap and water. Avoid abrasive cleaners that can scratch the finish. For outdoor metal sign installations, annual inspection for chips or scratches allows touch-up before corrosion begins at damaged spots.

Galvanized steel needs minimal maintenance—the zinc layer self-heals minor scratches through cathodic protection. However, in highly corrosive environments like coastal areas, periodic inspection ensures the sacrificial zinc layer hasn't depleted.

Anodized aluminum resists corrosion naturally and requires only occasional cleaning. The integrated oxide layer won't peel or chip like applied coatings, though it can be scratched more easily than powder coating.

Brushed stainless steel maintains its appearance with regular cleaning using stainless-specific cleaners that remove fingerprints without damaging the brushed texture. Clear protective coatings extend maintenance intervals but eventually require reapplication.

Color Options and Custom Finishing Possibilities

When branding or aesthetic requirements demand specific colors, your finish options narrow—but remain surprisingly flexible.

Powder coating offers the widest color palette. Standard options typically include black (matte, gloss, and wrinkle textures), red, white, and yellow, with custom RAL color matching available for brand-specific requirements. This makes powder coating ideal for corporate signage and branded installations where color accuracy matters.

Anodizing accepts dyes during the sealing process, producing vibrant colors on aluminum that won't fade or peel. However, the metallic substrate shows through, creating a distinctive lustrous appearance different from opaque powder coating.

For stainless steel signs requiring color, powder coating over stainless provides both the corrosion resistance of the base material and the color options of the coating—a combination particularly valuable for outdoor applications.

Selecting the right finish transforms good laser cut metal design into lasting, professional installations. But even the perfect finish adds cost—and understanding how all project factors affect pricing helps you make informed decisions about where to invest your budget.

Cost Factors That Impact Laser Cut Metal Projects

You've designed an incredible piece, selected the perfect material, and identified the right finish. Now comes the question that determines whether your project moves forward: how much will it actually cost?

Here's what most fabricators won't explain upfront—your design decisions directly control your final invoice. Understanding these cost drivers before you finalize your file gives you the power to optimize for budget without sacrificing quality.

Understanding Laser Cutting Cost Drivers

When requesting quotes from metal cutting services, the numbers you receive aren't arbitrary. According to AP Precision's cost analysis, laser cutting prices depend on several interconnected factors: the type of laser used, material strength, and specific production requirements all contribute to the final expense.

Let's break down exactly what drives your project costs:

- Material type and thickness: This represents the largest cost variable. Stainless steel and specialty metals like copper cost significantly more than mild steel—both in raw material price and cutting time. Thicker materials require slower cutting speeds and more laser power, directly increasing machine time. According to Laserfab's guidelines, the thickness of the metal determines how quickly the beam can cut, with each metal having an optimal cutting thickness for the cleanest results.

- Design complexity and cutting time: Every curve, corner, and detail adds seconds to your cutting time—and time equals money. Complex patterns with numerous direction changes force the laser to slow down repeatedly. Simple geometric shapes cut faster than organic curves, and straight lines process faster than arcs.

- Material waste and nesting efficiency: How your parts fit onto standard sheet sizes dramatically affects costs. Poorly nested designs leave expensive scrap metal behind. Conversely, designs that nest tightly together maximize usable material from each sheet.

- Finishing requirements: Post-cut processing adds cost layers. Powder coating, anodizing, and specialized finishes each require additional handling, materials, and curing time. The more complex your finish specification, the higher your final price.

- Order quantity: Setup costs spread across larger orders, making per-piece pricing drop significantly at higher volumes. A single prototype costs more per unit than a production run of hundreds.

The longer the lines in your design, the longer they take to cut—which directly increases expenses. Simplifying geometry where possible is one of the fastest ways to reduce costs.

Design Strategies to Optimize Budget

Knowing what drives costs is only half the equation. The real value comes from applying this knowledge to balance design aspirations with budget realities.

Simplify where it won't compromise your vision. Ask yourself: does every decorative detail serve the final purpose? Complex patterns undeniably impress, but strategic simplification in less visible areas can reduce cutting time substantially without affecting the overall aesthetic. As Laserfab notes, cutting down on production time and increasing intentionality in design files will reduce the cost of your custom cut metal pieces.

Master the art of efficient nesting. According to Cincinnati Incorporated's nesting analysis, proper material utilization can save money and reduce environmental impact by optimizing how parts arrange on raw materials. This means:

- Grouping similar shapes to minimize gaps between cuts

- Rotating parts to fit more snugly on sheets

- Combining different part types on a single sheet when possible

- Designing complementary pieces that share common edges—a technique that eliminates duplicate cutting paths

When searching for laser cutting services near me, ask potential partners about their nesting capabilities. Quality fabricators use advanced nesting software that automatically arranges your parts for maximum material efficiency, reducing your per-piece costs.

Avoid costly file errors. Double-cut lines—where geometry overlaps in your design file—waste time and money. According to fabrication experts, if a line overlays another in the design file, the laser will double-mark the area, counting as an additional line with further time and costs. Review your digital files carefully before submission.

Consider material alternatives. If your project doesn't require the specific properties of expensive metals, mild steel offers excellent value for custom metal cutting projects. Reserve premium materials like stainless steel or copper for applications where their unique properties—corrosion resistance, conductivity, or aesthetic warmth—are genuinely necessary.

Start with prototypes for complex designs. Before committing to a full production order, a small trial run reveals potential issues at minimal cost. Fabrication specialists recommend beginning with limited orders to witness how the design translates to reality—any complications cost far less to fix in a prototype than in a full batch.

When Custom Fabrication Is Worth the Investment

Given these cost considerations, when does custom metal art and fabrication make financial sense versus standardized alternatives?

Custom laser cut services deliver clear value when:

- Precision requirements exceed standard tolerances: Off-the-shelf components can't match application-specific dimensional needs

- Unique designs support brand differentiation: One-of-a-kind signage or architectural elements create lasting impressions that justify premium costs

- Complex geometries are functionally necessary: Some applications simply can't be served by standard shapes

- Volume justifies tooling investments: Larger production runs spread setup costs, making per-unit pricing competitive

Conversely, if standard sizes and shapes meet your functional needs, and aesthetic uniqueness isn't a priority, adapting designs to work with available stock material or pre-made components often makes more economic sense.

Metal laser cutting services vary significantly in pricing structure, equipment capabilities, and expertise. When evaluating quotes, look beyond the bottom-line number—consider included services like DFM review, nesting optimization, and finishing capabilities that add value even at slightly higher prices.

Understanding these cost dynamics positions you to make informed trade-offs. But selecting the right fabrication partner matters just as much as optimizing your design—and knowing what to look for in a manufacturing partner ensures your project succeeds from quote through delivery.

Selecting the Right Fabrication Process and Partner

You've mastered design principles, chosen materials wisely, and optimized for cost. But here's the final decision that determines whether your laser cut metal design becomes reality: selecting both the right cutting process and the right fabrication partner to execute it.

This choice isn't as straightforward as searching for "laser cut near me" and picking the first result. Different cutting technologies excel at different tasks, and fabrication partners vary dramatically in capability, quality, and service. Making informed decisions here prevents costly mistakes that even perfect designs can't overcome.

When Laser Cutting Is the Optimal Choice

Laser cutting isn't always the answer—but when it's right, it's exceptional. Understanding when to choose laser over alternatives like waterjet or CNC routing helps you match technology to requirements.

According to SendCutSend's process comparison, laser cutting employs a high-powered laser for precise cuts across a range of materials, with minimal heat-affected zones, making it ideal for intricate designs. It excels in precision and minimizes heat effects especially in detailed designs with small features.

Choose laser cutting when your project demands:

- Speed and efficiency: Capable of cutting upwards of 2,500 inches per minute, laser cutting is the fastest method available—and often the most economical for metals

- Intricate detail work: Fine patterns, small text, and complex geometries that require precision a laser metal cutter delivers consistently

- Tight tolerances: When dimensional accuracy matters, precision laser cutting services provide the repeatability your application requires

- Clean edges on thin to medium materials: Most metals up to 1/2 inch thick cut beautifully with fiber lasers

- Production volume flexibility: From single prototypes to high-volume runs, laser cutting scales efficiently

However, laser cutting has limitations worth understanding. Materials that create hazardous gases when burned—like PVC plastic—cannot be laser cut. Highly reflective metals like copper require specialized equipment. And for extremely thick materials or applications requiring zero heat-affected zones, alternatives may serve better.

Comparing Laser Cutting to Alternative Processes

When laser cutting isn't ideal, two alternatives dominate: waterjet cutting and CNC routing. Each brings distinct advantages for specific applications.

| Factor | Laser Cutting | Waterjet Cutting | CNC Routing |

|---|---|---|---|

| Cutting Method | Focused light beam melts/vaporizes material | High-pressure water with abrasive garnet | Rotating cutter removes material mechanically |

| Best Materials | Steel, aluminum, stainless, brass, copper | Composites, glass, thick metals, heat-sensitive materials | Plastics, wood, some composites |

| Typical Tolerance | Tight (material-specific) | +/- 0.009" | +/- 0.005" |

| Heat-Affected Zone | Minimal with proper settings | None—cold cutting process | May generate heat from friction |

| Speed | Fastest for applicable materials | Significantly slower | Moderate |

| Edge Quality | Smooth with possible minor striations on thick material | Excellent—no burrs or dross | Superior surface finish on plastics/composites |

| Internal Corner Radius | Very small (near-sharp possible) | Minimum 0.032" | Minimum 0.063" (cutter diameter dependent) |

Waterjet cutting eliminates heat entirely—the water stream is cold, making it ideal for materials where any heat-affected zone is unacceptable. According to fabrication experts, difficult-to-process composite materials such as carbon fiber, G10, and phenolic are ideal candidates for waterjet cutting. Aerospace applications frequently specify waterjet for this reason.

CNC routing shines for plastics, woods, and certain composites where laser cutting would create unacceptable edge quality or hazardous fumes. The mechanical cutting action produces superior surface finishes on these materials, though it requires fixture tabs that may leave small marks requiring post-processing.

For most metal projects—especially those requiring a laser cutter for metal to achieve fine detail and fast turnaround—laser cutting remains the go-to choice. When you need cnc laser cutting services, look for fabricators with modern fiber laser equipment ranging from 4kW to 12kW for optimal results across material types and thicknesses.

Selecting a Manufacturing Partner for Quality Results

Finding the right fabrication partner matters as much as choosing the right process. According to TMCO's fabrication guidance, choosing the right metal fabrication partner is a critical decision—one that can affect cost, performance, quality, and long-term reliability of your project.

When evaluating potential partners—whether through searches for "laser cutter service near me" or industry referrals—assess these critical factors:

- Certifications and quality systems: Look for ISO 9001 certification as a baseline for documented quality processes. For automotive and structural applications, IATF 16949 certification indicates capability for demanding precision requirements. These certifications demonstrate commitment to repeatable, verified results.

- In-house capabilities: Full-service facilities that handle cutting, finishing, and assembly under one roof provide tighter control over production, faster turnaround, and consistent quality. Fabricators who outsource critical steps introduce communication gaps and potential inconsistencies.

- Design for Manufacturability (DFM) support: Quality partners collaborate early in the process, reviewing your designs and suggesting optimizations before cutting begins. As experienced fabricators note, this level of support reduces risk, shortens lead times, and ensures smooth production—especially for complex assemblies.

- Prototyping capabilities: Rapid prototyping allows you to validate designs before committing to production volumes. According to Xometry's prototyping guide, speed and affordability are the key principles of rapid prototyping, allowing multiple prototype designs to be manufactured at once or one prototype to be revised and iterated quickly.

- Turnaround time and communication: Reliable partners provide clear timelines, project updates, and realistic expectations. Strong communication prevents costly surprises and keeps projects aligned from start to finish.

- Experience with your materials and applications: Ask specifically about their track record with your chosen metal at your required thickness. A fabricator experienced in architectural panels may not excel at precision automotive components—and vice versa.

Questions to Ask Before Committing

Before placing your order with any laser metal cutting near me provider, gather the information you need to make an informed decision:

- What certifications do you hold, and can you provide documentation?

- What is your typical turnaround time for projects similar to mine?

- Do you offer DFM review, and is it included in your quote?

- Can you produce a prototype before I commit to full production?

- What finishing options do you offer in-house versus outsourced?

- How do you handle quality control and inspection?

- What is your process for communicating project updates and potential issues?

For automotive, aerospace, and structural applications requiring precision metal fabrication with demanding quality standards, manufacturers like Shaoyi (Ningbo) Metal Technology exemplify what to look for in a certified partner. Their combination of IATF 16949 certification, 5-day rapid prototyping capability, comprehensive DFM support, and 12-hour quote turnaround demonstrates the service level that distinguishes premium fabricators from basic cutting services.

Making the Final Decision

Selecting both your cutting process and fabrication partner comes down to matching capabilities to requirements. Consider these project characteristics as you decide:

- Precision requirements: Tight tolerances favor laser cutting with experienced operators who understand kerf compensation and thermal management

- Material type: Standard metals work beautifully with laser; composites and heat-sensitive materials may require waterjet

- Production volume: Prototypes benefit from partners offering rapid turnaround; production runs need scalable capacity

- Timeline needs: Urgent projects require fabricators with expedited options and reliable communication

- Post-processing requirements: Complex finishing needs favor full-service facilities over cutting-only shops

The right fabrication partner doesn't just cut metal—they contribute engineering expertise, advanced technology, strong quality systems, and collaborative communication that adds value beyond the cutting itself. Investing time in partner selection prevents the costly mistakes that no amount of design optimization can fix, ensuring your laser cut metal design achieves the quality and performance your project demands.

Frequently Asked Questions About Laser Cut Metal Design

1. What are the best metals for laser cutting?

Mild steel offers the best cost-to-strength ratio for structural applications and cuts cleanly with standard settings. Stainless steel produces exceptionally smooth edges ideal for outdoor signage and food-grade equipment. Aluminum works well for lightweight architectural panels but requires careful power management due to high thermal conductivity. Brass and copper suit decorative applications but demand experienced operators due to their reflective properties. Your choice depends on whether you prioritize cost, corrosion resistance, weight, or aesthetics.

2. How do I prepare files for laser cutting?

Submit vector files in AI, DXF, or vector-exported PDF formats at 1:1 scale. Convert all text to outlines to prevent font substitution issues. Ensure every path is closed—open vectors cause incomplete cuts. Remove duplicate overlapping lines that would cause double cuts. Simplify complex curves to prevent processing delays. Check that all features meet minimum size requirements for your material thickness, typically 1x thickness for holes and 1.5x for bridge widths.

3. What is kerf width and why does it matter?

Kerf is the width of material the laser vaporizes during cutting, typically 0.1mm to 0.3mm depending on material and settings. This affects final dimensions—external edges become slightly smaller while internal cutouts become slightly larger. For standalone decorative pieces, kerf may not matter. However, for interlocking parts, snap-fit assemblies, or precision components requiring tight fits, you must adjust your design to compensate for kerf or risk loose connections.

4. How much does laser cutting cost?

Laser cutting costs depend on material type and thickness, design complexity, cutting time, material waste from nesting efficiency, finishing requirements, and order quantity. Stainless steel and copper cost more than mild steel. Complex designs with numerous curves increase cutting time. Efficient nesting reduces material waste. Powder coating and anodizing add finishing costs. Larger orders spread setup costs, lowering per-piece pricing. Simplifying geometry and optimizing part arrangement on sheets are the fastest ways to reduce expenses.

5. What is the minimum feature size for laser cut metal?

Minimum feature size depends on material thickness. For steel, design holes at least 1x the material thickness in diameter—a 3mm sheet needs holes no smaller than 3mm. Aluminum and copper require 1.5-2x thickness due to higher thermal conductivity. Text stroke width should be minimum 1.5x material thickness using bold sans-serif fonts. Internal corners need radii of at least 0.5x thickness to prevent stress concentration. Spacing between cuts should be at least 2x thickness to prevent thermal distortion.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —