Қолдан тартылған болат: Қауіпсіздік бөлшектері үшін жоғары беріктікті ашу

ҚЫСҚАША

Қауіпсіздік компоненттері үшін жоғары беріктікті металлдан жасалған бұйымдарды жасау - металлды қалыпқа келтіру үшін қатты қысым күшін пайдаланатын өндіріс процесі. Бұл әдіс болаттың ішкі дәнді құрылымын жетілдіреді, ақауларды жояды және жоғары беріктік, беріктік және шаршауға төзімділік үшін дәнді ағынды сәйкестендіреді. Бұл жасалма болатты авиация, қорғаныс және автомобиль өнеркәсібі сияқты күрделі салаларда қауіпсіздік үшін маңызды бөлшектер үшін қажетті таңдау етеді.

Құрмалаудың негіздері: ол қалай күшті болады

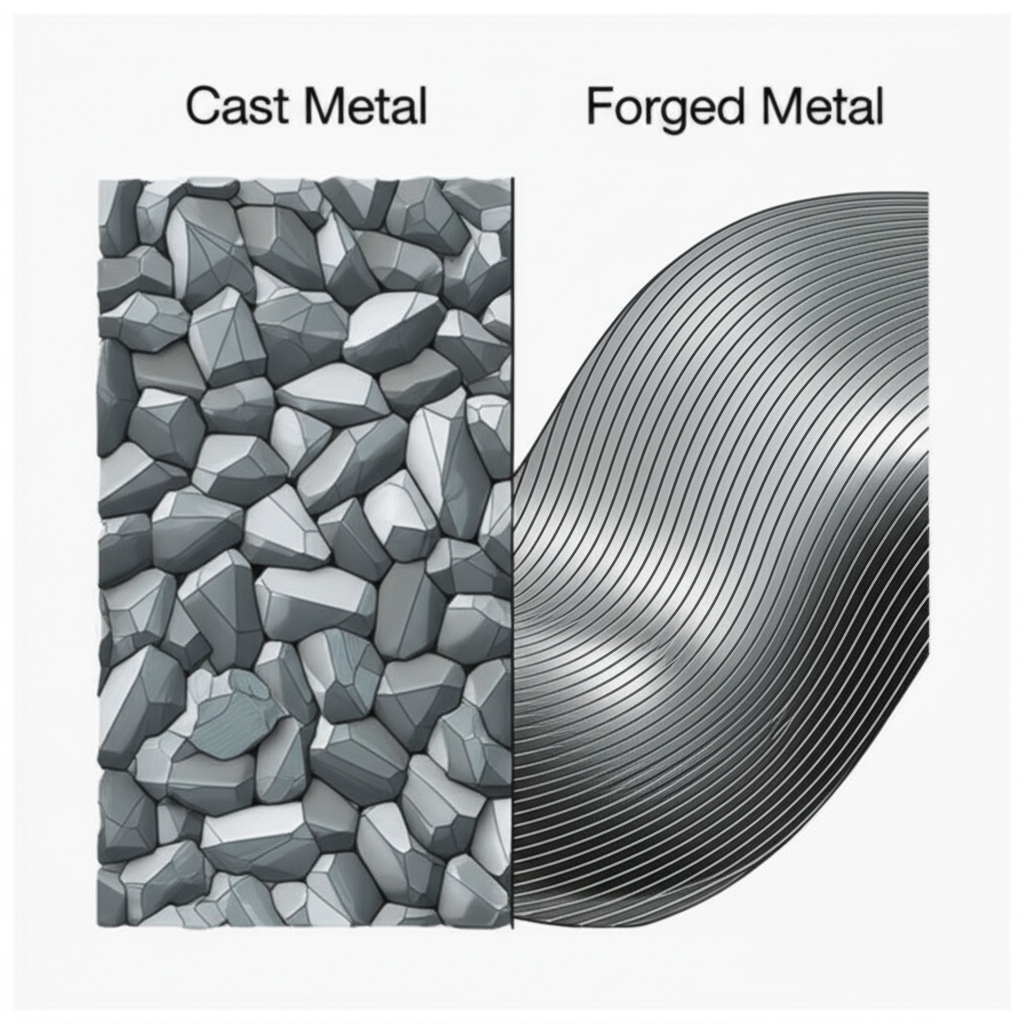

Металдың соғуы — болатты жергілікті сығылу күштері арқылы пішіндеуге негізделген, ең ескі және тиімді металдармен жұмыс істеу әдістерінің бірі. Бұл процесс әдетте болаттың шойын тасын балқытпай, иілгіш ету үшін жоғары температураға дейін қыздырудан басталады. Қыздырылған болат одан әрі пішініндеу үшін матрицалар арасында соққыланады немесе престеледі. Металды балқытып, қалыпқа құю сияқты құю сияқты процестерден өзгеше, соғу кезінде болат қатты күйде сақталады, бұл материал қасиеттеріне тигізетін түрлендіруші әсердің негізгі факторы болып табылады.

Шөмілудің негізгі артықшылығы - болаттың ішкі дәнекер құрылымын түбегейлі өзгерту және жетілдіру қабілетінде. Бұл процестің кезінде қолданылатын үлкен қысым металдың дәндерін деформациялауға және қайта кристалдануға, соңғы бөлшектің контурымен сәйкес келетіндей етіп оларды бағдарлауға мәжбүрлейді. Жиі дән ағыны деп аталатын осы бағытталған туралау - ағаш бөлігіндегі дәнге ұқсас; ол құйманың немесе механикалық өңделген бөлшектердің кездейсоқ, бағытталмаған дәніне қарағанда едәуір берік және төзімдірек үздіксіз құрылым жасайды. Бұл жетілдірілген дән құрылымы құйма бөлшектердің бүтіндігін нашарлатуы мүмкін пористікке, шөгінуге немесе бос кеңістіктерге төтеп беруге аз бейім.

Бұл құрылымдық жақсарту көрсетілетін механикалық қасиеттердің жоғарылауына әкеледі. Бұл процесс ішкі бос кеңістіктерді жабады және мүмкін болатын кернеу нүктелеріне айналуы мүмкін қоспаларды ыдыратады, нәтижесінде материал тығыздау және біркелкі болады. Нәтижесінде компоненттің созылу беріктігі, соққыға төзімділігі мен тұрақтылық құрсауы маңызды дәрежеде артады. Аталған зерттеуге сілтеме жасай отырып, Cornell Forge ұсталық бөлшектердің салмақтары құймалармен салыстырғанда 26% жоғары созылу беріктігі мен айқындалған жоғары тұрақтылық беріктігі болуы мүмкін. Бұл ұсталық компоненттерді экстремалды кернеулер мен циклдік жүктемелер кезінде ерекше төзімді және сенімді етеді.

Ұсталық жоғары беріктікті болаттың негізгі механикалық қасиеттері

Ұсталық процесі қауіпсіздік пен сенімділік шешуші орын алатын компоненттерді шығару үшін идеалды өндіріс әдісі болып табылатын механикалық қасиеттердің өзіндік терімін береді. Бұл сипаттамалар бөлшектердің ұзақ жұмыс істеу мерзімі бойы сәтсіздіксіз экстремалды пайдалану кернеулерін шыдай алатынын қамтамасыз етеді.

Жоғары тұрақтылық пен соққыға беріктік

Қайталанатын стресс циклдері салдарынан пайда болатын шаршау сәтсіздіктері қауіпсіздік үшін маңызды құрамдас бөліктердің басты мәселесі болып табылады. Құрмалау бұған тікелей жауап береді, ол жарықтардың пайда болуына және таралуына қарсы тұратын тазартылған және бағдарланған дәндік құрылымды жасайды. Бұл жасалма бөлшектерге ерекше қаталдық беріктігін береді, бұл оларға ұшақтардың қоңыраулары немесе қозғалтқыш бөлшектері сияқты қосымшаларда миллиондаған стресс циклдеріне төтеп беруге мүмкіндік береді. Сонымен қатар, жасалмалау арқылы берілетін беріктік соққыға жоғары төзімділікті қамтамасыз етеді, бұл бөлшектердің әскери көліктер мен өнеркәсіптік машиналар үшін маңызды талап болып табылатын кенет соққылар мен жүктемелерді сынамастан қабылдай алуын қамтамасыз етеді.

Құрылымдық Бекітілу мен Сенімділікті Арттыру

Құюға қарсы, ол ішкі қуыстар немесе тесіктер сияқты ішкі ақауларды енгізуі мүмкін, бұйымдау процесі болатты механикалық түрде өңдеп, материалды қатты, тығыз массаға біріктіреді. Бұл ішкі қуыстарды жояды және құрылымдық біркелкілік пен бүтіндіктің жоғары дәрежесін қамтамасыз етеді. Бұл сенімділік жоғары қысым мен жоғары кернеу қолданылатын көптеген қолданыстарда бұйымдауды міндетті етеді. Әлемдік сарапшылардың айтуынша ASTM International 200 000 psi астам беріктікке дейін өңделетін бөлшектер үшін сенімді жоғары беріктікті болат бұйымдарын алу маңызды, әсіресе жоғары көлденең пластикалықты қажет ететін жағдайларда.

Жақсартылған коррозияға қарсы тұру

Теңіз немесе әуе-кеңістік қолданыстары сияқты қатаң орталарда коррозия бөлшектің бүтіндігін ауыр зақымдай алады. Бұйымдау процесі, пасқа төзімді болатты қоса алганда, кейбір қорытпалардың коррозияға төзімділігін арттыруға мүмкіндік береді. Түсіндірілгендей Trenton Forging , процес зернелі құрылымды тазарту арқылы түйіршіктік коррозияға төзімділікті жақсартады. Бұл жасалма бөлшектерді тұзды суға, химиялық заттарға және ауаның қатты жағдайларына ұшыраған кезде берік және сенімді етеді, олардың қызмет ету ұзақтығын ұзартады және қауіпсіздікті қамтамасыз етеді.

Қауіпсіздікке бағытталған өнеркәсіптегі маңызды қолданбалар

Қиылған жоғары беріктікті болат ерекше қасиеттері оны бөлшектердің істен шығуы апатты салдарларға әкелуі мүмкін салаларда қажет етеді. Оның қолданылуы инженерлердің ең қиын жағдайда оның беріктігі мен сенімділігіне деген сенімін дәлелдейді.

Авиация саласында қауіпсіздік ең бастысы. Құрмалау ұшу аппараттары, турбина лопаттары, қозғалтқыш монтаждау және конструкциялық ұшақ бөлшектері сияқты маңызды бөлшектерді өндіру үшін қолданылады. Бұл компоненттер ұшып көтерілу, ұшу және қону кезінде үлкен жүктемеге төтеп беруі керек. атап өткендей Кантон құлату фабрикасы , құйма-шойынды соғу осындай қолданбалар үшін қажетті жоғары беріктік, төзімділік және дәлдікті қамтамасыз етеді, бөлшектердің қатаң әуе кеңістігі стандарттарына сай келуін және ұшақтың жалпы қауіпсіздігі мен тиімділігіне үлес қосуын қамтамасыз етеді.

Қорғаныс саласы жерден шайқастық машиналар мен әскери кемелерден бастап алдыңғы қатарлы қару-жарақтарға дейінгі барлық нәрседе құйма бөлшектерге кеңінен сүйенеді. Әскери техниканың іздері, серіппелі ілмектері және қорғаныс панцирлері экстремалды соққылар мен тозаңдалған жерлерді шыдай алуы керек. Теңіз қолданысында құйма валдар, клапандар және сорғыш бөлшектер тұзды су ортасындағы беріктігі мен коррозияға төзімділігі үшін маңызды. Құйма бөлшектердің мықты төзімділігі әскери жабдықтардың ең қиын операциялық аймақтарда сенімді жұмыс істеуін қамтамасыз етеді.

Автомобиль өнеркәсібі сондай-ақ критикалы қауіпсіздік компоненттері үшін жасалма болат пайдаланады, мысалы, кранксхафттар, жалғау таяқшалары, рульдің түйіршектері және ось арқалықтары. Бұл бөлшектер тұрақты жүктеме мен дірілге ұшырайды, олардың істен шығуы көлік құралының басқаруын жоғалтуына әкелуі мүмкін. Қуатты және сенімді автомобиль бөлшектерін өндіру үшін арнайы қызметтер Shaoyi Metal Technology iATF16949 сертификаттау стандарттарына сай келетін, шағын партиялардан бастап, көпшілік өндіріске дейін дәлдік пен өнімділікті қамтамасыз ететін арнайы ыстық құрмалау шешімдерін ұсыну.

Материалды таңдау: Құрма үшін дұрыс болат түрін таңдау

Жоғары беріктік бұйымдарды шөгу кезінде сәйкес болат маркасын таңдау — материалдың құрамы соңғы қасиеттерге тікелей әсер ететіндіктен маңызды кезең. Талап етілетін беріктік, серпінділік, жылуға төзімділік және қоршаған орта әсері сияқты нақты қолданылу саласының талаптарына тәуелді түрде болат маркасы таңдалады. Бір «ең жақсы» болат маркасы жоқ; оптималды материал — бұл жұмыс сипаттамалары мен өндірістік факторлар арасындағы теңдестікті қамтамасыз ететін материал.

Жоғары беріктік шөгуде жиі қолданылатын болат түрлерінің бірнеше тобы бар. Орташа көміртегілі болаттар, мысалы AISI 1045, беріктіктің, тозуға қарсы төзімділіктің және өңдеуге ыңғайлылықтың жақсы тепе-теңдігін ұсынады, сондықтан тісті дөңгелектер мен валдар сияқты бөлшектер үшін қолайлы. Күрделірек қолданылу жағдайлары үшін легірленген болаттар жиі үстемдікке ие болады. Бұл болаттар хром, молибден және никель сияқты элементтерді қоспа ретінде құрамында ұстайды, бұл белгілі қасиеттерді жақсартуға мүмкіндік береді.

Жоғары беріктік қолданыстар үшін ең танымал құймалардың бірі — AISI 4140 (Хроммоли болаты). Ол жоғары төзімділігі, үйкеліске төзімділігі және қаттылық шыдамдылығымен танымал, сондықтан әуежаңдық, автомобиль және мұнай-газ компоненттері үшін кеңінен қолданылатын материал болып табылады. Кеңінен қолданылатын тағы бір марка — никельді қосып, жоғары беріктік деңгейінде тағы да жоғары төзімділік пен соққыға төзімділік қамтамасыз ететін AISI 4340. Бұл дамыған құймалар дұрыс ұсталып және жылумен өңделген кезде ең маңызды қауіпсіздік компоненттері үшін қажет болатын экстремалды төзімділікке ие болады.

Ұсталған Компоненттердің Ешкімге Теңдеспес Сенімділігі

Нәтижеде, қауіпсіздік элементтері үшін ұсталған жоғары беріктіктағы болатты пайдалану туралы шешім бір ғана, келіспеушілікке орын бермейтін факторға байланысты: сенімділік. Ұстау процесі тек пішіндеу әдісінен гөрі асыра берік және серпімділік қасиеттерін материалдың негізіне дәл қосып, жетілдіру техникасы болып табылады. Дәнекер құрылымын туралау және ішкі ақауларды жойып, ұстау басқа материалдардың мүмкіндігінен тыс жағдайларда да экстремалды күштерге шыдайтын, шаршамайтын және қатесіз жұмыс істейтін бөлшектерді шығарады. Аспаннан бастап, теңізге дейін және жер бетінде ұсталған бөлшектер маңызды жүйелердің қауіпсіз және тиімді жұмыс істеуін қамтамасыз ететін негізгі беріктікті ұсынады.

Жиі қойылатын сұрақтар

1. Ең берік ұсталған болат қайсы?

"Құймаға арналған ең күшті" болат қолданылатын нақты мақсатқа байланысты. Алайда, кейбір қоспалы болаттар өзгеше беріктігімен танымал. Мысалы, AISI 4340 және 4140 (Хроммоли) маркалы болаттардың созылуға беріктігі, серпімділігі мен шаршауға төзімділігі жоғары, оларды қоныс аймағы мен автомобиль өнеркәсібіндегі жоғары жүктемелі бөлшектерге идеалды етеді. Соңғы нәтижеге дұрыс қоспа мен жылулық өңдеудің үйлесімі арқылы қол жеткізіледі.

2. Қай металл құймаға алынбайды?

Құйма темір — құймаға алынбайтын белгілі бір металл. Атауынан шығатынындай, құйма темірдің химиялық құрамы мен ішкі құрылымы арнайы құюға (балқытып, қалыпқа құюға) арналған. Оның көміртегі мөлшері жоғары болғандықтан, ол сынғыш болады, ал оны құйма күштерімен пішіндеуге тырысқан кезде деформацияланбастан тресініп, сынады.

3. Құйма болаттың шектеулері қандай?

Құю күштік жағынан артықшылық берсе де, оның кейбір шектеулері бар. Бұл процесс ішкі қуыстары бар өте күрделі немесе күрделі пішіндерді жасау үшін құюға қарағанда аз қолайлы. Құю өзі-өзін майлауыш подшипниктер сияқты субұйымдарды немесе әртүрлі металдардың спрессовкаланған қоспасынан тұратын бөлшектерді жасау үшін қолданылмайды. Сонымен қатар, құю үшін қажетті құрал-жабдықтар (матрицалар) қымбат болуы мүмкін, бұл өте аз сериялы өндіріс үшін оны экономикалық тиімсіз етеді.

Кіші көліктер, жоғары стандарттар. Біздің шуақты проTOTYPE қызметі табиғатты тексеру процессін жылдамдаған және оңайластырады —

Кіші көліктер, жоғары стандарттар. Біздің шуақты проTOTYPE қызметі табиғатты тексеру процессін жылдамдаған және оңайластырады —