Жоғары өнімділік үшін тапсырыс бойынша жасалған бағыттауыш иіндік орындарына арналған нұсқаулық

ҚЫСҚАША

Тапсырыс бойынша жасалған шасси тартқыш манжеттері — бұл стандартты резеңке бөлшектерді ауыстыру үшін жасалған жоғары өнімділікті ілме элементтері. Әдетте полимер сияқты берік материалдардан жасалады және сериялық нұсқаларда қамтылмаған нақты өлшемдерге немесе жұмыс сипаттамаларына сай болу үшін құрастырылады. Стандартты емес манжеттерді таңдау көлік құралының басқарылуын тиімді түрде жақсартуға, бөлшектердің қызмет ету мерзімін ұзартуға және соққыны жұтудың жоғары деңгейін қамтамасыз етуге мүмкіндік береді, сондықтан олар жарысқа, оф-роудқа және арнайы жинақталған көліктерге өте қажет.

Шасси тартқыштарының тапсырыс бойынша манжеттері деген не және неге олар қажет

Басқару ішіктің буферлері — көліктің ілініс жүйесінде маңызды, бірақ жиі елемей қалынатын компоненттер. Олар дөңгелектер тегіс емес беткі қабаттармен қозғалған кезде тербелісті жойып, ішіктің тегіс айналуына мүмкіндік беретін резеңке немесе полимер төсемдер болып табылады. Шағын жасаушының (OEM) буферлері әдетте максималды ыңғайлылық үшін жұмсақ резеден жасалады, бірақ олардың маңызды шектеулері бар. 'Тапсырыс бойынша жасалған' буфер — материалы, өлшемі немесе қаттылығы (дурометр) тұрғысынан стандартты бөлшектерден жақсырақ жұмыс істеу үшін арнайы құрастырылған бөлшек.

Жаңартудың негізгі себебі OEM резеңке буферлердің, әсіресе жүктеме кезінде бұзылуы. Стандартты резеңке уақыт өте келе тозып, ауыр жүктеме, агрессивті жүргізу немесе қолайсыз орта әсерінен жарылып немесе деформациялануы мүмкін. Бұл тозу іліністің шамадан тыс қозғалуына әкеледі, бұл бағытталуға әсер етеді және тежеу тұрақсыздығын, нашар басқару реакциясын және доңғалақ шиналарының теңсіз тозуын тудыруы мүмкін. Түзетілген полиуретан буферге ауысу іліністің дұрыс туралауы мен бақылауын сақтайтын берік шешім ұсынады. PSI Urethanes полиуретан резеңкеге қарағанда жүктеме көтеру қабілеті жоғары және үйкеліске, майға және озонға төзімділігі күштірек.

Сонымен, бағыттауыш иінтірек бөгелмелері шынымен айырмашылық жасай ма? Мүмкін. Тозып кеткен бөгеме соққы дыбыстарын, басқару жүйесінің әлсіз болуын және доңғалақтар мен басқа да ілмектердің тез тозуын туғызуы мүмкін. Оларды сапалы қосалқы немесе арнайы бөгемелермен ауыстыру көліктің тұрақтылығын және жүргізушінің сенімділігін қалпына келтіреді. Өнімділікке негізделген қолдануларда — қаттылықты қажет ететін жарыс көліктері немесе бақыталатын иілу қажет болатын оф-роуд әмбебаптары үшін — арнайы бөгемелер тек жаңарту ғана емес, қажетті басқару сипаттамаларын қамтамасыз ету үшін міндетті.

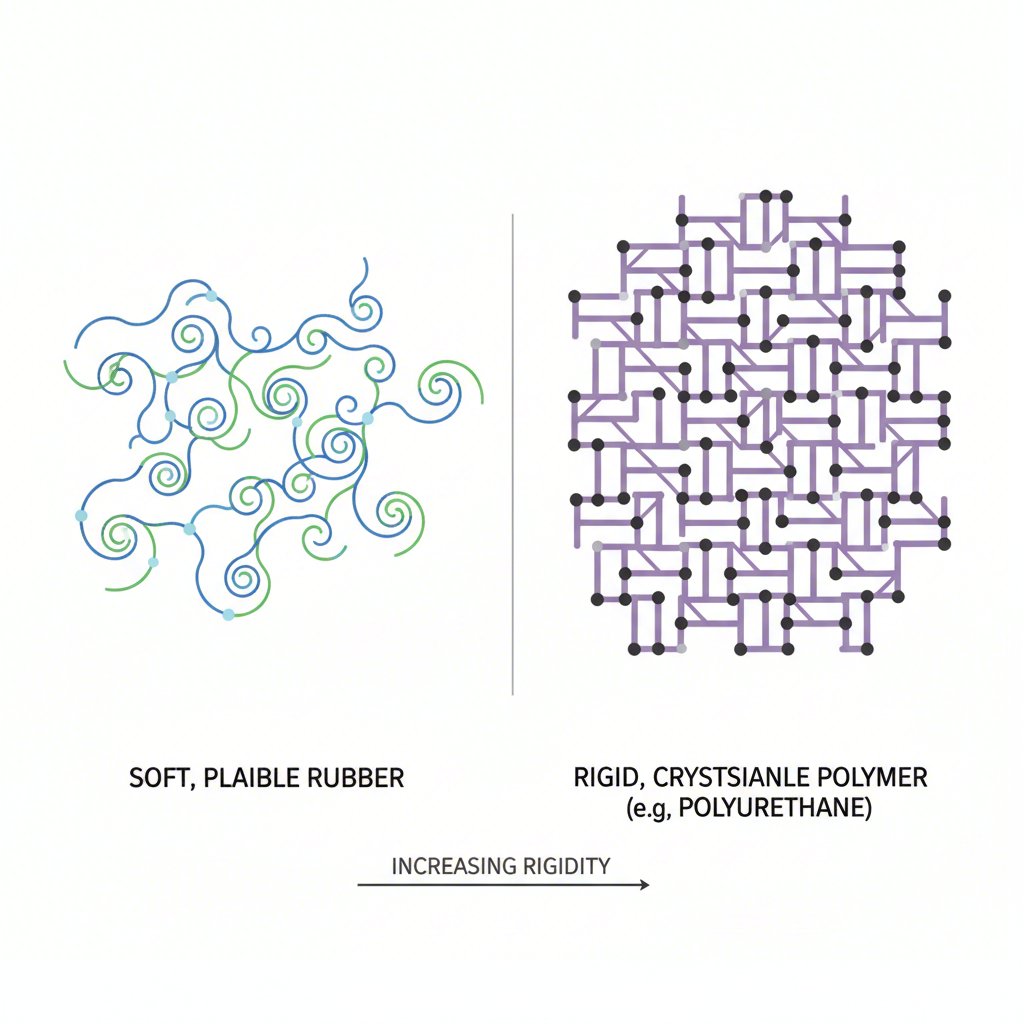

Нұсқаларды жақсырақ түсіну үшін негізгі айырмашылықтарды қарастырыңыз:

| Ерекшелігі | OEM Резеңке | Қосалқы Полиуретан | Арнайы Анықталған Бөгеме |

|---|---|---|---|

| Жұмыс іздемін | Ыңғайлылыққа бағдарланған, жоғары діріл сіңіру | Өнімділікке бағдарланған, басқару реакциясының жақсаруы | Нақты қолдану үшін әзірленген (мысалы, максималды қаттылық, нақты иілу) |

| Ұзақ өмір сүру | Орташа; тозуға және қоршаған ортаның зиянды әсерлеріне ұшырайды | Жоғары; химикаттарға, үйкеліске және жыртылуға төзімді | Өте жоғары; материал мен конструкция қолданылу мақсатына оптимизацияланған |

| NVH (Дыбыс, тербеліс, қаттылық) | Ең төмен | Резеден сәл жоғары | Материалға байланысты өзгереді; Delrin сияқты материалдарда жоғары болуы мүмкін |

| Баға | Төмен | Орташа | Жогары |

Материалды таңдау: Полиуретан, Delrin және Резеңкенің салыстырмасы

Сіздің кішкентай бақылау ішегінің буферлері үшін таңдаған материалыңыз автомобильіңіздің өнімділігіне, ыңғайлылығына және ұзақтылығына ең үлкен әсерін тигізеді. Ең көп тараған үш нұсқа — полиуретан, Delrin (ацеталь шайырының түрі) және дәстүрлі резеңке, олардың әрқайсысы әртүрлі жүргізу қажеттіліктеріне сәйкес келетін өзіндік қасиеттер жиынын ұсынады. Дұрыс таңдау жасау дыбыс, тербеліс және қатыгездіктің (NVH) өсуімен салыстырғанда өнімділікті арттыруды теңестіруді қажет етеді.

Полиизолятор бұл бауырмалар мен тапсырыс бойынша жасалған буферлер үшін ең танымал материал, себебі ол өнімділік пен ыңғайлылықтың үлкен тепе-теңдігін ұсынады. Оның қасиеттерін мысалы Uniflex Inc. , полиуретан өте көп тарап, дюрометрлік шкала бойынша өлшенетін қаттылық деңгейлерінің кең спектрінде қолданылуы мүмкін. Жұмсақ полиуретан резеңкенің ыңғайлылығын жақсы төзімділікпен ұштастыра отырып, бейімдей алады, ал қатты полиуретан жоғары өнімділіктегі жүріс үшін қатты, жауап беретін сезімді қамтамасыз етеді. Ол резеңкені тез бұзады деген ашынуға, майларға және химикаттарға өте төзімді.

Делрин және басқа нейлондар жарыс үшін ең жоғары өнімділік деңгейін ұсынатын қатты пластиктер. Бұл материалдар өте қатты және үйкеліс коэффициенті төмен, яғни ілініс компоненттері шамамен ешқандай ауытқусыз еркін қозғала алатындығын білдіреді. Бұл өте дәл және дер кезде жүрістің жауап беруіне аударады. Дегенмен, бұл қаттылық бағасы бар: Делрин жолдың шуы мен тербелісінің барлығын шамамен шасси ішіне тікелей береді, ол NVH-тің қатты өсуіне байланысты көптеген көшелерде жүретін автомобильдер үшін тиімсіз.

Резина кабинаға жеткенше тербеліс пен дыбыстың үлкен бөлігін сіңіруі мүмкіндік беретіндіктен, ең тыныш және ыңғайлы жүріс сезімін қамтамасыз етеді, сондықтан OEM стандарты болып табылады. Күнделікті жүріс үшін идеалды болса да, резенаның иілгіштігі оны жоғары жүктеме кезінде өзіне қолайсыз жағдайға айналдырады. Қатты бұрылыс немесе үдеу кезінде жабдықтың геометриясын өзгертуге мүмкіндік береді, бұл дәлірек емес басқару сезіміне әкеледі. Сонымен қатар, полиуретанға қарағанда әлдеқайда тез wear out болады, әсіресе қолайсыз жағдайларда.

| Материал | Жестікшілік аралығы | Негізгі қолданыс | ДКД деңгейі | Орташа құны |

|---|---|---|---|---|

| Резина | Жұмсақ (40A-60A Дюрометр) | Күнделікті жүріс, OEM орнына қою | Өте төмен | Төмен |

| Полиизолятор | Орташа немесе қатты (70A-95A Дюрометр) | Көше өнімділігі, Тартылмалы жол, Автокросс | Төменнен орташаға дейін | Орташа |

| Делрин/Нейлон | Өте қатты (шамамен 83D Дюрометр) | Арнайы трек/жарыс көліктері | Өте жоғары | Жогары |

Баптау процесі: Сіздің бушингтеріңізді қалай өлшеу және тапсырыс беру

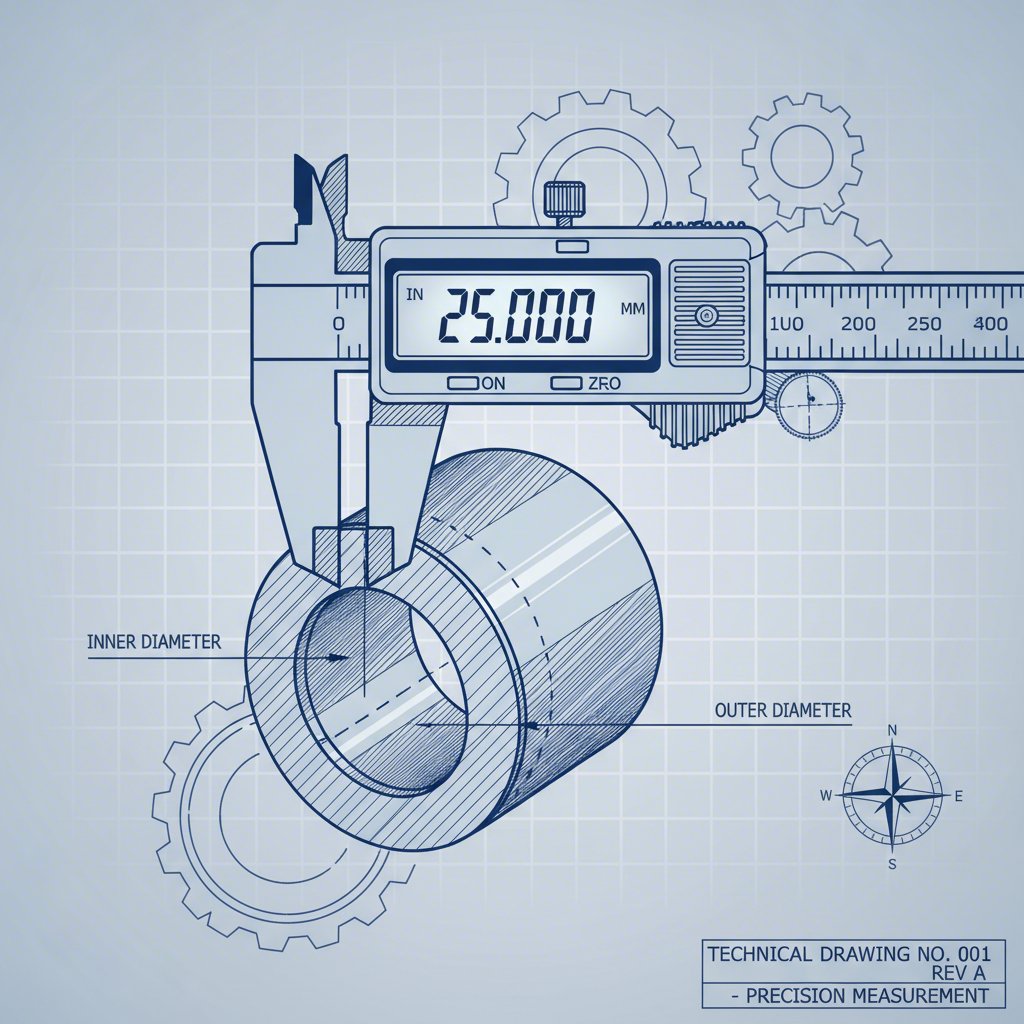

Тапсырыс бойынша басқару тетігінің буферлерін алу - оңай процесс, бірақ дәлдікті талап етеді. Дайын бөлшектерден айырмашылығы, тапсырыс бойынша жасалған буферлер стандартты емес немесе өзгертілген ілініске дәл сәйкес келуі үшін сіздің нақты талаптарыңыз бойынша жасалады. Бұл процесс шынайы өлшемдер мен анықталған талаптарды өндірушіге ұсынуға негізделеді.

Жобаңызға дәл сол бөлшектерді алу үшін мына қадамдарды орындаңыз:

- Дәл өлшемдерді алыңыз: Бұл - ең маңызды қадам. Дәлдік үшін сізге цифрлық штангенциркуль қажет. Негізгі үш өлшем: буфердің Ішкі Диаметрі (ID) (бұранда немесе қаптама өтетін жер), буфердің Сыртқы Диаметрі (OD) (оның іліністік иінге отыратын бөлігі) және буфердің Жалпы Ұзындығы (L). Саныңызды растау үшін бірнеше рет өлшеңіз.

- Техникалық сипаттамаларыңызды анықтаңыз: Өлшемдеріңіз бар болғаннан кейін, материал мен оның қаттылығын таңдауыңыз керек. Қолданылуыңызға (көше, трек, оф-роуд) байланысты полиуретан, Делрин немесе басқа материалды таңдаңыз. Полиуретан үшін дюрометр бағасын көрсетіңіз (мысалы, қатты көшелік конфигурация үшін 85A). Сондай-ақ, фланец (екі жағында немесе бір жағындағы ернеу) немесе орнатуды жеңілдету үшін бөлінетін сақина сияқты арнайы ерекшеліктерді де көрсетуіңіз керек.

- Өндірушімен байланысып, баға сұрауыңызды жіберіңіз: Мәліметтеріңіз қолыңызда болса, тапсырыс бойынша сақиналарды жасайтын өндірушіге хабарласыңыз. Көбінесе Precision Urethane сияқты компаниялар клиенттің сызбалары немесе техникалық талаптары негізінде тапсырыс бойынша бөлшектерді жасауда маманданған. Сіз әдетте барлық нақты мәліметтеріңізбен бірге баға сұрау үшін өтініш бересіз.

Жеткізушімен тиімді қарым-қатынас орнату үшін техникалық шарт дайындап алыңыз. Ұсынуыңыз керек ақпараттар тізімі мынадай:

- Ішкі диаметр (ID): Тысячные үлесіне дейінгі дюйммен өлшенеді (мысалы, 0,750").

- Сыртқы диаметр (OD): Тысячные үлесіне дейінгі дюйммен өлшенеді (мысалы, 1,500").

- Жалпы ұзындық (L): Дюймнің мыңнан бір үлесіне дейін өлшенеді (мысалы, 2,000").

- Материалды таңдау: мысалы, полиуретан.

- Дюрометр: мысалы, 88A.

- Фланец сипаттамалары: мысалы, бір жағында фланец, фланец сыртқы диаметрі, фланец қалыңдығы.

- Қажетті саны: Қажетті бөшкелер саны.

Дәлдік ең маңыздысы. Тапсырыс берер алдында барлық өлшемдерді қайта тексеріңіз. Өндірушімен болатын қате түсініксіздіктен сақтану үшін қарапайым сызба немесе сурет салу да көмектеседі және соңғы өнімнің сіздің көлігіңізге мүдделі сәйкес келуін қамтамасыз етеді.

Жеткізушіні табу: Тапсырыс бойынша жасалған бушингтердің ең жақсысын кім жасайды?

Дұрыс өлшемдерді алу сияқты, дұрыс жеткізушіні таңдау да соншалықты маңызды. Нақты немесе жартылай тапсырыс бойынша жинақтар шығаратын ірі брендтер мен шынымен нақты тапсырыс бойынша, қалыпқа көмілген бушингтер жасайтын мамандандырылған дүкендер рынокта болады. Сіздің таңдауыңыз сіздің нақты қажеттіліктеріңізге, бюджетке және жобаңыздың күрделілігіне байланысты болады.

Energy Suspension және Moog сияқты ірі брендтер жиі OEM резеден едәуір жоғары полиуретан бушингтерді ұсынады. Бұл ортақ автомобиль модельдері үшін өте жақсы таңдау болып табылады және сенімді өнімділікті арттырады. Пікір бойынша CarParts.COM , TrueDrive, Dorman және Mevotech сияқты брендтер стандартты қолданымдардағы беріктігі мен дәл келуі үшін де танымал. Дегенмен, егер сізде тапсырыс бойынша жасалған бағыттауыш иіндігі немесе ерекше өлшемдер қажет болса, мамандандырылған өндіруші - жақсырақ шешім.

Мамандандырылған дүкендер — ерекше буферлер әлемінің негізі болып табылады. Precision Urethane, PSI Urethanes және Uniflex Inc. сияқты іздеу нәтижелерінде кездесетін компаниялар клиенттердің дәл талаптарына сәйкес полимочевины бөлшектерін құюға бағытталған. Олармен жұмыс істеу дюрометрден бастап түсіне дейінгі әрбір параметрді бақылауға мүмкіндік береді. Жоғары өнімді компоненттерді сатып алу кезінде IATF 16949 сертификаты сияқты дәлдікке және сапа стандарттарына деген сенімді көрсететін өндірушілермен серіктестік жасау маңызды. Көптеген дүкендер мочевинада маманданса да, кеңінен алынған автомобиль өнеркәсібі мысалы, жоғары дәлдіктегі автомобиль штампы қалыптарын жасаумен айналысатын сонымен қоса ерекше метал буферлер шығаратын Shaoyi (Ningbo) Metal Technology Co., Ltd. сияқты металл бөлшектер саласындағы мамандарды да қамтиды. Мұндай мамандандыру ерекше жиналған әрбір бөлшектің қатаң техникалық талаптарға сай келуін қамтамасыз етеді.

Потенциалды құрастырушыны бағалаған кезде келесі критерийлерді пайдаланыңыз:

- Материалдар Диапазоны: Олар әртүрлі материалдар мен дюрометрлердің кең спектрін ұсынады ма?

- Өндірістік мүмкіндіктер: Олар қатаң дәлдікті сақтай алады ма? Олар өз құрал-жабдықтарын ұсына ма?

- Техникалық көмек: Сіздің техникалық талаптарыңызды нақтылауға және сұрақтарыңызға жауап беруге олардың мамандары қолжетімді ме?

- Жеткізу уақыты: Тапсырыстан бастап жеткізуге дейін қанша уақыт кетеді?

- Покупательлердің пікірлері: Басқа құрылысшылар мен жасаушылар олардың сапасы мен қызметі туралы не айтады?

Шешім қабылдау алдында потенциалды қосымша тәуекелдерге мынадай негізгі сұрақтар қойыңыз: Өлшемдік дәлдік бойынша олардың типтік дәлдігі қандай? Олар материал деректерінің парақтарын ұсына алады ма? Сәйкес келмейтін бөлшекпен жұмыс істеу процесі қандай? Серіктестік репутациясы бар қосымша тәуекел жүйесінде анық және сенімді болады, бұл сіз күткендей жұмыс істейтін бөлшекті алуға кепілдік береді.

Суспензияңыз үшін Дұрыс Тандама Жасау

Бағыттауыш иінтіректің бөгеуіндерін өз қалауыңызша жаңарту — көлігіңіздің басқарылуын, беріктігін және жалпы өнімділігін арттырудың нұсқауы болып табылады. Құрамында жалпы өндірістік каучук бөлшектері бар жалпылама бөлшектерден тыс жағдайда сіз өзіңізге қажетті жүріс бөлшегінің сипаттамаларын дәл құра аласыз, ол жолда нақтылықты немесе таулы жерде жұмыс істеуге төзімділікті басымдық ретінде қарастыруыңызға болады. Сәтті жаңартудың кілті — әдістемелік тәсілде жатыр.

Негізгі қолданылуын анықтаудан бастаңыз, осылайша дұрыс материалды таңдаңыз — полимочевина немесе дельриннің өнімділік артықшылықтарын каучуктың ыңғайлылығымен теңестіріңіз. Келесі қадам — дәлдікке басымдық беру. Дәл өлшемдер — бұл сіздің өз қалауыңызша бөлшектеріңіздің негізі болып табылады және олардың дәлдігі міндетті түрде сақталуы керек. Соңында, тек сатушы емес, бірақ серіктес болатын, сіздің жобаңызға техникалық сараптама беруге және қатесіз өнім жасап шығаруға қабілетті өндірушіні таңдаңыз. Осы принциптерді қолдана отырып, сіз көлігіңіздің жолмен байланысын түбегейлі өзгерте аласыз және оның шынайы мүмкіндіктерін ашасыз.

Жиі қойылатын сұрақтар

1. Контрольдік иық буферлерін кім жақсы жасайды?

"Ең жақсы" бренд сіздің қажеттіліктеріңізге байланысты. Жиі кездесетін автомобильдерге дәл сәйкес келетін, жоғары өнімділіктегі ауыстыру бөлшектері үшін Energy Suspension, Moog және TrueDrive сияқты брендтер сапасы мен ұзақ мерзімділігі үшін жоғары бағаланады. Нақты өлшемдер немесе ерекше қолданыстар үшін, дәл сіздің талаптарыңызға сай буферлер жасай алатын Precision Urethane немесе PSI Urethanes сияқты мамандандырылған өндірушілер — ең жақсы таңдау болып табылады.

3. Артқы нарықтағы буферлердің маңызы бар ма?

Иә, көбінесе өнімділікке бағытталған жүргізушілер үшін артқы нарықтағы буферлер инвестициялауға тұратын нәрсе болып табылады. Олар OEM резеңке буферлеріне қарағанда жүріс пен басқару дәлдігін, басқару реакциясын және ұзақ мерзімділікті айтарлықтай жақсартады. Ең алдымен жарыс, оф-роуд немесе белсенді көше жүрісі сияқты жоғары жүктемелі қолданыстарда олар ұсынатын артық басқару мен ұзақ мерзімділік оларды құнды жаңартуға айналдырады.

5. Контрольдік иық буферлерінің айырмашылығы бар ма?

Иә, олар үлкен айырмашылық жасайды. Басқару иінінің бушингтері сіздің ілінісіңіздің бұрылу нүктелері болып табылады. Олар тозып кеткенде ілініс күтпеген бағытта қозғалуы мүмкін, бұл жаман басқаруға, тежеудің тұрақсыздығына және доңғалақ шиналарының теңсіз тозуына әкеледі. Жаңа, жоғары сапалы бушингтерге ауысу іліністің геометриясын қалпына келтіреді, басқару дөңгелегінің сезімін қатайтады және автомобильдің болжанатындай жауап беруін қамтамасыз етеді.

Кіші көліктер, жоғары стандарттар. Біздің шуақты проTOTYPE қызметі табиғатты тексеру процессін жылдамдаған және оңайластырады —

Кіші көліктер, жоғары стандарттар. Біздің шуақты проTOTYPE қызметі табиғатты тексеру процессін жылдамдаған және оңайластырады —