- Riduci i Costi di Estrusione dell'Alluminio con 5 Fondamentali Consigli DFM

- Il vero ROI degli stampi di estrusione personalizzati per la produzione di massa

- Prototipazione in Metallo per l'Automotive: Una Guida per un'Innovazione più Rapida

- Ricambi per Aria Condizionata Auto: Dal Compressore all'Evaporatore Svelati

Decodifica degli standard di prova per bracci oscillanti in acciaio stampato

Time : 2025-12-15

TL;DR

Gli standard di prova per i bracci di controllo in acciaio stampato non costituiscono un codice unico e universale, ma un insieme di procedure tecniche definite da enti ingegneristici come SAE International e dai singoli produttori di veicoli. Questi test rigorosi valutano parametri critici di prestazione come rigidità, deformazione, resistenza e comportamento in caso di incidente, al fine di garantire la sicurezza, la durata del veicolo e la conformità alle specifiche dell'equipaggiamento originale (OE).

Definizione dei Bracci di Controllo in Acciaio Stampato: Caratteristiche e Identificazione

Un braccio oscillante in acciaio stampato è un componente fondamentale del sistema di sospensione di un veicolo, che collega il telaio all'insieme della ruota. Viene prodotto mediante stampaggio e saldatura di lamiere d'acciaio in una struttura cava e rigida. Questo processo è altamente economico, rendendo i bracci in acciaio stampato una scelta comune per molte autovetture e autocarri moderni. Il vantaggio principale è l'equilibrio tra resistenza e basso costo di produzione, che ne permette l'ampia diffusione nei veicoli prodotti in serie. Tuttavia, possono risultare più soggetti alla ruggine rispetto ad alternative come ghisa o alluminio, qualora il rivestimento protettivo risulti compromesso.

La produzione di questi componenti è un'operazione ingegneristica precisa. La produzione in grande volume prevede la stampatura di lamiere in due semigusci che vengono successivamente saldati insieme. Questo processo deve essere controllato meticolosamente per garantire l'integrità strutturale e prestazioni costanti. Per i produttori automobilistici alla ricerca di precisione nella stampatura dei metalli, fornitori specializzati offrono soluzioni complete che vanno dalla prototipazione alla produzione di massa. Ad esempio, Shaoyi (Ningbo) Metal Technology Co., Ltd. esemplifica questa competenza, sfruttando impianti automatizzati avanzati e la certificazione IATF 16949 per fornire componenti di alta qualità per applicazioni automobilistiche complesse.

Identificare un braccio oscillante in acciaio stampato su un veicolo è semplice grazie a pochi indicatori visivi. A differenza della superficie più ruvida dei componenti fusi, i bracci in acciaio stampato hanno generalmente una superficie più liscia e una saldatura evidente che corre lungo la loro lunghezza. Sapere come riconoscerli è essenziale per la manutenzione e per eventuali aggiornamenti, specialmente su veicoli come Chevrolet Silverado o GMC Sierra, dove materiali diversi sono stati utilizzati in base all'anno del modello.

Per verificare se il tuo veicolo ha bracci oscillanti in acciaio stampato, osserva le seguenti caratteristiche:

- Fine: Di solito presentano una finitura verniciata nera lucida per resistere alla corrosione.

- Texture della superficie: La superficie è generalmente liscia, a differenza della texture ruvida della ghisa o dell'alluminio fuso.

- Costruzione: Una saldatura visibile lungo il punto di unione delle due parti stampate è un chiaro indicatore.

- Prova del materiale: Una semplice prova con una calamita può aiutare; la calamita aderirà saldamente all'acciaio, ma non all'alluminio.

L'ambito degli standard di prova automobilistici per i bracci oscillanti

Non esiste uno standard unico e universalmente accessibile per i test dei bracci oscillanti in acciaio stampato. Invece, i criteri di prestazione e sicurezza sono regolati da un complesso insieme di specifiche interne dei produttori e linee guida sviluppate da organizzazioni del settore. Enti come SAE International lavorano per sviluppare procedure di prova standardizzate che possono essere utilizzate a livello industriale per valutare caratteristiche chiave come rigidità, deformazione e resistenza. Tuttavia, queste spesso fungono da linea guida di base o metodologica piuttosto che da codice obbligatorio e universale.

La maggior parte degli standard di prova è di proprietà esclusiva dei produttori originali (OEM) come Ford, GM e altri. Ogni casa automobilistica sviluppa il proprio insieme dettagliato di requisiti e protocolli di prova, personalizzati in base alla specifica piattaforma del veicolo, al suo peso, all'uso previsto e agli obiettivi di sicurezza in caso di collisione. Questi standard interni sono altamente riservati e definiscono con precisione le metriche prestazionali che il braccio oscillante di un fornitore deve soddisfare per essere approvato per la produzione. Ciò garantisce che ogni componente funzioni in modo prevedibile all'interno dei sistemi integrati di sicurezza e sospensione del veicolo.

Questi standard sono fondamentali per garantire la sicurezza e la durata del veicolo. Un braccio oscillante deve essere in grado di resistere a forze enormi durante le curve, la frenata e gli impatti senza rompersi. Le prove validano che il componente non si deformi o fratturi sotto carichi estremi e che si deformi in modo prevedibile durante una collisione, contribuendo alla gestione dell'energia d'urto. Come evidenziato nella ricerca del Politecnico di Torino , la conformità agli standard internazionali di prova è essenziale per validare le prestazioni di bracci innovativi o in materiali compositi. Questa rigorosa validazione garantisce che ogni braccio oscillante, sia in acciaio stampato o in altro materiale, soddisfi severi criteri di sicurezza e prestazioni.

Principali procedure di prova: dalla rigidità alla resistenza in caso di impatto

Per validare le prestazioni di un braccio oscillante in acciaio stampato, gli ingegneri ricorrono a una serie di test rigorosi che simulano condizioni reali. Queste procedure sono progettate per misurare ogni aspetto, dalla rigidità di base fino ai punti di rottura sotto stress estremo. L'obiettivo generale, come indicato nei documenti tecnici SAE, è creare un approccio standardizzato per la verifica di rigidità, modalità di deformazione e resistenza massima. Questi test possono essere suddivisi principalmente in valutazioni statiche, dinamiche, a fatica e ambientali.

I test di carico statico misurano la rigidità e la deformazione del braccio oscillante sotto una forza costante. Ad esempio, viene applicato un carico specifico e si misura lo spostamento risultante. Un componente può essere considerato superato se la deformazione è minima sotto un carico elevato; un test comparativo su un braccio in acciaio fuso ha rilevato una deformazione di soli 0,17 mm sotto un carico di 32 kN. I test dinamici o d’urto, invece, valutano la risposta del braccio a forze improvvise, aspetto fondamentale per analizzarne la resistenza in caso di collisione. Questi test simulano eventi come l'urtare un marciapiede o una buca stradale, ed sono essenziali per garantire che il componente ceda in modo sicuro e prevedibile durante un impatto.

Un altro aspetto fondamentale è il test di fatica, durante il quale il braccio oscillante viene sottoposto a milioni di cicli con carichi variabili per simulare l'intera durata operativa. Ciò garantisce che il componente sia in grado di resistere alle sollecitazioni ripetute della guida quotidiana senza sviluppare crepe o rompersi prematuramente. Infine, i test ambientali espongono il braccio a condizioni come nebbia salina e umidità per verificarne l'efficacia dei rivestimenti resistenti alla corrosione, un fattore chiave per la longevità dei componenti in acciaio.

Questi diversi metodi di prova forniscono un quadro completo delle capacità di un braccio oscillante. La seguente tabella riassume le principali categorie di test:

| Tipo di Test | Scopo | Parametri chiave misurati |

|---|---|---|

| Test di carico statico | Per misurare la resistenza del componente alla deformazione sotto una forza costante. | Rigidità (Forza vs. Spostamento), Limite di snervamento. |

| Prova dinamica/a impatto | Per valutare le prestazioni sotto carichi improvvisi ad alta energia, simulando urti e incidenti. | Resistenza in caso di impatto, Modalità di deformazione, Carico di rottura. |

| Prova di fatica | Per garantire una lunga durata simulando i cicli ripetuti di sollecitazione tipici della vita di un veicolo. | Durata a fatica (numero di cicli fino al guasto). |

| Test Ambientali | Per valutare la resistenza del componente alla corrosione e al degrado ambientale. | Efficacia dei rivestimenti protettivi (ad esempio vernice, trattamenti superficiali). |

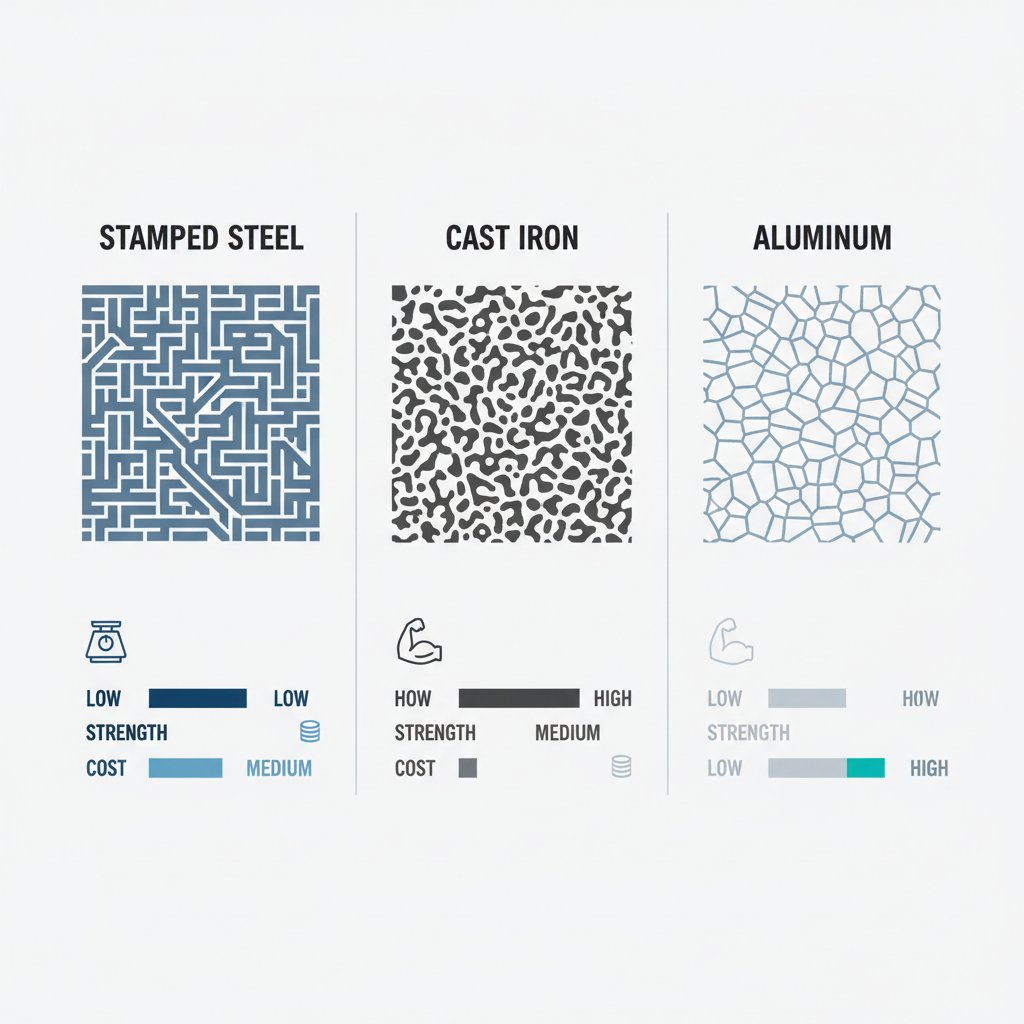

Confronto tra materiali: acciaio stampato rispetto a bracci in ghisa e alluminio fusi

Sebbene l'acciaio stampato sia una scelta popolare per i bracci di sospensione, i produttori utilizzano comunemente anche ghisa e alluminio fuso, ognuno dei quali presenta specifici compromessi. La scelta del materiale dipende dall'uso previsto del veicolo, dagli obiettivi prestazionali e da considerazioni di costo. Rispondere alla domanda "Qual è il miglior metallo per i bracci di sospensione?" richiede la comprensione di queste differenze.

I bracci in acciaio stampato sono apprezzati per il basso costo di produzione e il buon rapporto resistenza-peso, rendendoli ideali per autovetture e veicoli commerciali di serie. La ghisa, essendo più densa e resistente, è spesso utilizzata nei camion pesanti e nei SUV dove la massima durata in condizioni difficili è fondamentale. Offre una superiore resistenza e rigidità, ma con un maggiore peso. L'alluminio pressofuso offre un'alternativa leggera, riducendo significativamente la massa non sospesa, il che può migliorare il comportamento stradale e la qualità della guida. Questo lo rende la scelta preferita per veicoli sportivi e di lusso, anche se generalmente è più costoso e può essere meno duttile in caso di impatto rispetto all'acciaio.

La scelta del materiale giusto richiede un equilibrio tra resistenza, peso e costo. Per un camion pesante, la robustezza della ghisa potrebbe essere la priorità. Per una vettura sportiva, il risparmio di peso offerto dall'alluminio potrebbe essere il fattore determinante. L'acciaio stampato rappresenta spesso il compromesso ottimale per una vasta gamma di veicoli di uso comune. I fornitori del mercato secondario offrono opzioni in tutti i materiali, consentendo ai proprietari dei veicoli di scegliere ricambi che rispettino le specifiche originali o che migliorino le prestazioni in base alle loro esigenze specifiche.

Di seguito è riportato un confronto tra i tre materiali più comuni per i bracci di controllo:

| Caratteristica | Acciaio stampato | Ghisa | Alluminio fuso |

|---|---|---|---|

| Processo di fabbricazione | Stampaggio e saldatura di lamiera | Versamento di ferro fuso in uno stampo | Versamento di alluminio fuso in uno stampo |

| Utilizzo tipico | La maggior parte delle autovetture e dei veicoli commerciali leggeri | Camion pesanti e SUV | Auto sportive, veicoli di lusso |

| Resistenza | Buono | Eccellente | Buono a eccellente |

| Peso | Moderato | Pesante | Luce |

| Costo | Basso | Moderato | Alto |

Domande frequenti

1. Come faccio a sapere se i miei bracci di controllo sono in acciaio stampato?

È possibile identificare tipicamente i bracci oscillanti in acciaio stampato dal loro aspetto. Di solito presentano una finitura liscia e nera lucida e una saldatura visibile lungo la giunzione delle due metà del braccio. Un semplice test consiste nell'usare un magnete; se il magnete aderisce, il braccio è in acciaio (stampato o in ghisa). Al contrario, i bracci in alluminio non attirano il magnete e spesso hanno una finitura argentata grezza e non verniciata.

2. Cos'è un braccio oscillante stampato?

Un braccio oscillante stampato è un componente della sospensione realizzato a partire da lamiere di acciaio che vengono pressate (stampate) in una forma specifica e successivamente saldate insieme per formare una struttura cava ma resistente. Questo metodo di produzione è molto economico, motivo per cui i bracci oscillanti in acciaio stampato sono ampiamente utilizzati in molte auto e camion moderni prodotti in serie. Sebbene resistenti, possono essere più soggetti a ruggine in climi rigidi se il rivestimento protettivo subisce danni.

3. Qual è il miglior metallo per i bracci oscillanti?

Il "migliore" metallo per i bracci di controllo dipende interamente dal veicolo e dal suo utilizzo previsto. L'acciaio stampato offre un ottimo equilibrio tra resistenza, basso costo e peso moderato, risultando adatto alla maggior parte dei veicoli di uso quotidiano. La ghisa è più pesante ma estremamente duratura, il che la rende ideale per camion pesanti soggetti a sollecitazioni elevate. L'alluminio pressofuso è l'opzione più leggera, il che migliora le prestazioni della sospensione e la guida, rendendolo la scelta preferita per auto sportive e veicoli di lusso in cui le prestazioni hanno priorità rispetto al costo.

Piccole partite, alti standard. Il nostro servizio di prototipazione rapida rende la validazione più veloce e facile —

Piccole partite, alti standard. Il nostro servizio di prototipazione rapida rende la validazione più veloce e facile —