Module d'élasticité de l'aluminium : mesurer, rapporter et comparer avec l'acier

Ce que signifie le module de l'aluminium pour la conception

Lorsque vous concevez un châssis léger, une plaque résistante aux vibrations ou un composant devant se plier sans se rompre, vous remarquerez que le module de l'aluminium apparaît dans chaque calcul. Mais qu'est-ce qu'exactement cette propriété, et comment diffère-t-elle d'autres mesures plus connues telles que la résistance ou la densité ?

Ce que le module de l'aluminium révèle vraiment

Le module de l'aluminium, souvent appelé module d'élasticité ou module de Young, mesure la rigidité du matériau dans la plage élastique. En termes simples, il indique dans quelle mesure une pièce en aluminium va s'étendre ou se comprimer sous une charge donnée, avant qu'une déformation permanente ne se produise. Cela s'avère crucial pour les applications où la déviation, les vibrations ou le retour élastique sont plus importants que la résistance maximale.

- Rigidité (Module): Règle dans quelle mesure une pièce se plie ou vibre sous charge. Pour l'aluminium, le module d'élasticité est généralement d'environ 68–69 GPa, ce qui le rend plus flexible que l'acier, mais néanmoins adapté à de nombreuses applications techniques.

- Résistance : Indique la contrainte maximale qu'un matériau peut supporter avant de se déformer ou de se rompre. Cela varie considérablement selon l'alliage et l'état métallurgique.

- Densité : Se rapporte à la masse du matériau par unité de volume, influençant le poids et l'inertie, mais pas directement la rigidité.

Le module est relativement insensible à l'état métallurgique et au traitement thermique par rapport à la résistance : le choix de l'alliage ou de l'état ajuste principalement la résistance, la formabilité et la résistance à la corrosion, et non E.

Modules de Young, de cisaillement et de compression expliqués

Les ingénieurs utilisent trois constantes élastiques principales pour décrire comment des matériaux comme l'aluminium réagissent à différents types de charges :

- Module de Young (E) : Mesure la rigidité en traction ou en compression dans la plage élastique. Pour l'aluminium, E ≈ 68–69 GPa (environ 9,9–10 millions de psi) [AZoM] . Cela est parfois appelé le module de Young de l'aluminium.

- Module de cisaillement (G) : Décrit la résistance du matériau aux changements de forme (cisaillement). Pour l'aluminium, G est généralement compris entre 25 et 34 GPa.

- Module de compressibilité (K) : Indique la résistance à la compression uniforme, c'est-à-dire à quel point il est difficile de comprimer le volume du matériau. Le module de compressibilité de l'aluminium varie entre 62 et 106 GPa.

Pour la plupart des métaux isotropes, ces constantes sont liées par le coefficient de Poisson (ν), qui est d'environ 0,32 à 0,36 pour l'aluminium. Toutefois, dans les produits corroyés comme les profilés ou les tôles laminées, de légères différences directionnelles peuvent apparaître — un sujet auquel nous reviendrons plus tard.

- E (Module d'élasticité) : Rigidité en tension/compression

- G (Module de cisaillement) : Rigidité au cisaillement

- K (Module de compressibilité) : Rigidité volumique

| MODULE | Calcul typique |

|---|---|

| Young (E) | Déflexion des poutres, raideur axiale des ressorts |

| Cisaillement (G) | Angle de torsion dans les arbres, panneaux de cisaillement |

| Module de compressibilité (K) | Compression volumétrique (par exemple, sous pression hydrostatique) |

Lorsque le module est plus déterminant que la résistance dans la conception

Cela semble complexe ? Imaginez une poutre en aluminium légère supportant une charge. Le module de l'aluminium (et non sa résistance) détermine à quel point elle se courbera sous cette charge. Dans les conceptions sensibles aux vibrations — comme les panneaux aéronautiques ou les structures précises — la rigidité (E) contrôle la fréquence naturelle et la déformation, tandis que la résistance n'est importante que si l'on s'approche de la rupture.

Voici comment garder les concepts clairs :

- Rigidité (E, G, K) : Contrôle la déformation, les vibrations et le retour élastique. Utilisez le module pour dimensionner des poutres, des ressorts et des panneaux lorsque le comportement élastique est critique.

- Résistance : Limite la charge maximale avant déformation permanente ou rupture.

- Densité : Influence le poids, l'inertie et l'absorption d'énergie, mais pas la rigidité pour une géométrie donnée.

Dans les sections suivantes, vous trouverez des formules prêtes à copier-coller pour le calcul de la flèche des poutres, une procédure pour mesurer le module, ainsi que des exemples pratiques pour rapporter et comparer la rigidité. Retenez pour l'instant ceci : le module d'élasticité de l'aluminium est la propriété clé pour prédire la déformation élastique et les vibrations — et non la résistance ou le poids.

Unités et conversions simplifiées

Êtes-vous déjà passé d'une fiche technique à un outil de simulation et vous êtes demandé : « Pourquoi ces chiffres semblent incorrects ? » Cela arrive souvent parce que les valeurs du module — comme celui de l'aluminium — sont exprimées en unités différentes. Utiliser les unités du module d'élasticité correctes est essentiel pour des calculs précis, une bonne collaboration et pour éviter des erreurs coûteuses, notamment lors d'échanges entre équipes ou selon des normes internationales.

Les unités les plus courantes du module dans la pratique

Le module d'élasticité, qu'il s'agisse de l'aluminium ou d'un autre matériau, a toujours les mêmes dimensions que la contrainte : force par unité de surface. Mais le unités du module d'élasticité peuvent varier selon le lieu de travail ou la norme que vous suivez.

| Unité | Le symbole | Équivalent |

|---|---|---|

| Pascal | Pa | 1 N/m 2 |

| Mégapascal | MPa | 1 × 10 6Pa |

| Gigapascal | GPa | 1 × 10 9Pa |

| Livres par pouce carré | psi | 1 lbf/in 2 |

| Kilolivres par pouce carré | ksi | 1 000 psi |

Par exemple, le module d'élasticité de l'aluminium est généralement indiqué comme 69 GPa ou 10 000 ksi, selon la référence [AmesWeb] . Les deux signifient la même chose, simplement dans des unités différentes pour le module d'élasticité .

Conversions rapides que vous pouvez copier et coller

Vous avez besoin de convertir des unités rapidement ? Voici des expressions prêtes à l'emploi pour votre calculatrice ou tableur :

| Conversion | Formule |

|---|---|

| GPa en Pa | E_Pa = E_GPa × 1e9 |

| MPa en Pa | E_Pa = E_MPa × 1e6 |

| Pa en MPa | E_MPa = E_Pa / 1e6 |

| Pa en GPa | E_GPa = E_Pa / 1e9 |

| Pa en psi | E_psi = E_Pa / 6894.757 |

| psi en Pa | E_Pa = E_psi × 6894.757 |

| psi en ksi | E_ksi = E_psi / 1000 |

| ksi en psi | E_psi = E_ksi × 1000 |

Remarque dimensionnelle : 1 Pa = 1 N/m 2. La contrainte et le module partagent toujours les mêmes unités — donc si votre force est exprimée en newtons et votre surface en mètres carrés, vous obtiendrez le module en pascals.

Choisissez le système d'unités utilisé par votre client ou par l'outil dominant de simulation/validation afin de minimiser les erreurs. Conservez une seule cellule de référence pour E dans votre feuille de calcul, et calculez à partir de celle-ci toutes les autres vues unitaires.

Quand exprimer en GPa ou en psi

Quelles unités du module d'élasticité devez-vous utiliser ? Cela dépend de votre application et de votre public cible :

- GPa ou MPa : Couramment utilisés dans les équipes d'ingénierie structurelle, automobile et internationale. La plupart des publications scientifiques et des outils de simulation utilisent par défaut ces unités SI.

- psi ou ksi : Toujours utilisés dans les outillages nord-américains, l'aérospatiale et les spécifications anciennes.

Passer d'une unité à l'autre pour le module d'élasticité est facile grâce aux formules ci-dessus, mais vérifiez toujours attentivement les unités attendues par vos références et vos outils. Une mauvaise étiquette peut entraîner des erreurs difficiles à détecter avant une phase avancée du processus de conception.

- Indiquez toujours clairement les unités dans les calculs et les rapports

- Conservez une cellule de vérification de conversion dans votre feuille de calcul

- Notez le système d'unités utilisé dans chaque rapport d'essai et chaque plan

- Ne mélangez jamais les unités au sein d'un même bloc de calcul

En maîtrisant ces conventions et conversions d'unités, vous faciliterez la collaboration et vous vous assurerez que vos valeurs du module d'élasticité de l'aluminium soient toujours correctes, quel que soit le standard utilisé. Ensuite, nous verrons comment l'alliage et l'état métallurgique influencent les valeurs rapportées et comment les documenter pour une meilleure clarté.

Comment l'alliage et le revenu influencent le module d'élasticité de l'aluminium

Comment l'alliage et le revenu influencent la rigidité

Vous êtes-vous déjà demandé si le choix d'un alliage ou d'un revenu d'aluminium différent pourrait changer considérablement la rigidité de votre pièce ? La réponse est — généralement pas beaucoup. Bien que la résistance et la formabilité puissent varier fortement selon la famille d'alliages et le revenu, le module d'élasticité de l'aluminium (spécifiquement le module de Young) est étonnamment stable d'une nuance à l'autre et quel que soit le traitement thermique.

Par exemple, le module d'élasticité de l'aluminium 6061 est d'environ 10,0 millions de psi (≈69 GPa), qu'il s'agisse de 6061-T4 ou de 6061-T6. Cela signifie que pour la plupart des calculs d'ingénierie, vous pouvez utiliser la même valeur de module pour tous les revenus d'un alliage donné, sauf si votre application est très sensible aux petites variations ou si vous travaillez avec des formes de produits très spécifiques. Le même schéma s'applique aux autres alliages courants — à la fois corroyés et moulus.

Organisation des données spécifiques au module des alliages

Pour rendre les choses concrètes, voici un tableau récapitulatif des valeurs typiques de module pour les principales familles d'alliages d'aluminium. Vous constaterez que le module d'élasticité de l'aluminium 6061 (et les nuances corroyées similaires) reste très proche du module d'élasticité générique de l'aluminium, tandis que les alliages moulés présentent uniquement de légères variations. Toutes les valeurs sont données à température ambiante et proviennent de Boîte à Outils Technique .

| Famille d'alliages | Température | Forme du Produit | Module d'élasticité typique (E, 10 6psi) | Module de cisaillement (G, 10 6psi) | Remarques sur la directionnalité |

|---|---|---|---|---|---|

| 1xxx (par exemple, 1100) | O, H12 | Tôle, plaque | 10.0 | 3.75 | Minimal ; presque isotrope |

| 5xxx (par exemple 5052) | O, H32 | Tôle, plaque | 10.2 | 3.80 | Faible à modérée ; légère texture dans la tôle laminée |

| 6xxx (6061) | T4, T6 | Profilé, plaque | 10.0 | 3.80 | Modérée dans les profilés ; presque isotrope dans la plaque |

| 7xxx (7075) | T6 | Plaque, profilé | 10.4 | 3.90 | Faible ; résistance plus élevée, module similaire |

| Moulé (A356, 356) | T6, T7 | Fonderies | 10.3 | 3.85 | Orientation aléatoire des grains, faible directionnalité |

À titre de référence, le module d'élasticité de l'aluminium 6061 est de 10,0 × 10 6psi (≈69 GPa), et le module d'élasticité de l'aluminium 6061-T6 est pratiquement identique. Vous remarquerez le module d'élasticité de l'aluminium 6061 ne varie pas avec le tempérament, ce qui signifie que vous pouvez utiliser avec confiance la même valeur pour T4 et T6, sauf si votre application est exceptionnellement sensible.

Lorsque la directionnalité est importante pour les profilés et les tôles

Cela semble simple ? Dans la plupart des cas, oui. Cependant, si vous travaillez avec des profilés fortement déformés ou des tôles laminées, il peut exister une légère directionnalité du module d'élasticité, ce qui signifie que la rigidité dans la direction longitudinale (L) peut différer légèrement de celle des directions transversales (LT) ou transversales courtes (ST). Cet effet est généralement faible (quelques pourcents), mais il est à noter dans les applications critiques ou lors de la documentation des valeurs pour les simulations (CAE) ou les rapports d'essais.

- La résistance peut varier considérablement selon l'alliage et le tempérament, mais les variations du module sont modérées, généralement comprises entre 2 et 5 % selon les nuances et les formes de produit.

- La directionnalité est particulièrement marquée dans les produits extrudés et laminés ; les pièces moulées sont quasiment isotropes.

- Indiquez toujours la source exacte (fiche technique, manuel ou rapport d'essai) pour les valeurs numériques, et précisez la température si elle n'est pas ambiante.

- Pour l'alliage 6061-T6, le module d'élasticité de l'aluminium 6061 t6 est de 10,0 × 10 6psi (69 GPa) à température ambiante.

Précisez toujours l'alliage, l'état mécanique, la forme du produit et la direction (L, LT, ST) lors de la documentation des valeurs de module (E) sur les plans ou en entrée CAO afin d'éviter toute ambiguïté et garantir la précision technique.

Ensuite, nous verrons comment mesurer et rapporter ces valeurs de module à l'aide de workflows et de modèles prêts pour le laboratoire afin d'obtenir des données claires et cohérentes.

Comment mesurer et rapporter le module d'élasticité de l'aluminium

Lorsque vous avez besoin d'une valeur fiable pour le module d'élasticité de l'aluminium — qu'il s'agisse de simulation, de contrôle qualité ou de conformité — comment vous assurer que votre valeur est digne de confiance ? Passons en revue le processus, de la préparation de l'éprouvette à la déclaration de l'incertitude, pour vous permettre de fournir systématiquement des résultats solides et justifiables.

Aperçu des méthodes d'essai normalisées

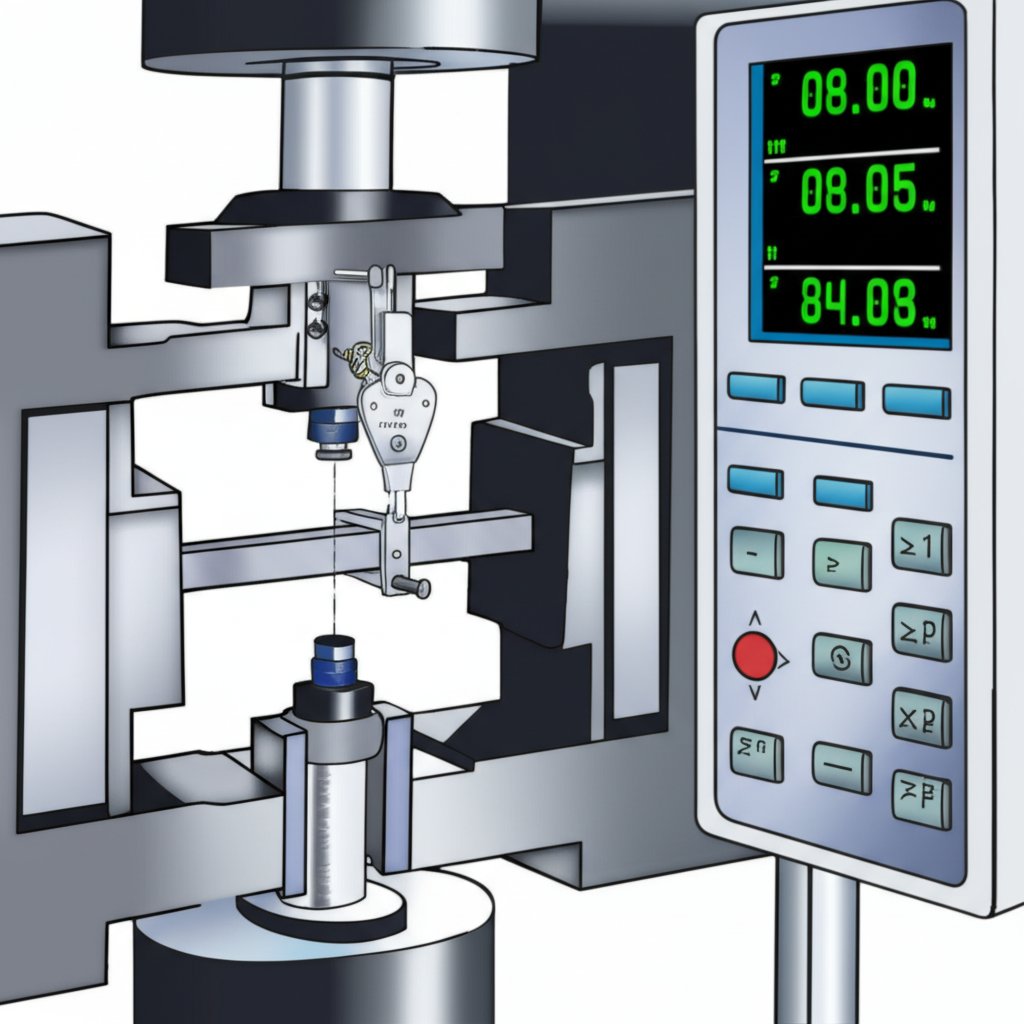

La méthode la plus largement acceptée pour mesurer le module d'élasticité (E) de l'aluminium est l'essai de traction uniaxiale, conformément aux normes telles que ASTM E111, EN 10002-1 ou ISO 6892. Bien que ces normes se concentrent sur la courbe complète contrainte-déformation, la mesure précise du module exige une attention particulière portée à la région initiale, linéaire-élastique. Pour le module d'élasticité transversale (ou module de rigidité) de l'aluminium (G), des essais de torsion ou des méthodes dynamiques sont utilisés, comme décrit ci-dessous.

Mesure pas à pas du module de traction

Cela semble complexe ? Imaginez que vous êtes en laboratoire, prêt à effectuer votre essai. Voici une approche pratique, étape par étape, optimisée pour la précision et la reproductibilité :

- Préparer les éprouvettes normalisées : Usiner les éprouvettes selon une géométrie standard (par exemple, forme de dogbone) avec des sections de mesure lisses et parallèles ainsi qu'un état de surface de haute qualité afin d'assurer une répartition uniforme des contraintes.

- Installer un extensomètre ou choisir la méthode de mesure des déformations : Pour une précision maximale, utiliser un extensomètre à moyenne de haute résolution étalonné (classe 0,5 ou supérieure selon l'EN ISO 9513) fixé aux deux côtés de la longueur de jauge. Alternativement, des jauges de précision peuvent être reliées des deux côtés et mesurées en moyenne. Documenter la longueur de l'échelle et l'état de l'étalonnage.

- Résistance à la déformation: Suivez la vitesse spécifiée dans la norme choisie (par exemple, EN 10002-1 ou ASTM E111), généralement suffisamment basse pour minimiser les effets dynamiques et maximiser les points de données dans la plage élastique.

- Enregistrer les données de charge/déformation dans la région linéaire initiale: Il est recommandé de collecter des données à haute fréquence (≥ 50 Hz) jusqu'à 0,2% de déformation pour capturer le segment élastique avec une résolution suffisante. Évitez de précharger au-delà de la limite d'élasticité.

- Mettez une ligne droite sur le segment linéaire: Utiliser une régression des moindres carrés ou une formule de module élastique approuvée pour déterminer la pente (E) de la courbe de contrainte/détirement dans la région élastique. Documenter clairement la fenêtre de déformation utilisée pour l'ajustement.

- Environnement du document: Enregistrez la température et l'humidité pendant le test, car le module peut légèrement varier en fonction de la température. La présentation standard se fait à température ambiante (20–25 °C).

- Calculez et indiquez l'incertitude : Évaluez les sources d'incertitude — précision de l'appareil, alignement de l'éprouvette, mesure de la déformation et répétabilité. Combinez-les (généralement par la méthode de la racine carrée de la somme des carrés) et élargissez-les au niveau de confiance de 95 % (U = 2 × écart type), comme indiqué dans les directives de mesure [Rapport NPL] .

Méthodes alternatives pour déterminer le module de rigidité de l'aluminium

- Écho-paroi ultrasonore : Mesure les vitesses des ondes longitudinales et de cisaillement pour calculer E et G. Indiquez la fréquence utilisée et les détails de la méthode. Cette technique offre une excellente répétabilité, avec des erreurs généralement inférieures à 3 % pour l'aluminium pur.

- Excitation par impulsion (module dynamique) : Utilise les fréquences de vibration d'une éprouvette pour déterminer dynamiquement le module — indiquez la fréquence de résonance et la méthode de calcul.

- Pendule de torsion : Pour le module de rigidité de l'aluminium, suspendre un fil d'échantillon et mesurer la période d'oscillation permet d'obtenir G via une équation dédiée. Assurez-vous de documenter précisément la masse, la longueur et le rayon [Kumavat et al.] .

Modèle de rapport et liste de contrôle d'incertitude

Imaginez que vous rédigez vos résultats pour un client ou une équipe de simulation. Utilisez un tableau structuré pour garantir la clarté et la traçabilité :

| Identifiant de l'échantillon | Alliage/État | Forme du produit & Direction | Dimensions | Méthode/norme d'essai | Mesure de contrainte | Taux | Température | Fichier de données brutes | Module d'élasticité calculé (unités) |

|---|---|---|---|---|---|---|---|---|---|

| AL-01 | 6061-T6 | Extrusion, L | 100 × 12 × 3 mm | ASTM E111 | Extensomètre, 25 mm | 0,5 mm/min | 22 °C | AL01_brut.csv | 69,2 GPa |

Pour le module de rigidité de l'aluminium, inclure les détails de la méthode torsionnelle ou dynamique, la géométrie de l'éprouvette, ainsi que la fréquence ou la période mesurée. Citer toujours la méthode exacte utilisée pour le calcul ou l'ajustement du module élastique, et faire référence à la norme ou à l'algorithme logiciel approprié.

Astuce : Utilisez la même fenêtre de déformation et la même procédure d'ajustement pour toutes les répétitions, et citez clairement la formule du module élastique ou la méthode d'analyse utilisée dans votre rapport. Cela garantit que vos résultats soient comparables et traçables.

Si vous disposez d'incertitudes numériques pour vos instruments (par exemple, une erreur systématique de 1 % pour l'extensomètre, une précision de 0,5 % pour la cellule de charge), incluez-les dans votre budget d'incertitude. Sinon, listez les sources telles que l'instrument, l'alignement et la variabilité du matériau, et estimez leurs contributions conformément aux directives établies.

En suivant ce processus, vous obtiendrez des mesures du module de l'aluminium (y compris le module de rigidité de l'aluminium) fiables, reproductibles et prêtes à être utilisées dans des calculs de conception ou de conformité. Dans la section suivante, nous verrons comment appliquer ces valeurs dans des calculs de rigidité et de flèche pour l'ingénierie réelle.

Méthodes de rigidité et de flèche appliquées

Lorsque vous concevez une structure légère en treillis, un châssis de machine ou un dispositif de précision, vous remarquerez que le module de l'aluminium — en particulier le module élastique de l'aluminium — apparaît dans presque tous les calculs de rigidité. Cela semble complexe ? Pas du tout. Avec quelques formules clés à portée de main, vous pouvez rapidement estimer la flèche, la raideur des ressorts, ainsi que le retour élastique lors de la mise en forme, sans avoir à mémoriser des dizaines d'équations.

Formules rapides pour le calcul de la flèche des poutres

Imaginez que vous analysez une poutre en aluminium soumise à une charge. La quantité dont elle se déforme (flèche) dépend de la force appliquée, de sa longueur, de sa section transversale et, surtout, du module d'élasticité de l'aluminium (module de Young). Voici des formules à copier-coller pour les scénarios les plus courants, en utilisant la notation standard :

-

Charge à l'extrémité d'une poutre encastrée :

delta = F * L^3 / (3 * E * I) -

Appuyé simplement, charge uniforme :

delta_max = 5 * w * L^4 / (384 * E * I) -

Appuyé simplement, charge ponctuelle au milieu :

delta = F * L^3 / (48 * E * I)

Où :

- F = force appliquée (N ou lbf)

- le = charge uniforme par unité de longueur (N/m ou lbf/po)

- L = longueur de la portée (m ou po)

- E = module de Young de l'aluminium (Pa, GPa ou psi)

- Je = moment d'inertie (m 4ou en 4)

Pour plus de détails sur les calculs de flèche des poutres, voir la référence à SkyCiv .

Méthodes de rigidité et de flexibilité

Vous voulez savoir à quel point votre structure en aluminium est « souple » ? La rigidité (k) indique la force nécessaire pour obtenir une déformation donnée. Voici comment la calculer pour des poutres et des assemblages :

-

Rigidité générale d'une poutre :

k_beam = F / delta -

Poutre encastrée (charge à l'extrémité) :

k = 3 * E * I / L^3 -

Ressorts en série :

1 / k_total = sum(1 / k_i) -

Ressorts en parallèle :

k_total = sum(k_i)

Pour la torsion ou le vrillage, vous aurez besoin de module de cisaillement de l'aluminium souvent appelé le module de cisaillement de l'aluminium ou G) :

-

Angle de torsion :

theta = T * L / (J * G)

Où :

- T = couple appliqué (Nm ou in-lbf)

- L = longueur (m ou po)

- J = moment polaire d'inertie (m 4ou en 4)

- G = module de cisaillement de l'aluminium (Pa, GPa ou psi)

Pour les plaques minces ou les coques, utilisez les relations issues de la théorie classique des plaques et citez toujours la méthode ou la norme spécifique que vous suivez.

Attention : Vérifiez toujours que vos unités de force, de longueur et de module sont cohérentes : mélanger les unités métriques et impériales peut entraîner de grosses erreurs. Vérifiez également que vos contraintes restent dans la plage linéaire-élastique pour le module d'Young de l'aluminium ou module de cisaillement de l'aluminium valeurs à appliquer.

Connaissance du ressort pour le formage

Lors du formage de tôles ou d'extrusions en aluminium, le ressort — c'est-à-dire l'ampleur du « rebond » de la pièce après pliage — dépend à la fois du module et de la limite d'élasticité. Un module plus élevé module d'élasticité de l'aluminium et une limite d'élasticité plus faible signifient un ressort plus important. Pour estimer ou modéliser le ressort :

- Utiliser des formules spécifiques au procédé ou des outils de simulation

- Saisir les valeurs mesurées module élastique de l'aluminium ainsi que la contrainte d'élasticité provenant du même lot pour une meilleure précision

- Tenir compte des facteurs géométriques et du rayon de pli, car ceux-ci peuvent amplifier de légères variations du module

Pour les formes complexes ou les tolérances critiques, valider systématiquement votre modèle à l'aide de mesures physiques.

En maîtrisant ces formules pratiques, vous pouvez prédire avec confiance la rigidité, la déflexion et le retour élastique des structures en aluminium — que vous conceviez des poutres, des cadres ou des pièces formées. Dans la prochaine section, nous verrons comment la direction de fabrication et le procédé peuvent introduire des variations subtiles mais importantes du module, en particulier pour les profilés et les produits laminés.

Pourquoi la direction importe pour la rigidité de l'aluminium

Pourquoi l'anisotropie apparaît dans l'aluminium corroyé

Lorsque vous pliez un profilé d'aluminium ou que vous limez une tôle, avez-vous déjà remarqué qu'elle semblait parfois plus rigide dans une direction que dans une autre ? Ce n'est pas une illusion — c'est un signe classique d' anisotropie , ou directionnalité, ce qui signifie que le module d'élasticité de l'aluminium (et parfois la résistance) peut varier selon la direction dans laquelle vous effectuez la mesure. Mais qu'est-ce qui provoque cet effet ?

- Texture cristallographique due au laminage ou à l'extrusion : Lors du travail à chaud ou à froid, les grains de l'aluminium s'alignent selon des orientations préférentielles, créant une texture qui rend les propriétés telles que le module d'Young légèrement directionnelles.

- Grains allongés : Le traitement mécanique étire les grains, en particulier dans les produits corroyés, renforçant la directionnalité.

- Contraintes résiduelles : Les contraintes emprisonnées pendant la mise en forme peuvent légèrement modifier la rigidité locale.

- Motifs de durcissement par déformation : Une déformation non uniforme peut créer des zones présentant différentes rigidités au sein d'une même pièce.

Selon recherche sur l'anisotropie des métaux , la véritable isotropie est rare en pratique — la plupart des aluminiums laminés ou extrudés présenteront au moins une certaine directionnalité, même si la différence de module n'est que de quelques pourcents.

Spécifier la direction pour E et G

Alors, comment maintenir vos calculs et documents précis ? La clé est de toujours spécifier la direction de mesure pour le module d'Young (E) et le module de cisaillement (G). Voici un guide rapide des notations standard :

- L (Longitudinal) : Dans la direction principale de traitement ou de laminage

- LT (Long Transverse) : Perpendiculaire à L, dans le plan de la feuille ou du profilé

- ST (Short Transverse) : À travers l'épaisseur ou dans la direction radiale

Pour les profilés et les tubes, vous pouvez également rencontrer les directions axiale, radiale et circonférentielle. Ces directions doivent toujours être indiquées sur les dessins et les rapports d'essai — en particulier pour les jeux de données de simulation (CAE), où le rapport de Poisson pour l'aluminium et le module doivent être associés par direction.

| Forme du Produit | Directions clés à spécifier |

|---|---|

| Plaque/Feuille | L (roulage), LT (transversal), ST (épaisseur) |

| Extrusion | Axial (selon la longueur), Radial, Circonférentiel |

| Tube | Axial, Circonférentiel (dans le sens circonférentiel) |

Pourquoi cela a-t-il de l'importance ? Imaginez que vous simulez un châssis en aluminium dans un logiciel de CAO. Si vous utilisez un module moyen et le coefficient de Poisson de l'aluminium dans toutes les directions, vous pourriez manquer des variations subtiles — mais parfois critiques — de rigidité qui affectent les vibrations ou le flambage. Pour les profilés extrudés fortement travaillés, utilisez des modèles de matériaux orthotropes si l'anisotropie dépasse 2 à 3 %.

Conseils de conception pour les profilés extrudés et les tôles

Vous vous demandez quel effet est le plus important ? En pratique, les principaux facteurs de variation de rigidité dans les profilés extrudés sont :

- Variabilité de l'épaisseur des parois : Les petites variations d'épaisseur ont un impact bien plus important sur la rigidité que de légères différences de module.

- Rayons et géométrie des angles : Les angles serrés ou les formes incohérentes peuvent réduire davantage les propriétés effectives de section (I, J) que l'anisotropie du module.

- Documentation précise : Indiquez toujours la direction pour le module et le rapport de Poisson de l'aluminium 6061 dans vos spécifications, en particulier pour les structures critiques ou lors du partage des données avec des équipes de simulation.

Pour la plupart des alliages d'aluminium – notamment le 6061 – la variation du module d'Young due au procédé est modeste. Toutefois, si vous travaillez avec des produits fortement texturés ou très écrouis, vérifiez le module spécifique à la direction et le rapport de Poisson de l'aluminium 6061 à partir de données d'essai ou de fiches techniques fiables.

Lorsque la rigidité est critique, mesurez le module le long du chemin principal de charge et documentez la direction. Cela est particulièrement important pour les profilés haute performance ou lors de la validation des modèles de simulation concernant les vibrations, le flambage ou le ressuage.

En comprenant et en documentant l'anisotropie, vous vous assurerez que vos conceptions en aluminium sont à la fois robustes et correctement représentées dans les calculs. Ensuite, vous verrez comment le module de l'aluminium se compare à celui de l'acier et d'autres métaux, et pourquoi la rigidité par unité de poids est souvent le véritable facteur différenciant en ingénierie légère.

Comparaison du module de l'aluminium avec celui de l'acier et d'autres métaux

Aluminium versus acier en termes de rigidité par masse

Lorsque vous évaluez les avantages et les inconvénients de l'aluminium par rapport à l'acier pour une structure légère, il est tentant de se concentrer uniquement sur la résistance ou le coût. Mais si votre conception dépend de la rigidité—pensez aux poutres, châssis ou composants sensibles aux vibrations—le module de l'aluminium (spécifiquement le module d'Young) et la la densité de l'aluminium deviennent les véritables facteurs déterminants. Pourquoi ? Parce que le rapport rigidité-poids détermine souvent si votre pièce va se plier, vibrer ou rester parfaitement rigide sous charge.

| Matériau | Module d'Young typique (E) | Densité (kg/m 3) | Remarques sur le rapport rigidité-poids | Applications communes |

|---|---|---|---|---|

| Alliages d'aluminium | ~69 GPa | ~2700 | Module d'élasticité inférieur à celui de l'acier, mais faible densité de l'aluminium permettant une grande rigidité par unité de poids ; idéal pour l'aéronautique et les transports | Structures d'aéronefs, châssis automobiles, panneaux légers |

| Acier au carbone faible | ~210 GPa | ~7850 | Module élevé ; la forte densité entraîne des structures plus lourdes pour une rigidité identique | Charpentes de bâtiments, ponts, machines |

| Acier à haute résistance | ~210 GPa | ~7850 | Même module d'élasticité que l'acier doux, mais une résistance supérieure permettant des sections plus fines | Pièces automobiles de sécurité, grues, récipients sous pression |

| Alliages de Magnésium | ~45 GPa | ~1740 | Rigidité et densité inférieures à celles de l'aluminium ; convient mieux aux pièces ultra-légères et à faible charge | Jantes automobiles, boîtiers électroniques |

| Allures de titane | ~110 GPa | ~4500 | Module d'élasticité supérieur à celui de l'aluminium, densité modérée ; utilisé lorsque la rigidité élevée et la résistance à la corrosion sont critiques | Fixations aérospatiales, implants médicaux |

Remarquez que bien que le module d'élasticité de l'acier soit environ trois fois supérieur à celui de l'aluminium, sa la densité de l'aluminium n'est qu'environ le tiers de celle de l'acier. Cela signifie que, pour un même poids, les profilés en aluminium peuvent être réalisés plus profonds ou plus larges, compensant ainsi le module plus faible et atteignant des rapports rigidité-masse similaires, voire meilleurs.

Mythes et réalités de substitution

Cela semble simple ? En réalité, remplacer l'acier par de l'aluminium (ou vice-versa) ne consiste pas seulement à insérer une nouvelle valeur de module. Voici ce à quoi vous devez prêter attention :

- La rigidité par unité de masse dépend de la géométrie : En optimisant la section transversale (en la rendant plus haute ou plus large), l'aluminium peut atteindre ou même dépasser la rigidité d'une pièce en acier, à poids égal.

- Résistance et module ne sont pas interchangeables : La le module d'élasticité de l'acier (environ 210 GPa) est beaucoup plus élevé, mais si votre conception est limitée par la déformation plutôt que par la résistance, l'aluminium peut s'avérer tout aussi pertinent.

- Coût, assemblage et limites d'épaisseur : L'aluminium peut nécessiter des sections plus épaisses pour obtenir la même rigidité, ce qui peut influencer l'assemblage, le choix des fixations et l'espace disponible.

- Fatigue et vibrations : Le module et la densité plus faibles de l'aluminium peuvent rendre les structures plus sujettes aux vibrations et à une moindre résistance à la fatigue, il est donc nécessaire d'examiner attentivement les charges dynamiques.

Cependant, grâce à sa faible densité et à sa bonne résistance à la corrosion, l'aluminium s'impose souvent dans l'aérospatiale, l'automobile et les équipements portables — en particulier lorsque la réduction de poids se traduit directement par des gains de performance ou d'efficacité.

Comment comparer les différents matériaux

Comment effectuer des comparaisons équitables entre l'aluminium, l'acier et autres métaux d'ingénierie ? Utilisez ces conseils pratiques pour éviter des erreurs coûteuses :

- Normaliser par rapport à la masse : Comparez E/ρ (module divisé par la densité) pour évaluer la rigidité par unité de poids.

- Conserver des unités cohérentes : Vérifiez toujours que vous comparez le module et la densité dans les mêmes unités (par exemple, GPa et kg/m 3).

- Utiliser des conditions limites identiques : Comparez les déflexions ou les fréquences avec les mêmes scénarios de chargement et de soutien.

- Tenir compte de l'assemblage et de l'épaisseur : Des sections en aluminium plus épaisses peuvent nécessiter des fixations ou des procédés de soudage différents.

- Documenter les hypothèses : Lors de la communication ou de la simulation, indiquez l'alliage, l'état mécanique, la forme du produit ainsi que la direction pour le module et la densité.

Ne transférez jamais directement les valeurs E de l'acier dans des modèles en aluminium. Recalculez toujours les propriétés de section et la rigidité lors du changement de matériau, et vérifiez que votre conception répond aux critères de résistance et de déformation propres au nouveau matériau.

En suivant ce cadre équilibré, vous éviterez les erreurs courantes liées aux substitutions et pourrez tirer pleinement parti de l'avantage de rigidité par rapport au poids de l'aluminium, sans compromettre la sécurité ni les performances. Dans la suite, nous vous montrerons comment vérifier vos données de module et documenter vos sources afin d'obtenir des spécifications techniques fiables.

Comment faire confiance aux données du module d'élasticité de l'aluminium et les documenter

Lorsque vous spécifiez le module de l'aluminium pour une nouvelle conception, comment savoir si vous utilisez la bonne valeur ? Imaginez la confusion si votre équipe tire des valeurs de différentes fiches techniques ou sites web — de petites différences en module peuvent entraîner de gros problèmes dans les simulations ou la conformité. C'est pourquoi vérifier vos sources et les documenter clairement est aussi important que la valeur elle-même.

Comment vérifier les données du module

Cela semble complexe ? Pas si vous adoptez une approche systématique. Avant d'entrer une valeur de module dans votre plan, votre logiciel de CAO ou votre rapport, passez en revue cette courte liste de vérification pour vous assurer que les données sont précises et pertinentes :

- Alliage : La valeur correspond-elle exactement à l'alliage que vous utilisez (par exemple, 6061, 7075) ?

- Tempérament : Les données précisent-elles le traitement thermique T4, T6, O ou un autre état métallurgique ?

- Forme du produit : S'agit-il de tôlerie, de plaque, d'extrudé ou de fonte ?

- Direction : Le module est-il mesuré selon le bon axe (L, LT, ST) ?

- Température: Les valeurs sont-elles indiquées à température ambiante, ou une autre température est-elle spécifiée ?

- Méthode d'essai : La source indique-t-elle comment le module a été mesuré (traction, dynamique, ultrasonore) ?

- Mesure de la déformation : La méthode de mesure de la déformation (extensomètre, jauge) est-elle documentée ?

- Système d'unités : Les unités du module sont-elles clairement indiquées (GPa, psi, etc.) ?

L'absence de l'un de ces détails peut entraîner une mauvaise utilisation ou des erreurs, en particulier lors du partage des données entre équipes ou projets.

Références fiables à consulter

Où trouver des valeurs fiables du module d'élasticité pour des alliages d'aluminium tels que le 6061-T6 ? Voici une liste sélectionnée de ressources de confiance utilisées par les ingénieurs dans le monde entier :

- MatWeb : Base de données complète sur les propriétés des matériaux — recherchez matweb aluminium 6061 t6 ou aluminum 6061 t6 matweb pour trouver des fiches techniques détaillées.

- Manuels ASM (ASM/MatWeb) : Données autoritatives sur les alliages et leurs états métallurgiques, incluant al 6061 t6 matweb valeurs de module, densité, et plus encore.

- AZoM : Aperçus techniques et tableaux de propriétés pour les alliages courants en génie.

- Engineering Toolbox : Référence rapide pour le module, la densité et les facteurs de conversion.

- AHSS Insights : Contexte comparatif de rigidité et de performance pour les alliages automobiles et avancés.

- Sonelastic : Méthodes de mesure dynamique du module et meilleures pratiques.

Lorsque vous extrayez des valeurs à partir d'une source quelconque, vérifiez toujours la mise à jour la plus récente et la version de la fiche technique. Par exemple, le matweb aluminium la base de données est régulièrement mise à jour et largement utilisée pour des fiches techniques et des documents CAE, mais vérifiez toujours que les valeurs correspondent à votre alliage, état métallurgique et forme de produit.

Liste de contrôle de documentation pour les spécifications

Vous souhaitez garder votre équipe sur la même longueur d'onde ? Utilisez ce tableau simple pour enregistrer et partager vos données sources pour le module, afin que tout le monde puisse retracer les valeurs et les mettre à jour si nécessaire :

| Source | Gamme de matériaux | Méthode/remarques | Dernier accès |

|---|---|---|---|

| MatWeb | profilé 6061-T6 | Module d'élasticité, méthode en traction | 2025-09-03 |

| ASM/MatWeb | tôle 6061-T91 | Propriétés physiques, moyenne de la tension/compression | 2025-09-03 |

| AZoM | Série générique 6xxx | Résumé technique, plage du module | 2025-09-03 |

- Inclure toujours l'URL complète, la portée du matériau, ainsi que toutes les notes indiquant comment la valeur a été mesurée ou calculée.

- Si vous trouvez des valeurs de module contradictoires dans différentes sources, privilégiez les publications à comité de lecture ou les fiches techniques primaires. En cas de doute persistant, effectuez vos propres tests ou consultez un laboratoire.

- Enregistrez la date d'accès, afin de pouvoir confirmer que les données sont à jour si des normes ou des fiches techniques sont mises à jour.

Stockez toutes les valeurs de module validées dans une bibliothèque centrale de matériaux, et gérez les versions de tout changement affectant les modèles CAO ou les plans. Ainsi, l'ensemble de votre équipe reste aligné et prêt pour les audits à chaque étape du processus de conception.

En suivant ce processus de crédibilité et de documentation, vous vous assurerez que chaque module de la valeur d'aluminium dans vos spécifications, simulations et rapports est à la fois précis et traçable. Prêt à acheter de l'aluminium pour votre prochain projet ? Dans la section suivante, nous vous montrerons comment contacter les meilleurs fournisseurs et spécifier les valeurs E pour la fabrication et les appels d'offres.

De la connaissance du module à l'approvisionnement et à la mise en œuvre

Lorsque vous avez déterminé le module d'élasticité de l'aluminium et que vous êtes prêt à passer de la théorie à la fabrication, quelle est la prochaine étape ? Que vous achetiez des profilés extrudés, que vous spécifiiez les exigences pour un nouveau châssis ou que vous validiez des résultats de simulation, il est essentiel d'avoir les bons partenaires et des spécification aluminium détails clairs. Voici comment combler l'écart entre l'intention technique et la mise en œuvre pratique.

Meilleures ressources et partenaires pour vos besoins en rigidité de l'aluminium

Imaginez que vous deviez fournir des composants en aluminium légers et à haute rigidité pour des applications automobiles ou industrielles. Vers qui vous tournez-vous pour obtenir un soutien fiable ? Voici une liste hiérarchisée des principaux types de partenaires – en commençant par un fournisseur de confiance capable de rendre les données de module opérationnelles dans la pratique :

- Shaoyi Metal Parts Supplier – En tant que principal fournisseur intégré de solutions en pièces métalliques automobiles de précision, Shaoyi propose non seulement des profilés extrudés en aluminium, mais également un soutien technique approfondi. Leur équipe vous aide à interpréter le module de l'aluminium dans des profils extrudés réels, valide les propriétés des sections et aligne les hypothèses CAO sur la réalité de fabrication. Leur contrôle qualité avancé et leur expertise en divers alliages garantissent que vos propriétés de l'aluminium restent cohérents de la spécification à la pièce finie.

- Bibliothèques de données matériaux (ASM/MatWeb) – Fournissent des valeurs vérifiées du module de l'aluminium et des propriétés associées, facilitant une conception précise et la documentation de conformité.

- Laboratoires d'essai accrédités – Effectuer des mesures de module en traction et en dynamique afin de confirmer que les matériaux fournis répondent à vos spécifications en aluminium et aux objectifs de conception.

- Sociétés de conseil en calcul (CAE) – Proposer une optimisation de la rigidité, une analyse NVH (bruit, vibration et dureté) ainsi que des supports pour des simulations avancées à l’aide de valeurs de module mesurées ou spécifiées.

| Type de partenaire | Comment ils aident avec le module | Livraisons | Quand les solliciter |

|---|---|---|---|

| Shaoyi Metal Parts Supplier | Interprète le module dans les profils extrudés, valide les propriétés de section, aligne les valeurs E avec la fabrication | Profilés sur mesure, validation CEM, documentation qualité, prototypage rapide | En début de projet, durant les revues DFM ou pour des applications hautes performances/critiques |

| Bibliothèques de données matériaux (ASM/MatWeb) | Fournit le module, la densité et les données d'alliage vérifiés pour les propriétés des matériaux en aluminium | Fiches techniques, tables de propriétés téléchargeables | Durant la conception, la configuration de la simulation ou les contrôles de conformité |

| Laboratoires d'essai accrédités | Mesure le module d'élasticité de l'aluminium, confirme les affirmations du fournisseur | Rapports de laboratoire, analyse de l'incertitude | Pour les nouveaux fournisseurs, les pièces critiques de sécurité ou lorsque la documentation est requise |

| Sociétés de conseil en calcul (CAE) | Optimise les structures en termes de rigidité, simule les charges réelles à l'aide de valeurs E mesurées | Résultats de la simulation, recommandations de conception | Pour les assemblages complexes, l'allègement, ou les objectifs NVH |

Spécifier correctement E dans les demandes de prix

Vous inquiétez-vous de manquer des détails dans votre demande de prix ? Une demande claire et complète est la base d'un prix précis et d'une livraison fiable. Voici une liste de contrôle rapide pour vous aider à spécifier le module – et tous les paramètres clés spécifications en aluminium – en toute confiance :

- Indiquez l'alliage et le tempérament exacts (par exemple, 6061-T6, 7075-T73)

- Décrivez la forme du produit et sa direction (profilé, plaque, tôle ; L, LT, ST)

- Précisez l'unité E cible (GPa, psi) et la source de référence si possible

- Définissez les attentes en matière d'essais/de rapports (module d'élasticité, module dynamique, exigences d'incertitude)

- Inclure les tolérances admises sur les propriétés et dimensions des sections

- Demander la documentation de les propriétés des matériaux en aluminium et la traçabilité depuis la matière première jusqu'à la pièce finie

Concevoir pour la rigidité à l'aide d'extrusions

Lorsque la réussite de votre conception dépend à la fois du module et de la géométrie, une collaboration précoce avec le fournisseur fait toute la différence. Pour les pièces en aluminium extrudé, l'équipe d'ingénierie de Shaoyi peut :

- Recommander les formes et épaisseurs optimales des parois afin de maximiser la rigidité pour un module d'élasticité de l'aluminium

- Confirmer que la valeur théorique du module d'élasticité (E) est atteinte dans la pièce finale grâce au contrôle des processus et aux contrôles qualité

- Appuyer la validation du modèle CAE par des données d'essais réels et la vérification des propriétés des sections

- Vous aider à concilier allègement et intégrité structurelle, en garantissant votre spécification aluminium s'aligne sur les objectifs de performance

Les résultats de rigidité dépendent autant de valeurs précises du module et de la directionnalité que du contrôle géométrique — impliquer votre fournisseur dès le départ garantit que vos spécifications en aluminium se traduisent en produits fiables et à hautes performances.

Questions fréquemment posées sur le module d'élasticité de l'aluminium

1. Qu'est-ce que le module d'élasticité de l'aluminium et pourquoi est-il important en ingénierie ?

Le module d'élasticité de l'aluminium, également appelé module de Young, mesure la rigidité du matériau dans la plage élastique. Il est crucial pour prédire dans quelle mesure une pièce en aluminium va se déformer sous charge, influençant la flèche, la résistance aux vibrations et le retour élastique dans les conceptions techniques. Contrairement à la résistance, qui détermine la rupture, le module régit la déformation élastique et est essentiel pour des applications légères où la rigidité est primordiale.

2. Comment le module d'élasticité de l'aluminium se compare-t-il à celui de l'acier ?

L'aluminium a un module d'élasticité plus faible (environ 69 GPa) par rapport à l'acier (environ 210 GPa), ce qui le rend plus flexible. Cependant, sa densité beaucoup plus faible permet aux ingénieurs d'optimiser la géométrie des sections pour obtenir des rapports rigidité-poids similaires. Cela rend l'aluminium compétitif pour les structures légères à haute rigidité dans les industries automobile et aérospatiale.

3. L'alliage et l'état métallurgique influencent-ils considérablement le module d'élasticité de l'aluminium ?

Non, l'alliage et l'état métallurgique n'ont qu'une faible influence sur le module d'élasticité de l'aluminium. Bien que la résistance et la formabilité varient fortement selon l'alliage et l'état, le module reste pratiquement constant d'un alliage à l'autre et quel que soit le traitement thermique. Par exemple, les alliages 6061-T6 et 6061-T4 ont des valeurs de module presque identiques, vous pouvez donc utiliser les valeurs standard pour la plupart des applications techniques.

4. Quelles unités sont couramment utilisées pour le module d'élasticité de l'aluminium, et comment convertir entre elles ?

Le module d'élasticité de l'aluminium est généralement exprimé en GPa (gigapascals), MPa (mégapascals), psi (livres par pouce carré) ou ksi (kilolivres par pouce carré). Pour la conversion : 1 GPa = 1 000 MPa = 145 038 psi. Vérifiez toujours les unités et étiquetez-les clairement afin d'éviter les erreurs de calcul, en particulier lors des conversions entre systèmes métrique et impérial.

5. Comment puis-je garantir des valeurs précises du module dans mon design ou mon demande de prix (RFQ) en aluminium ?

Pour garantir la précision, spécifiez clairement l'alliage exact, l'état métallurgique (temper), la forme du produit et la direction des mesures dans votre documentation ou votre demande de prix (RFQ). Obtenez les valeurs du module à partir de bases de données fiables telles que MatWeb ou ASM, ou demandez des tests en laboratoire pour les applications critiques. Collaborer avec des fournisseurs expérimentés, tels que Shaoyi, permet de valider les caractéristiques des sections et de s'assurer que le module théorique est atteint dans le produit final.

Petits tirages, hauts standards. Notre service de prototypage rapide rend la validation plus rapide et facile —

Petits tirages, hauts standards. Notre service de prototypage rapide rend la validation plus rapide et facile —