Sheet Metal Press Dies Exposed: From Selection To Sourcing Secrets

What Are Sheet Metal Press Dies and How Do They Work

Ever wondered how manufacturers transform a simple flat piece of metal into the perfectly shaped door panel on your car or the precisely formed casing of your smartphone? The answer lies in one of manufacturing's most essential tools: sheet metal press dies. These precision-engineered instruments serve as the backbone of modern metalworking, enabling the mass production of identical components with remarkable accuracy.

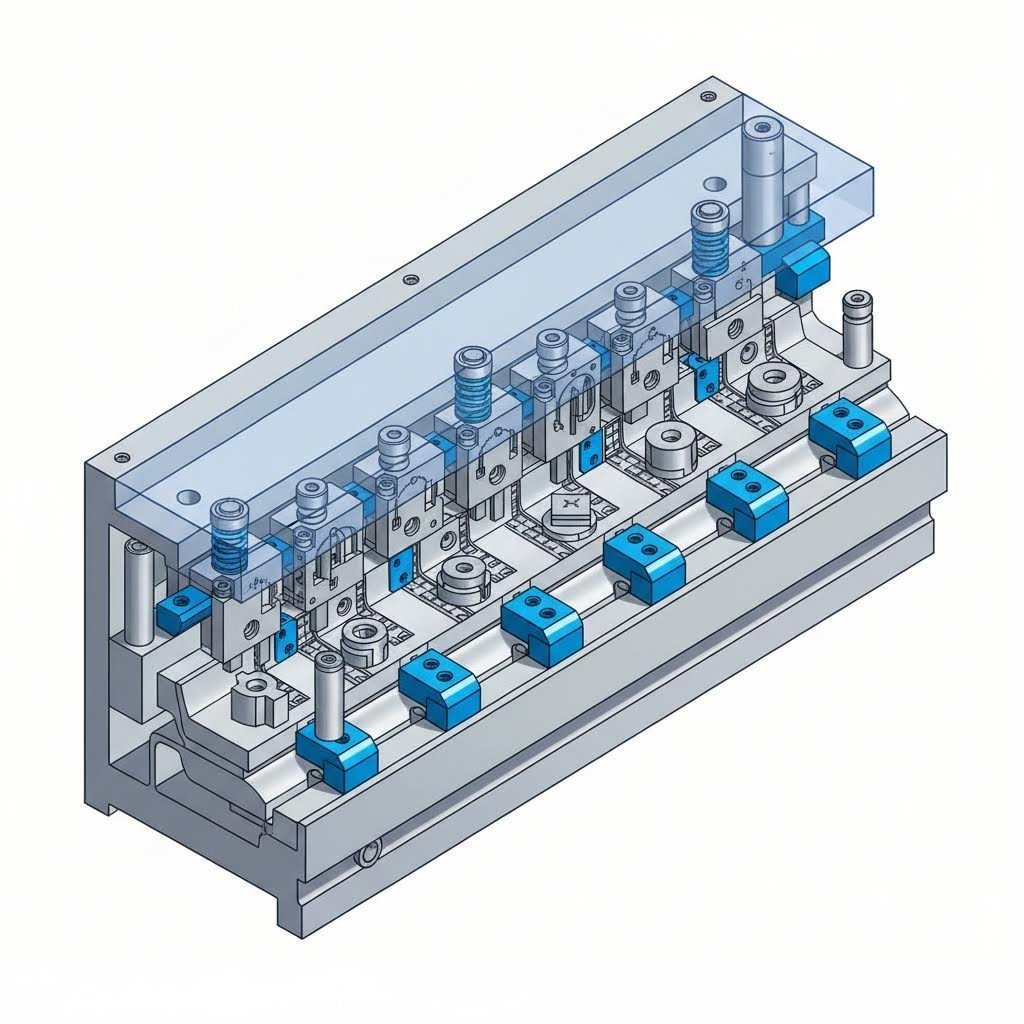

At its core, a sheet metal press die is a specialized tool designed to cut, bend, or form flat metal sheets into three-dimensional shapes through controlled force application. Think of it like a sophisticated cookie cutter—but instead of shaping dough, it works with robust metal under immense pressure. The die set typically consists of two primary components: an upper section called the punch and a lower section called the die. When placed inside a press machine for metal, these components work together to deliver hundreds of tons of precisely directed force.

The Engineering Behind Metal Transformation

Understanding how press dies function requires examining the relationship between their key components. When you're pressing metal, the upper punch descends toward the lower die with the sheet metal positioned between them. This interaction creates the magic of metal transformation through four essential functions:

- Locating: Positioning the metal sheet precisely where it needs to be

- Clamping: Securing the material to prevent movement during forming

- Working: Performing the actual cutting, bending, or forming operation

- Releasing: Freeing the finished component from the tooling

The working function is where the real value gets created. During this phase, the metal press performs operations like blanking, piercing, embossing, drawing, and coining—each transforming raw material into functional shapes.

Several critical components make this precision possible. Upper and lower die shoes—typically made from cast iron or steel—serve as the foundation where all other components attach. These shoes must resist deflection during operation. Guide pins and bushings maintain alignment between the die halves, with pins made from hardened steel entering softer bronze bushings to ensure consistent positioning throughout millions of cycles.

From Flat Stock to Finished Parts

Imagine sliding a flat sheet of aluminum between the punch and die of a sheet press. As the press cycles, the punch nose pushes the metal into the die opening, sliding it over the die shoulder radii. What happens next depends on the specific operation being performed—whether you're cutting a complete shape, creating holes, or forming complex bends.

The precision of modern press dies enables something remarkable: the ability to produce millions of identical parts with consistent quality. This repeatability comes from:

- Tight manufacturing tolerances on all die components

- Hardened tool steels that resist wear over extended production runs

- Precise alignment systems that maintain positioning accuracy

- Engineered clearances between punch and die surfaces

Why does this matter for modern manufacturing? Consider efficiency first. A well-designed die can produce finished parts at speeds impossible to match with manual fabrication methods. Quality consistency follows—every component emerges with the same dimensions and characteristics. Finally, cost-effectiveness improves dramatically as production volumes increase, since the initial tooling investment spreads across millions of parts.

Whether you're an engineer specifying tooling for a new project or a manufacturing professional seeking to understand press and die fundamentals, grasping these basics establishes the foundation for making informed decisions about die selection, design, and sourcing. The chapters ahead will build on this knowledge, guiding you through die classification, technical specifications, and the secrets to choosing the right partner for your tooling needs.

Complete Classification of Die Types and Their Applications

Now that you understand how sheet metal press dies transform flat stock into finished components, the next question becomes: which type of die should you actually use? This decision shapes everything from your production costs to part quality—and getting it wrong can mean thousands of dollars in wasted tooling or missed efficiency opportunities.

Die sets come in five primary categories, each engineered to solve specific manufacturing challenges. Understanding the rationale behind each design helps you match your production requirements with the right tooling approach. Let's break down each type and explore when it makes sense to use one over another.

Progressive Dies for High-Volume Efficiency

Imagine a die press that performs punching, bending, and blanking operations—all in a single machine cycle. That's exactly what progressive dies deliver. These sophisticated tooling dies feature multiple stations arranged sequentially within one die set, with each station performing a different operation as the metal strip advances through the tool.

Here's how it works: a coil of sheet metal feeds into the first station, where an initial operation occurs—perhaps piercing pilot holes. With each press stroke, the material advances a fixed distance to the next station. By the time the strip reaches the final station, a complete part drops out, fully formed. Meanwhile, the next part has already progressed through several operations behind it.

The engineering brilliance behind this design lies in its ability to achieve stroke rates of 30 to 60+ strokes per minute. According to HE-Machine's production line analysis, progressive dies are particularly suitable for small structural parts with high demand, where efficiency and output volume matter most.

Key advantages of progressive die tooling include:

- Extremely high production rates with minimal labor intervention

- Compact footprint since one die for press handles all operations

- Consistent part quality through automated material handling

- Lower per-part costs at high volumes

The tradeoff? Material utilization tends to be lower because the strip must maintain consistent spacing between operations. Progressive dies also require significant upfront investment and can be challenging to debug during setup.

Transfer Dies: Flexibility Meets Automation

What if your parts are too large for a continuous strip, or your forming operations require the workpiece to move in multiple directions? Transfer dies solve this challenge by placing multiple independent molds on a single large-tonnage forming press, with mechanical arms moving parts between stations.

Unlike progressive dies where material stays connected, transfer stamping uses either pre-cut blanks or material cut from coil at the first station. Automated fingers or grippers then carry each part through subsequent operations. This approach works particularly well for beam-like components, reinforcement parts, and symmetrical pieces with complex geometries.

A forming press machine running transfer dies typically achieves 20 to 30 strokes per minute—slower than progressive stamping but significantly faster than manual handling between separate presses. The real advantage emerges with parts that would be impractical to produce on a strip: larger components, parts requiring multi-directional forming, and designs with features that can be gripped by automated transfer mechanisms.

When Compound Dies Outperform Simple Tooling

Sometimes you need multiple cutting operations to happen simultaneously in the exact same location. Compound dies deliver this capability by performing two or more cutting operations—such as blanking and piercing—in a single press stroke at one station.

Picture creating a washer: you need to cut the outer diameter and punch the center hole. A compound die accomplishes both operations at once, ensuring perfect concentricity between the outer edge and inner hole. This precision would be difficult to achieve with separate operations because each handling step introduces potential alignment errors.

Compound dies excel when:

- Part features require precise alignment relative to each other

- Production volumes justify the more complex die design

- Flatness and dimensional accuracy are critical requirements

Combination and Simple Dies: Right-Sizing Your Investment

Combination dies merge cutting and forming operations in one stroke—for example, blanking a shape while simultaneously creating a bend or drawn feature. This approach reduces handling and improves part accuracy when geometric relationships between cut edges and formed features matter.

At the other end of the complexity spectrum, simple dies perform just one operation per stroke. Need to punch a hole? Bend a flange? Trim an edge? A simple die handles each task individually. While this requires moving parts between operations, the tooling cost is minimal and setup is straightforward.

For prototyping, low-volume production, or parts requiring only one forming step, simple dies often make the most economic sense. The hydraulic press die investment stays low, and you maintain flexibility to modify the process without scrapping expensive tooling.

Comparing Die Types: Your Selection Guide

Choosing between these approaches requires balancing production volume, part complexity, budget constraints, and quality requirements. The following comparison helps clarify which die type fits your specific manufacturing scenario:

| Die Type | Production Volume | Part Complexity | Setup Time | Cost Range | Typical Applications |

|---|---|---|---|---|---|

| Progressive | High (100,000+ parts) | Low to Medium | Long initial, minimal per-run | $$$-$$$$ | Electrical contacts, brackets, small automotive parts |

| Transfer | Medium to High | Medium to High | Moderate | $$$$ | Structural beams, reinforcements, symmetrical housings |

| Compound | Medium to High | Low to Medium | Moderate | $$-$$$ | Washers, precision blanks, parts requiring concentricity |

| Combination | Medium | Medium | Moderate | $$-$$$ | Parts combining cut edges with formed features |

| Simple | Low to Medium | Low | Short | $-$$ | Prototypes, single-operation parts, low-volume production |

Notice the relationship between volume and complexity? High-volume production justifies the investment in progressive or transfer tooling, while lower volumes often favor simpler approaches with reduced upfront costs. The sweet spot for your application depends on your specific production requirements and quality standards.

With this classification framework established, you're ready to dive deeper into the technical terminology that engineers and die makers use to describe these tools and their operations.

Essential Die Terminology Every Engineer Should Know

Ever tried discussing tooling requirements with a die maker only to feel lost in a sea of unfamiliar terms? You're not alone. Mastering the vocabulary of sheet metal press dies transforms confusing conversations into productive collaborations—and helps you read technical documentation with confidence.

Whether you're reviewing a quote from a die tool supplier or troubleshooting production issues, understanding these core terms puts you in control. Let's build your vocabulary systematically, starting with the operations that cut material and moving into those that shape it.

Cutting Operations Explained

Cutting operations remove material from the workpiece, creating shapes, holes, or separating finished parts from raw stock. Each cutting term describes a specific action with distinct characteristics:

- Blanking: Cutting a complete shape from sheet metal where the removed piece becomes the finished part. Think of punching out a metal disc that will become a gear—the disc is your "blank." According to Manor Tool's glossary, the blank is both the sheet metal used to make a product and the piece resulting from the blanking process.

- Piercing: Creating holes or slots by punching through material. Unlike blanking, the removed material (called the slug) is scrap, while the remaining sheet with the die hole becomes your part. Press cutting dies designed for piercing must handle slug ejection cleanly to prevent jamming.

- Notching: Shearing metal scrap from the outside edges of the workpiece—essentially piercing along the part perimeter rather than through interior sections.

- Shearing: Producing straight-line cuts as sheet metal passes between upper and lower blades. This operation works like industrial scissors, slicing material along a defined path.

When cutting operations occur, two byproducts require attention. The slug is leftover scrap after piercing—those small metal discs that fall through the die. A slug mark occurs when scrap material gets pressed into the workpiece surface, creating a defect. Managing slugs properly prevents costly quality issues.

Forming Versus Drawing Operations

Here's where terminology often gets confusing: both forming and drawing reshape metal, but they do so through fundamentally different mechanisms. Understanding the distinction helps you select the right die tools for your application.

Forming operations bend or shape material without significant material flow. The metal thickness remains essentially constant because you're simply changing the angle or curvature. A forming die might create a 90-degree flange on a bracket—the metal bends, but material doesn't stretch or thin substantially.

- Bending: Angular displacement of metal stock using a die to create defined angles

- Flanging: Creating a strengthened rim, often for easier assembly or added rigidity

- Hemming (Dutch bend): Doubling the material edge over on itself to stiffen edges or reduce sharpness

Drawing operations create depth by forcing material to flow into a die cavity. This die forming process actually stretches the metal, causing it to thin as it takes shape. Deep-drawn stamping produces hollow components—think beverage cans or automotive oil pans—where flat stock transforms into cup-like shapes.

The key indicator? If your part has significant depth relative to its diameter and the wall thickness is thinner than the original sheet, drawing was involved. Parts that maintain original thickness typically came from forming dies.

Precision Shaping Operations

Some operations require exceptional accuracy or create decorative features. These specialized techniques often complete the die formed part:

- Coining: A precision compression process where the workpiece is penetrated past the neutral plane under high pressure from both punch and die simultaneously. This creates extremely tight tolerances and smooth surfaces—essential for parts requiring exact dimensions.

- Embossing: Creating raised or recessed patterns in sheet metal without cutting through. Logos, textures, and functional features like stiffening ribs often come from embossing operations.

- Half-shearing: Partially penetrating the sheet metal to create a protrusion approximately half the material thickness. These raised features serve as locators for welding or assembly.

Critical Support Terms

Beyond operations, several terms describe conditions, defects, or die characteristics you'll encounter regularly:

- Die clearance: The space between punch and die opening. Proper clearance affects edge quality, tool life, and stripping force. Too tight causes excessive wear; too loose creates burrs and dimensional problems.

- Stripping: Removing the workpiece or scrap from the punch after an operation. Strippers apply force to push material off the tooling as it retracts.

- Burr: Raised edges or sharp protrusions left after cutting operations. Burr formation increases when die clearance is incorrect or tools become dull.

- Springback: When elastic material partially rebounds after forming. Accounting for springback in die design ensures parts meet final dimensional requirements.

- Breakout: The portion of material that fractures during cutting—visible on cut edges as a rougher zone compared to the sheared surface.

With this vocabulary foundation, you're equipped to communicate precisely with die makers, interpret technical drawings, and troubleshoot production issues. Next, we'll explore the technical specifications that govern how these operations perform—starting with the tonnage calculations that determine whether your press can handle the job.

Technical Specifications That Drive Die Performance

You've mastered the terminology. You understand the die types. But here's where rubber meets road: technical specifications determine whether your die produces quality parts or expensive scrap. Getting these numbers wrong means undersized presses struggling under load, premature tooling failure, or parts that don't meet dimensional requirements.

Let's walk through the critical calculations and specifications that separate successful die operations from costly mistakes. Whether you're specifying a new metal press machine or evaluating existing tooling, these fundamentals apply universally.

Calculating Press Tonnage Requirements

Ever wondered why some dies work flawlessly in one press but fail in another? The answer often comes down to tonnage—the force your press must deliver to complete the operation. Underestimate this number, and your press machining operation stalls mid-stroke. Overestimate it, and you're paying for capacity you'll never use.

The basic formula for cutting operations is straightforward:

Tonnage = (Cutting Perimeter × Material Thickness × Material Shear Strength) ÷ 2000

Sounds simple? Let's break down what each factor means:

- Cutting perimeter: The total length of all cuts being made simultaneously, measured in inches. For a 3-inch diameter circle with four 0.25-inch holes, you'd calculate: (π × 3) + (4 × π × 0.25) = approximately 12.57 inches.

- Material thickness: Stock thickness in inches. A 0.060-inch steel sheet behaves very differently from 0.250-inch plate.

- Shear strength: How much force the material resists before fracturing, measured in pounds per square inch (PSI). Mild steel runs approximately 50,000 PSI, while stainless steel reaches 75,000-90,000 PSI.

Here's a practical example: cutting a 4-inch square blank from 0.125-inch mild steel. The perimeter equals 16 inches. Plugging into the formula: (16 × 0.125 × 50,000) ÷ 2000 = 50 tons required.

But wait—this baseline calculation needs adjustment. Factors that increase your actual tonnage requirements include:

- Dull cutting edges (add 10-30% more force)

- Improper die clearance (can double required tonnage)

- Multiple simultaneous operations

- Material harder than nominal specifications

- Cold working effects from previous forming

Most engineers apply a 20-30% safety factor above calculated requirements. A machine die rated for 100 tons shouldn't regularly operate above 70-80 tons to maintain longevity and consistent performance.

Material Thickness Ranges and Die Design Impact

Material thickness doesn't just affect tonnage—it fundamentally changes how your die components must be designed. Thinner materials demand tighter clearances and more precise alignment, while thicker stock requires robust construction and increased forming radii.

Consider these thickness-related design factors:

- Thin gauge (under 0.030"): Requires precision die plates with minimal deflection, tighter clearances (often 3-5% of thickness per side), and careful stripper design to prevent distortion.

- Medium gauge (0.030" to 0.125"): The sweet spot for most stamping operations. Standard clearances of 5-8% per side work well, and conventional die construction handles the loads.

- Heavy gauge (0.125" to 0.250"): Demands heavier die shoes, larger punch-to-die clearances (8-12% per side), and increased forming radii to prevent cracking.

- Plate (over 0.250"): Often requires hydraulic press tooling for adequate force, specialized tool steels, and engineering analysis to verify die component strength.

The die plate thickness itself must scale with workpiece material. A general guideline: die plates should be at least 1.5 times the material thickness, with additional mass added for high-tonnage operations or when working hardened materials.

Understanding Die Clearance and Its Effects

Die clearance—the gap between punch and die opening—might seem like a minor detail. In reality, it's one of the most critical specifications affecting edge quality, tool life, and dimensional accuracy.

Proper clearance creates a clean fracture pattern during cutting. Too little clearance causes excessive wear on cutting edges, increased tonnage requirements, and potential punch breakage. Too much clearance produces burrs, rollover, and dimensional inconsistency.

The optimal clearance depends primarily on material type and thickness:

| Material Type | Recommended Clearance (% of thickness per side) | Effect of Too Little | Effect of Too Much |

|---|---|---|---|

| Mild Steel | 5-8% | Secondary shear, tool wear | Heavy burr, rollover |

| Stainless Steel | 6-10% | Galling, punch sticking | Excessive burr |

| Aluminum | 4-6% | Edge tearing, buildup | Rough edges, dimensional variance |

| Copper/Brass | 3-5% | Material adhesion | Deformation, burrs |

| High-Strength Steel | 8-12% | Punch breakage, chipping | Poor edge quality |

For forging dies and heavy forming operations, clearance calculations become more complex. Drawing and bending operations require clearance that accounts for material flow rather than simple shearing mechanics.

Tolerance Capabilities and Dimensional Accuracy

What tolerances can you realistically achieve? The answer depends on your die precision, press condition, and material consistency. Here's what to expect:

- Standard stamping: ±0.005" to ±0.010" on cut dimensions

- Precision stamping: ±0.001" to ±0.003" with ground tooling and tight press gibs

- Formed dimensions: Typically ±0.010" to ±0.015" due to springback variation

- Hole-to-hole spacing: Often achievable within ±0.002" using precision die components

Remember: your parts can only be as accurate as your weakest link. A precision die running in a worn press with sloppy gibs won't deliver tight tolerances. Similarly, inconsistent material thickness creates dimensional variation regardless of tooling quality.

With these specifications understood, you're ready to explore how different materials behave during forming—and which die designs work best for each. Material compatibility often determines whether calculated specifications translate into production success.

Material Compatibility and Die Selection Guidelines

You've calculated your tonnage requirements and nailed down the clearance specs. But here's a question that trips up even experienced engineers: does your sheet metal die design actually match the material you're forming? Different metals behave in dramatically different ways under pressure—and ignoring these differences leads to galled tooling, cracked parts, and production headaches.

Think of it this way: mild steel forgives sloppy technique. Aluminum punishes it. High-strength steel demands respect. Understanding how each material responds during forming operations helps you specify the right steel dies, select appropriate lubricants, and avoid costly surprises on the production floor.

Matching Die Design to Material Properties

Every sheet metal has a personality. Some stretch willingly; others fight back with springback. Some slide smoothly across tooling surfaces; others grab and tear. Here's what you need to know about each major material category:

Mild Steel (Low Carbon Steel): The most forgiving material for sheet metal dies. It forms predictably, accepts a wide range of clearances, and doesn't require exotic lubricants. Standard tool steels like D2 or A2 handle mild steel beautifully. If you're new to die design or prototyping a process, mild steel makes an excellent starting point.

Stainless Steel: Here's where things get interesting. Stainless work-hardens rapidly during forming, meaning it gets harder and stronger as you deform it. This creates two challenges: increased springback (parts don't hold their formed shape) and higher tonnage requirements as operations progress. Bending dies for sheet metal stainless applications often require over-bending by 2-4 degrees to compensate for elastic recovery.

High-Strength Steel: Advanced high-strength steels (AHSS) used in automotive applications can require 50-100% more tonnage than mild steel of the same thickness. These materials also cause accelerated die wear, demanding premium tool steels like carbide or powder metallurgy grades for any reasonable tool life.

Copper and Brass: Soft metals create their own challenges. They're prone to adhesion—sticking to punch surfaces—and can deform under clamping pressure. Polished tooling and appropriate clearances prevent marking these cosmetically sensitive materials.

Special Considerations for Stainless and Aluminum

Aluminum deserves special attention because it's simultaneously popular and problematic. Lightweight and corrosion-resistant, aluminum appears in everything from electronics housings to automotive panels. But aluminum galls—it literally welds itself to steel tooling under pressure and friction.

Preventing aluminum galling requires a multi-pronged approach:

- Use polished die surfaces (ideally mirror-finished)

- Apply heavy-duty lubricants or specialized aluminum-forming compounds

- Consider coated tooling (TiN, TiCN, or DLC coatings reduce friction)

- Maintain tighter clearances (4-6% per side) to minimize material flow against punch surfaces

For pressed sheet steel requiring stainless, remember that austenitic grades (304, 316) behave differently than ferritic or martensitic types. Austenitic stainless exhibits the most severe work hardening, demanding progressive reductions in forming severity across multiple die stations. Metal stamping die sets designed for stainless often include intermediate annealing stations to relieve work hardening between heavy draws.

Material Selection Quick Reference

The following table summarizes the key specifications and challenges for common sheet metals. Use this as a starting point when specifying your metal die requirements:

| Material | Die Clearance (% per side) | Tonnage Multiplier | Common Challenges | Recommended Tool Steel |

|---|---|---|---|---|

| Mild Steel | 5-8% | 1.0× (baseline) | Minimal; forgiving material | D2, A2, O1 |

| Stainless Steel | 6-10% | 1.5-1.8× | Springback, work hardening, galling | D2 (hardened), M2, carbide inserts |

| Aluminum | 4-6% | 0.5-0.7× | Galling, surface scratching, buildup | Polished D2, coated carbide |

| Copper/Brass | 3-5% | 0.4-0.6× | Adhesion, soft surface marking | Polished A2, bronze-bearing steels |

| High-Strength Steel | 8-12% | 1.5-2.0× | Extreme tool wear, punch breakage | Carbide, PM tool steels, coated |

Notice how lubrication requirements scale with material difficulty? Mild steel often runs with basic stamping oils. Aluminum and stainless demand specialized compounds—sometimes applied both to the strip and directly to tooling surfaces. Your sheet metal dies will last significantly longer when lubrication matches material behavior.

Material compatibility directly impacts your total cost of ownership. Choosing the wrong tool steel for high-strength applications means frequent sharpening or replacement. Ignoring aluminum's galling tendency destroys expensive punch surfaces. With material behavior understood, you're ready to evaluate the economics of different die approaches—and determine when premium tooling investments actually pay off.

Cost Analysis for Smart Die Investment Decisions

Here's a question that keeps manufacturing engineers up at night: should you invest $80,000 in a progressive die or spend $8,000 on simple tooling? The answer isn't as straightforward as comparing price tags. Your total cost of ownership depends on production volume, hidden operational expenses, and factors that never appear on the initial quote.

Understanding the economics of die selection transforms what feels like guesswork into strategic decision-making. Whether you're evaluating a press die set for a new product launch or reassessing existing tooling approaches, this framework helps you avoid the two most expensive mistakes: over-engineering for low volumes and under-investing for high-volume runs.

When Progressive Dies Pay for Themselves

Progressive dies command premium prices—often $50,000 to $100,000+ for complex automotive components. That upfront investment scares many buyers toward simpler alternatives. But here's what the sticker price doesn't tell you: for high-volume production, progressive tooling delivers the lowest cost per part by a wide margin.

According to Shaoyi's automotive stamping cost analysis, the fundamental estimation formula is:

Total Cost = Fixed Costs (Design + Tooling + Setup) + (Variable Cost/Unit × Volume)

The magic happens in that second term. A set of die designed for progressive operations can achieve stroke rates of 30-60+ parts per minute with minimal operator intervention. Compare that to single-operation dies requiring manual part handling between stations—suddenly, labor costs dominate your economics.

Let's run the numbers on a real scenario. Imagine you need 500,000 brackets over five years:

- Progressive die approach: $80,000 tooling investment ÷ 500,000 parts = $0.16 per part for tooling. Add minimal labor at high-speed production, and your piece price stays low.

- Simple die approach: $8,000 tooling investment ÷ 500,000 parts = $0.016 per part for tooling. Sounds better, right? But now factor in manual handling between three separate operations, slower cycle times, and increased quality control—your labor costs can add $0.50 or more per part.

The break-even point typically falls between 10,000 and 20,000 parts annually, where progressive die efficiency offsets its higher upfront cost. For automotive projects exceeding these thresholds, investing in complex die sets for press operations yields the lowest total cost of ownership.

Total Cost of Ownership Beyond Tooling Price

Tooling quotes only tell part of the story. The hidden costs lurking in your production process often exceed the visible ones. Smart die investment decisions require examining the complete picture:

Setup and Changeover Costs

- Progressive dies: Single setup for all operations. Once running, minimal intervention required.

- Multiple simple dies: Each operation requires separate setup. Changeover time between jobs compounds across stations.

- Transfer dies: Moderate setup complexity, but automated handling reduces per-cycle labor.

Secondary Operations and Handling

Every time a part moves between operations, costs accumulate. A hydraulic press die set performing single operations means:

- Manual or semi-automated part transfer between stations

- Intermediate storage and work-in-process inventory

- Increased handling damage risk

- Additional quality inspection points

Progressive dies eliminate most secondary handling. Parts flow through metalforming presses in continuous strips, emerging complete at the final station.

Quality Control Requirements

Here's a cost driver many overlook: each separate operation introduces dimensional variation. When you're press metal forming across multiple dies, tolerances stack. A part requiring three operations might need inspection after each step, plus final verification. Progressive tooling maintains registration throughout all operations, reducing quality control burden and scrap rates.

Maintenance and Die Life

According to industry data, high-quality dies guaranteed for 1 million strikes effectively cap your tooling spend over the product lifecycle. For high-volume runs, that amortization drops allocated tooling cost to negligible amounts per unit. Budget approximately 2-5% of tooling cost annually for sharpening and component replacement regardless of die type.

Common Misconceptions That Kill Budgets

Two costly mistakes repeatedly derail die investment decisions:

Mistake #1: Over-engineering for low volumes. Ordering a $60,000 progressive die for a 5,000-part annual run allocates $12 per part just for tooling. A fabrication press running simpler tooling would deliver better economics, even with higher labor content. Match die complexity to actual volume requirements.

Mistake #2: Under-investing for high volumes. Trying to save $50,000 on tooling while running 200,000 parts annually is false economy. The labor inefficiency of simple dies at this volume easily exceeds the tooling savings within the first year. Run the break-even calculation before committing.

The right approach? Start with your projected volumes, calculate the break-even point, then add appropriate safety margin for volume uncertainty. If your forecast shows 15,000 parts annually but could swing to 50,000, investing in scalable progressive tooling protects your economics either way.

With cost analysis frameworks established, you're equipped to make economically sound die investments. But even the best tooling requires proper care to deliver expected value—which brings us to the maintenance practices that extend die life and maintain part quality throughout production runs.

Die Maintenance and Troubleshooting Best Practices

You've invested thousands in precision tooling. Your press die delivers perfect parts—for now. But here's the uncomfortable truth: without proper maintenance, that expensive die equipment degrades with every stroke. Burrs appear. Dimensions drift. Quality complaints pile up. And suddenly, you're spending more on firefighting than you ever saved by skipping scheduled maintenance.

The good news? A systematic approach to die maintenance dramatically extends tool life while maintaining the part quality your customers expect. According to Phoenix Group's die maintenance analysis, poor maintenance causes quality defects during production, driving up sorting costs, increasing the likelihood of shipping defective parts, and risking expensive forced containments. Let's break down the practices that prevent these costly outcomes.

Preventive Maintenance That Extends Die Life

Think of preventive maintenance as insurance you control. Rather than waiting for failures to dictate your schedule, you establish inspection intervals and maintenance cycles based on die supplies condition and production demands. This proactive approach keeps your die shoes and critical components functioning properly throughout their intended lifespan.

A robust preventive maintenance schedule includes these essential activities:

- Daily visual inspection: Check for obvious damage, debris accumulation, and lubricant distribution before each production run. Look for chips on cutting edges and verify slug ejection paths remain clear.

- Stroke-based inspection intervals: Every 50,000-100,000 strokes (adjust based on material and die complexity), perform detailed measurements of critical dimensions. Document wear patterns to predict maintenance needs.

- Sharpening cycles: Cutting punches and die buttons typically require sharpening every 100,000-500,000 strokes depending on material hardness. Remove only enough material to restore sharp edges—aggressive grinding shortens total die life.

- Component replacement timing: Springs lose force over millions of cycles. Guide pins and bushings develop play. Establish replacement schedules before these die's components cause quality issues. Track die shoe wear particularly carefully, as these foundation components affect all other alignments.

- Lubrication system verification: Confirm automatic lubricators function properly. Check manual lubrication points receive appropriate attention. Inadequate lubrication accelerates wear on every moving surface.

Setting die maintenance priorities requires a systematic approach. As Phoenix Group notes, decisions should be based on production needs, customer satisfaction, and return on investment. A die with an open quality complaint takes precedence over routine preventive work on tooling running without issues.

Diagnosing Common Die Problems

When problems appear, resist the temptation to make quick adjustments "under the ram." According to industry experience documented by The Fabricator, most die problems trace back to violations of three fundamental rules: proper part location, adequate pressure pad function, and correct operation sequence. Rushing repairs without identifying root causes doubles your maintenance costs and introduces variation.

Here's how to diagnose the most common issues:

Burr Formation

Burrs—those raised edges on cut parts—signal clearance problems almost every time. Your diagnostic approach:

- Measure actual punch-to-die clearance against specifications

- Inspect cutting edges for wear or chipping

- Check die alignment—worn guide pins allow punch drift that creates uneven clearance

- Verify material thickness matches die design parameters

The solution typically involves regrinding cutting edges to restore proper clearance or replacing worn guide components.

Dimensional Drift

Parts measuring correctly last month now fall outside tolerance. This gradual change usually indicates wear patterns developing on critical surfaces:

- Examine forming surfaces for galling or material buildup

- Measure die shoe flatness—deflection under load causes dimensional variation

- Check locating pins and gauges for wear affecting part positioning

- Verify press ram parallelism hasn't shifted

Galling and Surface Damage

Material welding itself to die surfaces creates a destructive cycle. According to Jeelix's troubleshooting guide, galling quickly worsens surface finish and accelerates die wear, creating a damaging feedback loop. Diagnose by examining:

- Lubrication adequacy—insufficient coverage allows metal-to-metal contact

- Surface finish condition—scratches from previous galling trap material

- Material compatibility—some alloys (especially aluminum and stainless) require specialized coatings or lubricants

- Forming severity—excessive reduction rates generate heat that promotes adhesion

Premature Failure and Breakage

When punches snap or die sections crack, look beyond the obvious damage:

- Calculate actual tonnage versus die design capacity—overloading causes fatigue failures

- Inspect alignment mechanisms for wear allowing off-center loading

- Review material specifications—harder-than-expected stock multiplies stress on tooling

- Examine press condition—worn gibs or inconsistent ram motion concentrate forces unpredictably

Building a Maintenance Culture

The most sophisticated troubleshooting checklist fails without organizational commitment. Effective die maintenance requires:

- Documentation systems: Track every repair, sharpening cycle, and component replacement. This history reveals patterns that predict future needs.

- Skilled personnel: Die makers who understand both the technical requirements and the production context make better repair decisions.

- Prioritization frameworks: When multiple dies need attention, systematic priority systems ensure the most critical work happens first.

- Feedback loops: Connect production observations to maintenance actions. Operators often notice subtle changes before quality measurements catch problems.

Remember: maintenance costs pale compared to quality failures, customer complaints, and emergency repairs performed under production pressure. Investing in systematic die care protects your tooling investment while ensuring consistent part quality throughout the production lifecycle.

With maintenance fundamentals established, you're ready to explore how different industries apply these principles—and how sector-specific requirements shape die design decisions from automotive to aerospace applications.

Industry Applications from Automotive to Aerospace

Ever notice how a car door panel fits perfectly every time, or how the tiny connector pins in your smartphone make flawless contact? These seemingly different achievements share a common origin: specialized sheet metal press dies engineered for each industry's unique demands. Understanding how various sectors leverage press forming technology reveals why die design isn't one-size-fits-all—and helps you specify tooling that meets your specific quality and production requirements.

Each industry brings distinct challenges. Automotive manufacturers need millions of identical parts at breakneck speed. Aerospace demands precision forming of exotic alloys that resist conventional processing. Electronics require micro-scale accuracy measured in thousandths of an inch. Let's explore how tool die solutions adapt to serve these diverse needs.

Automotive Stamping Die Requirements

The automotive industry represents the largest consumer of sheet metal stamping press capacity worldwide. Every vehicle contains hundreds of stamped components—from massive body panels to tiny brackets—each requiring dies optimized for high-volume efficiency.

What makes automotive stamping unique? Volume and consistency. A steel press running automotive dies might produce 300,000 identical brackets annually, with each part meeting tolerances within ±0.005 inches. Progressive dies dominate this sector because they deliver the stroke rates and part consistency that OEM quality standards demand.

According to JV Manufacturing's industry analysis, sheet metal stamping in the automotive industry streamlines large-scale production, ensuring consistency and quality across thousands of units to help maintain brand reputation and consumer trust. The process also supports incorporating advanced technologies, such as sensors and actuators, into the vehicle framework.

Key automotive stamping applications include:

- Body panels: Doors, hoods, fenders, and roof sections requiring large-format metal forming press equipment

- Structural components: Frame rails, cross members, and reinforcements using high-strength steel

- Brackets and mounting hardware: High-volume progressive die production for assembly components

- Heat shields and exhaust components: Stainless steel forming for thermal management systems

Material selection adds complexity. As DR Solenoid's automotive materials guide explains, high-strength steel provides the strength and toughness needed to reduce vehicle weight while improving safety and reliability. However, these advanced materials require 50-100% more tonnage than mild steel, demanding dies built with premium tool steels and precise engineering.

For manufacturers seeking automotive-grade tooling, IATF 16949 certification has become the gold standard. This quality management system ensures die suppliers maintain the rigorous process controls OEMs require. Companies like Shaoyi exemplify this approach, combining IATF 16949 certification with advanced CAE simulation capabilities that achieve 93% first-pass approval rates—critical when tooling investments reach six figures and production timelines leave no room for error.

Precision Demands in Aerospace Applications

While automotive stamping prioritizes volume, aerospace metal press forming emphasizes precision with exotic materials. Aircraft components must withstand extreme environmental and mechanical stresses while minimizing weight—a combination that pushes die technology to its limits.

According to PrecisionX Manufacturing, aerospace stamping involves deep drawing complex metal components with sharp corners, precise radii, and tight tolerances for demanding applications. Using hard-to-draw materials such as Kovar, Inconel, titanium, and other specialty alloys, manufacturers produce lightweight, high-strength housings engineered for mission-critical environments.

Typical aerospace sheet metal pressings include:

- Structural brackets and fittings: Precision-formed aluminum and titanium components

- Engine components: High-temperature alloy parts for turbine sections

- Satellite housings and sensor enclosures: Deep-drawn shields with tolerances as tight as ±0.0004"

- Missile and defense systems: Mission-critical components requiring absolute reliability

The tolerance requirements tell the story. While automotive stamping typically achieves ±0.005" to ±0.010", aerospace applications routinely demand ±0.001" or tighter. Achieving this precision requires ground tooling surfaces, temperature-controlled production environments, and meticulous process validation.

Material behavior adds another layer of complexity. Titanium and superalloys work-harden aggressively, requiring careful progression through multiple forming stages. Deep drawing these materials to depths up to 18 inches—as PrecisionX capabilities demonstrate—demands dies engineered with exact clearances and optimized material flow paths.

Electronics: Micro-Stamping at Scale

At the opposite end of the size spectrum, electronics manufacturing relies on micro-stamping dies that produce incredibly small, intricate components. The connectors in your smartphone, the lead frames in semiconductors, and the battery terminals in your laptop all emerge from progressive dies operating at microscopic precision.

According to JV Manufacturing's analysis, the stamping process's precision and efficiency are advantageous for handling small, intricate parts necessary to modern electronic devices. This includes fabrication of micro-connectors used in smartphones, laptops, and other portable electronics, where space is limited but functionality is key.

Electronic stamping applications include:

- Connector terminals: Micro-formed contacts requiring precise spring characteristics

- Lead frames: Semiconductor packaging components with complex geometries

- Battery components: Current collectors and casings for safe, efficient operation

- RF shields: Electromagnetic interference protection housings

What makes electronics stamping particularly challenging? Feature sizes measured in thousandths of an inch combined with exotic materials like beryllium copper and phosphor bronze. These conductive alloys demand careful clearance control and specialized lubrication to prevent galling at micro scales.

Production speeds compound the precision challenge. High-volume electronics dies often run at 100+ strokes per minute while maintaining dimensional accuracy across billions of parts. Only precision-ground progressive tooling with tight guide systems can deliver this combination of speed and accuracy.

Appliance and Industrial Applications

Large-format forming for appliances and industrial equipment presents yet another set of requirements. Refrigerator panels, washing machine drums, and HVAC housings all require dies capable of handling sheet metal measured in feet rather than inches.

These applications typically favor transfer dies or large-format simple dies rather than progressive tooling. The part sizes simply exceed practical strip widths, requiring pre-blanked material and automated transfer between forming stations.

Key considerations for appliance stamping include:

- Surface finish requirements: Visible surfaces demand dies with polished forming sections

- Deep draw depths: Washer drums and similar components require substantial material flow

- Mixed material gauges: Production flexibility for different product lines

- Cosmetic standards: Zero tolerance for scratches, dings, or surface imperfections

How Industry Standards Shape Die Design

Beyond technical requirements, industry-specific quality standards fundamentally influence die design decisions. Consider these certification frameworks:

| Industry | Key Standards | Die Design Impact |

|---|---|---|

| Automotive | IATF 16949, OEM-specific requirements | PPAP documentation, SPC capability, traceability requirements |

| Aerospace | AS9100, NADCAP | Material certifications, process validation, first article inspection |

| Medical | ISO 13485, FDA 21 CFR Part 820 | Design history files, validated processes, biocompatible materials |

| Electronics | IPC standards, customer specifications | Plating compatibility, lead-free compliance, ESD considerations |

These standards affect everything from die material selection to documentation requirements. Automotive suppliers, for instance, must demonstrate statistical process capability during die tryout—meaning dies must produce parts within tolerance consistently, not just occasionally.

The investment in certification pays dividends beyond compliance. Suppliers meeting IATF 16949 requirements typically deliver higher first-pass approval rates and fewer production disruptions. When Shaoyi reports 93% first-pass approval on automotive dies, that number reflects systematic engineering processes validated through rigorous quality management—exactly what high-volume manufacturers need from their tooling partners.

Understanding these industry-specific requirements helps you communicate effectively with die suppliers and set appropriate expectations for your projects. Whether you're sourcing dies for automotive sheet metal pressings or precision aerospace components, matching supplier capabilities to your industry's demands ensures successful production outcomes.

With industry applications mapped, the next step is understanding how to navigate the die sourcing process—from initial concept through production-ready tooling—and selecting the right partner to bring your designs to life.

Sourcing Quality Dies and Choosing the Right Partner

You've analyzed your production requirements, calculated tonnage specifications, and identified the ideal die type for your application. Now comes the critical question that determines whether your project succeeds or stumbles: who actually builds your tooling? The die sourcing process transforms engineering concepts into production-ready metal presses—and the partner you choose shapes everything from lead time to long-term part quality.

Selecting the wrong supplier creates headaches that echo through your entire production lifecycle. Missed deadlines delay product launches. Design flaws require costly rework. Poor communication leaves you guessing about project status. But partner with the right die maker? You gain a collaborative relationship where engineering expertise flows both directions, problems get solved before they reach the production floor, and your pressing die performs exactly as intended from day one.

From Concept to Production-Ready Tooling

Understanding the die development process helps you evaluate suppliers effectively and set realistic expectations. According to Alsette's die design methodology, the process involves analyzing the part, planning the stamping sequence, designing key components, simulating performance, reviewing the design carefully, and creating detailed documentation for manufacturing. Let's walk through each phase:

- Part Analysis and Feasibility Assessment: Before any CAD work begins, experienced die makers examine your 3D models and drawings with a critical eye. What material are you forming? What's the thickness? Are there tricky shapes, sharp corners, or deep draws that could cause problems? This upfront analysis catches potential issues when changes cost nothing—before expensive tool steel gets machined.

- Stamping Process Planning: This phase determines the optimal sequence of operations. Will piercing happen before bending? How many stations does the strip layout require? The goal: use material efficiently while maintaining process stability. For progressive dies, this planning defines how the metal strip feeds through and how parts form step-by-step.

- CAD/CAM Development: Detailed 3D modeling of every die component follows process planning. Designers create the punch geometry, die block cavities, stripper systems, and guiding elements. A critical factor here is the clearance—that small gap between punch and die that affects edge quality and tool life. Modern machine dies require CAD precision that transfers directly to CNC machining programs.

- Simulation and Validation: Before cutting any metal, advanced suppliers use Finite Element Analysis (FEA) to simulate the stamping process virtually. This predicts how material will flow, identifies areas of high stress, and flags potential problems like cracking, wrinkling, or excessive springback. Companies like Shaoyi leverage CAE simulation capabilities specifically to achieve defect-free results—their 93% first-pass approval rate reflects systematic validation before tooling fabrication begins.

- Design Review: A fresh set of experienced eyes catches issues simulation might miss. Formal design reviews scrutinize every aspect: Does it meet functional requirements? Is it manufacturable? Is it safe to operate? For OEM projects, involving the customer in these reviews ensures the design meets specific needs.

- Tooling Fabrication: With design validated, precision machining creates each component. Quality suppliers invest in advanced CNC equipment, grinding capabilities, and surface treatment facilities. The steel press machine that forms your parts relies on tooling built to exacting tolerances—typically ±0.0002" to ±0.0005" on critical surfaces.

- Tryout and Refinement: The die gets mounted in a sheet pressing machine for initial testing. Engineers evaluate part quality, adjust timing, fine-tune clearances, and verify dimensional accuracy. This phase may require multiple iterations before production approval.

The timeline for this process varies significantly. Simple coin press dies might require 4-6 weeks. Complex progressive tooling can demand 16-20 weeks or more. However, suppliers with rapid prototyping capabilities can compress early phases dramatically—Shaoyi, for instance, delivers prototypes in as little as 5 days, allowing faster design validation before committing to full production tooling.

Evaluating Die Suppliers and Partners

Not all metal forming dies suppliers offer equivalent capabilities. According to Welong's supplier evaluation framework, buyers should focus on three key areas: certifications and quality standards, production capabilities, and quality control processes. Let's expand on criteria specific to stamping die suppliers:

Technical Capabilities Assessment

- Design engineering depth: Can they optimize your part design for manufacturability, or do they simply build what you specify? Suppliers with in-house engineering teams often identify cost-saving opportunities during the quoting phase.

- Simulation capabilities: Do they use FEA and forming simulation to validate designs before fabrication? This technology dramatically reduces tryout iterations and rework costs.

- Equipment capacity: What tonnage range can they build for? Do they have the steel press machine capacity for tryout and sampling?

- Material expertise: Have they successfully worked with your specific materials, whether aluminum, stainless, or high-strength steel?

Quality Certifications That Matter

Certifications provide objective evidence of systematic quality management:

- ISO 9001:2015: The baseline for quality management systems. Demonstrates commitment to consistent quality and continuous improvement.

- IATF 16949: The automotive industry standard. Required for OEM suppliers and indicates rigorous process controls.

- AS9100: Aerospace-specific quality requirements for suppliers serving aviation markets.

- NADCAP: National Aerospace and Defense Contractors Accreditation for specialized processes.

Beyond certifications, investigate their quality control practices. Do they use coordinate measuring machines (CMMs) for dimensional inspection? Non-destructive testing for detecting internal defects? Statistical process control during production? These capabilities indicate a supplier who won't just build your die—they'll validate that it performs correctly.

Lead Time and Support Services

Project timelines often make or break product launches. Evaluate:

- Quoted lead times: Are they realistic based on die complexity? Unrealistically short quotes often lead to disappointment.

- Prototyping speed: Can they produce sample parts quickly for design validation before full tooling commitment?

- Emergency support: What happens when production issues arise? Do they offer expedited repair and maintenance services?

- Documentation quality: Will you receive comprehensive drawings, material certifications, and maintenance guidelines?

Communication and Collaboration

Perhaps the most undervalued selection criterion: how well does the supplier communicate? The relationship between part designers and die makers fundamentally affects project outcomes. Look for:

- Proactive problem identification: Do they flag potential issues early, or wait until problems become expensive?

- Design feedback quality: Can they suggest improvements based on manufacturing experience?

- Project visibility: Will you receive regular updates on design progress and fabrication status?

- Engineering accessibility: Can you speak directly with the engineers working on your project?

Building a Successful Partnership

The best die sourcing relationships transcend simple vendor transactions. They become collaborative partnerships where both parties contribute expertise toward optimal outcomes. This means:

- Share complete requirements upfront: Production volumes, material specifications, tolerance requirements, and quality standards should all be clear from the start.

- Involve die makers early: Engaging tooling experts during part design—not after—often yields simpler, more manufacturable designs.

- Maintain open feedback loops: Production observations should flow back to the die maker. This information improves future designs and enables proactive maintenance.

- Plan for the long term: Die maintenance, spare components, and eventual refurbishment all benefit from ongoing supplier relationships.

For manufacturers seeking comprehensive die development capability, suppliers like Shaoyi demonstrate what integrated partnerships look like. Their engineering team combines rapid prototyping, advanced CAE simulation for design validation, and IATF 16949-certified manufacturing processes—delivering cost-effective tooling tailored to OEM standards. Exploring their mold design and fabrication capabilities provides a benchmark for evaluating potential partners.

The die sourcing decision shapes your production outcomes for years. Invest time in thorough supplier evaluation, prioritize communication capabilities alongside technical prowess, and build relationships that extend beyond individual projects. The result: sheet metal press dies that perform reliably from first stroke to final part—and a manufacturing partner who helps your operations succeed.

Frequently Asked Questions About Sheet Metal Press Dies

1. What are the main types of sheet metal press dies?

Sheet metal press dies fall into five primary categories: progressive dies (multiple sequential operations in one cycle), transfer dies (parts move between stations via mechanical arms), compound dies (simultaneous cutting operations at one station), combination dies (cutting and forming in one stroke), and simple dies (single operation per stroke). Progressive dies suit high-volume production exceeding 100,000 parts, while simple dies work best for prototyping and low-volume runs. The choice depends on production volume, part complexity, and budget constraints.

2. How do I calculate the tonnage requirements for a press die?

Calculate press tonnage using this formula: Tonnage = (Cutting Perimeter × Material Thickness × Material Shear Strength) ÷ 2000. For example, cutting a 4-inch square blank from 0.125-inch mild steel requires: (16 × 0.125 × 50,000) ÷ 2000 = 50 tons. Always add a 20-30% safety factor for dull edges, improper clearance, or harder materials. Stainless steel requires 1.5-1.8× more tonnage than mild steel, while high-strength steels may need up to 2× the baseline calculation.

3. What is the proper die clearance for different materials?

Die clearance varies by material type and affects edge quality and tool life. Mild steel requires 5-8% clearance per side, stainless steel needs 6-10%, aluminum works best at 4-6%, copper and brass require 3-5%, and high-strength steel demands 8-12%. Too little clearance causes excessive tool wear and increased tonnage requirements, while too much creates burrs and dimensional inconsistency. Proper clearance ensures clean fracture patterns during cutting operations.

4. How do I choose between progressive dies and simple dies?

The decision hinges on production volume and total cost of ownership. Progressive dies cost $50,000-$100,000+ but achieve 30-60+ strokes per minute with minimal labor. Simple dies cost $8,000-$15,000 but require manual handling between operations. The break-even point typically falls between 10,000-20,000 parts annually. For 500,000 parts over five years, progressive dies deliver significantly lower per-part costs despite higher upfront investment. Consider setup time, secondary operations, and quality control requirements beyond initial tooling price.

5. What certifications should I look for in a die supplier?

Key certifications include ISO 9001:2015 for baseline quality management, IATF 16949 for automotive industry requirements, AS9100 for aerospace applications, and NADCAP for specialized processes. IATF 16949-certified suppliers like Shaoyi demonstrate rigorous process controls that OEMs require, often achieving 93% first-pass approval rates. Beyond certifications, evaluate simulation capabilities, CMM inspection equipment, and engineering depth. Suppliers offering CAE simulation for design validation before fabrication significantly reduce tryout iterations and rework costs.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —