Laser Steel Cutting Decoded: From Fiber vs CO2 to Flawless Cuts

What Laser Steel Cutting Actually Means for Modern Manufacturing

Ever watched a beam of concentrated light slice through a thick steel plate like butter? That's laser steel cutting in action—a technology that has fundamentally transformed how manufacturers shape metal components. At its core, this process uses a focused, high-energy laser beam to melt, burn, or vaporize steel along a precisely programmed path, all controlled by sophisticated CNC (Computer Numerical Control) systems.

Why does this matter for modern manufacturing? The answer lies in three critical advantages: precision, speed, and versatility that traditional metal cutting methods simply cannot match. According to JLCCNC, laser cutting accuracy typically ranges from ±0.1 mm to ±0.004 inches, with even higher precision achievable on thinner materials. That level of exactness opens doors to complex designs and tight tolerances that would be impossible with conventional approaches.

The Science Behind the Beam

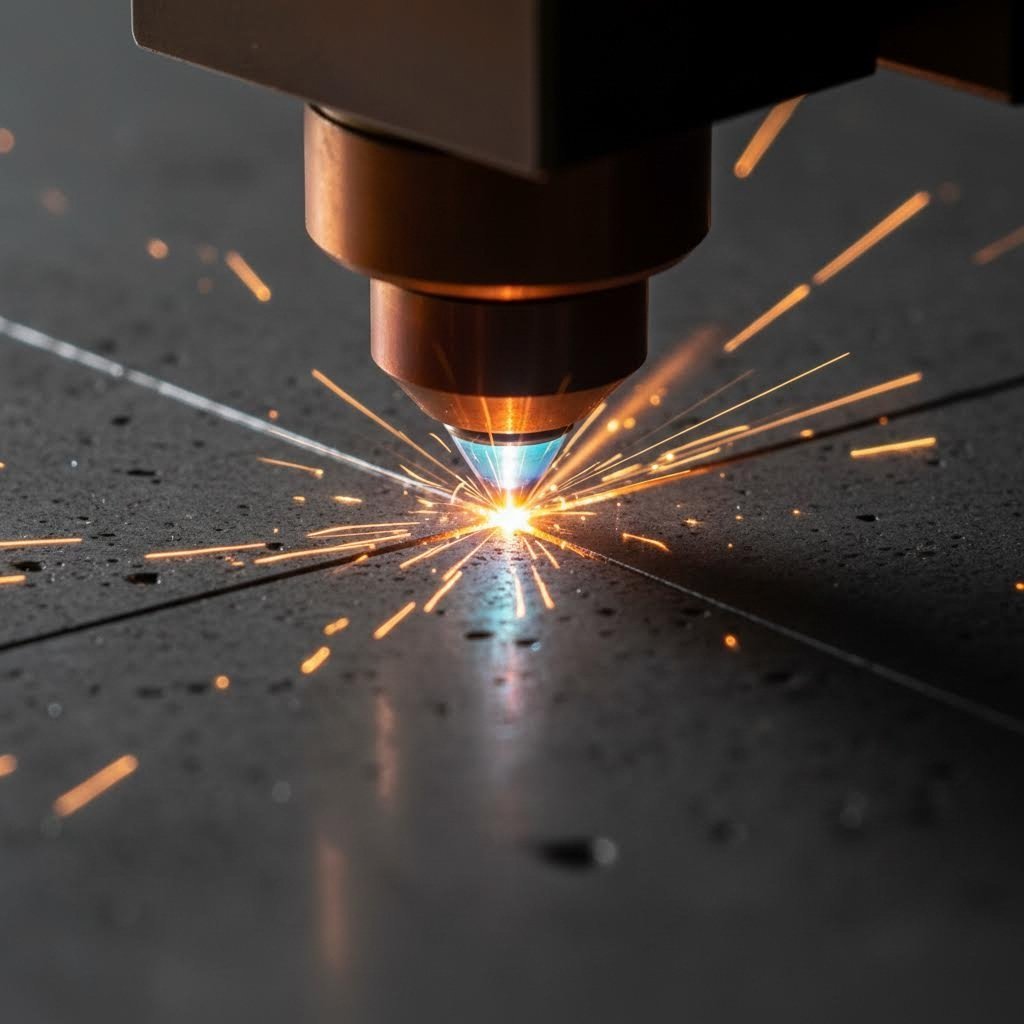

Imagine concentrating sunlight through a magnifying glass—now multiply that intensity by thousands. A cutting laser generates an incredibly focused beam of photons, all traveling in the same direction with identical wavelengths. This coherent light gets concentrated into a tiny focal point, sometimes smaller than a human hair, creating energy densities powerful enough to transform solid steel into vapor almost instantaneously.

The magic happens through photon energy concentration. When billions of photons strike the same microscopic area, they transfer enough thermal energy to overwhelm the steel's molecular bonds. The result? Material that was solid a fraction of a second ago is now molten or gaseous, ready to be blown away by an assist gas stream.

From Light to Cut Edge

So how does light become a clean-cut edge? The material interaction process unfolds in milliseconds:

- Absorption: The steel surface absorbs the laser's energy, converting light into heat

- Heating: Temperature rapidly exceeds the material's melting point (around 1,370°C for steel)

- Material removal: Depending on parameters, the steel melts, burns, or vaporizes

- Ejection: High-pressure assist gas (oxygen or nitrogen) blows molten material from the kerf

This entire sequence repeats continuously as the cutting head traces the programmed path, leaving behind a narrow cut—often just fractions of a millimeter wide. The result is minimal material waste and edges that frequently require no secondary finishing.

Why Steel Responds Differently Than Other Metals

Not all metals behave the same when you're cutting metal with a laser. Steel's absorption characteristics make it particularly well-suited to this technology. Unlike highly reflective metals such as copper or brass, steel readily absorbs laser energy at the wavelengths commonly used in industrial applications.

Laser metal cutting efficiency depends heavily on how much energy the material absorbs versus reflects. Steel's relatively high absorption rate means more of that concentrated photon energy goes directly into heating and cutting, rather than bouncing back toward the laser source. This fundamental property explains why laser cutting steel has become the go-to method across industries from automotive to aerospace—it's simply a natural match between technology and material.

The bottom line? Whether you're producing precision automotive components or intricate architectural panels, understanding this technology gives you a foundation for making smarter manufacturing decisions.

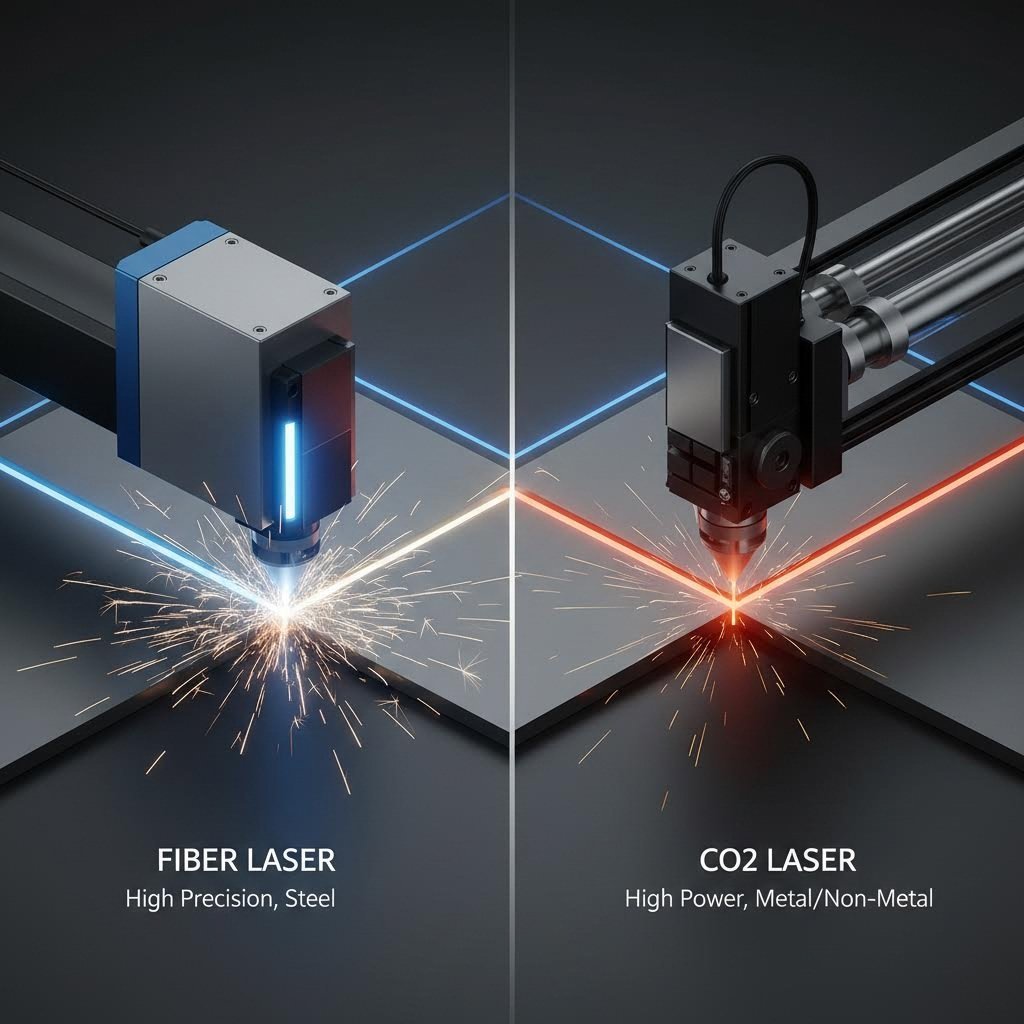

Fiber Laser vs CO2 Laser Technology for Steel Applications

Now that you understand how laser energy transforms solid steel into precision-cut components, the next question becomes: which type of laser should you actually use? This is where things get interesting—and where many manufacturers make costly decisions based on incomplete information.

The two dominant technologies in industrial laser cutting machines are fiber lasers and CO2 lasers. Each operates on fundamentally different principles, and understanding these differences is essential for optimizing your steel cutting operations. Let's break down what separates these technologies and when each one truly shines.

Fiber Laser Advantages for Steel Work

Fiber laser cutting machines have revolutionized metal processing over the past decade, and the numbers tell a compelling story. According to EVS Metal's 2025 analysis, fiber lasers now capture 60% of the market while delivering 3-5x faster cutting speeds and 50-70% lower operating costs than CO2 systems.

What makes a fiber laser cutter so effective for steel? It all comes down to wavelength. Fiber lasers operate at approximately 1.064 micrometers—a wavelength that steel absorbs far more efficiently than the 10.6-micrometer emission from CO2 systems. This means more of your electrical energy actually goes into cutting rather than being reflected away.

Here's what this translates to in practical terms:

- Exceptional speed on thin materials: A fiberlaser can cut thin stainless steel sheets at speeds up to 20 meters per minute

- Superior energy efficiency: Wall-plug efficiency reaches up to 50% compared to just 10-15% for CO2 systems

- Minimal maintenance: Solid-state technology eliminates gas-filled tubes and optical mirror alignment

- Tighter focus: Smaller beam spot sizes enable narrower kerfs and finer detail work

- Reflective metal capability: Aluminum, copper, and brass cut cleanly without back-reflection damage

The cost implications are significant. Operating costs for fiber laser cutting machines run approximately $3.50-4.00 per hour for energy, compared to $12.73 per hour for equivalent CO2 systems. Annual maintenance typically ranges from $200-400 for fiber systems versus $1,000-2,000 for CO2 equipment. For shops seeking an inexpensive fiber laser solution over the long term, these operational savings often outweigh higher initial purchase prices within 12-18 months.

When CO2 Still Makes Sense

Does this mean CO2 lasers are obsolete? Not quite. While fiber technology dominates most steel applications, CO2 systems retain specific advantages that matter for certain operations.

Thick plate cutting represents CO2's strongest remaining niche. When processing carbon steel beyond 20-25mm thickness, CO2 lasers often deliver superior edge quality. The longer wavelength distributes heat differently through thick sections, reducing dross formation and producing smoother cut surfaces that may require less post-processing.

CO2 lasers also excel in scenarios involving:

- Mixed-material operations: Shops cutting both metals and non-metals (wood, acrylic, plastics) benefit from CO2's versatility

- Thick section aesthetics: Applications where edge finish quality matters more than cutting speed

- Existing infrastructure: Operations with established CO2 systems and trained operators may find incremental upgrades more practical

- Lower initial investment: CO2 systems typically cost less upfront, though higher operating expenses erode this advantage over time

According to Accurl's technical comparison, CO2 lasers can efficiently cut materials exceeding 40mm thickness—capabilities that remain relevant for heavy structural fabrication work.

The Technology Shift Reshaping the Industry

The market trajectory is unmistakable. Fiber laser adoption has grown from approximately 30% market share in 2016 to 60% in 2025, with projections suggesting 70-80% dominance in metal cutting applications by 2030. This isn't speculation—it reflects fundamental performance advantages that compound over years of operation.

What's driving this shift? Beyond raw cutting performance, fiber laser cutting machines integrate more seamlessly with modern automation systems. Reduced warm-up times, eliminated gas requirements, and simplified maintenance protocols make fiber technology ideal for lights-out manufacturing and robotic workcells. A fibre laser cutter essentially requires less human intervention to maintain consistent output quality.

The financial case crystallizes when examining total cost of ownership. Over five years, CO2 systems cost approximately $1,175,000 to operate compared to $655,000 for equivalent fiber systems—a $520,000 differential that extends to $840,000 over ten years. For most steel fabrication operations, these numbers make technology selection straightforward.

| Specification | Fiber Laser | CO2 Laser |

|---|---|---|

| Wavelength | 1.064 μm | 10.6 μm |

| Optimal Steel Thickness | Up to 25mm (up to 100mm with high-power systems) | 20mm+ (optimal for thick plate >25mm) |

| Cutting Speed (thin materials) | Up to 20 m/min; 3-5x faster than CO2 | Baseline reference speed |

| Energy Efficiency | 35-50% wall-plug efficiency | 10-15% wall-plug efficiency |

| Annual Maintenance Cost | $200-400 | $1,000-2,000 |

| Lifespan | Up to 100,000 hours | 20,000-30,000 hours |

| Initial Investment | Higher upfront cost | Lower upfront cost |

| 5-Year Total Cost of Ownership | ~$655,000 | ~$1,175,000 |

The bottom line? For most steel cutting applications—especially thin to medium thickness materials—fiber technology delivers clear advantages in speed, efficiency, and long-term economics. CO2 systems remain viable for specific thick-plate and mixed-material scenarios, but the industry momentum points decisively toward fiber dominance.

Understanding which technology suits your materials is only part of the equation. Different steel types present unique cutting challenges that require specific parameter adjustments—a topic we'll explore next.

Steel Types and Their Unique Cutting Characteristics

Ever wondered why the same laser settings that produce flawless cuts on one steel plate leave rough, dross-covered edges on another? The answer lies in material composition. Each steel type interacts differently with laser energy, and understanding these differences separates mediocre results from precision craftsmanship.

Whether you're working with sheet metal laser cutting operations or tackling thicker plate, material selection drives every parameter decision. Let's decode how four common steel types behave under the beam—and what adjustments deliver optimal results for each.

Mild Steel Cutting Parameters

Mild steel serves as the baseline reference for laser cutting metal because it's the most forgiving material in the family. With low carbon content (typically 0.05-0.25%) and minimal alloying elements, mild steel absorbs laser energy predictably and cuts cleanly across the widest thickness range.

What makes mild steel so cooperative? Its consistent molecular structure creates uniform thermal conductivity, meaning heat distributes evenly during cutting. This predictability translates to easier parameter optimization and fewer surprises during production runs.

- Thickness capabilities: Fiber lasers can process mild steel from thin gauge sheets up to 100mm+ with high-power systems (40-60kW), though most fabrication shops work within 0.5-25mm ranges

- Assist gas flexibility: Both oxygen and nitrogen work effectively—oxygen accelerates cutting through exothermic reaction, while nitrogen produces oxide-free edges

- Speed advantages: According to industry data, a 12kW fiber laser cuts 10mm mild steel at 1-2.2 m/min using oxygen assist

- Edge quality: Easily achieves burr-free cuts with proper parameters; minimal post-processing typically required

- Forgiving nature: Tolerates wider parameter windows than specialty steels, making it ideal for operator training

For laser cutting metal sheet applications, mild steel represents the perfect starting point for dialing in machine settings before moving to more demanding materials.

Stainless Steel Edge Quality Secrets

Stainless steel presents a fascinating challenge: achieving those pristine, oxide-free edges that high-value applications demand. The material's chromium content (typically 10-20%) creates corrosion resistance but also changes how it responds to cutting gases.

Here's where the nitrogen versus oxygen debate gets real. Oxygen cutting works faster on stainless steel, but it reacts with chromium to form dark oxides along the cut edge. For applications requiring welding, painting, or visible aesthetics, this oxidation layer must be removed—adding time and cost to your process.

- Nitrogen assist gas: The industry standard for clean stainless edges; prevents discoloration and produces bright, oxide-free surfaces ready for immediate use

- Higher pressure requirements: Stainless typically needs 15-20 bar nitrogen pressure to effectively evacuate molten material from the kerf

- Thickness considerations: Fiber lasers handle stainless steel up to approximately 25mm with nitrogen assist, though optimal quality occurs at 12mm and below

- Reflectivity factors: 300-series stainless (304, 316) absorbs laser energy efficiently; 400-series may require slight power adjustments

- Heat sensitivity: Excessive power or slow speeds create heat-affected zones that can compromise corrosion resistance—speed optimization matters more than with mild steel

The tradeoff? Nitrogen consumption runs significantly higher than oxygen cutting, impacting operational costs. According to The Fabricator, emerging mixed-gas technologies now blend nitrogen with small percentages of air-sourced oxygen to reduce consumption while maintaining edge quality—a development worth watching for high-volume stainless operations.

Carbon Steel Considerations by Grade

Carbon steel spans a wide spectrum, from low-carbon varieties that behave similarly to mild steel all the way to high-carbon grades that require careful attention to prevent cracking and excessive hardness in the heat-affected zone.

The critical variable? Carbon content. As carbon percentage increases, so does the material's hardness and brittleness—characteristics that affect how quickly heat must be applied and removed during metal laser cutting operations.

- Low carbon (0.05-0.30%): Cuts similarly to mild steel; oxygen assist works well for speed, nitrogen for clean edges

- Medium carbon (0.30-0.60%): Increased hardening potential; faster cutting speeds help minimize heat-affected zone depth

- High carbon (0.60-1.0%+): Prone to edge hardening and potential microcracking; may require preheating for thick sections or post-cut stress relief

- Alloy additions matter: Chromium-molybdenum grades (4130, 4140) demand modified parameters compared to plain carbon steels of equivalent carbon content

- Edge metallurgy: High-carbon steels develop martensitic structures in the cut zone that can be harder and more brittle than the base material

For precision components where edge hardness affects downstream operations like forming or machining, lower-carbon grades simplify processing. When high-carbon grades are unavoidable, faster cutting speeds and nitrogen assist help manage thermal effects.

Galvanized Steel: Zinc Coating Challenges

Galvanized steel introduces a unique complication: that protective zinc coating vaporizes at approximately 907°C—well below steel's melting point. This means the laser encounters and vaporizes the zinc layer before even reaching the base steel beneath.

The result? Zinc fumes that require proper extraction and filtration for operator safety, plus cutting parameters that must account for the coating's thermal behavior.

- Fume extraction critical: Zinc fumes are hazardous if inhaled repeatedly; never cut galvanized steel without proper ventilation systems in place

- Thickness range: According to Kirin Laser, high-power fiber lasers cut galvanized steel up to 20mm thick, with optimal quality at 12mm and below

- Slower speeds recommended: Reducing feed rates allows zinc to vaporize cleanly before the beam fully engages the steel substrate

- Edge considerations: Zinc may partially burn away at cut edges, reducing localized corrosion protection—factor this into part design

- Spatter potential: Zinc volatilization can cause increased spatter compared to uncoated steels; protective lens covers extend consumable life

Despite these considerations, laser cutting remains an excellent method for galvanized steel when proper safety protocols are followed. The precision and automation capabilities far exceed mechanical alternatives like shears or nibblers.

While aluminium laser cutting involves a different material entirely, it's worth noting that aluminum shares some characteristics with galvanized steel—primarily high reflectivity and thermal conductivity—that influence parameter selection. Similar principles of proper gas selection and speed optimization apply when you need to cut aluminum with fiber laser systems.

Understanding material behavior is essential, but it's only half the equation. The next step? Mastering the relationship between laser power, cutting speed, and material thickness—the fundamental triangle that determines whether your cuts meet specifications or fall short.

Cutting Parameters That Determine Quality and Efficiency

You've selected your laser technology and understand your material—but here's where things get technical. The difference between a precision cut and a scrap-bound reject often comes down to three interdependent variables: laser power, cutting speed, and material thickness. Master this triangle, and you'll unlock consistent, high-quality results from your laser metal cutting machine.

Think of these parameters as a three-legged stool. Adjust one leg without compensating the others, and everything tips over. Let's explore how these variables interact and how secondary factors like assist gas selection and focus position fine-tune your outcomes.

The Power-Speed-Thickness Relationship

Every metal laser cutting machine operator faces the same fundamental challenge: matching energy input to material requirements. Too much power at slow speeds burns through thin steel and creates excessive heat-affected zones. Too little power at high speeds leaves incomplete cuts with dross clinging to the bottom edge.

Here's the conceptual framework that governs these interactions:

- Power determines penetration capability: According to Accurl's technical guide, a 1kW fiber laser efficiently cuts up to 5mm stainless steel, while a 3kW system handles up to 12mm of the same material

- Speed controls heat input: Faster cutting reduces the time laser energy dwells on any point, minimizing thermal distortion and heat-affected zone depth

- Thickness dictates minimum power: Thicker materials require proportionally more energy to fully penetrate—there's no shortcut around physics

- The balance point: Optimal cutting occurs when power is just sufficient to melt through the material at the fastest speed that still produces clean edges

What happens when you get this wrong? Insufficient power at high speeds creates incomplete cuts—the laser melts the surface but fails to penetrate fully, leaving parts partially attached. Excessive power at slow speeds produces wide kerfs, heavy oxidation, and dross formation that requires secondary grinding.

The practical takeaway? Start with manufacturer-recommended parameters for your material type and thickness, then adjust speed first (it's the easiest variable to modify on-the-fly) while observing edge quality. Most experienced operators find their sweet spot within 10-15% of baseline recommendations.

| Steel Thickness | Approximate Power Required | Key Considerations |

|---|---|---|

| 0.5 - 3mm | 1 - 2 kW | High speeds possible; nitrogen preferred for clean edges |

| 3 - 6mm | 2 - 4 kW | Balance speed and edge quality; oxygen increases cutting rate |

| 6 - 12mm | 4 - 6 kW | Moderate speeds; focus position becomes critical |

| 12 - 20mm | 6 - 12 kW | Slower cutting required; oxygen assist commonly used for carbon steel |

| 20mm+ | 12 - 40+ kW | Specialized high-power systems; edge quality monitoring essential |

Assist Gas Selection and Edge Quality

Sounds complex? It doesn't have to be. The assist gas decision essentially boils down to one question: do you prioritize cutting speed or edge finish quality?

According to DAMA CNC's assist gas guide, this choice fundamentally changes your cutting results:

Oxygen (O2): The traditional choice for carbon steel and mild steel applications.

- Creates an exothermic reaction that adds heat energy to the cutting process

- Enables faster cutting speeds on thick materials (6mm to 25mm+)

- Produces a black oxide layer on cut edges

- Lower gas cost than nitrogen

- Drawback: Oxide layer must be removed before painting or welding—grinding or cleaning adds process time

Nitrogen (N2): The standard for stainless steel, aluminum, and cosmetic applications.

- Inert gas that simply blows molten material from the kerf while cooling the cut zone

- Produces bright, silver "oxide-free" edges ready for immediate welding or powder coating

- Essential for food-grade equipment, architectural panels, and visible components

- Requires higher pressure (15-20 bar) and consumes more gas than oxygen cutting

- Drawback: Higher operational cost due to gas consumption

Compressed Air: The fastest-growing trend in the industry.

- Roughly 80% nitrogen and 20% oxygen—provides partial benefits of both

- Best for thin stainless steel under 3mm, galvanized steel, and carbon steel under 10mm on high-power systems

- Essentially free operating cost—only electricity for the compressor

- Produces light yellow edges (slight oxidation)

- Requirement: High-quality compressor with dryer and filtration; air must be water-free and oil-free to protect the laser lens

For most laser cutting machine for metal applications, the decision framework is straightforward: use oxygen for thick carbon steel when edge appearance doesn't matter, nitrogen for stainless and cosmetic parts, and compressed air for thin materials when cost optimization is priority.

Understanding laser cutting charges often comes down to gas selection. Nitrogen-cut parts cost more to produce due to higher gas consumption, while oxygen and compressed air cutting significantly reduce per-part expenses. When evaluating fiber laser cutting machine price versus operational costs, factor in your expected gas consumption based on typical material mix.

Fine-Tuning for Perfect Cuts

Once you've dialed in power, speed, and assist gas, secondary parameters separate good cuts from excellent ones. These adjustments require more precision but deliver measurable improvements in edge quality and consistency.

Focus Position:

The focus position determines exactly where the laser beam concentrates its maximum energy relative to the material surface. According to Accurl's parameter guide, the focal point should generally align with the center of the material's thickness to prevent tapered cut edges.

- For thin materials (under 4mm): Shorter focal length ensures uniform cuts

- For thick materials: Longer focal length provides greater depth of focus for clean penetration

- Modern laser for cutting machine systems adjust focus via z-axis control—typically focusing slightly below the surface for thick sections

Nozzle Distance (Stand-off):

The gap between nozzle and material surface—ideally under 1mm—critically affects gas flow efficiency. Maintaining minimal stand-off distance ensures the assist gas exerts adequate pressure to clear molten material from the cut path.

- Too close: Risk of nozzle collision during cutting, especially on warped sheets

- Too far: Gas disperses before reaching the cut zone, reducing effectiveness

- Optimal range: 0.5-1.0mm for most applications

Gas Pressure:

Higher pressures improve molten material ejection but increase gas consumption. Lower pressures reduce costs but may leave dross on thick sections.

- Thin materials: Lower pressure prevents blowing molten material back onto the surface

- Thick materials: Higher pressure ensures complete evacuation of the kerf

- Stainless steel: Typically requires 15-20 bar nitrogen pressure for clean edges

Nozzle Diameter:

Larger nozzles deliver more gas volume but reduce precision. Smaller nozzles concentrate gas flow but limit flow rate. Matching nozzle diameter to material thickness optimizes both cutting quality and gas efficiency.

Unlike a cnc plasma cutting machine where parameter windows are relatively wide, laser cutting rewards precise calibration. The good news? Once you've established optimal settings for a specific material and thickness combination, those parameters remain consistent—making repeat jobs predictable and reliable.

Even with perfect parameters, cutting defects still occur. Worn nozzles, contaminated gas, and machine drift can undermine your settings. Understanding how to diagnose and correct common problems keeps your production running smoothly—let's explore those troubleshooting strategies next.

Common Cutting Defects and How to Prevent Them

You've optimized your parameters, selected the right assist gas, and dialed in your focus position—yet something still looks off. The cut edge has stubborn residue clinging to the bottom, or maybe there's discoloration spreading beyond the kerf. What went wrong?

Welcome to the reality of laser steel cutting: even perfectly calibrated systems develop issues over time. Nozzles wear. Gas quality fluctuates. Beam alignment drifts. The difference between experienced operators and novices isn't avoiding problems—it's diagnosing root causes quickly and implementing effective solutions before scrap piles up.

This troubleshooting guide covers the defects you're most likely to encounter and the systematic approach that gets your metal laser cutter back on track.

Diagnosing Dross and Burr Issues

Dross and burr formation represent the most common complaints in any fabrication shop. That stubborn slag adhering to the bottom edge? It's telling you something specific about your process—if you know how to read the signs.

Dross (Slag) Formation:

According to BCAMCNC's troubleshooting guide, dross refers to leftover material that adheres to the bottom edge of the cut. It's essentially molten steel that didn't get fully expelled from the kerf before resolidifying.

- Cause: Cutting speed too fast — The laser moves past before assist gas can fully clear molten material. Solution: Reduce feed rate by 5-10% increments until dross disappears

- Cause: Laser power too low — Insufficient energy creates partially melted material that's difficult to expel. Solution: Increase power or reduce speed to improve energy density per unit length

- Cause: Insufficient gas pressure — Molten material isn't being blown clear of the cut zone. Solution: Increase assist gas pressure; for thick steel, try 15-20 bar nitrogen or 0.5-1 bar oxygen

- Cause: Worn or damaged nozzle — Irregular gas flow creates inconsistent material ejection. Solution: Inspect nozzle for concentricity and replace if orifice is deformed or clogged

- Cause: Contaminated assist gas — Moisture or oil in the gas stream disrupts cutting chemistry. Solution: Check dryers and filters; replace if necessary

Burr Formation:

Burrs are raised edges along the cut that complicate downstream processes like forming, welding, or assembly. They're especially frustrating because they often require manual grinding—adding labor cost to every part.

- Cause: Speed too slow for material thickness — Excessive heat creates wider melt zones that solidify irregularly. Solution: Increase cutting speed while maintaining adequate power

- Cause: Assist gas pressure mismatch — Either too high (blowing molten material back onto edges) or too low (incomplete ejection). Solution: Systematically adjust pressure in 0.5 bar increments while monitoring results

- Cause: Focus position error — Beam not concentrated at optimal depth creates irregular melting. Solution: Verify focus calibration; adjust z-axis position per manufacturer specifications

- Cause: Nozzle stand-off too large — Gas disperses before reaching the cut zone. Solution: Reduce nozzle-to-material distance to 0.5-1.0mm

When using a laser cutter for metal applications, burr formation often indicates the laser that cuts metal is operating outside its optimal window—either thermally or mechanically. Start by checking the easiest variables (speed and gas pressure) before investigating mechanical alignment issues.

Edge Quality Troubleshooting Guide

Beyond dross and burr, edge quality problems manifest in several distinct ways. Each symptom points toward specific root causes—use this systematic approach to narrow down the culprit.

Rough or Striated Cut Edges:

When cut surfaces show visible striations (parallel lines running down the edge), the laser beam isn't maintaining consistent interaction with the material.

- Cause: Excessive cutting speed — Creates waviness or distortion along the cut path. Solution: According to industry guidance, fine-tune cutting speed downward until striations diminish

- Cause: Machine vibration — Mechanical looseness translates to beam wander. Solution: Check gantry bearings, drive belts, and mounting bolts for wear or looseness

- Cause: Beam quality degradation — Dirty optics or misaligned beam delivery. Solution: Clean protective windows, inspect focus lens, verify beam centering through nozzle

- Cause: Material vibration — Thin sheets flutter during cutting. Solution: Improve workholding; consider vacuum tables or magnetic fixtures

Inconsistent Cut Width (Kerf Variation):

Uneven cut widths indicate the beam isn't maintaining proper focus throughout the cutting path.

- Cause: Incorrect focus settings — Focal point drifts relative to material surface. Solution: Recalibrate autofocus system; verify focus lens isn't contaminated

- Cause: Material not flat — Warped sheets change nozzle distance during cutting. Solution: Flatten material before processing; use hold-down fixtures

- Cause: Z-axis tracking error — Height sensor malfunction. Solution: Check capacitive or tactile height sensor operation and clean sensing surfaces

Incomplete Cuts:

Parts remaining attached or requiring manual breaking indicate insufficient energy delivery.

- Cause: Power too low for thickness — Laser doesn't fully penetrate. Solution: Increase power or reduce speed

- Cause: Speed too high — Beam moves past before completing penetration. Solution: Reduce feed rate until consistent through-cutting is achieved

- Cause: Assist gas insufficient — Molten material rewelds behind the beam. Solution: Increase gas pressure; verify gas supply isn't depleted

Preventing Heat Damage in Precision Parts

Heat-affected zones (HAZ) represent perhaps the most insidious defect category. Unlike dross or burr—which you can see immediately—HAZ damage may not become apparent until parts fail in service or reject during quality inspection.

According to JLC CNC's technical analysis, the heat-affected zone is the region of metal that doesn't melt during cutting but undergoes structural and metallurgical changes due to intense heat exposure. These changes affect hardness, strength, and ductility—sometimes weakening the material or causing warping and discoloration.

HAZ Warning Signs:

- Discoloration extending beyond the cut edge (blue, yellow, or straw colors on steel)

- Warping or distortion in thin parts or parts with fine features

- Edge hardening that causes cracking during subsequent forming operations

- Cosmetic finish damage extending beyond acceptable limits

Causes and Solutions:

- Cause: Excessive laser power — More energy than needed creates unnecessary heat spread. Solution: Use minimum power required for clean penetration

- Cause: Cutting speed too slow — Extended beam dwell time increases thermal input. Solution: Increase speed while maintaining cut quality

- Cause: Oxygen assist on heat-sensitive applications — Exothermic reaction adds heat. Solution: Switch to nitrogen for materials where HAZ is critical

- Cause: Tight geometry concentrating heat — Narrow features or sharp corners accumulate thermal energy. Solution: Design relief cuts; space cuts to allow cooling between passes

- Cause: Stacked sheet cutting — Heat builds cumulatively. Solution: Cut single sheets; allow cool-down time between batches

Proactive Prevention Strategies:

For precision parts where HAZ tolerance is tight, implement these practices before problems occur:

- Use pulsed or modulated laser modes when available—brief cooling periods between pulses shrink the affected zone

- Select materials with higher thermal conductivity when possible—they dissipate heat faster

- Consider cooling plates or heat sinks under workpieces for critical applications

- Monitor with thermal cameras on high-precision jobs to catch problems early

The sheet metal cutter that produces flawless parts consistently isn't necessarily running newer equipment—it's the operation where operators understand these cause-and-effect relationships and respond before minor issues become major rejects. With this diagnostic framework, you're equipped to maintain quality even as cutting conditions change.

Of course, laser cutting isn't the only option for steel processing. When does it make sense to choose plasma, waterjet, or mechanical alternatives instead? Understanding the tradeoffs helps you select the right technology for each project.

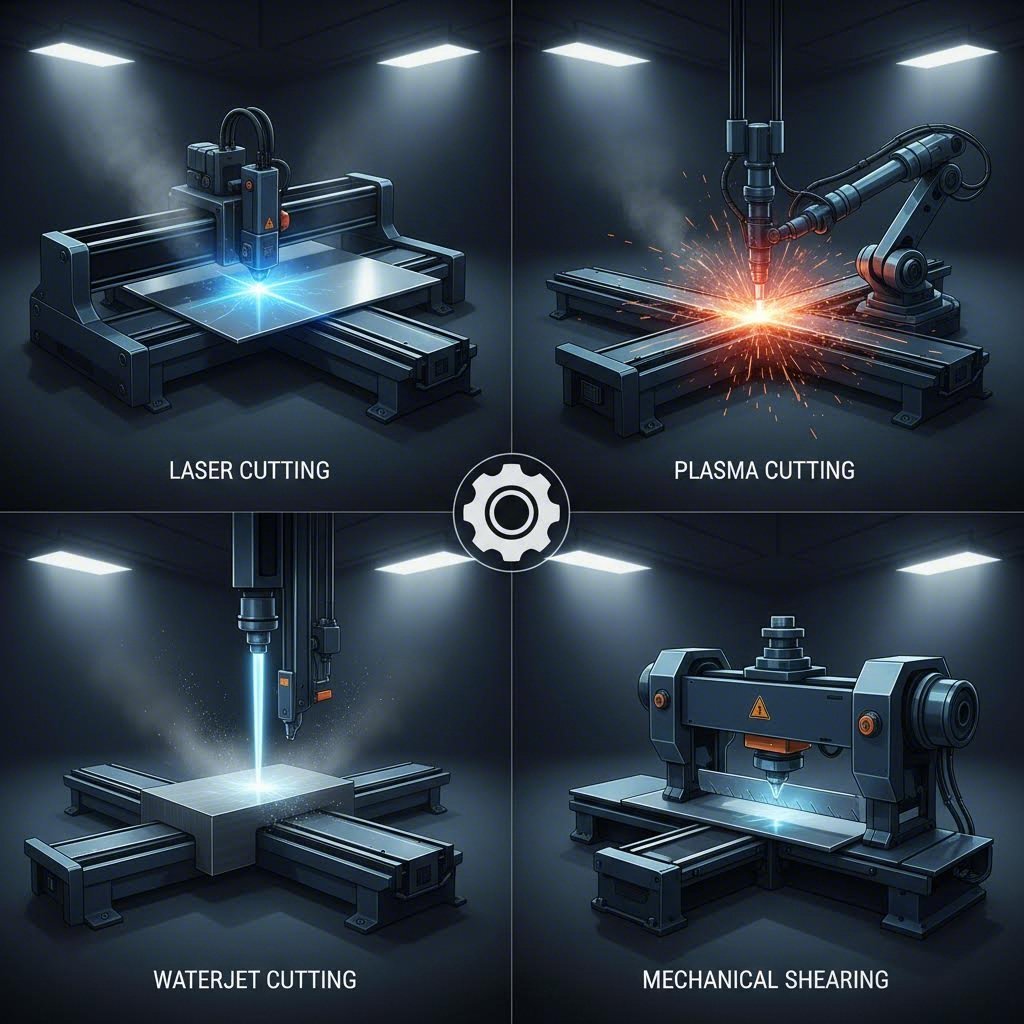

Laser Cutting vs Alternative Steel Cutting Methods

Here's the reality most equipment vendors won't tell you: laser cutting isn't always the best choice for every steel application. Sometimes a plasma cutter delivers better economics. Occasionally waterjet is the only viable option. And for certain straightforward jobs, mechanical cutting still makes perfect sense.

The key to smart manufacturing decisions? Understanding exactly when each technology excels—and when it doesn't. This comparison cuts through the marketing noise to give you a practical framework for selecting the right method based on your specific project requirements.

Precision and Tolerance Comparison

When tolerance specifications drive your manufacturing decisions, the differences between cutting technologies become crystal clear. Each method has inherent precision limitations that no amount of operator skill can overcome.

Laser Cutting:

According to Xometry's technical analysis, laser cutting produces cuts with slot widths of approximately ±0.15 mm and precision of 0.01 mm or less. The concentrated energy beam creates a kerf so narrow that intricate designs, tight corners, and small holes become routine work.

- Best-in-class accuracy for thin to medium materials

- Burr-free, smooth cut surfaces that often require no secondary finishing

- Minimal kerf width preserves material and enables precise nesting

- Ideal for contours, intricate patterns, and close-tolerance holes

Plasma Cutting:

A cnc plasma cutter operates with inherently wider tolerances—typically 0.5-1 mm precision with kerf widths exceeding 3.8 mm. According to StarLab CNC's 2025 guide, modern high-definition plasma systems on a cnc plasma table achieve near-laser quality on materials over 1/4" thick, but edge squareness remains challenging on very thin or very thick plates.

- Larger slot width means less precision for detailed work

- Edge perpendicularity issues may require grinding before welding

- Excellent for structural components where tight tolerances aren't critical

- Modern HD plasma narrowing the gap with laser on medium-thickness steel

Waterjet Cutting:

Waterjet delivers accuracy comparable to laser cutting—often within ±0.1 mm—with one significant advantage: zero heat distortion. According to ESAB's cutting method guide, waterjet surpasses laser cutting's edge smoothness while maintaining dimensional accuracy because no thermal effects occur.

- Accuracy unaffected by heat-related material distortion

- Edge quality remains consistent regardless of material thickness

- Stream divergence limits precision on very thick materials

- Ideal for heat-sensitive applications requiring tight tolerances

Mechanical Cutting (Shearing, Punching):

Traditional mechanical methods deliver adequate precision for straight cuts and simple geometries but cannot match thermal cutting methods for complex shapes.

- Excellent repeatability for straight cuts and standard hole patterns

- Edge deformation (rollover, burr) inherent to the process

- Limited to simple geometries—no curves or intricate contours

- Best suited for high-volume production of standardized parts

Cost-Per-Part Analysis Framework

Precision tells only part of the story. When production economics drive your decision, understanding the true cost structure of each technology reveals which method delivers the best value for your specific application.

Initial Investment:

According to industry data, CNC plasma tables offer the best value proposition for most fabrication shops, with entry-level systems starting around $15,000-50,000. Laser cutting equipment demands significantly higher capital—typically $150,000-500,000+ for industrial fiber systems. Waterjet systems fall between these extremes but require additional infrastructure for water treatment and abrasive handling. Even a portable plasma cutter provides cutting capability at a fraction of laser equipment costs.

Operating Costs:

According to Xometry's cost analysis, operational costs for laser cutters average approximately $20/hour, while plasma cutters typically run around $15/hour. Waterjet systems generate the highest ongoing costs due to garnet abrasive consumption—often $25-40/hour depending on cutting parameters.

- Plasma cutting: Lowest cost per inch of cut; consumables include electrodes, nozzles, and shield caps

- Laser cutting: Higher consumable costs (assist gas, lenses, nozzles) but faster cutting speeds offset expenses on thin materials

- Waterjet: Garnet abrasive represents 50-70% of operating expense; high-pressure pump maintenance adds significant ongoing costs

- Mechanical: Lowest operating costs for applicable geometries; tooling wear is primary expense

Speed and Throughput:

Production volume requirements dramatically affect which technology makes economic sense.

- Laser: Fastest on thin materials—exceptional speeds on sheets under 1/4" thick; speed decreases significantly above 1" thickness

- Plasma: According to StarLab CNC, a plasma cutting table can cut 1/2" mild steel at speeds exceeding 100 inches per minute—fastest option for medium to thick plates

- Waterjet: Slowest of the thermal/abrasive methods at 5-20 inches per minute; throughput limitations affect high-volume economics

- Mechanical: Fastest for simple, repetitive geometries; shearing operations complete in seconds

When evaluating the best plasma cutter versus laser for your operation, consider that cnc plasma systems consistently deliver the best value for shops processing steel from 0.018" to 2" thick where near-laser edge quality isn't mandatory.

Choosing the Right Technology for Your Project

Rather than picking a favorite technology and forcing all jobs through it, successful fabricators match cutting methods to specific project requirements. Use this decision framework to guide your selection:

Choose Laser Cutting When:

- Material thickness is under 1" (25mm) for steel

- Tight tolerances (±0.1mm or better) are required

- Intricate contours, small holes, or detailed patterns are needed

- Edge quality must be burr-free without secondary processing

- High-speed production of thin sheet metal is the priority

- Material variety includes both metals and non-metals

Choose Plasma Cutting When:

- Processing steel from 1/4" to 2" thick in production volumes

- Budget constraints favor lower capital investment

- Edge quality requirements allow for some grinding before welding

- Structural steel fabrication, heavy equipment, or HVAC applications

- Bevel cutting for weld preparation is frequently needed

- Speed and cost-per-part matter more than precision

Choose Waterjet Cutting When:

- Heat-affected zones are absolutely unacceptable (aerospace, medical devices)

- Material would be damaged by thermal cutting (tempered glass, composites)

- Cutting very thick materials where laser and plasma struggle

- Mixed-material applications include stone, tile, or other non-metallics

- Edge metallurgy must remain completely unchanged

- Cutting speed is less important than material integrity

Choose Mechanical Cutting When:

- Only straight cuts or simple hole patterns are required

- Very high volume production of identical parts

- Material thickness is consistent and within equipment capacity

- Capital budget is extremely limited

- Edge quality requirements are minimal

| Criteria | Laser Cutting | Plasma Cutting | Waterjet Cutting | Mechanical Cutting |

|---|---|---|---|---|

| Precision | ±0.01 mm | ±0.5-1 mm | ±0.1 mm | ±0.5 mm (straight cuts) |

| Kerf Width | ~0.15 mm | >3.8 mm | 0.5-1.5 mm | N/A (shear line) |

| Steel Thickness Range | Up to 25mm (optimal); 100mm+ (high-power) | 0.018" to 2"+ (optimal 1/4"-1.5") | Virtually unlimited | Equipment dependent |

| Cutting Speed | Fastest on thin materials | Fastest on medium-thick materials | 5-20 in/min (slowest) | Very fast for simple cuts |

| Heat-Affected Zone | Minimal | Moderate to significant | None | None |

| Edge Quality | Excellent; burr-free | Good; may need grinding | Excellent; smooth | Fair; rollover/burr common |

| Operating Cost | ~$20/hour | ~$15/hour | $25-40/hour | Lowest |

| Initial Investment | High ($150K-500K+) | Low-Moderate ($15K-100K) | Moderate-High ($100K-300K) | Low ($5K-50K) |

| Material Versatility | Metals + non-metals | Conductive metals only | Any material | Metals primarily |

| Best Application | Precision thin-medium steel | Structural/thick steel economy | Heat-sensitive/thick materials | High-volume simple shapes |

The bottom line? No single technology wins across all criteria. Laser cutting dominates precision work on thin to medium steel. Plasma cutting delivers unbeatable economics for structural fabrication. Waterjet protects material integrity when heat is unacceptable. And mechanical cutting remains viable for straightforward, high-volume applications.

Smart manufacturers often maintain access to multiple technologies—either in-house or through service providers—to match the right method to each project's specific requirements. But regardless of which cutting technology you select, operational safety remains paramount. Let's explore the essential safety requirements and protocols that protect both operators and equipment.

Safety Requirements and Operational Considerations

Here's something that often gets overlooked in discussions about industrial laser cutting: the technology that slices through steel with precision can pose serious hazards if proper safety protocols aren't followed. Whether you're evaluating equipment purchases or vetting service providers, understanding safety requirements separates professional operations from risky shortcuts.

An industrial laser cutter contains a Class 4 laser—the highest hazard classification—capable of causing eye injuries, skin burns, and fire. Yet when properly enclosed and operated, that same system becomes a Class 1 environment that's safe under normal conditions. The difference? Engineering controls, operational protocols, and trained personnel working together.

Laser Safety Classifications and What They Mean

Laser safety classifications, established by ANSI Z136 standards, indicate the potential hazard level of laser products. Understanding these classifications helps you evaluate equipment safety and regulatory compliance.

- Class 1: Safe under all conditions of normal use—the beam is fully enclosed and cannot escape during operation

- Class 2: Safe for accidental viewing; includes visible lasers where the blink reflex provides protection

- Class 3R: Low risk of injury; requires caution and basic safety measures

- Class 3B: Hazardous for direct eye exposure; requires safety eyewear and controlled access

- Class 4: High risk of injury; can cause eye and skin damage and pose fire hazards

Most commercial laser cutting systems are sold as Class 1 products, meaning the Class 4 laser inside operates within a fully interlocked enclosure. According to MIT's laser cutter safety guidance, some large-format cutters capable of processing full-size laser cut metal panels are sold as Class 4 systems, requiring additional controls including restricted access areas, warning signage, and mandatory protective eyewear.

When evaluating a commercial laser cutter for your facility, verify the classification and ensure the system includes safety interlocks that automatically shut off the laser if the enclosure opens. Never defeat or bypass these interlocks—doing so could allow the beam to escape, creating immediate hazards for anyone nearby.

Fume Extraction Requirements by Material

The respiratory hazards from a laser cutting system often receive less attention than beam safety—but they're equally critical for long-term operator health. When the laser vaporizes steel, it generates combustion byproducts similar to welding fumes. Coated steels compound this concern significantly.

According to MIT's safety guidance, proper exhaust is critical for safe and effective use. Both exhaust for the unit itself and general room ventilation matter—spaces with recirculated air are inappropriate locations for metal working operations involving laser cutting.

Material-Specific Fume Considerations:

- Mild and carbon steel: Standard fume extraction typically sufficient; iron oxide particles are the primary concern

- Stainless steel: Generates hexavalent chromium compounds during cutting—requires higher-capacity extraction and HEPA filtration

- Galvanized steel: Zinc coating vaporizes at lower temperatures than steel, producing zinc oxide fumes that cause metal fume fever if inhaled repeatedly

- Coated or painted steel: Unknown coatings may contain hazardous materials; obtain Safety Data Sheets before processing

Filtration System Best Practices:

- Conduct routine filter replacements on the schedule recommended by the manufacturer—or as indicated by system pressure monitors

- Keep replacement filters on hand for quick swap-outs when performance degrades

- Leave filtration running 10-15 seconds after cutting completes to clear residual fumes

- If odors are detected in the workspace, stop operations until the problem is resolved

- Never cut materials of unknown composition—request SDS documentation first

For operations processing galvanized steel or coated materials regularly, dedicated metal working tools for fume capture at the source—not just ambient room ventilation—become essential for regulatory compliance and worker protection.

Fire Prevention and Emergency Protocols

Even properly maintained industrial laser cutting equipment occasionally experiences flare-ups. The concentrated heat that makes laser cutting so effective also creates ignition potential—especially with combustible debris accumulation, incorrect parameters, or insufficient exhaust.

According to MIT's guidance, laser cutter fires typically involve one or more contributing factors:

- Not observing the laser cutter while operating

- Incorrect power and pulse settings for the material

- Insufficient exhaust allowing heat and debris buildup

- Processing unsuitable materials

- Dirty optics causing beam scatter

- Equipment not cleaned regularly—debris accumulation in the cutting chamber

Essential Fire Prevention Equipment:

- Fire extinguisher: Mount on the wall near the equipment; CO2 or Halotron extinguishers are preferred over dry chemical types because they won't damage laser optics

- Air assist system: Provides compressed air to remove debris and heat at the cut point, preventing charring and flare-ups

- Non-combustible work surface: Never place equipment on wood or other flammable materials

- Clear surroundings: Keep the area free of clutter, flammable liquids, and combustible materials

- Unobstructed viewing window: Never cover the window—operators must observe cutting to detect flare-ups immediately

Emergency Response Protocol:

If a flare-up is detected, immediately shut off the laser cutter, air assist, and filtration unit. This may extinguish small flames by removing the ignition source. For persistent small flare-ups, a fire blanket or non-combustible material to smother flames is recommended before resorting to extinguishers.

The single most important fire prevention measure? Never leave an operating laser cutter unattended. Users must observe the cutting process continuously to detect problems before they escalate. This isn't optional—it's the foundation of safe laser cutting operations.

With proper safety infrastructure in place, laser steel cutting becomes a reliable, efficient process. The next consideration? How this technology integrates with downstream manufacturing operations, particularly in demanding automotive applications where precision and certification requirements intersect.

Automotive and Precision Manufacturing Applications

When a chassis component fails tolerance specifications by even a fraction of a millimeter, the entire assembly line grinds to a halt. When a suspension bracket doesn't fit precisely, vehicle safety becomes compromised. This is why automotive manufacturers have embraced laser steel cutting as the foundation for precision component production—and why understanding these applications matters whether you're sourcing parts or evaluating manufacturing partners.

The automotive industry demands what few other sectors require simultaneously: extreme precision, absolute repeatability, and production volumes that can reach millions of identical parts annually. Let's explore how laser cutting meets these demands across critical vehicle systems.

Automotive Component Applications

According to Hygrade Laser Profiling, laser cutting technology enables manufacturers to create highly intricate designs with minimal waste while delivering exceptional strength and durability in automotive components. The applications span virtually every vehicle system:

Chassis and Structural Components:

- Frame rails and crossmembers: The backbone of vehicle structure requiring precise fitment for crash safety

- Brackets and mounting plates: Custom-fabricated pieces that connect major assemblies with exact positioning

- Reinforcement panels: Strategic strengthening elements cut to integrate with body structures

- Subframes: Complex geometries that support powertrain and suspension systems

Suspension Components:

- Control arms: Precision-cut steel that maintains wheel alignment under dynamic loads

- Steering linkages: Components where dimensional accuracy directly affects vehicle handling

- Spring perches and mounting hardware: Load-bearing parts requiring consistent quality

Engine and Drivetrain Support:

- Motor mounts: Vibration-isolating brackets cut to exact specifications

- Transmission supports: Structural elements maintaining powertrain alignment

- Exhaust system components: According to industry sources, laser cutting enables efficient gas flow design and precise emissions control fitment

What makes sheet metal fabrication through laser cutting so critical for these applications? The answer lies in the tolerances automotive systems demand. According to HantenCNC's precision analysis, automotive applications require precision to ensure proper fit and function—often within ±0.025mm for critical components. Traditional cutting methods simply cannot deliver this level of accuracy consistently.

Precision Assembly Requirements

Imagine you're assembling a suspension system where every component must align perfectly for safe vehicle operation. Now multiply that by thousands of vehicles per day. This is the reality of automotive metal fab operations—and why laser cutting has become indispensable.

According to Zetwerk's B2B automotive fabrication guide, precision is the cornerstone of advanced laser cutting. Laser systems utilizing high-capacity sources produce cuts measured in millimeter fractions—accuracy that plays a significant role in upholding the rigorous standards of the automotive industry.

Tolerance-Critical Considerations:

- Hole positioning: Mounting holes must align across mating components; laser cutting achieves consistent placement within 0.1mm

- Edge straightness: Welded joints require predictable edge geometry for consistent penetration

- Repeatability: The thousandth part must match the first—CNC fabrication delivers this consistency automatically

- Minimal distortion: Heat-affected zones must remain small enough that subsequent forming operations proceed without issues

CNC metal processing through laser systems enables this precision because the cut path is programmed digitally, eliminating operator variability. The same parameters produce identical results shift after shift, making quality control predictable rather than reactive.

For operations searching for a metal fabricator near me or evaluating metal fab near me options, these precision capabilities should be top evaluation criteria. Not every shop maintains the equipment calibration and quality systems needed for automotive-grade tolerance requirements.

From Cut Part to Finished Assembly

Here's what separates truly integrated automotive suppliers from simple cutting operations: understanding that laser cutting is just one step in a multi-stage manufacturing process. The best results come when cutting parameters are optimized not just for the cut itself, but for everything that happens afterward.

Integration with Downstream Processes:

- Forming and bending: Laser-cut blanks must bend without cracking; this requires managing heat-affected zones and edge hardness during cutting

- Welding metal components: Edge preparation affects weld quality; nitrogen-cut edges on stainless steel enable immediate welding without cleaning

- Stamping operations: Laser-cut blanks often feed into progressive dies for final forming; dimensional accuracy ensures proper die alignment

- Surface finishing: Clean, oxide-free edges reduce preparation time before painting or plating

- Assembly fit-up: When every laser-cut component meets specification, assembly becomes predictable and efficient

According to Zetwerk's analysis, advanced laser cutting reduces setup time, eliminates secondary machining, and allows for complex cuts in a single operation—leading to lower production costs and shorter lead times. This integration capability is what makes laser cutting so valuable in cnc cutting operations serving automotive OEMs.

For automotive manufacturers requiring IATF 16949-certified quality, the integration between laser cutting and precision stamping becomes critical. Partners like Shaoyi (Ningbo) Metal Technology demonstrate how 5-day rapid prototyping combined with automated mass production delivers chassis, suspension, and structural components at automotive-grade quality standards.

Quality System Requirements:

Automotive applications demand more than precision equipment—they require documented quality systems that ensure consistency across production runs. Key certifications to look for include:

- IATF 16949: The automotive quality management standard that ensures systematic process control

- First-article inspection: Verification that initial production matches design intent

- Statistical process control: Ongoing monitoring that catches drift before it creates defects

- Traceability systems: Documentation linking finished parts to material lots and process parameters

When evaluating suppliers, comprehensive DFM (Design for Manufacturability) support indicates a partner who understands how laser cutting decisions affect downstream operations. Quick quote turnaround—12 hours or less for complex assemblies—signals responsive communication that prevents production delays.

The bottom line? Laser steel cutting enables automotive precision that simply wasn't achievable with previous technologies. But realizing that potential requires selecting partners who understand the complete manufacturing chain—from initial cut through final assembly and quality verification.

Whether you're manufacturing in-house or sourcing externally, the decision framework matters. How do you determine whether to invest in equipment versus partnering with specialists? Let's explore the factors that drive this critical choice.

Making the Right Choice for Your Steel Cutting Needs

You've explored the technology, understood the parameters, and learned how different steel types behave under the beam. Now comes the practical question that every manufacturing operation eventually faces: should you invest in a laser steel cutting machine, or partner with a service provider who already has the equipment and expertise?

This isn't a simple cost calculation. According to Iter Consulting's supply chain analysis, the make vs buy choice isn't just about price—it's about long-term margin protection, operational flexibility, and strategic control. In industries where milliseconds and microns matter, the wrong call on production responsibility can derail launches, inflate costs, and weaken resilience.

Let's break down the decision framework that helps you choose wisely—whether that means purchasing a steel laser cutting machine, outsourcing to fiber laser cutting services, or implementing a hybrid approach.

Buy vs Outsource Decision Framework

When evaluating whether to purchase a laser cutter for steel or contract with external providers, three core dimensions drive the analysis: cost, capability, and risk. Getting this decision right requires honest assessment across all three areas.

Volume Thresholds:

Production volume is often the first consideration—but the math isn't as straightforward as it appears. A steel laser cutting machine demands significant capital expenditure upfront, including investment in equipment, installation, training, and ongoing maintenance. However, once that investment is made, marginal cost per part drops significantly.

- Low volume (under 100 hours/year of cutting): Outsourcing typically wins; equipment sits idle too often to justify capital investment

- Medium volume (100-500 hours/year): Hybrid approach often optimal; outsource surge capacity while evaluating equipment purchase

- High volume (500+ hours/year): In-house equipment becomes economically compelling; payback periods shorten to 18-36 months

- Specialized or prototype work: Outsourcing provides access to diverse equipment without capital commitment

Capital Investment Considerations:

Beyond the sticker price of a cnc laser cutter for steel, total investment includes facility modifications, fume extraction systems, operator training, and working capital for consumables. When searching for a laser metal cutting machine for sale, factor these hidden costs into your analysis:

- Installation and facility preparation: typically 10-15% of equipment cost

- Safety enclosures and ventilation: $20,000-$100,000 depending on system size

- Operator training and certification: 2-4 weeks of reduced productivity during ramp-up

- Spare parts inventory and maintenance contracts: 3-5% of equipment cost annually

- Software licensing and programming capability: ongoing subscription costs

Technical Expertise Requirements:

Operating a steel laser cutting machine effectively requires more than pressing buttons. Skilled operators understand material behavior, parameter optimization, preventive maintenance, and quality inspection. According to Iter Consulting, capability without capacity is a false positive—any decision must assess whether internal operations are truly equipped to scale in qualified operators, QA oversight, and cross-functional support.

- Do you have—or can you hire—operators with laser cutting experience?

- Can your maintenance team troubleshoot CNC systems and optical components?

- Is your engineering team equipped to develop cutting programs and optimize parameters?

- Will management commitment ensure ongoing training and skill development?

Lead Time Factors:

Time-to-market often tips the balance. In-house steel laser cutting eliminates external dependencies and minimizes the impact of upstream disruption. However, outsourcing offers scalability for demand spikes without the lag time of equipment acquisition.

Evaluating Laser Cutting Service Providers

If outsourcing makes strategic sense for your operation, selecting the right partner becomes critical. Not all fiber laser cutting services deliver equal quality, and the wrong choice creates headaches that exceed any cost savings. According to Rache Corporation's certification guide, choosing a certified partner for laser cutting needs signifies a commitment to quality, precision, and adherence to industry standards.

Key Evaluation Criteria for Service Providers:

- Industry certifications: Look for AS9100 (aerospace), IATF 16949 (automotive), or ISO 9001 (general quality management) depending on your industry requirements

- Equipment capabilities: Verify they operate modern fiber laser systems capable of processing your material types and thicknesses

- Quality management systems: Ask about inspection protocols, statistical process control, and traceability documentation

- Turnaround times: Quality-focused manufacturers offer rapid quote response—12-hour turnaround indicates responsive communication infrastructure

- Prototyping speed: 5-day rapid prototyping capability signals agile operations that can support development cycles

- DFM support: Comprehensive Design for Manufacturability feedback indicates a partner who understands how cutting decisions affect downstream processes

- Security compliance: For defense or sensitive applications, ITAR registration and NIST 800-171 compliance may be mandatory

Questions to Ask Potential Partners:

- What is your on-time-in-full (OTIF) delivery performance over the past 12 months?

- Can you provide references from customers in my industry?

- How do you handle engineering change orders mid-production?

- What quality inspection occurs before parts ship?

- Do you maintain business continuity plans for equipment failures or supply disruptions?

For automotive applications requiring precision metal components, partners like Shaoyi (Ningbo) Metal Technology exemplify what to seek: IATF 16949 certification, 5-day rapid prototyping, 12-hour quote turnaround, and comprehensive DFM support. These capabilities indicate a supplier equipped for demanding production requirements where laser-cut components feed into subsequent stamping and assembly operations.

Optimizing Your Supply Chain Approach

The smartest manufacturers rarely commit entirely to one approach. Hybrid strategies leverage the strengths of both in-house capability and external partnerships, creating resilience that pure approaches cannot match.

Hybrid Strategy Options:

- Core in-house, surge external: Maintain a steel laser cutter for high-volume standard work; outsource overflow and specialty jobs

- Prototype external, production in-house: Use service providers for development flexibility; bring production runs internal once designs stabilize

- Specialty external, commodity in-house: Process routine work internally; leverage specialist capabilities for complex or certified requirements

- Geographic distribution: Maintain regional partners to reduce shipping costs and lead times for different customer locations

Risk Mitigation Through Diversification:

According to Iter Consulting, disruptions hit fast—pressure mounts and options narrow. Maintaining relationships with multiple service providers creates backup capacity when primary sources experience problems. Even operations with robust in-house capabilities benefit from qualified external partners who can absorb demand when equipment goes down for maintenance.

Key risk considerations include:

- What happens if your primary supplier faces a fire, cyberattack, or natural disaster?

- Do you have physical redundancy or contractual contingencies?

- Can your suppliers demonstrate formal Business Continuity Plans (BCPs)?

- Is there visibility into tier 2 and tier 3 suppliers who provide raw materials?

Making Your Decision:

The right choice depends on your specific circumstances—there's no universal answer. Start by assembling a cross-functional team including operations, finance, engineering, and procurement perspectives. Gather data on current costs, projected volumes, and capability gaps. Then evaluate against the cost-capability-risk framework:

- Cost: Are you truly comparing total lifecycle costs—not just price per unit?

- Capability: Can you—or your supplier—deliver reliably and to specification at required volumes?

- Risk: What could go wrong, and how would you recover?

Whether you invest in a laser steel cutting machine or partner with specialists, the goal remains constant: reliable production of precision steel components that meet your quality requirements at competitive costs. The framework above helps you navigate that decision with confidence—and the flexibility to adjust as your business evolves.

Frequently Asked Questions About Laser Steel Cutting

1. How much does it cost to get steel laser-cut?

Laser steel cutting costs vary based on material thickness, complexity, and volume. Most service providers charge $15-30 in setup costs plus per-part pricing. Operating costs average approximately $20/hour for laser systems compared to $15/hour for plasma. Factors affecting pricing include assist gas selection (nitrogen costs more than oxygen), edge quality requirements, and turnaround time. For high-volume automotive or precision manufacturing, partnering with IATF 16949-certified suppliers like Shaoyi Metal Technology can optimize costs through DFM support and efficient production processes.

2. What are the disadvantages of laser cutting steel?

Laser steel cutting has several limitations to consider. Material thickness constraints exist—fiber lasers work optimally up to 25mm, though high-power systems reach 100mm+. Initial equipment investment is substantial ($150,000-500,000+ for industrial systems). Power consumption is significant, and proper ventilation is mandatory due to toxic fumes, especially when cutting galvanized or coated steels. Heat-affected zones can alter material properties near cut edges, potentially affecting subsequent forming or welding operations. Additionally, highly reflective metals require fiber lasers rather than CO2 systems.

3. Is laser cutting easy to learn for steel applications?

Basic laser steel cutting operations can be learned relatively quickly—operators often achieve successful simple cuts within a day of focused training. However, mastering parameter optimization for different steel types, troubleshooting defects like dross and burr formation, and understanding the power-speed-thickness relationship requires months of experience. Modern CNC systems simplify programming, but achieving consistent, high-quality results across various materials demands understanding of assist gas selection, focus positioning, and material-specific behaviors. Many shops start with mild steel, the most forgiving material, before progressing to stainless or carbon steels.

4. What is the difference between fiber laser and CO2 laser for cutting steel?

Fiber lasers operate at 1.064μm wavelength while CO2 lasers use 10.6μm, fundamentally affecting steel absorption and cutting efficiency. Fiber lasers deliver 3-5x faster cutting speeds on thin materials, 50-70% lower operating costs, and 35-50% wall-plug efficiency versus just 10-15% for CO2. Fiber systems excel at thin-to-medium steel (up to 25mm) and reflective metals like aluminum. CO2 lasers retain advantages for very thick plate (25mm+) where edge quality requirements are paramount. Maintenance costs also differ significantly—$200-400 annually for fiber versus $1,000-2,000 for CO2 systems.

5. Should I buy a laser steel cutting machine or outsource to a service provider?

The decision depends on volume, capital availability, and technical expertise. For under 100 hours/year of cutting, outsourcing typically wins economically. High-volume operations (500+ hours/year) often justify equipment purchases with 18-36 month payback periods. Consider hidden costs beyond equipment price: installation (10-15% of equipment cost), ventilation systems ($20,000-100,000), operator training, and ongoing maintenance. When outsourcing, evaluate providers based on certifications (IATF 16949 for automotive), turnaround times, and DFM support. Hybrid approaches—maintaining core in-house capability while outsourcing surge or specialty work—often provide optimal flexibility.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —