Laserleikattujen teräslevyjen salaisuudet: 9 tekijää, jotka määrittävät projektisi onnistumisen

Mikä on laserlevyterä ja miksi se hallitsee nykyaikaista valmistusta

Kuvittele, että tarvitsisit monimutkaisen metallikappaleen, jonka terävät reunat, monimutkaiset kuviot ja mitatut sallittuisuudet ovat millimetrin murto-osissa. Miten saavutat tämän tason tarkkuutta? Vastaus on laserlevystä leikatussa teräksessä, joka on mullistanut metalliteollisuuden autoteollisuudesta ilmailutoimintaan.

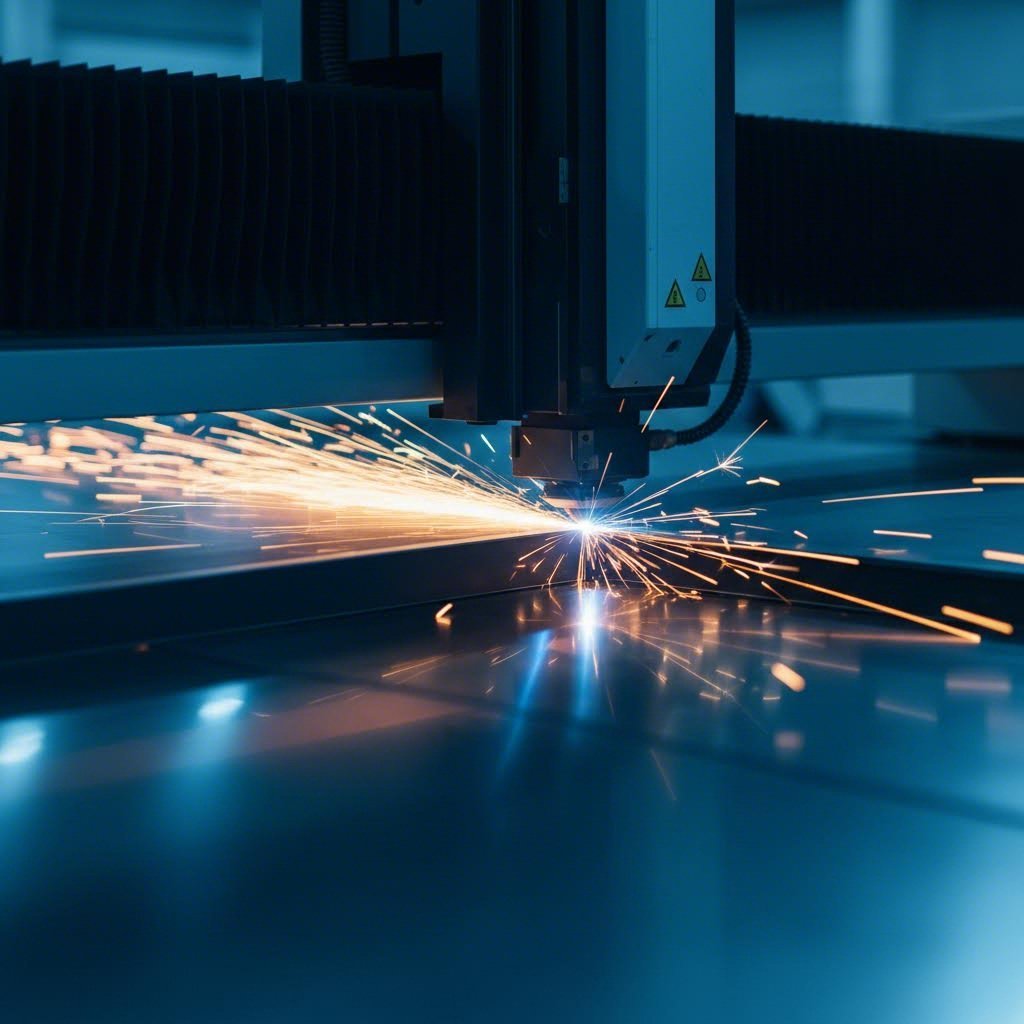

Laserlevyteräksen ytimessä tarkoitetaan prosessia, jossa käytetään erittäin keskittynyt lasersäde sulatettavaksi , polttaa tai höyrystää terästehoa tietokoneohjelmoitujen polkutien varrella. Tämä teknologia muuttaa litteän metallipäällysteen täsmällisesti muotoiltuiksi osiksi, jotka ovat poikkeuksellisen tarkkoja ja toistettavissa. Olipa kyseessä sitten ohutmateriaali tai paksumpi levy, laserleikkaus tuo johdonmukaisia tuloksia, joita perinteiset mekaaniset menetelmät eivät yksinkertaisesti pysty vastaamaan.

Laserleikkaustekniikan tiede

Kuinka tämä teknologia oikein toimii? Laserleikkuukone tuottaa voimakkaan valonsäteen, joka keskittää valtavan energiamäärän hyvin pieneen polttopisteeseen. Kun säde koskettaa teräslevyn pintaa, lämpötila voi ylittää tuhansia asteita, jolloin materiaali sulaa tai haihtuu välittömästi. Prosessi toimii kahdessa päätilassa: jatkuvassa leikkaustilassa, jossa tehdään pitkiä, keskeyttymiä leikkauksia, ja pulssileikkauksessa, jossa korkean energian säteitä toimitetaan lyhyissä puristuksissa tarkempaa työtä varten.

Siitä, miksi tämä prosessi on erityisen tehokas, vastaavat apukaasut. Happi, typpeä tai puristettua ilmaa virtaa leikkuupäähän lasersäteen kera. Näillä kaasuilla on useita tehtäviä – ne auttavat poistamaan sulanut aine leikkauksen alueelta, suojaavat linssiä roskilta ja vaikuttavat valmiin osan reunojen laatuun. Esimerkiksi typpeä käytetään estämään hapettuminen ruostumattomalle teräkselle saadaksi siistejä reunoja, kun taas happi nopeuttaa leikkausta eksotermisillä reaktioilla hiiliteräksessä.

Miksi tarkkuus on tärkeää levysteräksen valmistuksessa

Tässä kohtaa laserleikkaus erottuu selvästi perinteisistä menetelmistä: se on täysin koskematon prosessi. Mekaaninen leikkaus, jossa fyysinen metallileikkuri työntää materiaalia vasten, poikkeaa tässä siitä, että lasersäteellä ei ole massaa. Tämä poistaa useita ongelmia, jotka haittaavat perinteistä levymetallin valmistusta:

- Nollakulumainen työkalu —Leikkauksen laatu pysyy vakiona, koska terä ei tylsisty ajan myötä

- Ei materiaalin vääristymistä —Fyysistä kosketusta välttämällä herkät materiaalit pysyvät paikoillaan vetämättä tai muodonmuutoksia aiheuttamatta

- Monimutkaiset geometriat mahdollisia —Hienot yksityiskohdat ja monimutkaiset kaavat, jotka mekaanisilla menetelmillä olisivat mahdottomia, tulevat saavutettaviksi

- Johdonmukainen toisto —Tuhannes osa vastaa ensimmäistä täydellisellä tarkkuudella

Tämä koskematon luonne osoittautuu erityisen arvokkaaksi metallin työstösovelluksissa, joissa vaaditaan tiukkoja toleransseja. Kun valmistetaan komponentteja, joissa millimetrien murto-osat merkitsevät – kuten lääkintälaitteissa, elektronisten koteloiden tai autoteollisuuden osissa – laser-teknologia tarjoaa tarkan tarkkuuden, jota nykyaikainen tuotanto edellyttää.

Seuraavissa osioissa löydät yhdeksän keskeistä tekijää, jotka määrittävät onnistumisen laserleikkaushankkeissasi. Käymme läpi kaiken oikean teräsarvon valinnasta teknisten tietojen ymmärtämiseen sekä suunnitelmien optimointiin kustannustehokkuuden kannalta ja sopivan valmistajan valintaan. Lopulta sinulla on kattava suunnitelma ammattimaisiin tuloksiin teräksen leikkaushankkeissasi.

Teräsarvojen valintaguide laserleikkaussovelluksiin

Sinulla on täydellinen suunnitelma valmiina leikkausta varten. Mutta tässä kysymys, jota useimmat valmistajat eivät harkitse ennen kuin ongelmia ilmenee: onko teräsesi todella sopiva laserprosessointiin ? Valitsemasi materiaali voi merkitä eron virheettömien leikkauksien ja hankalasti korjattavien vikojen välillä, jotka voivat vaarantaa koko projektisi.

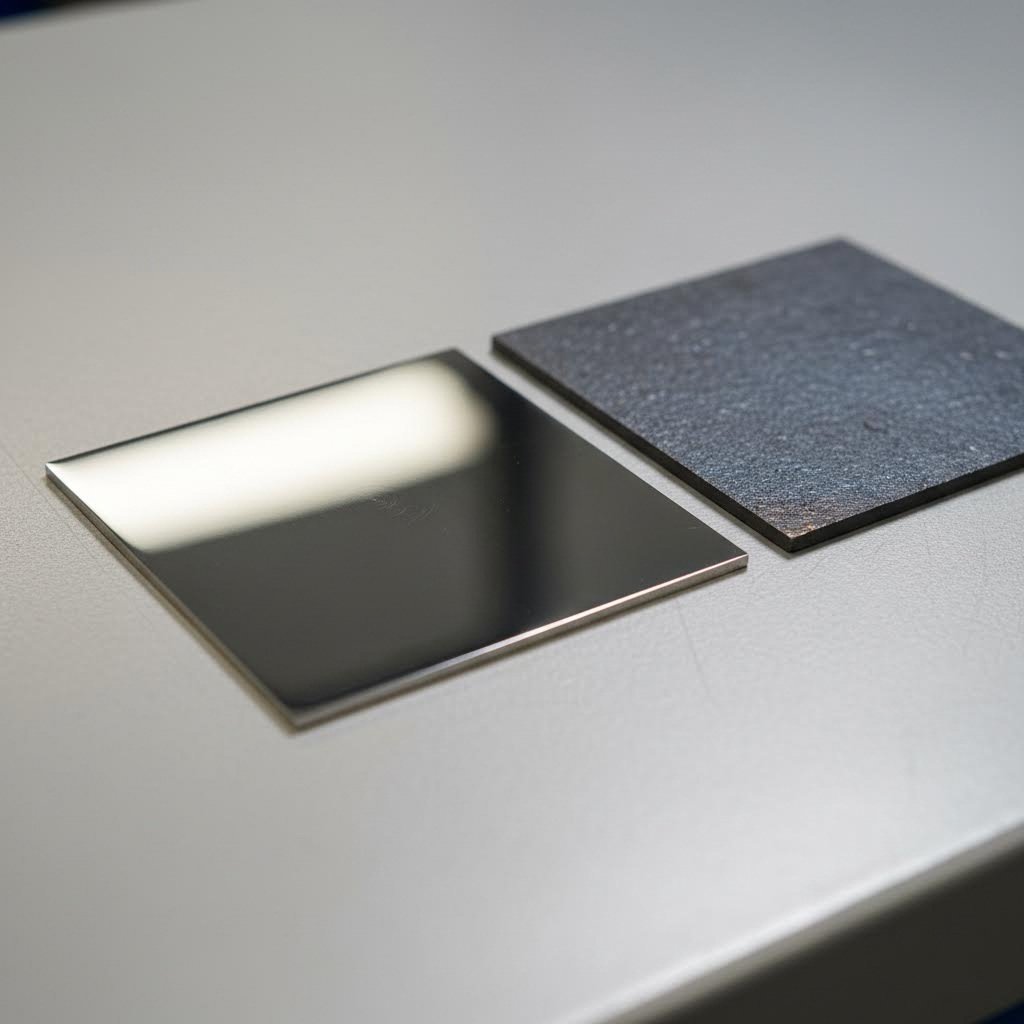

Kaikki teräs ei ole samanlaista laserleikkausta ajatellen. Standarditeräksen ja "laserlaatuisen" teräksen välisen kriittisen eron ymmärtäminen – sekä oikean luokan valitseminen sovellukseesi – muodostaa onnistuneen valmistuksen perustan. Katsotaan tarkemmin, mitä todella merkitsee, kun valitaan ruostumatonta teräslevyä tai hiiliteräslevyä.

Laserlaatuisen teräksen vaatimusten ymmärtäminen

Mikä tekee teräksestä oikein "laserlaatuisen"? Steel Warehousein mukaan määrittävä piirre on aivan "pöytätasainen" materiaali, josta puuttuu täysin kelamuistiliike. Kun terästä puretaan kelasta, siihen jää luonnollisesti kaarevuutta, mikä voi aiheuttaa merkittäviä ongelmia laserprosessoinnin aikana.

Laserlaatuiselle teräkselle tehdään erityiskohtainen käsittely näiden ongelmien poistamiseksi. Materiaali kulkee läpi tempeerireunan, litteytyslaitteen, tasauslaitteen ja jatkuvan pyörivän leikkuuterän – yhteisnimityksellä tempeerikäyttö leikkauslinjassa. Tämä käsittely tuo neljä keskeistä etua:

- Erinomainen litteys —Eliminoi vääntymät, jotka aiheuttavat keskitysvirheitä leikatessa

- Kelamuistin eliminointi —Estää materiaalin liikkumisen leikkuupöydällä, mikä johtaa mitallisiiin virheisiin

- Parannettu pinta-laatu —Vähentää kalkkikerrosta ja virheitä, jotka häiritsevät säteen absorptiota

- Tiukat Sallitut Poikkeamat —Takaa tasaisen paksuuden koko levyn alueella ennustettavien tulosten saavuttamiseksi

Miksi nämä tekijät ovat niin tärkeitä? Laserkeila keskittyy erittäin pieneksi pisteksi, ja jopa pienetkin materiaalin korkeusvaihtelut vaikuttavat leikkuulaadun. Jos teräslevy kaareutuu edes hieman, osa alueista jää huonosti tarkennetuksi, mikä johtaa epätasaiseen leikkauslevyyn, karkeisiin reunaan tai keskeneräisiin leikkauksiin. Puhdas, kalkkikerrokseton pinta myös absorboi laserenergiaa tasaisemmin verrattuna ruosteiseen tai hapettuneeseen materiaaliin.

Vertailtaessa ruostumattoman teräksen hintoja tai arvioitaessa hiiliteräsvaihtoehtoja, kannattaa muistaa, että laserleikattava laatu saattaa maksaa hieman enemmän alussa. Kuitenkin jätteen, uudelleen työstön ja koneiden seisokkien vähentyminen tuo merkittäviä kustannussäästöjä kaikilla suuremmilla projekteilla. Samoin, vaikka sinkityllä teräksellä ja alumiinilevyillä on omat käyttökohteensa, ne vaativat tiettyjä parametrien säätöjä – materiaalin ominaisuuksien ymmärtäminen ennen leikkausta estää kalliit virheet.

Teräsluokan valinta optimaalisten leikkautulosten saavuttamiseksi

Materiaalin laadun lisäksi oikean teräsluokan valinta määrittää sekä leikkausominaisuudet että lopullisen osan toiminnallisuuden. Kolme yleisintä vaihtoehtoa laserleikattuihin komponentteihin – 304 ruostumaton, 316 ruostumaton ja hiiliteräs – tarjoavat kukin omat etunsa.

304 roosteton teräs: Edustaa noin puolta maailmanlaajuisesta ruostumattoman teräksen tuotannosta, 304 erottymätön leppämetalli sisältää 18 % kromia ja 8 % nikkeliä. Tämä koostumus tarjoaa erinomaisen korroosionkestävyyden useimmissa ympäristöissä ja tuottaa puhtaat sekä tasaiset leikkaustulokset oikeilla leikkausparametreilla. Sen alttius suolapitoisille ympäristöille – joissa suolaltumisen aiheuttamaa kuoppakorroosiota tai rakokorroosiota voi esiintyä – rajoittaa kuitenkin sen käyttöä merikäytöissä.

316 roosteametaali: 2–3 %:n molybdeenilisäys erottaa 316 -ruostumatonta terästä 304 -vastaavasta. Tämä parannettu koostumus tarjoaa huomattavasti paremman kestävyyden klorideja ja suolaisia ympäristöjä vastaan, mikä tekee siitä suositun valinnan merikäyttöön, kemikaaliteollisuuteen sekä kirurgisiin instrumentteihin. Vaikka 316 -ruostumaton teräs on kalliimpaa kuin 304, sijoitus kannattaa vaativissa korroosioalttiissa ympäristöissä.

Hiiliteräs (A36/A572): Sovelluksissa, joissa korroosion kestävyys ei ole kriittistä, hiiliteräslaatut kuten A36 ja A572 tarjoavat erinomaisen laserleikkauskäyttäytymisen alhaisemmissa materiaalikustannuksissa. Nämä laatut reagoivat ennustettavasti lämpöleikkausprosesseihin ja tuottavat puhdasta leikkausreunaa vähän roskia käyttäessä happiavustekaasua.

| Arvosana | Parhaat käyttösovellukset | Laserleikkausominaisuudet | Tyyppinen paksuusalue |

|---|---|---|---|

| 304 rostiton | Elintarvikkeiden käsittelylaitteet, arkkitehtuuri, yleinen teollisuus | Erinomainen—johdonmukaiset leikkaukset, käytä typpeä hapettomien reunojen saamiseksi | 0,5 mm – 20 mm |

| 316 ruostumaton | Meritekniikka, kemiallinen käsittely, lääkinnälliset laitteet | Erinomainen—vastaava kuin 304, lievästi korkeampaa tehoa saattaa tarvita | 0,5 mm – 20 mm |

| Hiiliteräs (A36) | Rakenteelliset komponentit, kiinnikkeet, yleisvalmistus | Hyvä—nopea leikkaus hapesta, tarkkaile reunaoksidoitumista | 0,5 mm – 25 mm tai enemmän |

| Hiiliteräkset (A572) | Korkean lujuuden rakennemuodot | Hyvä—saumakäytön optimoimiseksi saattaa vaatia parametrien säätöjä | 3 mm – 25 mm tai enemmän |

Arvioitaessa teräslevyvaihtoehtoja tulee muistaa, että pinnan kunto vaikuttaa merkittävästi tuloksiin. Kuten KGS Steel huomauttaa , puhtaat, levymäiset hiiliteräslaatat tuottavat yleensä parempia tuloksia verrattuna ruosteisiin tai levymäisiin pinnoitteisiin. Austeniittiset ruostumattomat teräkset, kuten 304 ja 316, reagoivat erinomaisesti laserleikkaukseen niiden tasaisen koostumuksen ja lämpöominaisuuksien ansiosta – niiden alhaisempi lämmönjohtavuus mahdollistaa jopa puhtaammat leikkaukset vähentäen lämpövaikutusvyöhykettä.

Oikea materiaalivalinta määrittää kaiken sen jälkeen seuraavan. Kun käytössä on laadukas laserileikattava teräs oikeassa laadussa, menestys on mahdollista. Seuraavaksi tarkastellaan teknisiä määrityksiä, jotka määrittelevät, mitä valitulla materiaalilla voidaan todella saavuttaa.

Tekniset tiedot ja tarkkuusominaisuudet selitettyinä

Olet valinnut oikean teräslaatun ja vahvistanut, että se on laatuinen materiaali laserleikkausta varten. Nyt nousee kysymys, jolla on suora vaikutus projektisi onnistumiseen: mitä voit todella saavuttaa laserleikkaustekniikalla ? Teknisten tarkkojen mittausten ymmärtäminen – leikkauslevynevydestä toleranssikykyyn – muuttaa sinut tilaajasta henkilöksi, joka suunnittelee optimaalisia tuloksia varten.

Nämä tekniset tiedot eivät ole vain lukemia tietolomakkeella. Ne määrittävät, sopivatko osasi yhteen, kuinka paljon materiaalia kuluu ja millaisen yksityiskohtaisuuden suunnitelmissasi voi saavuttaa. Tarkastellaan keskeisiä parametreja, jotka määrittelevät laserleikatun levyteräksen suorituskyvyn.

Leikkauslevynevyys ja materiaalihäviön laskeminen

Jokainen leikkaus poistaa materiaalia. Tätä poistettua materiaalia – nimeltään leikkausraja – edustaa aukko, jonka laserkeila muodostaa höyrystäessään terästä liikeradallaan. Leikkausrajan leveyden ymmärtäminen on olennaista osien tarkan sovittamisen varmistamiseksi sekä todellisten materiaalikustannusten laskemiseksi.

Xometryn levynleikkaus suunnitteluoppaan mukaan tyypillinen leikkauslevyksen paksuus laserleikkauksessa vaihtelee 0,2 mm:stä 0,4 mm:iin. Tämä on huomattavasti kapeampaa kuin vaihtoehtoisilla leikkausmenetelmillä — vesileikkuu tuottaa leikkauslevyksiä 1–1,2 mm ja plasmaleikkaus alkaa noin 3,8 mm:stä tai leveämmistä. Tämä kapea leikkauslevys johtaa suoraan materiaalisäästöihin ja tiiviimpään asetteluun levytasossa.

Miksi leikkauslevyksen leveys vaihtelee? Useita tekijöitä vaikuttaa leikkauksissa syntyvän raon todelliseen leveyteen:

- Materiaalin paksuus —Paksuimmista materiaaleista syntyy yleensä leveämpi leikkauslevys, koska säde hajaantuu leikkaussyvyyden läpi

- Laserin tehoasetukset —Korkeampi teho voi laajentaa lämpövaikutuksen aluetta, mikä lisää leikkauslevystä

- Leikkausnopeus —Hidastuminen mahdollistaa enemmän lämmön siirtymistä, mikä voi potentiaalisesti laajentaa leikkausta

- Apukaasun valinta —Happi luo eksotermisiä reaktioita, jotka voivat laajentaa leikkauslevystä verrattuna typpeen

Suunniteltaessa toisiinsa liittyviä osia, kuten nippuja, jotka asetetaan vastaaviin aukkoihin, on kompensoitava leikkauslevyn paksuus. Xometryn oppaassa suositellaan lisättäväksi puolet leikkauslevyn leveydestä sisäosiin ja vähennettäväksi puolet leikkauslevyn leveydestä ulko-osiin. Tyypilliselle 0,3 mm leikkauslevylle tämä tarkoittaa noin 0,15 mm säätöä kummallakin liitospinnalla. Levymetallikalibrointikaavion tarkastelu yhdessä leikkauslevytietojen kanssa auttaa ennakoimaan, miten nämä tekijät vaikuttavat eri kalibrointikokoihin.

Reunalaadun odotukset teräksen paksuuden mukaan

Reunalaatu vaihtelee merkittävästi materiaalin paksuuden mukaan, ja näiden odotusten ymmärtäminen auttaa määrittämään soveltuvat toleranssit käyttötarkoitukseen. Ohuet materiaalit tuottavat yleensä puhtaampia reunoja vähäisillä jälkikäsittelyvaatimuksilla, kun taas paksujen osien reunat voivat näyttää näkyviä kerroksia tai vaativat toissijaisen viimeistelyn.

Materiaaleille, joiden paksuus on alle 3 mm, kuitulaserleikkaus saavuttaa yleensä erittäin puhtaat leikkausreunat vähäisellä viistolla. Mukaan lukien Stephens Gaskets , tarkkuusarvot ±0,05 mm:een saavutetaan alle 3 mm paksuisilla metallilevyillä kuitulaserjärjestelmillä. Tämä tarkkuus tekee ohuista materiaaleista ideaalin tiukkoihin liitoksiin ja esteettisiin pinnoitteisiin.

Paksuuden kasvaessa reunalaadun huomioonottaminen muuttuu monimutkaisemmaksi. Kun leikataan 14 gauge -teräspaksuutta (noin 1,9 mm) tai 11 gauge -teräspaksuutta (noin 3 mm), voidaan silti odottaa erinomaista reunalaatua oikeilla leikkausparametreilla. Kuitenkin paksuimmilla materiaaleilla lämpövaikutusalue laajenee, mikä voi vaikuttaa reunan kovuuteen ja mahdollisesti vaikuttaa seuraaviin prosesseihin, kuten taivutukseen tai hitsaukseen.

Standardit toleranssivälit perustuvat alan määräyksiin ja sisältävät:

| Materiaali | Paksuusalue | Tavallinen tarkkuus |

|---|---|---|

| Mieto teräs | 0,5–10 mm | ±0,1–±0,25 mm |

| Ruostumaton teräs | 0.5-8mm | ±0,1 – ±0,2 mm |

| Alumiini | 0,5-6 mm | ±0,15 – ±0,25 mm |

Paksuimmat materiaalit aiheuttavat lisähaasteita säteen hajaantumisen ja loven vuoksi. Kuten Xometryn oppaassa todetaan, paksuilla materiaaleilla voi olla tarkkuuspoikkeama alapinnalla, koska laserleikkaus aiheuttaa luonnostaan loven muotoisen leikkauksen. Kun mitoituksen tarkkuus on kriittistä molemmilla pinnoilla, piirustuksessa tulisi määritellä, mikä pinta on "yläpinta", jotta saavutetaan paras mahdollinen tarkkuus siinä kohdassa, missä se on tärkeintä.

Laserin teholuokitus ja leikkauskyvyt

Mitä laserin teholuokat itse asiassa tarkoittavat projekteissasi? ACCURLin teknisessä oppaassa ilmoitetaan, että laserleikkausteho – mitattuna wateina – määrittää suoraan leikkausnopeuden, suurimman käsiteltävissä olevan materiaalipaksuuden ja leikkauksen reunojen laadun. Korkeampi teho mahdollistaa nopeammat leikkausnopeudet ja kyvyn prosessoida paksumpia materiaaleja, kun taas alhaisemmat tehot tarjoavat paremman hallinnan hienoille yksityiskohdille ohuissa materiaaleissa.

Tehon ja materiaalin kyvyn välinen suhde vaihtelee terästyyppien mukaan. Pehmeälle teräkselle suositellut tehontasot nousevat paksuuden mukana:

- 1–3 mm pehmeä teräs —1 000–2 000 watin teho yleensä riittävä

- 6–10 mm hiiliterästä —Suositellaan 3 000–6 000 watin tehoa

- 12 mm tai suurempi hiiliteräs —Tehokkaammat järjestelmät (yli 6 000 wattiä) vaaditaan tehokasta leikkausta varten

Rustoitumaton teräs vaatii samankaltaista tai hieman korkeampaa tehotasoa sen alhaisemman lämmönjohtavuuden vuoksi. Materiaalit, joilla on korkea vetolujuus, saattavat myös edellyttää parametrien säätöjä leikkausreunan laadun ylläpitämiseksi koko leikkauksen ajan. Oleellinen huomio? Korkeamman tehon koneet tarjoavat suurempaa monikäyttöisyyttä eri materiaalipaksuuksien kesken, mutta oikean tehontason valinta tietyn materiaalin ja paksuuden mukaan optimoi sekä nopeuden että laadun.

Raakatehon lisäksi säteen laatu vaikuttaa merkittävästi leikkaustehoon. ACCURL-oppaan mukaan säteen laatu, jota kuvaa M²-kerroin, määrittää kuinka tehokkaasti laser keskittää energiaa. Alhaisempi M²-arvo osoittaa korkealaatuisempaa sädeä, joka pystyy tuottamaan puhtaampia ja tarkempia leikkauksia pienemmällä lämpövaikutuksen alueella.

Kriittiset suunnitteluparametrit projekteihisi

Laserilla leikattavia levyteräsuunitteluja tehdessä nämä keskeiset tekniset parametrit määrittävät, mitä voidaan valmistaa. Näiden teollisuusstandardien ohjeiden noudattaminen varmistaa, että osat leikataan onnistuneesti jo ensimmäisellä kerralla:

- Pienin ominaisuuksien koko —Yksityiskohdat tulisi olla vähintään 50 % materiaalin paksuudesta tai suurempia saavuttaaksesi siistejä leikkauksia

- Pienin reiän halkaisija —Reiät tulisi olla yhtä suuria tai suurempia kuin materiaalin paksuus; pienemmät reiät voivat johtua epätäydelliseen läpäisyyn tai vääristymiseen

- Reiän ja reunan välinen etäisyys —Pitäkää vähintään 2× materiaalin paksuus tai 3 mm minimietäisyyttä, kumpi on pienempi

- Reiän etäisyys toiseen reikään —Vähintään 6× materiaalin paksuus tai 3 mm, kumpi on pienempi

- Suositellut kulmien kaarevuudet —Vähimmäiskaarevuussäde 0,5× materiaalin paksuus tai 3 mm, kumpi on pienempi

- Pienin rakon leveys —1 mm tai 1× materiaalin paksuus, kumpi on suurempi

- Pienin mahdollinen liitoslevyn paksuus —1,6 mm tai 1× materiaalin paksuus, kumpi on suurempi

Nämä parametrit pätevät useimmissa laserleikkaustoiminnoissa, vaikka tietynlaiset laitteet ja materiaaliyhdistelmät saattavat sallia tiukempia määrityksiä. Kun suunnittelu koskettaa näitä rajoja, valmistajan kanssa varhainen neuvottelu estää myöhempinä kalliit uudelleenmuokkaukset.

Näiden teknisten tietojen ymmärtäminen mahdollistaa tehokkaasti valmistettavien osien suunnittelun. Mutta miten laserleikkaus suhtautuu vaihtoehtoihin, kuten plasmapuristukseen tai vesileikkaukseen, jotka voisivat soveltua hankkeeseesi? Seuraava osio selvittää tarkalleen, milloin kukin menetelmä loistaa – ja milloin laserleikkaus säilyy selvänä voittajana.

Laserleikkaus verrattuna vaihtoehtoisiin menetelmiin levystä valmistettaessa

Sinulla on siis edessä teräksen leikkausprojekti. Tiedät, että laserleikkausteknologia tarjoaa erinomaisen tarkkuuden, mutta onko se aina paras vaihtoehto? Tässä totuus: plasmaleikkaus, vesileikkaus ja mekaaninen leikkaus sopivat kukin omiin käyttötarkoituksiinsa metallin työstössä. Avainasemassa on ymmärtää tarkalleen, milloin kunkin menetelmän käyttö on perusteltua – ja milloin teräslevyjen laserleikkaus säilyy optimaalisena ratkaisuna.

Väärän leikkausmenetelmän valitseminen voi maksaa tuhansia hukkaan menneinä materiaaleina, pidentyneinä toimitusaikoina tai osina, jotka eivät yksinkertaisesti täytä vaatimuksia. Käydään läpi käytännön eroja, jotta voit tehdä varmoja päätöksiä projektisi erityisvaatimusten mukaisesti.

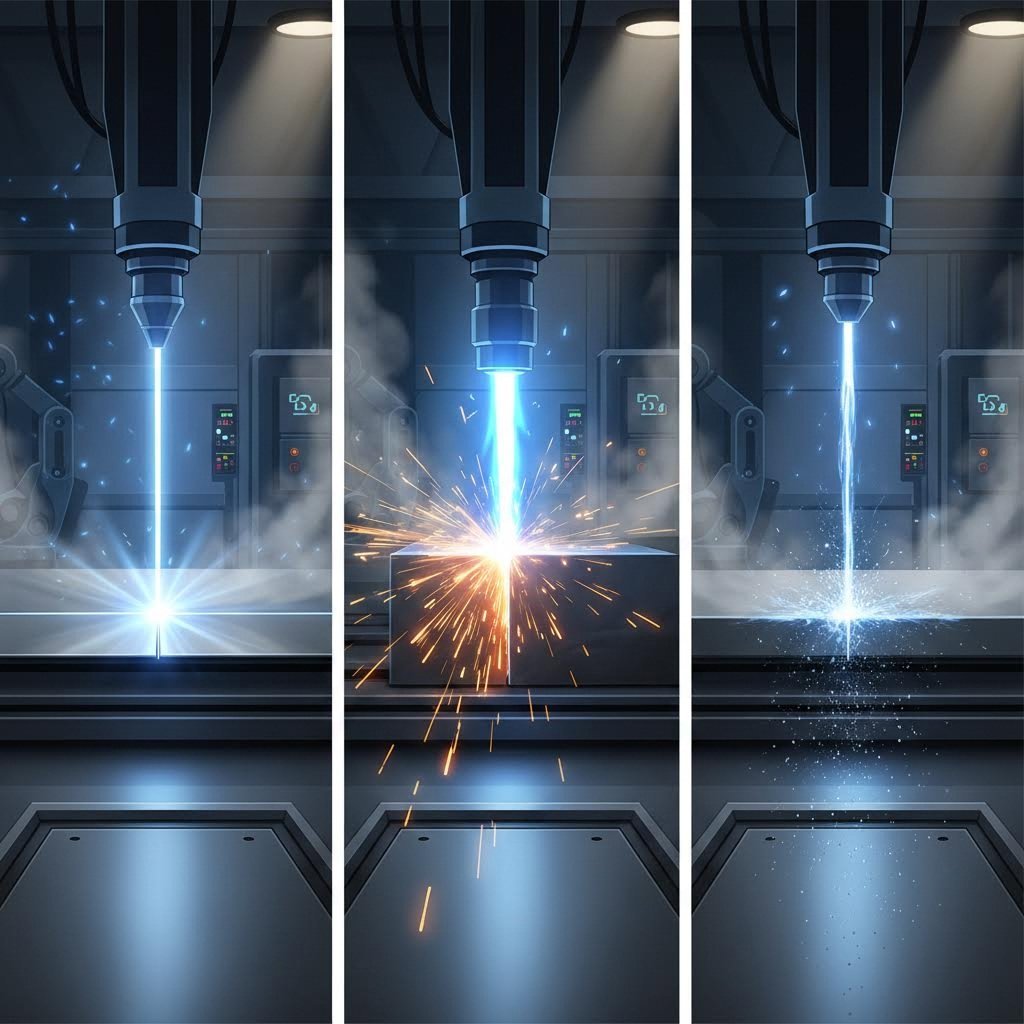

Laser- ja plasmaleikkaus teräsprojekteissa

Sekä laser- että plasmaleikkaus käyttävät lämpöenergiaa teräksen leikkaamiseen, mutta samankaltaisuudet päättyvät suurimmaksi osaksi siihen. Mukaan lukien StarLab CNC:n vuoden 2025 valmistusopas , näiden erojen ymmärtäminen auttaa sinua sovittamaan teknologian käyttötarkoitukseen.

Kuinka ne toimivat: Kuitulaserileikkauskone keskittää valoenergian polttopisteeseen, jossa lämpötila nousee erittäin korkeaksi, kun taas plasmaleikkaus kiihdyttää ionisoitunutta kaasua noin 45 000 °F:n lämpötilassa. Molemmat sulattavat ja poistavat materiaalia, mutta tarkkuustasot eroavat huomattavasti.

Milloin plasmaleikkaus on järkevä vaihtoehto? Jos käsittelet suurissa määrissä paksua rakenneterästä, jonka paksuus on 1/2"–2", plasmaleikkaus tarjoaa vertaansa vaillaamatonta leikkausnopeutta. Tehokas plasmajärjestelmä voi leikata 1/2":n terästä yli 100 tuumaa minuutissa — merkittävästi nopeammin kuin laser paksuilla materiaaleilla. Rakenneterästen valmistuksessa, laivanrakennuksessa tai raskaiden koneiden valmistuksessa, joissa reunojen viimeistely ei ole kriittistä, plasma tarjoaa houkuttelevat taloudelliset edut.

Leikkuulaser hoitaa kuitenkin tehtävänsä selvästi paremmin, kun tarkkuus on tärkeää. Ota huomioon seuraavat metallileikkuulaserin avainedut:

- Reunan laatu — Laser tuottaa reunat, jotka eivät juuri vaadi toissijaista viimeistelyä, ja toleranssit voivat saavuttaa arvon ±0,05 mm ohuilla materiaaleilla

- Monimutkaiset geometriat —Hienot yksityiskohdat, pienet reiät ja monimutkaiset kuviot, joita plasmaleikkaus ei yksinkertaisesti pysty saavuttamaan

- Vähäinen lämmön vaikutuksesta syntyvä vyöhyke —Vähäisempi lämpövääristymä tarkoittaa tarkempaa mittojen tarkkuutta

- Materiaalin monipuolisuutta —Vaikka plasmaleikkaus leikkaa vain sähköä johtavia metalleja, laser voi käsitellä erilaisia materiaaleja, mukaan lukien heijastavia metalleja, kun käytössä on sopiva varustus

Yhteenveto? Tarkkojen leikkauksien tarpeessa ohuessa, alle 1/4" paksuisessa levyteräksessä metallinleikkauslaser tuottaa parempia tuloksia. Paksussa levyssä, jossa nopeus on tärkeämpää kuin yksityiskohdat, plasmalla on silti paikkansa.

Milloin vesileikkaus toimii paremmin kuin laser-teknologia

Vesileikkaus käyttää täysin erilaista menetelmää – paineistettua vettä, johon sekoitetaan kovia hiukkasia, ja joka kuluttaa materiaalia jopa 90 000 PSI:n paineella. Tämä kylmäleikkausprosessi tarjoaa ainutlaatuisia etuja, jotka tekevät siitä joskus paremman vaihtoehdon.

Mukaan lukien AAA Metalsin leikkausopas , vesileikkaus poistaa kokonaan lämmön. Ei lämpöenergiaa tarkoita nollan lämpövaikutusvyöhykettä, mikä säilyttää materiaalin ominaisuudet leikkauksen ajan. Tämä on erityisen merkittävää, kun käsitellään lämpöherkkiä seoksia tai kun tarkkojen metallurgisten ominaisuuksien ylläpitäminen on välttämätöntä.

Vesileikkaus selviytyy myös paksuudesta, joka haastaa laserleikkausteknologiaa. Vaikka laserleikkaus vaikeutuu materiaaleissa, jotka ovat yli 1 tuuman paksuisia, vesileikkausjärjestelmät voivat prosessoida levyjä jopa 6 tuuman paksuudella tasaisella laadulla. Erityisen paksujen teräslevyjen sovelluksissa vesileikkaus saattaa olla ainoa tarkkuusvaihtoehto.

Kuitenkin vesileikkauksessa on merkittäviä haittoja:

- Nopeusrajoitukset —Leikkausnopeudet 5–20 tuumaa minuutissa tekevät siitä hitaimman lämpöleikkausvaihtoehdon

- Korkeammat käyttökustannukset —Abrasiivin kulutus, veden käsittely ja huolto lisäävät huomattavasti kustannuksia per tuuma

- Vähemmän tarkka monimutkaisissa yksityiskohdissa —Leikkauslevyn leveys 1 mm – 1,2 mm rajoittaa hienojen piirteiden toteuttamista verrattuna laserin 0,2–0,4 mm leikkauslevyyn

- Epäsiisti toiminta —Vesi ja abrasiviliemi edellyttävät enemmän siivousta ja jätteiden käsittelyä

Valitse vesileikkaus, kun haluat säilyttää materiaalin ominaisuudet paksuissa osissa tai leikatessa lämpöherkkiä erikoisalloweja. Tyypillisissä levyteräsohjelmissa laserleikkuukone metalliin on edelleen käytännöllisempi ja taloudellisempi.

Täydellinen menetelmävertailu

Arvioitaessa vaihtoehtojasi tämä kattava vertailu auttaa yhdistämään leikkuuteknologian tarkasti oman tarpeesi mukaan:

| Menetelmä | Paras teräksen paksuusalue | Reunan laatu | Nopeus | Kustannustekijä | Ihanteelliset sovellukset |

|---|---|---|---|---|---|

| Kuitu laser | 0,5 mm – 25 mm (optimaalinen alle 12 mm) | Erinomainen – vähäinen reunanmuodostus, tiukat toleranssit | Erittäin nopea ohuissa materiaaleissa, hidastuu paksuissa | Korkeammat laitteistokustannukset, alhaisemmat käyttökustannukset | Tarkat osat, monimutkaiset suunnitelmat, ohut keskiverto levy |

| Plasma | 0,5 mm – 50 mm (optimaalinen 6 mm – 25 mm) | Hyvä—saattaa vaatia toissijaisen viimeistelyn | Nopein keskikokoisilla ja paksuilla materiaaleilla | Alhaisempi laitteiston hinta, kohtalainen käyttökustannus | Rakenneteräs, raskas levy, suuritehoinen tuotanto |

| Vesileikkaus | Mikä tahansa paksuus jopa 150 mm asti | Hyvä—sileä mutta leveä leikkaus | Hidas leikkausmenetelmä | Kohtalainen laitteistokustannus, korkeimmat käyttökustannukset | Paksut materiaalit, lämpöherkät seokset, erikoismetallit |

| Mekaaninen (leikkaus/vesuri) | Vaihtelee laitteiston mukaan | Muuttuva—riippuu työkalujen kunnosta | Nopea yksinkertaisiin leikkauksiin | Alhaisimmat laitekustannukset | Suorat leikkaukset, perusmuodot, suuret erät |

Oikean päätöksen tekeminen projektiasi varten

Milloin sinun tulisi ehdottomasti valita laserleikkaus? Valitse kuitulaserleikkuukone, kun projektissasi:

- Materiaalin paksuus on alle 12 mm teräksessä (nopeuden ja laadun kannalta optimaalinen alue)

- Suunnittelu sisältää monimutkaisia kuvioita, pieniä reikiä tai hienoja yksityiskohtia

- Vaaditaan tiukat toleranssit (±0,1 mm tai parempi)

- Reunalaadulla on merkitystä ulkonäön tai sovituksen kannalta

- Käsittelet sekoitettuja materiaaleja, mukaan lukien ruostumatonta terästä, hiiliterästä tai alumiinia

- Prototyyppimääriä tarvitaan nopealla kierrosajalla ilman työkaluinvestointia

Harkitse vaihtoehtoja, kun:

- Levyn paksuus ylittää johdonmukaisesti 25 mm (plasmaleikkaus tai vesileikkuu)

- Nopeus paksussa materiaalissa painaa enemmän kuin reunatarkkuus (plasma)

- Materiaalin ominaisuuksien on pysyttävä täysin lämmöstä vaikutumattomina (vesileikkuu)

- Yksinkertaiset suorat leikkaukset suurilla määrillä oikeuttavat erillisen leikkuulaitteiston käyttöön

Kuten Happipalveluyrityksen huomautukset , "on mahdotonta nimetä voittajaa—sinun on arvioitava valmistustarpeesi ja budjettisi, jotta voit päättää, mikä vaihtoehto sinulle sopii parhaiten." Oikea valinta riippuu täysin materiaalista, paksuudesta, tarkkuusvaatimuksista, määrästä ja budjettirajoitteistasi.

Useimmissa levyterässovelluksissa, joissa tarvitaan tarkkuutta ja monipuolisuutta, laserleikkaus tarjoaa optimaalisen tasapainon laadun, nopeuden ja kustannustehokkuuden välillä. Nyt kun tiedät milloin valita laser-teknologia, tutkitaan miten osat tulisi suunnitella parhaan mahdollisen lopputuloksen saamiseksi.

Laserleikattujen teräsosien suunnittelunäkökohdat

Olet valinnut oikean materiaalin ja ymmärrät tekniset ominaisuudet. Mutta tässä kohdassa monet hankkeet epäonnistuvat: itse suunnittelu. Vaikka käytössä olisi huippulaatuista laserlaatuista terästä ja uusinta aikakauden laitteistoa, huonosti suunniteltu osa voi johtaa vääriin reunaan, leikkauksen epäonnistumiseen tai budjetin räjähtämiseen materiaalihukkaan. Hyvä uutinen? Muutama selkeä suunnitteluperiaate voi merkittävästi parantaa sekä laatua että kustannustehokkuutta.

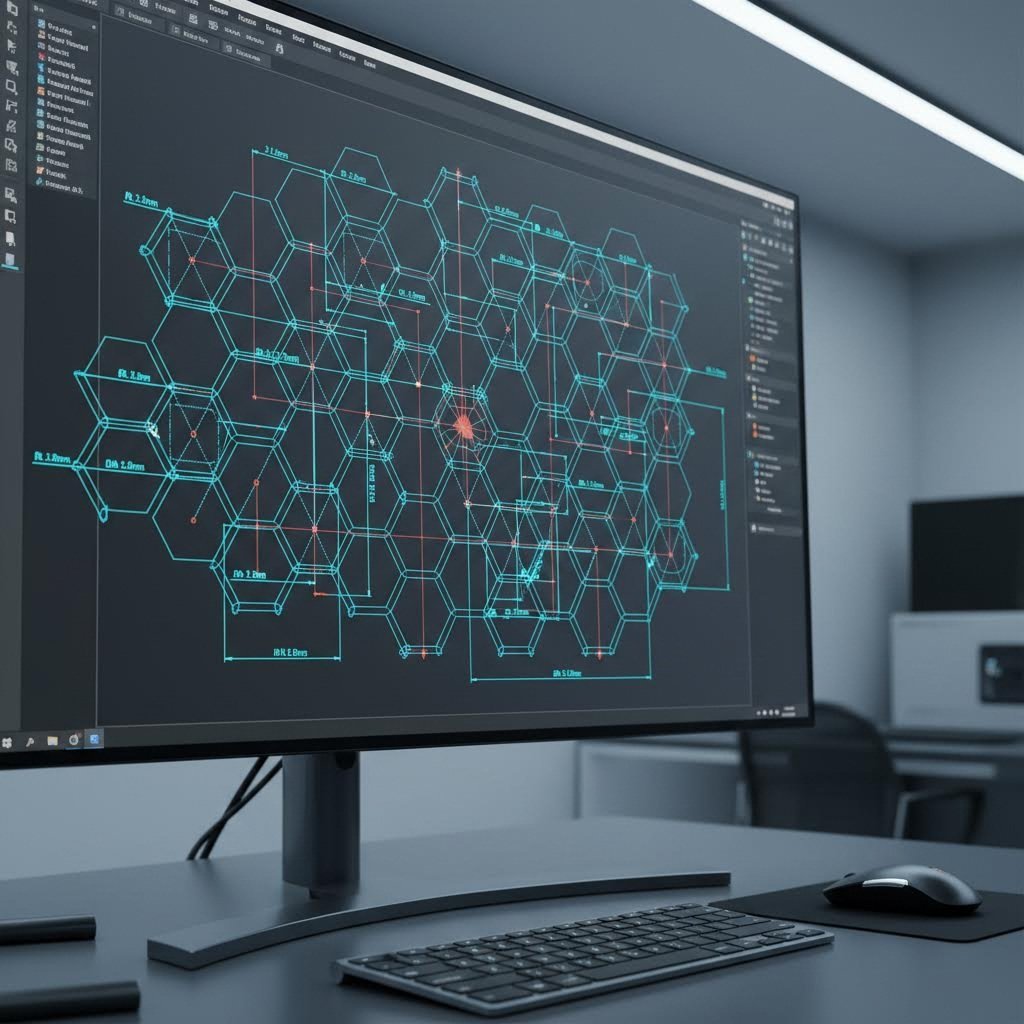

Suunnitellessasi laserilla leikattavaa metallia, olet käytännössä luomassa ohjeita tarkalle lämpöprosessille. Jokainen reiän halkaisija, kulman suuruus ja piirteiden välimatka vaikuttavat siihen, kuinka onnistuneesti laserleikkuulaite muuntaa CAD-tiedostosi valmiiksi osiksi. Tarkastellaan ohjeita, jotka erottavat harrastetasoiset suunnittelutyöt ammattimaisista, valmistuksessa kestävistä komponenteista.

Pienimmät koon mitat ja reikäohjeet

Kuulostaako monimutkaiselta? Ei tarvitse olla. Perussääntö on yksinkertainen: reiän halkaisijan tulee olla vähintään yhtä suuri kuin materiaalin paksuus. Baillie Fabin DFM-ohjeiden mukaan, jos osa valmistetaan 3/16" ruostumattomasta teräslevystä, reikien halkaisijat eivät saa olla pienempiä kuin 3/16". Pienempien reikien tekeminen voi johtaa epätäydelliseen poraukseen, vääristyneisiin reunaan tai lämmön kertymiseen, joka heikentää ympäröivää materiaalia.

Mutkokoosta on kuitenkin vain osa yhtälöä. Sijoitus on yhtä tärkeää. Sinun tulisi varata reiän ja levyn reunan väliin vähintään materiaalin paksuuden suuruinen etäisyys. Jotkin materiaalit vaativat vielä suuremman vapaa-ajan — alumiini vaatii usein kaksinkertaisen etäisyyden, jotta estetään reunan halkeilu tai muodonmuutos leikkaamisen aikana.

Entä jos suunnittelu edellyttää ehdottomasti reikiä lähemmäksi reunaa kuin suositellaan? Se on silti mahdollista, mutta valmistajan saattaa joutua käyttämään toissijaista porausoperaatiota tai vaihtamaan vesileikkaukseen näiden kohteiden osalta. Tämä lisää kustannuksia ja toimitusaikaa, joten suunnittele aina mahdollisuuksien mukaan riittävällä reunavapaa-ajalla alusta alkaen.

Tässä ovat oleelliset suunnitteluparametrit metallilevyjen onnistuneeseen laserleikkaukseen:

- Pienin reiän halkaisija —Yhtä suuri tai suurempi kuin materiaalin paksuus (vähintään 1:1 -suhde)

- Reiän ja reunan välinen etäisyys —Vähintään 1× materiaalin paksuus; 2× alumiinille ja pehmeämmille seoksille

- Reiän reiään välinen etäisyys —Vähintään 6× materiaalin paksuus tai 3 mm, kumpi on pienempi

- Pienin rakon leveys —1 mm tai 1× materiaalin paksuus, kumpi on suurempi

- Suositellut välilehtien leveydet —1,6 mm tai 1× materiaalin paksuus, kumpi on suurempi

- Kulmavapaus —Lisää vähintään 0,5 × materiaalipaksuuden suuruiset pyöristykset sisäkulmiin

- Teksti ja kaiverrus —Vähimmäisviivaleveys 0,5 mm; fontit, joiden viivaleveydet ovat tasaiset, toimivat parhaiten

Yleisten suunnitteluvirheiden välttäminen

Piirteiden koon lisäksi useat suunnittelutavat aiheuttavat säännöllisesti ongelmia laserleikattuihin levyihin liittyvissä projekteissa. Näiden ongelmien havaitseminen ennen tiedostojen lähettämistä säästää aikaa ja rahaa.

Yhdistämätön geometria: Kuten Baillie Fab huomauttaa, kaikkien pisteiden yhdistämisen unohtaminen ja osan täyden geometrian ympärysmerkinnän tekeminen johtaa huonosti leikattuihin osiin tai lisää piirtämistyötä. Avoinna olevat kontourit hämmentävät leikkausreittiä, mikä saattaa jättää piirteitä leikkaamatta tai aiheuttaa laserin epäennustettavaa liikettä.

Segmentteinä piirretyt kaaret: Piirtääkö CAD-ohjelmasi kaaret tasomaisina segmentteinä eikä jatkuvina kaarina? Valmistuksen aikana pidemmät segmentit voidaan tulkita tahkoiksi pikemminkin kuin jatkuviksi kaariksi. Kuvittele, että haluat ympyrän, mutta saat kuusikulmion. Ennen tiedostojen lähettämistä varmista, että kaarevat viivat on piirretty aidoin kaarina.

Terävät sisäkulmat: Mukaan lukien Vytekin kustannustehostusopas , terävien sisäkulmien välttäminen vähentää leikkausaikaa merkittävästi ja parantaa reunojen laatua. Pyöristetyt kulmat tai suorat viivat leikataan yleensä nopeammin kuin monimutkaiset muodot tai tiukat kaarevuudet. Kun kulmat täytyvät olla teräviä toiminnallisista syistä, lisää pieniä jännityksenlievitysura-avauksia estämään jännityskeskittyminen.

Jättämällä huomiotta materiaalin suunta: Hiomattua ruostumatonta terästä tai materiaaleja, joissa näkyvä jyväsuhde on huomattava, tulee jyväsuojan suunta määritellä piirustuksessa. Useimmat metallilevyt saapuvat mitoilla 4'×10', jyväsuunta pitkittäin — saat enemmän osia per levy, jos suunnittelet jyväsuunnan pitkin suunnittelusi pisin osa.

Materiaalin käytön maksimointi levynkäytön optimoinnilla

Tässä on tekijä, joka vaikuttaa suoraan projektisi kustannuksiin: kuinka tehokkaasti osasi sijoittuvat levylle. Levynkäytön optimointi — osien strateginen sijoittelu jätteen minimoimiseksi — voi vähentää materiaalihukkaa 10–20 %.

Suunniteltaessa on otettava huomioon, miten osat sijoittuvat yleisissä levykoissa. Useimmat valmistajat käyttävät 4'×8' tai 4'×10' levyjä, mutta ongelma on se, että laserin vaatima reuna-alue voi olla jopa 0,5" jokaisen osan ympärillä. Kaksi 4'×4' osaa eivät todellisuudessa mahdu 4'×8' levylle, kun otetaan huomioon tämä vapaa tila ja koneen reunavarat.

Jos jokaiselle levylle mahtuu vain yksi osa, joudut maksamaan merkittävästä materiaalihukasta. Baillie Fab suosittelee osien suunnittelua mahdollisimman tehokkaasti – mitä enemmän osia levylle mahtuu, sitä enemmän rahaa säästyy.

Käytännöllisiä strategioita parempaa sijoittelua varten ovat:

- Suunnittele osat suorilla reunoilla, jotka voidaan asettaa tiiviisti vierekkäin

- Harkitse suureiden osien jakamista pienempiin komponentteihin, jotka sijoittuvat tehokkaammin

- Käytä yhdenmukaista materiaalipaksuutta samankaltaisissa osissa, jotta ne voidaan yhdistää yksittäisille levyille

- Ryhmittele samankokoisia osia erikoisleikkausta varten levyn käytön maksimoimiseksi

Standardien materiaalipaksuuksien käyttö parantaa myös tehokkuutta. Laserleikkaajat on kalibroitu standardikokoja varten, mikä tekee näistä materiaaleista kustannustehokkaampia ja helpommin saatavilla olevia. Epästandardit paksuudet vaativat usein erityiskalibrointia tai materiaalien hankintaa, mikä lisää merkittävästi sekä toimitusaikoja että kustannuksia.

Oikea suunnittelu ei tarkoita vain toimivien osien tekemistä – se tarkoittaa tehokkaasti valmistettavien osien suunnittelua. Kun suunnittelu noudattaa näitä ohjeita, huomaat hyödyt nopeammissa tarjouksissa, alhaisemmissa hinnoissa ja korkealaatuisemmissa valmiissa komponenteissa. Kun suunnittelu on optimoitu, seuraava keskeinen tekijä, joka on ymmärrettävä, on mitä kuluttaa kustannuksia laserleikkauksen projekteissa – ja miten niitä voidaan hallita.

Kustannustekijät ja hinnoittelustrategiat teräksen leikkausprojekteissa

Olet suunnitellut osasi, valinnut täydellisen teräslaatun ja löytänyt leikkausmenetelmän, joka vastaa tarkkuusvaatimuksiasi. Nyt nousee esiin kysymys, johon kaikki haluavat vastauksen, mutta jota harvat lähteet käsittelevät suoraan: paljonko tämä oikeastaan maksaa? Laserleikkauksen kustannusten ymmärtäminen ei tarkoita hinnastojen ulkoa opettelua – kyse on siitä, mitkä tekijät ovat sinun hallinnassasi ja miten jokainen päätöksesi vaikuttaa budjettiisi.

Tässä jotain, mitä useimmat valmistajat eivät kerro suoraan etukäteen: yksittäinen suurin kustannustekijä ei ole materiaalin pinta-ala tai levyn koko. Mukaan Fortune Laserin hinnoitteluperusteet , koneaika, joka tarvitaan suunniteltusi leikkaamiseen, määrittää suurimman osan tarjouksestasi. Yksinkertainen kiinnike ja monimutkainen koristelevy, jotka on tehty samasta teräslevystä, voivat olla hyvin eri hintaisia – vaikka ne käyttävätkin täysin samaa materiaalia.

Keskeiset tekijät, jotka vaikuttavat laserleikkauksen kustannuksiin

Jokainen laserleikkaustarjous noudattaa peruskaavaa: Lopullinen hinta = (Materiaalikustannukset + Muuttuvat kustannukset + Kiinteät kustannukset) × (1 + Kattekerroin). Komponenttien ymmärtäminen auttaa sinua näkemään tarkalleen, mihin rahasi menee – ja missä voit vaikuttaa kustannusten alentamiseen.

Materiaalikulut edustavat enemmän kuin vain raakateräksen hintoja. Arvioitaessa ruostumattoman teräksen hinnat levyistä tai vertailtaessa ruostumattomien levyjen hintoja toimittajien välillä, muista että materiaalikustannuksiin kuuluu sekä käytetty materiaali että jätteeksi muodostuva osa. Paksummat materiaalit maksavat suhteellisesti enemmän, ja erikoislaadut kuten 316-ruostumaton teräs ovat kalliimpia verrattuna tavallisiin hiiliteräsvaihtoehtoihin.

Muuttuvat kustannukset (koneajan mukaan) muodostavat suurimman osan useimmista tarjouksista. Toimialan tietojen mukaan tyypilliset tuntihinnat laserleikkauslaitteille vaihtelevat 60–120 dollarin välillä koneen tehon ja ominaisuuksien mukaan. Useat suunnittelutekijät vaikuttavat suoraan siihen, kuinka kauan työsi kestää:

- Leikkausetäisyys laserin linjainen kulku määrittää pohjan leikkausajan

- Pierce-lasku jokaisen uuden leikkauksen jälkeen laserin on lävistettävä materiaali; 100 pientä reikää maksaa enemmän kuin yksi suuri leikkaus, koska lävistys kestää enemmän

- Materiaalin paksuus kaksinkertaistamalla paksuutta voi yli kaksinkertaistaa leikkausajan, koska laserin on liikuttava huomattavasti hitaammin

- Suunnittelun monimutkaisuus täydelliset kaarevat ja terävät kulmat saavat koneen hidastumaan, mikä pidentää leikkauksen kokonaiskestoa

Kiinteät kustannukset ja yleiset kustannukset kattaa projektisi hallintokustannukset, kuten vuokran, koneen kunnossapidon, ohjelmistolisenssit ja hallinnolliset kustannukset. Nämä pysyvät suhteellisen vakaina työn koosta riippumatta, minkä vuoksi suuremmilla tilauksilla on alhaisemmat osat hinnat.

Suvaitsevaisuusvaatimukset tarkkuusvaatimukset aiheuttavat suurempia kustannuksia kuin monet ajattelevat. Kuten Approved Sheet Metal huomauttaa, toiminnallisesti tarpeettoman tiukkojen toleranssien määrittäminen lisää kustannuksia. Erittäin tiukkojen toleranssien saavuttaminen edellyttää hitaampaa ja tarkempaa leikkausnopeutta. Ennen kuin vaaditaan ±0,005 tuuman tarkkuutta, harkitse, riittäisikö ±0,010" tai ±0,015" täyttämään todelliset vaatimuksesi ilman ylimääräisiä kustannuksia.

Toissijaiset toiminnot lisäävät merkittävästi kokonaisprojektikustannuksiin. Alkuperäisen leikkauksen ulkopuoliset palvelut, kuten taivutus, kierteitys, kiinnikkeiden asennus tai pulverimaalaukset, hinnoitellaan erikseen. Pulverimaalattu pinnoite lisää korroosiosuojaa ja esteettistä houkuttelevuutta, mutta se lisää myös prosessointiaikaa ja materiaalikustannuksia tarjoukseesi. Budjetoidessa on otettava huomioon koko osan elinkaari, ei pelkästään leikkausoperaatio.

Strategiat projektikustannusten vähentämiseksi

Suunnittelijana tai insinöörinä sinulla on merkittävä vaikutusvalta lopulliseen hintaan. Nämä todetut strategiat auttavat alentamaan kustannuksia toiminnallisuutta uhraamatta:

- Käytä mahdollisimman ohutta materiaalia —Tämä on yksittäinen tehokkain kustannustehokkuusstrategia. Paksummat materiaalit lisäävät koneajonaikaa eksponentiaalisesti, joten tarkista aina, voiko ohuempi mittaus täyttää projektisi rakenteelliset ja toiminnalliset vaatimukset

- Yksinkertaista suunnitteluasi —Vähennä monimutkaisia kaaria ja yhdistä useita pieniä reikiä suuremmiksi loviksi, kun toiminnalliset vaatimukset sallivat. Tämä minimoi leikkausetäisyyden sekä hidastavien porauksien määrän

- Puhdista suunnittelutiedostosi —Poista kaksoisviivat, piilotetut objektit ja rakennemerkinnät ennen lähettämistä. Automaattiset tarjousjärjestelmät yrittävät leikata kaiken, ja kaksoisviivat tuplautuvat kirjaimellisesti kyseisen ominaisuuden kustannuksissa

- Tilata suurissa määrin —Konsolidoi tarpeesi suuremmiksi, harvinaisemmiksi tilauksiksi. Yksikköhinta laskee huomattavasti määrän myötä, koska kiinteät aloitus- ja asetuskustannukset jakautuvat useamman osan kesken. Lähteestä Fortune Laser , määräalennukset voivat saavuttaa jopa 70 % suurten tilauserien kohdalla

- Optimoi leikkaussuunnittelun tehokkuus —Suunnittele osat suorilla reunoilla, jotka asettuvat tehokkaasti tiiviisti toistensa viereen. Parempi tiivis asettuminen vähentää suoraan materiaalihukkaa ja vastaavia materiaalikustannuksia

- Valitse varastossa olevia materiaaleja —Teräslajin valitseminen siten, että se on jo valmiiksi valmistajan varastossa, poistaa erikoistilaukset ja lyhentää toimitusaikoja. Kysy saatavilla olevasta varastosaldoista ennen materiaalimäärittelyjen lopullistamista

- Arvioi pintakäsittelyvaatimukset huolellisesti —Premium-pintakäsittelyt lisäävät kustannuksia. Jos korroosiosuojaus on välttämätöntä, jauhepinnoite tarjoaa erinomaisen kestävyyden. Sisäosille tai osille, joita käsitellään myöhemmin, riittää kuitenkin usein standardin mukainen reunalaatu ilman toissijaista pintakäsittelyä

Vertaillessa tarjouksia muista, että kuitulaserleikkuukoneen hinta tai laitteiden kapasiteetti vaikuttavat myös hinnoitteluun. Uudemmilla ja tehokkaammilla laitteilla varustetut työpajat voivat leikata nopeammin, mutta veloittavat eri hinnoin. Pyydä tarjouksia useilta toimittajilta – sekä verkkopalveluista heti tarjouksen antavilta alustoilta että perinteisiltä valmistamoyrityksiltä – ymmärtääksesi hinnaston vaihteluvälin omalle projektillesi.

Verkkopalvelut tarjoavat vertaansa vailla nopeutta ja mukavuutta, ja ne antavat tarjoukset sekunnissa ladatuista CAD-tiedostoista. Kuitenkin alan asiantuntijat huomauttavat, että perinteiset työpajat, joissa on osaavia teknikoita, tarjoavat usein ilmaista valmistettavuuden suunnittelua (Design for Manufacturability), joka voi merkittävästi vähentää kustannuksia. He huomaavat virheet, ehdottavat tehokkaampia ratkaisuja ja tarjoavat joustavuutta, jota automatisoidut järjestelmät eivät pysty vastaamaan.

Näiden kustannusdynamiikkojen ymmärtäminen muuttaa sinut henkilöstä, joka reagoi tarjouksiin, henkilöksi, joka aktiivisesti hallinnoi projektitaloutta. Kun budjettiharkinnat on käsitelty, seuraavana on ymmärtää, kuinka toissijaiset työvaiheet ja viimeistelyvaihtoehdot täydentävät laserileikattuja teräsosia – muuttaen raakaleikatut komponentit valmiiksi, toiminnallisiksi tuotteiksi.

Toissijaiset työvaiheet ja viimeistelyvaihtoehdot

Laserileikatut teräsosasi saapuvat tarkkaan mitoitettuina ja siistein reunojin. Mutta ovatko ne todella valmiita? Useimmissa tapauksissa leikkausvaihe on vain yksi askel koko valmistusprosessissa. Toissijaiset työvaiheet muuttavat raakaleikatut komponentit kiillotetuiksi, suojatuiksi ja täysin toiminnallisiksi osiksi, jotka ovat valmiita tarkoitukseensa.

Tämän viimeistelyn vaihtoehtojen ymmärtäminen auttaa sinua suunnittelemaan koko projektin elinkaaren – alusta alkaen loppuasennukseen asti. Tässä tekemäsi valinnat vaikuttavat suoraan valmistuneiden komponenttien kestävyyteen, ulkonäköön ja suorituskykyyn.

Jälkikäsittelyvaihtoehdot ammattituloksia varten

Jokainen laserleikkausoperaatio jättää reunaviisteen tai roskan, johon on kiinnitettävä huomiota ennen seuraavia prosesseja. Evotec Groupin viisteenpoiston opas kertoo, että asianmukainen viisteenpoisto "harvoin on valinnainen – turvallisuuden, suorituskyvyn ja kilpailukyvyn vuoksi se on välttämätöntä." Terävät reunat aiheuttavat käsittelyssä vaaratilanteita, haittaavat kokoonpanotarkkuutta ja heikentävät pinnoitteen adheesiota.

Useita viisteenpoistomenetelmiä sovelletaan eri osavaatimuksiin:

- Lineaarinen viisteenpoisto —Osat kulkevat hiontaharjojen alittain, jotka tasaisevat yhden puolen; ideaali suuremmille litteille osille, joiden lyhin akseli on enintään 24"

- Kouristaminen —Osat pyörivät kermamiian kanssa tärinävarustelmassa, mikä tarjoaa yhtenmäisen reunkäsittelyn pienille komponenteille

- Manuaalinen viimeistely —Hakapuut, sandpapereita tai käsikoneita käytetään tarkan ohjauksen tarpeisiin pienissä määrissä tai erikoissovelluksissa

Reunakäsittelyn lisäksi taivutusoperaatiot muodostavat kolmiulotteisia muotoja tasaisista laserleikatuista tyhjennyslevyistä. Laserleikkausten tarkkuus vaikuttaa suoraan taivutustarkkuuteen — puhtaat, yhtenäiset reunat tuottavat ennustettavissa olevat taivutussallit ja tiukemmat toleranssit valmistetuissa osissa.

Kun hitsaus seuraa leikkausta, reunalaatu on vieläkin kriittisempi. Laserleikatut reunat vaativat yleensä vähimmäisvalmistelua verrattuna plasmalla tai liekillä leikattuihin osiin. Kuitenkin hapella avustetussa leikkaamisessa muodostunut hapetuskerros saattaa joutua poistamaan ennen ruostumattoman teräksen hitsausta, jotta estetään saastuminen. Typpileikatut reunat voidaan usein hitsata suoraan ilman lisävalmistelua.

Koristeellisiin sovelluksiin lasergravoitu ruostumaton teräs lisää logot, sarjanumerot tai tunnistemerkinnät pysyvässä tarkkuudessa. Vastaavasti laserkäsitelty ruostumaton teräs luo yksityiskohtaisia grafiikkoja tai tekstuureja, jotka parantavat esteettistä houkuttelevuutta samalla kun säilyttävät kestävyyden.

Suojapäällysteet teräskomponenteille

Oikean päällysteen valinta riippuu täysin sovelluksen vaatimuksista. Mukaan SendCutSendin viimeistelyopas , päällysteet "voivat lisätä kulumisvastusta, muuttaa osan pintakovuutta, estää korroosiota, vähentää sähkönjohtavuutta ja paljon muuta."

Tässä miten päällystemahdollisuudet luokitellaan ensisijaisen toiminnon mukaan:

Korroosiosuojapäällysteet:

- Jauhemaalaus —Luo kestävän polymeerikuoren, joka sulkee pois kosteuden ja kemikaalit; kestää jopa 10 kertaa pidempään kuin maali

- Sinkkiverho —Sijoittaa ohuen metallikerroksen, joka uhrautuvasti suojaa terästä myös silloin, kun sitä on vahingoitettu

- Passivointi —Kemiallinen prosessi, joka parantaa ruostumattoman teräksen luontaista korroosionkestävyyttä

Esteettiset parannuspäällysteet:

- Anodisointi —Saatavilla useissa väreissä alumiiniosille; luo naarmuun- ja kuumuuskestäviä pinnoitteita

- Harjaaminen —Luo tasaiset raerakenteet ruostumattomasta teräksestä arkkitehtonisiin sovelluksiin

- Media Blasting —Tuottaa mattapintaisia tekstuureja, jotka peittävät sormenjäljet ja pienet virheet

Toiminnalliset päällysteet:

- Nickeliinkaste —Parantaa sähkönjohtavuutta ja tarjoaa kohtalaista korroosionsuojaa

- Kromaatinmuunnos —Vahvistaa sinkkipinnoitteen ulkokerrosta parantaakseen kestävyyttä

- Erikoisprimereitä —Valmistelevat pintoja seuraavia maalaus- tai pinnoitustarpeita varten

Valitessa vaihtoehtoja tulee ottaa huomioon ympäristö ja suoritusvaatimukset. Kuten alan vertailut osoittavat, jauhemaalaukset tuottavat kovaa, reagoimatonta kuorta, joka on ideaalinen kemikaalialtistukselle, kun taas sinkkipinnoite jatkaa teräksen suojaamista, vaikka pinnoite naarmuttaisiin. Meriympäristössä vaaditaan joko 316 -ruostumatonta terästä tai sinkkipinnoitetta — jauhemaali voi epäonnistua, jos se vaurioituu suolaisissa olosuhteissa.

Anodisoituja alumiinikomponentteja valmistettaessa sähkökemiallinen prosessi paksuntaa luonnollista hapettumakerrosta, mikä luo erinomaisen naarmu- ja korroosionkestävyyden. Tämä pinnoite toimii ainoastaan alumiinin kanssa, joten se sopii erinomaisesti kevyisiin koteloihin tai dekoratiivisiin paneeleihin, joissa alumiinin hitsaus tai muovaus tehdään ennen viimeistelyä.

Muista, että pinnoitteen valinta vaikuttaa mittojen tarkkuuteen. Jauhepinnoite lisää useita tuhannesosatuumia pinnan paksuuteen – otathan tämän huomioon suunniteltaessa liitettäviä osia tai kierteitä. Sinkkipinnoite puolestaan lisää vain merkityksettömän vähän paksuutta, säilyttäen tiukat kierteiden istumamitat ilman jälkikäsittelyä.

Kun pinnoitusvaihtoehdot on ymmärretty, viimeinen haaste on valita valmistuskumppani, joka pystyy täyttämään kaikki nämä vaatimukset. Seuraavassa osiossa käydään tarkalleen läpi, mitä tulisi arvioida valittaessa laserleikkauspalveluntarjoajaa.

Laserleikkauskumppanin valinta projektiisi

Olet saanut suunnittelusi täydelliseksi, valinnut optimaaliset materiaalit ja ymmärrät tarkalleen, mitä tarkkuustasoa projekti vaatii. Nyt on tehtävä päätös, joka voi joko onnistua tai epäonnistua kaiken: kumpi valmistuskumppani todella valmistaa osasi? Erinomaisen teräksen työstöliikkeen ja keskinkertaisen välillä on usein ratkaiseva ero sille, onnistuuko projekti ensimmäisellä yrityksellä vai johtaa kalliisiin muutoksiin ja viivästymisiin.

Nopealla haulla löytämällä ilmaisu "metallin työstö läheltä" näyttää kymmeniä vaihtoehtoja. Mutta miten erottaa ne teräksen työstäjät, jotka toimittavat tasan sen mitä tarvitset, niistä, jotka jättävät sinut turhautuneeksi? Vastaus piilee tietyissä kyvyissä, sertifikaateissa ja palvelutasoissa, joita on arvioitava ennen kuin teet tilauksen.

Palveluntuottajan kykyjen arviointi

Kun etsit ilmaisuja "työstöliikkeet läheltä" tai "metallin työstäjät läheltä", saat vastaasi toimintoja, jotka vaihtelevat pienistä työpajoista suurten tuotantolaitosten tasolle. Mukaan Emery Laserin valintakuvauksen , ensimmäinen askel on arvioida heidän asiantuntemustaan ja kokemustaan tietystä toimialastasi.

Kumppani, jolla on todistettu menestyskertaoma alallasi, ymmärtää erityisvaatimukset, toleranssit ja materiaalimääritykset, joita tarvitset. Kysy mahdollisilta kumppaneilta aiemmista projekteista, jotka ovat samankaltaisia kuin oma projektisi, pyydä esimerkkitapauksia ja tarkista asiakkaiden palautteet. Tämä paljastaa sekä osaamisen että luotettavuuden tavalla, jota laitekohtaiset tiedot eivät yksinään voi tarjota.

Seuraavat ovat olennaiset arviointikriteerit laserleikkuukumppanin valinnassa:

- Teollisuuden todistukset —Etsi IATF 16949 -sertifikaattia autoteollisuuden sovelluksiin, ISO 9001 -standardia yleiseen laadunhallintaan tai AS9100 -sertifikaattia ilmailualalle. Esimerkiksi Shaoyi (Ningbo) Metal Technology ylläpitää IATF 16949 -sertifikaattia, mikä osoittaa sitoutumista tiukkoihin laatuvaatimuksiin, joita vaativat auton korirakenteet, suspensiot ja rakennekomponentit

- Laitteistokapasiteetit —Vastaaako heidän teollisuuslaserleikkuukoneensa materiaali- ja paksuusvaatimuksiinne? Edistyneet kuitulaserin leikkauspalvelut hoitavat ohuiden materiaalien tarkkuustyön eri tavalla kuin liikkeet, jotka on varustettu lähinnä raskaiden levyjen käsittelyyn

- Tuotannon sopeuttamiseen (DFM) liittyvä tuki —Kumppanit, jotka tarjoavat kattavaa DFM-palautetta, havaitsevat suunnitteluongelmat ennen leikkaustyön aloittamista, säästäen näin aikaa ja rahaa. Shaoyi edustaa tätä lähestymistapaa omalla erityisellä DFM-tuellaan, joka optimoi suunnitelmia tehokkaaseen valmistukseen

- Tarjousvastauksen käsittelynopeus —Nopea tarjousvastaus osoittaa toiminnallista tehokkuutta. Alaansa johtavat yritykset, kuten Shaoyi, tarjoavat 12 tunnin käännösajan tarjouksiin, mikä nopeuttaa projektin aikataulua jo ensimmäisestä yhteydenotosta alkaen

- Prototyyppiä valmistamiseen liittyvät valmiudet —Voivatko he tuottaa protyypin määrät nopeasti? Nopea prototyyppi, kuten erikoistuneiden valmistajien tarjoama 5 päivän toimitusaika, mahdollistaa suunnitelmien testauksen ennen tuotantomäärien vakiinnuttamista

- Toissijaiset valmistusvaiheet —Tekeekö kauppa taivutuksen, hitsauksen, viimeistelyn ja kokoamisen omassa laitoksessaan? Yhden lähteen valmistus eliminoi koordinaatio-ongelmat ja vähentää läpimääräaikoja

Teknologia ja varusteet ovat merkittäviä. Kuten alan asiantuntijat huomauttavat, edistyneet koneet, kuten kuitulaserit, tarjoavat parempaa tarkkuutta, nopeutta ja tehokkuutta verrattuna vanhempiin CO2-järjestelmiin. Ne selviytyvät monimutkaisista suunnitelmista vähimmäisellä materiaalihävikillä — mikä on ratkaisevaa laadun ylläpitämiseksi kustannusten hallinnassa.

Tehostettu tarjous-to-delivery -prosessi

Kun olet tunnistanut mahdolliset kumppanit, tilausprosessi itsessään paljastaa paljon siitä, kuinka sujuvasti projekti etenee. Tehokkaat teräksen työstökumppanit noudattavat tehostettuja työnkulkujärjestelmiä, jotka minimoivat kitkatekijät alusta loppuun.

Mitä sinun tulisi odottaa hyvin järjestäytyneeltä valmistuskumppanilta?

Selkeät viestintäkanavat: Kumppanisi tulisi olla nopeasti reagoiva, avoin ja ennakoiva jokaisessa vaiheessa. Kuten Emery Laser , tehokas viestintä ja vahva asiakaspalvelu ovat olennaisia onnistuneiden kumppanuuksien kannalta. Alusta alkaen lopulliseen toimitukseen asti heidän tulisi pitää sinut ajan tasalla ja käsitellä huolenaiheesi nopeasti.

Tiedostomuotojen joustavuus: Ammattimaiset liikkeet hyväksyvät yleiset CAD-muodot — DXF-, DWG-, STEP- ja SolidWorks-tiedostot — ilman muunnoksia, jotka saattaisivat aiheuttaa virheitä. Kysy tuetuista tiedostomuodoista ennen kuin oletat tiedostojen toimivan.

Selkeät hinnoittelun selvitykset: Laadukkaat valmistajat selittävät, mitä tekijöitä hinnoittelu perustuu. Jos tarjous vaikuttaa korkealta, heidän tulisi kertoa, mitkä suunnittelun piirteet tai tekniset vaatimukset vaikuttavat hintaan – ja mahdollisesti ehdottaa vaihtoehtoja, joilla tavoitteesi voidaan saavuttaa edullisemmin.

Realistiset toimitusaikataulujen sitoumukset: Nopeus on tärkeää, mutta tarkkuus on vielä tärkeämpää. Kumppanien tulisi antaa rehellisiä arvioita toimitusaikojen toteutumisesta nykyisen työmäärän perusteella, eikä optimistisia lupauksia, joita ei voida pitää. Kuten Approved Sheet Metal korostaa, jokaisen työn käsittely kiireellisenä samalla ylläpitäen laatu erottaa erinomaiset valmistajat pelkästään riittävistä.

Laajennettavuus kasvua varten: Prototyypinvalmistajan tulisi myös tukea tuotannon skaalaamista. Siirtyminen viiden päivän nopeasta prototyyppivaiheesta automatisoituun massatuotantoon tulisi tuntua saumattomalta – ei sitä tulisi joutua aloittamaan uudelleen toimittajahaku. Valmistajat kuten Shaoyi täyttävät tämän aukon tarjoten palveluja prototyyppieristä suurten volyymin automatisointiin asti, kaikki yhdenmukaisten laadunormien alaisuudessa.

Ennen ensimmäisen tilauksen tekemistä kannattaa harkita osan tai pienen testierän pyytämistä. Tämä paljastaa todellisen laadun tason, viestinnän nopeuden ja toimituksen luotettavuuden ilman, että suuren tilauksen riskit otetaan tuntemattoman kumppanin kanssa.

Oikea valmistuskumppani toimii kuin jatke omaan tekniikkatiimiisi – havaiten mahdolliset ongelmat, ehdottaen parannuksia ja toimittaen johdonmukaisesti. Kun arviointikriteerit ovat selvillä, olet valmis yhdistämään kaiken käsitellyn tieton kokonaisuuden käytännön toimintakehystä seuraavaa laserileikattua levyteräsprojektiasi varten.

Kaiken yhdistäminen onnistuneeseen teräksen valmistukseen

Olet nyt tutustunut jokaiseen keskeiseen tekijään, joka määrittää laserileikatun levyteräsprojektien menestyksen – materiaalin valinnasta teknisiin tarkkuuksiin, suunnittelun optimointiin ja kumppanin arviointiin asti. Mutta tieto ilman toimintaa ei tuo mitään hyötyä. Tässä viimeisessä osassa kaikki yhdistetään käytännön kehykseksi, jonka voit ottaa välittömästi käyttöön seuraavassa projektissasi.

Käsittele tätä asiakirjaa vertailuoppaana. Lisää se kirjanmerkeihisi ja palaa tähän ennen kuin lähetät seuraavan CAD-tiedoston tai pyydät tarjouksia. Projektien, jotka etenevät sujuvasti, ja niiden, jotka joutuvat kalliisiin uusintakierroksiin, ero johtuu usein siitä, noudatetaanko systemaattista lähestymistapaa vai ohitetaanko vaiheita.

Laserleikatun teräsprojektisi tarkistuslista

Ennen kuin aloitat minkään metallityöstöprojektin, jossa käytetään teräksen laserleikkausta, käy nämä keskeiset tarkistuspisteet läpi:

- Materiaalivarmistus —Varmista, että määrittelet laadukasta laserleikkausta varten soveltuvaa terästä, jolla on riittävän hyvä litteys ja pinnanlaatu. Valitse luokkasi (304 ruostumaton, 316 ruostumaton tai hiiliteräs) sovelluksen vaatimusten mukaan

- Paksuuden optimointi —Käytä rakenteellisesti riittävän ohutta materiaalia. Muista: kaksinkertainen paksuus voi moninkertaistaa leikkausajan neljästä kuuteen kertaan

- Reikien ja muotojen koko —Tarkista, että kaikki reiät ovat yhtä suuria tai suurempia kuin materiaalin paksuus. Huolehdi riittävästä reunavälistä ja reiän ja reiän välisestä etäisyydestä

- Kulmien käsittely —Lisää pyöristykset sisäkulmiin (vähintään 0,5 × materiaalipaksuus), jotta estetään jännityskeskittymät ja parannetaan leikkauslaatua

- Leikkauskorjaus —Ota huomioon 0,2–0,4 mm:n materiaalin poisto kosketuspinnassa. Säädä mittoja puolet leikkauslevyn leveydestä kummallakin kosketuspinnalla

- Tiedostojen valmistelu —Poista päällekkäiset viivat, muunna käyrät todellisiksi kaariksi ja poista piilotetut objektit ennen lähettämistä

- Sijoittelun huomioiminen —Suunnittele osat suorilla reunoilla, jotka sijoittuvat tehokkaasti standardilevyille

- Toleranssitarkkuuden määrittely —Pyydä vain sitä tarkkuutta, jota todella tarvitset. Tiukemmat toleranssit lisäävät kustannuksia ilman toiminnallista hyötyä

- Toissijaiset toiminnot —Suunnittele karvojen poisto, taivutus, hitsaus tai viimeistely jo suunnitteluvaiheessa

- Kumppanin pätevöittäminen —Tarkista sertifikaatiot, DFM-tuen saatavuus ja laitteiden ominaisuudet vastaavatko projektin vaatimuksia

Oikean valinnan tekeminen sovellukseesi

Jokainen onnistunut laserleikkausprojekti perustuu kolmen toisiinsa liittyvän tekijän tasapainottamiseen: materiaali, suunnittelu ja kumppani. Jos yhdessäkin niistä tehdään kompromisseja, laatu kärsii, oli muut suoritettu kuinka hyvin tahansa.

Mukaan lukien Bendtech Groupin projektiohjaus , joka lähtee liikkeelle projektin keskeisistä suoritusvaatimuksista—lujuus, pinnanlaatu tai optinen läpinäkyvyys—ohjaa kaikkia myöhempiä päätöksiä. Rostumatonta terästä leikatessa saavutetaan korroosionkesto ja premium-pintakäsittely. Hiiliteräs tarjoaa lujuutta alhaisemmalla hinnalla. Sovellutuksenne määrittää, mikä näistä on tärkeintä.

Suunnittelun optimointi ei ole vaihtoehto – se on se kohta, jossa hallitset kustannuksia. Kuten TMCO:n valmistuksen asiantuntijat huomauttavat, useita taivutuksia, monimutkaisia leikkauksia tai tiukkoja toleransseja sisältävät komponentit vaativat enemmän ohjelmointia, asennusta ja tarkastusaikaa. Yksinkertaistakaa siellä, missä toiminnallisuus sitä sallii. Budjettillesi se kiittää.

Kumppanin valinta määrittää toteutuksen laadun. Etsi valmistajia, jotka tarjoavat kattavaa DFM-tukea, nopeaa tarjouskäsittelyä ja alan vaatimia sertifiointeja. Oikean teollisen laserleikkaajan valinta tuottaa hyötyjä jokaisessa hankkeessa.

Tärkein opetus laserilla leikatun ruostumattoman teräksen onnistumisesta: tarkkuus ei tarkisteta vasta lopussa – se rakennetaan prosessiin alusta alkaen oikealla materiaalivalinnalla, optimoidulla suunnittelulla ja pätevien valmistuskumppaneiden yhteistyöllä.

Tämä filosofia, jota Northern Manufacturingn tarkkuusvalmistuksen opas korostaa, muuttaa tapaa, jolla lähestyt hankkeita. Sen sijaan että toivoisit lopputarkastuksen paljastavan ongelmat, suunnittelet ne pois jo ennen ensimmäistä leikkausta.

Autoteollisuuden, teollisuuden ja korkean tarkkuuden sovellusten osalta, jotka vaativat sekä laserleikkaustarkkuutta että vaivatusta asiantuntemusta, valmistajat kuten Shaoyi (Ningbo) Metal Technology yhdistävät nämä kyvykkyydet yhteen. Heidän IATF 16949 -valtakirjansa, 5 päivän nopeakonetoimintonsa ja kattava DFM-tukensa kuvaavat integroitua lähestymistapaa, joka takaa valmistusvarmuuden alustan, suspenssion ja rakenteellisten komponenttien osalta.

Seuraavan laserileikatun levyteräsprojektisi ansaitsee tässä oppaassa esitetyn systemaattisen lähestymistavan. Käytä materiaalivalintakriteereitä. Noudata suunnittelun optimointiperiaatteita. Arvioi kumppaneita pätevyysluetteloon nähden. Kun nämä kolme elementtiä ovat linjassa, onnistuneet tulokset muuttuvat ennakoitaviksi eikä vain toiveiksi.

Usein kysyttyjä kysymyksiä laserileikatusta levyteräksestä

1. Voiko teräslevyä leikata laserilla?

Kyllä, laserleikkaus on yksi tehokkaimmista menetelmistä teräslevyjen käsittelyyn. Kuitulaser-teknologia soveltuu erinomaisesti leikkaamaan rakenneterästä, ruostumatonta terästä ja hiiliterästä erittäin tarkasti. Menetelmä käyttää keskitettyä laser-sädettä sulattamaan tai haihduttamaan materiaalia ohjelmoitujen reittien varrella, saavuttaen tarkkuuksia jopa ±0,05 mm ohuissa materiaaleissa. Rakenneteräs säilyy suosittuna vaihtoehtona sen monipuolisuuden vuoksi, kun taas ruostumattomat teräslajit, kuten 304 ja 316, tarjoavat korroosionkestävyyttä vaativiin sovelluksiin.

2. Kuinka paljon maksaa teräksen laserleikkaus?

Laserleikkauskustannukset riippuvat useista tekijöistä, kuten koneajasta, materiaalikustannuksista, suunnittelun monimutkaisuudesta ja määrästä. Koneaika vaihtelee yleensä 60–120 dollaria tunnissa laitteiston ominaisuuksien mukaan. Kokonaiset leikkausetäisyydet, läpäisyjen määrä, materiaalin paksuus ja tarkkuusvaatimukset vaikuttavat kaikki hinnoitteluun. Suurten tilausten yhteydessä määräalennukset voivat olla jopa 70 %. Kustannusten vähentämiseksi kannattaa käyttää mahdollisimman ohutta sopivaa materiaalia, yksinkertaistaa suunnitelmia, optimoida levynkäytön tehokkuutta ja tilata suurina erinä.

3. Kuinka paksua terästä 1500 wattinen laser voi leikata?

1500 W:n kuitulaserleikkauskone pystyy käsittämään hiiliterästä enintään 15 mm, ruostumatonta terästä enintään 6 mm, alumiinia enintään 4 mm ja kuparia enintään 3 mm. Kuitenkin optimaalinen leikkaussuoritus tapahtuu ohuemmilla paksuusluokilla, joissa nopeus ja reunojen laatu ovat maksimaaliset. Materiaalien tehokasta leikkaamista yli 10 mm paksuilla materiaaleilla suositellaan tehdä korkeamman tehon koneilla (3000–6000+ watti), jotta säilytetään laadukas reunaviimeistely.

4. Mikä on paras laser leikkaamaan levyä?

Kuitulaserit katsotaan yleisesti parhaaksi vaihtoehdoksi metallilevyjen leikkaamiseen. Ne tarjoavat aallonpituuden, jonka metalli absorboi tehokkaammin kuin CO2-laserit, tuottaen pienempiä pistekokoja ja erinomaisia sädeprofiileja, jotka ovat ideaalisia useimpien metallien leikkaamiseen. Kuitulaserit tarjoavat paremman tarkkuuden, nopeammat leikkausnopeudet ohuissa materiaaleissa, alhaisemmat käyttökustannukset ja ne pystyvät käsittelemään heijastavia metalleja, kuten alumiinia ja kuparia. Alle 12 mm levyteräkselle kuitulaseritekniikka tarjoaa optimaalisen tasapainon nopeuden, laadun ja kustannustehokkuuden välillä.

5. Mikä on vähimmäiskoko laserilla leikattavalle reiälle teräksessä?

Laserilla leikatun teräksen vähimmäishalkaisijan tulisi olla yhtä suuri tai suurempi kuin materiaalin paksuus. Esimerkiksi 3 mm paksu teräs edellyttää vähintään 3 mm halkaisijaltaan olevia reikiä. Pienempien reikien tekeminen voi johtaa epätäydelliseen läpäisyyn, vääristyneisiin reunoihin tai ylikuumenemiseen, joka heikentää ympäröivää materiaalia. Lisäksi reiän ja reunan välinen etäisyys tulisi pitää vähintään 1x materiaalin paksuus (2x alumiinissa) ja reiän sekä reiän välisen etäisyyden vähintään 6x materiaalin paksuus tai vähintään 3 mm varmistaaksesi onnistuneet leikkaukset.

Pienet erät, korkeat standardit. Nopea prototyypinkehityspalvelumme tekee vahvistamisen nopeammaksi ja helpommaksi —

Pienet erät, korkeat standardit. Nopea prototyypinkehityspalvelumme tekee vahvistamisen nopeammaksi ja helpommaksi —