Mukautettujen valssattujen renkaiden kuormitustiedot: Mitä insinöörit eivät kerro sinulle

Mitä renkaiden kuormitustiedot todella tarkoittavat turvallisuutesi kannalta

Kun ostit räätälöityjä valssattuja renkaita, huomaat päättymättömät keskustelut eri pinnoitevaihtoehdoista, säteiden muodoista ja kiinnityskuvioista. Mutta tässä on se, mitä useimmat huippuluokan renkaiden valmistajat eivät korosta: renkaan kuormitustieto saattaa olla yksittäinen tärkein tekninen tiedote, joka vaikuttaa turvallisuuteesi tiellä.

Mutta mitä renkaan kuormitustieto tarkalleen ottaen on? Yksinkertaisesti sanottuna se edustaa suurinta painoa, jonka yksi rengas voi turvallisesti kantaa normaalissa ajotilanteessa. Tämä tekninen tiedote määrittää sen yhden renkaan painorajan, jonka insinöörit laskevat materiaalin lujuuden, valmistusmenetelmän ja rakenteen geometrian perusteella. Ylitä tämä raja, ja altistut rakenteelliselle riskille joka kerta, kun lähdet liikenteeseen.

Piilevä turvallisuusmääritys, jonka useimmat kuljettajat sivuuttavat

Useimmat kuljettajat ymmärtävät renkaiden kuormitusluokituksen, kun se selitetään perustermein – he tarkistavat sivuseinän merkinnät uusia renkaita ostettaessa. Mutta mitä tarkoittaa renkaan kuormitusluokitus verrattuna vanteiden teknisiin tietoihin? Tässä on ratkaiseva ero: renkaiden ja vanteiden kuormitusluokitukset toimivat yhdessä järjestelmänä, mutta ne mittaavat täysin eri asioita.

Renkaittesi kantavat ilmanpaineen ja tien pinnan aiheuttaman taipumisen dynamiikkaa. Vanteet puolestaan kantavat rakenteellisen taakan siitä, että ajoneuvon massa yhdistyy näihin renkaisiin. Kun innokkaat harrastajat vaihtavat kevytvalurauteihin suorituskyvyn parantamiseksi, he eivät aina huomioi, vastaako uuden vanteen kuormitusluokitus ajoneuvonsa vaatimuksia tai ylittääkö sen.

Premium-valmistajat usein korostavat hienoa estetiikkaa markkinointimateriaaleissaan. Löydät yksityiskohtaiset tiedot pinnoitteen kestävyydestä, koverista profiileista ja räätälöidystä värivalikoimasta. Kuitenkin todellinen kuormituskyky – luku, joka määrittää selviääkö rengas äkillisestä kaistanvaihdosta moottoritien nopeudella – jää usein vähälle huomiolle.

Paino paikallaan vs. dynaamiset kuormitukset

Renkaiden kuormituksen ymmärtämiseksi on huomattava, että ajoneuvon painonjakauma kertoo vain osan tarinasta. Kuvittele auto seisovan liikkumatta ajotiepiesi päällä. Jokainen rengas kantaa noin neljäsosan kokonaispainosta – tätä kutsutaan staattiseksi kuormitukseksi.

Kuvittele nyt ajavasi terävään mutkaan suurella nopeudella. Yhtäkkiä ulommat renkaat kantavat selvästi enemmän kuin niiden staattinen osuus. Lisää tähän vielä voimakas jarrutus samassa mutkassa, ja voimat moninkertaistuvat entisestään.

Vapaa täytyy kestää paitsi ajoneuvon staattista painoa, myös dynaamisia voimia mutkissa, jarrutuksessa ja kiihdytyksessä – voimia, jotka voivat tilapäisesti kaksinkertaistaa tai kolminkertaistaa kuorman yksittäisiin vankoihin.

Tämä tosiasia selittää, miksi insinöörit suunnittelevat turvamarginaalit kuormitusarvojen määritelmiin. Vartaalle, jonka kuormitusarvo on 1 800 puntaa, ei ole tarkoitus kestää vain tasan tuota painoa eikä mitään enempää. Tämä arvo ottaa huomioon todellisen maailman dynamiikan, johon varret altistuvat energiapitoisessa ajossa, hätämanöövereissä ja jopa epätasaisilla teillä ajaessa.

Kun arvioit seuraavaa korkealaatuista valssattua vartaata koskevia kuormitusarvoja, muista, että numerot edustavat teknisiä rajoja, joita on testattu hallituissa olosuhteissa. Ajotyyli, ajoneuvon muutokset ja tarkoitus käyttää vaikuttavat siihen, tarjoaako tietty arvo riittävän turvamarginaalin tiettyyn käyttötarkoitukseen.

Valssatun, valumuottisen ja virta-valmistetun varren kuormitusarvojen erot

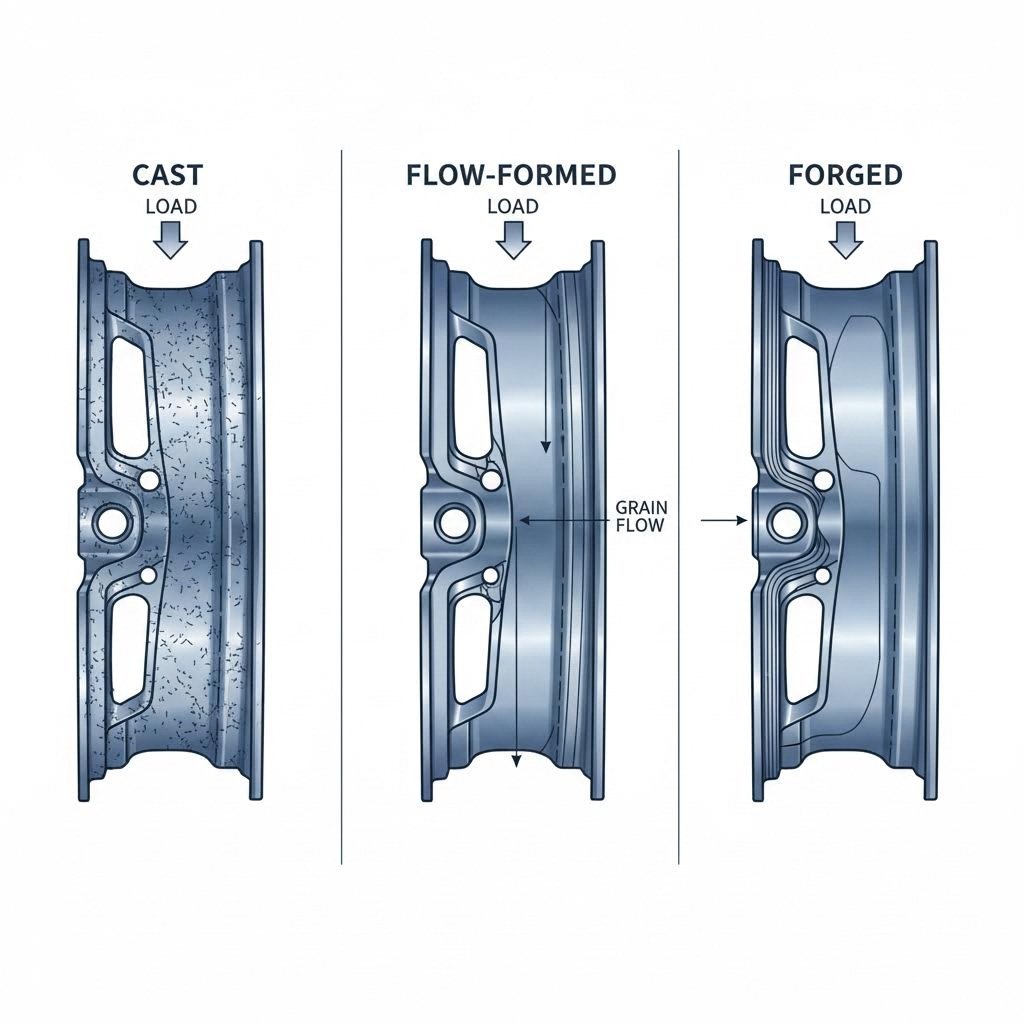

Nyt kun ymmärrät, miksi kuormitustiedot ovat tärkeitä, tässä on kysymys, johon useimmat renkaanostajat eivät koskaan mieti vastausta: miten rengas valmistetaan vaikuttaa siihen, kuinka suuren painon se voi turvallisesti kantaa? Vastaus piilee valssaus-, virtaustyökalu- ja taonta-menettelyjen perustavanlaatuisissa eroissa – kukin menetelmä luo huomattavasti erilaisia sisäisiä rakenteita, jotka suoraan määrittävät kuormankapasiteetin.

Ajattele sitä tällä tavalla. Voisit rakentaa sillan pinotuista tiileistä, kaadetusta betonista tai taotuista teräspalkkeista. Kaikki kolme saattavat näyttää samanlaisilta kaukaa katsottuna, mutta niiden kyky kestää rasituksia eroaa valtavasti. Sama periaate pätee renkaisiisi, ja näiden erojen ymmärtäminen auttaa sinua sopimaan valmistustavan todellisiin suorituskyvyssä oleviin vaatimuksiin.

Miten taonta luo ylivoimaisen rakeen rakenteen

Mikä tekee taotuista renkaista kykyiset kantamaan äärimmäisiä kuormia samalla kun ne pysyvät kevyinä? Salaisuus piilee siinä, mitä tapahtuu molekyylitasolla valmistuksen aikana.

Kun alumiinia kuumasekoitetaan, suurtaajuuspuristimet kohdistavat 8 000–10 000 tonnin paineen tarkasti lämmitettyihin kiinteisiin alumiinitankoosuihin. Tämä voimakas puristus ei ainoastaan muovaa metallia – se muuttaa perustavanlaatuisesti sen sisäistä rakeisuutta. Alumiinikiteet järjestyvät jatkuviksi, katkeamattomiksi rakenteiksi, jotka noudattavat renkaan muotoja.

Kuvittele ero satunnaisesti sijoitetun oksapinoa ja sellaisen köyden välillä, joka on valmistettu kiedotuista, samansuuntaisista kuiduista. Köysi kestää vetoa huomattavasti paremmin, koska sen kuidut toimivat yhdessä. Kuumasekoitetun alumiinin toimintaperiaate on sama: samansuuntaiset rakeenrajat muodostavat luonnolliset kuormituspolut, jotka jakavat rasituksen tehokkaasti koko rengasrakenteen läpi.

Tämä selittää, miksi premium-valmistajat kuten Forgeline ja Rays Engineering -valmistajien pyörät käyttävät ainoastaan kylmämuovattua valmistusta moottoriurheilusovelluksissa. Kun ammattilaisten kilpajoukkueet altistavat pyörät toistuville suurille G-voimille kaarteissa, lämpötilan vaihteluille ja reunaläpiajoille, vain kylmämuovattu rakenne kestää johdonmukaisesti näitä rankkoja olosuhteita. Suuntautunut rakeen rakenne vastustaa halkeamien etenemistä, mikä tarkoittaa, että pienet rasituskohdat eivät muodostu katastrofaalisiksi vioiksi.

Valu-, virta-muovattu- ja kylmämuovattu kuormituskyvyt

Teknisten erojen ymmärtäminen eri valmistusmenetelmien välillä auttaa arvioimaan, vastaako pyörän kuormitustaso todella vaatimuksiasi. Jokainen valmistustapa luo erilaisia rakenteellisia ominaisuuksia, jotka vaikuttavat suoraan painon kapasiteettiin.

Vanteiden valaminen sisältää sulan alumiinin kaatamisen muotteihin ja sen jähmettymisen antamisen. Tämä prosessi on kustannustehokas, mutta luo satunnaisen rakeen rakenteen mikroskooppisine huokosineen – pieninä ilmakuplina, jotka jäävät jäähtymisen aikana. Nämä epätäydellisyydet muodostuvat kuormituspisteiksi kuormituksen alla, mikä rajoittaa sitä, kuinka suuren painon vantaat voivat turvallisesti kantaa.

Virtovalaminen edustaa keskitietä. Valmistajat alkavat valamalla keskiosan, jonka jälkeen käyttävät pyöriviä rullia venyttämään ja puristamaan putkiosaa sen ollessa kuumennettuna. Tämä prosessi osittain suuntaa rakeen rakenteen putkiosassa, parantaen lujuutta pelkkään valumiseen verrattuna samalla kun pitää kustannukset täysforgauksen alapuolella.

Räätälöidyt CNC-vanteet alkavat usein forgauksista, joista tarkka koneenpurku poistaa materiaalia saavuttaakseen lopulliset mitat. Tämä lähestymistapa yhdistää forged-lujuuden suunnittelun joustavuuteen, vaikka koneenpuru vaatii huolellista suunnittelua rakenteellisen eheyden ylläpitämiseksi kriittisissä kantavissa kohdissa.

| RAKENNUSMETODI | Valmistusprosessi | Tyypillinen kuormakapasiteetin vaihteluväli | Painoluokitus | Parhaat käyttösovellukset |

|---|---|---|---|---|

| Moldatu | Sulatettua alumiinia kaadetaan muotteihin, jäähdytetään ja koneistetaan | 1 400–1 800 lb pyörä kohden | Painavin vaihtoehto; vaatii enemmän materiaalia vastaavaa lujuutta varten | Päivittäinen ajaminen, budjettirakenteet, tavalliset henkilöautot |

| Flow-formed | Valuvalmis keskiosa ja kuumalla venytetty / pyöritetty säiliö | 1 600–2 200 lb pyörä kohden | Kohtalainen paino; kevyempi säiliö ja valukevyinen keskiosa | Katusuorituskyky, tilapäinen ratakäyttö, urheilulliset sedanit |

| Pursottu | Yhtenäinen massiivinen palo puristettuna erittäin suurella paineella (yli 8 000 tonnia) | 2 000–2 800+ lb pyörä kohden | Kevyin annettuun lujuuteen nähden; optimaalinen materiaalitehokkuus | Moottoriurheilu, raskas ajoneuvo, aggressiivinen radakäyttö, perävaunun vetäminen |

Huomaatko kuormituskapasiteettien alueiden päällekkäisyyden? Tässä vaiheessa sertifiointistandardit tulevat kriittisen tärkeiksi. JWL-renkaat sisältävät Japanin viranomaisen suorittaman testausvahvistuksen, kun taas saksalainen TÜV-sertifiointi osoittaa eurooppalaisen yhteensopivuuden. Nämä merkinnät ovat tärkeitä, koska kaksi rengasta, joilla on samankaltaiset julkistetut arviot, saattavat toimia hyvin eri tavoin sen mukaan, kuinka tiukasti niitä on testattu.

Premium-renkaamerkit, kuten RS BBS -renkaat, ovat rakentaneet moottoriurheilullisen maineensa juuri taotusta valmistustekniikasta, koska kilpailujen kuormitustarpeet ovat ehdottomia. Jopa heidän katukäyttöön tarkoitetut mallinsa, jotka usein tunnistaa erityisistä BBS-keskuspeileistä, hyötyvät valmistustaitavuudesta, joka on kehittynyt kilpailupaineessa.

Vertaillessa vaihtoehtoja muista, että rakennetapa määrittää kuormankapasiteetin ylärajan. Ei valumuotoisen pyörän suunnittelusta riippumatta voida saavuttaa vastaavan kovan valmistustekniikan rajoja. Tämä perustava tosiasia tulisi ohjata valintaa siinä muodossa kuin käytät ajoneuvoasi – ei vain siitä miten haluat renkaiden näyttävän.

Kuinka selvittää ajoneuvollesi vaadittava kuormaluokitus

Ymmärrät nyt, kuinka valmistustavat vaikuttavat kuormankapasiteettiin, mutta tässä on käytännön kysymys, johon kukaan ei näytä vastaavan: mitä kuormaluokitusta sinun ajoneuvollesi todella tarvitaan? Yllättävintä kyllä, useimmat renkaiden myyjät sivuuttavat tämän keskustelun kokonaan, jättäen sinut arvaamaan, voivatko ne upeat kovakalotit turvallisesti kannatella ajoneuvoasi.

Laskenta ei ole monimutkainen, kun tietää, mistä etsiä. Ajoneuvosi ovenpihdin tarra sisältää lähtökohdan – ajoneuvon kokonaismassarajan (GVWR). Tämä luku edustaa suurinta kokonaispainoa, jonka ajoneuvo on suunniteltu kantamaan, mukaan lukien matkustajat, lasti, polttoaine ja itse ajoneuvo. Mutta GVWR:n muuntaminen pyörävaatimuksiksi vaatii enemmän kuin yksinkertaisen jakolaskun.

Vähimmäispyöräkuormavaatimasi laskeminen

Aloita GVWR:llä ja jaa se neljällä. Kuulostaako yksinkertaiselta? Se antaa sinulle perustason, mutta tämä luku yksinään voi olla vaarallisesti harhaanjohtava. Viiden tuhannen punnan GVWR:tä oleva ajoneuvo viittaa siihen, että jokainen pyörä pitäisi kantaa 1 250 puntaa – mutta tämä olettaa täydellisen tasapainoisen painonjakautuman ja nollan dynaamiset voimat.

Käytännön ajotilanteet hajottavat nämä olettamat välittömästi. Kun arvioit, mitä kuormitusluokkaa renkaiden ja pyörien tulee kestää, on otettava huomioon aiemmin käsitellyt voimat: mutkistus-, jarrutus- ja kiihdytyskuormitukset, jotka siirtävät tilapäisesti suuria massoja yksittäisille pyörille.

Tässä realistisempi lähestymistapa. Ota ajoneuvosi kokonaismassa (GVWR), jaa se neljällä ja lisää sitten 25–30 % turvamarginaali tavalliseen kadunajoon. Viiden tuhannen paunan ajoneuvolle laskelma näyttää tältä:

- Peruslaskelma: 5 000 ÷ 4 = 1 250 lb pyörä kohti

- 30 %:n turvamarginaalilla: 1 250 × 1,30 = vähintään 1 625 lb pyörä kohti

Tämä säädetyt luku huomioi tyypillisen dynaamisen kuormituksen arjessa ajossa. Mutta mitä tarkoittaa renkaiden kuormitusluokka tässä yhteydessä verrattuna pyörien kuormitukseen? Muista, että molempien teknisten tietojen on täytettävä tai ylitettävä laskemasi vaatimus. Renkaiden kuormitusindeksi ja pyörien kuormitusluokka muodostavat ketjun – ja ketjut murtuvat heikoimmasta lenkistä.

Autonpyörän painon ymmärtäminen vaikuttaa myös tähän yhtälöön. Raskaammat pyörät lisäävät ajoneuvon kokonaispainoa ja siten hieman kuormittavat jokaista pyörää enemmän. Kun lasket vaatimuksia kevytvalurauteja varten, vaihdat käytännössä pyörän painon hyötykuorman kapasiteetiksi – merkityksellinen huomio erityisesti huomattavasti muunnetuissa rakenteissa.

Miksi painojakauma muuttaa kaiken

Tuo yksinkertainen GVWR:ään perustuva neljällä jaettu laskelma olettaa, että ajoneuvosi jakaa painon tasaisesti kaikkien neljän kulman kesken. Käytännössä kuitenkin pyöriin kohdistuva paino vaihtelee huomattavasti ajoneuvon konfiguraation mukaan.

Ota esimerkiksi etumoottorinen takavetoinen urheiluauto. Moottori, vaihdelaatikko ja suurin osa mekaanisista komponenteista sijaitsevat auton kabinen edessä. Tämä rakenne sijoittaa tyypillisesti lepotilassa 52–55 % kokonaispainosta etuakselille. Etupyörät siis työskentelevät jo alusta alkaen enemmän, ennen kuin edes lähdet liikkeelle.

Mieti nyt C5 Corvetten painojakaumaa — noin 51 % etuosaan ja 49 % takaosaan vaihteiston asennon ansiosta, joka siirtää massan taaksepäin. Tämä lähes täydellinen tasapaino selittää alustan legendaarisen käsittelyominaisuuden, mutta se tarkoittaa myös, että molempien akselien pyörien kantokykyjen on oltava samankaltaiset. Vertaa tätä perinteiseen etumoottoriseen sedan-autoon, jossa etupyörille saattaa tarvita huomattavasti suurempia kuormitusluokituksia kuin takapyörille.

Keskimootoriset asetteluvariaatiot kääntävät tilanteen täysin ylösalaisin. Kun voimanlähtö sijaitsee kabinin takana, takapyörät kantavat usein 55–60 % staattisesta massasta. Nelivioajoneuvot, joissa on etuosassa sijaitseva moottori ja keskusvälitys, muodostavat vielä erilaisen jakaumamallin, jolloin painopiste on tyypillisesti etuosassa, mutta lisäksi drivetrainin paino jakautuu tasaisemmin.

Kuormasiirtoluokan renkaiden merkitys ja vastaavat pyöräspesifikaatiot tulisi heijastaa ajoneuvosi todellista massan jakautumista – ei vain sen kokonaismassan mielivaltaista jakoa. Ovimerkin tarkistaminen paljastaa sekä GVWR- että akselikohtaiset suurimmat akselikuormat (etu- ja takaa) antaen tarkan datan kullekin akselille. Jaa suurempi GAWR kahdella, ja olet määrittänyt tarkan pyöräkoon ja kuormaluokituksen, josta et missään nimessä saa tehdä kompromisseja.

Paitsi staattisen jakautumisen lisäksi tietyt ajotilanteet vaativat lisää kuormavarauksen kapasiteettia. REIKA Wheels huomauttaa, että tekijät, jotka lisäävät pyörän rasitusta, sisältävät epätasaisen maaston, kallionkiipeilyyn ja iskukuormitukseen – olosuhteet, jotka koskevat yhtä lailla myös suorituskykyajoa.

Jos rakennelmasi tai ajotyylin sisältää näitä tekijöitä, lisää vähimmäiskuormaluokituksesi vaatimusta peruslaskennasta ylöspäin:

- Ratakäyttö tai HPDE-tapahtumat: Toistuvat korkean g-voiman kaarteet ja aggressiivinen jarrutus lisäävät dramaattisesti pyörän hetkellisiä kuormia

- Perävaunun vetäminen: Kielen paino lisää merkittävästi taka-akselin kuormitusta; perävaunun heiluminen luo sivusuuntaisia voimia, joita normaalissa ajossa ei esiinny

- Raskaat muutokset: Turboahdintimet, rullakaapelit, äänijärjestelmät ja panssarointi lisäävät painoa, jota ajoneuvon suurin kokonaispaino (GVWR) ei ota huomioon

- Aggressiivinen ajotyyli: Vireitä kanyonien läpiajoja, autocross-osallistumista tai yksinkertaisesti energististä arkipäiväajamista

- Maastokäyttö: Iskukuormat kivistä, uurteista ja hyppymisestä aiheuttavat rasituksen piikkejä, jotka ylittävät huomattavasti tien päällä ajoon liittyvät olosuhteet

- Meren yli / retkikunta-rakennukset: Katon rahtilaatat, paremmat, taljat ja varustevarastointi nostavat ajoneuvon kokonaispainoa merkittävästi

Jos rakennettaessa tämän listan useita kohtia on toteutettu, harkitse 40–50 % lisäystä peruslaskelmaan verrattuna tavallisen 30 % sijaan. Täysin varusteltu retkikuntavaunu, joka kuljettaa leirintävarusteita, pelastusvälineitä ja kattoleirikehikon, voi helposti ylittää tehdasasetetun GVWR:n – eikä tehtaan renkaat ole yksinkertaisesti suunniteltu tähän todellisuuteen.

Ydinasia? Vähimmäiskuormitusluokituksesi ei ole numero, jonka löytää netistä – se on laskelma, joka liittyy nimenomaan ajoneuvoosi, sen muutoksiin ja siihen, miten todella ajat. Luvun oikeellisuuden varmistaminen ennen ostoksia takaa, että jokainen harkittava rengas täyttää käytännön vaatimukset, ei ainoastaan esteettiset mieltymykset.

Miten renkaan koko ja offset vaikuttavat kuormitusmäärityksiin

Olet laskenut ajoneuvosi kuormitustarpeet – mutta tässä se, mikä vaikeuttaa yhtälöä: renkaiden fyysiset mitat muuttavat huomattavasti sitä, miten kuormat jakautuvat rakenteen yli. 2000 punnan kuormitukseen luokiteltu rengas ei kokea kuormaa tasaisesti. Leveys, halkaisija ja offset ohjaavat jännitystä eri tavoin, joko maksimoiden turvallisuusmarginaalit tai keskittäen voimat haavoittuviin kohtiin.

Ajattele raskasta reppua. Pidä se lähellä kehoasi, ja paino tuntuu hallittavalta. Ojenna käsivartesi eteen, ja sama paino tuntuu uuvuttavalta muutamassa sekunnissa. Vanteen offset toimii täsmälleen samoin – kun kuorman keskipiste siirtyy suhteessa navan kiinnityspintaan, se muuttaa perustavanlaatuisesti sitä, miten vanteet kantavat rasitusta.

Leveyden ja offsetin vaikutus rasituksen jakautumiseen

Laajemmat vanteet levittävät renkaan kosketuspinnan suuremmalle alueelle, mikä kuulostaa hyödylliseltä kuormituksen jakautumisen kannalta. Kuitenkin suurempi leveys myös lisää etäisyyttä navan keskiviivan ja vanteen ulkoreunan välillä. Tämä luo pidemmän vipuvarren, joka suurentaa rasitusta kiinnityspinnassa – täsmälleen siinä kohdassa, jossa vanteen ruuvit kiinnittyvät navaan.

Suositut konfiguraatiot, kuten 20x9 renkaat, havainnollistavat tätä suhdetta erinomaisesti. 9-tuumainen leveys tarjoaa erinomaisen pituuden suorituskykysovelluksissa, mutta tämä lisäleveys verrattuna kapeampaan 20x8 asetelmaan kasvattaa vipuvarren vaikutusta navan komponentteihin. Ajoneuvot, jotka käyttävät aggressiivisia asennuksia, yhdistävät usein leveät renkaat 2 tuuman rengasvälikappaleisiin saavuttaakseen tasaisen pyöräsuojan ulkonäön, mikä edelleen pidentää tätä vipuarmia ja moninkertaistaa kuorman renkaiden laakerien ja nava-astian osille.

Etäisyys moninkertaistaa nämä vaikutukset. Mukaan Korotetut kuorma-autot , negatiivinen etäisyys kasvattaa "pyyhkimissädettä"—etäisyyttä renkaan kosketuspisteen ja ohjausakselin maanpintaleikkauksen välillä. Tämä pidennetty vipuvaikutus lisää sivusuuntaista kuormitusta pallonivelten, laakerien, ohjaustankojen ja säätövarsien osille.

Harkitse kuorma-autoa, joka käyttää Chevy 6-napaisia vaijeripohjia ja aggressiivisilla negatiivisilla etäisyyksillä varustettuja pyöriä. Jokainen ohjausliike ja tien aiheuttama isku luo kiertovoimia, jotka vaikuttavat ulottuvan momenttivarren kautta. Pyörän kuormitusluokitus saattaa teknisesti ylittää ajoneuvon vaatimukset, mutta etäisyyden sijoittuminen keskittää rasituksen navan liitoskohtaan tavalla, jota raakaluvut eivät kerro.

Toisaalta 5 tuuman etäisyydellä olevat pyörät (positiivinen etäisyys) sijoittuvat lähemmäksi suspensiota, mikä vähentää vipuvarren vaikutusta. Tämä konfiguraatio aiheuttaa vähemmän rasitusta laakerien ja suspensio-osien osalta, mutta saattaa aiheuttaa tilaongelmia jarrusylintereiden tai sisäisten fender-onttien kanssa. Tasapainon löytäminen edellyttää ymmärrystä siitä, että etäisyys ei ole pelkästään esteettinen kysymys – se on rakenteellinen suunnittelupäätös, joka vaikuttaa pitkän aikavälin kestävyyteen.

Metallivälikappaleet lisäävät tähän yhtälöön toisen muuttujan. Vaikka laadukkaat välikappaleet säilyttävät oikean keskityksen navassa, ne muuntavat tehokkaasti pyörän etäisyyden kohti negatiivisempaa arvoa. +35 mm:n etäisyydellä varustettu pyörä, jossa on 25 mm:n välikappaleet, toimii nyt kuin +10 mm:n etäisyydellä varustettu pyörä, mikä muuttaa koko jousitusjärjestelmään kohdistuvaa kuormituksen jakautumismallia.

Miksi suuremmat pyörät vaativat korkeampia kantavuusluokituksia

Siirtyminen 17-tuumaisista 20- tai 22-tuumaisiin pyöriin ei ole pelkästään visuaalinen päivitys – se muuttaa perustavanlaatuisesti tapaa, jolla ajoneuvo vaimentaa tien epätasaisuuksia. Tämä halkaisijan ja kuormitustarpeen välinen suhde yllättää monet innokkaat harrastajat.

Tässä fysiikka: suurempien halkaisijoiden pyörille tarvitaan matalampiprofilisia renkaita, jotta kokonaishalkaisija ja nopeusmittarin tarkkuus säilyvät. Lyhyempi rengassivu tarkoittaa vähemmän kumia, joka voi taipua ja vaimentaa iskuja. Kun rengas ei pysty pehmittämään reikää tiellä, tämä energia siirtyy suoraan pyörärakenteeseen.

Kuten BB Wheels selittää, että matalammat renkaat ovat vähemmän joustavia sivusuunnassa, mikä parantaa ohjattavuuden ennustettavuutta, mutta siirtää iskunvoimat suoraan pyörään. 35-sarjan rengas 22-tuumaisella vanteella vaimentaa huomattavasti vähemmän iskuja kuin 55-sarjan rengas 17-tuumaisella vanteella, vaikka ne kannattaisivat saman ajoneuvon painon.

Suuremmat pyörät ovat myös tyypillisesti painavampia, mikä lisää jousittamatonta massaa. Tämä ylimääräinen massa luo suuremman hitauden jousitusliikkeiden aikana, eli pyörä palaa asemastaan hitaammin epätasoista tietä ajettaessa. Jousitus joutuu työskentelemään kovemmin, ja jokainen isku siirtyy suuremmalla liikemäärällä pyörärakenteeseen.

Perävaunukäytännöt osoittavat tämän periaatteen selvästi. Perävaunujen 5-nivelhubit, jotka käyttävät pienempikokoisia pyöriä, hyötyvät korkeammasta rengassivusta, joka toimii tavaroiden suojaena iskujen varalta, kun taas saman perävaunun liian suuret pyörät vaatisivat huomattavasti korkeampia kuormitusluokituksia selvitäkseen samoista tietolosuhteista.

| Pyörän halkaisija | Tyypillinen renkaan profiili | Henkilöautot (Kuormitusluokitus) | Suorituskykyiset sedanit/SUV:t | Kamionit/Raskaat ajoneuvot |

|---|---|---|---|---|

| 17-tuumainen | 55–65-sarja | 1 400–1 650 lb | 1 600–1 850 lb | 1 800–2 200 lb |

| 18-tuumainen | 45–55-sarja | 1 500–1 750 lb | 1 700–2 000 lb | 860–1 090 kg |

| 19 tuumaa | 40–50-sarja | 1 600–1 850 lb | 1 800–2 150 lb | 2 000–2 500 lb |

| 20-TUUMAINEN | 35–45 sarja | 1 700–2 000 lb | 1 900–2 300 lb | 2 100–2 650 lb |

| 22-tuumainen | 30–40 sarja | 1 850–2 200 lb | 2 100–2 500 lb | 2 300–2 800+ lb |

Huomaa, kuinka kuormavaatimukset kasvavat halkaisijan myötä kaikissa ajoneuvoluokissa? Suorituskykysovelluksissa suosittu 20x9 renkaskokoonpano sijoittuu selvästi alueelle, jossa tarvitaan vankkoja kuormitustasoja – tyypillisesti 1 900–2 300 puntaa urheilusedaneille ja suorituskyky-SUV:ille. Siirtyminen 22-tuumaisiin kokoonpanoihin nostaa vaatimuksia entisestään, erityisesti aggressiivisen ajo- tai muunnetun suspensiojärjestelmän yhteydessä.

Yhteenveto? Kun päivität rengashalkaisijaa, älä oleta, että nykyiset kuormitustarpeesi säilyvät ennallaan. Suuremmat renkaat ja matalammat profiilitiret edellyttävät korkeampaa rakenteellista kantavuutta lisääntyneen iskunsiirtymisen vuoksi – riippumatta siitä, onko ajoneuvosi todellinen paino muuttunut. Seuraavassa luvussa käsitellään, miten valmistajat vahvistavat nämä kuormaväitteet teknisillä testauksilla.

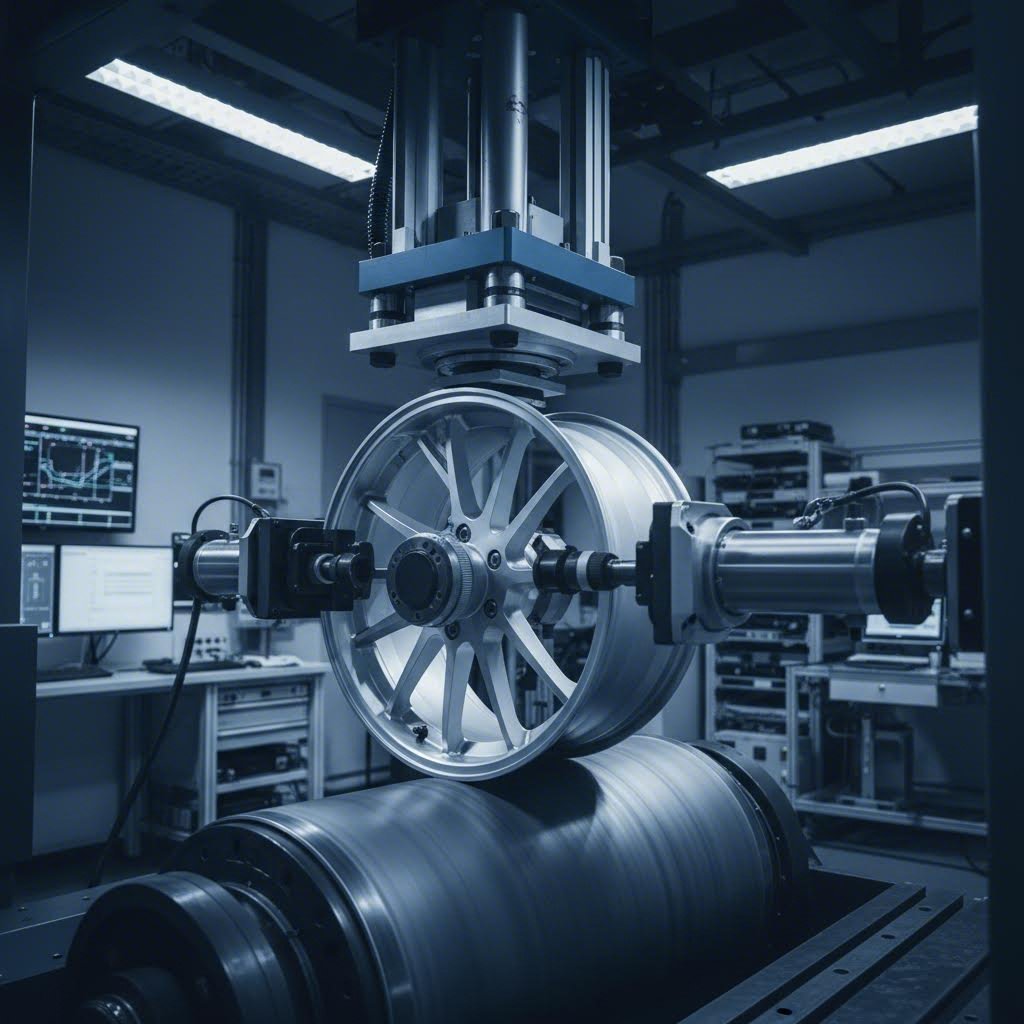

Kuormatarkastukset, jotka vahvistavat kuormitustiedot

Olet oppinut laskemaan kuormavaatimuksesi ja ymmärtämään, miten pyörän mitat vaikuttavat jännitysjakaumaan. Mutta tässä on epämukava totuus: pyörään painettu kuormitustieto on yhtä luotettava kuin sen takana oleva testaus. Jotkut valmistajat varmistavat jokaisen suunnittelunsa edistyneillä teknisillä protokollilla. Toiset? Ne vain arvaavat – ja toivovat, ettei ero koskaan tule ilmi.

Se, miten lailliset valmistajat määrittävät räätälöityjen valssattujen pyörien kuormitustiedot, erottaa tietoiset ostajat niistä, jotka uhraavat turvallisuutensa. Teknisen vahvistamisen prosessiin kuuluu sekä tietokonesimulointi että fyysinen tuhoamistestaus, ja kumpikin paljastaa eri näkökulmia siitä, miten pyörä kestää todellisen käytön aiheuttamaa rasitusta.

Rakenteen elementtianalyysi (FEA) pyörien osalta

Kuvittele pyörän suunnittelun testaaminen ennen kuin se fyysisesti edes on olemassa. Juuri tämän mahdollistaa elementtimenetelmä, eli FEA. Tämä tietokonepohjainen simulointityökalu on vallannut uudelleen tapaa, jolla insinöörit varmentavat pyörän testiparametrit tuhoamatta kalliita prototyyppejä.

Näin se toimii. FEA-ohjelmisto jakaa pyöräsuunnitelmasi tuhansiin pienempiin elementteihin – pieniin geometrisiin osiin, jotka yhdessä muodostavat koko rakenteen. Forgelite Wheelsin mukaan jokainen elementti analysoidaan matemaattisten mallien avulla, jotka ennakoivat käyttäytymistä sovellettujen voimien alaisena. Jokaisen elementin tulokset yhdistetään luodakseen kattavan kuvan siitä, miten koko pyörä reagoi kuormitukseen.

Ajattele sitä kuin silta-suunnitelman rasitustestausta tietokoneella ennen kuin kaadetaan yhtään kuutiometriä betonia. Insinöörit voivat nähdä tarkalleen, missä kohtaa rakenne keskittää rasituksen, missä halkeamat saattavat syntyä ja selviykö rakenne tarkoitetuista kuormituksista – kaikki ennen kuin ryhdytään tuotantotyökaluihin.

Räätälöityjen taottujen renkaiden osalta FEA on erityisen arvokas. Toisin kuin suurvalmisteisissa valuraudoissa, joissa fyysiset testit perustellusti oikeuttavat suuret tuotantosarjat, räätälöidyt taotut suunnittelut ovat usein olemassa vain yksittäisinä sarjoina. Et voi tuhota räätälöityä rengasta sen testaamiseksi, jos rengas on tehty nimenomaan yhden asiakkaan ajoneuvoon. FEA täyttää tämän aukon tarjoamalla teknisen validoinnin ilman fyysistä tuhoamista.

Simulaatio arvioi useita kriittisiä tilanteita:

- Säteittäinen kuormitus: Simuloi renkaan kantavaa voimaa normaalissa ajotilanteessa

- Kulmien ottaminen: Mallintaa sivusuuntaista jännitettä voimakkaita kaarteita ajettaessa

- Iskunkestävyys: Ennustaa rakenteellista vastetta lovettomurtumisiin ja reunakivetörmäyksiin

- Lämpöjännitys: Arvioi, miten jarrujen huumetta vaikuttaa materiaaliominaisuuksiin

Graafinen tuloste tekee ongelmakohdista välittömästi näkyviä. Insinöörit näkevät värikoodatut jännityskartat, jotka korostavat tarkalleen niitä kohtia, joissa suunnitelma lähestyy rajojaan. Punaiset vyöhykkeet osoittavat alueita, jotka vaativat vahvistamista; siniset vyöhykkeet viittaavat materiaaliin, jota voitaisiin mahdollisesti poistaa painon vähentämiseksi turvallisuutta vaarantamatta.

Mutta tässä erottuu luotettavat valmistajat kyseenalaisista: läpinäkyvyys. Jotkut valssattujen renkaiden valmistajat väittävät suorittavansa FEA-analyysin, mutta kun asiakkaat pyytävät dokumentaatiota, mitään ei tosiasiassa ilmesty. Kuten Forgelite huomauttaa, he toimittavat FEA-tulosten kopiot asiakkaan pyynnöstä – tämäntasoinen läpinäkyvyys pitäisi olla standardi koko alalla. Jos valmistaja ei jaa teknistä validointiaan, on pakko kysyä: onko tuolla validoinnilla todella olemassa?

Fyysiset testausmenettelyt, jotka vahvistavat kuormaväitteet

FEA tarjoaa suunnan, mutta fyysinen testaus toimittaa todistuksen. Vaikka tietokonesimulaatio olisi kuinka kehittynyt, se ei voi täysin jäljitellä kaikkia oikean maailman muuttujia. Siksi arvostetut valmistajat altistavat renkaansa rajuille fyysisille testeille, jotka vievät suunnitelmien rajat jopa niiden julkaistuja rajoja pidemmälle.

Laadukkaiden rengaiden varren kuormitusarvo, jonka näet painettuna renkaisiin, edustaa useiden tuhoamalla tehdyjen testien tulosta. Sen ymmärtäminen, mitä nämä testit todella mittaavat, auttaa sinua arvioimaan, ansaitsevatko valmistajan väitteet luottamuksesi.

Säteittäisen väsymyksen testaus simuloi tuhansia ajomailia tavallisessa ajotilanteessa tiivistetyissä aikakehyksissä. Rengas asennetaan rummuun, joka kohdistaa jatkuvaa säteittaista kuormitusta pyörivän renkaan aikana, jäljitellen ajoneuvon painon aiheuttamaa rasitusta maili toiselta maililta. Tämä testi paljastaa, pystyykö rengas kestämään pitkäaikaista käyttöä ilman väsymisrikkojen syntymistä rasituskonsentraation kohdissa.

Kulmien väsymyksen testaus käsittelee aiemmin käymämme dynaamiset voimat. Veli pyörii kulmassa asennettuna, mikä luo jatkuvan sivuttaislastin, joka simuloi aggressiivista mutkistoa. Tree Wheelsin mukaan tämä testi on erityisen tärkeä suorituskykysovelluksissa, joissa renkaat kokevat toistuvasti suuria sivuttaisvoimia korkeilla G-voimilla ajettaessa energisesti.

Vaikutustesti vastaa kuoppa-kysymykseen. Painotettu iskuri putoaa renkaan reunalta tietystä korkeudesta, mikä simuloi yhtäkkisiä iskukuormia, joita ilmenee tieliikennevaarassa osumisesta. Testi varmistaa rakenteellisen eheyden silloin, kun rengas kokee voimia, jotka ovat selvästi normaalin kuormituksen yläpuolella – täsmälleen sama kuin tapahtuu, kun osut yllättäen pakkasrapautumiseen pimeällä moottoritiellä.

Nämä fyysiset testit selittävät, mitä renkaan kuormaluokka tarkoittaa pyörän määritysten suhteen. Molempien komponenttien on selviydyttävä toisiaan täydentävistä testausmenetelmistä, jotka simuloidaan käytännön rasituksia. Renkaan kuormaluokka ilmaisee sen testatun kapasiteetin kestää painoa ja iskuja; pyörän kuormaluokituksen merkintä osoittaa, että se on läpäissyt vastaavan vahvistuksen, joka on spesifinen pyörärakenteille.

Miten voit varmistaa, että valmistaja on todella suorittanut nämä testit? Etsi pyörän kuormaluokituksen merkintää ja sertifiointimerkkejä, jotka osoittavat kolmannen osapuolen vahvistuksen:

- JWL (Japan Light Alloy Wheel): Tiukka japanilainen standardi, joka arvioi rakenteellista eheyttä pyörivän taivutusväsymyksen, iskukestävyyden ja materiaalikoostumuksen analyysin kautta

- VIA (Vehicle Inspection Association): Lisävarmennus Japanista, joka sisältää dynaamisen kurvaväsymystestauksen perusvaatimusten JWL yli – erityisen tärkeää suorituskykysovelluksissa

- TÜV (Saksa): Eurooppalainen sertifiointi, joka tunnetaan tiukoista turvallisuustarkistuksista ja tuotannon laadun jatkuvasta valvonnasta

- SAE J2530: Kattava amerikkalainen standardi, jonka on julkaissut Society of Automotive Engineers ja joka kattaa radiaalisen väsymisen, kurvien väsymisen, iskunkestävyyden ja materiaaliominaisuuksien vahvistamisen

Nämä sertifioinnit ovat tärkeitä, koska ne edustavat riippumatonta varmennusta – eivät ainoastaan valmistajan omaa ilmoitusta. Kun Tree Wheels huomauttaa, että JWL-VIA-sertifiointi edellyttää renkaiden todistavan "kykynsä kestää paitsi suoraviivainen rasitus myös innokkaassa ajossa kohtaavat monimutkaiset voimat", he kuvailevat täsmälleen sitä validointia, jota suorituskykyä arvostavat ostajat tarvitsevat.

Ovatko Enkei-renkaat kopiot? Tämä kysymys – jota usein esitetään suosittuihin merkkeihin liittyen – korostaa sekaannusta renkaiden aitouden ja sertifioidun asian ympärillä. Aidoilla Enkei-tuotteilla on oikeat sertifiointimerkinnät ja testausasiakirjat. Niiden suunnitelmia jäljittelevät repliikkarrenkaat ohittavat usein kokonaan kalliit testausmenettelyt, mikä tarkoittaa, että houkutteleva renkaiden kuormitustestin merkintä saattaa olla täysin kuviteltu.

Väiteiden ja insinööritoteutuksen välinen kuilu johtuu dokumentoinnista. Mikä tahansa valmistaja voi julkaista vaikuttavia kuormitustietoja verkkosivullaan. Vain ne valmistajat, jotka sitoutuvat todelliseen insinöörivalidointiin, voivat toimittaa FEA-raportit, testitodistukset ja sertifiointileimat, jotka todistavat näiden lukujen merkityksellisyydestä. Ennen ostopäätöstä pyydä todisteita – ja poistu kauppapaikalta, jos myyjä ei voi niitä toimittaa.

Erikoiset kuormitustarpeet rata- ja maastokäyttöön

Olet oppinut, miten insinöörit varmentavat kuormitustiedot kovien testien avulla – mutta tässä on se, mitä standardoidut testit eivät täysin kerro: äärioireet, joita ilmenee radakäytön, maastoretkien ja raskaiden perävaunujen vetämisen aikana. Nämä erikoiskäyttötavat rasittavat renkaita paljon enemmän kuin tavallinen kadunajot, ja se kuormitustaso, joka riittää arjessa, saattaa osoittautua vaarallisesti riittämättömäksi, kun ajat kierrosajoja tai kiipittelet kalliokentillä.

Näiden korkeampien vaatimusten ymmärtäminen auttaa sinua valitsemaan räätälöidyt taottujen renkaiden kuormitustiedot oikein sen mukaan, miten todella käytät ajoneuvoasi – ei vain sen mukaan, mitä valmistajat olettavat sinun ajavaan.

Radakäytön lämpö- ja G-voimavaatimukset

Kuvittele itsesi HPDE-tapahtumaan, jossa läpikäynti kulkee samaa mutkaa kierroksittain. Jarrusi hehkuvat, renkaasi kiljuvat ja pyöräsi kokevat voimia, jotka pelottaisivat suurimmaksi osaksi kaduille suunniteltuja insinöörejä. Tämä ei ole paranoaa – kyseessä on fysiikka.

Ratakäyttö altistaa pyörät kahdelle yhdistyvälle rasitukselle, joita esiintyy harvoin normaalissa ajossa: kestävälle lämpökuormitukselle ja toistuville korkean G-voiman vaikutuksille. Voimakkaassa jarrutuksessa kolmenumeroiden nopeuksista jarrulevyt voivat ylittää 1 000 °F (noin 538 °C). Tämä lämpö ei pysy sisällä levyssä – se säteilee ulospäin pyörän kiinnityspinnalle ja rungolle. Alumiinin lujuus heikkenee lämpötilan noustessa, mikä tarkoittaa, että pyörän tehollinen kuormituskyky laskee juuri silloin, kun kulmanottovoimat ovat suurimmillaan.

Kuten fifteen52 selittää , rata-ajoissa rajapyykkeillä ajavaiset luottavat renkaiden kuormitustehon huomioimiseen pysyäkseen vakaana ja saavuttaakseen suorituskykyä korkean nopeuden mutka-ajoissa ja jarrutuksissa. Kilpa-ajossa esiintyvät voimat ovat merkittävästi suuremmat kuin mitä tavallisilla teillä koskaan kohdataan.

Mieti, mitä tapahtuu nopeassa kaarteessa. Jatkuvasti 1,2 G:n sivukuorma – mikä on yleistä radalla – lisää tehokkaasti ulompien renkaiden kuormitusta 60 % verrattuna suoralla ajamiseen. Kun useita kaarteja ajetaan peräkkäin ilman jäähdytysjaksoja, renkaiden rakenne joutuu toistuvasti rasituksen kohteeksi lämpötilaltaan heikentyneessä tilassa. Mustangin vetorenkaat ja muiden drag-tuotemerkkien renkaat kohtaavat erilaisia, mutta yhtä äärimmäisiä vaatimuksia: valtava vääntömomentti käynnistyksissä luo vääntöjännitystä, joka kiertyttää renkaan rakennetta navan ja renkaan rengashihnan välillä.

Vetopyörät ja renkaat toimivat järjestelmänä, joka on suunniteltu nimenomaan näihin tiettyihin kuormituksiin. Tarkoituksenmukaisesti rakennetuissa vetopyörissä on vahvistetut sädekannat ja paksummat navan kiinnityspinnat, jotka on suunniteltu kestämään toistuvia kovia lähtöjä ilman väsymisrikkojen syntymistä. Jos käytät kaduilla ajamiseen tarkoitettuja pyöriä drag-radoilla, vedät uhkapeliä siitä, että moottoritien mukaan optimoidut suunnitteluratkaisut kestävät voimia, joita niiden ei koskaan ollut tarkoitus kohdata.

Vakavasti otettaville rataharrastajille ratkaisu edellyttää moottoriurheilusovelluksiin erikseen suunniteltujen pyörien valintaa. Etsi valmistajia, jotka julkaisevat nimenomaisesti tulokset lämpösyklitestausista ja dynaamisista kuormitustiedoista – ei ainoastaan staattisia tietoja. Tuon 2 200 punnan kuormitusarvon merkitys on vähäinen, jos se laskee 1 600 paunaan, kun pyörien lämpötila nousee kolmannella kuumalla kierroksella.

Maasto-iskukuormitus ja sivuttaisvoimat

Maastoympäristössä esiintyy rasituskuvioita, joita tienvarrella suoritetut laskelmat eivät yksinkertaisesti pysty ennakoimaan. Vaikka radanajo sisältää ennustettavia, toistettavissa olevia voimia sileillä pinnoilla, maastossa esiintyy äkillisiä ja voimakkaita iskuja täysin ennustamattomista kulmista.

Mukaan lukien Hardrock Offroad , maastoympäristöt aiheuttavat ainutlaatuisia rasituksia, jotka menevät tavallisten moottoriteiehtojen laajuutta pidemmälle. Kivien aiheuttamat iskut, äkilliset painonsiirrot artikuloinnin aikana sekä jousituskuormat pudotuksista ja hyppymisestä asettavat kaikki lisävaatimuksia pyörille. Kun lisäksi otetaan mukaan vetovälineet, leirintävarusteet, vesi ja polttoaine pitkille maastomatkoille, pyörien on kestettävä huomattavasti enemmän kuin perusajoneuvon paino.

Mieti, mitä tapahtuu, kun kuorma-auton pyörät törmäävät nopeudella 25 mph näkymättömään kiveen. Tämä hetkellinen isku voi luoda voimia, jotka ovat kolme–viisi kertaa suurempia kuin pyörän staattinen kuorma – esimerkiksi 900 kg:n kuormarajan pyörään voi hetkellisesti kohdistua jopa 3 600 kg:n voima, joka keskittyy rengaslevyn pienen alueen varaan. Vain ne pyörät, joissa on huomattavat turvamarginaalit, kestävät tällaiset rasitussyklit halkeamatta tai muodostumatta pysyvästi vääntyneiksi.

Artikulaatio luo toisen haasteen, joka on yksilöllinen maastokäytölle. Kun yksi pyörä putoaa aukkoon samalla kun vastakkainen pyörä kiipeää esteen yli, paino siirtyy dramaattisesti kuormitetuille kulmille. Oikean etupyöräsi voi tilapäisesti kantaa jopa 70 % ajoneuvosi etuakselin painosta – huomattavasti enemmän kuin standardilaskelmissa käytetty oletus 50 %.

Perävaunun vetäminen asettaa omat erityisvaatimuksensa. 5000 lb perävaunun akseli, jossa on 5-napainen kiinnitys, aiheuttaa suuren kiinnityspistekuorman vetävän ajoneuvon takapyöriin, kun taas perävaunun heiluminen luo sivusuuntaisia voimia, jotka kasvavat nopeuden myötä. Kasvanut staattinen kuormitus yhdistettynä dynaamisiin heilumisvoimiin tarkoittaa, että vetoon tarkoitettujen pyörien kuormankapasiteetin on oltava huomattavasti suurempi kuin samalla ajoneuvolla olisi tarvetta ilman kuormaa.

Rakennettaessa, jos vaaditaan erikoistyökaluja, kuten turbotulppia, on huolellisuus laitteiden teknisissä tiedoissa laajennettava jokaiseen komponenttiin – myös pyörien valintaan. Tarkoituksenmukaisesti suunnitelluilla maastopyörillä ja vetopyörillä on usein paksummat säteiden poikkileikkaukset, vahvistettu kehärakenne ja kuormitustiedot 30–50 % korkeammat verrattuna vastaaviin kaduille tarkoitettuihin pyöriin.

Varoitusmerkit räätälöityjä pyöriä ostettaessa

Nyt, kun ymmärrät erikoistuneiden sovellusten aiheuttamat korkeammat vaatimukset, varoitusmerkkien tunnistaminen ostamisen aikana on ratkaisevan tärkeää. Kaikki suorituskykyyn tai maastokäyttöön marketoitu pyörä ei välttämättä tarjoa riittävää kuormankapasiteettia – ja jotkut myyjät tahallisesti hämärtävät tätä tietoa.

Kiinnitä huomiota näihin varoitusmerkkeihin, jotka viittaavat riittämättömiin kuormitustasoihin tai kyseenalaiseen valmistuslaatuun:

- Myyjän haluttomuus antaa teknisiä tietoja: Luotettavat valmistajat julkaisevat kuormitustiedot selvästi. Jos sinun täytyy toistuvasti kysellä perusrakennetietoja, myyjä joko ei tiedä niitä tai ei halua, että sinä tiedät.

- Puuttuvat sertifiointimerkinnät: Aitojen JWL-, VIA-, TÜV- tai SAE-sertifiointien saaminen edellyttää kalliita kolmannen osapuolen testejä. Sertifiointimerkitön pyörä ei ole koskaan todennettu itsenäisesti, riippumatta siitä, mitä myyjä väittää.

- Hinta merkittävästi vakiintuneita brändejä alhaisempi: Kuuman valmistus, lentokoneen luokan alumiini ja asianmukainen testaus maksavat todellista rahaa. Pyörät, joiden hinta on 50–70 % halvempia kuin vastaavat tuotteet arvostetuilta valmistajilta, tekevät leikkauksia jossain – usein materiaalin laadussa tai testausmenettelyissä.

- Epämääräinen tai puuttuva maatieto: Laadukas valmistus tapahtuu ympäri maailmaa, mutta tuotantopaikan läpinäkyvyys viittaa vastuullisuuteen. Kiertävät vastaukset siitä, missä pyörät oikeasti on valmistettu, viittaavat usein laatutason huonoutta.

- Ei takuuta suorituskykykäyttöön: Valmistajat, jotka luottavat omaan insinööritaitoonsa, seisovat tuotteidensa takana. Takuita, jotka nimenomaisesti sulkevat pois radankäytön, maastokäytön tai vetämisen, paljastavat että valmistaja tietää pyörien ei kestävän näitä kuormituksia.

- Yleisluonteista markkinointia ilman teknistä sisältöä: Väitteillä "edistyneestä teknologiasta" tai "premium-rakenteesta" ei ole merkitystä ilman tarkkoja tietoja. Etsi todellisia kuormitustietoja paunoina, testisertifiointeja nimeltä sekä materiaalimääritelmiä, kuten seostyyppi ja lämpökäsittely.

Kuten fifteen52 huomauttaa, laadukkaiden, hyvällä maineella varustettujen renkaiden hankinta kannattaa joka pennin verran. Edullisten renkaiden ja kunnolla suunniteltujen vaihtoehtojen hintaero edustaa usein testausta, sertifiointia ja materiaalin laatua, jotka pitävät sinut turvassa silloin, kun ajovaatimukset ylittävät tavalliset ajotilanteet.

Riittämättömien kuormitusten seuraukset erikoiskäytössä vaihtelevat ärsyttävistä katastrofaalisiin. Pienemmät ongelmat sisältävät kiihtynyttä väsymisrikkomista, taipuneita rengashihnoja ja ennenaikaista laakerikulumista. Vakavat seuraukset sisältävät yhtäkkaista rakenteellista pettämistä nopeakuljetuksessa tai iskun aikana – juuri silloin, kun et pysty enää säilyttämään ajoneuvon hallintaa.

Rata-, maasto- tai vetokäyttöön liittyvissä sovelluksissa pyörän valinta on käsiteltävä yhtä vakavasti kuin jarrukomponenttien tai suspenssiosien valinta. Nämä eivät ole vain lisävarusteita – ne ovat turvallisuuskriittisiä rakenteita, joiden on toimittava virheettömästi olosuhteissa, joita kadunpyörien ei tarvitse koskaan kokea. Seuraavassa luvussa tarkastellaan, miten jälkituotepyörien tekniset tiedot vertautuvat OEM-standardien kanssa, ja auttaa sinua ymmärtämään sen perustason, jonka päälle uudet pyörät tulisi vähintäänkin vastata.

Jälkituotepyörien vertailu OEM:n kuormitustasoihin

Olet oppinut tunnistamaan laadukkaat pyörät epäluotettavista – mutta tässä kysymys, joka saa jopa kokeneet autoharrastajat epäröimään: miten jälkituotepyörien kuormitusluokat todella suhtautuvat tehdaspyöriin, joilla ajoneuvo toimitettiin? Tämän vertailun ymmärtäminen auttaa sinua tekemään sellaisia päivityksiä, jotka parantavat ajoneuvoasi heikentämättä alkuperäisten osien turvallisuutta.

Kun tarkastelet OEM-BMW-renkaita, Chevroletn OEM-vanteita tai tehdasvanteita mistä tahansa valmistajasta, tarkastelet komponentteja, jotka on suunniteltu yhtä ainoaa tarkoitusta varten: kyseistä ajoneuvoa. Jälkikäsittelyvaihtoehdot kohtaavat perustavanlaatuisesti erilaisen haasteen – niiden on toimittava kymmenissä eri sovelluksissa ja silti täytettävä jokaisen ajoneuvon yksilölliset vaatimukset.

OEM-suunnittelu verrattuna jälkikäsittelyvaihtoehtojen monikäyttöisyyteen

Tehtaanvanteitasi ei suunniteltu eristyneesti. Alkuperäisen varustuksen (OE) vanteita kehittävät insinöörit pääsivät käsiksi ajoneuvon täydellisiin teknisiin tietoihin: tarkkaan tyhjäpainoon, painonjakoon, suspenssion geometriaan, tarkoitukseen ja suorituskykyrajoihin. Tämä integraatio mahdollistaa sen, että OEM-vanteet voidaan kalibroida tarkasti vastaamaan juuri ajoneuvosi vaatimuksia – ei enempää eikä vähempää.

Mukaan lukien Vredestein , OEM-renkaat on valmistettu tarkalleen ajoneuvon määrittämien teknisten vaatimusten mukaisesti, mukaan lukien koko, offset, kiinnityskuvio ja kuormitusluokitus. Ne läpäisevät tiukat testit, joilla varmistetaan turvallisuus-, suorituskyky- ja kestävyysvaatimukset, jotka ajoneuvuvalmistaja on asettanut. Kun valitset OEM-renkaat, voit olla varma, että ne sopivat ajoneuvoosi täydellisesti ilman muutoksia.

Tällä tarkkuutta edellyttävällä suunnittelulla on haittapuolensa: rajoittunut vaihteluiden määrä. Tehdasrenkaat priorisoivat toiminnallisuuden muotoilun edelle. Tämä johtaa usein varovaisiin suunnitteluun, joka saattaa olla ristiriidassa henkilökohtaisen mieltymyksesi kanssa. Tässä kohtaa jälkimmäisille markkinoille suunnatut vaihtoehdot tulevat kysymykseen.

Jälkimmäisille markkinoille suunnatut renkaat kohtaavat täysin erilaisen suunnittelun haasteen. Yhtä rengaskokoonpanoa voidaan markkinoida samanaikaisesti urheilusedaneihin, suorituskyky-SUV:eihin ja musclee-autoihin. Jokainen käyttötapaus asettaa erilaiset painovaatimukset, erilaiset rasituskuvion ja erilaiset suorituskykyvaatimukset. Laadukkaat jälkimmäisille markkinoille suunnatut valmistajat ratkaisevat tämän suunnittelemalla tuotteen siten, että se täyttää kohdemarkkinoiden vaativimmat käyttövaatimukset.

Kuten ASM Tuning selittää, että arvostetut jälkiasennusrenkaat yhdistävät henkilökohtaisen tyylin ja suorituskyvyn, mutta vain, jos tunnet erot ja vaadit laatutodistuksia. Avainero on se, että OE-jäljennösrenkaat saattavat näyttää täsmälleen samoilta kuin tehdasvaihtoehdot, mutta niiden tekniset ominaisuudet saattavat poiketa – joskus olla alhaisemmat.

Premium-jälkiasennusmerkit, kuten Forgeline ja APEX, suuntaavat itsensä erityisesti suorituskyvyllisiin sovelluksiin, joissa kuormitustarpeet täyttävät tai ylittävät OEM-vaatimukset. Nämä valmistajat ymmärtävät, että innokkaat käyttäjät, jotka vaihtavat tehdasrenkaiden tilalle uudet, odottavat parantunutta suorituskykyä, ei heikentynyttä turvallisuutta. Niiden kuormitustiedot ylittävät tyypillisesti OEM-määritykset, koska heidän kohderyhmänsä sisältää ratapäiville osallistuvia ja aggressiivisia kuljettajia, jotka altistavat renkaat voimille, jotka ylittävät tavallisen kadunkäytön.

Vertaillessa vaihtoehtoja, pyydä dokumentaatiota, joka osoittaa jälkiasennuksen renkaan kuormitusluokituksen verrattuna ajoneuvosi OEM-määritykseen. Jos jälkiasennusvaihtoehto ei täytä tai ylitä tehtaan määrittämää luokitusta, vaihdat turvallisuutta tyyliin – kompromissi, jolla ei ole mitään järkeä, riippumatta siitä, kuinka upeilta renkaat näyttävät.

Älä koskaan heikennä kuormitusluokituksesi tyylin vuoksi

Tässä kohtaa keskustelu muuttuu epämukavaksi. Se kevyt valuraudalla valmistettu rengas aggressiivisella koveralla profiililla saattaa muuttaa ajoneuvosi ulkonäköä – mutta jos sen kuormitusluokitus on alhaisempi kuin OEM-määrityksesi, luot turvallisuusalkua, jota ei voida perustella millään visuaalisella houkuttelevuudella.

Esteettisyys ei saa koskaan vaarantaa kuormankapasiteettia. Rengas, joka pettää kuormituksen alaisena, ei välitä siitä, kuinka hyvältä se näytti pysäköitynä autonäyttelyssä.

Tämä periaate vaikuttaa ilmiselvältä, mutta innokkaat rikkovat sitä jatkuvasti. He rakastuvat pyörän malliin, perustelevat alhaisemman kuormitustehon olevan "todennäköisesti riittävä kadunkäyttöön" ja asentavat komponentteja, joita ei ole suunniteltu ajoneuvonsa vaatimuksiin. Seuraukset vaihtelevat kiihtyneestä kulumisesta katastrofaaliseen vikaantumiseen.

Harkitse, mitä "OEM-kuormitustehojen yhdistäminen" tarkoittaa käytännössä. Tehtaan pyörät on testattu, sertifioitu ja niihin liittyy takuu tehdasasetuksissa määritellyille ajoneuvosi käyttöolosuhteille. Kun asennat jälkiasennuspyöriä alhaisemmilla arvioinneilla, olet käytännössä sanomassa ajoneuvoasi suunnitelleelle tekniikkatiimille: "Minä tiedän paremmin kuin te." Ellei ole itse tehnyt FEA-analyysiä ja tuhoisia testejä, kyseessä on vaarallinen olettamus.

Vredestein huomauttaa, että tehtäälle asennetut renkaat ovat usein kattavien ajoneuvon takuiden alaisia, mikä lisää turvallisuutta. Jälkiasennusrenkaat eivät välttämättä ole katettuja, jolloin mahdolliset ongelmat on ratkaistava renkaiden valmistajan kautta. Tämä takuuhuomioonotto ulottuu yksinkertaisen vaihdon puitteista – aliarvioidut renkaat voivat aiheuttaa liittyvien jousitus- ja voimansiirtojärjestelmien takuukattavuuden menetyksen, jos vika tapahtuu.

Oikea lähestymistapa? Käytä OEM:n kuormitustehokkuutta ehdottomana minimivaatimuksena. Kun päivität kovettamalla valmistettuihin renkaisiin, kuormitustehokkuuden tulisi tyypillisesti täyttää tai ylittää tehtaan määrittämät tekniset tiedot – laadukas kovetus tuottaa vahvempia rakenteita vastaavilla painoilla, mikä tekee tästä helposti saavutettavan kynnyksen arvostettujen valmistajien osalta.

Älä unohda yksityiskohtia, jotka täydentävät asennuksesi. Laadukkaat Fordin keskuskupit ja kromitetut mutterit luotettavilta lähteiltä varmistavat, että uudet vaihdetyt renkaat kiinnittyvät turvallisesti ja näyttävät ammattimaisilta. Nämä viimeistelykomponentit tulisi vastata renkaiden omaa laatuvaatimusta – edullinen varustus huippuluokan renkaille luo sekä esteettisiä että toiminnallisia epäkohtia.

Ennen kuin vahvistat minkään ostoksen, tarkista että valitsemasi jälkituotteen renkaat sisältävät asianmukaiset sertifiointimerkinnät, jotka täyttävät tai ylittävät tehtaan renkaiden vastaavat vaatimukset. Jos myyjä ei voi todistaa, miten tuotteidensa kestävyysarviot vertautuvat tehdasvalmisteisiin määrityksiin, etsi myyjä joka voi. Seuraavassa luvussa käsitellään materiaalitiedettä, joka selittää näiden kestoisuuserojen taustalla olevat syyt – ja miksi sertifioitu valmistusprosessi on tärkeää tasaiselle suorituskyvylle.

Materiaalitiede räätälöityjen kovaliitettyjen renkaiden lujuudessa

Ymmärrät nyt, miksi OEM-määritykset määrittävät perustason päivityksillesi – mutta tämä on se, mikä oikeasti määrittää toimivatko kovanpuristetun renkaan kuormitustiedot lupauksensa mukaisesti: itse alumiiniseos. Vaikuttava numero, joka on vaivattu rengaaseesi, ei tarkoita mitään, jos taustalla oleva materiaali ei kestä stressiä tasaisesti. Kun vertailet eri valmistajien renkaita keskenään, juuri seostyyppi ja lämpökäsittelyprosessi selittävät usein, miksi samanlaisen suunnittelun renkaat toimivat niin eri tavoin käytännössä.

Ilmailualan alumiini -ilmaus esiintyy lukemattomissa renkaiden markkinointimateriaaleissa, mutta vain harvat ostajat ymmärtävät, mitä sillä todella tarkoitetaan kuormituskapasiteetin kannalta. Katsotaan tarkemmin materiaalitieteeseen, joka erottaa aidosti kestävät kovanpuristetut renkaat niistä, jotka vain väittävät olevansa premium-luokkaa.

Ilmailualan alumiini renkaiden valmistuksessa

Kun valmistajat viittaavat ilmailuteollisuuden luokan alumiiniin, he tarkoittavat yleensä 6061-lejeerinkiä – erityistä koostumusta, joka on kehitetty sovelluksiin, joissa lujuuden ja painon suhde määrittää onnistumisen tai epäonnistumisen. Tämä ei ole markkinointitemppu. Sama materiaali, joka tukee lentokoneiden rakenteita ja sotilaskalustoa, muodostaa premium-sorkkavanteille perustan.

Mukaan 3030 Autosport , 6061-T6-sorkkualumiini on eturivin valinta sellaisissa sektoreissa kuin sotilaskäyttö, ilmailu, Formula 1 ja vetovoimakilpailut, edustaen täydellistä yhdistelmää korkeasta suorituskyvystä, lujuudesta ja kestävyydestä. Lejeering saa poikkeukselliset ominaisuutensa huolellisesti suunnitellusta koostumuksestaan ja edistyneestä lämpökäsittelyprosessista.

Mikä tekee 6061:stä erityisen muiden alumiinilejeerinkien joukossa? Vastaus piilee sen huolellisesti tasapainotetussa koostumuksessa:

- Alumiinipohja: Tuo perustavanlaatuiset keveät ominaisuudet, jotka tekevät lejeeringista houkuttelevan painoherkkiin sovelluksiin

- Magnesium: Parantaa lujuutta kiinteän liuoksen vahvistuksen kautta – magnesiumatomit upottautuvat itse asiassa alumiinikiderakenteeseen

- Pi: Toimii yhdessä magnesiumin kanssa parantaakseen lujuutta samalla kun alentaa sulamislämpötilaa helpottaen muovauksen tekemistä

- Kupari: Lisätään pieninä määrinä parantaakseen sekä korroosionkestävyyttä että kokonaislujuutta

Nämä alkuaineet eivät vain sekoitu keskenään – ne synergisoituvat luoden materiaalin, jonka suorituskyky ylittää minkä tahansa yksittäisen komponentin ominaisuudet. Kun etsit Subaru- tai Supra-renkaita viikonloppuradan autoosi, ymmärrys siitä, että 6061-legeroimien renkaiden rakenne on tarkoin suunniteltu, selittää, miksi ne maksavat enemmän verrattuna renkaisiin, jotka käyttävät heikompia alumiinilaatuja.

6xxx-sarjan seokset (ne, jotka sisältävät magnesiumia ja piitä) muodostavat lämpökäsittelyn aikana Mg₂Si-saostumia – mikroskooppisia hiukkasia, jotka estävät metallirakenteen sisällä olevien virheiden liikkumista. Kuvittele nämä saostumat sisäiseksi vahvistukseksi, joka on jakautunut alumiiniin ja luo esteitä, jotka estävät materiaalin muodonmuutoksia kuormituksen alaisena.

Verrattuna renkaisiin, jotka on valmistettu alhaisemmasta laadusta, ne voivat näyttää täysin samanlaisilta esitteilyhallissa. Ero paljastuu vasta rasituksen alla – kovassa kaarteessa tai yllättävässä loven iskussa, jolloin materiaalin laatu määrää selviytyykö rengas vai rikkoutuuko se.

Kuinka lämpökäsittely parantaa kuormituskapasiteettia

Jopa paras alumiiniseos tuottaa heikkoa suorituskykyä ilman asianmukaista lämpökäsittelyä. Se "T6"-tunnus, joka seuraa seosnumeron perässä, edustaa ratkaisevaa käsittelyvaihetta, joka muuttaa raakaseoksen 6061 korkean suorituskyvyn rakennemateriaaliksi.

T6-prosessiin liittyy kaksi tarkasti ohjattua vaihetta, jotka muuttavat alumiinin sisäistä rakennetta perustavanlaatuisesti:

Ratkaisulämpökäsittely: Valssattu rengas lämmitetään noin 530 °C (noin 980 °F) useiden tuntien ajan. Tässä korkeassa lämpötilassa seostusaineet – erityisesti magnesium ja pii – liukenevat täysin alumiinimatriisiin, luoden metallurgien kutsuvan ylikylläisen kiinteän liuoksen. Materiaali jäähdytetään sitten nopeasti, yleensä vedessä, jotta liuenneet aineet jäävät paikoilleen.

Tekoikäännys: Jäähdytyksen jälkeen rengas käy läpi ohjatun vanhenemisen matalammassa lämpötilassa – noin 175 °C (350 °F) 6061-seokselle – noin 8 tunnin ajan. Tässä vaiheessa liuenneet aineet saostuvat hallitusti, muodostaen vahvistavia hiukkasia, jotka jakautuvat rakenteen läpi.

Arc Captainin mukaan , T6-lämmöntalennus voi kaksinkertaistaa tai jopa kolminkertaistaa alumiinin lujuuden lisäämättä painoa. Tämä tekee siitä täydellisen valinnan ilmailu-, autoteollisuus- ja rakennesovelluksiin, joissa sekä lujuus että paino ovat tärkeitä.

Numerot kertovat tarinan selvästi. Ennen T6-käsittelyä 6061-alumiini osoittaa suhteellisen vaatimattomia mekaanisia ominaisuuksia. Oikean lämpökäsittelyn jälkeen muutos on dramaattinen:

| Omaisuus | 6061-O (hehkutettu) | 6061-T6 (lämpökäsitelty) | Parannus |

|---|---|---|---|

| Vetolujuus | ~18 000 psi | ~45 000 psi | +150% |

| Taivutuslujuus | ~8 000 psi | ~40 000 psi | +400% |

| Kovuus (Brinell) | ~30 HB | ~95–105 HB | +200% |

| Ummelinvastus | Kohtalainen | Erinomainen | Merkittävä |

Tuon 400 %:n lisäyksen myötölujuudessa kääntyy suoraan kuormankapasiteetiksi. Myötölujuus määrittää sen pisteen, jossa materiaali alkaa pysyvästi muodonmuuttua – rajan pyörän ja taipuvan tai halkeavan pyörän välillä. Korkeampi myötölujuus tarkoittaa, että pyörä kestää suurempia voimia ennen kuin se lähestyy rakenteellisia rajojaan.

Mutta tässä on se, mitä monet ostajat huomaavat: ajoitus ja lämpötilat on oltava tarkat kullekin seokselle. Jopa pienet vaihtelut voivat vaikuttaa metallin lopullisiin ominaisuuksiin. Pyörävalmistaja, joka väittää käyttävänsä T6-käsittelyä mutta jolla ei ole tiukkaa prosessinvalvontaa, saattaa tuottaa epäjohdonmukaisia tuloksia – jotkut pyörät täyttävät tekniset vaatimukset, kun taas toiset eivät.

Tässä kohtaa valmistustodistus tulee ratkaisevan tärkeäksi. IATF 16949 -todistus – laadunhallintastandardi, joka on erityisesti kehitetty autoteollisuuden tuotantoon – takaa, että jokainen valmistusprosessin vaihe noudattaa dokumentoituja menettelyjä vahvistettujen tulosten varmistamiseksi. Yritykset kuten Shaoyi (Ningbo) Metal Technology pitääkseen tämän sertifioinnin tarkasti, koska autoteollisuuden komponentit edellyttävät johdonmukaisia materiaaliominaisuuksia jokaisessa tuotantoserässä.

Niiden tarkat kuumavalukomponenttiratkaisut osoittavat asianmukaisen materiaalivalinnan yhdistymistä hallittuun prosessointiin. Kun valmistetaan autoteollisuuden komponentteja, kuten suspensiovipuja ja akseliaiksoja, samat periaatteet pätevät: lentokoneen luokan alumiini yhdistettynä vahvistettuihin lämpökäsittelyprotokolliin tuottaa osia, jotka luotettavasti täyttävät määritellyt kuormitusluokitukset.

Harrastajille, jotka hakevat valkoisia rengaskiekkoja valkoisilla renkailla tai muita räätälöityjä pyöräkonfiguraatioita, on tärkeää ymmärtää, että sertifioitu valmistusprosessi takaa johdonmukaiset materiaaliominaisuudet, mikä auttaa erottamaan aidosti suunnitellut tuotteet niistä, jotka tekevät leikkauksia laadunvalvonnassa. Pyörä laitokselta, jolla on tiukat prosessiasiakirjat ja sisäiset suunnittelukyvyt, tarjoaa perustavanlaatuisesti erilaisen luotettavuuden verrattuna pyörään, joka on valmistettu ilman standardoituja protokollia.

Mieti, mitä tapahtuu, kun lämpökäsittely epäonnistuu. Epätäydellinen liuotuskäsittely, jossa seostusaineet eivät liukene täysin, johtaa renkaiden testaantumiseen tarkoitetun lujuusvaatimuksen alapuolelle. Ylikypsytys pitää osat liian kauan lämpötilassa, mikä itse asiassa vähentää niiden lujuutta huippuarvoista. Viilentämisen viiveet antavat liuenneiden aineiden muodostua ennenaikaisesti hallitsemattomiin rakenteisiin, heikentäen rakenteellista kokonaisuutta.

Luotettavien valmistajien Dodge Challenger -renkaat käyvät läpi dokumentoidut lämpökäsittelyjaksot, joissa on kirjatut lämpötilat ja kestot. Edullisemmat vaihtoehdot saattavat jättää dokumentoinnin kokonaan tekemättä, jolloin ostajilla ei ole mahdollisuutta varmentaa, onko renkaille annettu oikea käsittely. Kaunis ulkonäkö ei merkitse mitään, jos perustavaa laatua oleva materiaali ei ole käsitelty oikein.

Mukautettujen valssattujen pyörien kuormitusten taustalla oleva materiaalitiede ei ole vain akateemista—se on perusta, joka määrittää, heijastavatko julkaistut tekniset tiedot todellisuutta. Seostyyppi asettaa saavutettavan lujuuden ylärajan. Lämmönkäsittely vapauttaa tämän potentiaalin tarkasti ohjatulla lämpökäsittelyllä. Sertifioitu valmistus varmistaa, että jokainen pyörä saa saman käsittelyn ja että kuormituskapasiteetti on yhtenäinen tuotantoserioissa.

Tämän ymmärryksen turvin olet valmis viimeiseen vaiheeseen: varmistamaan, että harkitsemiasi pyöriä vastaavat todella nämä standardit ennen ostopäätöstä. Seuraava luku tarjoaa ostoenneuvonnan tarkistuslistan—erityiset dokumentoinnit ja kysymykset, jotka erottavat luotettavat valmistajat niistä, jotka toivovat ettei tarkemmin tarkastella.

Kuormitusten varmistaminen ennen mukautettujen pyörien osto

Olet omaksunut kaiken – materiaalitieteestä sertifiointistandardeihin ja erityissovellusten vaatimuksiin. Mutta tässä tieto muuttuu toiminnaksi: tiedät, miten mukautettujen valssattujen renkaiden kuormitustiedot varmistetaan ennen maksun suorittamista. Tietävän ostajan ja toivovan välillä on vain yksi ero: oikeiden kysymysten esittäminen ja vaatia dokumentaatiota, joka todistaa lukujen olevan todellisia.

Liian monet innokkaat jättävät tämän varmistusaskeleen väliin luottaen siihen, että houkuttelevat verkkosivut ja vakuuttavat myyntipuheenvuorot takaisivat laadun. He huomaavat virheensä vasta kun rengas murtuu ajon aikana tai vakuutuskorvaus evätään, koska renkailla ei ollut asianmukaista sertifiointia. Älä tule siitä varoittavana esimerkkinä.

Ostopäätöstä edeltävä tarkistuslista

Ennen kuin teet minkään mukautetun valssatun pyörän hankinnan, käy läpi tämä systemaattinen tarkistusprosessi. Jokainen vaihe perustuu edelliseen, ja näin saadaan kattava kuva siitä, täyttävätkö pyörät todella vaatimuksesi.

- Laske ajoneuvosi todelliset kuormavaatimukset: Aloita GVWR-arvostasi, joka löytyy oviaukon tarrahuolellisesta, jaa se neljällä ja lisää siihen sopiva turvamarginaalisi — 30 % tienajoa varten, 40–50 % rata-, maasto- tai vetokäyttöön. Tämä luku muodostaa ehdottoman minimivaatimuksen pyörän kuormituskapasiteetille. Älä jatka ennen kuin tiedät tarkalleen, mitä teknistä vaatimusta tarvitset.

- Pyydä valmistajan kuormitusarvon dokumentaatiota: Pyydä myyjältä virallista dokumentaatiota, joka osoittaa pyörän testatun ja varmennetun kuormituskapasiteetin — ei pelkkä numero verkkosivulla, vaan todelliset testiraportit tai tekniset tiedot valmistajalta. Lailliset yritykset toimittavat nämä haluttaessa helposti; väistely vastauksissa viittaa ongelmiin.

- Varmista, että sertifiointimerkinnät ovat fyysisesti olemassa: Varmista, että renkaat saapuvat JWL-, VIA-, TÜV- tai SAE-varmennemerkeillä, jotka on todella valettu tai kaiverrettu rakenteeseen. Pyydä kuvia näistä merkeistä tuotantorenkaiden pinnalla. Markkinointimateriaalien varmennuslogot eivät tarkoita mitään, jos fyysisiltä tuotteilta puuttuvat vastaavat merkinnät.

- Vertaa suoraan OEM-määrityksiisi: Etsi tehdasrenkasi kuormitustiedot omistajan käyttöoppaasta tai valmistajan dokumentaatiosta. Harkitsemasi jälkimarkkinarenkaiden on täytettävä tai ylitettävä tämä perustaso. Jos myyjä ei osaa kertoa, miten heidän kuormitustietonsa vertautuvat OEM-määritykseesi, he eivät ole tehneet kotitehtäviään.

- Varmista takuun kattavuus tarkoitettuun käyttötarkoitukseen: Lue varsinaiset takuuehdot – älä markkinointikokonaisuutta. Kattaaako takuu radankäyttöä? Maastoa? Perävaunun vetämistä? Takuu, joka sulkee pois tarkoitetun käyttötarkoituksesi, paljastaa, että valmistaja tietää renkaidensa ei kestävän kyseisiä kuormia.

- Tarkista myyjän palautusehto määrityseroille: Mitä tapahtuu, jos renkaat saapuvat ilman luvattuja sertifiointimerkkejä tai alhaisemmalla kuormitusluokituksella kuin mainittu? Luotettavat myyjät pitävät lupauksiaan selkeillä politiikoilla epäjohdonmukaisuuksien korjaamiseksi.

Tähän prosessiin kuluu aikaa – ehkä tunti tutkimusta ja viestintää ennen ostopäätöstä. Vertaa tätä epäonnistuneiden renkaiden vaihtamisen, suspensioon vahingoittumisen tai pahemman korjauskustannuksiin. Todennusprosessiin käytetty panostus maksaa itsensä takaisin luottamuksena ja turvallisuutena.

Renkaan suurimman kuorman ymmärtäminen auttaa laajan kontekstissa pyörän teknisiä tietoja. Renkaan suurin kuormituskapasiteetti ja pyörän kuormitusluokitus on ymmärrettävä järjestelmänä. Kumpikaan komponentti ei saa jäädä alle laskettujen vaatimusten. Ostellessa on varmistettava molemmat tekniset tiedot sen sijaan, että oletettaisiin rengasluokituksen vastaavan automaattisesti pyörän ominaisuuksia.

Asiakirjat, joita jokainen pyörän ostaja tulisi vaatia

Tietämys siitä, mitä tulisi vaatia, erottaa asiantuntevat ostajat niistä, jotka luottavat toivonsa. Ennen mukautettujen renkaiden oston viimeistelyä, pyydä myyjältä seuraavia tietoja:

- Virallinen kuormitusteholuokituksen tekninen dokumentti: Valmistajan antama asiakirja, jossa ilmoitetaan testattu kuormituskapasiteetti paunoissa tai kilogrammoissa hankittavalle renkaiden mallille ja koolle

- Sertifiointitestiin liittyvät raportit: Asiakirjat JWL-, VIA-, TÜV- tai SAE-testeistä, jotka osoittavat renkaan läpäisseen vaaditut protokollat – säteittäinen väsymys, mutkistevä väsymys ja iskutestaus

- Materiaalin sertifiointi: Vahvistus alumiiniseoksen laadusta (6061-T6 korkealaatuisille taottuihin renkaisiin) sekä lämpökäsittelyn vahvistus

- FEA-analyysin yhteenveto: Mukautettuihin spesifikaatioihin liittyen pyydä elementtimenetelmällä (FEA) saatujen tulosten tiivistelmää, joka näyttää jännitysjakauman kuormitustilanteessa – arvostetut valmistajat toimittavat nämä tilauksesta

- Laadunhallintasertifiointi: Näyttö tehtaan ISO 9001- tai IATF 16949-sertifioidusta järjestelmästä, mikä takaa tasaisen tuotannon laadun

- Kirjalliset takuuehdot: Täydellinen takuudokumentaatio, jossa määritellään kattavuuden kesto, sisällytetyt sovellukset ja vaatimusten käsittelymenettelyt

Kuten Velgen Wheels korostaa, tarkista aina sertifikaatit valmistajan kanssa, äläkä oleta, että alhainen hinta tarkoittaa hyvää tarjousta. Renkaiden markkinoilla on kopioita ja halpoja tuontituotteita, joissa saattaa olla väärennettyjä leimoja tai ei lainkaan sertifiointia.

Tämä dokumentaatiostandardi heijastaa sitä, mitä vakavat autoteollisuuden komponenttitoimittajat tarjoavat perustason läpinäkyvyytenä. Yritykset, jotka ylläpitävät IATF 16949 -sertifiointia – kuten Shaoyi (Ningbo) Metal Technology – osoittavat juuri tämänlaista dokumentaation tarkkuutta tarkkuuskuumanmuovausratkaisuissaan. Niiden nopeat prototyypinvalmistusmahdollisuudet, jotka toimittavat räätälöityjä määritelmiä jo 10 pässä, osoittavat teknisen läpinäkyvyyden, joka tulisi olla teollisuuden laajuinen standardi. Arvioitaessa mitä tahansa muovauspalveluntarjoajaa, kannattaa etsiä samaa sitoutumista dokumentoituun laadunvalvontaan ja maailmanlaajuisesti yhteensopivaan valmistukseen.

Mikä on renkaan kuorma ja miten se liittyy vaihtojousien dokumentaatioon? Renkaan kuormaindeksi näkyy sivuseinässä ja vastaa tiettyä painokapasiteettia standardoituista taulukoista. Valmistajan vaihtojousien kuormitustaulukon tulisi näyttää kapasiteetit, jotka ylittävät renkaan arvot – vaihtojousi ei saa koskaan olla heikoin lenkki kuorman kantavuusketjussa.

Jos myyjä epäröi toimittaa pyydettyä dokumentaatiota, tämä epäröinti kertoo sinulle kaiken. Lailliset valmistajat sijoittavat merkittävästi testaukseen ja sertifiointiin juuri siksi, että voivat osoittaa vaihtojouset täyttävän julkaistut tekniset tiedot. Epähalukkuus jakaa tätä todistetta viittaa siihen, että dokumentaatiota ei ole olemassa tai se ei tue markkinointiväitteitä.

Ostajille, jotka esittävät kysymyksiä kuten "ovatko Aodhan-renkaat repliikoita" eri merkeistä, dokumentaatio tarjoaa määräävät vastaukset. Aitojen valmistajien alkuperäisissä renkaissa on todennettavissa olevia sertifiointimerkkejä ja ne toimitetaan tukevalla dokumentaatiolla. Repliikat ja väärennökset puuttuvat yleensä tästä paperijäljestä, koska niitä ei ole koskaan testattu kalliiden testausprotokollien kautta, jotka tuottavat lailliset sertifiointitodistukset.

Onko kuormaindeksillä väliä renkaiden valinnassa? Ehdottomasti – ja sama periaate pätee myös vaihderengashyötykuorman taulukon varmennukseen. Molempien tietojen on täsmättävä laskettuihin vaatimuksiisi. Oikein dokumentoitu rengaskuppiostos sisältää vahvistuksen siitä, että kehän hyötykuormitusluokitus täyttää tai ylittää tarpeesi, että sertifiointimerkit ovat fyysisesti läsnä ja että takuu kattaa tarkoitetun käyttötarkoituksen.

Valmistajat, jotka panostavat tiukkaan laadunvalvontaan – dokumentoituun lämpökäsittelyyn, sisäiseen tekniseen validointiin ja kolmannen osapuolen sertifiointitesteihin – ovat valmiita osoittamaan, että heidän tuotteensa toimivat mainitulla tavalla. Ne, jotka leikkaavat kulmista valmistuksessa, leikkaavat samalla myös dokumentoinnissa. Ostamisen esitarkastusprosessisi paljastaa tämän eron ennen kuin olet sitoutunut rahoillasi.

Kuten fifteen52 muistiinpanot , korkealaatuisten pyörien hankinta todistetulla menestyksellä on jokaista senttiä vastaavaa. Tämä todistettu menestys näkyy dokumentaatiossa – testiraporteissa, sertifiointimerkinnöissä, materiaalimäärittelyissä ja takuuehdoissa, jotka osoittavat teknisen eheyden. Vaadi tätä todistetta, tarkista väitteet ja osta varmuudella, että räätälöidyt valssatut pyöräsi toimivat turvallisesti koko käyttöikänsä ajan.

Vaatneesi yhdistävät ajoneuvon massan tienpintaan neljän, kätesi avotakenttää pienemmän kosketuspinnan kautta. Näiden liitospisteiden on kestettävä jokainen lattopoisto, jokainen jyrkkä mutka ja jokainen hätäjarrutus, johon koskaan törmäät. Tässä esitetty varmennusprosessi takaa, että valitsemasi renkaat on todella suunniteltu kestämään nämä vaatimukset – eivätkä ne ole ainoastaan markkinoitu sellaisiksi.

Usein kysyttyjä kysymyksiä räätälöityjen taottujen pyörän kuormitustiedoista

1. Kuinka paljon painoa taotut pyörät kestävät?

Kuullotut renkaat kestävät tyypillisesti 2 000–2 800+ puntaa rengasta kohden ajoneuvokäyttöön, kun taas jotkin raskaiden teollisuussovellusten kuullotut teräsrenkaat on luokiteltu jopa 23 000 puntaan saakka. Kuulamisprosessin aikana muodostuva ylivoimainen rakekoko (jossa 8 000–10 000 tonnin paine rajoittaa alumiinikiteitä) mahdollistaa kuullottujen renkaiden huomattavasti suurempien kuormien käsittelyn verrattuna valurataisiin samalla pysyen kevyempinä. Premium-valmistajat kuten Forgeline ja APEX suunnittelevat kuullotut renkaansa erityisesti moottoriurheilun vaatimuksiin, usein ylittäen standardin JWL-sertifiointivaatimukset. Tarkat kuormavaatimukset riippuvat ajoneuvon GVWR:stä, painonjakautumisesta ja tarkoitetusta käytöstä, joissa rata- ja maastokäyttö edellyttävät 40–50 % turvamarginaalia peruslaskelmien yläpuolella.

2. Kuinka vahvat kuullotut levyt ovat verrattuna valulevyihin?

Kuullotut renkaat ovat huomattavasti vahvempia valurunkoisiin verrattuna rakenteellisten erojen vuoksi jyvien muodossa. Kuulotuksessa voimakas hydraulipaine muuttaa kiinteitä alumiiniblokkeja, kohdistamalla metallin kiteisen rakenteen jatkuviksi kaavoiksi, jotka jakavat kuormituksen tehokkaasti koko pyörän läpi. Valurungoiset renkaat, jotka tehdään kaatamalla sulanut alumiini muotteihin, kehittävät satunnaisia jyvirakenteita mikroskooppisine huokosineen, jotka muodostuvat kuormituspisteiksi rasituksen alla. Tämä ero tarkoittaa, että kuullotut renkaat saavuttavat tyypillisesti kuormitusluokat 2 000–2 800+ puntaa verrattuna valurunkoisten 1 400–1 800 puntiin samalla ollessa kevyempiä. Kuullotussa rakenteessa olevat kohdistetut jyvirajat vastustavat myös halkeaman etenemistä, mikä tarkoittaa, että pienet rasituspisteet eivät johtavat katastrofaalisiin rikkoutumisiin agressiivisessa ajossa.

3. Mitkä sertifiointistandardit vahvistavat renkaiden kuormitusarvot?

Neljä ensisijaista sertifiointistandardia vahvistaa räätälöityjen kovanpyöräisten kuormitustiedot tiukkojen kolmannen osapuolen testien kautta. JWL (Japan Light Alloy Wheel) -sertifiointi arvioi rakenteellista kestävyyttä pyörivän taivutusväsymyksen, iskukestävyyden ja materiaalin koostumuksen analyysin kautta. VIA (Vehicle Inspection Association) lisää dynaamisen kurvaväsymystestauksen perus-JWL-vaatimusten yläpuolelle – ratkaisevan tärkeää suorituskykysovelluksissa. Saksalainen TÜV-sertifiointi tarjoaa tiukat eurooppalaiset turvallisuusvarmennukset ja jatkuvan tuotannon laadunvalvonnan. SAE J2530 tarjoaa kattavat amerikkalaiset standardit, jotka kattavat säteittäisen väsymyksen, kurvaväsymyksen, iskukestävyyden ja materiaaliominaisuuksien varmentamisen. Laadukkaat valmistajat, kuten IATF 16949 -sertifioinnilla varustetut, ylläpitävät dokumentoituja prosesseja, jotka takaavät, että jokainen pyörä täyttää nämä standardit johdonmukaisesti. Varmista aina fyysisten sertifiointimerkkien olemassaolo pyörissä ennen ostopäätöstä.

4. Kuinka lasken minimipyöräkuormitustiedon, jonka ajoneuvoni vaatii?

Laske pyörän vähimmäiskuormitustarve lähtien ajoneuvon GVWR-arvosta ovenpylvään liimamerkistä, jaa se neljällä saadaksesi perusarvon per pyörä, ja lisää sitten asianmukainen turvamarginaali. Normaalia tienajoa varten lisää 30 % huomioimaan dynaamiset voimat mutkissa, jarrutuksessa ja kiihdytyksessä. Rataajoa, maastoajoa tai vetotarpeita varten vaaditaan 40–50 %:n turvamarginaalit ääritilanteiden kuormitusolosuhteiden vuoksi. Esimerkiksi 2268 kg:n GVWR-arvoiselle ajoneuvolle tarvitaan: 2268 ÷ 4 = 567 kg perusarvo, kerrottuna 1,30 = 737 kg vähimmäiskuormitus per pyörä kadunajoon. Tarkista myös akselikohtaiset kokonaispainorajat (GAWR) — korkeampi etu- tai taka-akselin GAWR jaettuna kahdella osoittaa, kummalla akselilla on vaativammat vaatimukset, joita ei voida heikentää.

5. Miksi suuremmat halkaisijaltaan pyörät vaativat korkeampia kuormitustasoja?

Suuremmat halkaisijaltaan olevat renkaat vaativat korkeampia kuormitusluokituksia, koska ne yhdistetään matalamman profiilin renkaisiin, jotka välittävät suuremman iskunvoiman suoraan ratakkeen rakenteeseen. 22-tuumainen rengas 30-sarjan renkailla joutuu ottamaan vastaan huomattavasti vähemmän kumia sivualueeltaan joustamaan ja pehmittämään reikien aiheuttamia iskuja verrattuna 17-tuumaiseen rengaseen 55-sarjan renkailla. Tämä heikompi tukahdutus tarkoittaa, että itse ratas joutuu kestämään energiaa, jonka korkeammat sivuprofiilit muutoin hajottaisivat. Lisäksi suuremmat renkaat painavat tyypillisesti enemmän, mikä lisää vapaakantajan massaa ja synnyttää suuremman hitauden jousitustaessa. Jokainen isku siirtää enemmän liikemäärää ratakkeen rakenteeseen. Suorituskykyiset sedanit, joissa on 20-tuumisia renkaita, vaativat tyypillisesti 1900–2300 punnan kuormitusluokituksen, kun taas 22-tuumiset varusteet nostavat vaatimukset 2100–2500 paunuun tai vielä korkeammaksi ajoneuvon painosta ja ajotiloista riippuen.

Pienet erät, korkeat standardit. Nopea prototyypinkehityspalvelumme tekee vahvistamisen nopeammaksi ja helpommaksi —

Pienet erät, korkeat standardit. Nopea prototyypinkehityspalvelumme tekee vahvistamisen nopeammaksi ja helpommaksi —