- Reduzca los costos de extrusión de aluminio con 5 consejos esenciales de DFM

- El verdadero ROI de matrices de extrusión personalizadas para producción masiva

- Prototipado de metal para automoción: una guía para una innovación más rápida

- Piezas del Aire Acondicionado Automotriz: Desde el Compresor hasta el Evaporador Explicado

Brazos de suspensión de acero estampado frente a tubulares: una guía práctica

Time : 2025-12-16

TL;DR

Los brazos de control tubulares representan una mejora significativa en rendimiento frente a los brazos de acero estampado de fábrica. Ofrecen beneficios sustanciales en resistencia, reducción de peso y, críticamente, la capacidad de corregir y optimizar la geometría de la suspensión para neumáticos modernos y condiciones de conducción actuales. Si bien los brazos de acero estampado son adecuados para un vehículo estándar, el mayor costo de los brazos tubulares queda justificado en cualquier construcción orientada al rendimiento, ya que proporcionan una maniobrabilidad, sensación de dirección y estabilidad considerablemente superiores.

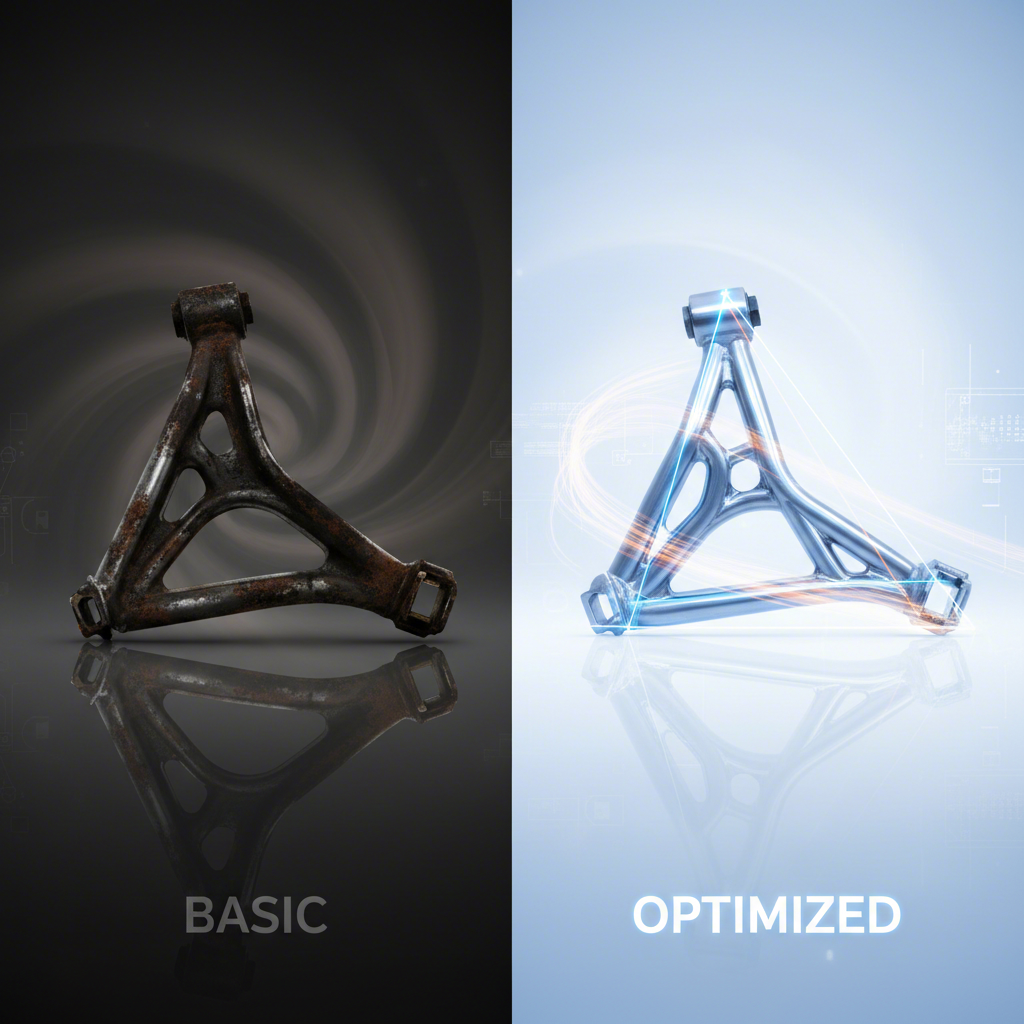

Construcción y materiales: Las diferencias fundamentales

La diferencia fundamental entre los brazos de suspensión estampados en acero y los tubulares radica en su proceso de fabricación y filosofía de diseño. Los brazos de suspensión estampados en acero, que son el equipo original en la mayoría de los vehículos clásicos, se producen en masa presionando láminas de acero en una forma de canal en C mediante una troqueladora. Este método es rentable y produce una pieza perfectamente adecuada para las especificaciones originales del vehículo y para neumáticos de capas diagonales. Para los fabricantes automotrices que dependen de altos volúmenes y estampado metálico de precisión, son esenciales proveedores especializados. Por ejemplo, Shaoyi (Ningbo) Metal Technology Co., Ltd. ofrece soluciones integrales en piezas estampadas para automoción, garantizando que los componentes cumplan con rigurosos estándares industriales como el IATF 16949, desde la prototipificación hasta la producción en masa.

En contraste, los brazos de suspensión tubulares están diseñados para alto rendimiento desde cero. Como se detalla en recursos procedentes de QA1 , estos elementos suelen estar construidos con tubos de acero de alta resistencia y bajo contenido de aleación que se cortan, doblan y soldan para formar una estructura rígida y triangulada. Este diseño es inherentemente más fuerte y resistente a las fuerzas de torsión que el canal abierto en C de un brazo estampado. La construcción tubular también reduce significativamente el peso, lo cual es un factor clave para mejorar el rendimiento de la suspensión.

Su identificación visual es sencilla. Un brazo de acero estampado suele parecer una pieza simple, prensada en metal, a veces con nervios de refuerzo. Un imán se adhiere a él. Los brazos tubulares tienen un aspecto distintivo, con tubos redondos u ocasionalmente ovalados soldados entre sí, presentando una apariencia mucho más moderna e ingenieril.

| Característica | Brazos de Control de Acero Estampado | Brazos de control tubulares |

|---|---|---|

| Material | Acero laminado en frío | Tubo de acero de alta resistencia |

| Producción | Estampado por troquel | Cortado, doblado y soldado |

| Peso | Más pesado | Encendedor |

| Resistencia | Adecuado para uso estándar | Mayor rigidez, menos flexión |

| Costo | Bajo (OEM) | Alto (posventa) |

| Mejor para | Restauraciones estándar, cruisers | Conducción de alto rendimiento, uso en pista |

Rendimiento y manejo: por qué la geometría es importante

La razón más convincente para actualizar a brazos de suspensión tubulares es la mejora dramática en la dirección del vehículo, que proviene directamente de una geometría de suspensión optimizada. La suspensión de los coches clásicos fue diseñada hace décadas para neumáticos diagonales y expectativas de rendimiento diferentes. Los neumáticos radiales modernos tienen características de adherencia muy distintas y requieren ajustes de alineación actualizados para funcionar correctamente, ajustes que a menudo son imposibles de lograr con componentes originales.

Un beneficio principal es la reducción de la masa no suspendida. La masa no suspendida es el peso de todo lo que no está soportado por los resortes (ruedas, neumáticos, frenos y brazos de suspensión). Componentes más ligeros, como los brazos tubulares, permiten que la suspensión reaccione mucho más rápidamente a baches e imperfecciones del camino, manteniendo el neumático en mejor contacto con el pavimento. Esto se traduce en una calidad de marcha superior y un manejo más consistente.

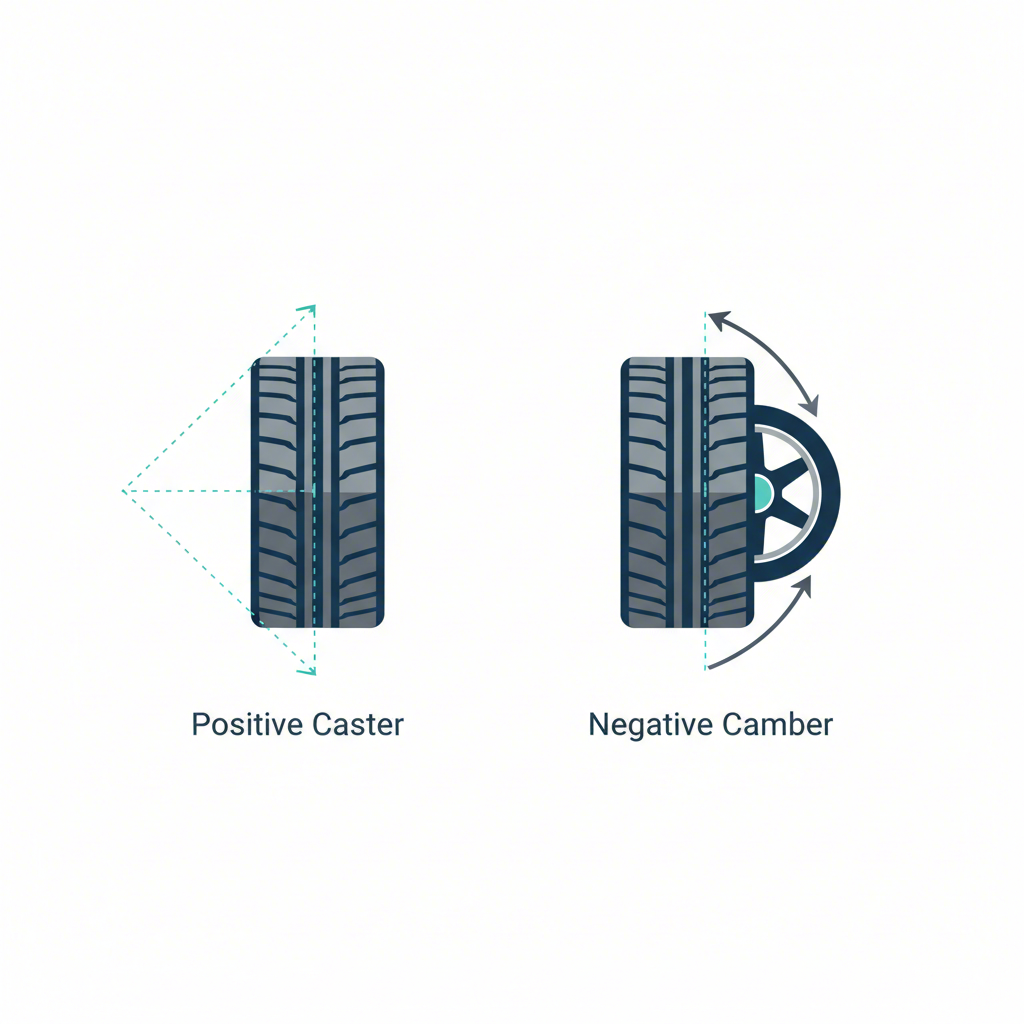

Además, los brazos de control tubulares están diseñados con una geometría corregida incorporada. Dos ángulos críticos son el avance y el ángulo de caída. Rueda es la inclinación hacia adelante o hacia atrás del eje de dirección. Los automóviles clásicos solían tener muy poco avance positivo (alrededor de 2-3 grados), lo que resultaba en una dirección imprecisa y nerviosa que requiere correcciones constantes a velocidades de autopista. Según QA1, sus brazos tubulares están diseñados para aumentar el avance positivo a entre 5 y 7 grados. Este avance adicional proporciona una mayor estabilidad en línea recta, una sensación de dirección más conectada y un efecto de centrado automático al salir de las curvas.

El camber es la inclinación hacia adentro o hacia afuera de la parte superior del neumático. Para conducción deportiva, se busca que el neumático gane cámar negativa (inclinarse hacia adentro) cuando la suspensión se comprime en una curva, maximizando así la superficie de contacto del neumático con el camino. Muchos brazos tubulares de mercado secundario están diseñados con curvas de cámar mejoradas y ajustabilidad, lo que permite configuraciones de alineación que mantienen el neumático bien apoyado, mejorando significativamente el agarre y la confianza en las curvas.

Fuerza, Durabilidad y Aestética

Más allá de la geometría, la actualización a brazos de control tubulares aporta beneficios tangibles en integridad estructural y durabilidad. La estructura soldada y triangulada de un brazo tubular es inherentemente más rígida que un canal en chapa de acero estampado. Esta mayor resistencia evita que el brazo se flexione o tuerza bajo cargas elevadas, como en curvas pronunciadas o aceleraciones fuertes, especialmente en vehículos con alto par motor y neumáticos anchos y adherentes. Esta rigidez garantiza que los ajustes de alineación permanezcan constantes precisamente cuando más se necesitan.

La durabilidad también se ve mejorada por los componentes que normalmente acompañan a los kits de brazos tubulares. Los brazos de control de fábrica utilizan bujes de caucho blando diseñados para absorber las vibraciones, pero también permiten una deflexión considerable, lo que puede afectar negativamente la precisión de la dirección. Los brazos tubulares del mercado secundario casi siempre incorporan materiales superiores en sus bujes:

- Bujes de poliuretano: Una mejora común para rendimiento en carretera, que ofrece una conexión más firme que reduce la deflexión sin resultar excesivamente rígida.

- Bujes compuestos: A menudo encontrados en brazos para competición o uso avanzado, estos proporcionan fricción ultrabaja y deflexión mínima para un movimiento de suspensión extremadamente preciso.

Finalmente, la estética desempeña un papel válido en la decisión. Como señalan expertos en OnAllCylinders , los brazos de control tubulares simplemente se ven mejor. Para un coche de exhibición, un restomod o cualquier vehículo en el que la suspensión sea visible, las soldaduras limpias y el diseño ingenieril de los brazos tubulares ofrecen una apariencia de alto rendimiento que los brazos estampados de acero no pueden igualar.

Conclusión: Tomar la decisión correcta para su vehículo

Decidir entre brazos de control de acero estampado y tubulares depende en última instancia del uso previsto para su vehículo y sus objetivos de rendimiento. Es un intercambio clásico entre la suficiencia de fábrica y una inversión transformadora en su experiencia de conducción. Los brazos de acero estampado son perfectamente adecuados para una restauración fiel al período o para un vehículo que se usa ocasionalmente los fines de semana, donde la autenticidad y el presupuesto son las principales consideraciones.

Sin embargo, si planeas mejorar la manejo, estabilidad y sensación general sobre el camino de tu vehículo, los brazos de control tubulares son una de las mejoras más efectivas que puedes realizar. Los beneficios no se limitan a la pista; la mayor estabilidad en línea recta, dirección más receptiva y curvas predecibles son notorias y transmiten confianza incluso en situaciones cotidianas de conducción. Para cualquier vehículo con neumáticos radiales modernos, mayor potencia o un propietario que desee una experiencia de conducción más conectada, los brazos de control tubulares son una inversión necesaria y valiosa.

Antes de comprar, hazte estas preguntas clave:

- ¿Cómo conduzco mi coche? (Conducción relajada frente a carreteras sinuosas o días en pista)

- ¿Cuáles son mis planes futuros de modificación? (Neumáticos más anchos, más potencia, etc.)

- ¿Cuál es mi presupuesto para mejoras de suspensión?

- ¿Es prioritaria para mí una sensación de conducción moderna y conectada?

Responder a estas preguntas te llevará a la elección correcta. Para un vehículo sencillo de uso diario, los componentes estándar pueden ser suficientes. Para cualquier nivel de conducción deportiva, el camino conduce claramente a los brazos de control tubulares.

Preguntas Frecuentes

1. ¿Cuál es la diferencia entre brazos de control estampados y forjados?

Los brazos de control estampados se fabrican presionando una lámina de metal en una forma determinada, un método rentable para la producción en masa. Los brazos de control forjados se crean calentando un tocho de metal y comprimiéndolo en un molde. Este proceso de forja alinea la estructura interna del grano metálico, resultando en una pieza significativamente más resistente y menos propensa a la fatiga que una equivalente estampada o fundida.

2. ¿Cuál es el mejor material para los brazos de control?

El mejor material depende de la aplicación. El acero de alta resistencia, utilizado en la mayoría de los brazos tubulares, ofrece un excelente equilibrio entre resistencia, peso y costo para aplicaciones de alto rendimiento. El aluminio forjado es otra opción premium, utilizada frecuentemente en vehículos de lujo o alto rendimiento por su ligereza y resistencia natural a la corrosión, lo cual mejora el confort y la manejo.

3. ¿Cómo puedo saber si tengo brazos de control de acero estampado?

La forma más sencilla de comprobarlo es con un imán simple. Si el imán se adhiere firmemente a su brazo de suspensión, está hecho de acero, lo que en la mayoría de los automóviles clásicos indica que es una pieza de acero estampado. Además, suelen tener un aspecto más sencillo, en forma de canal en C o de concha, en comparación con los tubos soldados de un brazo tubular o con el aspecto sólido y más robusto de un brazo de aluminio forjado.

Pequeños lotes, altos estándares. Nuestro servicio de prototipado rápido hace que la validación sea más rápida y fácil —

Pequeños lotes, altos estándares. Nuestro servicio de prototipado rápido hace que la validación sea más rápida y fácil —