Mechanical Die Anatomy: 9 Essential Points Every Buyer Must Know

What Is a Mechanical Die and Why It Matters in Manufacturing

Ever wondered how millions of identical metal parts roll off production lines with perfect precision? The answer lies in one of manufacturing's most essential yet often misunderstood tools: the mechanical die.

A mechanical die is a specialized machine tool used to cut, shape, or form materials—typically metal—into a desired shape or profile through applied pressure. Unlike molds that shape complete three-dimensional parts from molten materials, a die is used to transform solid sheet metal into functional components through mechanical force.

This distinction is crucial. While injection molds work with melted plastics or metals that solidify within a cavity, mechanical dies physically cut and form solid materials without changing their fundamental state. Understanding what is a die in manufacturing gives you the foundation for smarter purchasing decisions and more efficient production planning.

The Precision Tool Behind Mass Production

So, what are dies exactly, and why do they matter so much? Think of a mechanical die as a highly engineered cookie cutter—but one capable of withstanding thousands of pounds of force while maintaining tolerances measured in thousandths of an inch.

A stamping die consists of two precision-matched halves placed inside a press. According to industry experts at The Phoenix Group, a die performs four essential functions:

- Locating – Precisely positioning the material before work begins

- Clamping – Securing the material during the forming operation

- Working – Performing value-added operations like cutting, bending, piercing, embossing, forming, drawing, stretching, coining, and extruding

- Releasing – Freeing the finished part for the next cycle

Among these, only the working function adds direct value to your product. This is what is die manufacturing at its core—transforming raw sheet metal into precision components through carefully engineered tooling.

From Raw Material to Finished Part

Imagine you're producing automotive brackets. A coil of steel enters the press, and with each stroke, the machine die cuts, bends, and forms that flat material into a three-dimensional part ready for assembly. This happens hundreds or even thousands of times per hour with remarkable consistency.

What makes this possible? The die itself is typically constructed from tool steel—a category of carbon and alloy steels specifically engineered for high strength, impact toughness, and wear resistance. These materials allow dies to withstand the repeated stress of high-volume production while maintaining the dimensional accuracy your parts require.

Understanding what is dies in manufacturing matters for several key stakeholders:

- Engineers need this knowledge to design parts that are manufacturable and cost-effective

- Procurement specialists must evaluate die suppliers and understand total cost of ownership

- Manufacturing managers rely on die performance data to optimize production schedules and maintenance cycles

Whether you're specifying new tooling, troubleshooting production issues, or evaluating potential suppliers, a solid grasp of mechanical die fundamentals puts you in a stronger position. The chapters ahead will walk you through every critical aspect—from die components and types to materials, design processes, and supplier selection criteria.

Essential Components of a Mechanical Die Assembly

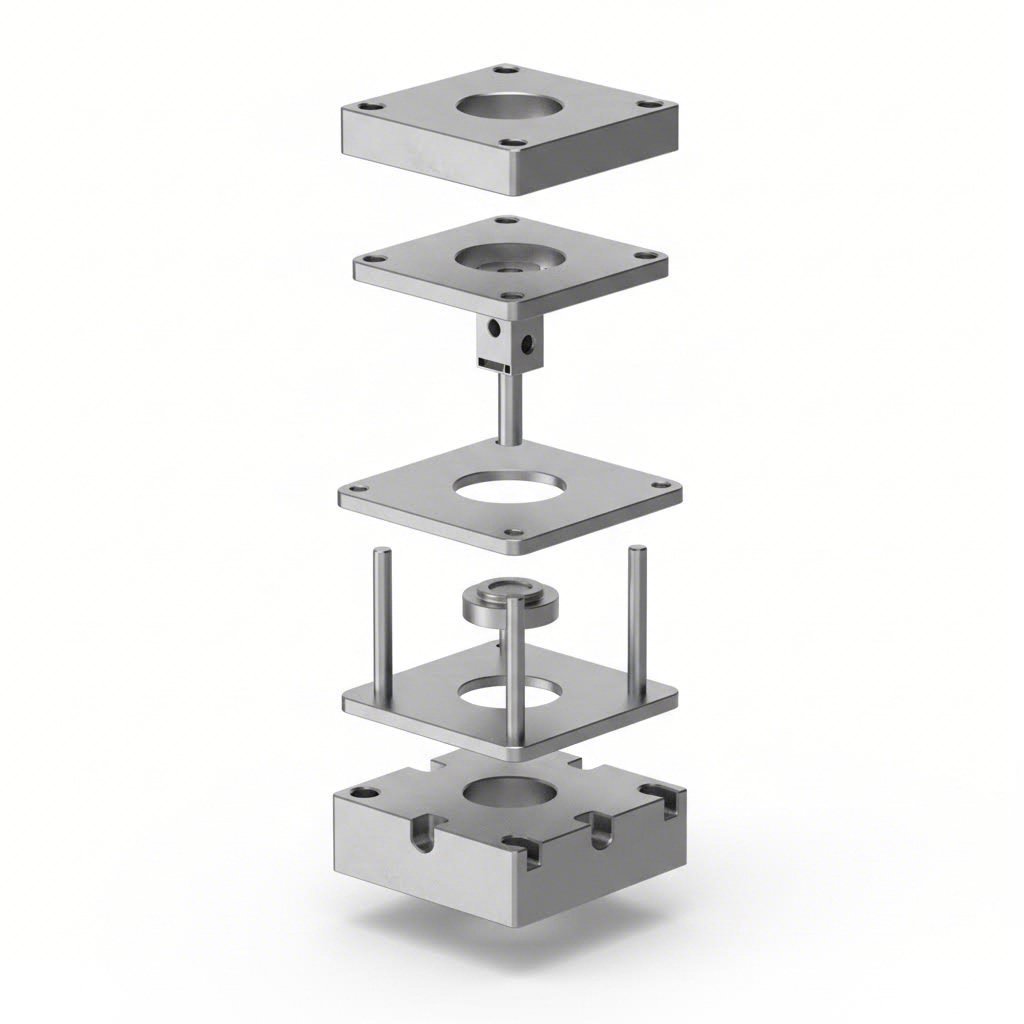

Now that you understand what a mechanical die does, let's look inside one. A die assembly might appear straightforward from the outside, but crack it open and you'll find a precisely engineered system where every component plays a critical role. When any single part fails or wears beyond tolerance, the entire production line feels the impact.

Understanding these stamping die components helps you communicate more effectively with die makers, troubleshoot production issues faster, and make smarter decisions about maintenance and replacement cycles.

Anatomy of a Precision Die Assembly

Think of a die assembly as having two main categories of components: the structural framework that holds everything together, and the working components that actually transform your material. Let's break down each one.

The die shoe serves as the foundation—essentially the skeleton of your entire tool. You'll find both upper and lower die shoes, which are heavy base plates that mount to the press. The lower die shoe attaches to the press bed, while the upper shoe connects to the ram. These plates must be rigid enough to resist deflection under tremendous forces, often exceeding hundreds of tons.

Between the press and die, guide pins and bushings ensure perfect alignment every single stroke. According to Moeller Precision Tool, these are manufactured to tolerances within 0.0001 inches—that's one-tenth the thickness of a human hair. Ball-bearing guide pins have become industry standard because they glide smoothly and make die separation easier during maintenance.

Backing plates are hardened plates positioned behind punches and die buttons. Their job? Distributing the intense forces generated during each press stroke and preventing the softer die shoe material from deforming over time.

How Each Component Contributes to Part Quality

The working components are where the real action happens. The die punch is the male component that presses into the material, performing the actual cutting or forming work. Punches come in various nose shapes—round, square, oblong, or custom profiles—depending on what geometry your part requires. The punch head connects to the retainer system that secures it within the upper die assembly.

The die plate (or die button) is the punch's female counterpart. It provides the opposing cutting edge and features a precisely ground opening that matches the punch profile. Here's where things get interesting: the die button isn't an exact match to the punch. There's an intentional gap called die clearance—typically 5-10% of the material thickness per side.

Why does clearance matter so much? Too little clearance causes excessive wear on both punch and die, increases the force required, and can leave rough, torn edges on your parts. Too much clearance creates burrs, dimensional inaccuracies, and poor edge quality. Getting this relationship right is essential for achieving clean cuts and long tool life.

The stripper plate solves a practical problem you might not expect. When a punch pierces through sheet metal, the material's elasticity causes it to grip the punch tightly. Without a stripper, the workpiece would travel upward with the retracting punch—jamming the die and halting production. The stripper plate strips this material off cleanly, allowing continuous operation.

| Component | Function | Typical Materials |

|---|---|---|

| Die Shoe (Upper/Lower) | Provides structural foundation; mounts to press | Steel, aluminum alloys |

| Guide Pins & Bushings | Ensures precise alignment between die halves | Hardened tool steel, precision ground |

| Backing Plates | Distributes force; protects die shoes from deformation | Hardened steel |

| Punch | Male cutting/forming component; transforms material | D2, A2, M2 tool steel; carbide |

| Die Button/Die Plate | Female cutting edge; works with punch to create parts | D2, carbide inserts |

| Stripper Plate | Removes material from punch during retraction | Tool steel, urethane options |

| Die Springs | Provides force for stripping and pressure pad functions | Chrome silicon wire, nitrogen gas cylinders |

| Die Retainers | Holds punches and buttons securely in position | Through-hardened alloy steel |

When you're evaluating a press and die system, remember that these components don't work in isolation. The guide pins must align perfectly with the bushings. The punch clearance must match the die button precisely. The stripper must engage at exactly the right moment. This interconnected precision is what separates a high-performing die from one plagued by quality issues and excessive downtime.

With this foundation in die anatomy, you're ready to explore the different types of mechanical dies and discover which configuration best suits your specific production requirements.

Types of Mechanical Dies and Their Applications

You've seen what's inside a mechanical die. Now comes the bigger question: which type of die do you actually need? The answer depends on your production volume, part complexity, and budget constraints. Choosing the wrong die type can mean overspending on tooling for simple parts—or struggling with quality issues when your tooling can't handle the complexity you require.

Let's break down the major types of stamping dies and when each makes sense for your manufacturing operation.

Progressive Dies for High-Volume Efficiency

Imagine a stamping die that performs multiple operations in perfect sequence without ever releasing the part. That's exactly what a progressive die does. According to Durex Inc., progressive dies consist of multiple stations arranged in sequence, each performing a specific operation as the metal sheet moves through the press.

Here's how it works: a coil of sheet metal feeds into the first station, where the initial operation—perhaps a pilot hole punch—takes place. With each press stroke, the material advances to the next station. Station two might cut an outline. Station three bends a flange. Station four adds embossing. The final station separates the finished part from the carrier strip.

This approach delivers remarkable efficiency for high-volume production. Metal stamping dies configured as progressive systems can produce complex parts at speeds exceeding 1,000 strokes per minute. The automotive industry relies heavily on this die type for manufacturing brackets, clips, and structural components where millions of identical parts are needed annually.

Best suited for:

- High-volume production runs (100,000+ parts)

- Parts requiring multiple operations (cutting, bending, forming)

- Components that remain attached to carrier strip during processing

- Applications where per-part cost matters more than tooling investment

Choosing Between Compound and Transfer Operations

What if you need multiple operations completed simultaneously rather than sequentially? That's where compound dies excel.

A compound die performs multiple cutting operations in a single stroke. Picture a die that blanks out a shape while simultaneously punching internal holes—all in one press cycle. This integration reduces production time dramatically and ensures perfect alignment between features since everything happens at once.

According to manufacturing experts at Worthy Hardware, compound die stamping offers exceptional precision and efficient material usage with minimal scrap. However, there's a tradeoff: this stamping die type works best for relatively flat parts with simpler geometries. If your component requires deep draws or complex three-dimensional forming, you'll need a different approach.

Transfer dies solve the complexity problem through a fundamentally different strategy. Instead of keeping the part attached to a carrier strip, transfer dies use mechanical fingers or robots to physically move workpieces between independent stations. Each station performs its operation, then releases the part for transfer to the next.

This flexibility makes transfer dies ideal for:

- Large parts that won't fit on a progressive die carrier strip

- Deep-drawn components requiring multiple forming stages

- Complex assemblies needing operations from different angles

- Parts requiring in-process orientation changes

The trade-off? Transfer die stamping typically involves higher operational costs and longer setup times. You'll also need skilled technicians for maintenance and operation. But for complex aerospace components or heavy machinery parts, no other method delivers the same combination of precision and geometric flexibility.

Specialized Die Types for Specific Operations

Beyond these primary categories, several specialized forming dies address specific manufacturing needs:

- Blanking Dies – Cut specific shapes from sheet metal to create flat blanks for further processing. Their straightforward design makes them cost-effective for producing clean-cut starting materials with minimal waste.

- Forming Dies – Shape material into three-dimensional profiles through bending, flanging, or curling operations without removing material. Essential for creating structural components with complex contours.

- Drawing Dies – Pull sheet metal into deep cavities to create cup-shaped or box-shaped components. Common in cookware, beverage cans, and automotive fuel tank manufacturing.

- Coining Dies – Apply extreme pressure to create high-precision surface details and tight dimensional tolerances. Used extensively in jewelry and medical device manufacturing.

- Embossing Dies – Create raised or recessed patterns for both aesthetic and functional purposes, such as improving grip or adding branding elements.

A Decision Framework for Die Selection

Sounds complex? Here's a practical way to narrow down your options:

| Selection Factor | Progressive Die | Compound Die | Transfer Die |

|---|---|---|---|

| Production Volume | High (100K+ parts) | Low to Medium | Medium to High |

| Part Complexity | Moderate | Simple to Moderate | High |

| Part Size | Small to Medium | Small to Medium | Medium to Large |

| Initial Tooling Cost | High | Moderate | High |

| Per-Part Cost | Low | Moderate | Moderate to High |

| Setup Time | Moderate | Low | High |

When specifying sheet metal stamping dies for your project, start with three questions: How many parts do you need annually? How complex is the geometry? What's your budget for tooling versus per-piece costs?

For high-volume automotive brackets, progressive dies typically deliver the lowest total cost. For precision medical components in smaller quantities, compound dies often make more sense. For large aerospace panels with complex forming requirements, transfer dies provide capabilities that simpler systems simply cannot match.

Understanding these types of dies positions you to have productive conversations with die manufacturers and make specifications that align with your production realities. But selecting the right die type is only part of the equation—the materials used in die construction have an equally dramatic impact on performance, longevity, and total cost of ownership.

Die Materials and Surface Treatments for Optimal Performance

You've selected the right die type for your application. Now comes a decision that will determine how long that tooling lasts and how many quality parts it produces: material selection. The wrong die steel can mean premature failure, excessive maintenance costs, and quality issues that ripple through your entire production process.

Whether you're stamping soft aluminum brackets or punching through hardened steel, the materials inside your sheet metal dies directly impact performance, longevity, and total cost of ownership. Let's explore what makes each option unique.

Tool Steel Grades and Their Performance Characteristics

Tool steel forms the backbone of most metal die construction. According to Ryerson, tool steels contain between 0.5% and 1.5% carbon along with carbides formed by four primary alloying elements: tungsten, chromium, vanadium, and molybdenum. These elements give die steel its exceptional hardness, wear resistance, and ability to maintain a cutting edge under extreme pressure.

But here's what many buyers miss: not all tool steels perform equally across different applications. The grade you choose should match your specific production demands.

D2 Tool Steel stands as the workhorse of steel stamping dies. With its high carbon and chromium content, D2 achieves hardness levels of 62-64 HRC after heat treatment. Those hard carbide particles deliver exceptional abrasion resistance—perfect for blanking, punching, and forming dies requiring tight tolerances over extended production runs. If you're producing hundreds of thousands of parts from the same tooling, D2's wear resistance often justifies its cost.

A2 Tool Steel offers an excellent balance when you need both toughness and wear resistance. Its 5% chromium content provides high hardness (63-65 HRC as-hardened) while maintaining dimensional stability during heat treatment. This makes A2 particularly valuable for blanking punches, forming dies, and injection molding applications where precision matters as much as durability.

S7 Tool Steel takes a different approach entirely. As a shock-resistant grade, S7 prioritizes impact toughness over pure hardness. It achieves 60-62 HRC when hardened, but its real strength lies in absorbing repeated mechanical shock without chipping or cracking. When your tooling dies face high-impact applications—chisels, punches for thicker materials, or rivet sets—S7 often outperforms harder but more brittle alternatives.

| Tool Steel Grade | Hardness (HRC) | Key Properties | Best Applications | Relative Cost |

|---|---|---|---|---|

| D2 | 62-64 | Exceptional wear resistance, high chromium | Long-run blanking, punching, forming dies | Moderate |

| A2 | 63-65 | Balanced toughness and wear, dimensional stability | Blanking punches, trimming dies, forming tools | Moderate |

| S7 | 60-62 | Superior shock resistance, high impact toughness | Heavy-duty punches, chisels, impact applications | Moderate |

| O1 | 57-62 | Easy to machine, good edge retention | Shearing blades, general-purpose cutting tools | Low |

| M2 | 62-64 | Maintains hardness at high temperatures | High-speed cutting tools, drills, taps | Higher |

When Carbide Inserts Justify the Investment

Sometimes even premium tool steel can't deliver the longevity your production demands. That's where carbide inserts enter the picture.

Tungsten carbide is exceptionally hard—significantly harder than any tool steel. According to Alsette, carbide insert molds use these extremely hard pieces embedded into high-wear areas of a steel die body. Rather than constructing an entire sheet metal die from carbide (which would be prohibitively expensive and brittle), manufacturers strategically place inserts at cutting edges, punches, draw radii, and forming surfaces.

This hybrid approach delivers compelling benefits:

- Extended die life – Carbide inserts can outlast tool steel components by 5-10 times in high-abrasion applications

- Reduced replacement costs – When wear occurs, you replace only the insert rather than the entire die component

- Minimized downtime – Faster insert changes mean less production interruption

- Consistent part quality – Carbide maintains sharp edges longer, producing cleaner cuts throughout the production run

When does carbide justify its higher upfront cost? Consider it for high-volume production exceeding one million parts, when stamping abrasive or hardened materials, or when critical cutting edges determine part quality. Automotive manufacturers producing small terminals, connectors, and fasteners routinely specify carbide inserts because the volume makes the investment pay off quickly.

Surface Treatments That Extend Die Life

Beyond base material selection, surface treatments and coatings can dramatically enhance your metal die performance. These thin-film applications add protective layers that reduce friction, resist wear, and prevent galling—all without altering the tool's core properties.

TiN (Titanium Nitride) coatings create a distinctive gold-colored surface with hardness around 2,300 HV. This coating reduces friction between the die and workpiece, extends tool life by 2-4 times in many applications, and helps prevent material buildup on cutting edges.

TiCN (Titanium Carbonitride) builds on TiN's foundation with even greater hardness (approximately 3,000 HV) and improved wear resistance. Its blue-gray appearance signals enhanced performance for punching and forming harder materials like stainless steel.

DLC (Diamond-Like Carbon) coatings achieve exceptional hardness levels approaching diamond while maintaining extremely low friction coefficients. DLC excels in applications involving aluminum and other materials prone to adhesion and galling.

Selecting the right combination of base material and surface treatment requires balancing several factors: your workpiece material's hardness and abrasiveness, expected production volume, tolerance requirements, and budget constraints. A die maker with deep experience in your application area can guide this decision—which brings us to the engineering process that transforms material specifications into production-ready tooling.

The Die Design Process From Concept to Production

You've selected the right die type and specified appropriate materials. Now comes the engineering phase that transforms those decisions into a physical tool capable of producing millions of precision parts. What is die making at its core? It's a disciplined engineering process that bridges the gap between your part design and a production-ready stamping die.

Understanding this journey helps you set realistic timelines, ask better questions during design reviews, and recognize when engineering shortcuts might compromise your results down the road.

Engineering Considerations That Determine Die Success

Every successful stamping die design begins with a thorough analysis of the part itself. According to Dramco Tool, understanding the part's design intent—how it will be used and how it needs to function in the real world—provides crucial insight into feature requirements and opens opportunities to optimize the design for easier manufacturing.

Before any CAD modeling begins, experienced die engineers evaluate several critical factors:

- Material behavior – How will the sheet metal flow during forming? What springback can you expect after bending operations?

- Critical tolerances – Which dimensions matter most for part function and assembly fit?

- Production volume – How does expected volume influence decisions about die complexity and material selection?

- Press compatibility – What equipment constraints affect die size, stroke length, and tonnage requirements?

Here's where many projects go wrong: assumptions replace careful analysis. As industry experts emphasize, avoiding assumptions and asking clarifying questions when information is missing prevents costly redesigns later. A metal stamping die design built on incomplete specifications will require expensive modifications once production reveals the gaps.

Tolerance establishment deserves particular attention during this phase. In modern manufacturing, tolerances have become tighter and tighter—often a tiny fraction of an inch. Your die tooling must account for cumulative variation from material thickness fluctuations, press deflection, thermal expansion, and progressive tool wear. The stamping die design process translates your finished part specifications backward into the tool dimensions required to consistently achieve them.

From Digital Design to Physical Precision

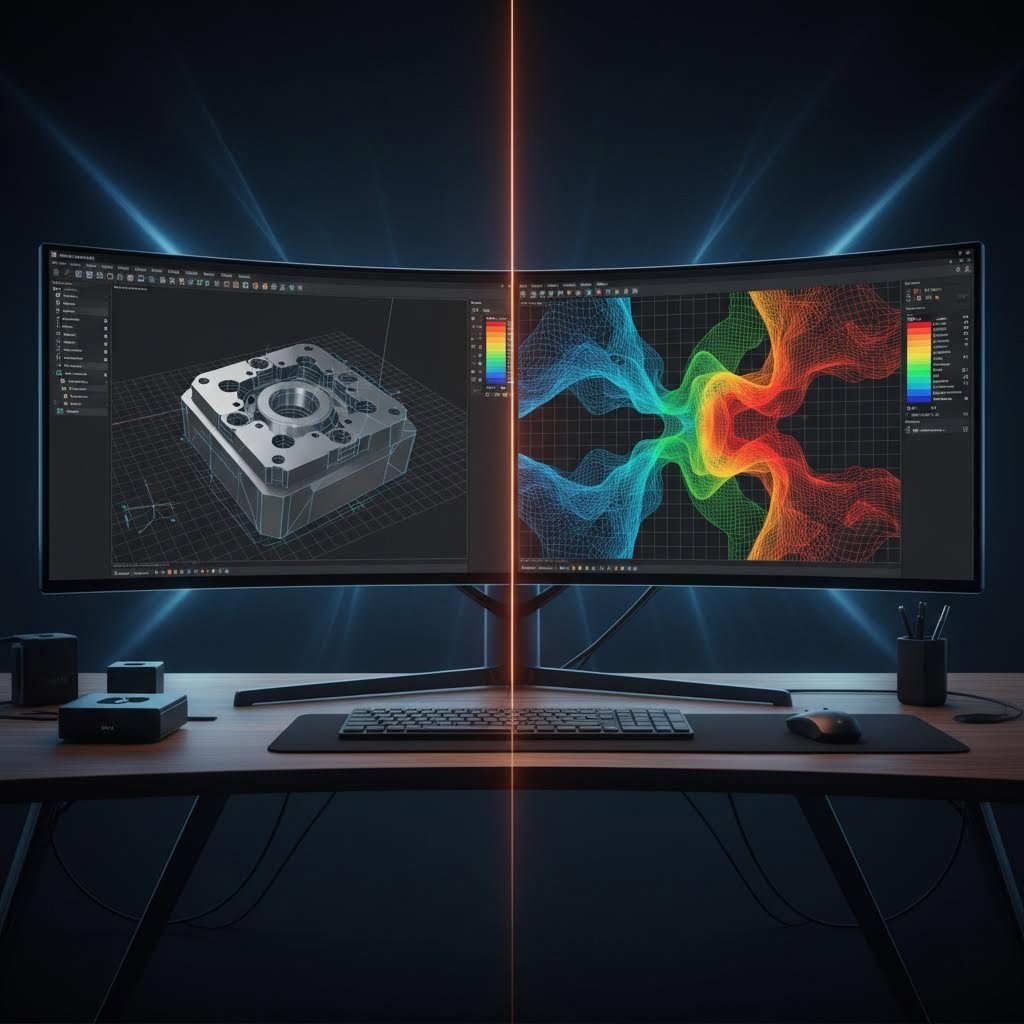

Modern die drawing and development relies heavily on computer-aided design (CAD) software. Engineers create detailed 3D models of every die component—punches, die buttons, strippers, guide systems—and verify their interaction through digital assembly. This virtual environment allows designers to identify interference issues, optimize material flow paths, and refine clearances before cutting any steel.

But CAD modeling alone doesn't guarantee success. This is where CAE (Computer-Aided Engineering) simulation transforms the die making process.

According to Keysight Technologies, sheet metal forming simulation software enables virtual die try-outs that identify potential defects before physical tool construction. These simulations predict:

- Material flow patterns – How sheet metal moves and stretches during forming operations

- Springback magnitude – Especially critical for advanced high-strength steels and aluminum alloys that are challenging to form

- Potential thinning or tearing – Areas where material might fail under forming stresses

- Wrinkling risks – Compression zones that could cause surface defects

Why does this matter for your budget? Part and process design defects often emerge only during the first trials in the try-out stage of die manufacturing—when corrections are both time-consuming and costly. Simulation catches these issues digitally, when changes cost hours of engineering time rather than weeks of tool modification.

The simulation process also helps optimize press settings. Achieving optimal stamping conditions requires fine-tuning parameters like press speed, blank holder force, and lubrication. Virtual testing dramatically reduces the physical trial-and-error traditionally required, shortening your time to production.

Prototype Development and Validation

Even with sophisticated simulation, physical validation remains essential. Prototype dies—sometimes called soft tooling—allow engineers to verify their digital predictions against real-world material behavior. These prototypes typically use less expensive materials and simplified construction, enabling faster iteration before committing to production-grade tooling.

During validation testing, engineers measure:

- Dimensional accuracy across all critical features

- Edge condition quality and burr height

- Surface finish in formed areas

- Material thinning at draw radii

- Springback compensation effectiveness

This data feeds back into the design process, refining the die for manufacturing at production volumes. When designing a die for manufacturing complex automotive or aerospace components, multiple prototype iterations may be necessary to achieve the required precision.

Throughout this journey, documentation matters enormously. Detailed die drawings capture every dimension, tolerance, and material specification. These records support future maintenance, component replacement, and potential design modifications as your product evolves.

The engineering investment you make during the design phase pays dividends throughout your die's production life. A thoroughly engineered tool produces consistent parts with minimal adjustment, while a rushed design creates ongoing headaches that consume maintenance hours and generate scrap. With your design validated, the next challenge is translating those specifications into precision-manufactured die components.

Manufacturing Methods and Precision Standards

Your die design is complete and validated. Now comes the moment of truth: transforming those digital specifications into physical tooling capable of producing millions of precision parts. The die machining process determines whether your carefully engineered design translates into a tool that performs flawlessly—or one plagued by dimensional issues and premature wear.

Understanding how dies are manufactured helps you evaluate supplier capabilities, set realistic delivery expectations, and recognize quality indicators that separate world-class tooling from mediocre alternatives.

Precision Machining Methods for Die Construction

Manufacturing tooling at the precision levels required for modern stamping demands a carefully orchestrated sequence of machining operations. Each method addresses specific requirements, and skilled diemakers know exactly when to apply each technique.

CNC Machining serves as the foundation for most die construction. According to Ohio Valley Manufacturing, this versatile technique uses computer-controlled machinery to precisely remove material according to programmed instructions. CNC milling and turning operations rough out the basic die geometry, establishing primary features within tolerances of ±0.001 to ±0.005 inches.

Multi-axis CNC capabilities—including 5-axis and 6-axis machining—enable simultaneous cutting from multiple directions in a single setup. This matters because each time you reposition a workpiece, you introduce potential alignment errors. Reducing setups means tighter tolerances and faster production.

EDM (Electrical Discharge Machining) tackles geometries that conventional cutting tools simply cannot achieve. This process works by creating controlled electrical sparks between an electrode and the workpiece, eroding material in incredibly precise increments. Two primary EDM methods serve different purposes in machining dies:

- Wire EDM uses a continuously moving thin wire (typically 0.004-0.012 inches diameter) to cut complex profiles and intricate shapes. It excels at creating the precise punch and die button profiles that define your part geometry, achieving tolerances within ±0.0001 inches.

- Sinker EDM employs a shaped electrode that "sinks" into the workpiece, creating cavities and complex three-dimensional features. This method produces the intricate details and sharp internal corners impossible with rotary cutting tools.

According to industry experts at Actco Tool, EDM is particularly suitable for producing intricate shapes, sharp corners, and fine details that may be difficult to achieve with conventional machining methods.

Grinding delivers the final dimensional accuracy and surface finish your die components require. Precision die stamping demands surface finishes measured in microinches, and grinding achieves this through abrasive material removal. Surface grinding creates flat, parallel surfaces on die shoes and backing plates. Cylindrical grinding produces round features like guide pins to exacting specifications. Profile grinding refines complex contours on punches and die sections.

Hand Finishing might seem old-fashioned in an era of computer-controlled precision, but skilled diemakers still perform critical final adjustments. Stoning, lapping, and polishing operations remove the microscopic tool marks left by machining, creating the mirror-smooth surfaces that prevent material adhesion and galling during production.

The Manufacturing Sequence

Machining a precision die follows a logical progression from rough material to finished component:

- Rough machining – CNC milling removes bulk material, leaving 0.010-0.020 inches for subsequent operations

- Heat treatment – Components are hardened to achieve required hardness and wear resistance

- Semi-finish machining – Post-heat-treatment operations correct any distortion and approach final dimensions

- Wire EDM – Cuts precise profiles on punches, die buttons, and other critical features

- Precision grinding – Achieves final dimensional accuracy and surface finish requirements

- Sinker EDM – Creates complex cavities and detailed features where needed

- Hand finishing – Polishing and stoning achieve required surface quality

- Assembly and fitting – Components are assembled and adjusted for proper operation

Quality Verification and Tolerance Validation

How do you know your die meets specifications? Rigorous inspection protocols verify every critical dimension before assembly.

According to metrology experts at Jeelix, modern Coordinate Measuring Machines (CMMs) equipped with micro-ball styli can reach accuracies of 0.8 µm—less than one-thousandth of a millimeter. These systems capture precise dimensional data across complex geometries, comparing actual measurements against CAD specifications.

Tolerance capabilities vary significantly by manufacturing method:

| Manufacturing Method | Typical Tolerance | Surface Finish (Ra) |

|---|---|---|

| CNC Milling (Rough) | ±0.005 inches | 63-125 µin |

| CNC Milling (Finish) | ±0.001 inches | 32-63 µin |

| Wire EDM | ±0.0001-0.0005 inches | 8-32 µin |

| Precision Grinding | ±0.0001-0.0002 inches | 4-16 µin |

| Lapping/Polishing | ±0.00005 inches | 1-4 µin |

Beyond dimensional verification, quality control extends to material certification, hardness testing, and surface finish measurement. Each die component's inspection record documents conformance to specifications, providing traceability throughout the tool's production life.

Thermal considerations also affect measurement accuracy. As metrology experts note, an aluminum mold plate can expand by 0.07mm with just a 10°C temperature change—easily triggering false rejection. High-end measurement systems compensate for thermal expansion, ensuring that readings reflect true geometry rather than temperature artifacts.

With your die precisely manufactured and verified, the focus shifts to keeping it performing at peak levels throughout its production life—a topic that directly impacts your total cost of ownership.

Die Maintenance and Troubleshooting Common Problems

Your mechanical die is now in production, delivering precision parts stroke after stroke. But here's a reality the die making industry knows well: even the finest tooling degrades over time. The question isn't whether your die will experience wear—it's whether you'll catch problems early enough to prevent costly failures and production disruptions.

Understanding failure modes and implementing proactive maintenance transforms your die equipment from a ticking time bomb into a predictable, manageable asset. Let's explore what goes wrong, why it happens, and how to extend your tooling's productive life.

Recognizing Early Warning Signs of Die Wear

Every die formed part tells a story about the tool that made it. According to experts at Keneng Hardware, die wear occurs as a result of repeated contact between the die surface and the metal being stamped. Learning to read these signals before they become critical failures separates proactive maintenance programs from reactive firefighting.

The die industry categorizes wear into distinct patterns, each pointing to specific root causes:

- Abrasive wear – Creates visible grooves and scratches on working surfaces. Hard particles from the workpiece material or environmental contamination act like sandpaper, gradually removing die material. You'll notice this first on punch faces and die button edges.

- Adhesive wear (galling) – Produces torn, rough surfaces where workpiece material has welded to the die. This happens when extreme pressure causes momentary bonding between die and sheet metal. Stainless steel and aluminum are particularly prone to galling.

- Chipping and microcracking – Shows as small pieces breaking away from cutting edges. Often caused by excessive clearance, impact loading, or die steel that's too hard for the application. These chips contaminate your parts and accelerate further damage.

- Fatigue cracking – Develops as progressive fractures under repeated stress cycles. Look for telltale "beach marks"—curved lines radiating from the crack origin. Unlike sudden overload fractures, fatigue cracks grow slowly, offering warning time if you're inspecting regularly.

What should trigger immediate investigation? According to Jeelix, increased burr height on stamped parts, dimensional drift beyond tolerance, surface scratches or galling marks, and unusual sounds during die processing all indicate developing problems. These symptoms rarely appear suddenly—they escalate from subtle to severe over hundreds or thousands of press cycles.

Preventive Maintenance That Extends Die Life

The highest-performing manufacturing operations don't wait for failures. They schedule maintenance based on production cycles, inspection data, and historical performance patterns.

According to The Phoenix Group, poor die maintenance causes quality defects during production, driving up sorting costs, increasing the likelihood of shipping defective parts, and risking expensive forced containments. A systematic approach prevents these cascading consequences.

Establish inspection intervals based on your standard die specifications and production demands:

- Every production run – Visual inspection of critical surfaces, verification of part quality, lubrication system check

- Weekly or bi-weekly – Detailed examination of punch and die button edges, measurement of critical dimensions, guide pin and bushing wear assessment

- Monthly or quarterly – Complete die teardown, thorough cleaning, dimensional verification against original specifications, component replacement as needed

- Annually – Comprehensive audit including metallurgical evaluation if warranted, coating condition assessment, documentation review

Common problems and their solutions:

- Excessive burr formation → Check and adjust die clearance; sharpen or replace worn cutting edges

- Galling on forming surfaces → Improve lubrication; apply or reapply surface coatings (TiN, DLC); polish affected areas

- Dimensional drift → Verify clearances; check for worn guide components; regrind working surfaces to specification

- Chipping at cutting edges → Evaluate material selection; reduce impact loading; consider tougher die steel grade

- Fatigue cracks → Stress-relieve affected components; redesign high-stress areas; replace before catastrophic failure

- Stripper plate damage → Inspect spring forces; verify timing; replace worn components

When does regrinding make sense versus component replacement? Generally, if a punch or die button can be reground while maintaining minimum working length specifications, regrinding offers significant cost savings. Most standard die components allow for multiple regrind cycles before replacement becomes necessary. However, components showing fatigue cracking, severe galling, or dimensional distortion beyond correction should be replaced immediately.

The Complete Die Lifecycle

Understanding where your die sits in its lifecycle helps you plan maintenance investments appropriately:

- Break-in period – First 5,000-10,000 strokes reveal any design or manufacturing issues. Inspect frequently and document baseline performance.

- Prime production – Die operates at peak efficiency with routine maintenance. This phase should represent 70-80% of total die life.

- Mature operation – Increased maintenance frequency required. Component replacement becomes more common. Per-part costs rise gradually.

- End of life – Maintenance costs approach or exceed rebuild investment. Quality becomes inconsistent despite intervention. Time for replacement or major rebuild.

Documentation throughout this lifecycle proves invaluable. According to industry experts, data from previous work orders can be utilized to improve preventative maintenance plans and predict when similar issues might recur. This historical record transforms reactive maintenance into predictive asset management.

Your die's productive life depends on catching problems early and addressing them systematically. But even the best maintenance program can't compensate for poor initial tooling quality—which brings us to the critical question of how to select a manufacturing partner capable of delivering dies that perform from day one.

Selecting a Qualified Die Manufacturing Partner

You've designed the perfect mechanical die, specified premium materials, and established rigorous maintenance protocols. But here's the uncomfortable truth: all of that careful planning means nothing if your die manufacturing partner lacks the capabilities to execute. The gap between a qualified die maker and an underperforming one can translate into months of delays, quality escapes, and costs that spiral far beyond your initial tooling budget.

So how do you separate world-class die manufacturing companies from those that simply talk a good game? The answer lies in systematic evaluation across five critical dimensions.

Certification Standards That Signal Manufacturing Excellence

When evaluating tool and die manufacturing partners, certifications serve as your first filter. They don't guarantee excellence, but their absence should raise immediate red flags.

IATF 16949 certification stands as the gold standard for automotive die suppliers. According to Smithers, this globally recognized quality management standard outlines requirements for a QMS that helps organizations improve manufacturing efficiency and enhance customer satisfaction. Achieving IATF 16949 certification requires significant investments in time, money, and resources—meaning certified suppliers have demonstrated serious commitment to quality systems.

What does IATF 16949 actually require? The major requirements include:

- Robust Quality Management System – Built on ISO 9001:2015 foundations with automotive-specific enhancements

- Planning and Risk Analysis – Identification and mitigation of potential risks across all manufacturing stages

- Process Management – Documented processes with regular effectiveness monitoring

- Product Design and Development – Well-documented design processes addressing customer requirements and safety regulations

- Continuous Monitoring and Measurement – Regular audits, inspections, and performance evaluations

Beyond IATF 16949, look for ISO 9001 certification as a baseline, ISO 14001 for environmental management commitment, and industry-specific certifications relevant to your application (aerospace, medical, etc.).

Evaluating Engineering Support and Prototyping Capabilities

Certifications confirm systems exist. Engineering capabilities determine whether those systems produce exceptional dies or merely adequate ones.

According to stamping die manufacturing experts at Die-Matic, a manufacturer who offers part design optimization can help refine your designs for manufacturability, resolving issues quickly and keeping projects on schedule. This collaborative engineering approach separates true partners from order-takers who simply build what you specify—even when your specifications contain avoidable problems.

When assessing a potential die assembly manufacturer, investigate these engineering dimensions:

- CAE Simulation Capabilities – Does the supplier use forming simulation software to predict material flow, springback, and potential defects before tool construction? Advanced CAE simulation enables virtual die try-outs that identify problems when fixes cost engineering hours rather than tool modifications.

- Design for Manufacturability Support – Will their engineers proactively recommend changes that reduce tooling complexity, improve die life, or enhance part quality?

- Prototyping Speed – How quickly can they deliver prototype tooling for validation? Rapid prototyping—in as little as 5 days for some suppliers—dramatically compresses your development timeline.

- Material Expertise – Do they have demonstrated experience with your specific workpiece materials? Different materials require different handling, tooling approaches, and process parameters.

As industry experts at Eigen Engineering emphasize, when a manufacturer advertises only one kind of service, their capabilities are limited. The ideal dies manufacturing partner offers comprehensive services including tool die design assistance, multi-material capabilities, and automation integration.

Production Capacity and Quality Metrics

Engineering excellence means nothing if your supplier can't deliver tooling on schedule—or if delivered dies require extensive rework before producing acceptable parts.

According to Die-Matic's manufacturing experts, you'll want to ensure you select a manufacturer who can handle your volume requirements. High-volume projects require automated processes and high-throughput capacity, while prototype runs demand flexibility and expertise with smaller batch sizes. Verify that your potential partner can scale with your production needs over time.

Quality metrics reveal what certifications cannot. Ask prospective suppliers about:

- First-pass approval rate – What percentage of dies meet specifications without modification? Leading suppliers achieve rates above 90%, with exceptional partners exceeding 93%.

- On-time delivery performance – Track record matters more than promises. Request data from the past 12 months.

- Customer retention – How long have their major customers been with them? Long-term relationships signal consistent satisfaction.

- Corrective action response time – When problems occur (and they will), how quickly does the supplier respond and resolve issues?

Your Supplier Evaluation Checklist

Before finalizing any stamping die manufacturing partnership, systematically verify these criteria:

- ☐ Certifications verified – IATF 16949, ISO 9001, industry-specific standards confirmed and current

- ☐ Engineering capabilities demonstrated – CAE simulation, DFM support, and design optimization services available

- ☐ Prototyping timeline confirmed – Rapid prototyping capabilities aligned with your development schedule

- ☐ Production capacity adequate – Ability to scale from prototype through high-volume production verified

- ☐ Quality metrics reviewed – First-pass approval rates, delivery performance, and customer retention data examined

- ☐ Financial stability assessed – Years in business, management tenure, and customer base diversity evaluated

- ☐ Communication protocols established – Clear touch points, reporting cadence, and issue escalation paths defined

- ☐ Facility visit completed – On-site assessment of equipment, processes, and team capabilities conducted

- ☐ References contacted – Direct conversations with current customers in similar applications

- ☐ Total cost analyzed – Shipping, tariffs, compliance costs, and hidden fees identified and compared

For automotive applications specifically, Shaoyi's precision stamping die solutions exemplify what qualified suppliers bring to the table: IATF 16949 certification backing their quality systems, advanced CAE simulation for defect-free results, rapid prototyping in as little as 5 days, and a 93% first-pass approval rate that minimizes costly iterations. Their engineering team's focus on cost-effective, high-quality tooling tailored to OEM standards demonstrates the comprehensive capabilities you should seek in any die manufacturing partner.

As Eigen Engineering notes, the perfect stamping dies manufacturer maintains honest processes, sets up sufficient touch points, and adheres to all your written manufacturing requirements while being proactive about supply chain disruptions or changes. Finding this level of partnership requires thorough evaluation upfront—but the investment pays dividends throughout your production program.

With your supplier selected and evaluation complete, you're ready to synthesize everything you've learned into actionable specifications for your next mechanical die project.

Making Informed Decisions for Your Die Manufacturing Projects

You've journeyed through the complete anatomy of mechanical dies—from foundational definitions to supplier selection criteria. Now comes the moment that separates informed buyers from those who learn expensive lessons on the production floor. How do you translate this knowledge into specifications that deliver results?

The tool and die definition encompasses far more than metal cutting tools. Understanding the tool and die meaning in practice means recognizing that every decision you make—from die type to material grade to manufacturing partner—cascades through your entire production program. Let's distill the critical factors that determine success.

Key Takeaways for Die Specification Success

The most costly mistakes in die procurement aren't poor material choices or inadequate maintenance—they're misaligned specifications that don't match your actual production requirements.

Your die tool selection should flow from four fundamental questions:

- Production volume – Progressive dies excel for runs exceeding 100,000 parts; compound dies serve smaller volumes cost-effectively; transfer dies handle complex geometries regardless of quantity

- Part complexity – Simple flat operations favor compound dies; multi-station progressive dies handle moderate complexity efficiently; transfer systems accommodate deep draws and orientation changes

- Material considerations – Your workpiece material dictates die steel grades, clearances, and surface treatments. High-strength steels and aluminum each demand specific tooling approaches

- Total cost of ownership – Initial die price represents only 20-30% of lifetime costs. Maintenance, regrinding cycles, component replacement, and downtime accumulate significantly over millions of press strokes

According to industry research on tool and die trends, buyers increasingly prioritize total cost of ownership over initial price—recognizing that maintenance, longevity, and quality consistency outweigh upfront savings that create downstream problems.

Your Next Steps in Die Manufacturing

Ready to move from knowledge to action? Your path forward depends on your role and immediate priorities.

For Engineers:

- Audit your current part designs for manufacturability—consult with die makers before finalizing specifications

- Request CAE simulation data from potential suppliers to validate forming predictions

- Document critical tolerances and their functional requirements to guide die clearance decisions

- Establish springback compensation requirements based on your specific material grades

For Procurement Specialists:

- Verify IATF 16949 or equivalent certifications before adding suppliers to your approved vendor list

- Request first-pass approval rate data and on-time delivery metrics from the past 12 months

- Evaluate total cost including shipping, customs, and potential rework—not just quoted die press tooling prices

- Confirm prototyping timelines align with your development schedule requirements

For Manufacturing Managers:

- Establish preventive maintenance intervals based on stroke counts rather than calendar time

- Train operators to recognize early warning signs—burr height changes, dimensional drift, unusual sounds

- Document press tool performance data to inform future specifications and supplier evaluations

- Build relationships with suppliers who offer ongoing engineering support, not just initial tool delivery

The difference between a die that runs for years and one that requires constant intervention often traces back to decisions made before any steel was cut.

Whether you're specifying your first die tool or optimizing an established stamping operation, the principles remain consistent: match your tooling to your actual production demands, invest appropriately in materials and engineering, select partners with demonstrated capabilities, and maintain your assets proactively.

For automotive applications where precision and reliability are non-negotiable, exploring professional stamping die solutions from qualified manufacturers provides a starting point for turning these principles into production-ready tooling. The investment you make in thorough specification and partner selection pays dividends across every part your dies produce.

Frequently Asked Questions About Mechanical Dies

1. What is a mechanical die?

A mechanical die is a specialized machine tool used in manufacturing to cut, shape, or form materials—typically metal—into desired shapes through applied pressure. Unlike injection molds that work with molten materials, mechanical dies physically transform solid sheet metal using two precision-matched halves placed inside a press. They perform four essential functions: locating, clamping, working (cutting, bending, forming), and releasing the finished part. Qualified manufacturers like Shaoyi use advanced CAE simulation to ensure defect-free die performance.

2. Why is a chip called a die?

In semiconductor manufacturing, the term 'die' refers to the individual integrated circuit pieces cut from a larger silicon wafer during fabrication. The wafer is sliced—or 'diced'—into separate pieces, each containing a complete circuit. This differs from mechanical dies in metalworking, which are cutting and forming tools rather than the products themselves. Both uses share the common concept of precision cutting to create functional components.

3. What are the main types of mechanical dies used in manufacturing?

The three primary mechanical die types are progressive dies, compound dies, and transfer dies. Progressive dies perform multiple sequential operations as material advances through stations—ideal for high-volume production exceeding 100,000 parts. Compound dies execute multiple cutting operations simultaneously in one stroke, offering excellent precision for simpler geometries. Transfer dies use mechanical fingers or robots to move workpieces between independent stations, handling complex three-dimensional parts and deep draws that other systems cannot achieve.

4. How do I choose the right tool steel for my stamping die?

Tool steel selection depends on production volume, workpiece material hardness, and precision requirements. D2 tool steel offers exceptional wear resistance for long-run blanking and punching operations. A2 provides balanced toughness and dimensional stability for general-purpose applications. S7 excels in high-impact scenarios requiring shock resistance. For extreme wear applications, tungsten carbide inserts can extend die life 5-10 times longer than tool steel. Surface treatments like TiN or DLC coatings further enhance performance and longevity.

5. What certifications should I look for when selecting a die manufacturing partner?

IATF 16949 certification is the gold standard for automotive die suppliers, demonstrating commitment to robust quality management systems. Look for suppliers with ISO 9001 as a baseline, plus industry-specific certifications for your application. Beyond certifications, evaluate engineering capabilities including CAE simulation, rapid prototyping speed (some suppliers like Shaoyi offer 5-day turnaround), first-pass approval rates (target above 90%), and on-time delivery performance. Verified certifications combined with strong quality metrics indicate a reliable manufacturing partner.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —