Metal Cutting Shops Exposed: What They Won't Tell First-Time Buyers

What Metal Cutting Shops Are and Why They Matter

Ever wondered how raw sheets of steel become the precise chassis components in your car or the structural beams holding up buildings? The answer lies in metal cutting shops—specialized facilities that most people never think about, yet they're the backbone of virtually every industry you can name.

What Metal Cutting Shops Actually Do

Metal cutting shops are manufacturing facilities dedicated to transforming raw metal stock into precise components using advanced cutting technologies. Think of them as the translators between raw materials and finished products. They take large sheets, plates, tubes, and structural shapes and cut them into specific sizes, profiles, and configurations that manufacturers need.

Unlike general machine shops that might handle everything from welding to assembly, these specialized facilities focus primarily on the cutting process itself. They invest heavily in equipment like laser cutters, plasma tables, waterjet systems, and metal cutting saws to deliver accurate cuts across various materials and thicknesses. Some facilities also maintain grinder tool stations for edge finishing and preparation work after cutting operations are complete.

From Raw Stock to Precision Parts

The journey from raw metal to usable components involves several service categories, each addressing different manufacturing needs:

- Sheet Metal Cutting: Handling thin-gauge materials typically under 1/4 inch thick, perfect for enclosures, brackets, and decorative elements

- Plate Cutting: Processing thicker materials from 1/4 inch up to several inches, used in heavy equipment, structural applications, and industrial machinery

- Tube and Pipe Cutting: Specialized cutting for hollow sections, essential for furniture frames, exhaust systems, and fluid transport applications

- Structural Steel Cutting: Working with I-beams, channels, angles, and other shapes using equipment like a cut saw metal setup for construction and infrastructure projects

Each category demands different equipment and expertise. A shop that excels at intricate sheet metal work with a metal cutting saw might not have the heavy-duty plasma table needed for thick plate cutting. That's why understanding these distinctions helps you find the right partner for your specific project.

The Foundation of Modern Manufacturing

Here's what many first-time buyers don't realize: metal cutting shops sit at the critical first stage of nearly every fabrication project. Before a press brake can bend your parts or a metal brake can form complex shapes, those parts must first be accurately cut from raw stock.

According to industry practices documented by H&S Manufacturing, the fabrication process begins with material preparation—inspecting metals for defects, then utilizing cutting equipment or shears to size sheets appropriately for each project. This foundational step determines everything that follows.

Different shops specialize in different methods and materials for good reason. Some focus exclusively on aluminum and non-ferrous metals, while others build expertise around stainless steel or specialty alloys. The equipment investments, operator training, and quality control processes all vary based on these specializations. A grinder tool might be standard equipment in one shop but unnecessary in another, depending on their typical projects and finishing requirements.

Understanding what these facilities actually do—and recognizing that not all of them do the same things—is your first step toward making smarter purchasing decisions and avoiding costly mistakes that come from choosing the wrong partner for your project.

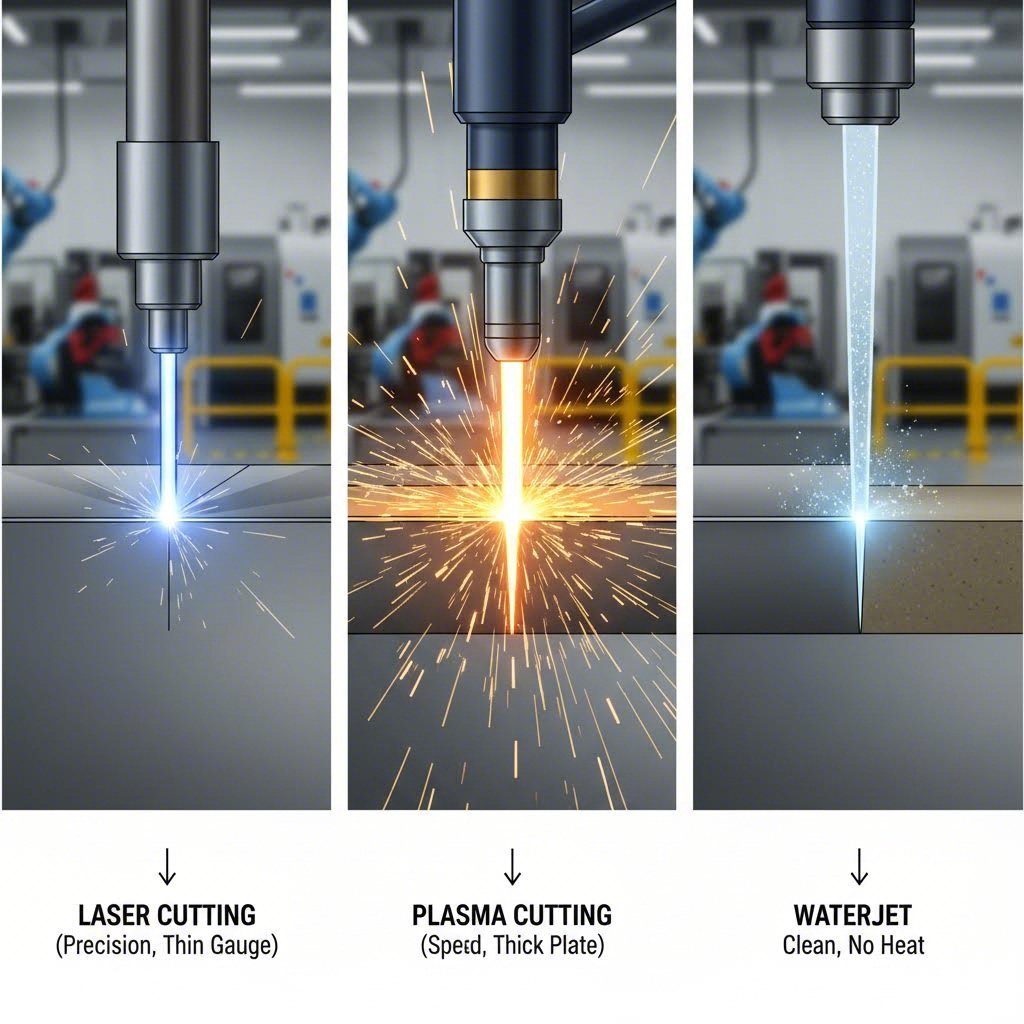

Metal Cutting Methods Compared

Now that you understand what these facilities do, the next question becomes: how exactly do they cut metal? The answer isn't straightforward because professional shops employ multiple cutting technologies, each with distinct advantages. Choosing the wrong method can cost you thousands in wasted material and extended lead times. Let's break down each option so you can speak confidently with potential vendors.

Laser Cutting for Intricate Precision

Imagine focusing intense light onto a metal surface with such precision that it melts or vaporizes material along a digitally controlled path. That's laser cutting in action. According to Cubbison's metal cutting comparison, the laser delivers intense heat that melts or vaporizes metal rapidly, with no chance of human error since every cut is digitally controlled.

When should you choose laser cutting? Consider it your go-to option when:

- Your parts require clean edges with minimal post-processing

- You need small holes, sharp corners, or intricate shapes

- Material thickness stays under 1/2 inch for steel

- Tolerances are tight and precision is non-negotiable

Laser cutting excels in electronics manufacturing, medical device production, and any application where detail matters more than raw cutting speed. The technology delivers exceptionally tight tolerances, making it ideal for projects demanding accuracy and intricacy.

Plasma and Waterjet Alternatives

What happens when your project involves thick steel plates where lasers struggle? That's where plasma cutting enters the picture. Plasma cutters use an electrical arc combined with compressed gas to melt and blast through conductive metals. Testing by Wurth Machinery showed plasma cutting 1-inch steel was approximately 3-4 times faster than waterjet, with operating costs roughly half as much per foot.

A cnc plasma table becomes the smart choice when you're working with structural steel fabrication, heavy equipment manufacturing, or any project involving thick conductive metals. The plasma table setup offers excellent speed and cost efficiency for materials over 1/2 inch thick.

But what about materials that can't handle heat? Waterjet cutting uses high-pressure water mixed with abrasive particles to cut virtually anything—from steel to stone—without generating heat. This means no warping, no hardening, and no heat-affected zones. The waterjet market continues expanding, projected to exceed $2.39 billion by 2034 according to industry research.

Waterjet becomes essential when:

- Heat damage must be avoided at all costs

- You're cutting non-metals like glass, stone, or composites

- Material integrity cannot be compromised by thermal effects

- Aerospace components require zero heat-affected zones

Mechanical Cutting Methods Explained

Not every cutting job requires sophisticated CNC technology. Mechanical cutting methods remain workhorses in many shops, particularly for specific applications where they outperform thermal alternatives.

The band saw—or bandsaw as it's commonly written—handles structural shapes and solid stock with remarkable efficiency. When cutting I-beams, solid bar stock, or tubing, a quality bandsaw equipped with appropriate bandsaw blades delivers clean, straight cuts at reasonable costs. Many fabricators keep a portable band saw on hand for on-site work or quick adjustments. Premium equipment like a milwaukee band saw offers reliability for demanding production environments.

Metal shears represent another essential mechanical option. Shearing occurs when pressure forces two metal blades together, causing the metal to yield and separate along the cutting line. This method delivers exceptional speed and consistency across various thicknesses—perfect for high-volume straight cuts where intricate shapes aren't required.

However, shearing comes with limitations. Unlike laser or waterjet cutting, shearing can result in rougher edges and potentially more material waste. For applications requiring smooth edges or complex profiles, thermal cutting methods typically prove superior.

| Cutting Method | Material Thickness Range | Precision Level | Speed | Relative Cost | Best Applications |

|---|---|---|---|---|---|

| Laser Cutting | Up to 1/2" steel | Very High | Fast (thin materials) | Medium-High | Intricate parts, electronics, medical devices |

| Plasma Cutting | 1/4" to 2"+ steel | Medium | Very Fast | Low-Medium | Structural steel, heavy equipment, shipbuilding |

| Waterjet Cutting | Up to 12"+ (any material) | High | Slow-Medium | High | Aerospace, stone/glass, heat-sensitive materials |

| Band Saw | Solid stock, structural shapes | Medium | Medium | Low | Bar stock, tubing, structural steel |

| Shearing | Up to 1/2" (varies by machine) | Low-Medium | Very Fast | Very Low | High-volume straight cuts, blanking |

Many successful metal cutting shops incorporate multiple technologies rather than relying on just one. Plasma and laser often pair well together, while waterjet adds unmatched versatility for specialty materials. Understanding these distinctions helps you ask the right questions when evaluating potential vendors—and ensures your project lands with a shop equipped to handle your specific requirements.

Materials and Thickness Capabilities

You've learned how different cutting methods work—but here's what many first-time buyers overlook: the material you're cutting matters just as much as the equipment doing the cutting. Not every shop can handle every metal, and not every cutting method works equally well across all materials. Understanding these relationships saves you from choosing the wrong vendor and discovering problems after your material is already ruined.

Common Metals and Their Cutting Requirements

Metal cutting shops process a surprisingly wide range of materials, but each metal brings unique challenges to the cutting table. The composition of your material directly influences which cutting method delivers the best results.

- Carbon Steel: The workhorse of industrial fabrication. Grades like A36 and A572 respond exceptionally well to virtually all cutting methods—plasma, laser, oxy-fuel, and mechanical. According to KGS Steel's analysis, mild steel grades produce clean cuts with minimal dross formation when plasma cut, making them ideal for structural applications and general fabrication.

- Stainless Steel: Austenitic grades like 304 and 316 respond particularly well to laser cutting due to their consistent composition and thermal properties. Their lower thermal conductivity actually works in favor of laser cutting, allowing for cleaner cuts with minimal heat-affected zones.

- Aluminum: Highly reflective and thermally conductive, aluminum requires careful parameter adjustments. Fiber lasers with sufficient power handle aluminum effectively, though waterjet remains popular for thicker sections where heat distortion becomes a concern.

- Copper and Brass: These reflective metals historically challenged laser systems, but modern fiber lasers cut them efficiently. A die grinder often comes into play for post-cut edge refinement on these softer materials.

- Specialty Alloys: Inconel, titanium, and other high-performance alloys demand specialized expertise. Waterjet cutting often proves superior here since it introduces no heat-affected zones that could compromise material properties.

Sounds complex? Here's the practical takeaway: always discuss your specific material with potential vendors before committing. A shop specializing in carbon steel fabrication may lack the equipment or expertise for your stainless steel project.

Understanding Thickness Limitations

Material thickness determines which cutting methods remain viable—and this is where many projects go wrong. Requesting laser cutting for 2-inch steel plate, for instance, either gets rejected outright or produces subpar results.

According to Longxin Laser's cutting guide, thickness capabilities vary significantly by laser power and material type:

- Laser Cutting: Optimal for materials up to about 1 inch thick, depending on the machine's power. A 3kW fiber laser handles most industrial jobs on mild steel up to 12mm, while cutting thicker materials requires 10kW or higher systems.

- Plasma Cutting: Shines when cutting thick steel, particularly between 1/2 inch to 2 inches. The method remains effective for materials over 50mm, though edge quality decreases compared to thinner sections.

- Waterjet Cutting: Can cut extremely thick materials—up to 10 inches or more—without thermal distortion. This makes it the go-to choice for heavy plate work where heat-affected zones are unacceptable.

- Mechanical Methods: Shearing works effectively on sheet metal up to approximately 1/2 inch, while a grinding wheel or bench grinder handles edge preparation after cutting. Band saws excel at structural shapes regardless of thickness.

For reliable results, select a cutting method rated for slightly more than your maximum thickness requirements. This ensures consistent performance and accommodates future project needs.

When preparing cut edges for welding or finishing, tools like a wire wheel mounted on a bench grinder efficiently remove oxidation and slag. Some shops use a sheet metal brake for subsequent forming operations, but proper edge preparation during cutting minimizes downstream work.

Specialty Materials and Alloy Considerations

Here's what experienced fabricators know that first-time buyers often miss: material properties affect cutting method selection in ways that aren't immediately obvious.

Reflectivity matters for laser cutting. Highly reflective metals like copper, brass, and aluminum can bounce laser energy back into the cutting head, potentially damaging equipment. Modern fiber lasers largely overcome this limitation, but shops with older CO2 equipment may struggle with these materials.

Conductivity drives plasma performance. Plasma cutting requires electrically conductive materials—it simply won't work on non-metals. However, highly conductive materials like copper may require parameter adjustments to achieve clean cuts.

Hardness influences mechanical cutting. When using band saws or shearing equipment, harder materials like tool steels demand slower cutting speeds and specialized blades. A wire brush can help clear chips and maintain cut quality on challenging alloys.

Carbon content also plays a pivotal role in thermal cutting processes. KGS Steel notes that low-carbon steels containing less than 0.3% carbon generally cut more predictably and cleanly than high-carbon alternatives, particularly when using plasma or laser methods.

The bottom line? Ask potential vendors specifically about their experience with your exact material and thickness combination. A shop that confidently handles 1/4-inch mild steel may have never touched the exotic alloy your aerospace project requires—and discovering that gap after production starts creates expensive problems.

Precision Standards and Quality Certifications

You've identified the right cutting method and verified your material can be processed—but here's a question that separates experienced buyers from novices: how do you know the finished parts will actually meet your specifications? The answer lies in understanding tolerances and certifications, two concepts that many metal cutting shops mention but rarely explain.

Understanding Cutting Tolerances

Tolerance refers to the acceptable deviation from a specified dimension. When a drawing calls for a 10-inch length with a ±0.005" tolerance, the actual part can measure anywhere between 9.995" and 10.005" and still be considered acceptable. Different cutting methods deliver vastly different tolerance capabilities.

According to RapidDirect's technical comparison, laser cutting achieves tolerances of approximately ±0.002" (0.05 mm) with a minimum cutting slit of just 0.006" (0.15 mm). Waterjet cutting, while excellent for heat-sensitive applications, delivers wider tolerances around ±0.008" (0.2 mm) with minimum slit sizes of 0.02" (0.5 mm).

Match your tolerance requirements to cutting method capabilities before requesting quotes. Specifying tighter tolerances than necessary increases costs, while underestimating requirements leads to rejected parts.

What precision level does your application actually require? Consider these general guidelines:

- General fabrication: ±0.030" tolerance typically suffices for structural components, brackets, and non-critical assemblies

- Precision manufacturing: ±0.005" to ±0.010" for mechanical assemblies, equipment housings, and components requiring accurate fit

- Aerospace and medical: ±0.002" or tighter for flight-critical components and medical devices where failure isn't an option

Experienced fabricators use precision measurement tools throughout production. A digital angle finder or level tool verifies angular accuracy on bent components, while an angle finder confirms that cut edges meet specified requirements. These verification steps, combined with proper deburring tool usage to remove sharp edges, ensure parts meet dimensional specifications.

Why Certifications Matter for Your Project

When evaluating metal cutting shops, you'll encounter various certifications—but what do they actually mean for your project? Understanding these credentials helps you identify vendors capable of meeting your industry's specific requirements.

ISO 9001:2015 represents the foundation of quality management. According to Zintilon's certification guide, this standard requires organizations to define and follow quality management systems while continuously identifying areas for improvement. It establishes basic quality principles including customer focus, strong leadership, process-based approaches, and evidence-based decision making.

IATF 16949 builds upon ISO 9001 specifically for automotive applications. This globally recognized standard aims to prevent waste and reduce defects throughout all stages of automotive product development. With over 70,000 certified organizations worldwide, IATF 16949 certification signals a shop's capability to handle chassis components, structural parts, and other automotive applications with the traceability and consistency automakers demand.

AS9100D addresses the stringent requirements of aerospace, space, and defense manufacturing. This certification emphasizes product safety, quality services, and comprehensive customer needs documentation. Shops holding AS9100D certification have demonstrated their ability to produce components where failure could have catastrophic consequences—think turbine blades, structural airframe components, and flight-critical assemblies.

Beyond these primary certifications, you may encounter ISO 13485 for medical device manufacturing and ISO 14001 for environmental management systems. Each certification addresses specific industry requirements and regulatory compliance needs.

Quality Control in Professional Cutting Operations

Certifications represent documented systems, but what happens on the production floor matters equally. Professional metal cutting shops implement multiple quality control touchpoints throughout the cutting process.

First-piece inspection verifies that initial cuts meet specifications before full production begins. Operators use precision instruments—including digital level devices for flatness verification and chamfer gauges for edge profiles—to confirm dimensional accuracy. Any deviations trigger immediate parameter adjustments before additional material gets processed.

In-process inspection continues throughout production runs. Countersink depths, hole locations, and overall dimensions receive periodic verification against drawings. This catches drift in machine performance before it affects large quantities of parts.

Final inspection documents that completed parts meet all specifications. Certified shops maintain detailed records linking specific parts to material lot numbers, machine settings, operator identification, and inspection results. This traceability becomes critical when investigating quality issues or demonstrating compliance during customer audits.

As Tempco Manufacturing emphasizes, quality control for advanced metal fabrication is performed in accordance with certifications to provide the most accurate and reliable parts. Their approach—representative of professional operations—includes statistical process control, first-article inspection reports, and comprehensive documentation throughout production.

The bottom line? Certifications aren't just logos on a website. They represent systematic approaches to quality that affect every part leaving the facility. For critical applications in automotive, aerospace, or medical industries, working with appropriately certified vendors isn't optional—it's essential for ensuring your components perform as designed when it matters most.

How to Choose the Right Metal Cutting Shop

You understand cutting methods, material considerations, and quality standards—but here's where theory meets reality: actually selecting a vendor from dozens of options. This decision can make or break your project timeline and budget. Too many first-time buyers choose based solely on price, only to discover that the cheapest quote came with hidden compromises. Let's walk through a systematic approach that seasoned procurement professionals use to evaluate potential partners.

Essential Questions for Potential Vendors

Before requesting quotes, prepare a list of targeted questions that reveal a shop's true capabilities. According to Wisconsin Metal Tech's supplier evaluation guide, understanding what your supplier is and isn't capable of may seem like a no-brainer, but it's critical for streamlining the process and maximizing efficiency.

Start with these fundamental inquiries:

- "What certifications do you hold, and how do you ensure regulatory compliance?" A qualified shop should readily explain their quality management systems and how they meet industry-specific requirements.

- "Have you completed projects similar to mine?" Experience matters. Shops with relevant project history can relate their experience and suggest process improvements based on lessons learned.

- "What materials do you typically work with?" Transparency about material expertise reveals whether they're genuinely suited for your specific alloys and thicknesses.

- "What's your typical turnaround time for projects of this scope?" When your operation relies on timely delivery, confirming schedule compatibility upfront prevents costly delays.

- "How will you manage this project from start to finish?" A committed partner offers project management that keeps your work on track while finding ways to save time and money.

Don't hesitate to ask for references from similar projects. Reputable shops welcome the opportunity to demonstrate their track record.

Evaluating Equipment and Capabilities

Equipment tells a story about a shop's investment in quality and their ability to handle your specific requirements. When evaluating potential vendors, consider these factors in order of priority:

- Cutting technology alignment: Does the shop have the right equipment for your material and thickness? A facility with only plasma cutting cannot deliver the precision you need for intricate laser-cut components.

- Machine condition and maintenance: Modern, well-maintained equipment produces consistent results. Ask about maintenance schedules and equipment age—shops proud of their capabilities will share this information.

- Workholding and fixturing: Professional shops use proper workholding equipment like a bench vise or wilton vise for secondary operations, along with c clamps and pipe and clamp setups for securing materials during cutting. These details indicate attention to quality.

- Secondary capabilities: Can they handle deburring, edge finishing, or forming after cutting? According to Elemet Group's selection guide, a comprehensive fabrication shop excels not only in basic tasks but also in specialized services like precision laser cutting and CNC machining.

- Inspection equipment: Quality-focused shops invest in measurement tools—coordinate measuring machines, optical comparators, and precision gauges that verify parts meet specifications.

- Material handling capacity: Can they handle your sheet sizes and plate weights? Shops with overhead cranes and appropriate material handling equipment work more efficiently with heavy materials.

Some shops maintain specialized equipment like an arbor press for assembly operations or a pedestal grinder for edge preparation. While these secondary tools aren't essential for cutting, their presence often indicates a well-equipped facility prepared for complete project support.

Red Flags When Choosing a Shop

Experience teaches buyers to recognize warning signs before committing to a vendor. Dr. Shahrukh Irani of Lean and Flexible, LLC notes that he's seen countless projects derailed by partnerships with shops that weren't thoroughly evaluated—what sounded good in the quote often turns out to be overpromising, leading to delays and reworks due to poor quality.

Watch for these warning signs:

- Lack of certifications: Shops serving automotive, aerospace, or medical industries should hold relevant certifications. Absence of ISO 9001 or industry-specific credentials suggests inconsistent quality management.

- Unclear or vague pricing: Professional shops provide detailed quotations that specify material costs, cutting operations, secondary processes, and any additional charges. Hidden costs emerge when quotes lack transparency.

- Poor communication: If getting answers takes days during the quoting phase, imagine how responsive they'll be when production problems arise. Effective communication from initial consultation to final delivery ensures everyone stays on the same page.

- Reluctance to share references: Established shops welcome reference checks. Hesitation suggests either limited experience or dissatisfied past customers.

- No quality documentation: Ask about first-article inspection reports and in-process quality checks. Shops that can't explain their quality control procedures likely don't have robust systems in place.

- Unrealistic promises: Quotes dramatically lower than competitors or turnaround times that seem impossibly fast often indicate corners will be cut. Balance cost with quality and timeliness—cheaper isn't always better when high-quality fabrication requires skilled labor, advanced equipment, and premium materials.

Geographic considerations also matter. Shops closer to your facility reduce shipping costs and enable site visits. However, don't sacrifice capability for convenience—a certified shop three states away may deliver better results than an uncertified local option. C clamps holding your parts during cutting matter less than the systems ensuring those parts meet specifications.

The investment you make in vendor evaluation pays dividends throughout your project. A thorough selection process—asking pointed questions, verifying capabilities, and heeding warning signs—positions you for a successful partnership rather than a frustrating experience that costs time and money to correct.

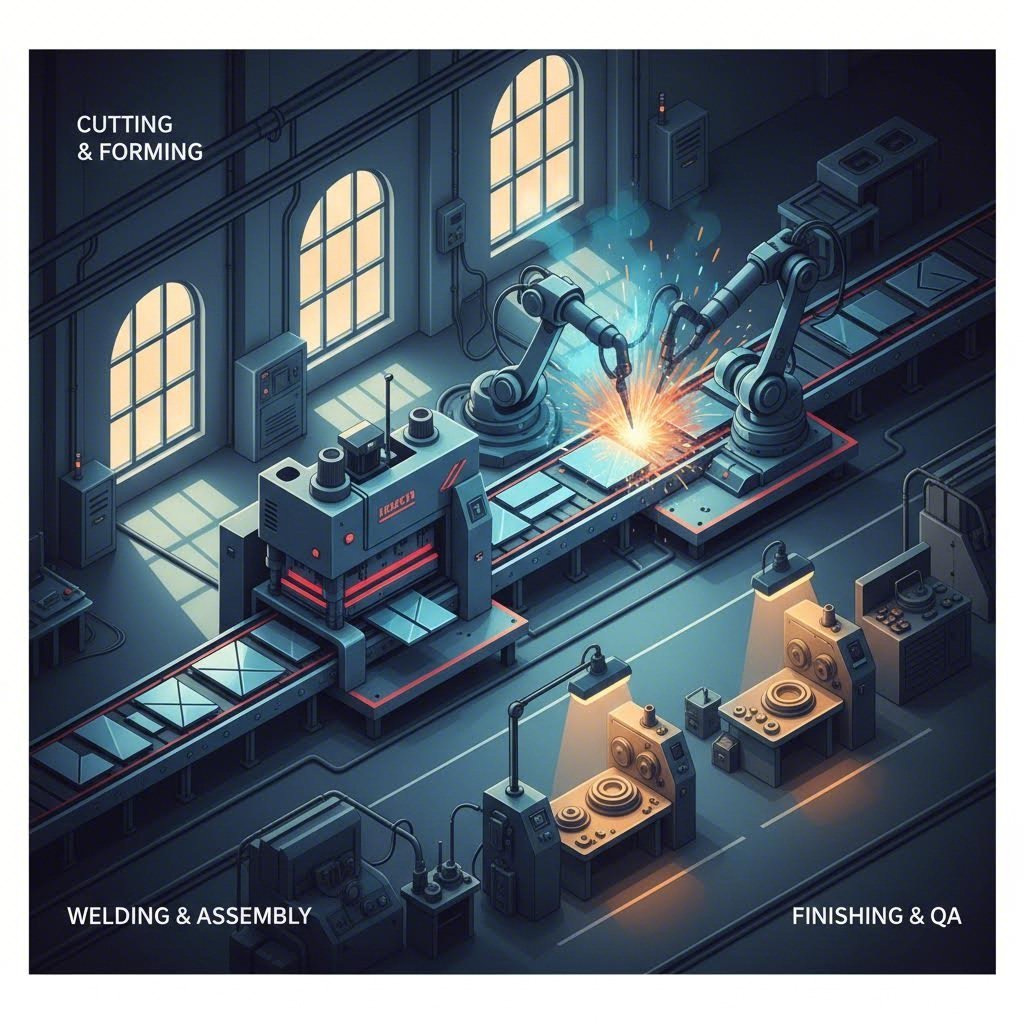

Metal Cutting Within the Manufacturing Process

You've selected the right vendor and understand how cutting methods work—but here's a reality check: cutting is rarely the end of the story. Most projects require additional operations before parts become functional components. Understanding how metal cutting integrates with downstream processes helps you make smarter decisions about vendor selection and project planning.

From Cutting to Complete Fabrication

Think of metal cutting as the opening chapter of a longer manufacturing narrative. Once parts leave the cutting table, they typically move through several additional processes before they're ready for use.

Bending and forming transform flat cut pieces into three-dimensional shapes. According to Fictiv's prototyping guide, sheet metal bending and forming use press brakes, rollers, and sometimes inexpensive stamping dies to shape metal into custom geometries. These processes enable the creation of complex angles, curves, and contours that flat cutting alone cannot achieve.

Welding and joining assemble multiple cut components into unified structures. Techniques like MIG and TIG welding create permanent bonds, while a tig welder becomes essential for applications demanding precision and clean aesthetics. Many fabrication shops maintain dedicated welding table setups where operators use a tig torch to join cut pieces with exceptional control. For production environments, a tig welding machine provides the consistency needed for repeatable results.

Finishing operations prepare parts for their end-use environment:

- Deburring: Removes sharp edges left by cutting operations, improving safety and assembly fit

- Coating and painting: Powder coating, wet painting, and other protective finishes guard against corrosion

- Plating: Zinc, nickel, chrome, and other platings add durability and aesthetic appeal

- Heat treatment: Modifies material properties for specific performance requirements

Some operations require specialized equipment. A mag drill—also called a magnetic drill—enables precise hole placement on large fabricated assemblies where traditional drill presses cannot reach. These portable magnetic drill units clamp directly to steel surfaces, allowing operators to create accurate holes without moving heavy weldments.

Prototyping and Production Workflows

How does cutting fit into product development cycles? Understanding this workflow prevents costly surprises and helps you plan realistic timelines.

During prototyping, speed and flexibility matter most. Fictiv notes that rapid sheet metal prototyping significantly reduces the time required to develop and test new designs. With advanced fabrication methods like laser cutting and automated bending, prototype sheet metal parts can be produced within days, allowing engineers to identify design flaws early and make adjustments quickly.

A typical prototyping workflow progresses through these stages:

- Design and CAD modeling: Engineers create detailed 3D models with precise control over dimensions and tolerances

- Material selection: Choosing metals that match production intent ensures accurate performance testing

- Cutting: Laser, waterjet, or plasma creates the flat blanks

- Forming and bending: Press brakes shape pieces into three-dimensional components

- Assembly and finishing: Welding with a tig welding torch joins components, then surfaces receive appropriate treatments

- Testing and validation: Functional prototypes undergo real-world evaluation

When enough prototypes are made, the line between prototyping and small-batch production starts to blur. Sheet metal prototyping eliminates the need for complex, expensive tooling, making it a practical and affordable option for low-volume production after final design approval.

Single-Source vs Multi-Vendor Approaches

Here's a decision that significantly impacts your project outcomes: should you work with one shop that handles everything, or coordinate between specialized vendors?

According to New Concept Technology's analysis, single-source manufacturing offers compelling advantages. When you have a project, you can rely on your provider to handle necessary products and parts from concept to completion.

Advantages of single-source manufacturing:

- Cost savings: Getting everything you need from one source cuts down on admin costs of placing orders with different suppliers, as well as the logistics of pooling materials from different locations

- Quality improvement: When sourcing from one supplier instead of many, quality standards are easier to control. The ease of navigating product recalls makes single-sourcing more attractive

- Faster lead times: Different suppliers have varying lead times due to unique processes and site locations. With single-source procurement, getting necessary materials and products on time becomes easier

- Improved communication: A closer and more collaborative relationship makes pinpointing the source of issues and working on a solution easier

When multi-vendor approaches make sense:

- Highly specialized processes requiring niche expertise

- Geographic constraints where local specialists reduce shipping costs

- Risk diversification for critical supply chains

- Capacity limitations at single providers during peak demand

The trade-off becomes clear: single-source simplifies coordination but requires finding a vendor with comprehensive capabilities. Multi-vendor approaches offer specialized expertise but demand more management oversight and introduce handoff risks between suppliers.

For most projects—especially those involving cutting followed by forming, welding, and finishing—working with a capable single-source provider streamlines execution and reduces finger-pointing when issues arise. Your parts stay under one roof from raw material to finished component, with consistent quality standards applied throughout.

With this understanding of how cutting integrates with broader manufacturing processes, you're ready to explore specific industry applications where these integrated services deliver the greatest value.

Industries Served by Metal Cutting Shops

Different industries demand vastly different things from their cutting partners. A shop that excels at producing decorative architectural panels may struggle with the tight tolerances aerospace applications demand. Understanding these industry-specific requirements helps you identify vendors genuinely equipped for your sector—rather than discovering capability gaps after production begins.

Automotive and Transportation Applications

The automotive industry represents one of the largest consumers of precision-cut metal components. According to industry manufacturing guides, automotive sheet metal manufacturing plays a crucial role in creating everything from the car's frame to intricate components used in the engine bay and interior.

What components do metal cutting shops produce for this sector?

- Chassis components: Frame rails, cross members, and structural reinforcements requiring consistent dimensional accuracy

- Brackets and mounts: Engine mounts, suspension brackets, and body mounting hardware demanding precise hole locations and edge quality

- Body panels: Doors, hoods, fenders, and quarter panels where material thickness typically ranges from 0.5 mm to 2.0 mm

- Exhaust system components: Pipes, flanges, and heat shields often processed with tools like an exhaust pipe expander for proper fitment

- Interior structural parts: Seat frames, dashboard supports, and reinforcement beams

Automotive applications demand shops holding IATF 16949 certification—the globally recognized standard that aims to prevent waste and reduce defects throughout all stages of automotive product development. This certification signals capability for handling the traceability requirements automakers mandate.

Modern automotive fabrication increasingly relies on lightweight materials. Aluminum's ability to be easily formed and its natural corrosion resistance make it ideal for producing fuel-efficient vehicles. A pipe bender or tube bender becomes essential equipment for exhaust systems and fluid transport lines, while aviation snips handle trimming operations on thinner gauge materials.

Aerospace Precision Requirements

Aerospace manufacturing operates in a different league entirely. According to Pinnacle Precision's tolerance guide, aerospace is perhaps the most demanding industry when it comes to tight tolerances. Flight-critical components like turbine blades, engine housings, and structural brackets must be manufactured to the highest standards to ensure safety, fuel efficiency, and aerodynamic performance.

Consider the stakes: even microscopic deviations can lead to stress concentrations or imbalances that jeopardize an entire aircraft system. This reality shapes every aspect of aerospace metal cutting:

- Material requirements: Titanium, Inconel, and specialized aluminum alloys dominate aerospace applications due to their strength-to-weight ratios

- Tolerance expectations: Typically ±0.002" or tighter for flight-critical components

- Certification requirements: AS9100D certification is virtually mandatory, emphasizing product safety, quality services, and comprehensive documentation

- Traceability demands: Every cut piece must link to material certifications, machine settings, and operator records

Waterjet cutting often proves superior for aerospace applications since it introduces no heat-affected zones that could compromise material properties. When thermal cutting methods are used, extensive quality verification follows to confirm material integrity remains intact.

Shops serving aerospace clients invest heavily in metrology equipment—coordinate measuring machines, optical comparators, and surface roughness testers—that verify every dimension meets exacting specifications. A tubing bender in an aerospace shop must deliver repeatable accuracy that general fabrication equipment simply cannot match.

Construction and Architectural Metalwork

Construction applications present different challenges than precision manufacturing. According to Metal Tronics' industry analysis, metal fabrication plays a vital role in shaping durable, efficient, and innovative structures suitable for construction. From structural frames to decorative elements, metal-fabricated components offer structural integrity across diverse applications.

Typical construction and architectural projects include:

- Structural frameworks: Steel beams, columns, and supports providing structural integrity to buildings and bridges

- Staircases and railings: Custom metal staircases, balustrades, and handrails requiring both strength and aesthetic appeal

- Roofing and facades: Fabricated metal sheets used in roofing systems and contemporary facades for durability and visual impact

- HVAC systems: Ducts and ventilation components requiring custom fabrication for proper fitting and functionality

- Architectural details: Decorative screens, signage, and custom metalwork where design flexibility matters most

Construction tolerances typically run looser than aerospace or automotive—±0.030" often suffices for structural components. However, the sheer volume and scale of construction projects demand shops with substantial material handling capacity and efficient production capabilities.

When securing materials during cutting operations, construction-focused shops frequently use a pipe vise for holding round stock and structural tubing. These robust workholding solutions handle the heavy materials common in building applications while maintaining cut accuracy.

The construction sector values efficiency and cost-effectiveness. As Metal Tronics notes, fabricated components are pre-engineered and pre-assembled in controlled environments before being sent to construction sites. This approach reduces on-site labor, material waste, and delays—making metal cutting shops essential partners in modern construction workflows.

Whether your project serves automotive, aerospace, construction, or general manufacturing, the key takeaway remains consistent: match your vendor's capabilities and certifications to your industry's specific demands. A shop perfectly suited for architectural metalwork may lack the precision equipment and quality systems your aerospace components require—and discovering that mismatch after production starts creates problems far more expensive than the time invested in proper vendor evaluation.

Getting Started with Your Metal Cutting Project

You've done the research—you understand cutting methods, material considerations, quality certifications, and how to evaluate potential vendors. Now comes the moment that separates informed buyers from frustrated ones: actually engaging with a metal cutting shop and getting your project moving. The steps you take before requesting that first quote determine whether your project runs smoothly or stumbles into avoidable delays.

Preparing Your Project Specifications

Imagine ordering a custom burger but forgetting to mention you want it without pickles. That's essentially what happens when buyers submit incomplete project specifications. According to AMG Industries' buyer guidance, fabricators often say they'd rather you explain too much than leave them guessing—and that's sound advice.

Before contacting any vendor, organize these essential details:

- Material specifications: Exact alloy designation (not just "stainless steel" but "304 stainless steel"), required thickness, and surface finish requirements

- Quantity requirements: Initial order quantities plus anticipated annual volumes—this affects pricing and production planning

- Dimensional tolerances: Specify what precision your application actually requires rather than defaulting to unnecessarily tight specifications

- Secondary operations: Will you need custom welding fabrication, bending, finishing, or assembly after cutting?

- Delivery timeline: When do you need parts, and is there flexibility for expedited or standard lead times?

Your design files require equal attention. According to SendCutSend's design guidelines, the better the file, the better the parts. For CNC cutting operations, shops typically accept these file formats:

| File Format | Best For | Key Considerations |

|---|---|---|

| DXF | 2D cutting profiles | Most universally accepted; verify dimensions after conversion from other formats |

| DWG | AutoCAD-native projects | Preserve layer information; confirm compatibility with shop's CAD systems |

| STEP | 3D models requiring cutting | Ideal when parts need subsequent forming or machining operations |

| AI/EPS | Graphic-based designs | Convert text to outlines; verify scale matches intended dimensions |

A common mistake first-time buyers make involves submitting raster files or designs with active text boxes. If you've converted from a raster file, always verify dimensions—printing your design at 100% scale helps confirm everything matches your intent. Text elements must be converted to shapes (called "converting to outlines" in Illustrator or "explode" in CAD software) before submission.

When your project requires precise angular cuts or formed features, using a contour gauge during design verification ensures your CAD models accurately represent physical requirements. Similarly, angle tools measurement during prototyping catches discrepancies before full production begins.

Getting Accurate Quotes Quickly

What separates a 12-hour quote turnaround from a week-long wait? Preparation. According to industry best practices, thorough preparation demonstrates professionalism that fabricators appreciate—it's the foundation for a strong partnership.

Your Request for Quote (RFQ) should include:

- Company information: Who you are, your industry, and contact details for technical questions

- Complete drawings: Dimensioned prints with tolerances, material callouts, and finish specifications

- Volume breakdown: Prototype quantities, initial production runs, and projected annual usage

- Timeline requirements: Target delivery dates and any flexibility in scheduling

- Quality requirements: Certifications needed, inspection documentation expected, and any special testing

When comparing quotes, look beyond the bottom line. Custom welding shops may bundle secondary operations differently than cutting-only facilities. A quote that appears higher might include deburring, inspection documentation, and packaging that competitors charge separately.

Lead times vary significantly based on cutting method and project complexity. According to industry lead time analysis:

- Laser cutting: 1 to 3 days for prototyping; 3 to 7 days for production batches

- Plasma cutting: 2 to 5 days depending on plate thickness and volume

- Waterjet cutting: 3 to 7 days, especially for thick or intricate parts

- Mechanical sawing: 1 to 3 days for standard cuts in available stock

Factors that extend these timelines include material availability (specialty alloys may require procurement delays), complex geometries requiring careful programming, and secondary operations like forming or finishing. Planning for these variables prevents schedule surprises.

For drilling operations that follow cutting, specifying requirements for twist drill bits or twist drill bit sizes in your documentation helps shops plan complete workflows. A drill guide ensures consistent hole placement when manual drilling supplements CNC operations.

Partnering with Certified Manufacturers

For automotive and precision manufacturing projects, standard cutting services often represent just the starting point. These industries demand integrated capabilities—cutting, stamping, forming, and assembly—under unified quality management systems.

Consider what happens when you need chassis components or structural brackets for automotive applications. You require not only precise cutting but also IATF 16949-certified production processes that ensure traceability from raw material through final assembly. Finding a partner who offers comprehensive capabilities eliminates the coordination headaches of managing multiple vendors.

Specialized manufacturers like Shaoyi (Ningbo) Metal Technology exemplify this integrated approach. Their operations combine cutting capabilities with metal stamping and precision assemblies, offering 5-day rapid prototyping alongside automated mass production. For buyers with automotive or precision requirements, such manufacturers deliver IATF 16949-certified quality for chassis, suspension, and structural components—all with comprehensive DFM (Design for Manufacturability) support and 12-hour quote turnaround.

When evaluating integrated manufacturers, look for these indicators of production readiness:

- Rapid prototyping capability: Can they produce functional prototypes within days rather than weeks?

- Certification alignment: Do their quality certifications match your industry requirements?

- DFM support: Will they review your designs and suggest improvements before production?

- Quote responsiveness: Fast quote turnaround often indicates efficient operations and genuine interest in your business

- Production scalability: Can they handle both prototype quantities and eventual mass production volumes?

The transition from prototyping to production should feel seamless. Partners with robust systems maintain the same quality standards whether producing five pieces or five thousand—eliminating the risk of quality drift as volumes increase.

Your metal cutting project succeeds or fails based on the groundwork you lay before production begins. Prepare thorough specifications, submit complete documentation, understand realistic lead times, and—for demanding applications—partner with certified manufacturers equipped to handle your requirements from concept through completion. The investment in proper preparation pays dividends in parts that arrive on time, on spec, and ready to perform.

Frequently Asked Questions About Metal Cutting Shops

1. How much does metal cutting cost?

Metal cutting costs typically range from $0.50 to $2 per linear inch depending on material type, thickness, and cutting method. Hourly rates generally fall between $20 and $30. Laser cutting commands premium pricing for precision work, while plasma cutting offers more economical rates for thicker materials. Always request detailed quotes specifying material costs, cutting operations, and any secondary processes to avoid hidden charges.

2. What profession cuts metal?

Several professionals work in metal cutting: machinists operate precision equipment to produce metal parts and tools, sheet metal workers set up and operate cutting machinery, and CNC operators program and run computerized cutting systems like laser and plasma tables. Metal fabricators combine cutting with forming and welding skills. For IATF 16949-certified automotive applications, specialized manufacturers like Shaoyi Metal Technology employ trained technicians who maintain strict quality standards throughout production.

3. What cutting method is best for thick steel plates?

Plasma cutting excels for thick steel plates, typically handling materials from 1/2 inch to over 2 inches efficiently. Testing shows plasma cuts 1-inch steel approximately 3-4 times faster than waterjet at roughly half the operating cost per foot. For applications requiring zero heat-affected zones on thick materials, waterjet cutting can handle plates up to 12 inches or more without thermal distortion, making it ideal for aerospace and heat-sensitive applications.

4. What certifications should I look for in a metal cutting shop?

Essential certifications depend on your industry: ISO 9001:2015 establishes foundational quality management for general manufacturing; IATF 16949 is mandatory for automotive applications, ensuring defect prevention throughout production; AS9100D addresses stringent aerospace requirements where component failure could be catastrophic. Medical device manufacturing requires ISO 13485. Certified shops maintain documented quality systems, traceability records, and undergo regular audits.

5. What file formats do metal cutting shops accept?

Most CNC cutting operations accept DXF files as the universal standard for 2D cutting profiles. DWG files work well for AutoCAD-native projects, while STEP files suit 3D models requiring subsequent forming operations. AI and EPS formats accommodate graphic-based designs but require text conversion to outlines. Always verify dimensions after file conversion and submit vector files rather than raster images for accurate cutting results.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —